Book gluing system

A technology for gluing and books, which is applied in book binding, printing, and adhesives used for binding, etc., can solve the problems of unsatisfactory gluing effect and low efficiency of gluing system, and achieves adjustable gluing thickness and transmission. Stable and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

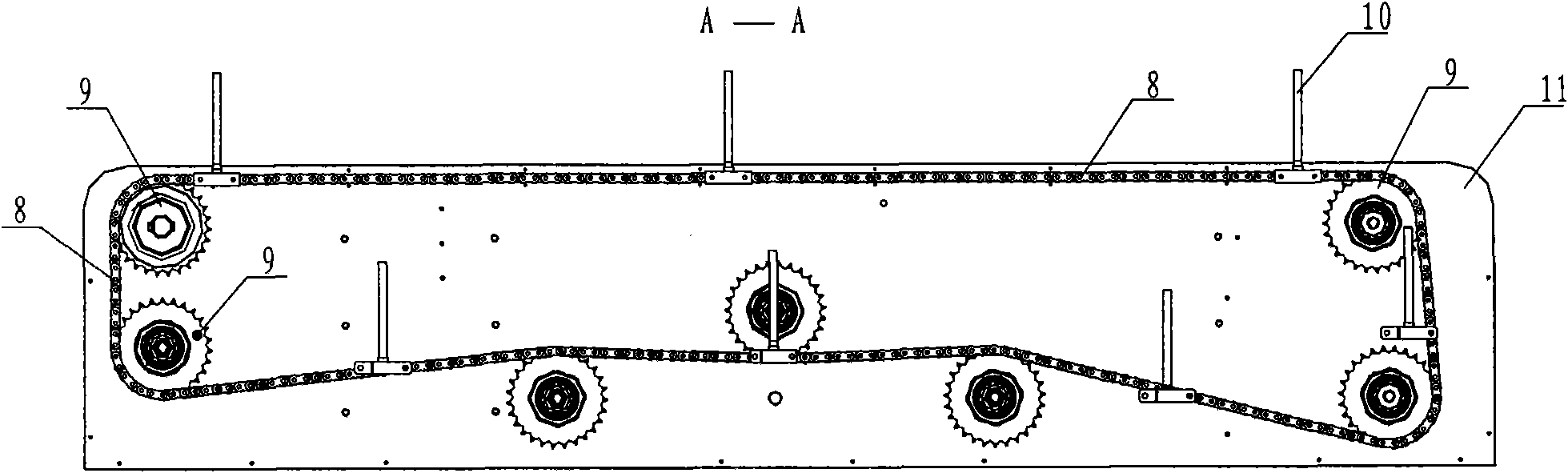

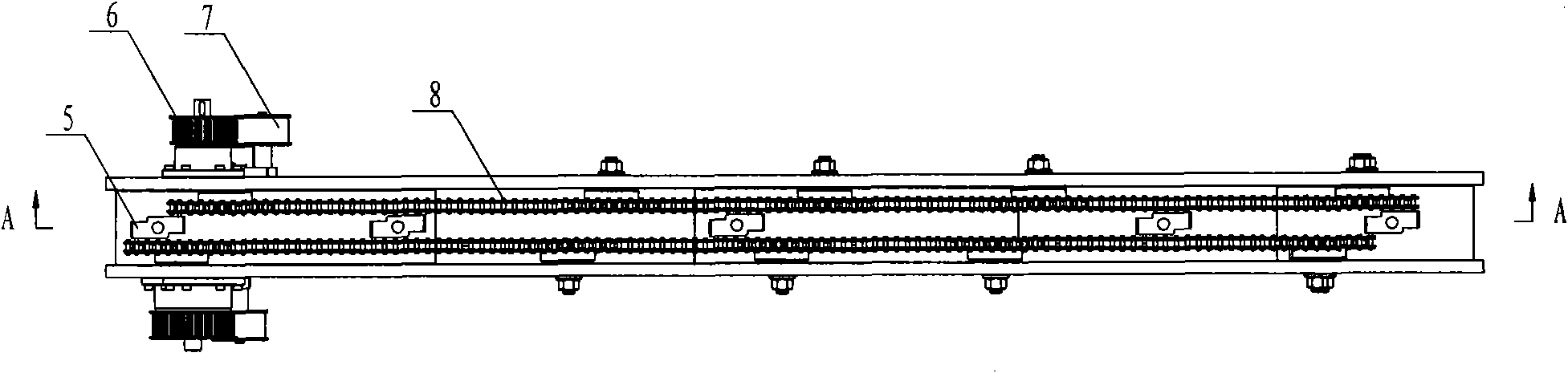

[0034] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

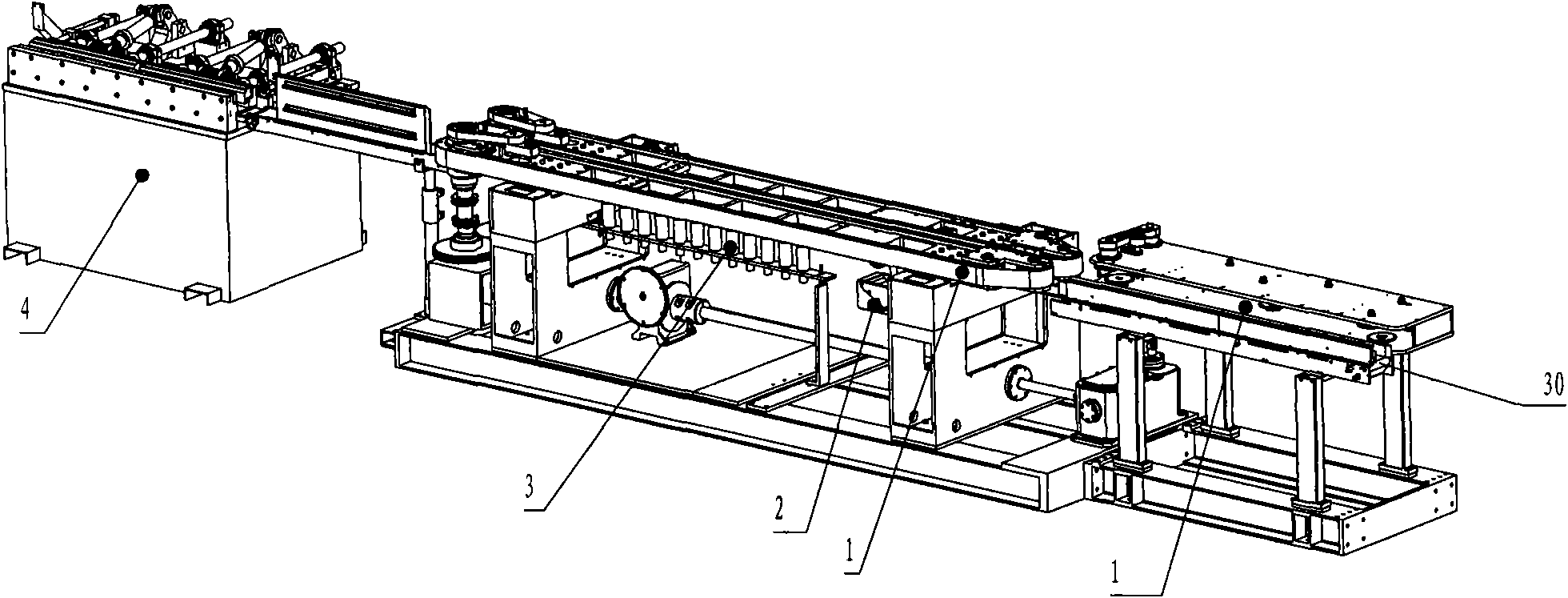

[0035] like figure 1 The shown discloses a book gluing system, which is mainly used for gluing the spine of hardcover books. After the paper of the hardcover books to be glued is folded, arranged, and threaded, it will pass through the front pressing device and count the paper. The air in the process of folding and threading is exhausted to make the signatures smooth, and then enters the book gluing system.

[0036] The book gluing system of the present invention comprises a book-feeding transmission mechanism 1, an automatic gluing mechanism 2, a drying mechanism 3 and a compacting mechanism 4, the book-feeding transmission mechanism 1 is directly connected with the compacting mechanism 4, the automatic gluing mechanism 2 and the drying mechanism 4 The dry mechanism 3 is arranged on the book feeding transmission mechanism 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com