Patents

Literature

136 results about "Municipal solid waste incineration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

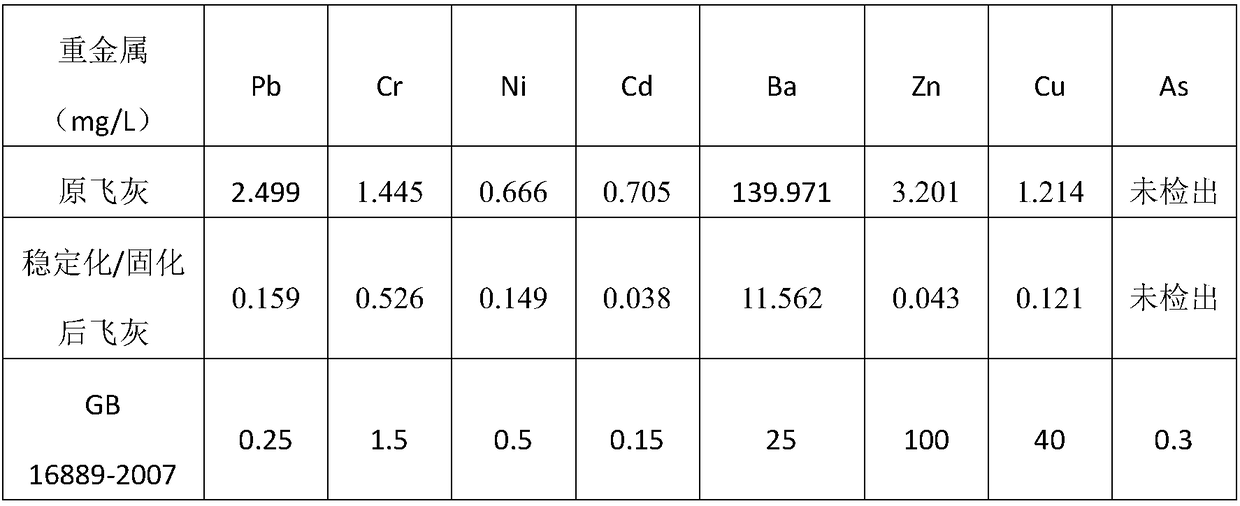

Curing agent and curing method for heavy metals in fly ash from mswi (municipal solid waste incineration)

InactiveCN106377867ARealize harmless treatmentStrong Stabilizing TetheringChemical protectionHydration reactionResource utilization

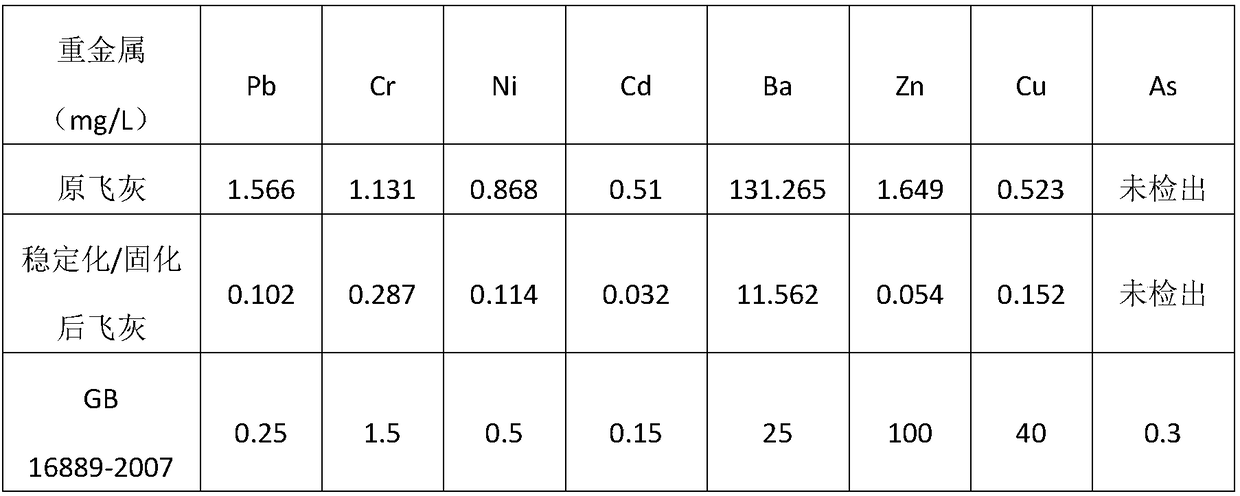

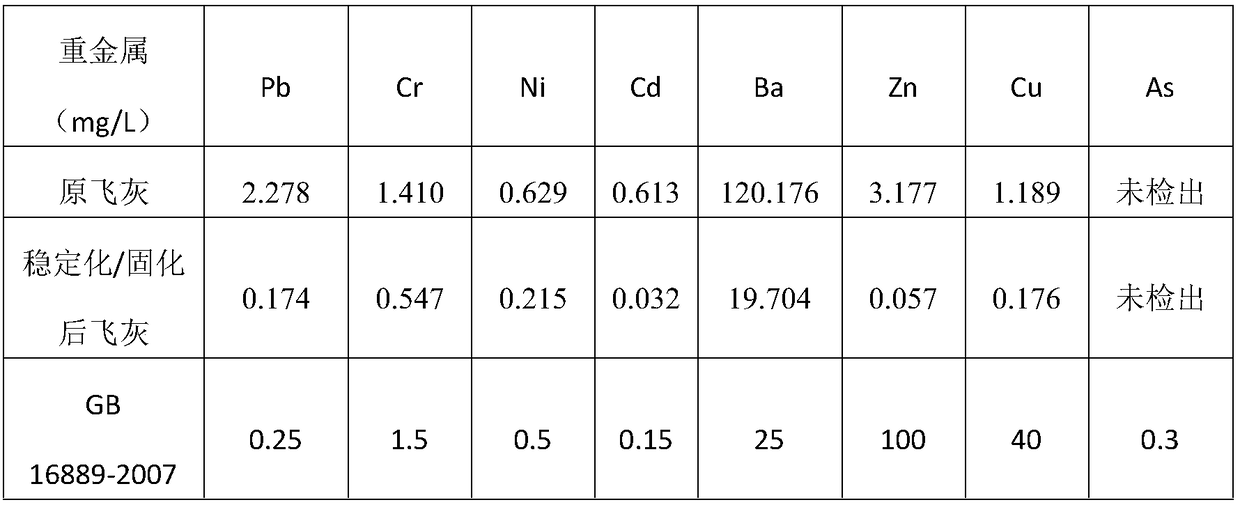

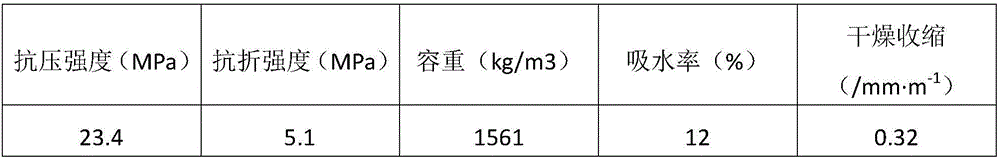

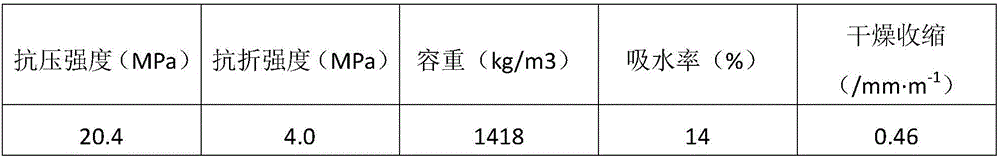

The invention provides a curing agent and a curing method for heavy metals in fly ash from mswi (municipal solid waste incineration). The curing agent comprises an aluminum-rich high-silicon material and an alkaline exciting agent, wherein the mass of the aluminum-rich high-silicon material is 15% to 25% of the mass of the fly ash from mswi; the mass of the alkaline exciting agent is 3% to 5% of the mass of the fly ash from mswi. The curing agent adopts industrial waste residues, and raw materials are cheap and easy to obtain; according to the curing method, lots of calcium oxide, chloride and sulfide existing in the fly ash from mswi have a hydration reaction with the aluminum-rich high-silicon material to generate a C-S-H (calcium silicate hydrate), Friedel (calcium chloroaluminate) phase and Aft (ettringite) phase system; during the formation process of the mineral system, a solid solution is formed through ion exchange, a new phase is formed through coprecipitation, and a relatively strong stable constraint effect can be played on heavy metals through physical adsorption and coating, so that wastes can be treated by using wastes, and harmless treatment of the fly ash from mswi and resource utilization of the industrial waste residues are realized.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

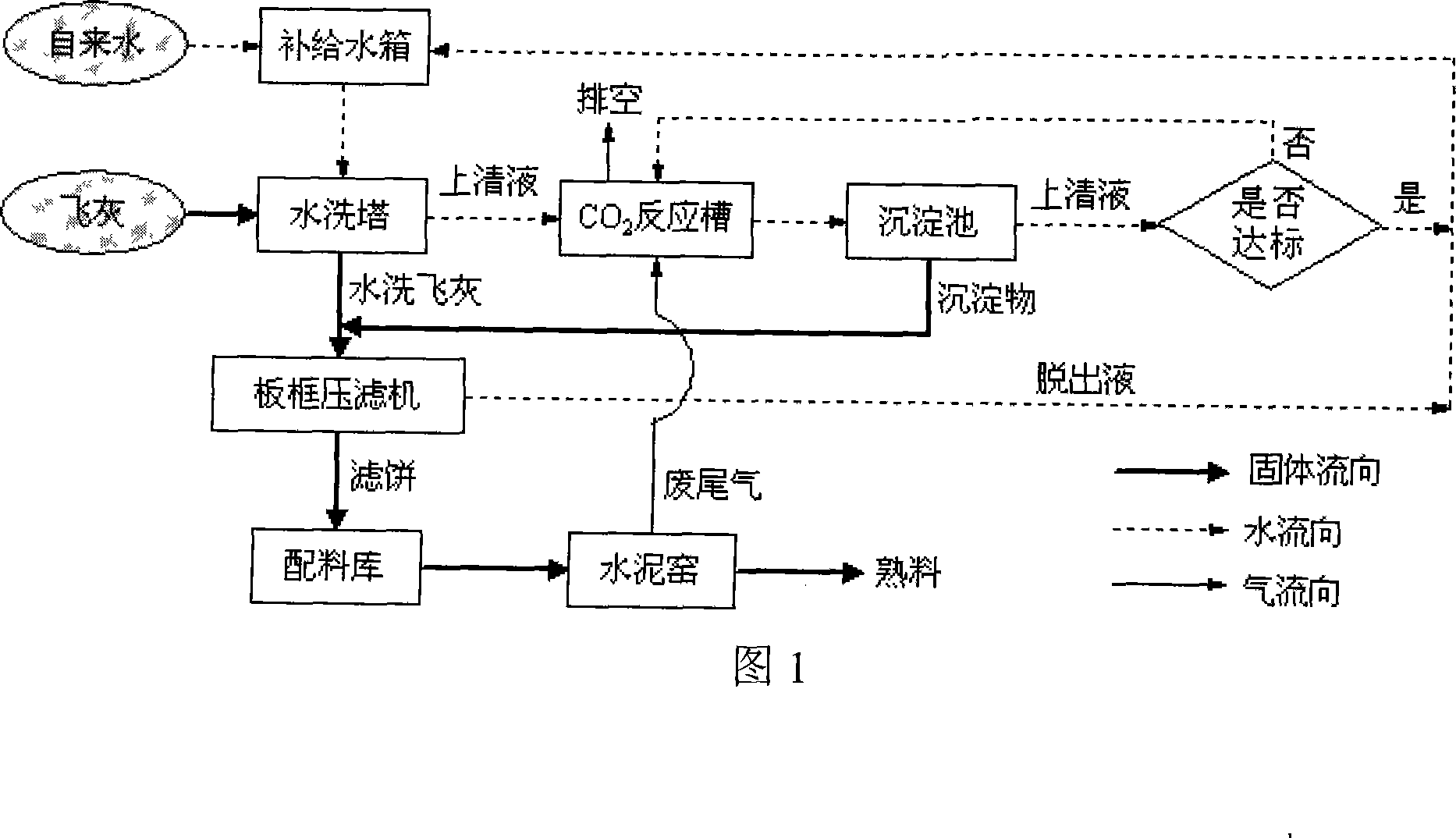

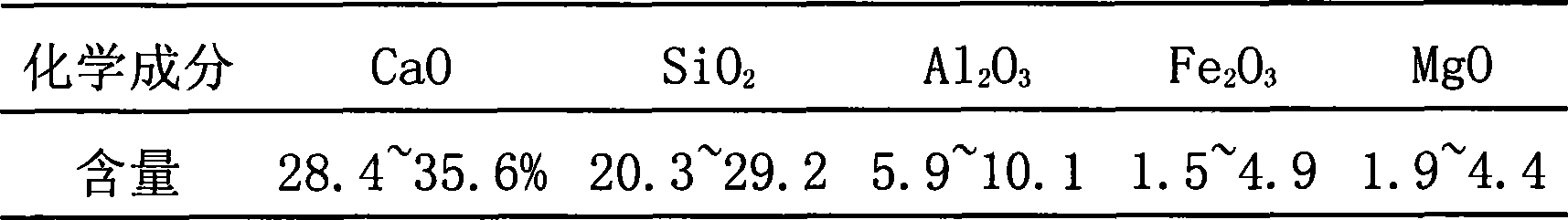

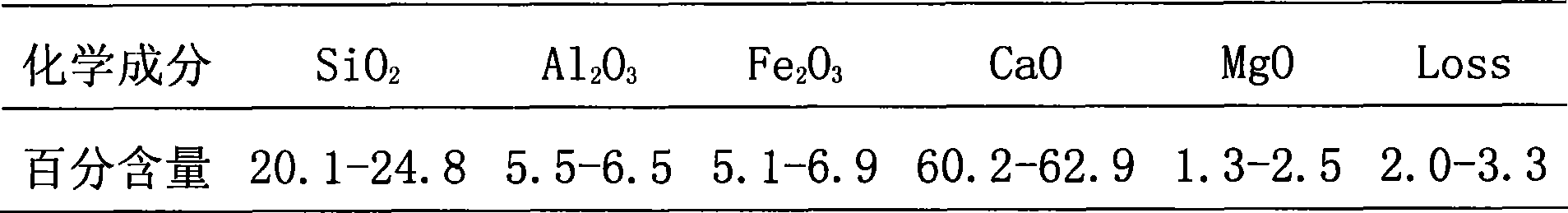

Cement kiln calcining resource method for domestic waste burning fly ash

The invention discloses a municipal solid waste incineration fly ash cement kiln calcining resource recovery method, which belongs to the solid waste treatment and disposal technical field. Firstly, the washing pretreatment is implemented on municipal solid waste incineration fly ash to dissolute alkali metal chloride, then supernatant and washed fly ash are obtained through the natural sedimentation. Waste tail gas is pumped in the supernatant, CO2 in which is used to realize the carbonate neutralization and the heavy metal co-sedimentation to reach to the first grade of the national sewage comprehensive discharge standard. The washed fly ash and carbonate are pressed and filtered together for the dehydration. A filter cake is used as cement raw to be input in a cement kiln for the calcining to produce cement clinker. The invention can realize the harmless resource recovery treatment of incineration simply and economically.

Owner:TSINGHUA UNIV

Method for preparing light concrete by municipal solid waste incineration fly ash

InactiveCN101531492ATo achieve the purpose of harmless treatmentSimple processSolid waste managementApparent densityPortland cement

The invention discloses a method for preparing light concrete by municipal solid waste incineration fly ash. The light concrete comprises the following compositions according to material ratio: 330 to 370kg / m<3> of the municipal solid waste incineration fly ash, 450 to 475kg / m<3> of 525# common Portland cement, 325 to 340kg / m<3> of water-granulated slag, 350 to 370kg / m<3> of ordinary clay porcelain granules, 230 to 240kg / m<3> of diabase slag, and 2.7 to 2.9kg / m<3> of admixture. The method uses the municipal solid waste incineration fly ash to prepare the light concrete, can solidify heavy metal in fly ash, thereby achieving the aim of innocent treatment of the municipal solid waste incineration fly ash. The method has a simple process, and the obtained finished product has strength grade of CL40 and apparent density of 1800, and has good macroscopic performance.

