Patents

Literature

204 results about "Plasma irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

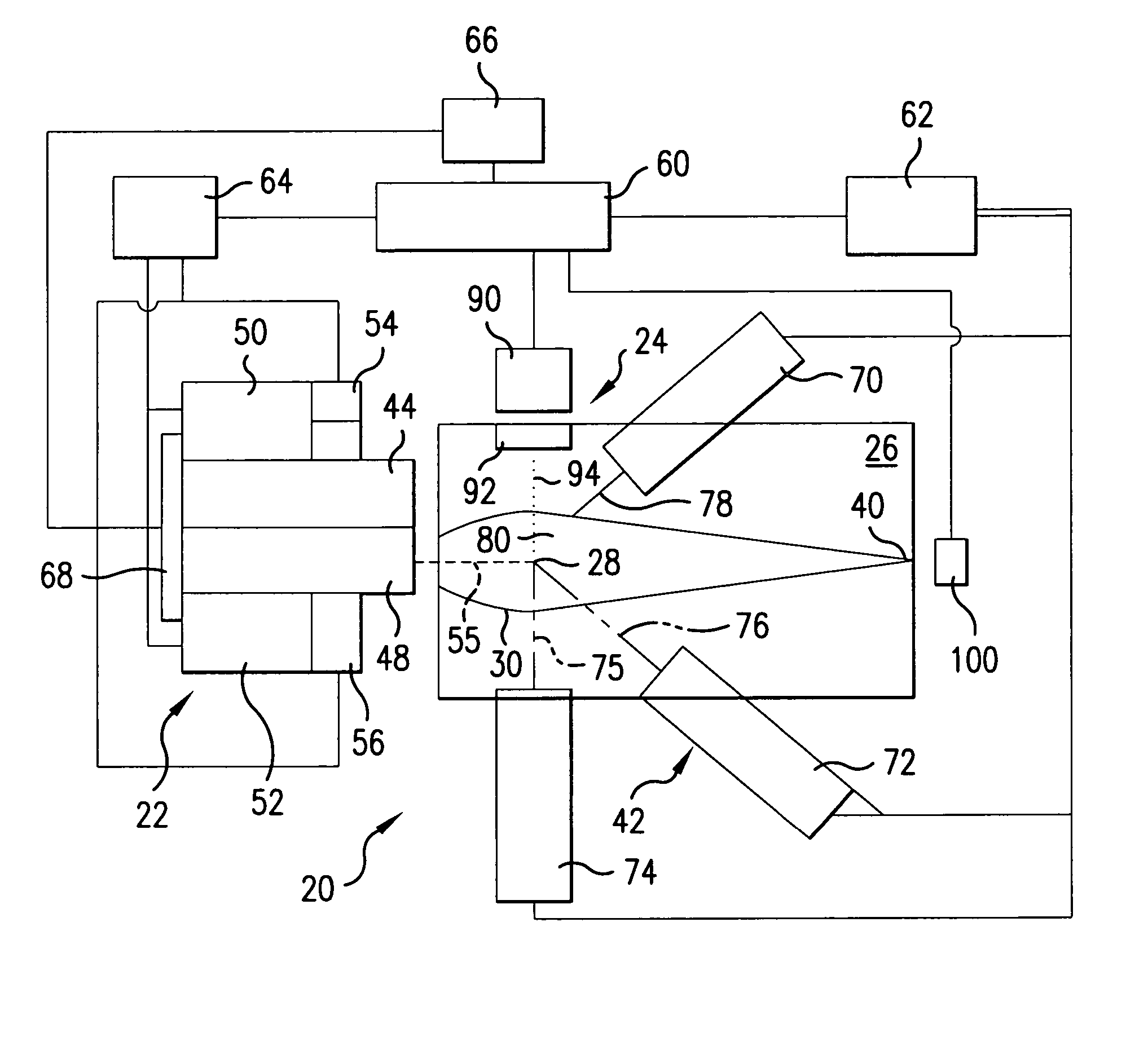

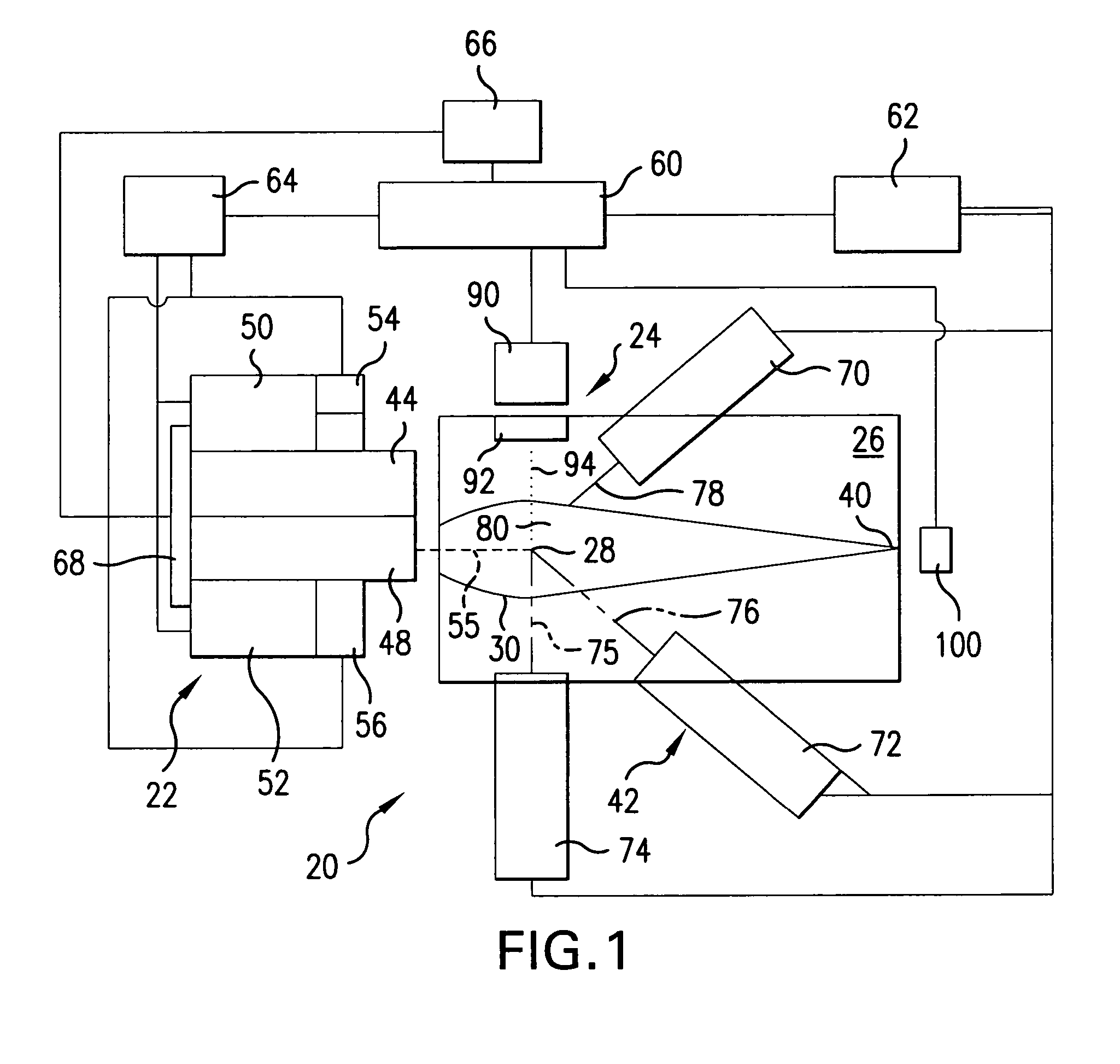

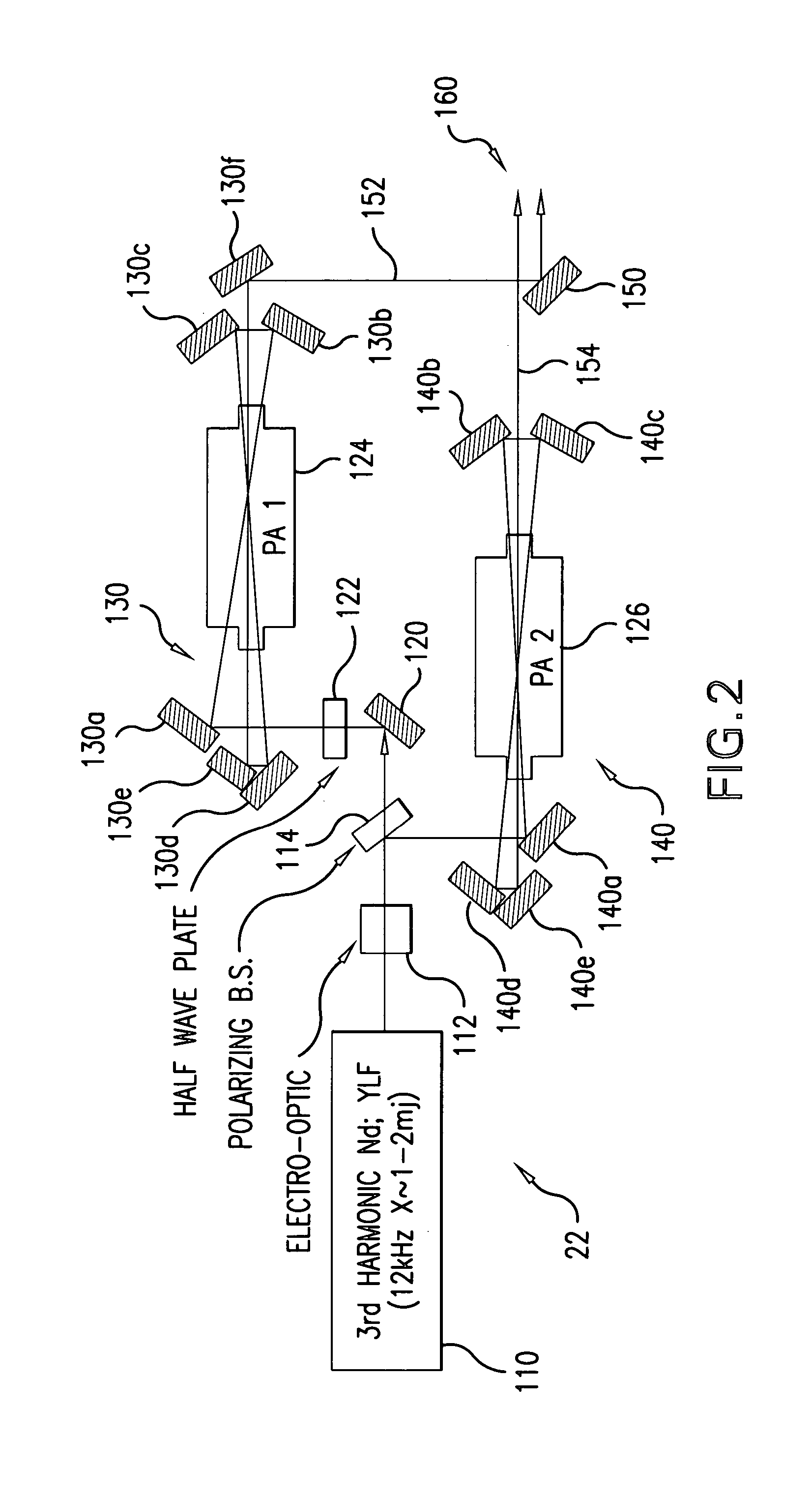

LPP EUV light source

An apparatus and method is described for effectively and efficiently providing plasma irradiation laser light pulses in an LPP EUV light source which may comprise a laser initial target irradiation pulse generating mechanism irradiating a plasma initiation target with an initial target irradiation pulse to form an EUV generating plasma having an emission region emitting in-band EUV light; a laser plasma irradiation pulse generating mechanism irradiating the plasma with a plasma irradiation pulse after the initial target irradiation pulse so as to compress emission material in the plasma toward the emission region of the plasma. The plasma irradiation pulse may comprise a laser pulse having a wavelength that is sufficiently longer than a wavelength of the initial target irradiation pulse to have an associated lower critical density resulting in absorption occurring within the plasma in a region of the plasma defined by the wavelength of the plasma irradiation pulse sufficiently separated from an initial target irradiation site to achieve compression of the emission material, and the may compress the emission region. The laser plasma irradiation pulse may produce an aerial mass density in the ablating cloud of the plasma sufficient to confine the favorably emitting plasma for increased conversion efficiency. The deposition region for the plasma irradiation pulse may be is removed enough from the initial target surface so as to insure compression of the favorably emitting plasma. A high conversion efficiency laser produced plasma extreme ultraviolet (“EUV”) light source may comprise a laser initial target irradiation pulse generating mechanism irradiating a plasma initiation target with a target irradiation pulse to form an EUV generating plasma emitting in-band EUV light; a plasma tamper substantially surrounding the plasma to constrain the expansion of the plasma.

