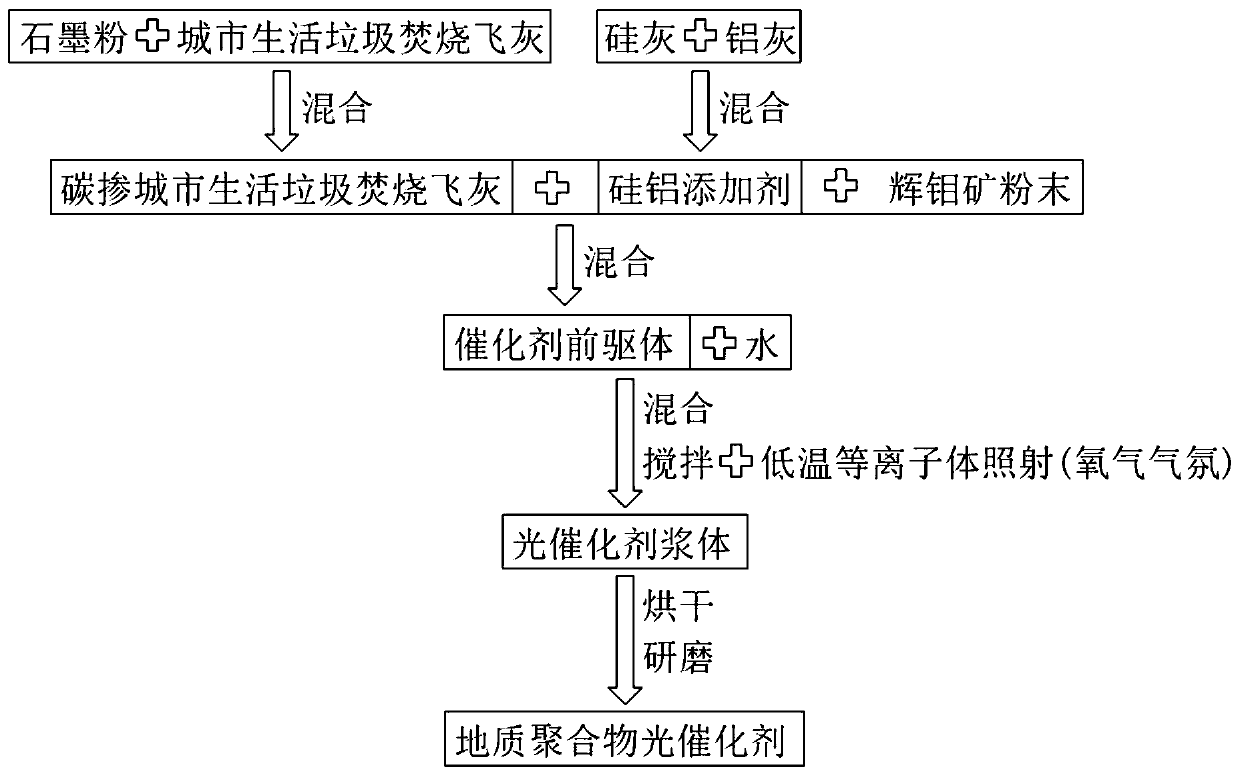

Method for preparing geopolymer photocatalyst from municipal solid waste incineration fly ash

A technology for municipal solid waste and geopolymers, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as difficult synchronous removal, restrictions on commercialization of photocatalytic technology, etc., to achieve preparation The effect of simple process and wide source of preparation raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Influence of the Mass Ratio of Graphite Powder and Municipal Solid Waste Incineration Fly Ash on the Performance of the Prepared Geopolymer Photocatalyst

[0029] According to the mass ratio of graphite powder to municipal solid waste incineration fly ash 2.5:100, 3:100, 4:100, 5:100, 10:100, 15:100, 16:100, 17:100, 17.5:100 Graphite powder and municipal solid waste incineration fly ash are mixed to obtain nine groups of carbon-doped municipal solid waste incineration fly ash. According to the mass ratio of silica fume and aluminum ash of 1:1, respectively weigh silica fume and aluminum ash, and mix them to obtain a silica-alumina additive. Weigh molybdenite powder, silicon-aluminum additive, carbon-doped municipal solid waste incineration fly ash respectively according to the mass ratio of molybdenite powder, silicon-aluminum additive, and carbon-doped municipal solid waste incineration fly ash 2: 20: 100, and mix to obtain nine group of catalyst precursor m...

Embodiment 2

[0043] Embodiment 2 Silica fume and aluminum ash mass ratio influence on the performance of the prepared geopolymer photocatalyst

[0044] According to the mass ratio of graphite powder and municipal solid waste incineration fly ash of 15:100, graphite powder and municipal solid waste incineration fly ash were weighed and mixed to obtain carbon-doped municipal solid waste incineration fly ash. Weigh silica fume and aluminum respectively according to the mass ratio of silica fume to aluminum dust: 0.5:1, 0.7:1, 0.9:1, 1:1, 2:1, 3:1, 3.2:1, 3.4:1, 3.5:1 Ash, mixed to get nine groups of silicon-aluminum additives. Weigh molybdenite powder, silicon-aluminum additive, carbon-doped municipal solid waste incineration fly ash respectively according to the mass ratio of molybdenite powder, silicon-aluminum additive, and carbon-doped municipal solid waste incineration fly ash 3: 30: 100, and mix to obtain nine group of catalyst precursor materials. According to the liquid-solid ratio ...

Embodiment 3

[0049] Example 3 Influence of molybdenite powder, silicon-aluminum additive, and carbon-doped municipal solid waste incineration fly ash mass ratio on the performance of the prepared geopolymer photocatalyst

[0050] According to the mass ratio of graphite powder and municipal solid waste incineration fly ash of 15:100, graphite powder and municipal solid waste incineration fly ash were weighed and mixed to obtain carbon-doped municipal solid waste incineration fly ash. According to the mass ratio of silica fume and aluminum ash of 3:1, respectively weigh silica fume and aluminum ash and mix them to obtain a silica-alumina additive. According to the mass ratio of molybdenite powder, silicon-aluminum additive, and carbon-doped municipal solid waste incineration fly ash 2:5:100, 2:10:100, 2:15:100, 0.5:20:100, 1:20:100, 1.5:20:100, 2:20:100, 3:20:100, 4:20:100, 2:30:100, 3:30:100, 4:30:100, 2:40:100, 3: 40:100, 4:40:100, 4.5:40:100, 5:40:100, 5.5:40:100, 4:45:100, 4:50:100, 4:5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com