Mud and sludge sintered brick and preparation method thereof

A technology of sintered bricks and sludge, which is applied in the direction of biological sludge treatment, pyrolysis sludge, clay products, etc., can solve the problems of occupying large fields, secondary pollution, etc., and achieve improved volume load, good physical and mechanical properties, shortened The effect of volume loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

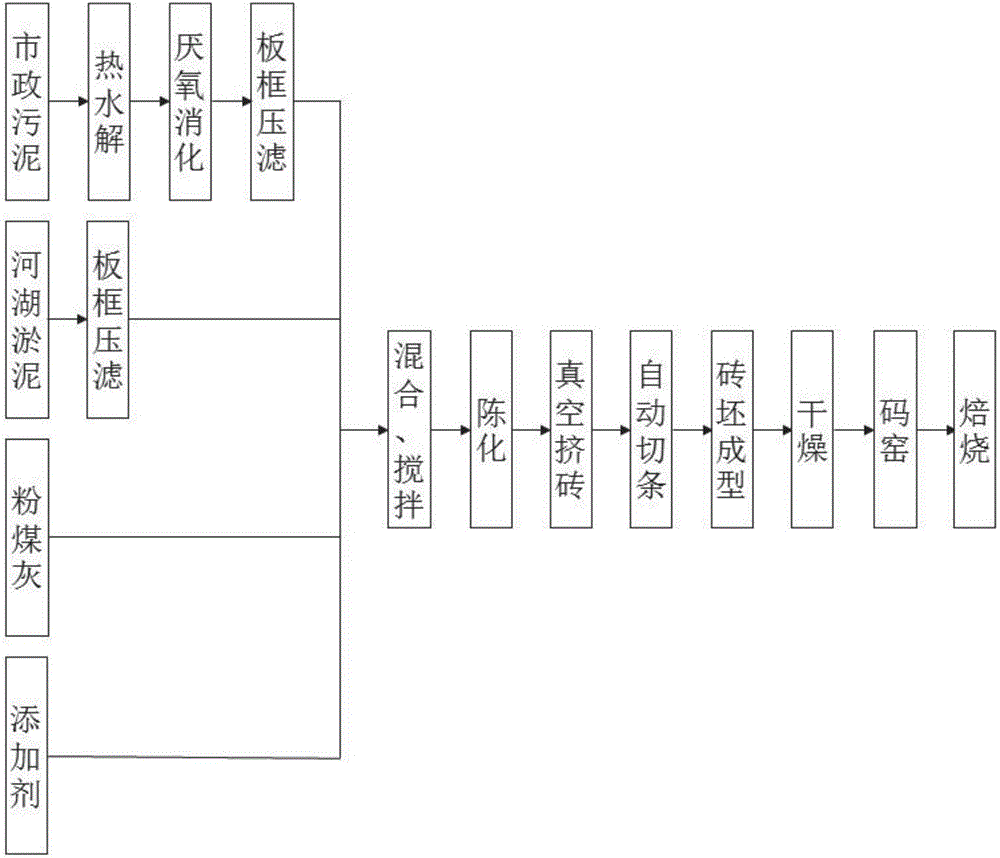

[0035] Such as figure 1 Shown, a kind of above-mentioned sludge and the preparation method of mud sintered brick of the present invention specifically comprise the following steps:

[0036] (1) Pretreatment of municipal sludge

[0037] Add water to the dewatered sludge in the municipal sewage treatment plant, adjust the TS to about 10%, pump it to the slurry tank of the thermal hydrolysis section for slurry treatment, and then transport it to the thermal hydrolysis flash integrated tank through the screw pump, and Inject saturated steam of 1.8-2.3MPa from the steam boiler from the upper part of the reaction kettle, stop injecting saturated steam when the temperature rises to 160-180°C, and keep it for 20min, exhaust steam and pressure and discharge the mud, the sludge is passed through After cooling, transport it to the anaerobic digestion system for medium-temperature anaerobic digestion T=35°C, SRT=20d, and then directly enter the digested mud into the plate and frame filte...

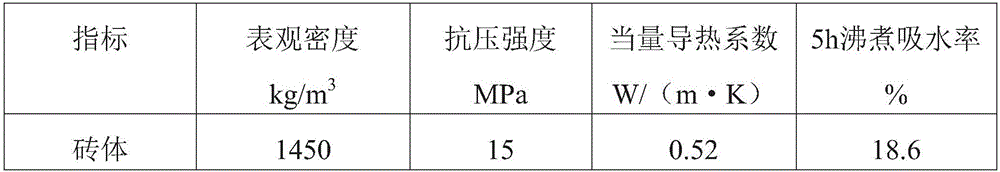

Embodiment 1

[0050]Embodiment 1: The preparation method of a kind of sludge and silt fired brick of present embodiment 1 specifically comprises the following steps:

[0051] (1) Pre-treatment of municipal sludge: add water to the dewatered sludge (TS=20%) of the municipal sewage treatment plant to adjust the TS to about 10%, pump it to the slurry tank for slurry treatment, and then transport it to the Thermal hydrolysis flash integrated tank, and inject saturated steam of 1.8-2.3MPa from the steam boiler from the upper part of the reactor, stop injecting saturated steam when the temperature rises to 160-180°C, and keep it for 20min, exhaust The pressure is released and the mud is discharged. After cooling, the sludge is transported into the anaerobic digestion system for mesophilic anaerobic digestion (T=35°C, SRT=20d). The above mud directly enters the plate and frame filter press to achieve solid-liquid separation. The moisture content of the solid phase after separation is reduced to ab...

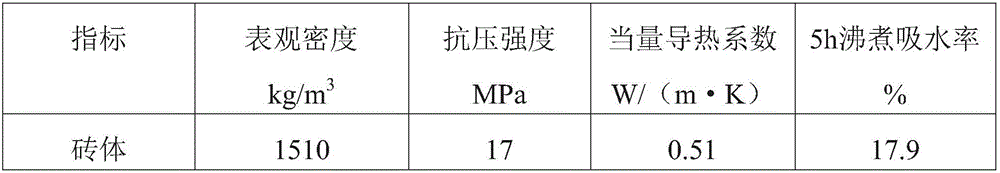

Embodiment 2

[0060] Embodiment 2: the preparation method of a kind of sludge and silt fired brick of present embodiment 2 specifically comprises the following steps:

[0061] (1) Pre-treatment of municipal sludge: Add water to the dewatered sludge (TS=20%) of the municipal sewage treatment plant to adjust the TS to about 10%, pump it to the slurry tank for slurry treatment, and then transport it to the Thermal hydrolysis flash integrated tank, and inject saturated steam of 1.8-2.3MPa from the steam boiler from the upper part of the reactor, stop injecting saturated steam when the temperature rises to 160-180°C, and keep it for 20min, exhaust The pressure is released and the mud is discharged, and the sludge is cooled and transported into an anaerobic digestion system for mesophilic anaerobic digestion (T=35°C, SRT=20d). The above mud directly enters the plate and frame filter press to realize solid-liquid separation, and the moisture content of the solid phase after separation is reduced t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com