Water washing and softening system for waste incineration fly ash

A waste incineration fly ash and fly ash technology, applied in cement production, chemical instruments and methods, solid waste removal, etc., can solve problems such as unstable water output, affecting water output, large amount of sludge in the evaporation system, etc., to achieve treatment The process is stable, the cement quality is guaranteed, and the performance is stable and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

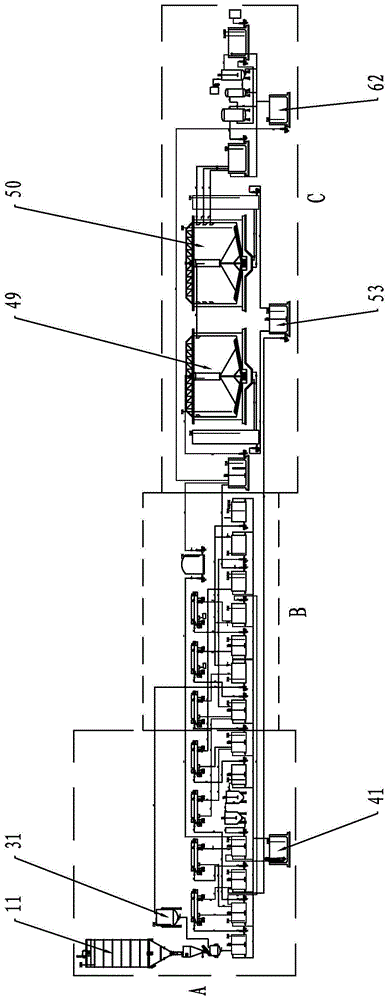

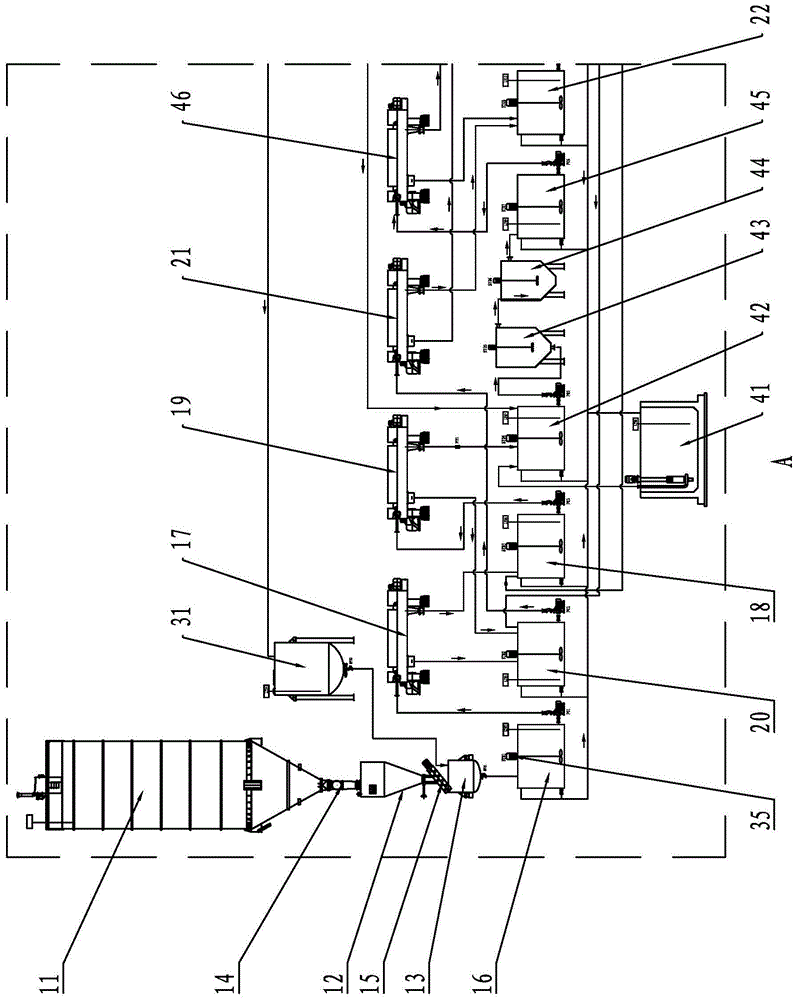

[0029] Such as Figure 1-Figure 4 As shown, the water washing and softening system for waste incineration fly ash of the present invention includes a fly ash conveying part, a fly ash washing part, and a water treatment part. The fly ash conveying part includes a first fly ash silo 11, a second fly ash silo 12, a screw Input machine 15, a rotary feeder 14 is installed at the discharge port at the bottom of the first fly ash silo 11, and the rotary feeder 14 communicates with the feed port of the second fly ash silo 12, and the second fly ash silo 12 Screw feeder 15 is installed below the discharge port.

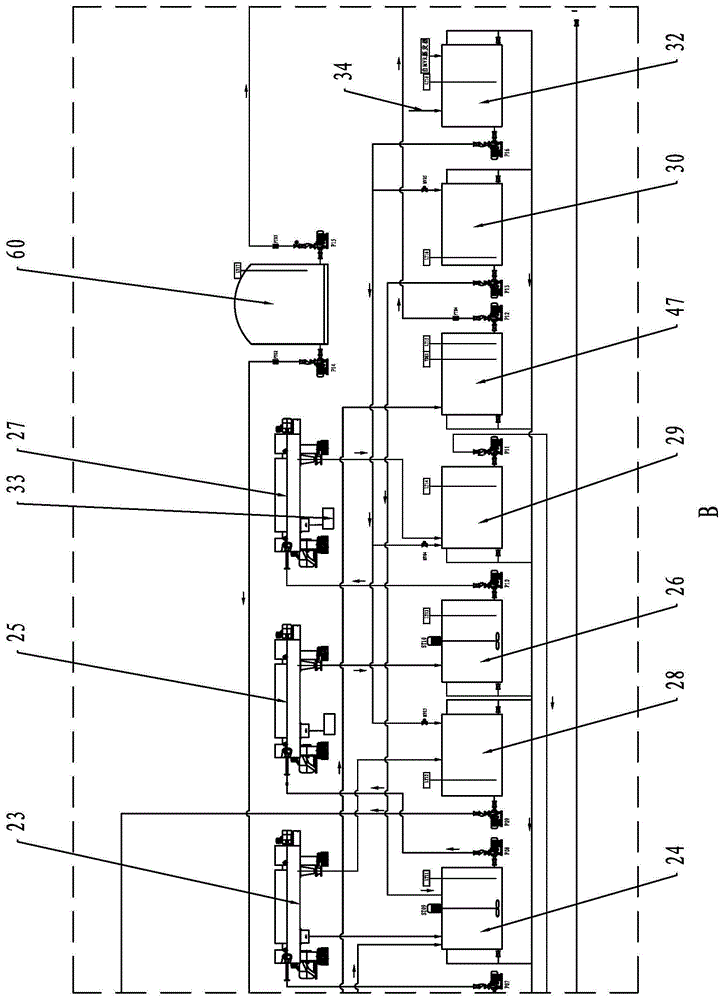

[0030] Fly ash washing part includes pre-mixing tank 13, primary washing tank 16, primary centrifuge A17, primary filtrate tank 18, primary centrifuge B19, secondary washing tank 20, secondary centrifuge A21, secondary filtrate tank 22. Two-stage centrifuge B23, three-stage washing tank 24, three-stage centrifuge A25, three-stage filtrate tank 26, three-stage centrifuge B27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com