Owner:SHANGHAI INST OF TECH

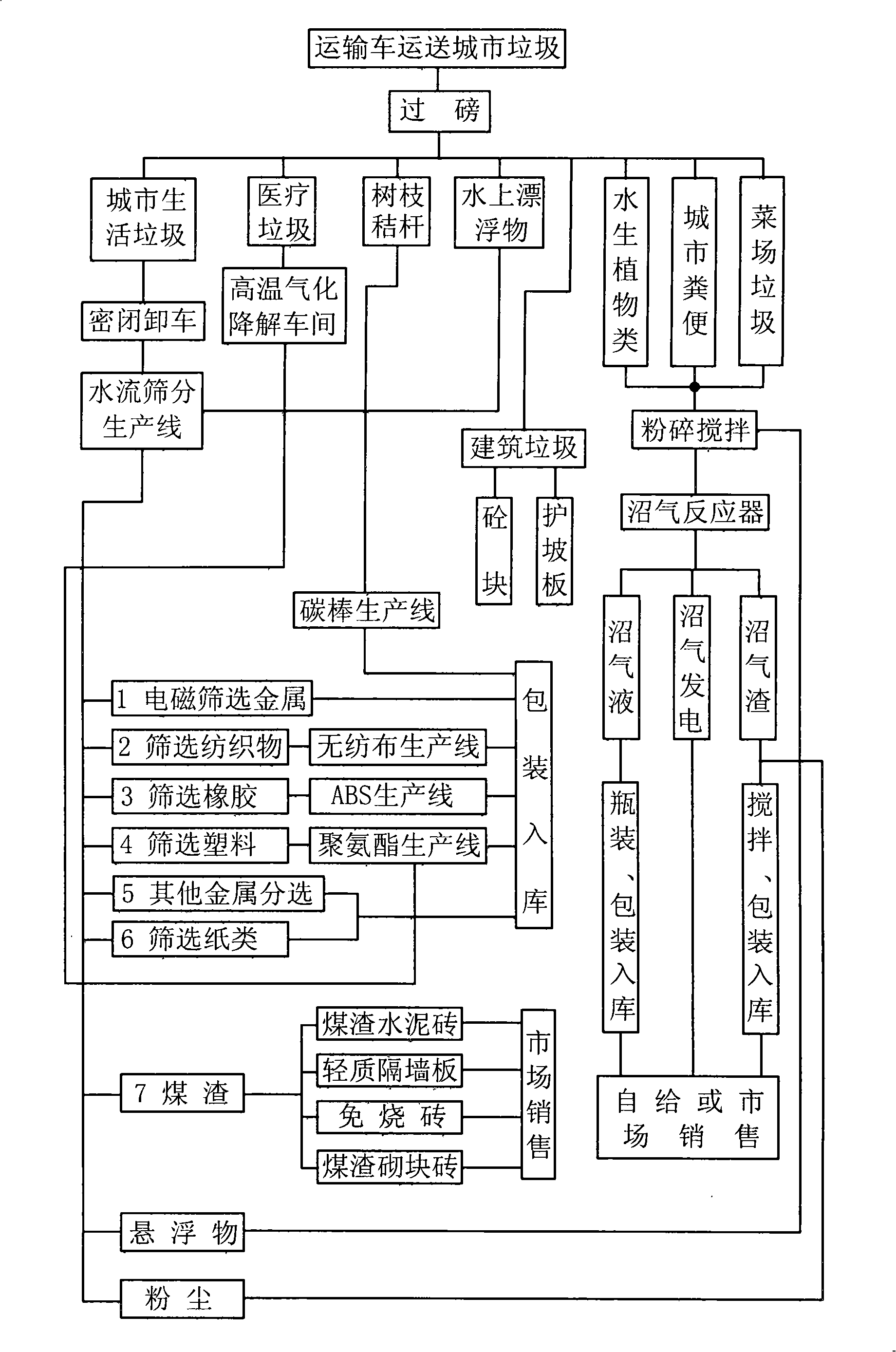

Comprehensive treatment and utilization technique for urban domestic garbage

InactiveCN101318192AAvoid occupyingAvoid pollutionBio-organic fraction processingSolid waste disposalMedical treatmentNight soil

The invention relates to a comprehensive treatment utilization technology for municipal domestic waste, which belongs to the technical field of treating and recycling municipal waste; the technology is as follows: the municipal waste is transported to a waste treatment plant so as to carry out harmless treatment, then is classified into eight kinds, that is, the municipal domestic waste, medical waste, branches and straws, floater on water surface, construction waste, aquatic plant, urban night soil and market waste, and is transported to a department belonging to one kind so as to be treated and recycled. The technology of the invention solves the problems of occupying a lot of lands, and polluting environment and groundwater resources caused by the landfill mode which is adopted to treat the municipal waste for a long time, solves the problems in municipal solid waste incineration that dioxin, a carcinogenesis gas, is released into air and 40 percent of waste residues still need to be land-filled, so that lands still needs to be occupied; therefore, the technology can change the municipal waste into valuables, recycle natural resources, give full play to the value of resource recycling, and realize the measures advocated by the country such as 'waste reduction', 'resource recycling' and 'harmlessness', thus being suitable for waste treatment in different cities.

Owner:武汉生宝丰泽环保科技有限公司

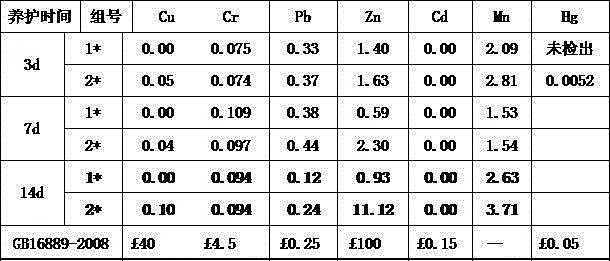

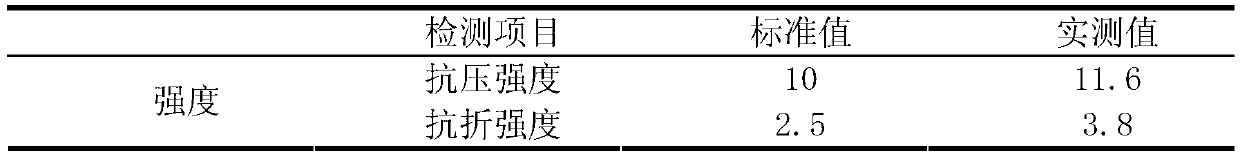

Municipal solid waste incineration fly ash curing method

InactiveCN104607434AReduce dosageRealize comprehensive utilizationSolid waste disposalStrontium carbonateEnvironmental engineering

The invention discloses a municipal solid waste incineration fly ash curing method. The method comprises the steps of mixing waste incineration fly ash, cesium carbonate waste residue, potassium carbonate and cement according to the ratio of (40-50): (25-38): (3-6): (15-25); then, feeding right amount of purified water into the mixture, evenly mixing, enabling a molding model to be filled with the mixture, extruding and compacting; after that, standing the model in the air for 24 hours, and then demoulding to obtain a cured green body; maintaining the cured green body to obtain a cured body which can be directly buried, wherein the maintaining time is not shorter than 14 days. According to the method, the cesium carbonate waste residue is taken as an important raw material for curing the fly ash, so that the consumption of the cement is greatly reduced, waste recycling is realized, and the waste incineration fly ash curing cost is lowered. After the method is used, the compressive strength of the cured body and the heavy metal leaching completely meet the landfill requirements.

Owner:CHONGQING UNIV

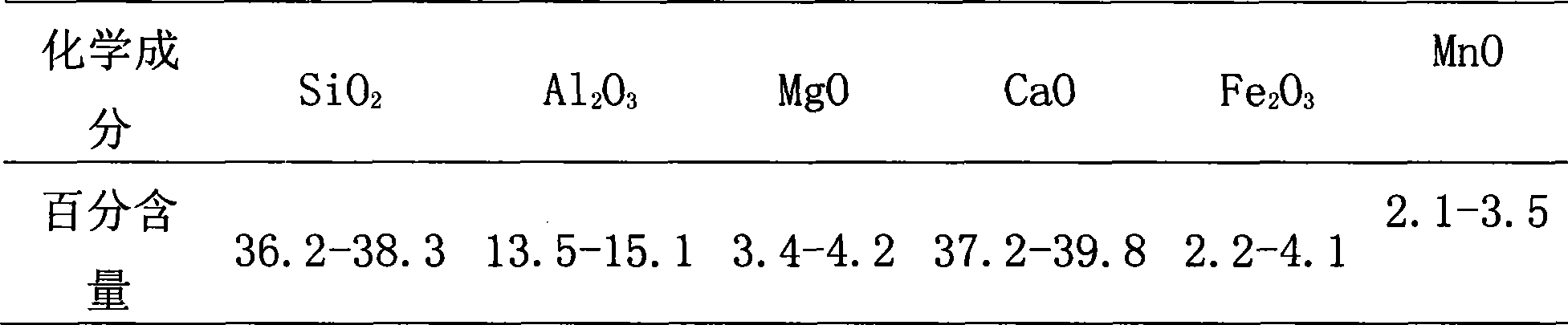

Method for preparing sintered ore by utilizing municipal solid waste incineration fly ash

InactiveCN106011459AEfficient use ofImprove low temperature pulverization performanceSolid waste disposalTransportation and packagingSludgeSlag

The invention provides a method for preparing sintered ore by utilizing municipal solid waste incineration fly ash. The method comprises the following steps of uniformly mixing the fly ash, water and an auxiliary material to obtain a mixture; mixing the mixture, iron ore powder, a solvent, fuel, returning ore and water to obtain a sintered material; sintering the sintered material at the ignition temperature of 1,000 to 1,100 DEG C to obtain the sintered ore, wherein the auxiliary material comprises at least one of blast furnace gas ash, bof dust sludge and sulfate slag. Compared with the prior art, the method for preparing the sintered ore by utilizing the municipal solid waste incineration fly ash has the following beneficial effects that (1) valuable components such as CaO, Fe2O3, MgO and Al2O3 in the fly ash can be effectively utilized, and the components and the performance of the sintered ore are adjusted by utilizing the fly ash; (2) chloride in the fly ash can be effectively utilized, and the low-temperature pulverization property of the domestic sintered ore is improved by adding CaCl2 usually.

Owner:宝武集团环境资源科技有限公司

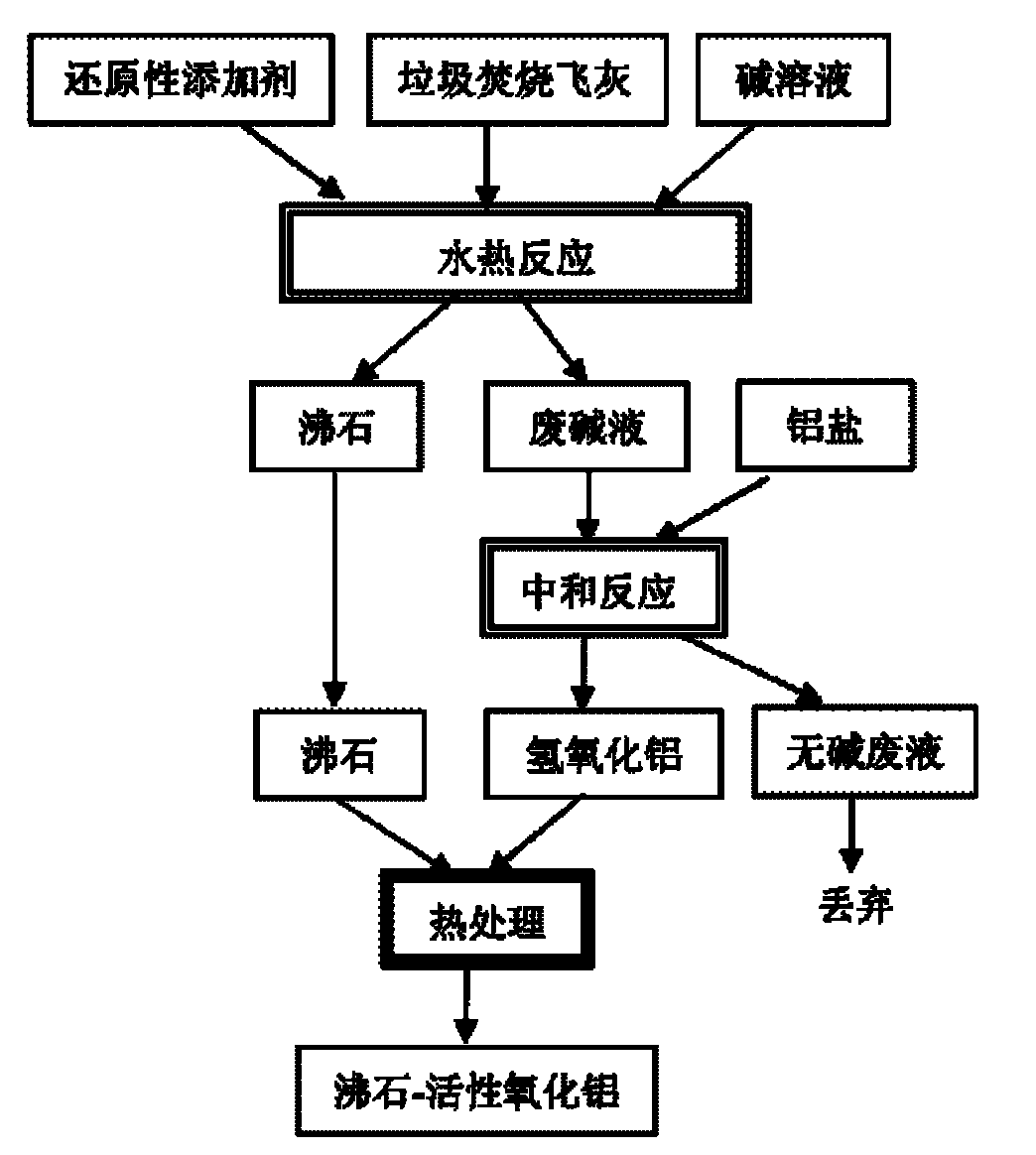

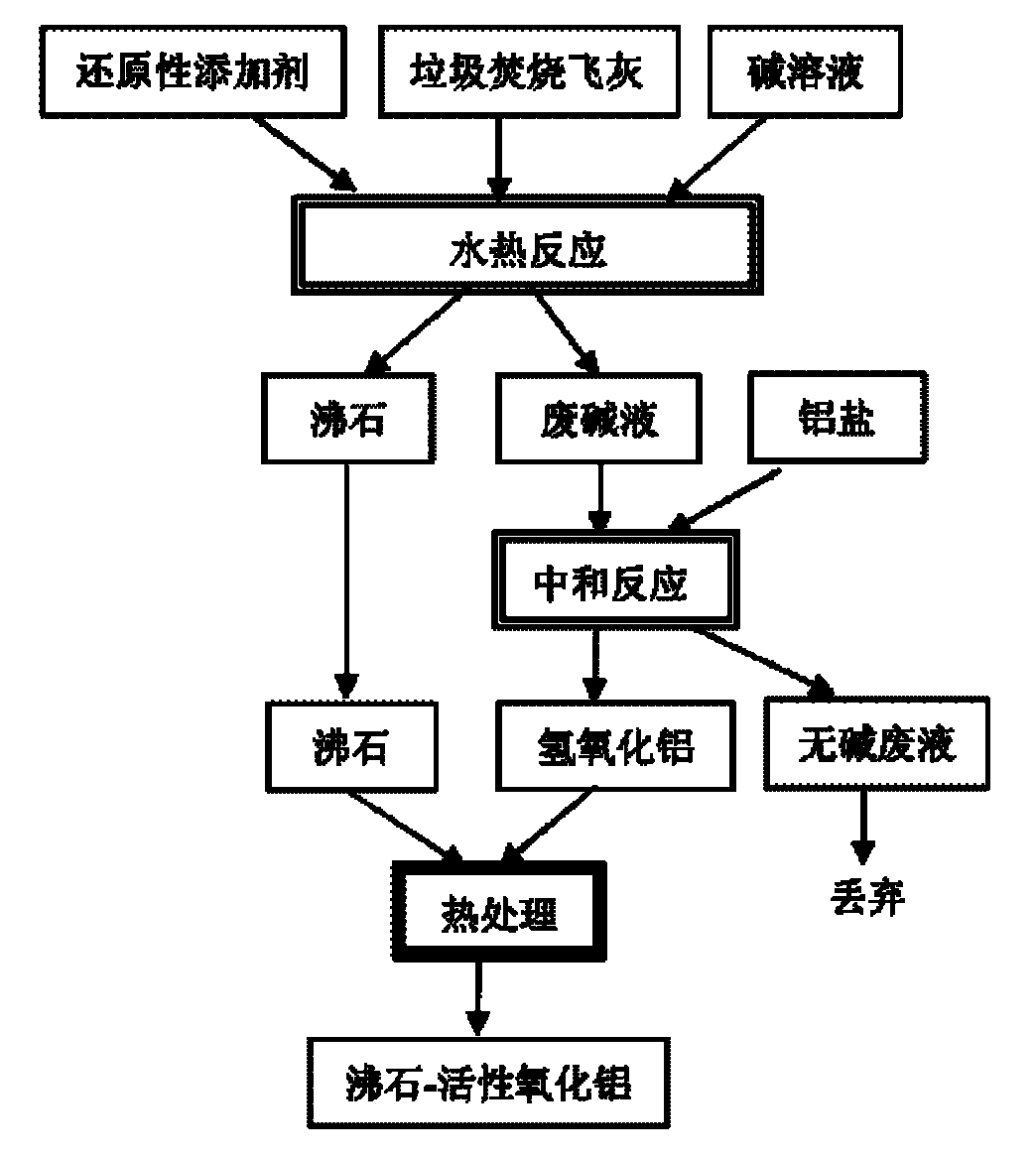

Heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash

InactiveCN102206757AWith resource recyclingAchieving harmlessnessOther chemical processesSolid waste disposalSorbentWater soluble

