Straightening process with external cold water for working rolls of straightening machine

A technology of external cooling water and straightening machine, which is applied in the field of steel rolling, which can solve problems such as poor plate shape, surface flesh loss, peeling, and affect the surface quality of steel plates, so as to achieve the effect of ensuring surface quality, surface brightness and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

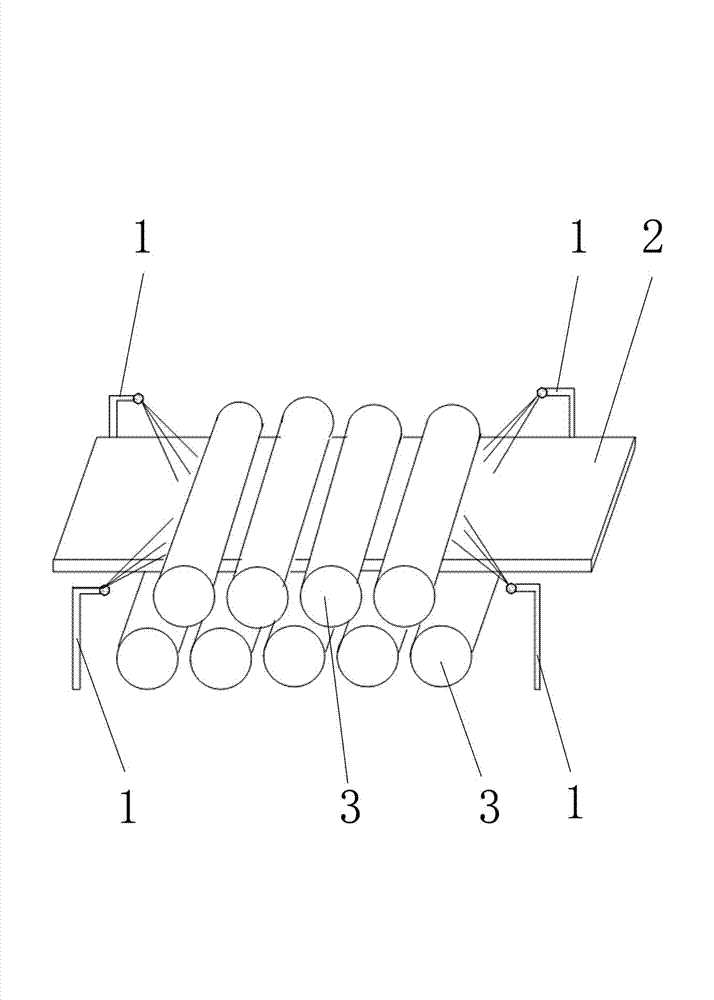

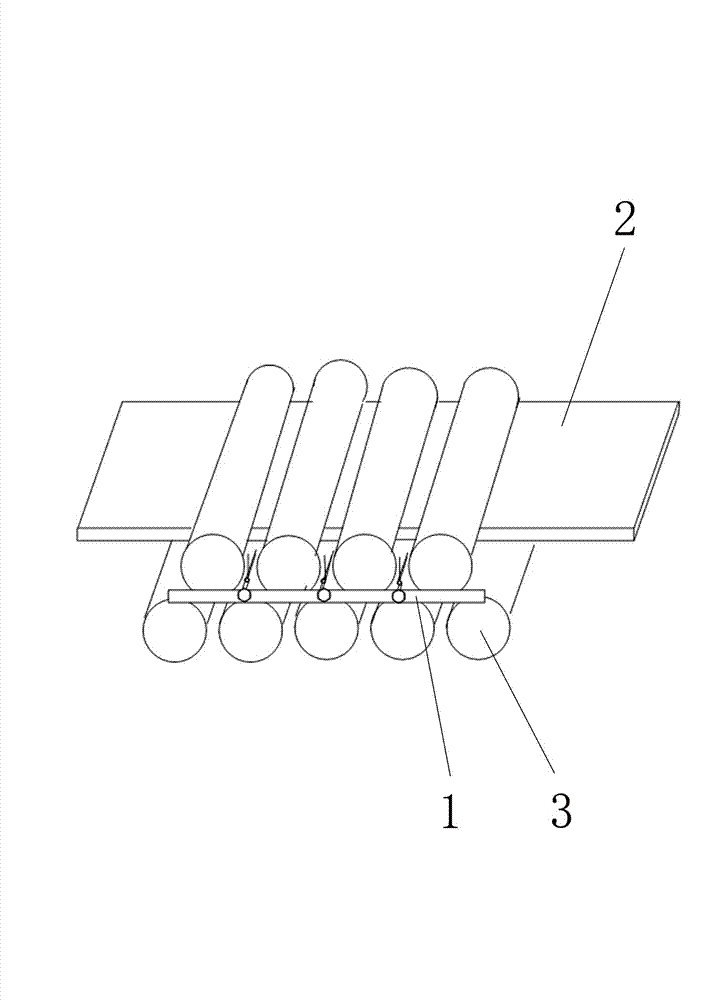

[0025] A straightening process for the cold water outside the work roll of the straightening machine. When the rolled piece enters the straightening machine for straightening, the two ends of the front end of the machine, the two ends of the rear end of the machine and the outer cold water on the operating side are in the open state. The cold water at the front and rear ends of the straightening machine can wash the surface of the steel plate, and the cold water at the operating side can wash the foreign matter on the straightening roller surface, so that the surface of the straightened steel plate is bright and clean without indentation The purpose is to ensure the surface quality of the steel plate.

[0026] In this embodiment, the continuous casting billet is selected. The actual size of the billet is 150×2480×4000mm, the thickness of the finished product is 11mm, and the final rolling temperature is 650-700°C.

[0027] When the rolled piece enters the straightening machine...

Embodiment 2

[0029] A straightening process for the cold water outside the work roll of the straightening machine. In the straightening process, before the rolled piece enters the straightening machine and after the straightening is completed, the two ends of the front end, the two ends of the rear end of the machine and the outer cold water on the operating side are in the In the open state, the temperature is too high due to the long-term contact between the straightening roller and the steel plate, which will cause the local hardness of the roller surface to decrease, pile up or lose meat, and cause unevenness or roll marks on the surface of the steel plate, ensuring the surface quality of the steel plate.

[0030] In this embodiment, the continuous casting billet is selected. The actual size of the billet is 250×2220×7200mm, the thickness of the finished product is 50mm, and the final rolling temperature is 900-950°C.

[0031] Before the rolled piece enters the straightening machine, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com