Owner:ASML NETHERLANDS BV

Crosslinkable elastomer composition and formed product comprising the same

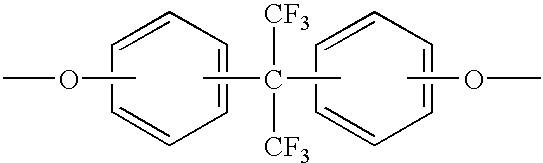

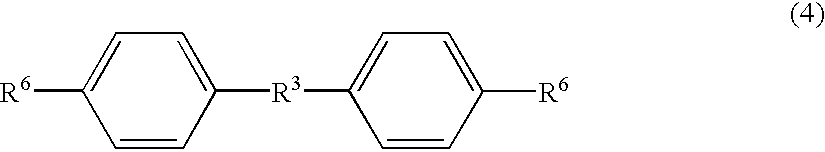

ActiveUS20050070637A1Reduce weightGeneration amountFibre treatmentConductive materialElastomerNon oxide ceramics

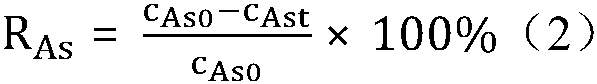

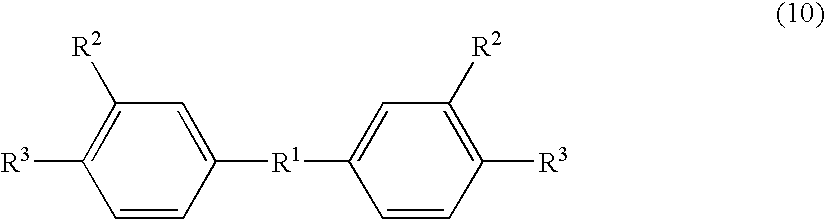

The present invention provides a crosslinkable elastomer composition, in which generation of HF under high temperature conditions is reduced, the decrease in weight to both NF3 plasma treatment and O3 treatment in the semiconductor manufacturing process is small and generation of foreign substances (particles) in these treatments is suppressed significantly. Specifically, the present invention relates to a crosslinkable elastomer composition comprising a crosslinkable elastomer and a filler having a specific surface area of at least 0.5 m2 / g and containing a synthetic polymer having a thermally and chemically stable aromatic ring in the main chain, a crosslinkable elastomer composition comprising a crosslinkable elastomer and nonoxide ceramics and a crosslinkable elastomer composition wherein the decrease in weight by NF3 plasma irradiation is at most 0.20%.

Owner:DAIKIN IND LTD

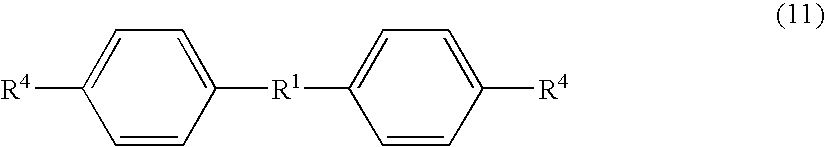

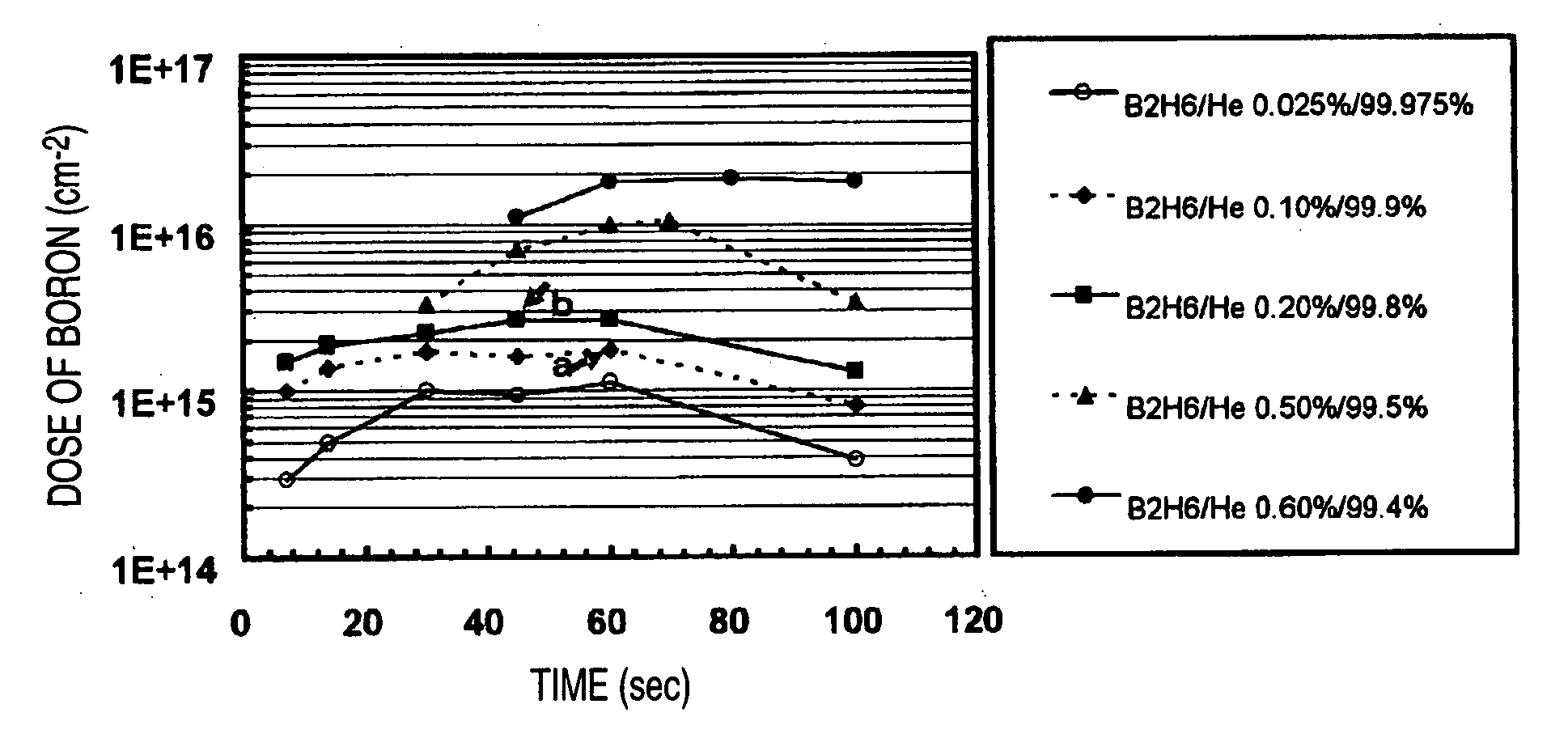

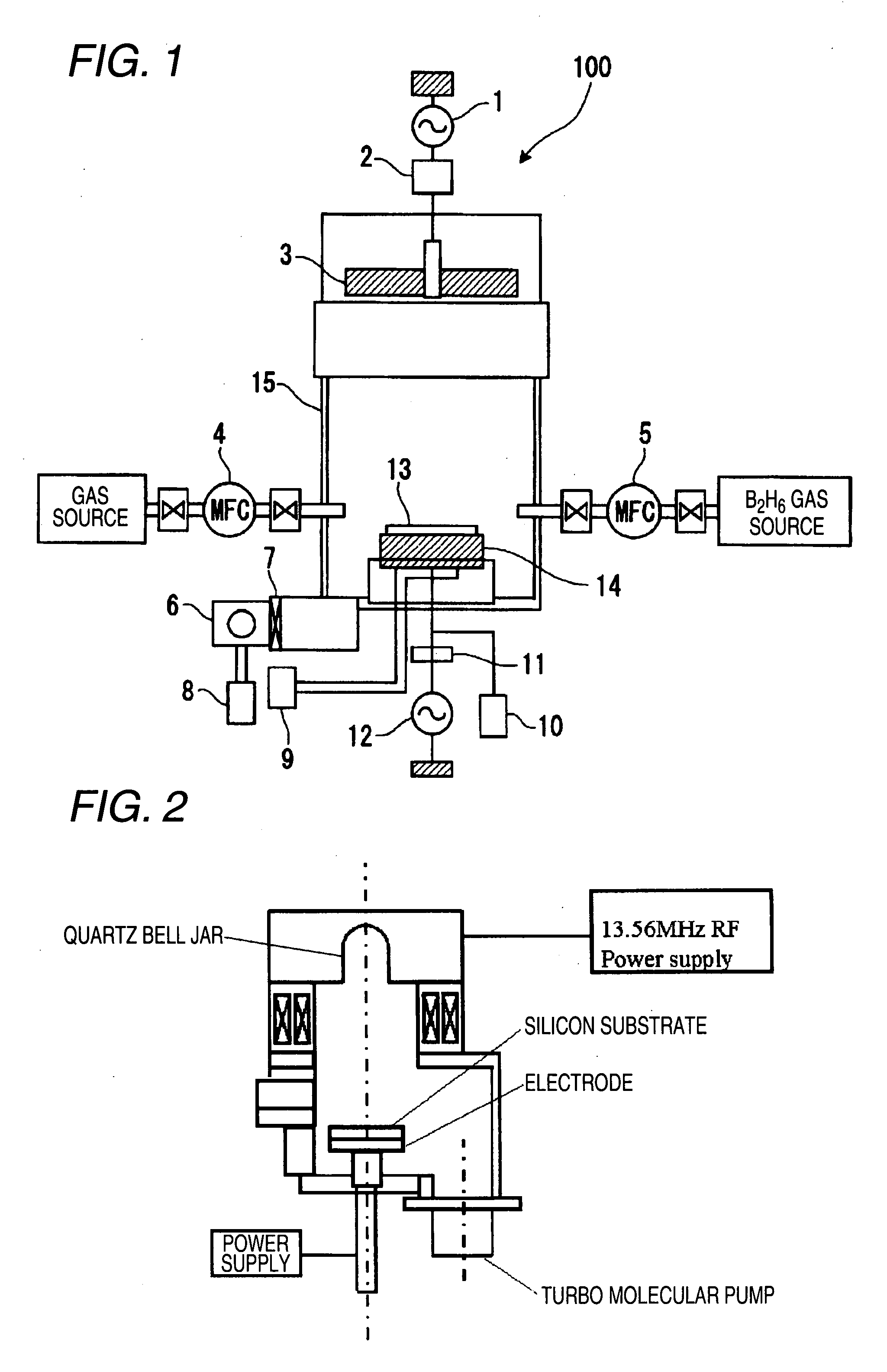

Plasma doping method

InactiveUS20070166846A1Improve uniformityControl doseSemiconductor/solid-state device testing/measurementElectric discharge tubesIn planeMedicine

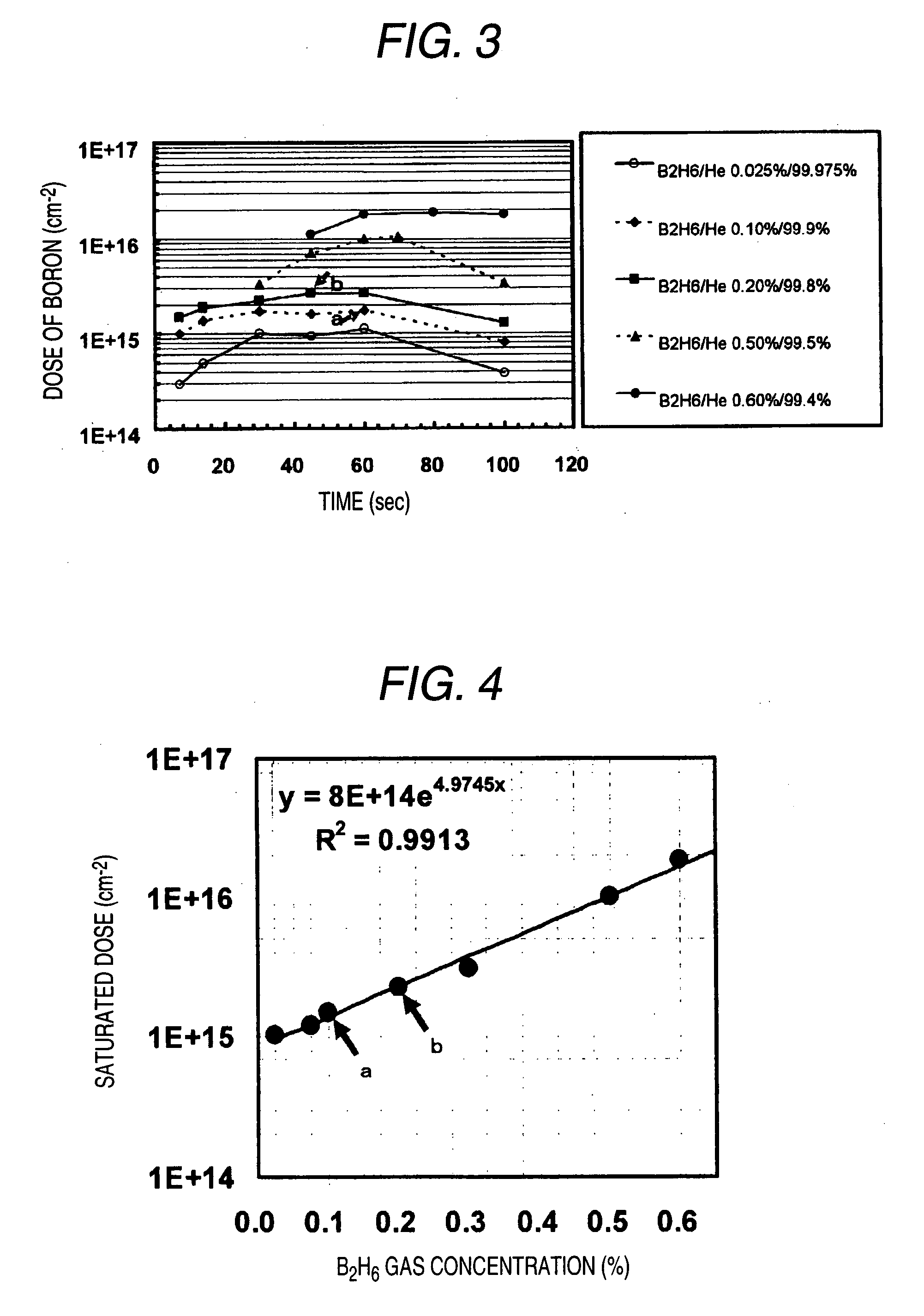

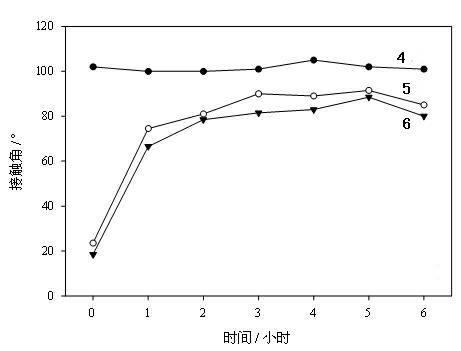

A plasma doping method that can control a dose precisely is realized. In-plane uniformity of the dose is improved. It has been found that, if a bias is applied by irradiating B2H6 / He plasma onto a silicon substrate, there is a time at which a dose of boron is made substantially uniform, and the saturation time is comparatively long and ease to stably use, compared with a time at which repeatability of an apparatus control can be secured. The invention has been finalized focusing on the result. That is, if plasma irradiation starts, a dose is initially increased, but a time at which the dose is made substantially uniform without depending on a time variation is continued. In addition, if the time is further increased, the dose is decreased. The dose can be accurately controlled through a process window of the time at which the dose is made substantially uniform without depending on the time variation.