The invention relates to a heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash in the technical field of treatment for environmental protection. After an alkali solution and hydrazine substances are added to the MSWI fly ash and heated, and a water-soluble aluminum salt solution is further dripped; finally, after solid and liquid separation is conducted, heat treatment is carried out on an obtained solid phase to obtain a zeolite-active alumina compound absorbant; and the absorbant is put into sewage full of heavy metal to absorb and recycle the heavy metal. In the preparation process of the absorbant provided by the invention, dioxin in the MSWI fly ash is decomposed and removed; the MSWI fly ash is recycled as resources, and the heavy metal in the MSWI fly ash and the heavy metal in the sewage are recycled as the resources; and because the dioxin is decomposed and removed and the heavy metal is also extracted, the recycling method provided by the invention is safer and more reliable compared with the traditional treatment manner.

Owner:SHANGHAI JIAO TONG UNIV

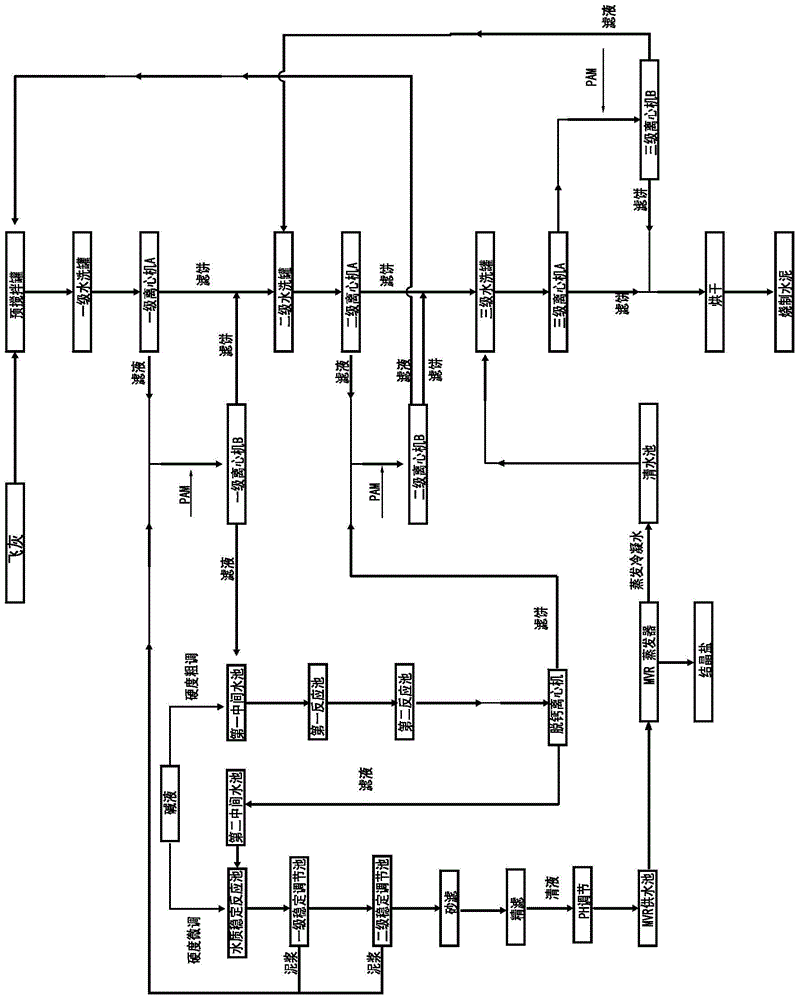

Washing softening technology for MSWI (Municipal Solid Waste Incineration) fly ash

ActiveCN104803537ASolving Excessive Chlorine ProblemsGuaranteed qualityWater/sewage treatment by centrifugal separationSludge treatmentWater qualityTherapeutic effect

The invention discloses a washing softening technology for MSWI (Municipal Solid Waste Incineration) fly ash. The technology comprises the following steps of performing primary washing on the fly ash; performing primary centrifugal dewatering on the washed fly ash after the washing operation is completed; adding a PAM (Polyacrylamide) solution into the separated filter liquor and uniformly blending; feeding the mixture into a first-level centrifugal machine B for performing secondary centrifugal dewatering; feeding the filter liquor separated from the first-level centrifugal machine B into a decalcified centrifugal machine for centrifuging after the filter liquor is subjected to hardness coarse-adjustment and heavy metal removal treatment; finely adjusting the hardness of the filter liquor separated from the decalcified centrifugal machine, sequentially precipitating and filtering the filter liquor, and adjusting the PH value of the filter liquor to be 7-8; finally feeding the filter liquor to an MVR (Mechanical vapor recompression) evaporator. According to the washing softening technology for the MSWI (Municipal Solid Waste Incineration) fly ash, the washing treatment effect is good, and the effluent quality is stable; a filter cake separated from the decalcified centrifugal machine is mixed with the filter liquor discharged by a second-level centrifugal machine A, and then the mixture is subjected to subsequent treatment, so that the mixture can be washed twice again, therefore the content of chloride ions in the filter cake is smaller than 0.5%, and the problem of high chlorine content in the filter cake is solved, and the cement quality is guaranteed.

Owner:BEIJING ZKGR ENVIRONMENTAL PROTECTION TECH CO LTD

Municipal solid waste incineration fly ash resource utilization method

ActiveCN103128005ARealize resource utilizationMeet harmless requirementsFlotationBrickResource utilization

The invention provides a municipal solid waste incineration fly ash resource utilization method and relates to municipal solid waste treatment. The method includes a first step of mixing fly ash and water in a floatation tank, adding in sodium sulphide and stirring the mixture so as to enable salt in the fly ash to be dissolved into the water, and enabling heavy metal such as plumbum (Pb) and zinc (Zn) in an oxidation state in the fly ash to achieve vulcanizing to generate plumbum sulfide (PbS) and zinc sulfide (ZnS), a second step of adding collecting agents into the floatation tank again and stirring so as to enable the collecting agents to fully contact with the fly ash and enable the collecting agents to be adsorbed on the surfaces of vulcanized heavy metal, a third step of adding foaming agents and terpenic oil in the floatation tank, carrying out flotation separation and centrifugal dewatering, adding cement, sand, water, exciting agents, namely sodium delicate, and alum into the obtained fly ash and stirring, filling stirred samples into a trial mould, compacting the stirred samples, placing and maintaining the stirred samples and then demoulding to obtain cement blocks, and a fourth step of carrying out centrifugal dewatering on floating objects in the floatation tank, sending the floating objects into a household garbage incineration plant, and carrying out high-temperature processing on dioxin, wherein the dioxin can be completely resolved under an environment with the temperature larger than 850 DEG C and smoke stay time more than 2 hours (s), and smoke reaches the standard and is exhausted.

Owner:XIAMEN UNIV +1

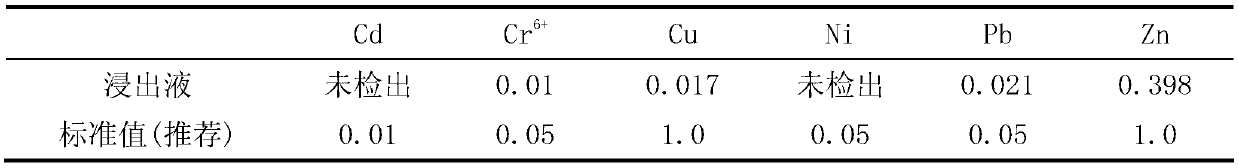

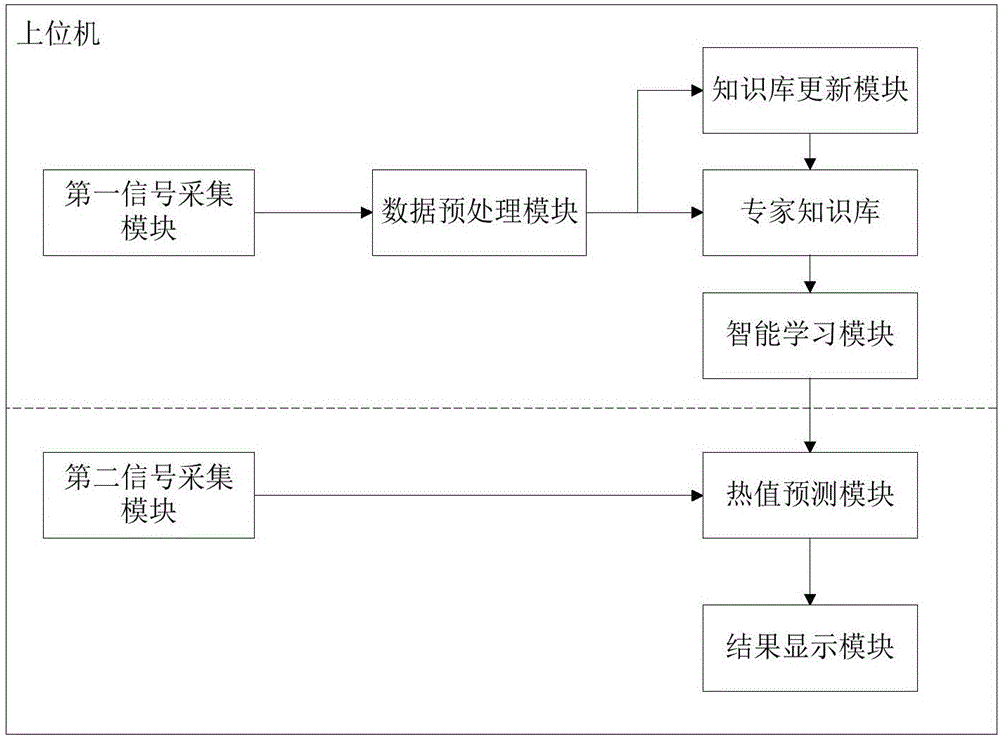

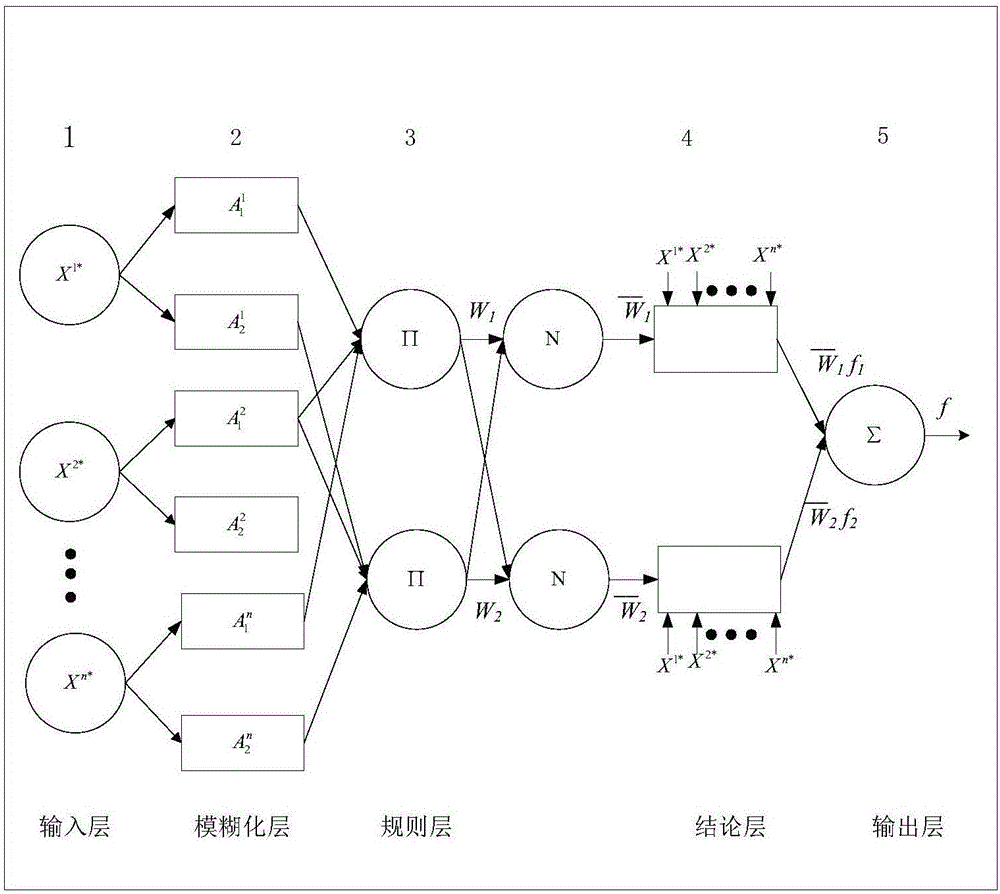

Method and system for predicting bed temperature of circulating fluidized bed municipal solid waste incineration boiler

ActiveCN106224939AHigh degree of automationPrevent overfittingFluidized bed combustionIncinerator apparatusCluster algorithmTacit knowledge

The invention discloses a method and system for predicting the bed temperature of a circulating fluidized bed municipal solid waste incineration boiler. Based on tacit knowledge in operation mechanisms and operation history data of the circulating fluidized bed municipal solid waste incineration boiler, a modeling method is integrated by a Gamma Test algorithm, a PSO (particle swarm optimization) algorithm, a subtractive clustering algorithm and an ANFIS (adaptive neuro-fuzzy inference system) algorithm for predicting a bed temperature of the boiler in real time to avoid from complex mechanism modeling work. The whole modeling process is clear in logic, few in set parameters, high in modeling automation degree and easy to master and popularize. Meanwhile, an excellently trained ANFIS bed temperature diction model can serve control algorithms based on the model to provide help for ACC (automatic combustion control) system actuation of the circulating fluidized bed municipal solid waste incineration boiler.

