Washing softening technology for MSWI (Municipal Solid Waste Incineration) fly ash

A technology of waste incineration fly ash and process, applied in the field of waste incineration fly ash treatment, can solve the problems of unstable effluent, high chloride ion content in mud cake, affecting effluent quantity, etc., achieving good water treatment effect, stable effluent quality, Guarantee the effect of cement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A process for washing and softening waste incineration fly ash, comprising the following steps:

[0037] (1) Pass water into the fly ash, stir it, and then carry out a water wash. After the water wash is completed, pass it into the primary centrifuge A for a centrifugal dehydration. Add the PAM solution to the separated filtrate and mix it evenly, then pass it into The primary centrifuge B performs secondary centrifugal dehydration;

[0038] (2) Wash the filter cake separated by the primary centrifuge A and B for the second time, then pass it into the secondary centrifuge A for centrifugal dehydration, add the PAM solution to the separated filtrate and mix well, then pass it into the secondary centrifuge A and carry out centrifugal dehydration. Stage centrifuge B for secondary centrifugal dehydration;

[0039] (3) Add lye, such as saturated sodium carbonate solution, to the filtrate separated from the first-stage centrifuge B, and perform the first rough adjustment of ...

Embodiment 2

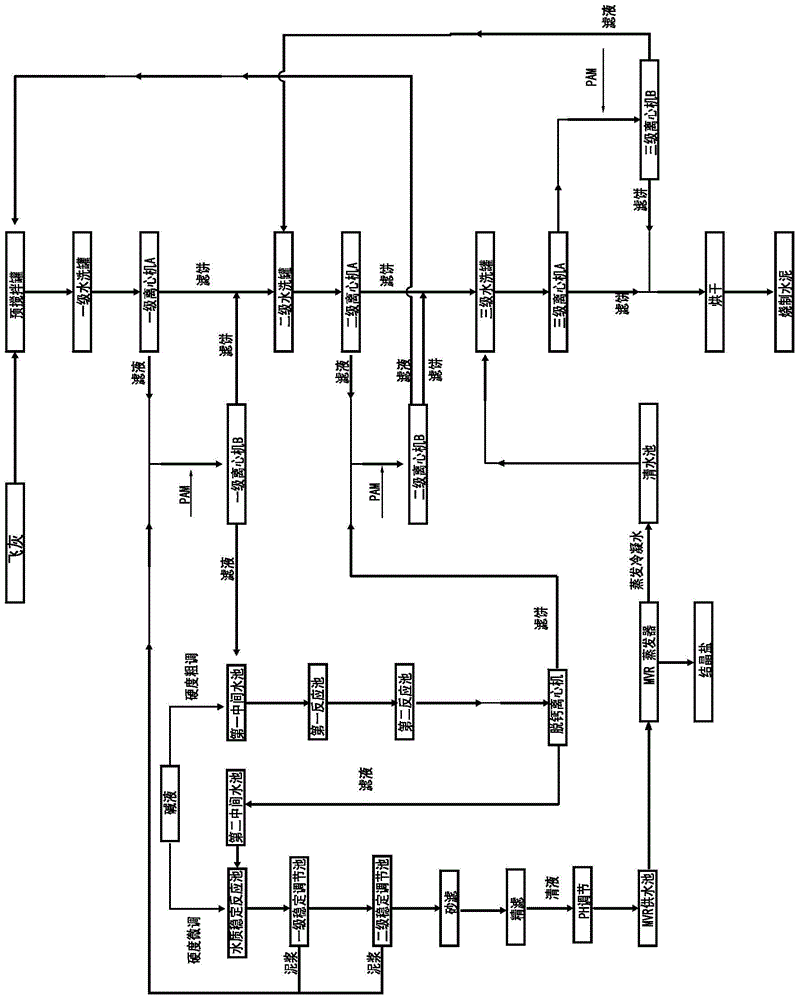

[0044] Such as figure 1 Shown, a kind of waste incineration fly ash washing softening process comprises the following steps:

[0045] (1) Put the fly ash into the pre-mixing tank, and feed water at the same time, the water-cement ratio is 3:1, and stir, and then pass into the first-level washing tank for a water wash, after the washing is completed, enter the first-level centrifuge A for Centrifugal dehydration, the separated filter cake enters the secondary water washing tank, adds PAM solution to the filtrate and mixes evenly, the dosing ratio is 0.1Kg / ton of dry fly ash, the concentration of PAM solution is 1.5g / L, and then passes into the primary Centrifuge B performs secondary centrifugal dehydration, the separated filter cake enters the secondary washing tank, and the filtrate enters the first intermediate pool;

[0046](2) The filter cakes separated by the primary centrifuges A and B are washed twice in the secondary washing tank, and then enter the secondary centrifug...

Embodiment 3

[0057] Such as figure 1 Shown, a kind of waste incineration fly ash washing softening process comprises the following steps:

[0058] (1) Put the fly ash into the pre-mixing tank, and at the same time pass into the water, the water-cement ratio is 4:1, and stir, and then pass into the primary washing tank for a water washing, after the washing is completed, enter the primary centrifuge A for Centrifugal dehydration, the separated filter cake enters the secondary washing tank, add PAM solution to the filtrate and mix evenly, the dosing ratio is 0.2Kg / ton of dry fly ash, the concentration of PAM solution is 1g / L, and then pass into the primary centrifuge Machine B performs secondary centrifugal dehydration, the separated filter cake enters the secondary washing tank, and the filtrate enters the first intermediate pool;

[0059] (2) The filter cakes separated by the primary centrifuges A and B are washed twice in the secondary washing tank, and then enter the secondary centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com