Owner:PANASONIC CORP

Method for preparing sintering-free cement from municipal solid waste and product

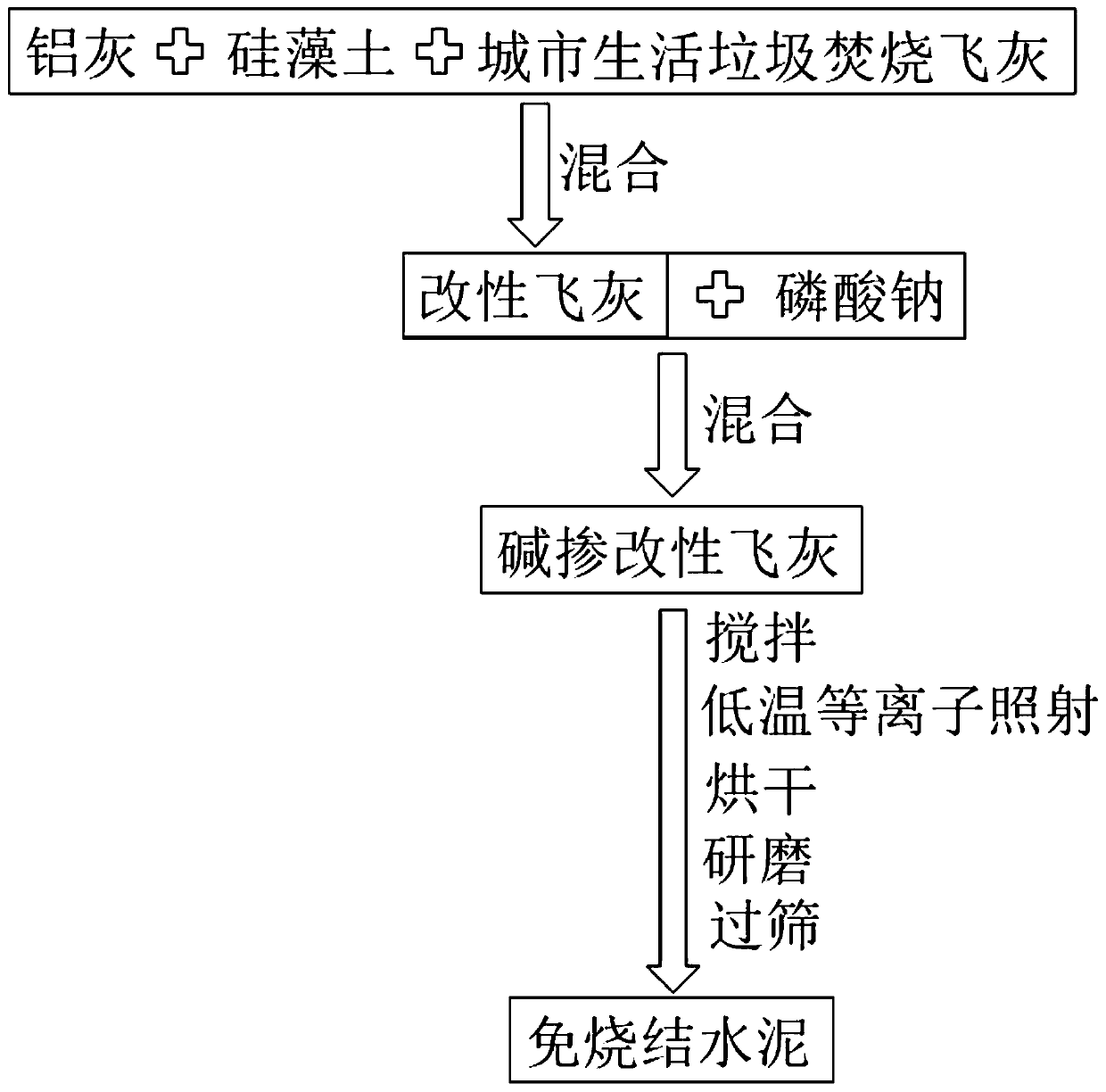

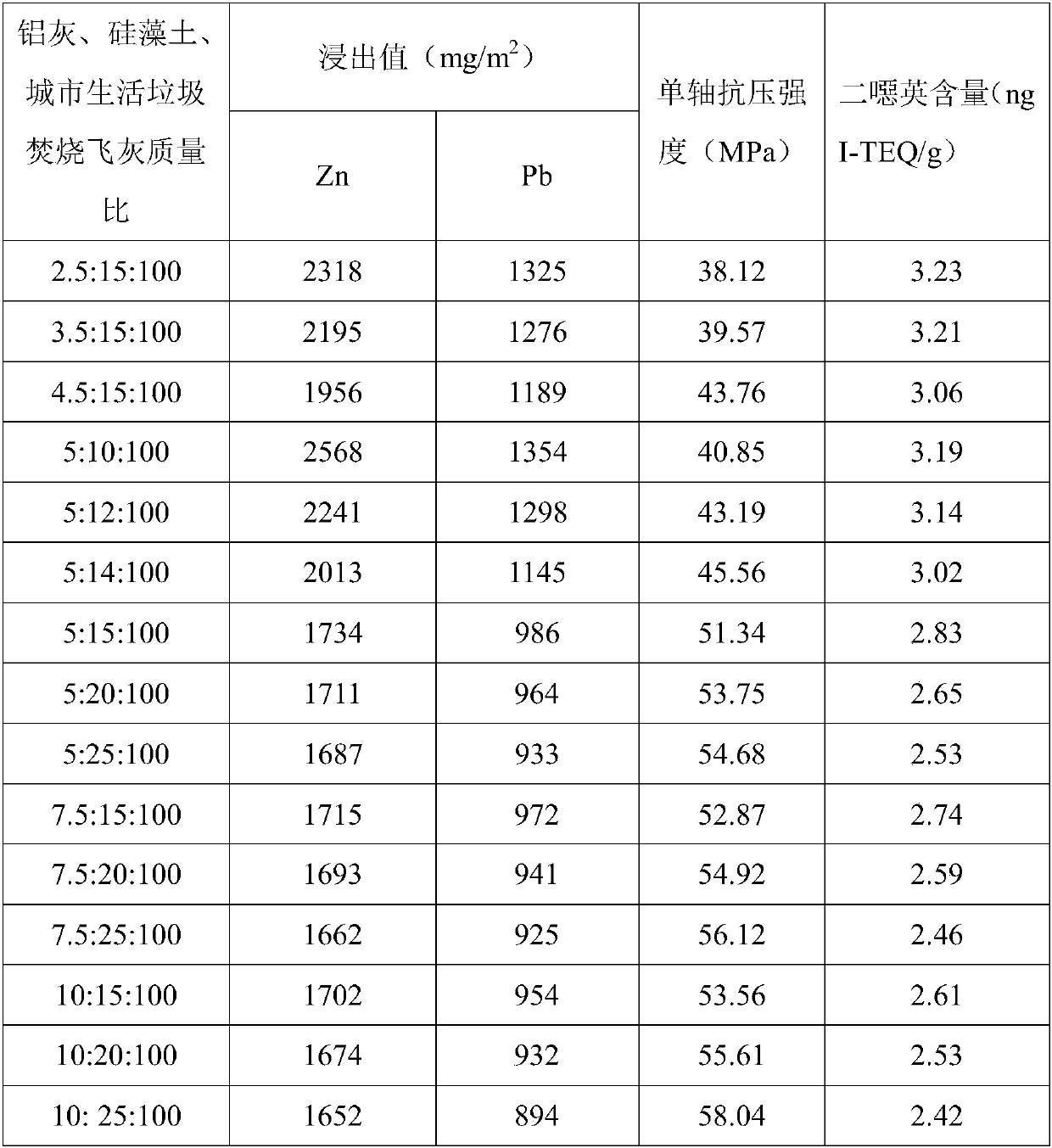

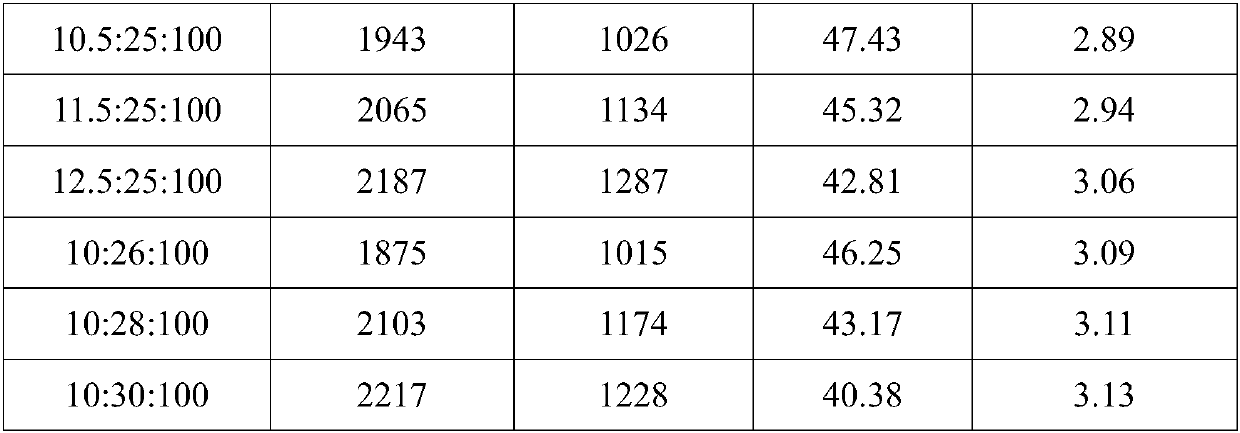

The invention discloses a method for preparing sintering-free cement from municipal solid waste, which comprises the following steps: respectively weighing aluminum ash, diatomite and municipal solidwaste incineration fly ash, and mixing to obtain modified fly ash; respectively weighing sodium phosphate and the modified fly ash, and mixing to obtain alkali-doped modified fly ash; respectively weighing water and the alkali-doped modified fly ash, stirring, Meanwhile, carrying out low-temperature plasma irradiation, so as to obtain water-boiling-free mud slurry; and drying, grinding and sievingthe water-boiling-free mud to obtain the sintering-free cement prepared from the municipal solid waste. The invention also discloses the sintering-free cement prepared by the method. The minimum leaching values of Zn and Pb of the prepared sintering-free cement are far lower than the limit values of inorganic pollutants Zn and Pb in the Holland building material standard, and the content of dioxin is far lower than the limit values in the Household Refuse Landfill Pollution Control Standard (GB16889-2008).