Owner:ZHEJIANG UNIV

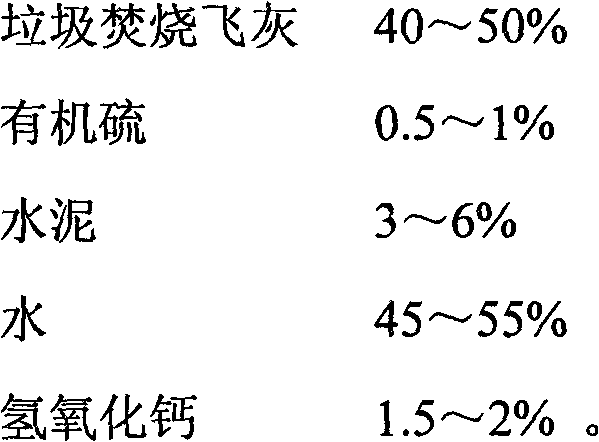

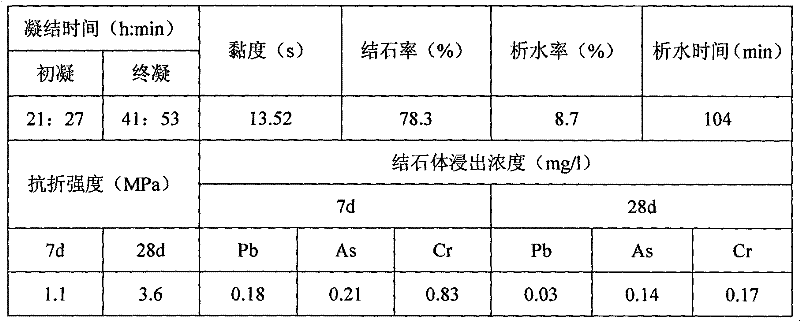

Grouting material for impervious curtain of refuse landfill and preparation method of grouting material

The invention relates to a grouting material for an impervious curtain of a refuse landfill and a preparation method of the grouting material. The grouting material comprises the following components in percentage by mass: 40 to 50 percent of MSWI (Municipal Solid Waste Incineration) fly ash, 0.5 to 1 percent of organic sulfur, 3 to 6 percent of cement, 45 to 55 percent of water, and 1.5 to 2 percent of calcium hydroxide. The method for preparing the grouting material comprises the following steps of: (1) weighing raw materials; (2) mixing the MSWI fly ash, the water and the organic sulfur, and uniformly stirring for 5 to 10 minutes; and (3) interfusing the cement and the calcium hydroxide, and uniformly stirring for 3 to 5 minutes. According to the grouting material, the problems of material selection difficulty, high cost, poor fluidity, low stability and poor impermeability of a conventional grouting material can be solved. The preparation method has the advantages of short processroute, simple operation, time saving and the like.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

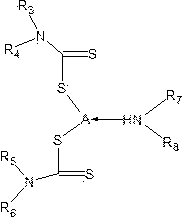

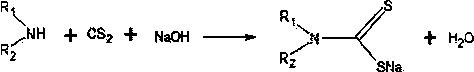

Novel synthetic heavy metal chelating agent

The invention belongs to the technical field of harmless treatment of municipal solid waste incineration fly ash, and solves the solidification problem of heavy metal ions in fly ash. A method for preparing a novel synthetic heavy metal chelating agent comprises the following steps: mixing a polyethyleneimine water solution with a sodium hydroxide water solution, and dropwise adding carbon disulfide to obtain an orange red jelly-like solid, namely the heavy metal chelating agent. The method is simple in process, low in cost, easy and convenient to operate, wide in application range, low in environmental pollution and suitable for industrialized production.

Owner:SICHUAN UNIV

Method for recycling inorganic salt in municipal solid waste incineration fly ash

ActiveCN106185989AReduce wasteRealize high-value utilizationCalcium/strontium/barium chloridesAlkali metal chloridesInorganic saltsLitter

The invention discloses a method for recycling inorganic salt in municipal solid waste incineration fly ash. The method includes the steps of firstly, extracting fly ash multiple times to improve the concentration of an extraction solution; secondly, through the design of the evaporation step, separating out sodium chloride, separating out potassium chloride and sodium chloride through evaporation and separating out calcium chloride through evaporation to extract all main inorganic salt including calcium salt; thirdly, recycling a mother solution in the extraction process to avoid secondary pollution. Energy consumption in the evaporation process is reduced, high-purity potassium chloride, sodium chloride and calcium chloride are obtained, and the resourceful utilization of fly ash is achieved.

Owner:HEBEI UNIV OF TECH

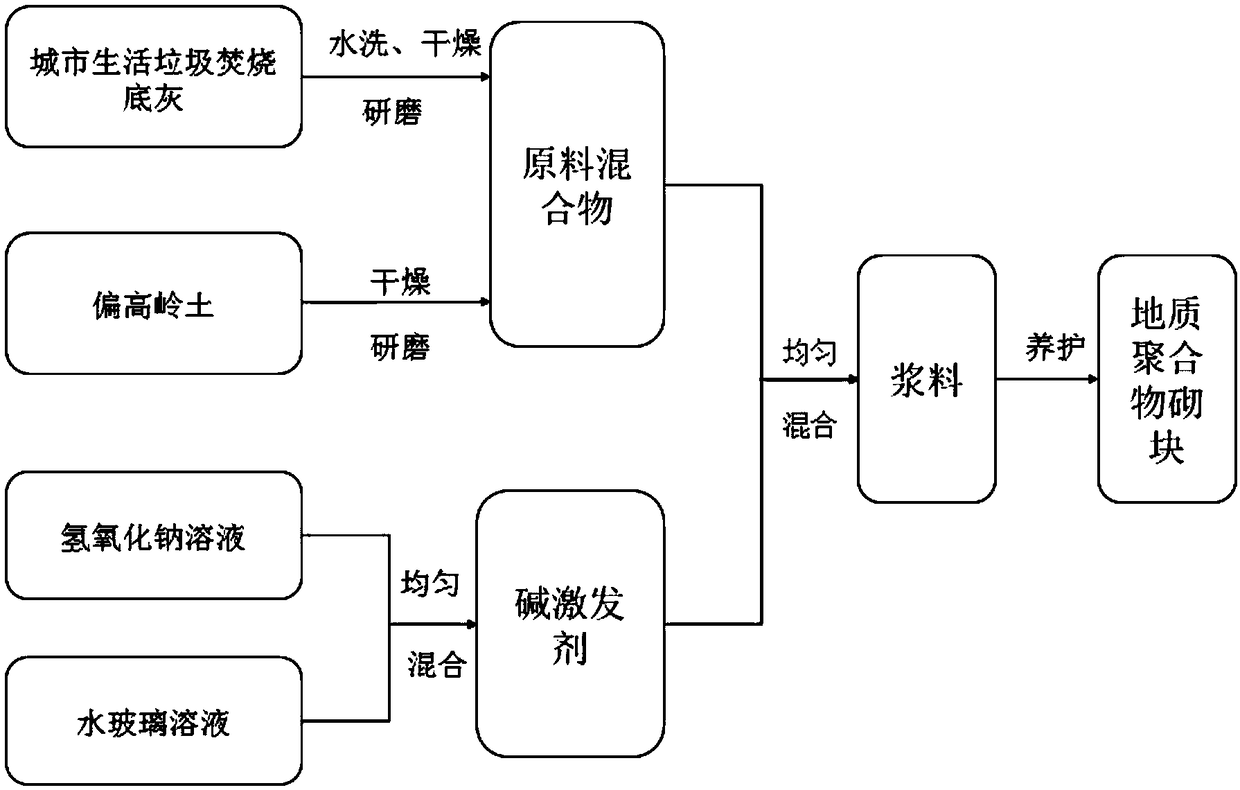

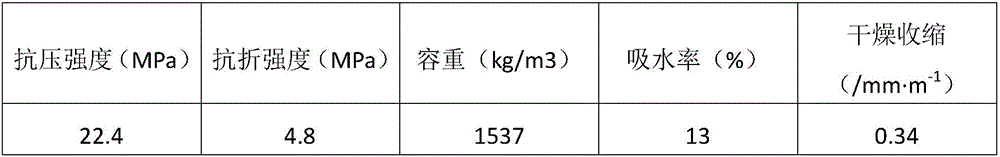

Geological polymer porous heat-insulation material based on municipal solid waste incineration bottom ash and preparation method of geological polymer porous heat-insulation material

The invention discloses a geological polymer porous heat-insulation material based on municipal solid waste incineration bottom ash and a preparation method of the geological polymer porous heat-insulation material. The geological polymer porous heat-insulation material is prepared from the following raw materials: the incineration bottom ash, metakaolin and an alkali activator. The preparation method of the geological polymer porous heat-insulation material comprises the steps that the incineration bottom ash is washed, dried and ball-milled firstly into incineration bottom ash powder; then the metakaolin is dried and ball-milled into metakaolin powder; the incineration bottom ash powder is mixed with the metakaolin powder; mixed powder and the alkali activator are mixed and stirred; prepared geological polymer slurry is poured; and after drying is conducted at 60-80 DEG C for 12-24 h, demoulding is conducted, and the porous heat-insulation material is obtained after maintenance. Themunicipal solid waste incineration bottom ash is utilized to be matched with the small amount of added metakaolin, a polymerization reaction is generated under the effect of the alkali activator to prepare a geological polymer, and thus secondary utilization of the municipal solid waste incineration bottom ash is achieved.

