Grouting material for impervious curtain of refuse landfill and preparation method of grouting material

A technology for landfills and grouting materials, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of good permeability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the grouting material for the anti-seepage curtain of the landfill site, the preparation of the grouting material is carried out according to the following steps:

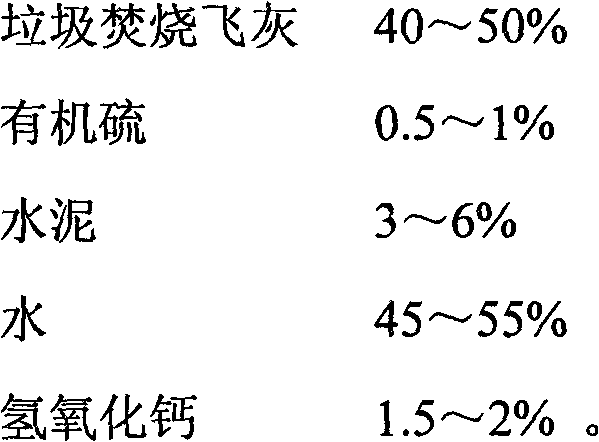

[0022] a Weigh each raw material according to mass percentage: waste incineration fly ash 40-50%, organic sulfur 0.5-1%, cement 3-6%, water 45-55%, calcium hydroxide 1.5-2%.

[0023] b Mix 40-50% of waste incineration fly ash, 0.5-1% organic sulfur and 45-55% water weighed above and stir for 5-10 minutes. Heavy metal ions (mercury, lead, copper, cadmium, nickel, manganese, zinc, chromium, etc.) react quickly to form chelates that are insoluble in water and have good chemical stability. The mobility is effectively controlled, and the detoxified garbage incineration fly ash slurry is obtained.

[0024] c. Mix the 3-6% cement and 1.5-2% calcium hydroxide weighed above into the waste incineration fly ash slurry obtained in step b, and stir for 3-5 minutes. The stirring is carried out i...

Embodiment 1

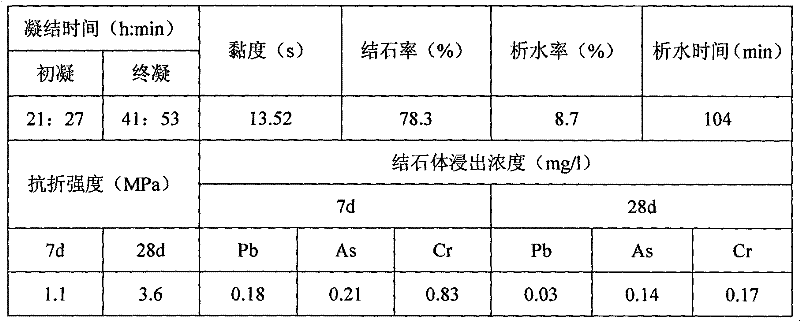

[0026] In this embodiment, 500g of waste incineration fly ash is weighed, the average particle diameter of the fly ash is 78 μm and Al 2 o 3 +SiO2 2 The content is 28%, organic sulfur 5.5g, deionized water 500g, 32.5# ordinary Portland cement 50g and calcium hydroxide 20g, first mix the waste incineration fly ash, organic sulfur and deionized water in a strong mixer and stir evenly 5 minutes to obtain the detoxified waste incineration fly ash slurry, then mix cement and calcium hydroxide into it and stir again for 3 minutes to obtain the grouting material for the anti-seepage curtain of the landfill, and then use the consistency meter method to measure the initial setting of the slurry Time and final coagulation time, the viscosity was tested by the viscometer method, the calculus rate was tested by the titration method, and the water separation rate was measured by the graduated cylinder method. The test piece is formed by a 40mm×40mm×160mm test mold, demoulded after pourin...

Embodiment 2

[0030] In this embodiment, 500g of waste incineration fly ash is weighed, the average particle diameter of the fly ash is 48 μm and Al 2 o 3 +SiO2 2 The content is 64%, organic sulfur 10.0g, deionized water 600g, fly ash Portland cement 60g and calcium hydroxide 25g, first mix the waste incineration fly ash, organic sulfur and deionized water in a strong mixer and stir evenly 8 minutes to obtain the detoxified waste incineration fly ash slurry, then mix cement and calcium hydroxide into it and stir again for 5 minutes to obtain the grouting material for the anti-seepage curtain of the landfill, and then use the consistency meter method to measure the initial setting of the slurry Time and final coagulation time, the viscosity was tested by the viscometer method, the calculus rate was tested by the titration method, and the water separation rate was measured by the graduated cylinder method. The test piece is formed by a 40mm×40mm×160mm test mold, demoulded after pouring for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com