Owner:浙江中陶环保科技集团有限公司

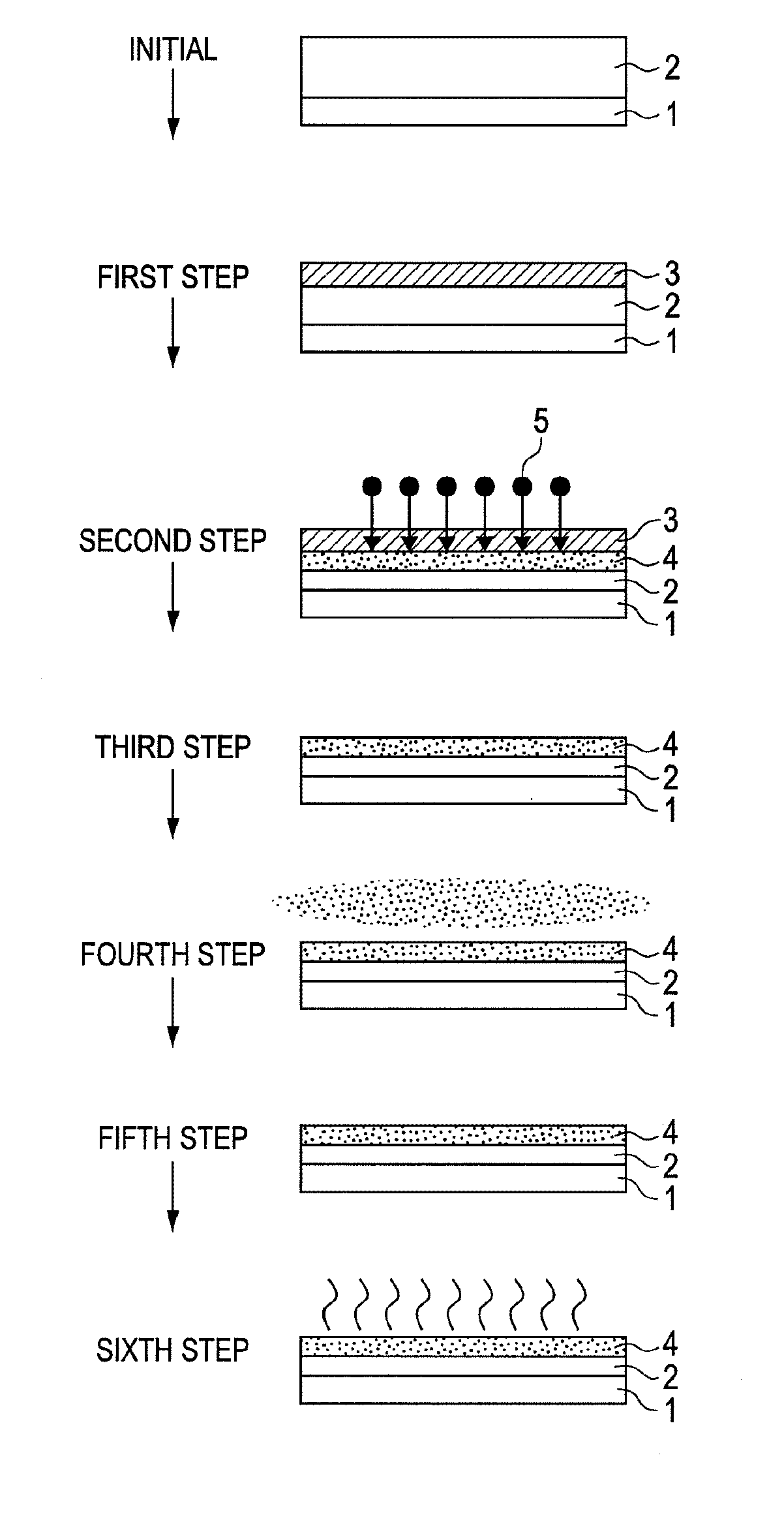

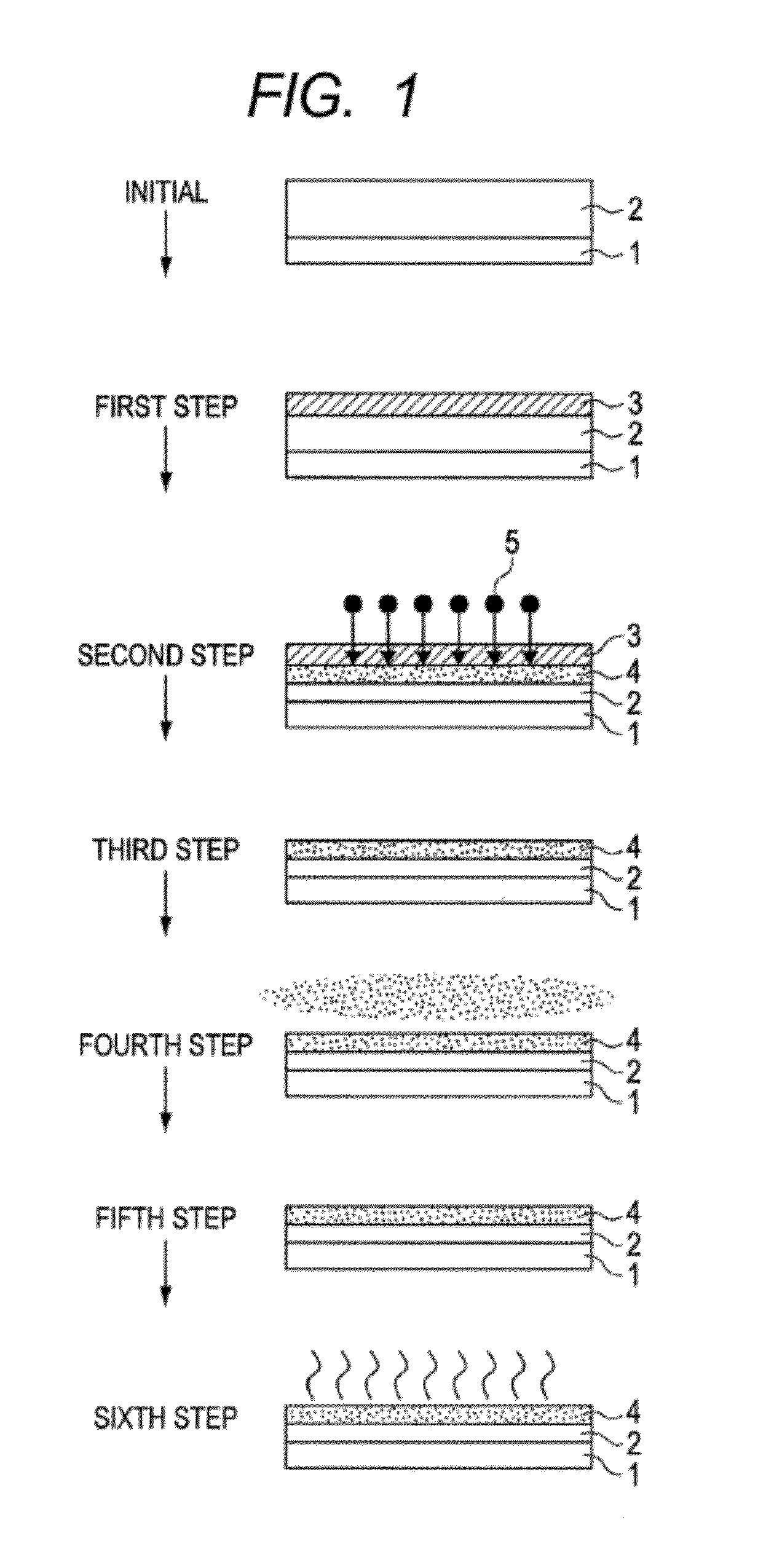

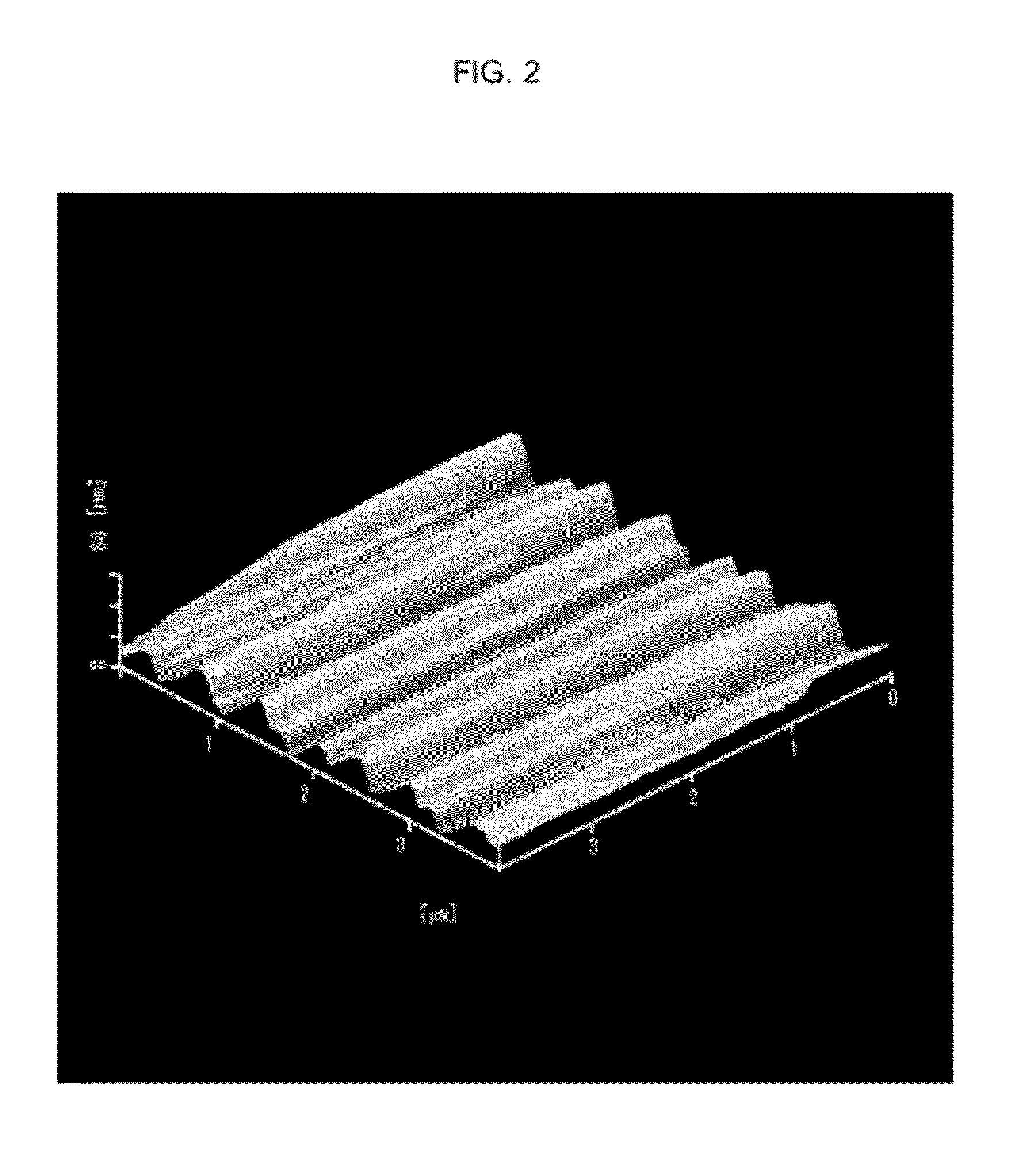

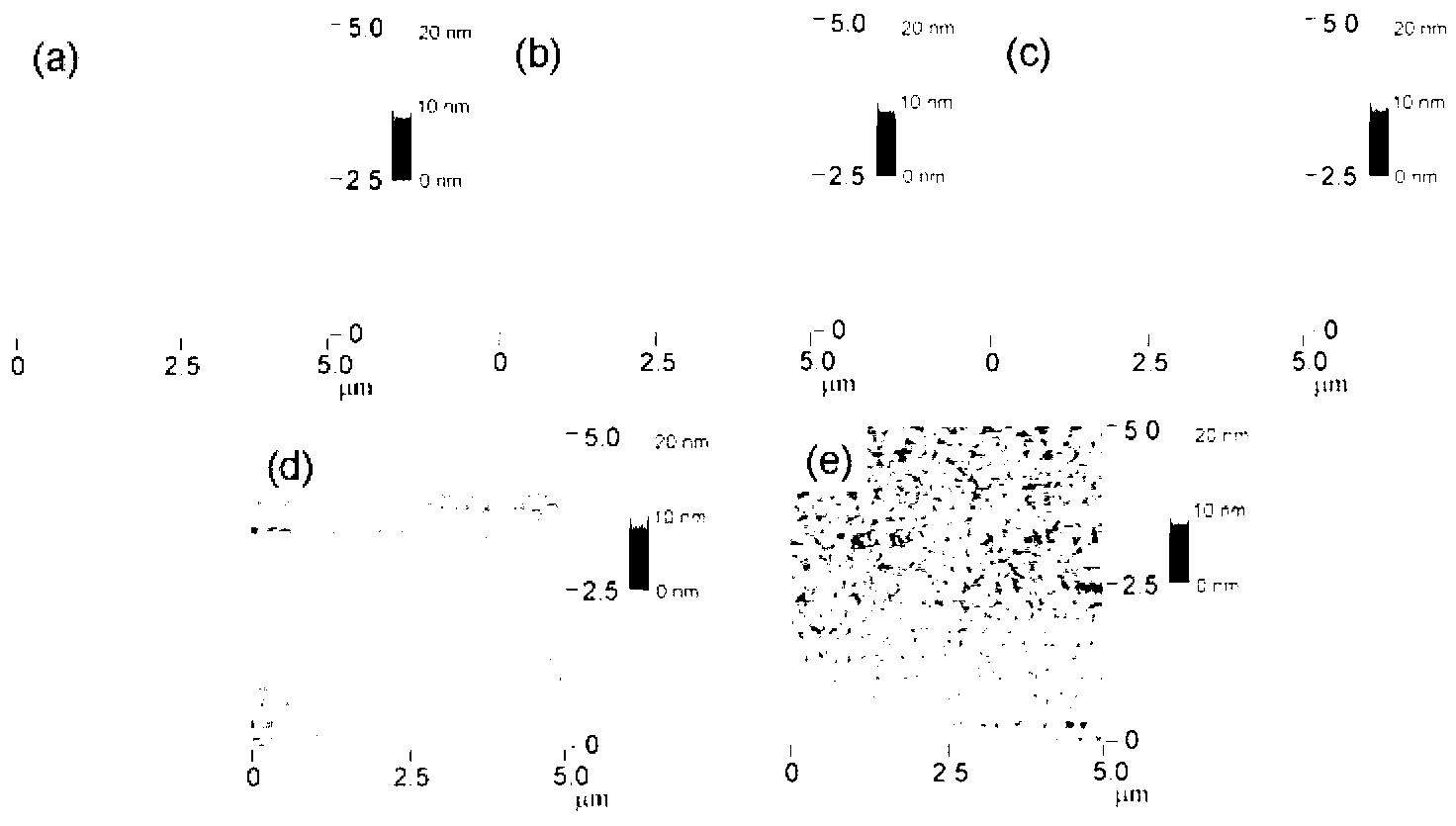

Substrate processing method and method of manufacturing crystalline silicon carbide (SIC) substrate

ActiveUS20120070968A1Reduce surface roughnessIncrease productionSemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessCarbide

The present invention provides a method of processing a substrate and a method of manufacturing a silicon carbide (SiC) substrate in which, when annealing processing is performed on a crystalline silicon carbide (SiC) substrate, the occurrence of surface roughness is suppressed. A substrate processing method according to an embodiment of the present invention includes a step of performing plasma irradiation on a single crystal silicon carbide (SiC) substrate (1) and a step of performing high temperature heating processing on the single crystal silicon carbide (SiC) substrate (1) in which the plasma irradiation is performed.