Owner:YANCHENG INST OF TECH

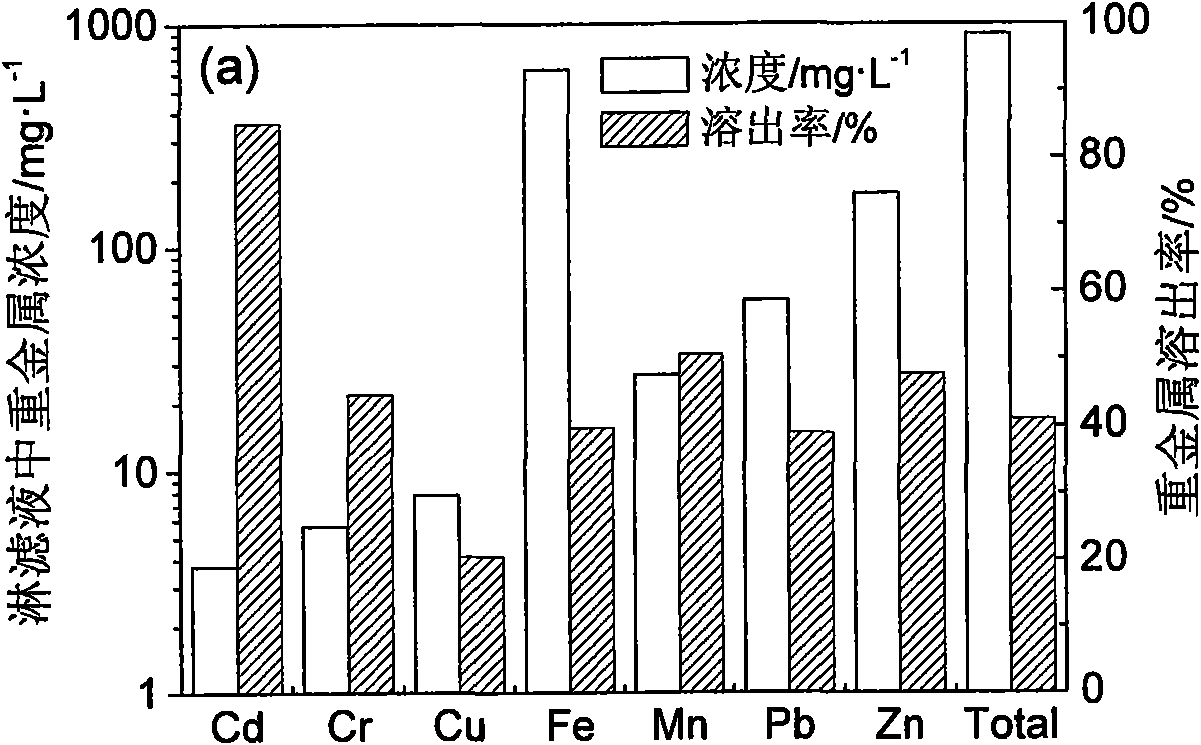

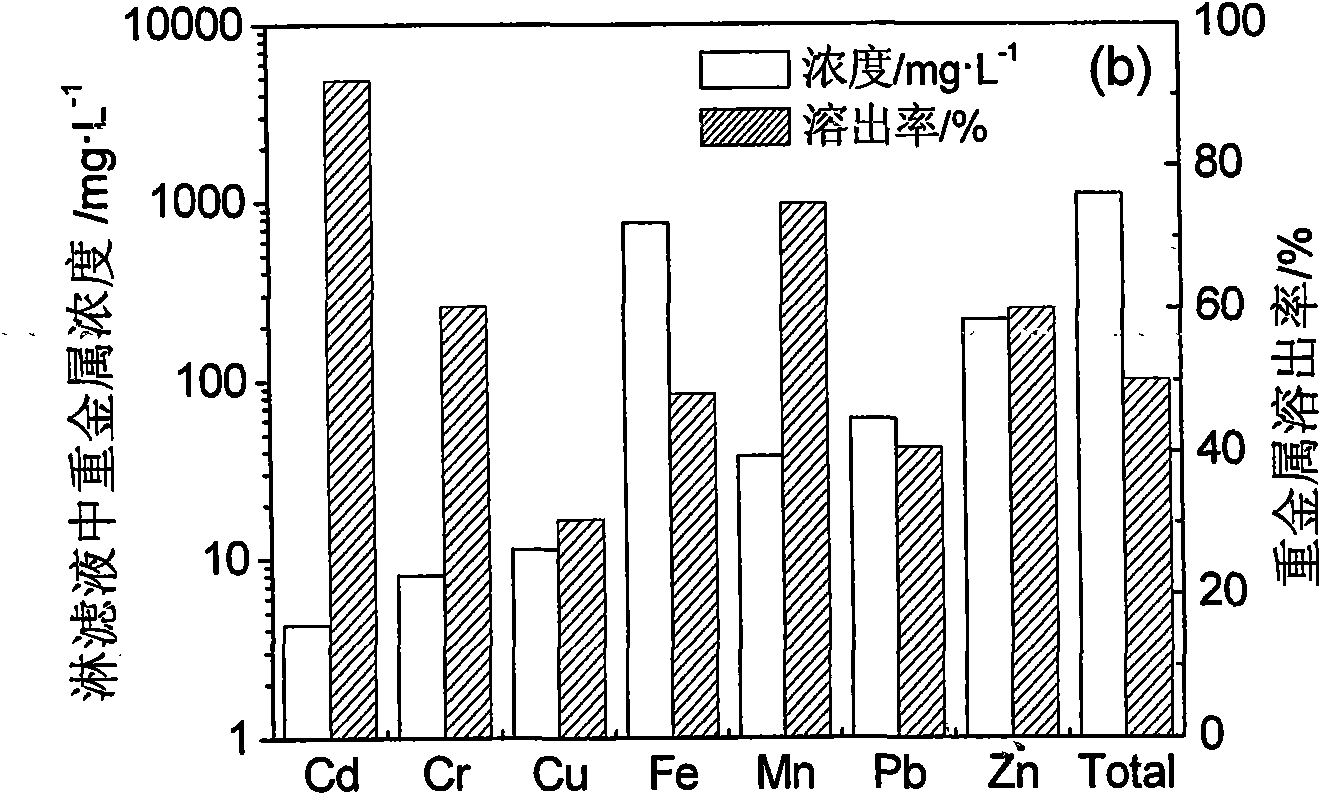

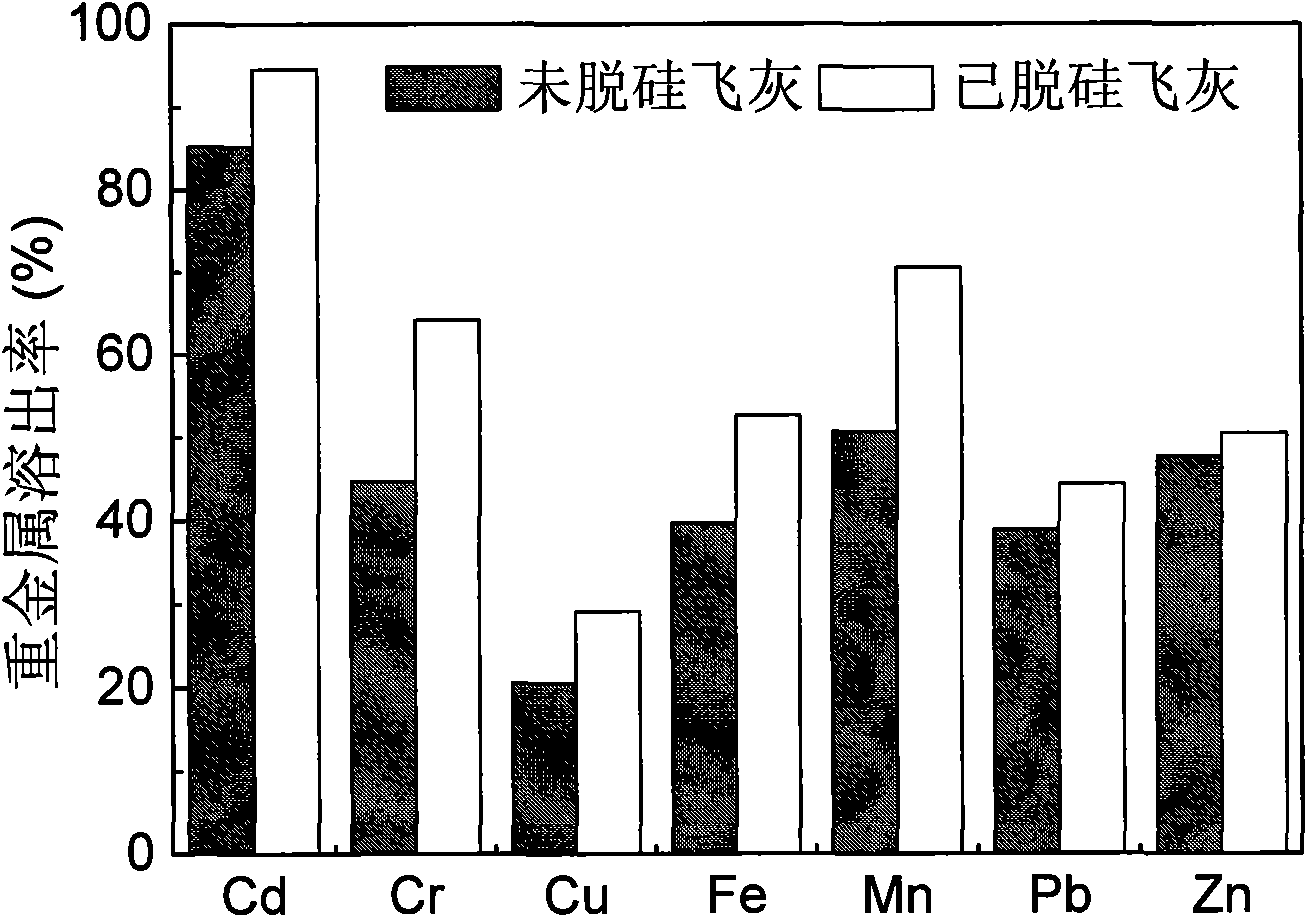

Method for improving bioleaching effect of municipal solid waste incineration flying ash

InactiveCN101555548AEfficient removalHigh dissolution rateFungiBacteriaAspergillus nigerContact reaction

A method for improving bioleaching effect of municipal solid waste incineration flying ash relates to a method for leaching the heavy metal in the waste incineration flying ash by the combination of biological desiliconization and bioleaching. The specific steps include: using silicate bacteria to conduct biological desiliconization treatment on the flying ash and damaging the mineral crystal lattice in the flying ash to release more metal oxide; and using Aspergillus niger to conduct bioleaching on the flying ash after the desiliconization treatment, thus remarkably improving the leaching effect of heavy metal in the bioleaching process due to the full contact reaction between more heavy metal oxide and the organic acid generated by the Aspergillus niger. The method is simple and convenient in operation, high in efficiency, economical and feasible and safe, is an environment-friendly effective method for removing the heavy metal in waste incineration flying ash; and leaching toxicity thereof is far lower than the authentication standard of hazardous wastes and the flying ash can enter a landfill yard or is prepared for further resource recycling.

Owner:UNIV OF SCI & TECH BEIJING

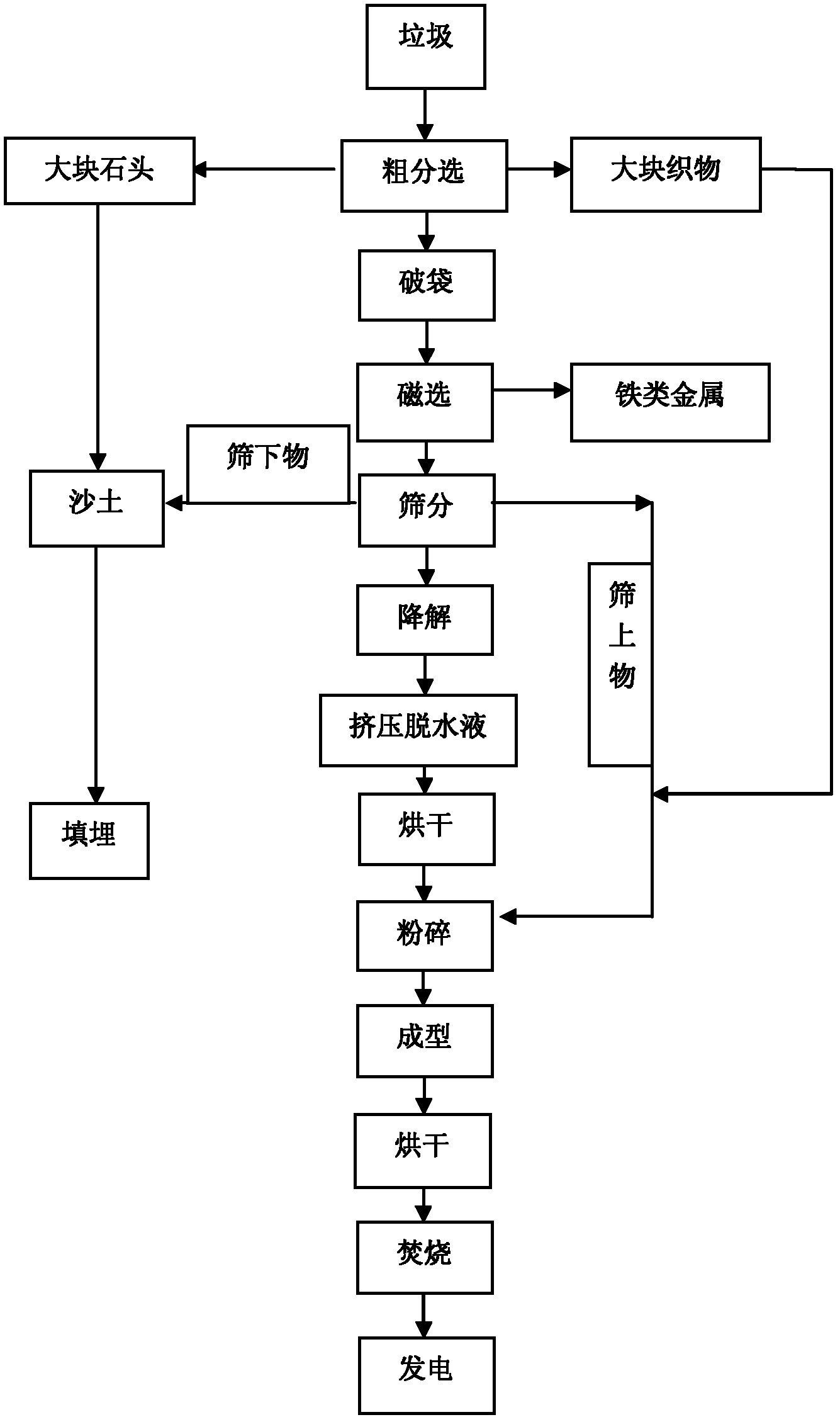

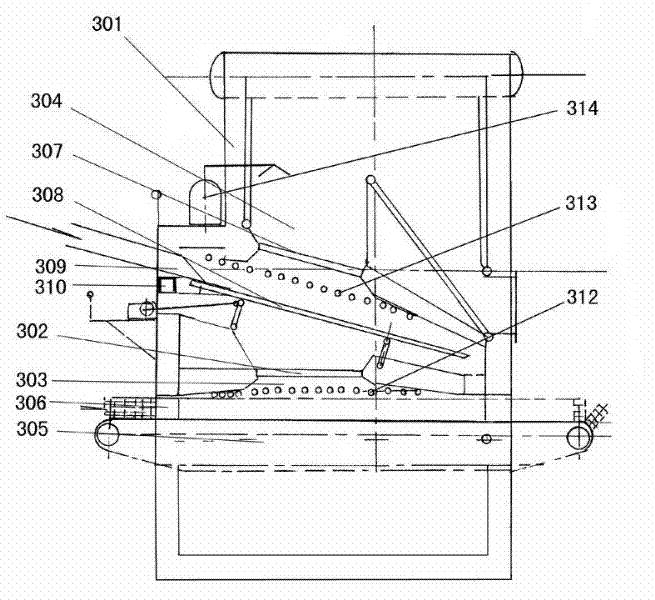

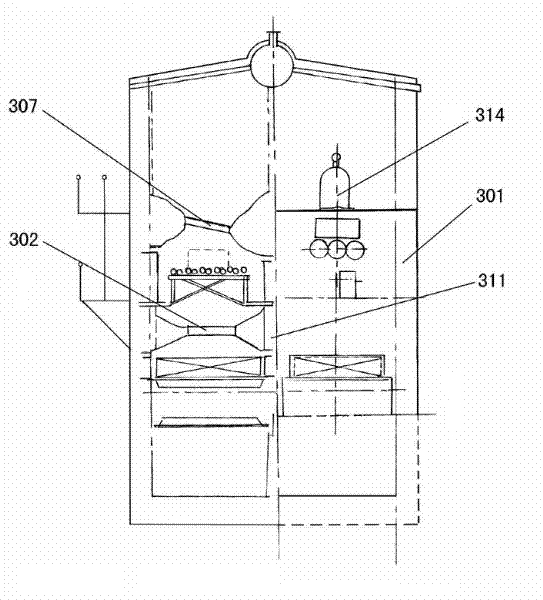

High-efficiency incineration power generation system for municipal solid waste

A high-efficiency incineration power generation system for municipal solid waste, comprising the following steps: (1) rough separation; (2) breaking the plastic bag to disperse the internal materials; (3) magnetic separation, separating ferrous metals ; (4) Screening; the material under the screen (sand) is harmlessly landfilled, and the material on the screen is directly crushed; (5) degradation, the material in the screen is degraded, (6) extrusion dehydration; (7) drying (8) crushing; (9) molding; (10) incineration; (11) power generation; slag can be made into burn-free bricks. The invention not only solves the problem that municipal solid waste is difficult to handle, but also turns it into a renewable fuel block with high calorific value, which becomes a new energy source, has small investment and occupied area, short processing cycle and low operating cost.

Owner:TIANJIN DEWEI ENVIRONMENTAL PROTECTION ENG EQUIP

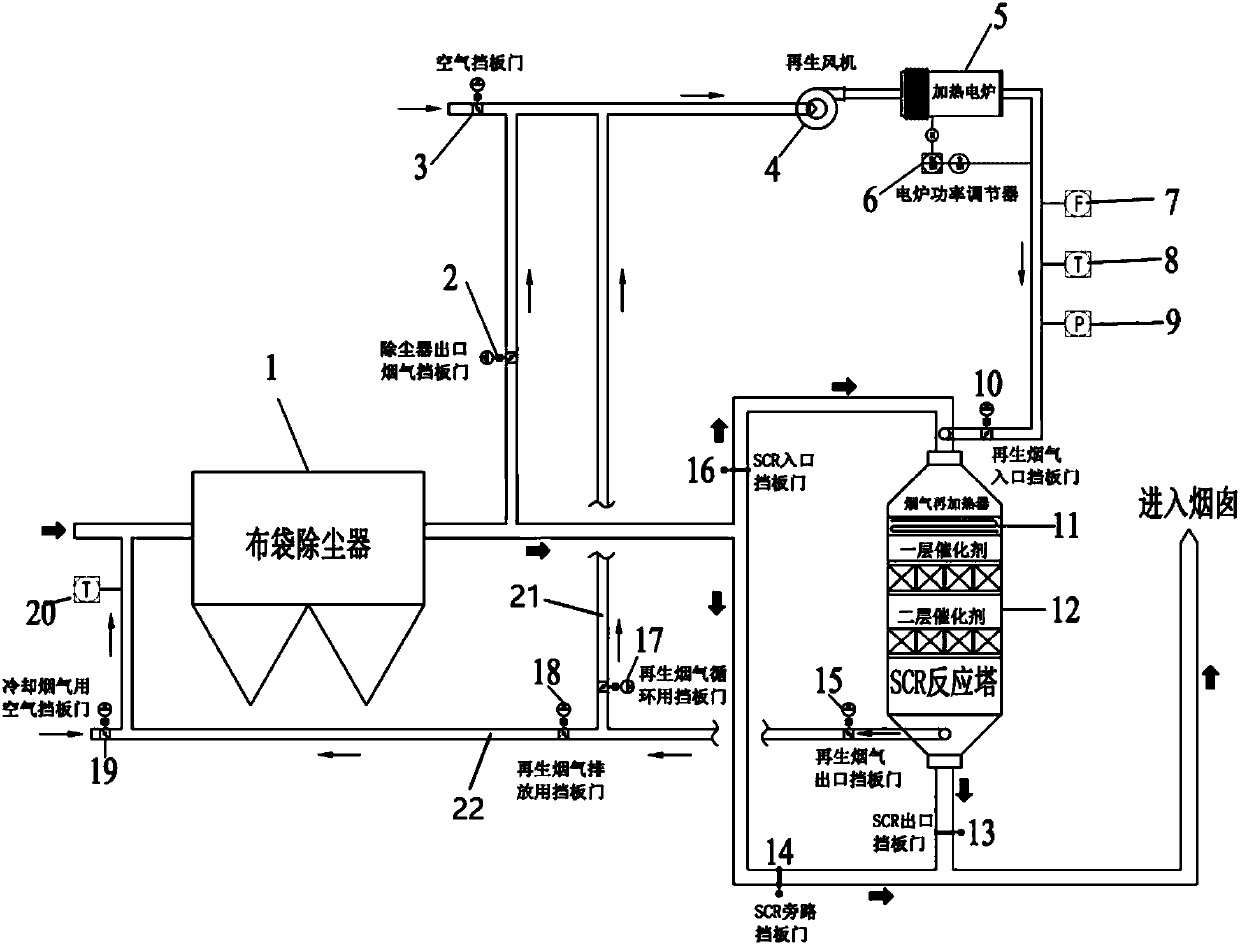

Municipal solid waste incineration plant SCR low-temperature denitration catalyst on-line regeneration system and regeneration method thereof

PendingCN107913598AImprove denitrification efficiencyExtend your lifeDispersed particle separationFlue gasPollutant emissions

The invention discloses a municipal solid waste incineration plant SCR low-temperature denitration catalyst on-line regeneration system and a regeneration method thereof. The regeneration system comprises a regeneration blower fan, a heating electric furnace and a SCR reaction tower. An inlet of the regeneration blower fan is connected to an outlet of a deduster through a pipeline. An outlet of the regeneration blower fan is connected to an inlet of the heating electric furnace, an outlet of which is connected to an inlet of the SCR reaction tower through a pipeline. An outlet of the SCR reaction tower is connected to an inlet of the deduster through a pipeline. A predetermined amount of flue gas is drawn off from the outlet of the deduster by the utilization of the regeneration blower fan; and the flue gas is circularly heated by the utilization of the heating electric furnace until the flue gas is heated to 250-450 DEG C; and after the status is maintained at the temperature for 12-56 h so as to complete the catalyst regeneration. The regeneration method provided by the invention is simple to operate, and is energy-saving and environmentally-friendly. There is no need to dismounta catalyst module for regeneration at different locations, and power consumption of the electric furnace and pollution emission amount are also can be reduced.