Owner:CANON ANELVA CORP

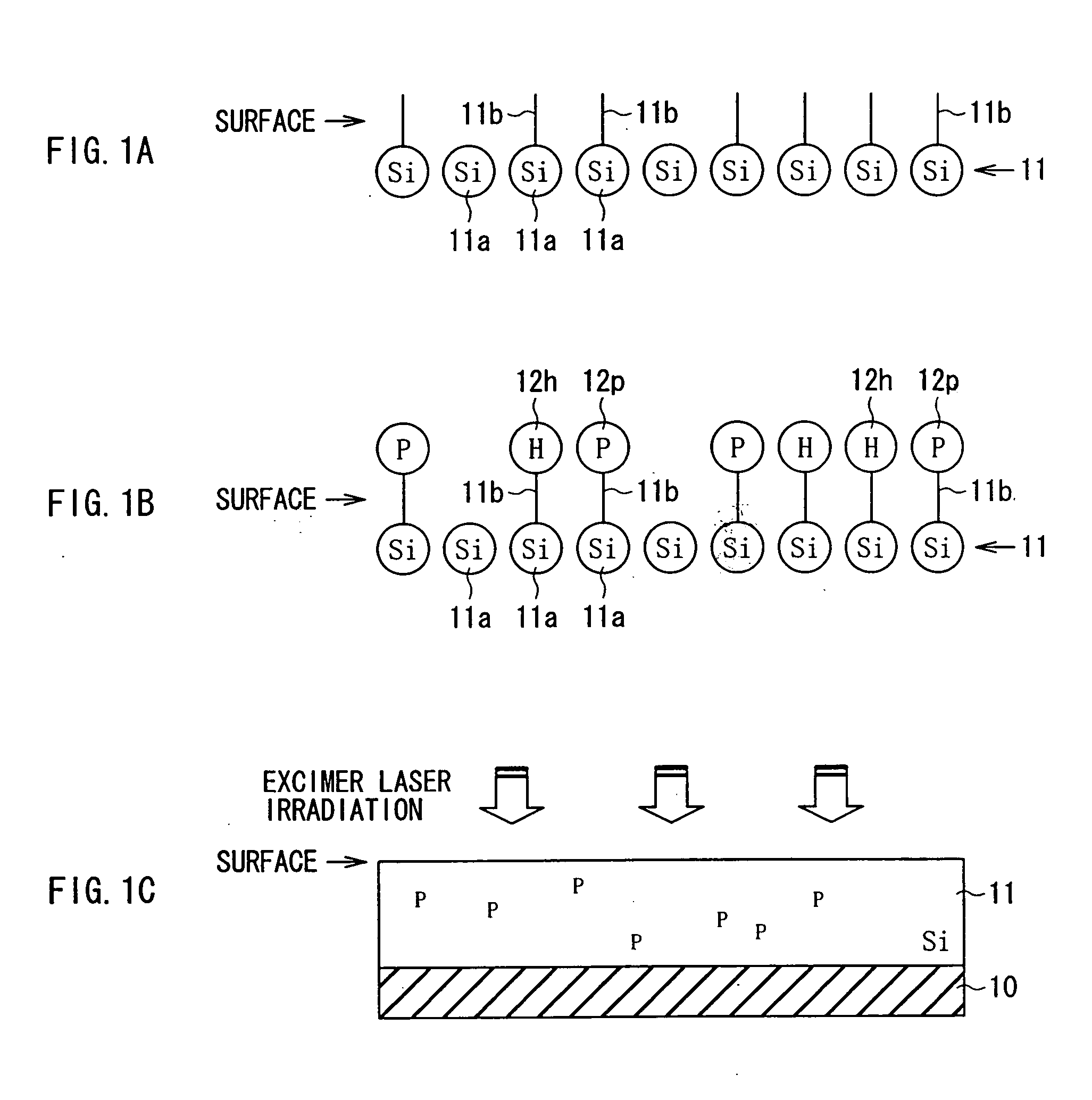

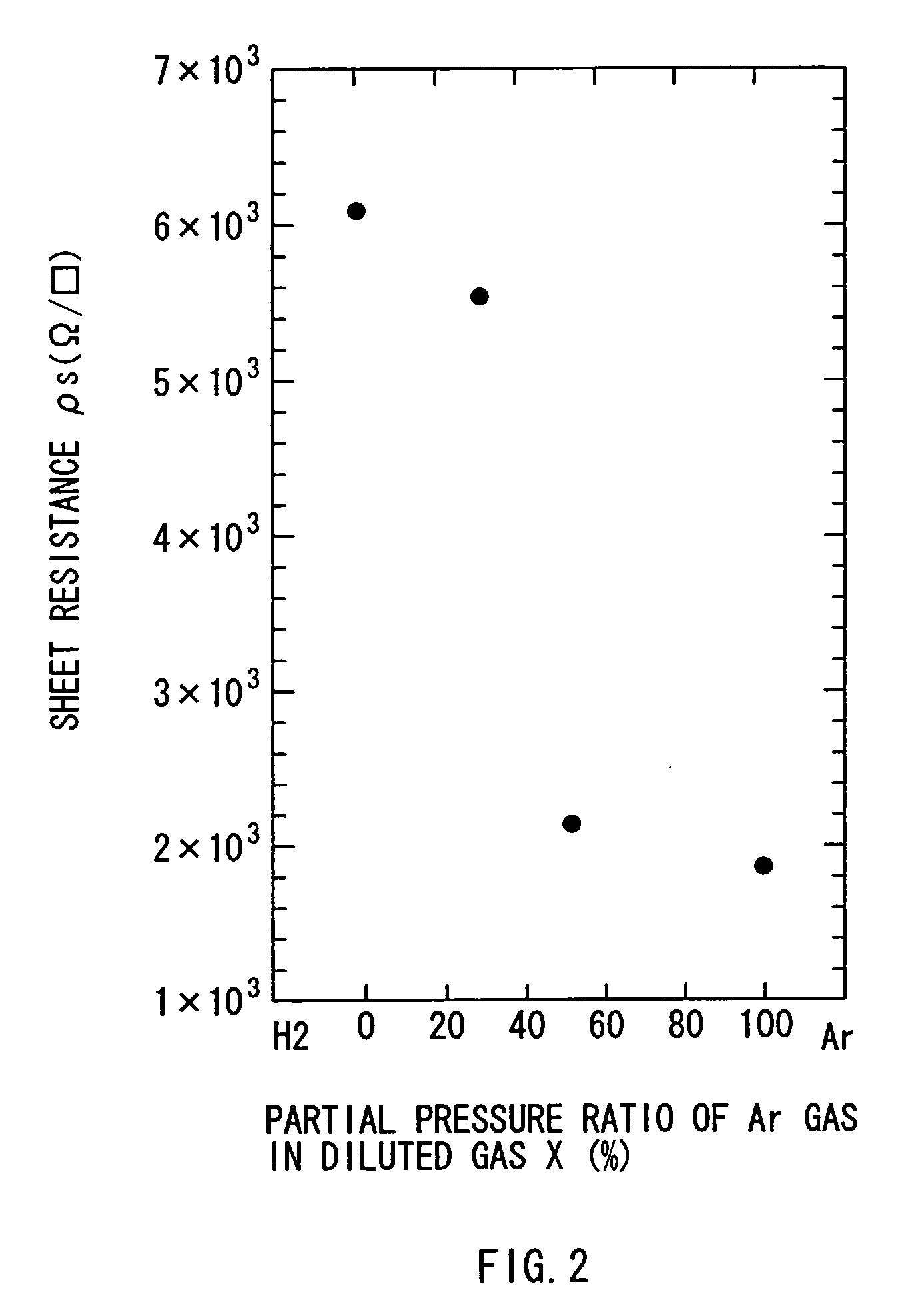

Method for doping semiconductor layer, method for manufacturing thin film semiconductor device, and thin film semiconductor device

Owner:MACHIDA AKIO +2

Preparation method of polyether sulfone functional separation membrane supporting dendritic polyamide-amine functional group

InactiveCN107875869AImprove grafting efficiencyImprove the effect of treatmentMembranesSemi-permeable membranesEthylenediaminePhosphate

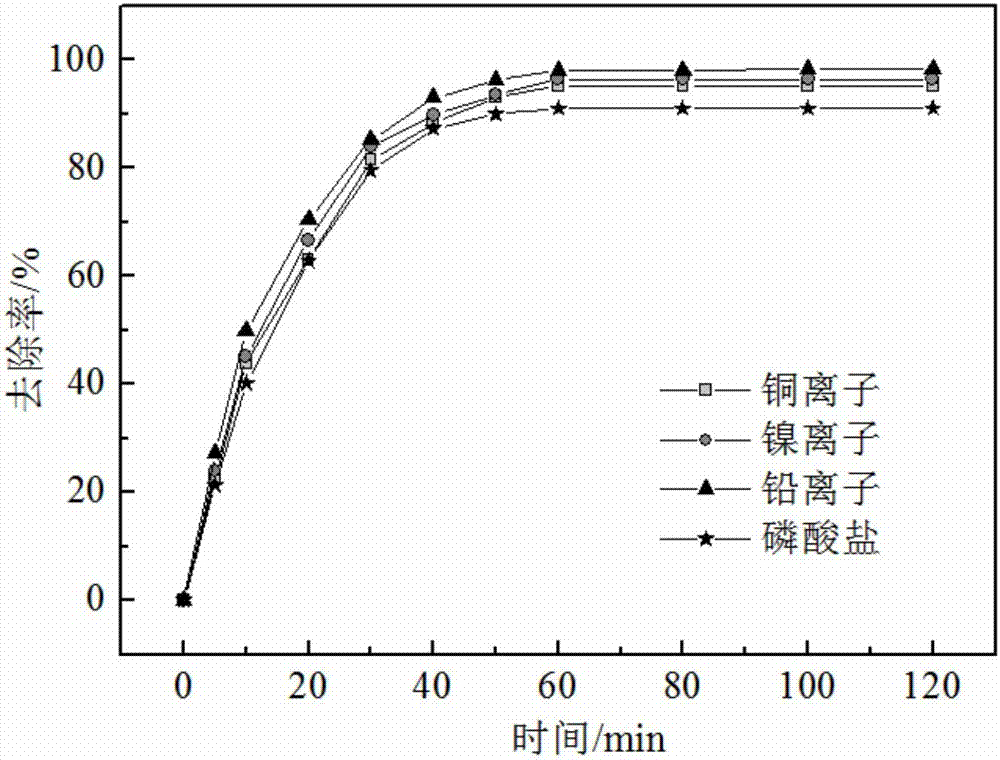

A preparation method of a polyether sulfone functional separation membrane supporting a dendritic polyamide-amine functional group includes the steps of: 1) performing chloroacetylation and aminationmodification treatment to polyether sulfone successively and preparing chloroacetylchlorine-diethylenetriamine-polyether sulfone separation membrane chips; 2) with methyl acrylate and ethylenediamineas main reagents, performing modification to the membrane chips by means of Michael addition and amidation reactions with plasma irradiation grafting synergistic technology; 3) preparing the polyethersulfone functional separation membrane supporting the dendritic polyamide-amine functional group via phase-transfer technology. The method is simple, wherein the grafting efficiency of the dendriticpolyamide-amine functional group is high. The functional group has large supporting quantity in the separation membrane, is stable in the separation membrane and is not liable to lose. The polyether sulfone functional separation membrane can remove heavy metals and phosphates in water body high-effectively and has a board application prospect in the field of water pollution control.

Owner:YANSHAN UNIV +1

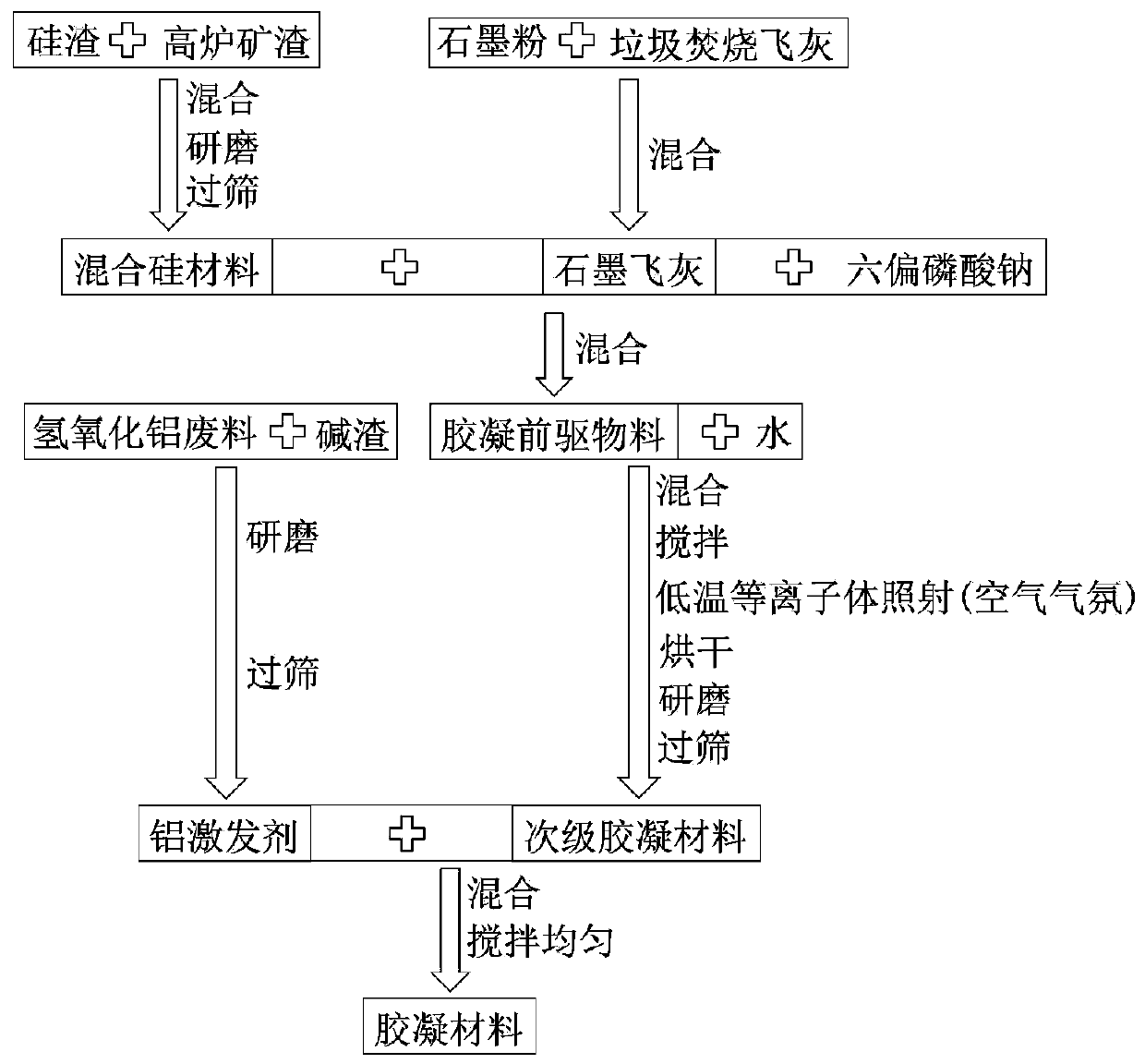

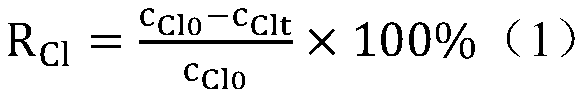

Method for preparing sintering-free cementing material from waste incineration fly ash

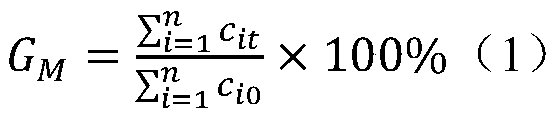

The invention discloses a method for preparing a sintering-free cementing material from waste incineration fly ash. The method comprises the following steps: (1) mixing silicon slag and blast furnaceslag, grinding, sieving to obtain a mixed silicon material, and mixing graphite powder and waste incineration fly ash to obtain graphite fly ash; (2) mixing sodium hexametaphosphate, the mixed siliconmaterial and graphite fly ash to obtain a gel precursor material; (3) dissolving the gelling precursor material in water, stirring while performing low-temperature plasma irradiation, drying, grinding and sieving to obtain a secondary cementing material; (4) mixing aluminum hydroxide waste and alkaline residues, grinding, and sieving to obtain an aluminum activator; and (5) uniformly mixing the aluminum activator and the secondary cementing material to obtain the cementing material. High-temperature sintering is not needed in the preparation process, so that process energy consumption is greatly reduced; the cementing material can achieve the highest heavy metal curing rate of 99.24%, the highest chlorine removal rate of 98.75% and the highest dioxin substance removal rate of 98.37%; andthe uniaxial compressive strength of a prepared mortar test block is as high as 50.68 MPa.