Owner:SHANGHAI ENVIRONMENTAL ENG DESIGN & RES INST CO LTD +1

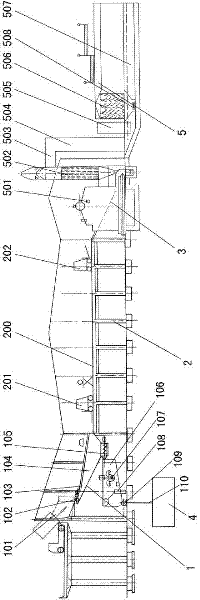

Harmless treatment system and method for municipal waste incineration

ActiveCN102294340AShort dry burn timeIncineration realizedSievingScreeningEnvironmental engineeringTreatment system

The invention relates to a refuse treatment system, especially to a harmless treatment system for city refuse burning, and a method thereof. The harmless treatment system for the city refuse burning has the following structure that: the rear of a screening system is connected with a hand-picking system; the hand-picking system is connected with an incinerator; a refuse outlet end of the screeningsystem is connected with a biomass pool; a high temperature gas outlet end of the incinerator is connected with a gas purification treatment system; a gas outlet end of the gas purification treatmentsystem is connected with a reutilization apparatus. According to the present invention, the process is simple; the residual heat can be used for heat supplying, power generation and the like; the system has characteristics of low investment, low operating cost and no environmental pollution.

Owner:李东国 +1

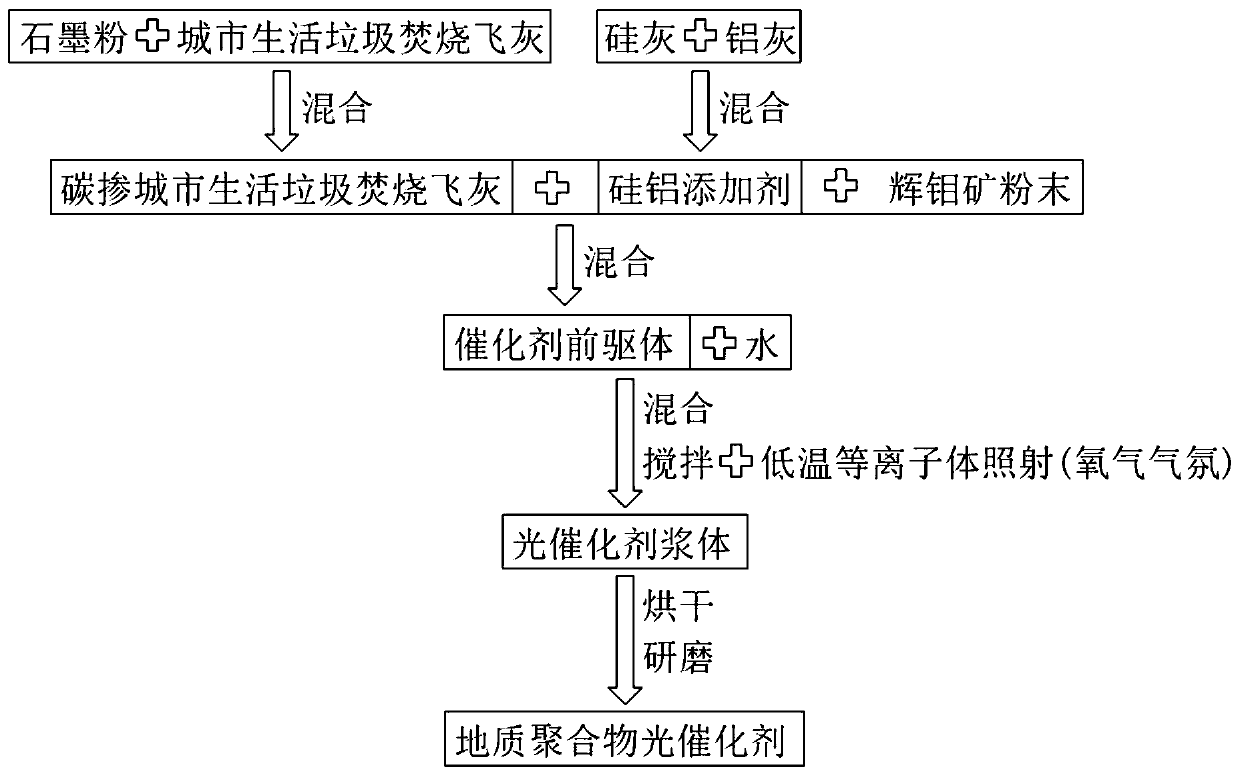

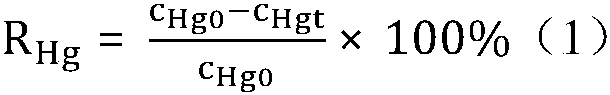

Method for preparing geopolymer photocatalyst from municipal solid waste incineration fly ash

PendingCN111569917AWide variety of sourcesAchieve stabilizationWater/sewage treatment by irradiationWater contaminantsPtru catalystPlasma irradiation

The invention discloses a method for preparing a geopolymer photocatalyst from municipal solid waste incineration fly ash. The method comprises the following steps of: weighing graphite powder and municipal solid waste incineration fly ash, and mixing the graphite powder and the municipal solid waste incineration fly ash to obtain carbon-doped municipal solid waste incineration fly ash; weighing silica fume and aluminum ash, and mixing the silica fume and aluminum ash to obtain a silica-alumina additive; weighing molybdenite powder, the silicon-aluminum additive and the carbon-doped municipalsolid waste incineration fly ash, and mixing the molybdenite powder, the silicon-aluminum additive and the carbon-doped municipal solid waste incineration fly ash to obtain a catalyst precursor material; weighing water and the catalyst precursor material, and performing low-temperature plasma irradiation to obtain photocatalyst slurry; and drying and grinding the photocatalyst slurry to obtain thegeopolymer photocatalyst. The invention also discloses a geopolymer photocatalyst and application thereof. According to the method, the stabilization of heavy metal and the mineralization of dioxin in the fly ash can be achieved, and part of the heavy metal can be converted into a semiconductor material. A molybdenum source and a carbon source are a low-value molybdenite raw material and graphitepowder respectively. The geopolymer photocatalyst can remove 98% of COD, 99% of heavy metal pollutants, 99% of ammonia nitrogen and 98% of total phosphorus at most.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Method for fully recycling municipal solid waste

ActiveCN104128350ANo long-term occupationResource does not existSolid waste disposalPlastic recyclingLand resourcesResource utilization

The invention discloses a method for fully recycling municipal solid waste. The method includes steps of garbage classification, garbage stabilization and catalytic cracking. The municipal solid waste is fully recovered and recycled. A harmless and resource-utilization treatment is achieved. Defects of long-period occupying land and polluting land resource in municipal solid waste incineration and landfill are avoided. Discharges of waste water, waste residue and waste gas are avoided. A Defect that landfill leachate and stink in the landfill seriously pollute the environment is avoided. A highest temperature during a production process is not higher than 180 DEG C and the method is free of generation of dioxin. A finished product can be a building product without generation of organic fertilizers. The defect that heavy metal in garbage compost harms human and livestock through food chain is avoided. All the environmental-protection indexes of the building product generated in the method reach requirements in national relative standard. The building product is huge in a market capacity. A problem that the building product is turned into new garbage since the product is lack of outlet is avoided.

Owner:广州同欣体育股份有限公司

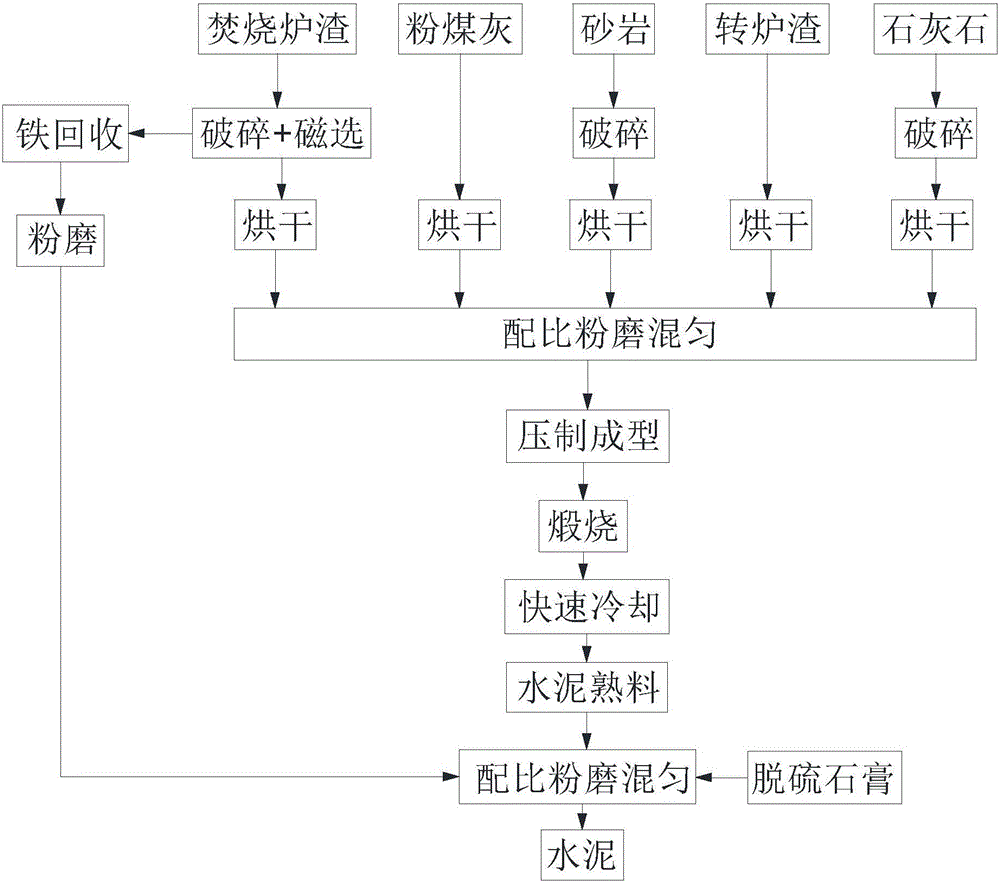

Method for preparing cement from municipal solid waste incineration furnace slag

The invention discloses a method for preparing cement from municipal solid waste incineration furnace slag.According to the method, the municipal solid waste incineration furnace slag substitutes raw materials of the cement to make cement raw meal, portland cement clinker is fired, and safety use of the cement is guaranteed.In the actual cement production process, a bypass air discharging system is arranged, normal operation of a cement kiln is guaranteed, the crusting and blocking phenomena of volatile components which are wrapped and carried by the raw materials to a cement kiln system caused by the circular enrichment rule are eliminated, and quality of a cement product can be guaranteed.By means of the method, waste materials can be changed into things of value, the municipal solid waste incineration furnace slag is adopted as the substitute raw material in the cement production process, on one hand, the effect that the incineration furnace slag is reutilized can be achieved, and on the other hand, the demand for natural raw materials of the cement can be reduced.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

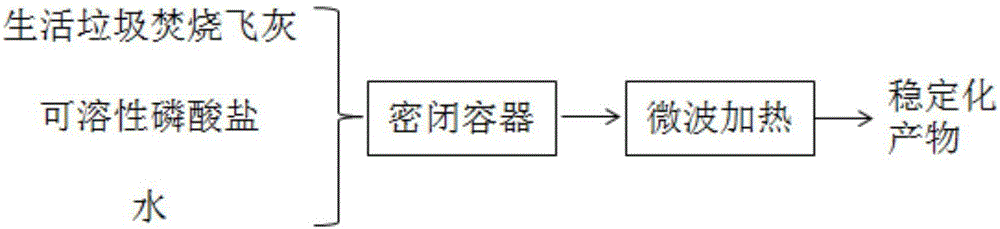

Disposition method for municipal solid waste incineration fly ash with microwave hydrothermal method applied

InactiveCN106077031AImprove adsorption capacityLow costSolid waste disposalTransportation and packagingMicrowaveResource utilization

The invention discloses a stabilizing method for municipal solid waste incineration fly ash with microwave applied. The stabilized products can be obtained by adding fly ash to be processed, a certain concentration of additive agent and water into a polytetrafluoroethylene container directly and then performing heating by the microwave to solidify heavy metal in the fly ash. After disposed by the method, the leaching concentration of the heavy metal in the fly ash can be far below the limiting value of national standard 16889-2008. By means of the stabilizing method, hazardous wastes such as the municipal solid waste incineration fly ash can be processed efficiently and rapidly to meet the requirements of secure landfill and post resource utilization. The method is simple in technology, convenient to operate, high in heavy metal solidified rate, capable of making up for deficiencies that the conventional hydrothermal disposition is high in energy consumption, long in computing time and the like, and high in practical application potential of large-scale disposition of the municipal solid waste incineration fly ash.

Owner:ZHEJIANG UNIV

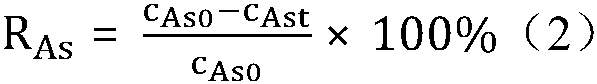

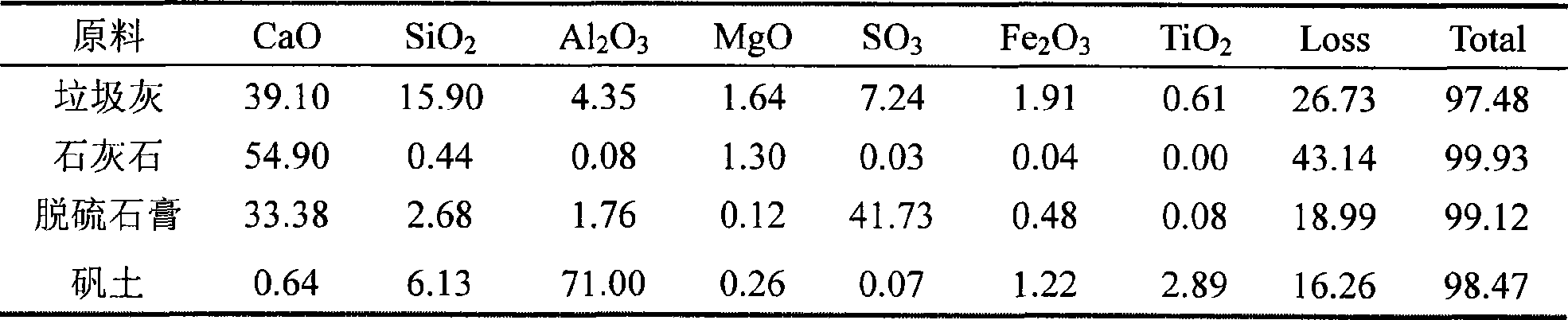

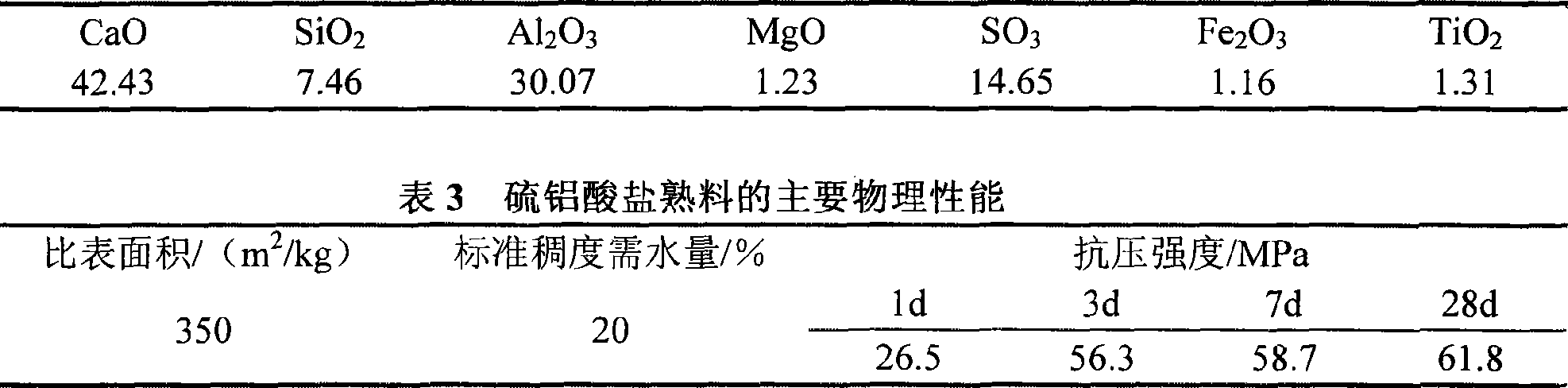

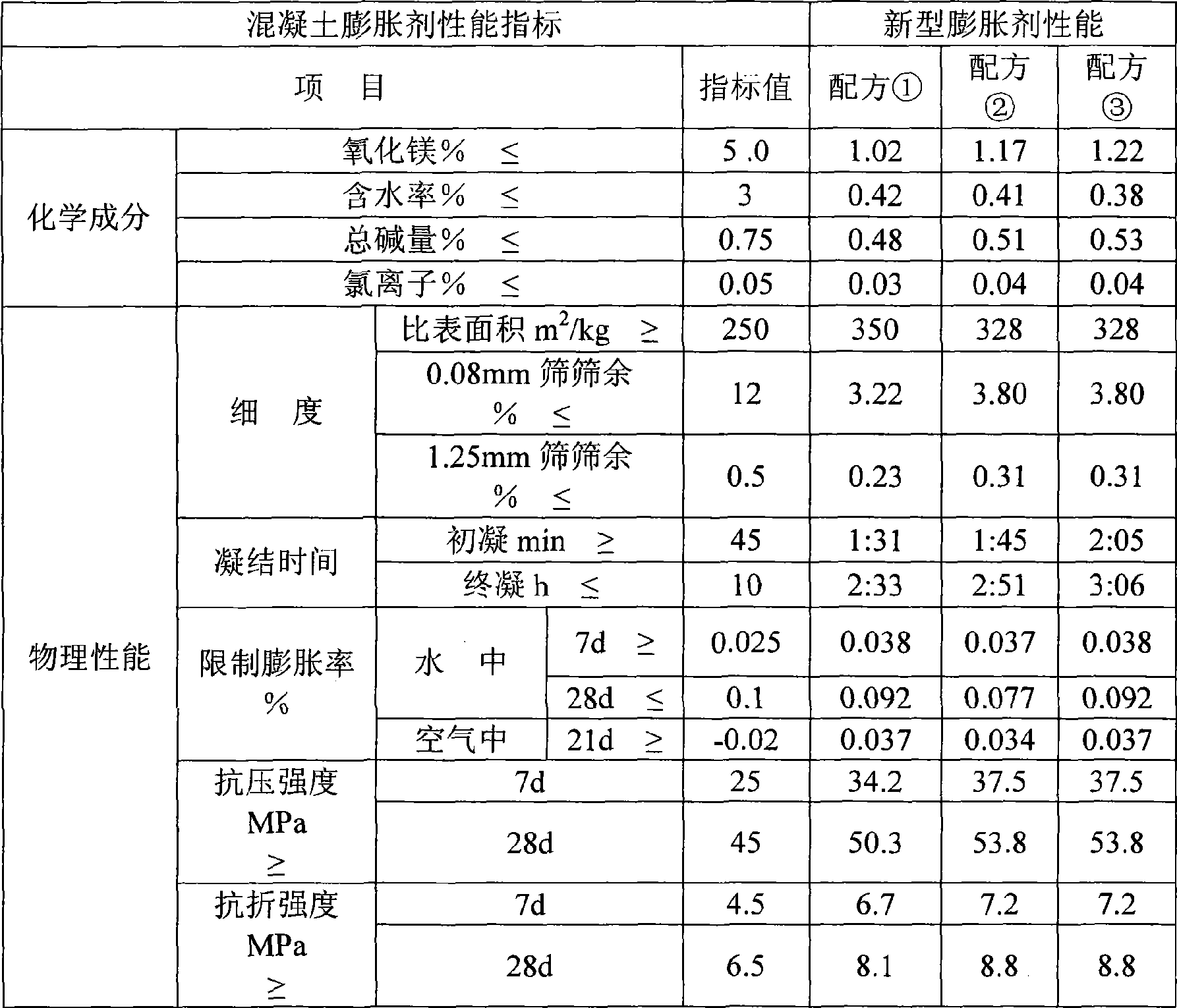

Method for producing cement expansive material by using flying ash, desulfurized gypsum from incineration of refuse

InactiveCN101508533ALighten the serious burdenReduce processing costsCement productionSocial benefitsThermal insulation

The invention discloses a method for preparing a concrete expansion agent by utilizing MSWI (municipal solid waste incineration) fly ash and desulfurization gypsum, which comprises the two steps of: (1) adopting the MSWI fly ash, the desulfurization gypsum, limestone, and bauxite as raw materials to obtain sulphoaluminate clinker through temperature increase and thermal insulation in an electric furnace; and (2) cogrinding the sulphoaluminate clinker and the desulfurization gypsum to obtain the concrete expansion agent. In the step (1), the raw materials are heated to be between 1,200 and 1,250 DEG C in the electric furnace according to the temperature-rising speed of between 20 and 30 DEG C / min, and then the sulphoaluminate clinker is obtained after the thermal insulation for 1 to 2h; and in the step (2), the sulphoaluminate clinker and the desulfurization gypsum are coground until the specific surface area is more than 250m / kg. The method comprehensively utilizes solid wastes such as the MSWI fly ash and the desulfurization gypsum to completely substitute natural gypsum and partially substitute non-renewable mineral resources such as the limestone, the bauxite and the like; and the method can lighten the serious burden to the environment and the treatment cost due to the unuse of fly ash and the desulfurization gypsum when ensuring the performance of products, and has good economic and social benefits.

Owner:TONGJI UNIV

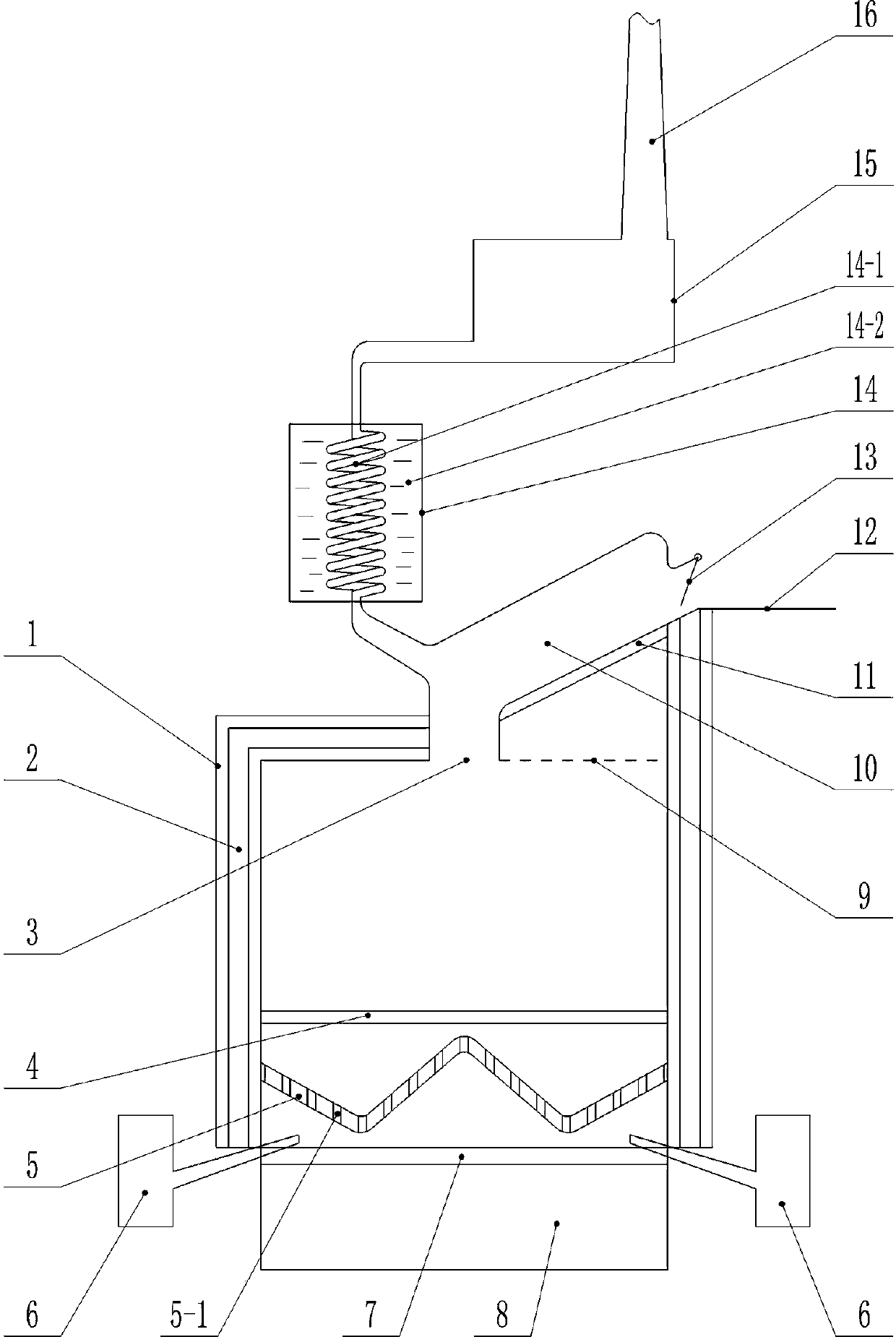

Municipal solid waste incineration device capable of burning without causing atmospheric contamination

ActiveCN103742917AReduce the temperaturePrevent regenerationIncinerator apparatusAtmospheric contaminationFlue gas

The invention discloses a municipal solid waste incineration device capable of burning without causing atmospheric contamination. The device is characterized by comprising a waste grab bucket, a waste incinerator body, an air blower, a waste preheating chamber, flue gas quenching equipment, flue gas filtering equipment and a chimney, wherein the air blower is communicated with the hearth of a waste incinerator; the hearth is communicated with the waste preheating chamber; the waste preheating chamber is communicated with the flue gas quenching equipment; the flue gas quenching equipment is communicated with the flue gas filtering equipment and the chimney. By adopting the device, waste can burn completely, the production and emission of dioxin can be reduced greatly, and the atmospheric contamination is prevented. Moreover, the municipal solid waste incineration device is simple in structure and small in investment. The waste preheating chamber is placed oblique, thereby bringing convenience to operation and saving force. The municipal solid waste incineration device is very suitable for treating municipal solid waste in counties and towns under the current condition.

Owner:平南县食品药品检验检测中心

Process for gelling solidifying of heavy metals in municipal solid waste incineration fly ash by adding mineral powder

InactiveCN109092851AEfficient use ofAchieve reuseSolid waste disposalTransportation and packagingSocial benefitsDistilled water

The invention relates to a process for gelling solidifying of heavy metals in municipal solid waste incineration fly ash by adding mineral powder. The process comprises the steps that 80-120 parts ofthe municipal solid waste incineration fly ash are taken and placed in a container, 4-6 parts of pretreatment agents and 60-80 parts of water are added, stirring and drying are performed sequentially,and grinding and sieving are performed for standby application; 70-85 parts of pre-treated waste incineration fly ash and 15-30 parts of mineral powder admixtures are taken and mixed uniformly in a blender, then 3-5 parts of exciting agents and 35-50 parts of distilled water are taken to prepare an alkali solution to be added into the mixture, and the mixture is placed in the blender to stir to aslurry state; the slurry is taken out and beaten into a mud pie and sealed in a constant temperature climate box for curing, and then a solidified body is placed in a water curing box for curing for5-28d to obtain a gelling solidified body. The municipal solid waste incineration fly ash is subjected to gelling solidifying by being added with the mineral powder, the migration of the heavy metalsis effectively reduced, industrial waste can be used according to local conditions, water and soil resources are protected, and environmental pollution is controlled. Significant environmental, economic and social benefits are achieved.

Owner:NANJING UNIV OF TECH

Process for preparing gelling material from municipal solid waste incineration fly ash

InactiveCN106565166AEfficient use ofPollution controlCeramic shaping apparatusSocial benefitsWater resources

The invention relates to a process for preparing a gelling material from municipal solid waste incineration fly ash. The process comprises the following steps: weighing 80 to 100 parts by mass of the municipal solid waste incineration fly ash and 2 to 4 parts by mass of a pretreatment chemical agent alkali, adding 50 to 70 parts by mass of water, carrying out a reaction at 20 to 50 DEG C for 0.5 to 2 h, and carrying out drying, grinding and sieving so as to obtain pretreated municipal solid waste incineration fly ash; weighing 60 to 80 parts by mass of the pretreated municipal solid waste incineration fly ash, 20 to 40 parts by mass of an admixture and 2 to 8 parts by mass of an activator, and carrying out uniform mixing; adding 40 to 60 parts by mass of water, and carrying out stirring so as to obtain a mixed material; injecting the mixed material into a mold, and carrying out vibration compaction; placing the grouted mold in a constant-temperature weather curing box with a temperature of 20 to 60 DEG C, carrying out curing for 12 to 48 hours, and carrying out demolding; and carrying out placing in a water curing box with a temperature of 20 to 60 DEG C, and carrying out curing for 21 to 28 d so as to obtain the gelling material. According to the invention, industrial wastes can be utilized according to local conditions, so land and water resources are effectively protected; environmental pollution is controlled; and significant environmental, economic and social benefits are obtained.