Owner:浙江慧科环保科技有限公司

Molded fluoro elastomer with excellent detachability and process for producing the same

InactiveCN1423673ALayered productsSemiconductor/solid-state device detailsSurface roughnessResin coating

A fluoroelastomer molding which is either a fluoroelastomer molding obtained by irradiating a molded fluoroelastomer with a plasma and having a center-line average surface roughness of 0.65 mu m or larger or a coated fluoroelastomer molding which is obtained by coating a fluoroelastomer base with a resin coating layer and has a low peel strength and a low etching rate during plasma irradiation. It is excellent not only in detachability but in whiteness. The molding is suitable for use as various sealing materials especially for semiconductor production apparatuses.

Owner:DAIKIN IND LTD

Elastomer molded article and crosslinkable fluorine-containing elastomer composition for semi-conductor production apparatuses

Elastomer molded article for semiconductor production apparatuses which is obtained by crosslinking and molding a crosslinkable fluorine-containing elastomer composition comprising a crosslinkable fluorine-containing elastomer component and fine particles of aluminum oxide having an average particle size of not more than 0.5 mum. The elastomer molded article is excellent in plasma resistance and an amount of micro particles generated after irradiation of plasma is very small and therefore a very clean molded article for semiconductor production apparatuses, particularly a sealing material to be used in an environment of plasma irradiation is provided.

Owner:DAIKIN IND LTD

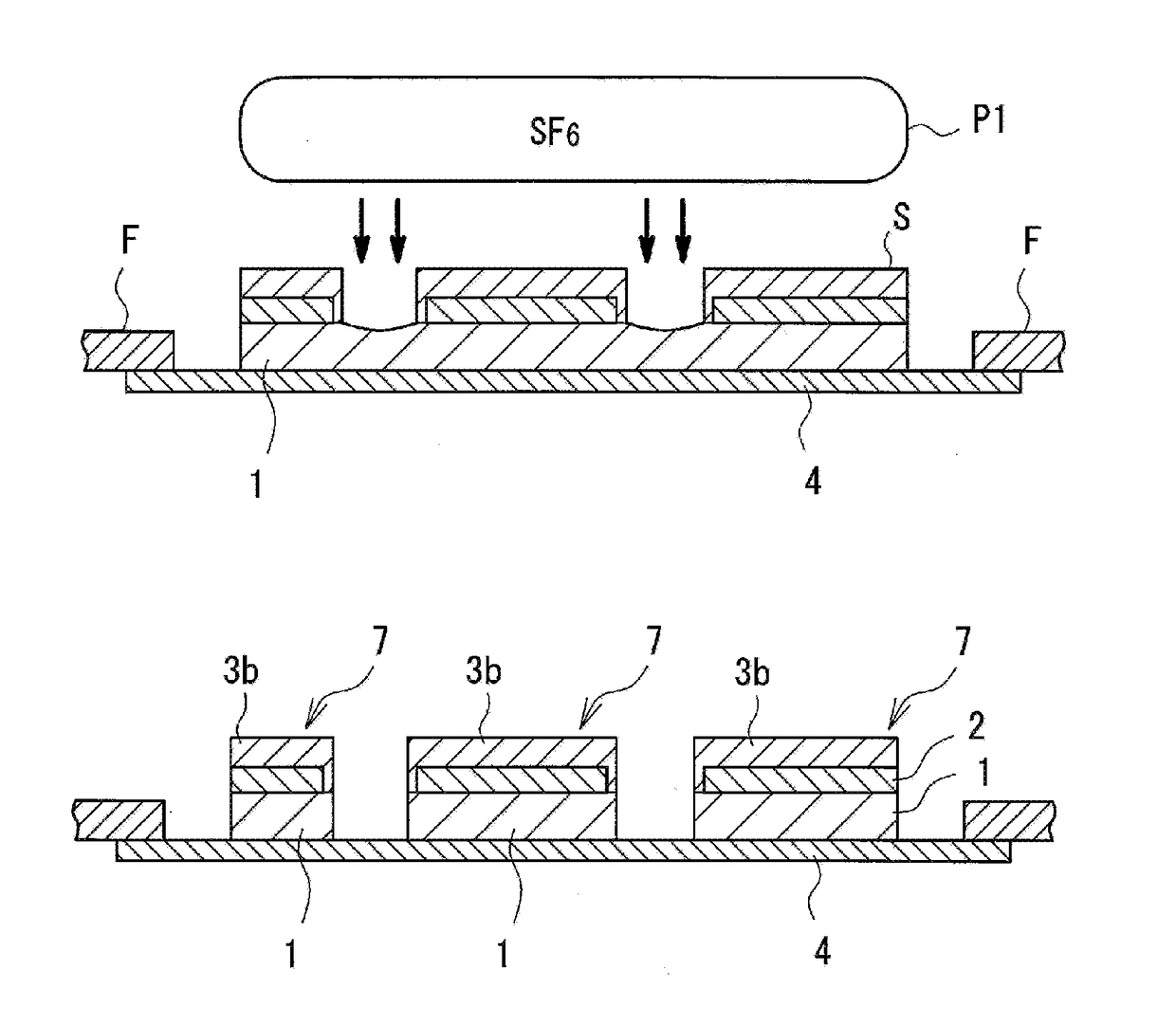

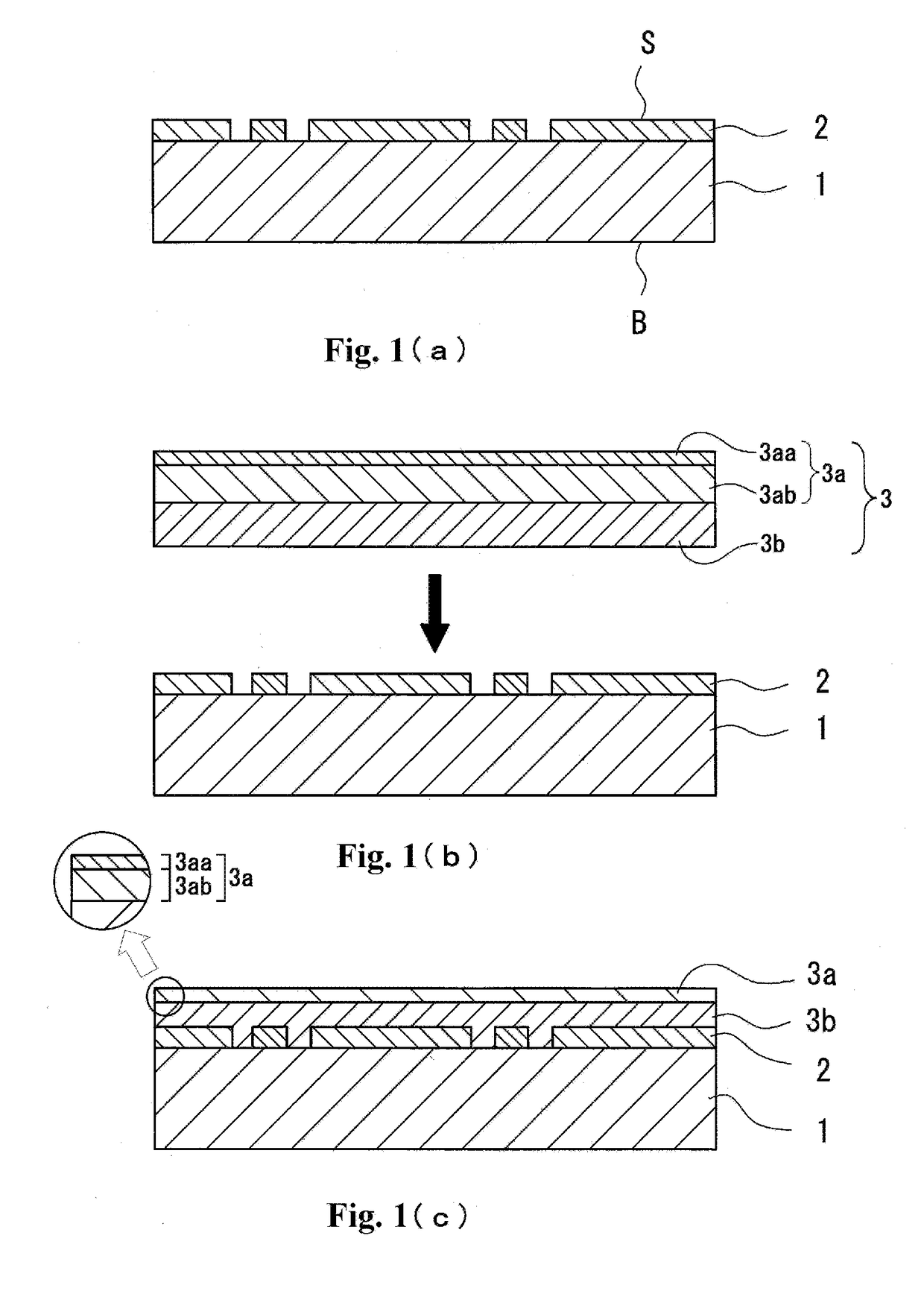

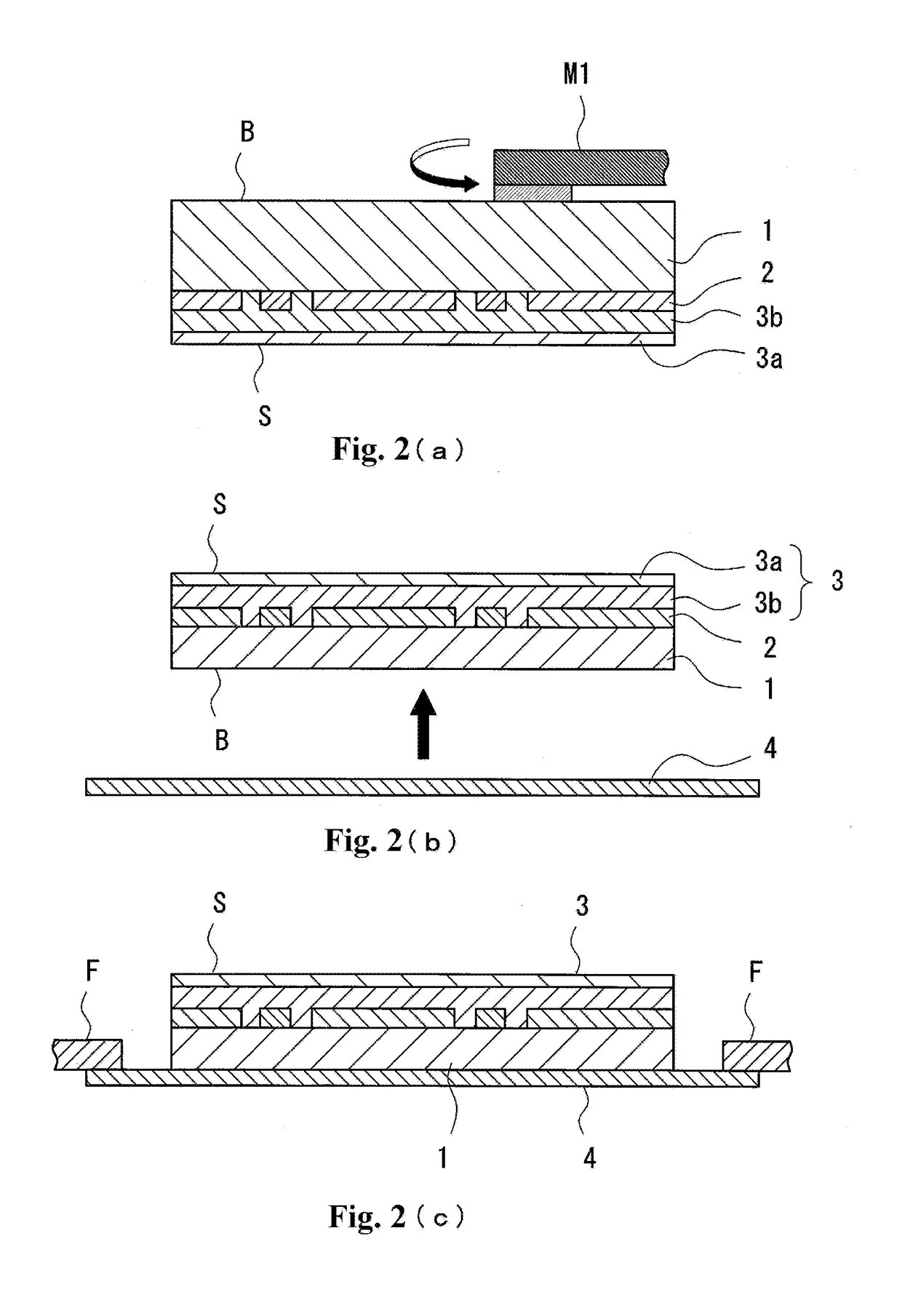

Method of producing semiconductor chip, and mask-integrated surface protective tape used therein

ActiveUS20180185964A1Simple processThe formation process is simpleFilm/foil adhesivesSolid-state devicesSemiconductor chipPlasma irradiation

A method of producing a semiconductor chip, including the following steps (a) to (d):(a) a step of, in the state of having laminated a mask-integrated surface protective tape on the side of a patterned surface of a semiconductor wafer, grinding the backing-face of the semiconductor wafer; laminating a wafer fixing tape on the backing-face side of the ground semiconductor wafer; and supporting and fixing the wafer to a ring flame;(b) a step of, after peeling the surface protective tape thereby to expose the mask material layer on top, forming an opening of a street of the semiconductor wafer;(c) a plasma dicing step of segmentalizing the semiconductor wafer by a plasma irradiation to singulate it into semiconductor chips; and(d) an ashing step of removing the mask material layer by the plasma irradiation.