Owner:NANJING UNIV OF TECH

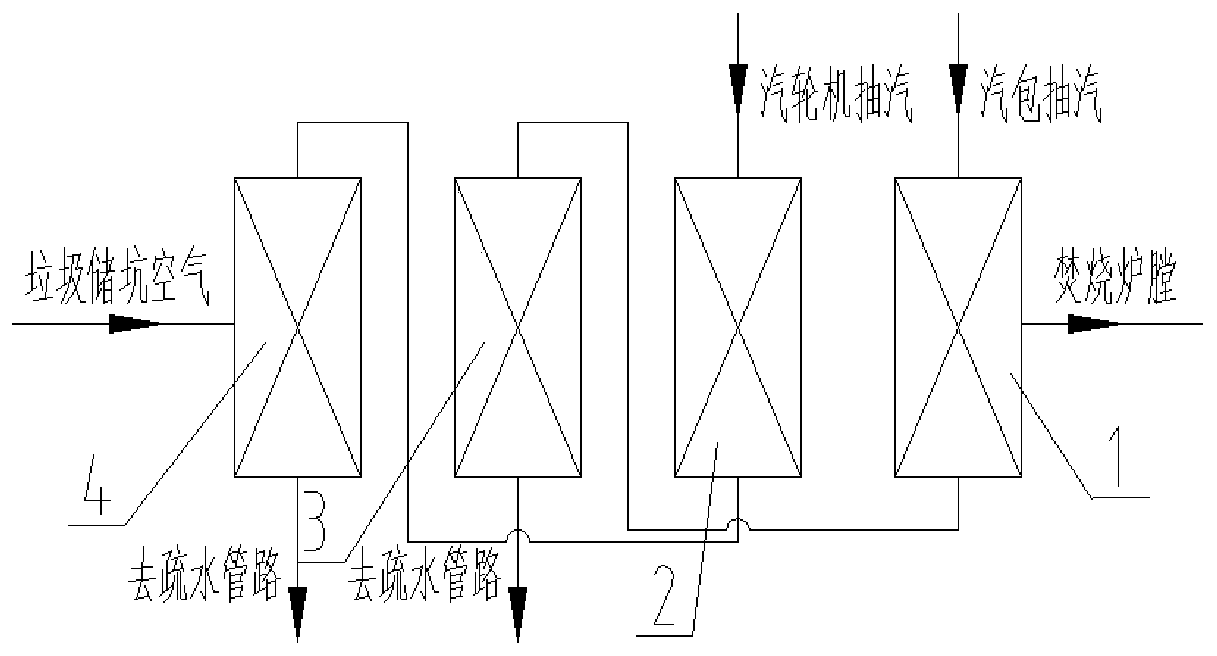

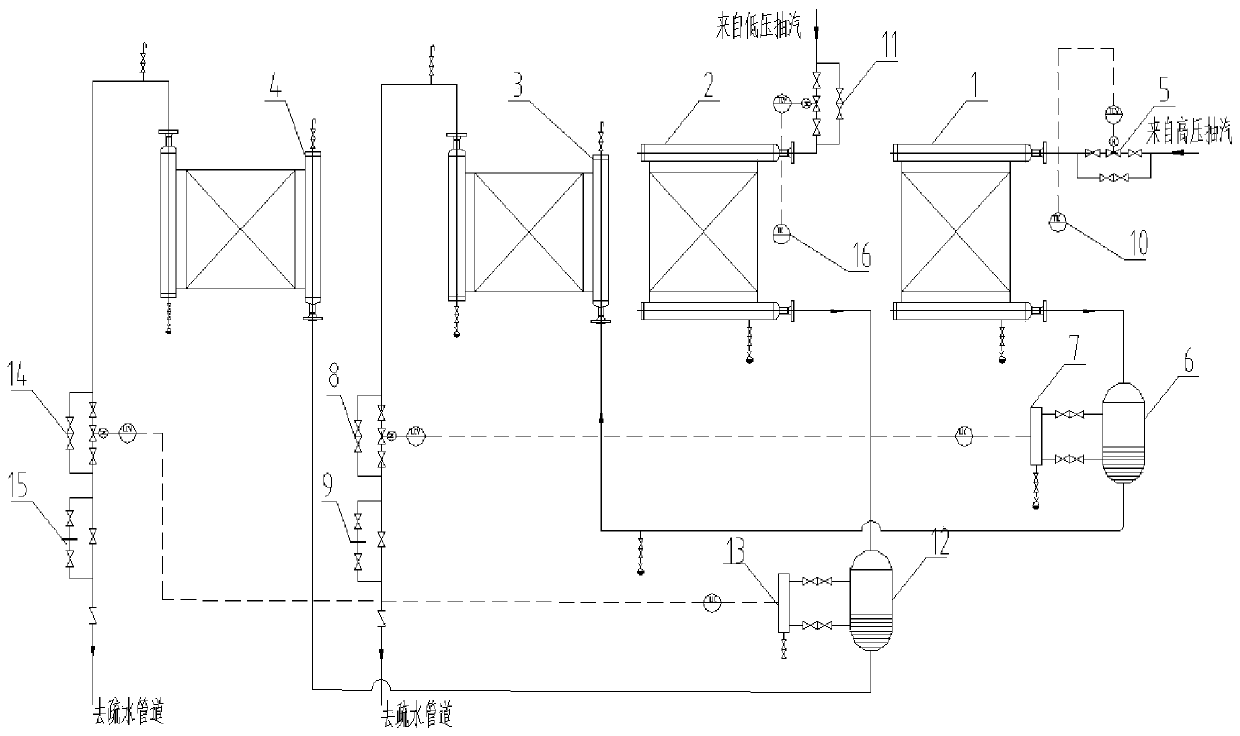

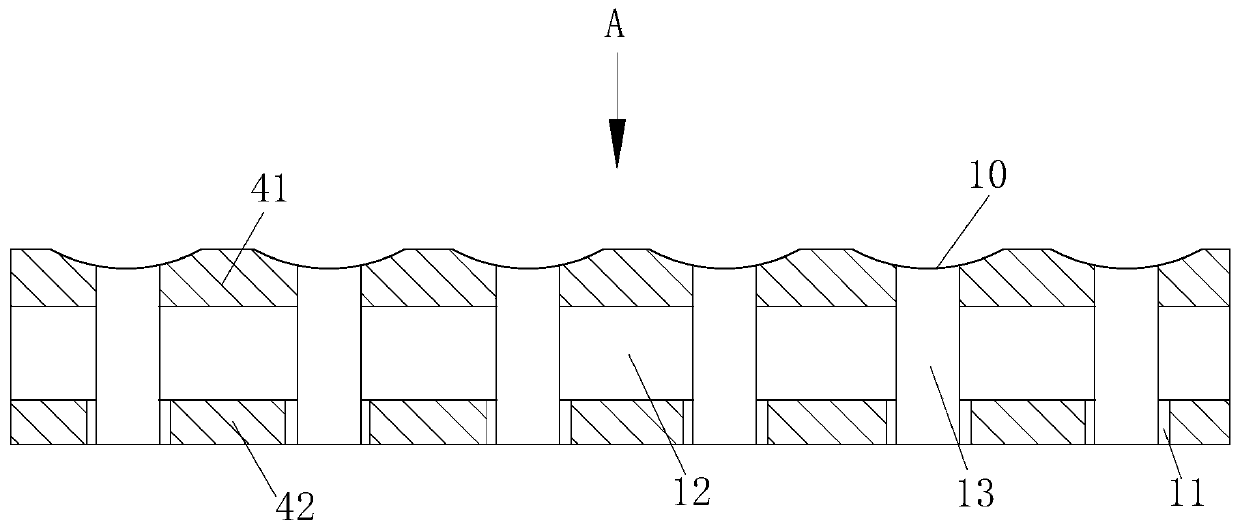

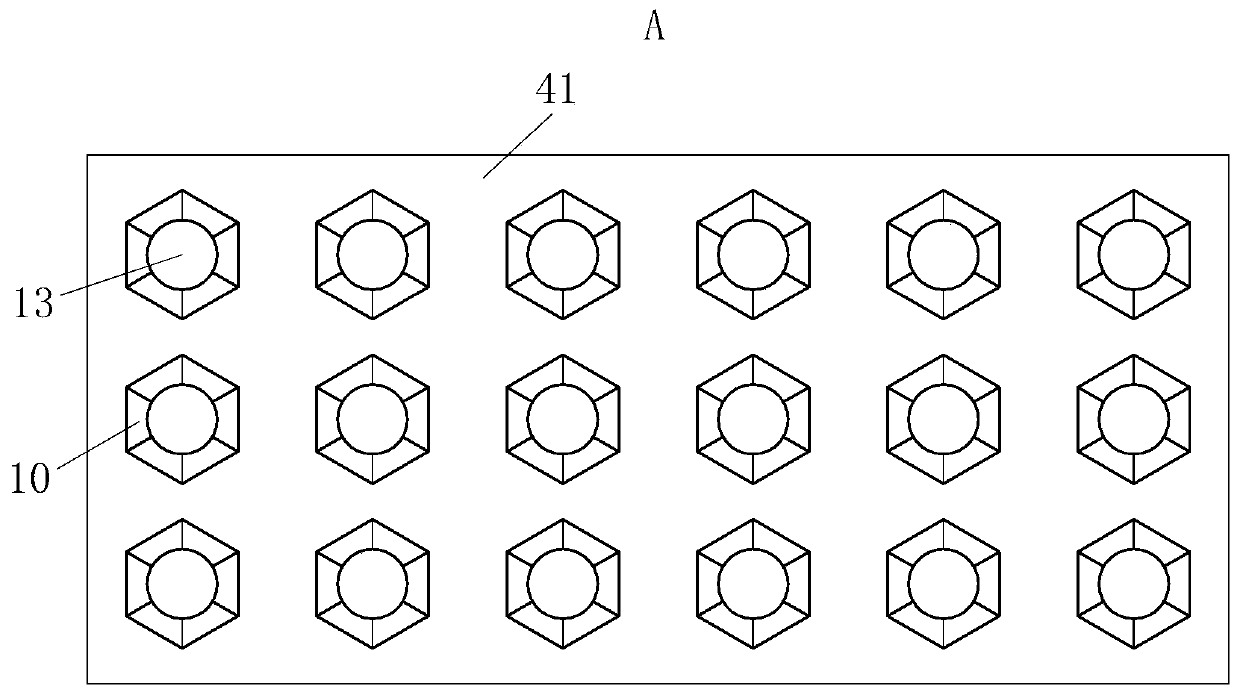

Four-section type steam air preheater drainage system

The invention relates to the field of municipal solid waste incineration, in particular to a four-section type steam air preheater drainage system for heating garbage incinerator combustion air. The four-section type steam air preheater is sequentially provided with a low-pressure supercooling section heat exchanger (4), a high-pressure supercooling section heat exchanger (3), a low-pressure condensation section heat exchanger (2) and a high-pressure condensation section heat exchanger (1) according to an air flow direction, steam pocket extracted steam enters the high-pressure condensation section heat exchanger (1) for heat exchange, then enters the high-pressure supercooling section heat exchanger (3) and finally enters a drain pipeline, steam turbine extracted steam passes through thelow-pressure condensation section heat exchanger (2) for heat exchange, then enters the low-pressure supercooling section heat exchanger (4) and finally enters the drain pipeline, and a drain regulating valve is used for regulating the drain flow through a buffer tank liquid level signal so as to ensure the heat exchange capacity and the extracted steam heat utilization rate and enable the systemto safely and stably operate for a long time.

Owner:SHANGHAI SUS ENVIRONMENT

Domestic garbage burning processing method

ActiveCN101285579AReduce the cost of purification treatmentReduce generationIncinerator apparatusSolid removalAtmospheric airPollution

The invention discloses a method for incineration treatment of domestic waste, relating to a method for processing waste, which solves the problem of high purification treatment cost for smoke gas which is generated after incineration in the prior art. The method for incineration treatment of domestic waste comprises the following steps of: 1. incinerating; 2. deacidifying and dust-removing exhaust fume of the incinerating; 3. feeding smoke gas which undergoes the dust removal into a vertical kiln for secondary incineration; 4. post processing the smoke gas after the secondary incineration, and discharging into air. The method for incineration treatment of domestic waste also comprises the step of burning sufficiently unburnt organic pollution pollutant in the vertical kiln at a temperature of between 1400 and 1700 DEG C and further purifying the pollutant in the smoke gas by using humid green pellets in the middle section and the upper section of the cement vertical kiln. The domestic waste is processed by the method, the index of exhausted gas is better than Standard for Pollution Control on the Municipal Solid Waste Incineration in China (GB18485-2001), at the same time, the purification treatment cost for the smoke gas is reduced greatly.

Owner:湖南哈工机器人研究院有限公司

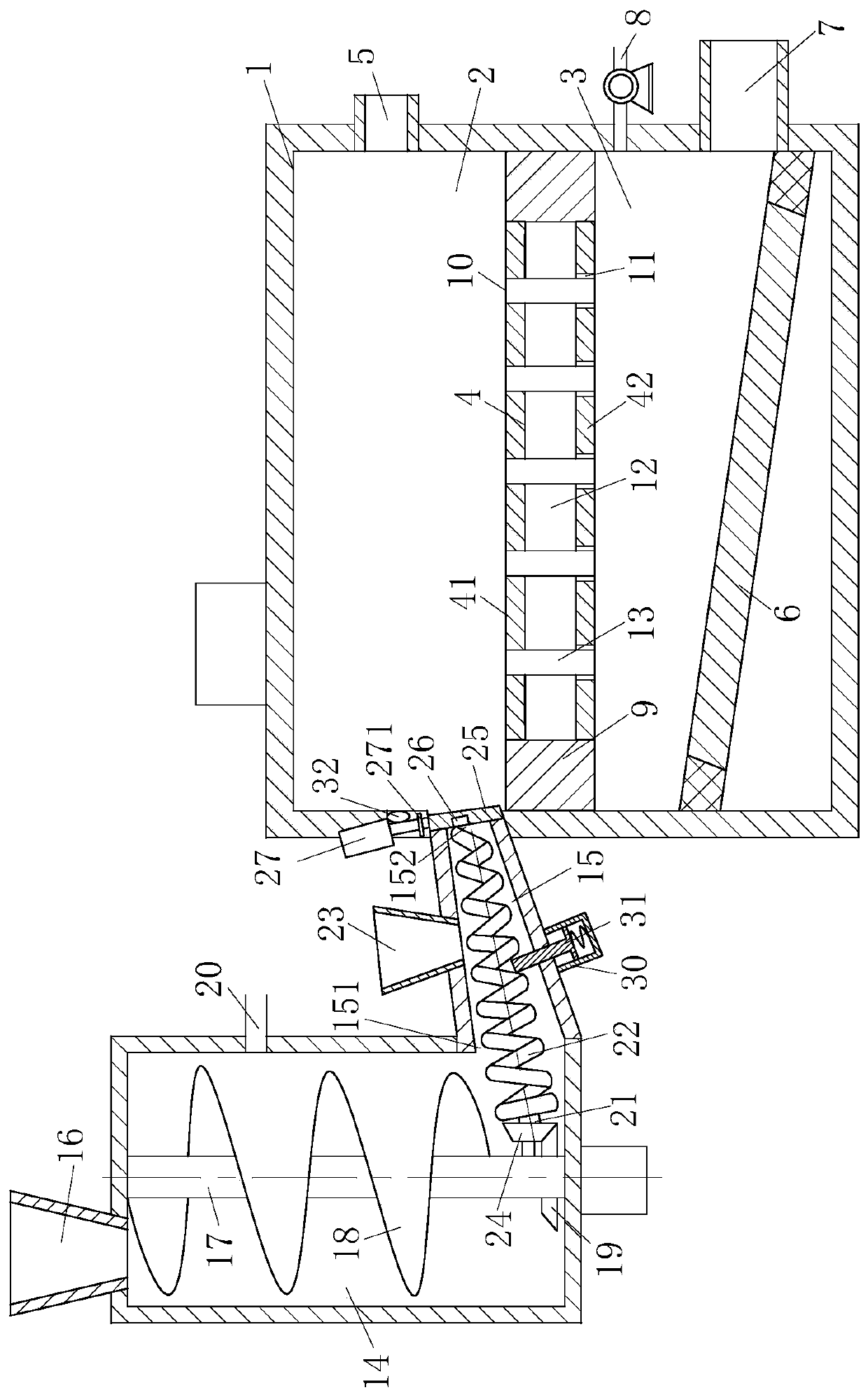

Municipal solid waste incineration device

ActiveCN109708119AImprove incineration effectFully dryIncinerator apparatusSlagMunicipal solid waste incineration

The invention belongs to the technical field of waste processing equipment, and particularly relates to a municipal solid waste incineration device. The municipal solid waste incineration device comprises an outer shell. The outer shell is internally provided with an incineration chamber and a slag discharging chamber. An incineration plate is arranged in the incineration chamber. A slag guide plate is obliquely arranged in the slag discharging chamber. An oxygen conveying pipe is arranged on the lateral face of the bottom end of the incineration plate. The incineration plate comprises an upper incineration plate and a lower incineration plate. Slag discharging holes are formed in the upper incineration plate. Air inlets are formed in the lower incineration plate. A cavity is formed between the upper incineration plate and the lower incineration plate. A drying chamber is arranged on the lateral face of the outer shell. The drying chamber is connected with the incineration chamber by afeeding chamber. An air inlet pipe is arranged on the drying chamber. The air inlet pipe is connected with the cavity. Heat generated by the upper incineration plate can heat oxygen in the cavity. The heated gas enters the drying chamber through the air inlet pipe. Stirring blades in the drying chamber stir the waste, and therefore the heated gas can dry the waste in the drying chamber more fully, and the municipal solid waste incineration effect can be improved.

Owner:LISHUI INST OF ECOLOGY ENVIRONMENT NANJING UNIV

Municipal solid waste incineration fly ash solidification method based on rice hull ash-red mud composite cementing material

ActiveCN110922108AStable and excellent performance structureHigh zeolite molecular sieve structureCeramic shaping apparatusMunicipal solid waste incinerationChemical adsorption

Belonging to the field of low-carbon cementing materials and solid waste environmental protection, the invention discloses a municipal solid waste incineration fly ash solidification method based on arice hull ash-red mud composite cementing material. The method includes: firstly mixing rice hull ash, sodium hydroxide and a proper amount of mixing water uniformly, placing the mixture in a high-temperature bath pot, carrying out intensified excitation reaction, performing cooling to room temperature, pouring the product into a stirring pot, adding red mud until the slurry is stirred uniformly,then adding municipal solid waste incineration fly ash, and further performing stirring for 2-5min to obtain a uniform slurry, i.e. a solidified body of municipal solid waste incineration fly ash. The solidification technology for municipal solid waste incineration fly ash provided by the invention utilizes the high-alkali characteristic of red mud, the excellent physical-chemical adsorption performance, cation exchange capacity and other performance characteristics of the rice hull ash and red mud to greatly reduce the harm of municipal solid waste incineration fly ash to the ecological environment and human health, at the same time, the production process adopted by the invention is simple, performs waste control by waste, is low in cost, efficient and environment-friendly, and has remarkable economic and environmental protection significance and wide market prospects.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com