Owner:FURUKAWA ELECTRIC CO LTD

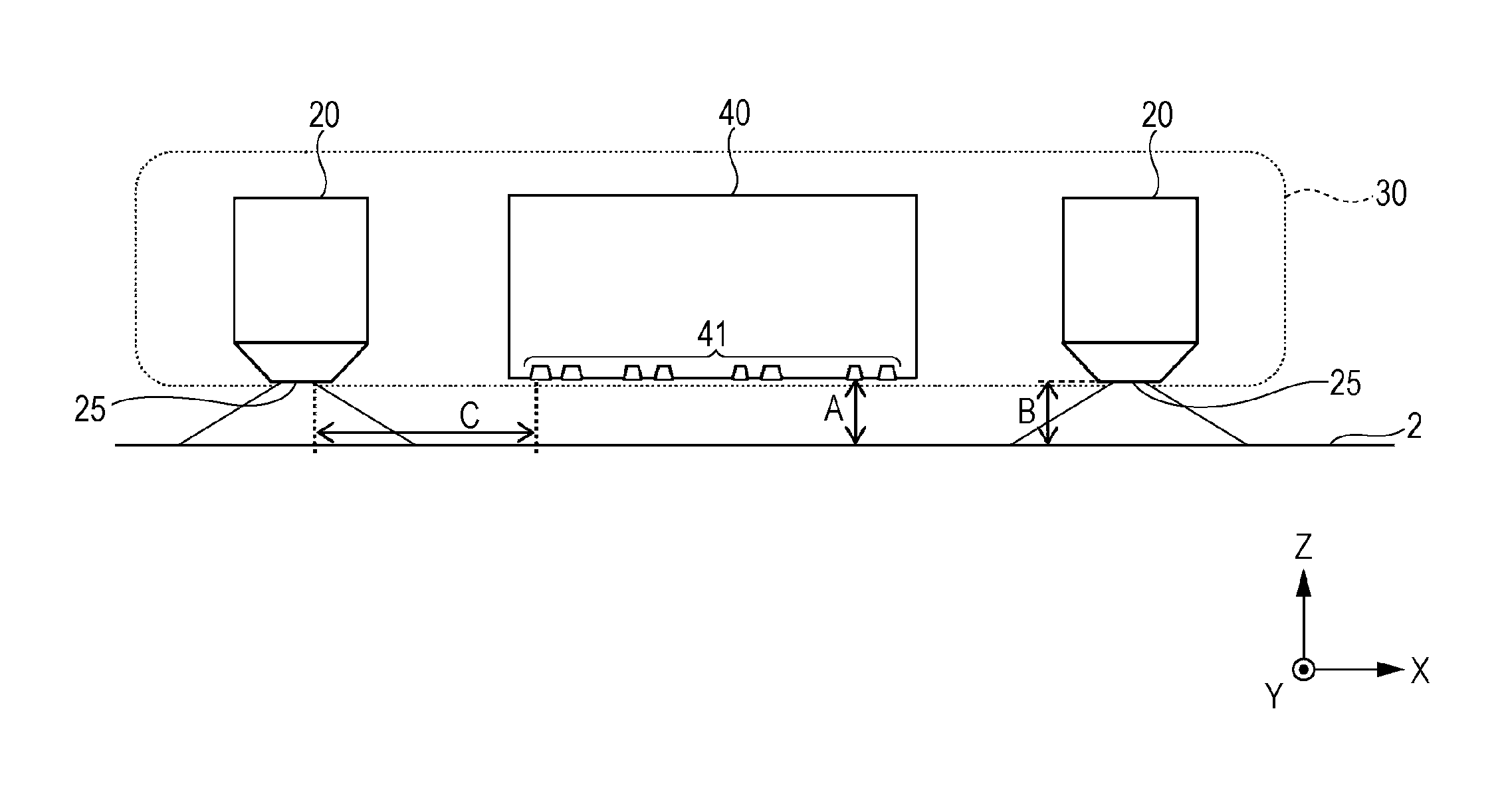

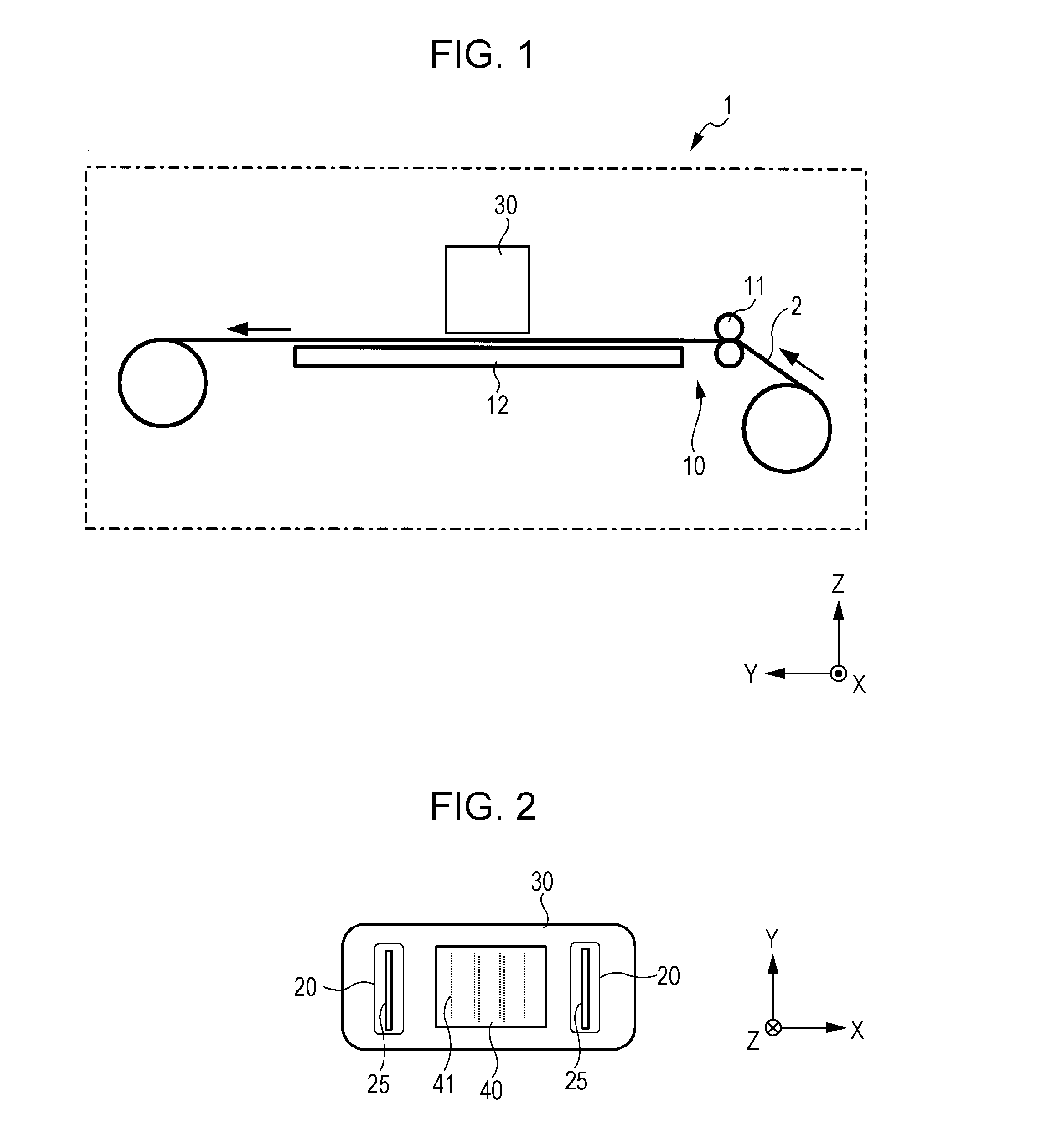

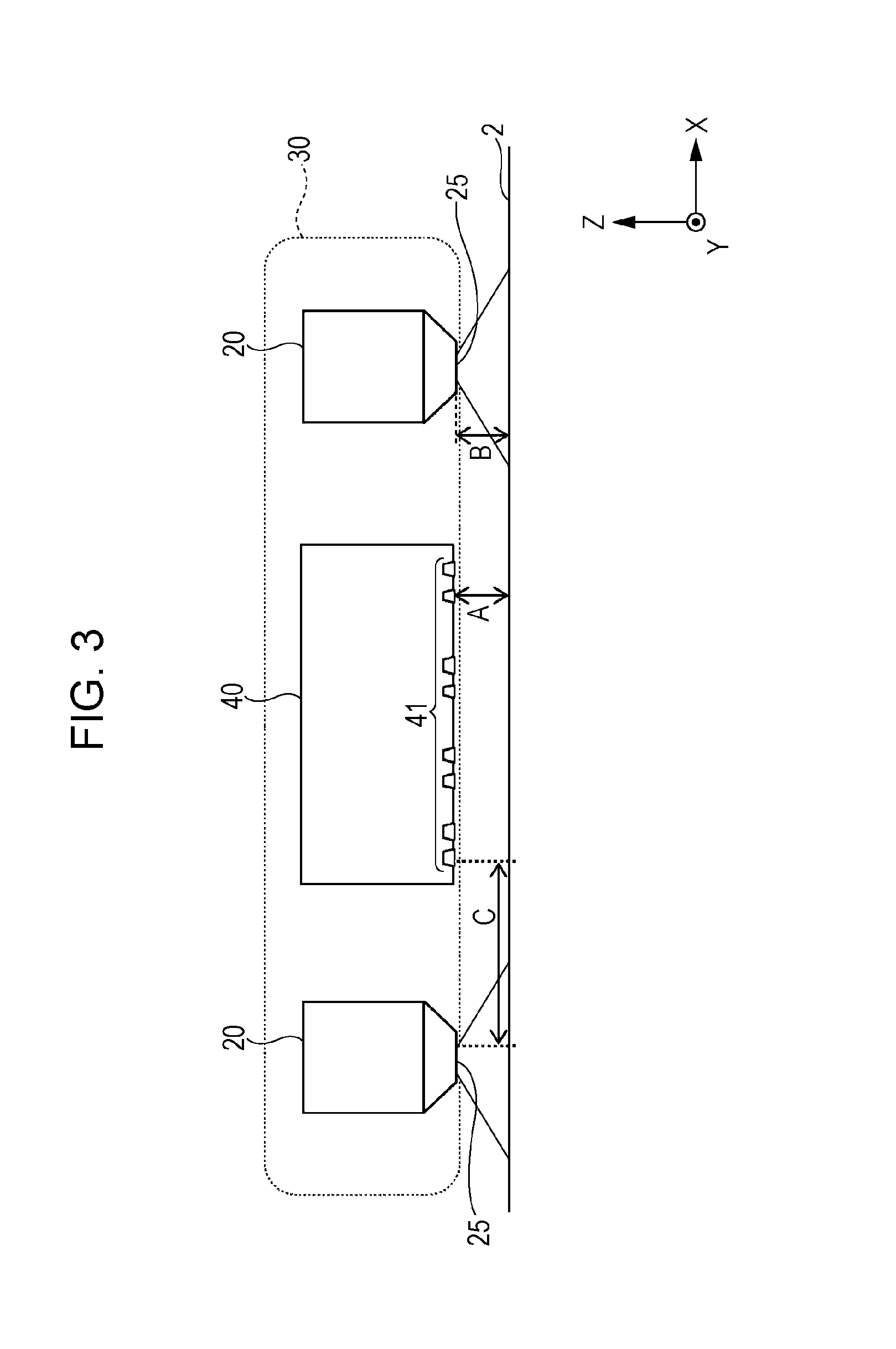

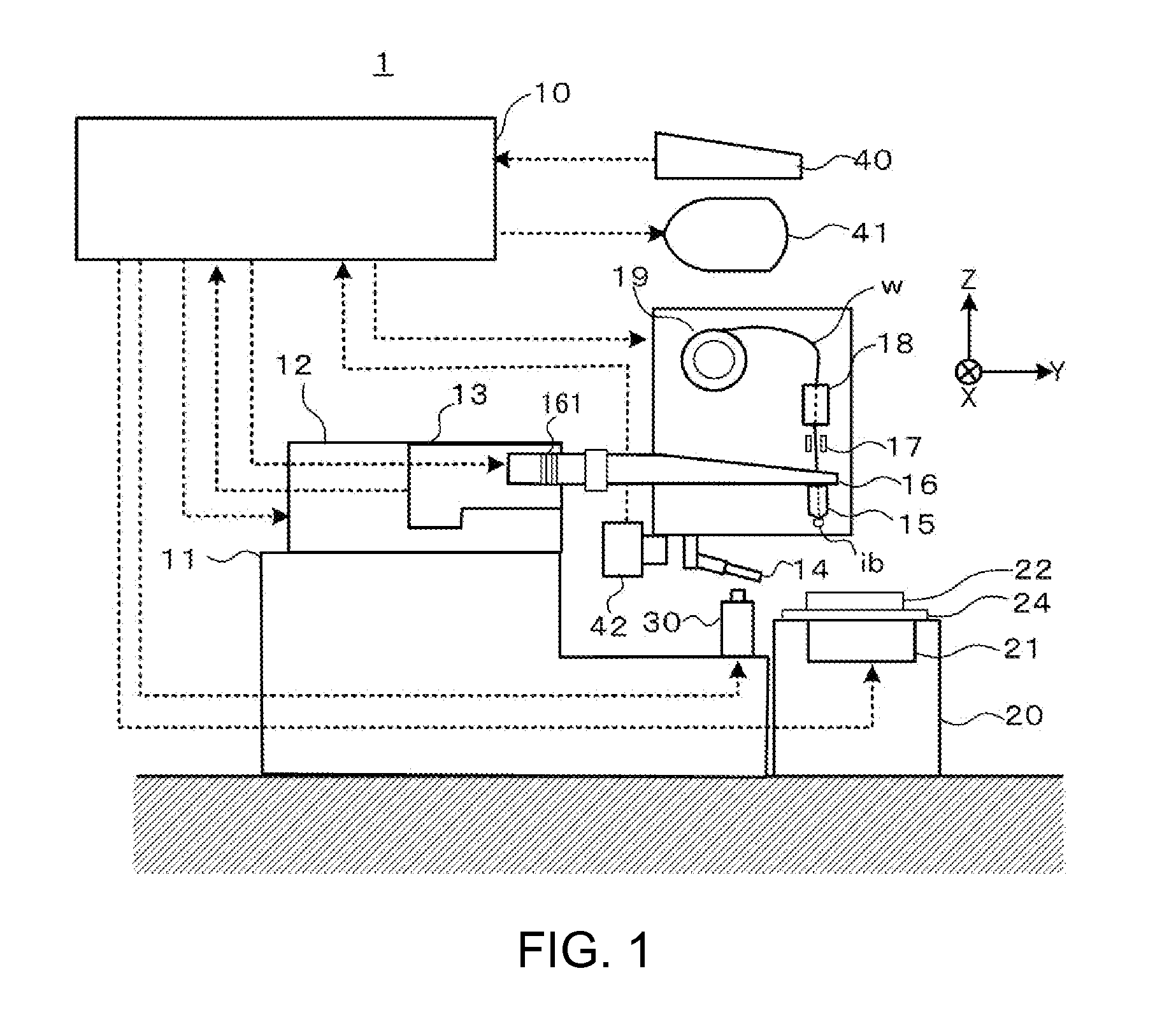

Ink jet printer and printing method

ActiveUS20150202894A1Suppressing at least one of damage and discoloration of a mediumDuplicating/marking methodsDyeing processInk printerPlasma irradiation

An ink jet printer includes a transport mechanism that transports a medium in a first direction; and a carriage that includes a plasma irradiation mechanism, which emits plasma generated in a discharge portion from a plasma irradiation port and then irradiates at least a part of the medium with the plasma, and a head which ejects ink onto the part of the medium which is irradiated with the plasma, and that moves in a second direction intersecting with the first direction, in which the plasma irradiation mechanism is provided on one side of the head in the second direction, and the discharge portion of the plasma irradiation mechanism is disposed so as not to come in contact with the medium.

Owner:SEIKO EPSON CORP

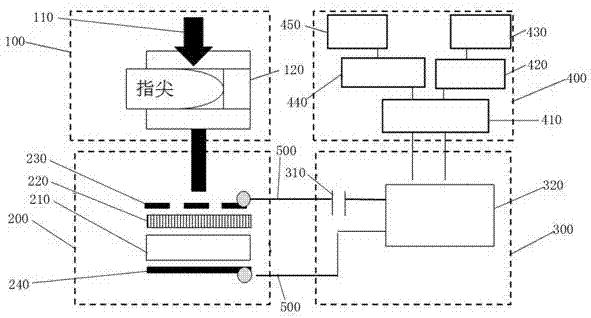

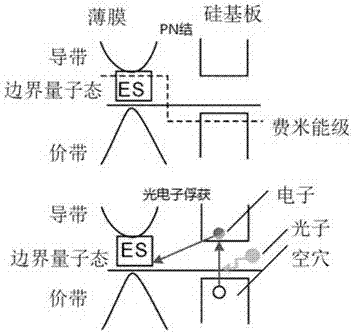

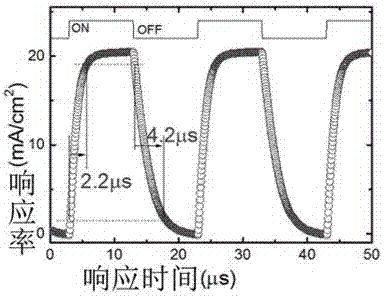

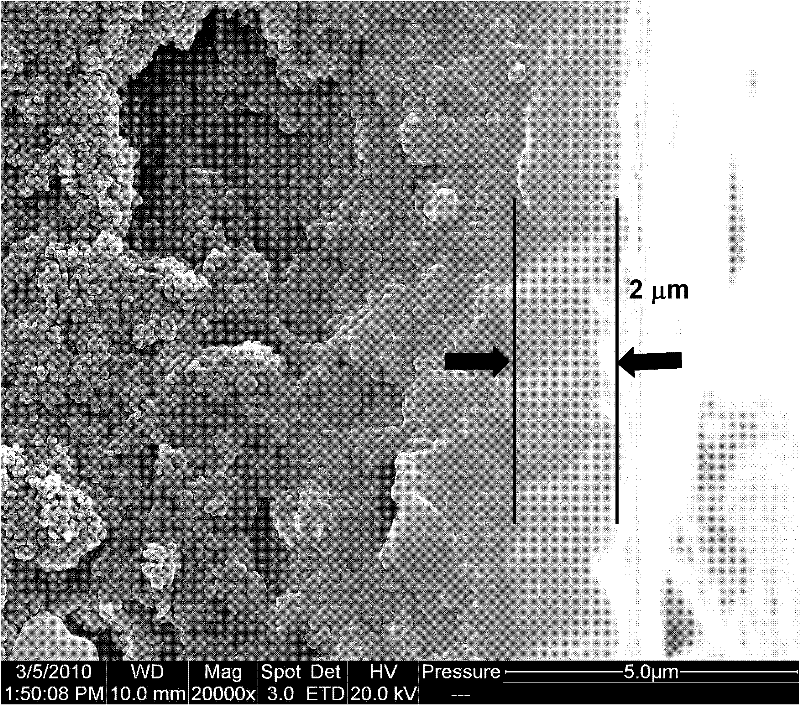

Pulsimeter based on graphene edge embedded type nano-film photoelectric sensor

ActiveCN107334464AReduce compoundingAccurate and stable measurementDiagnostics using lightCatheterQuantum wellPlasma irradiation

The invention discloses a pulsimeter based on a graphene edge embedded type nano-film photoelectric sensor. The pulsimeter comprises an infrared light source unit for fixing a finger, to be detected, of a user and emitting infrared light of a specified wavelength to penetrate through the finger of the user; a photoelectric sensor unit for collecting an infrared light signal and generating a photoelectric signal according to the infrared light signal, wherein a graphene edge embedded type nano-film is grown on the surface of a silicon substrate of the photoelectric sensor unit through ECR plasma irradiation; a rectifying and amplifying unit for rectifying and amplifying the photoelectric signal to obtain a rectified and amplified signal; and a signal acquisition unit for acquiring and storing the rectified and amplified signal. According to the pulsimeter, by capturing photogenerated electrons with a boundary quantum well, recombination of photogenerated electron-hole pairs can be reduced greatly, the photoresponse rate can be increased, and human fingertip pulse signals can be measured more accurately and stably.

Owner:SHENZHEN UNIV

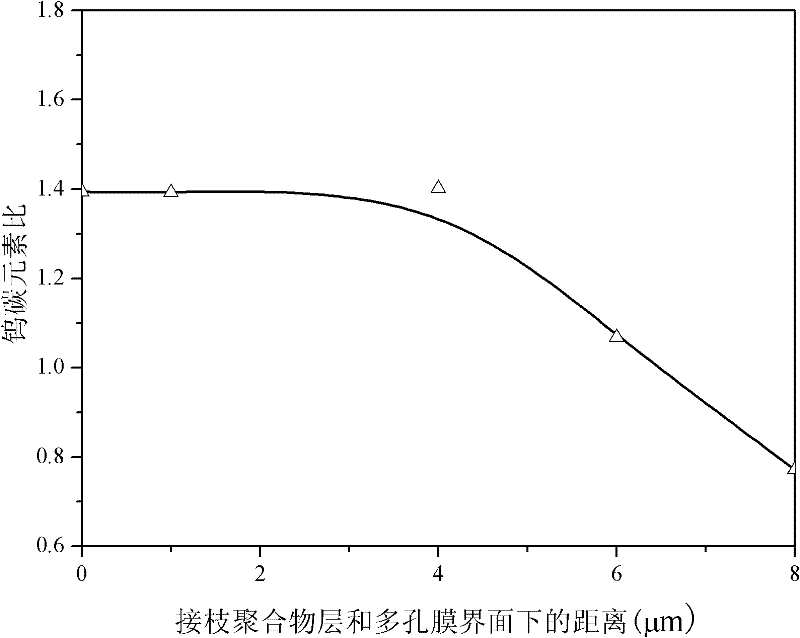

Composite membrane prepared by low-temperature plasma technology under normal pressure

The invention discloses a composite membrane prepared by a low-temperature plasma technology under low pressure. The composite membrane is prepared by the following steps of: pre-coating grafting monomers on a porous membrane serving as a basement membrane; irradiating the porous membrane pre-coated with the grafting monomers by using plasmas to initiate synchronous irradiation grafting reaction;performing grafting reaction after plasma irradiation; and performing posttreatment to obtain the composite membrane, wherein the porous membrane is insoluble in aromatic hydrocarbon and the graftingmonomers have high affinity to alcohol and the aromatic hydrocarbon. The invention has the advantage that: under normal pressure, the composite membrane prepared by graft-filling polymerization initiated by the low-temperature plasma technology has good selectivity and penetration flux. The composite membrane prepared by the low-temperature plasma technology under normal pressure has the characteristics of environment-friendly preparation process and suitability for industrial production, and has good application prospect.

Owner:DALIAN UNIV OF TECH

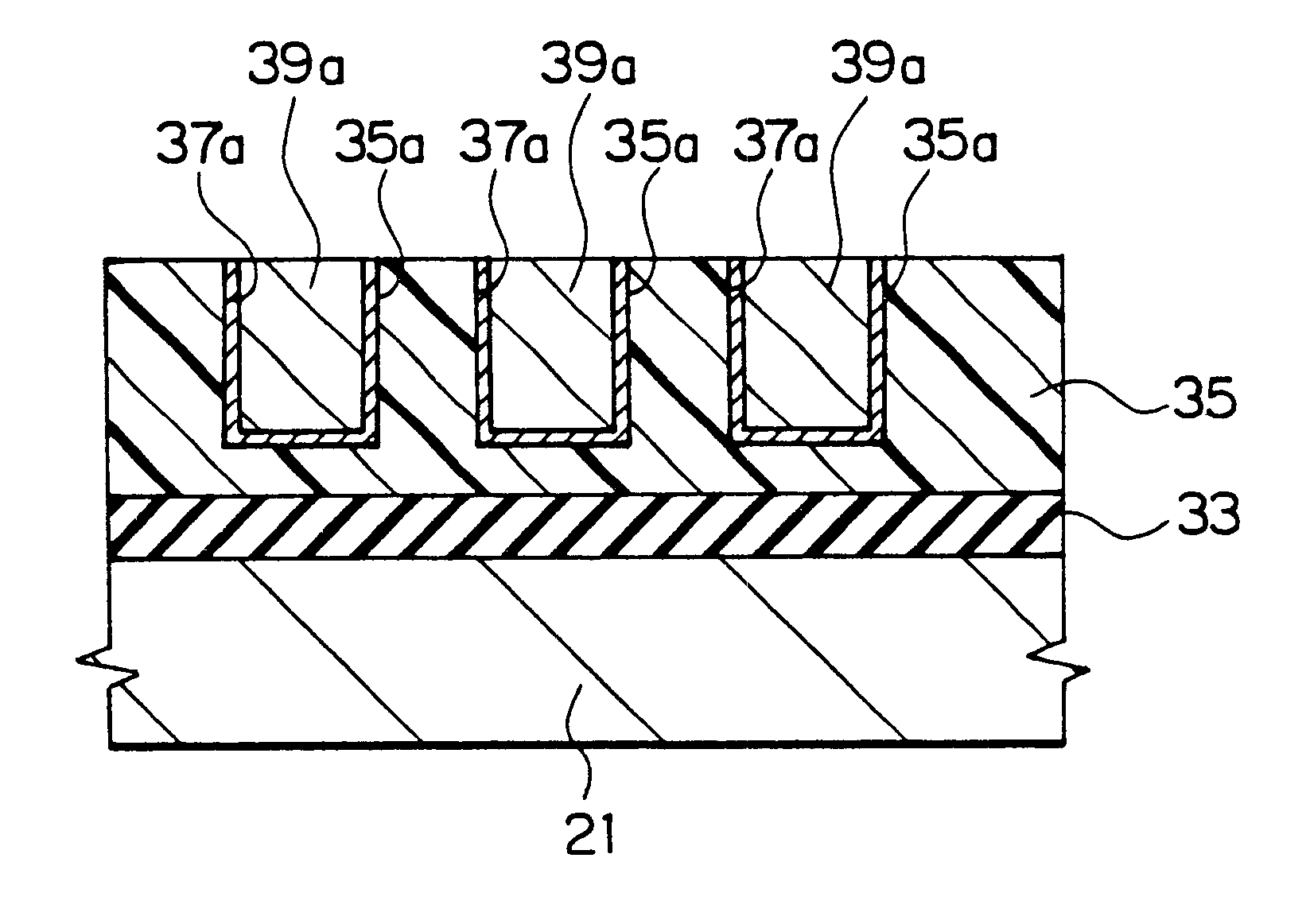

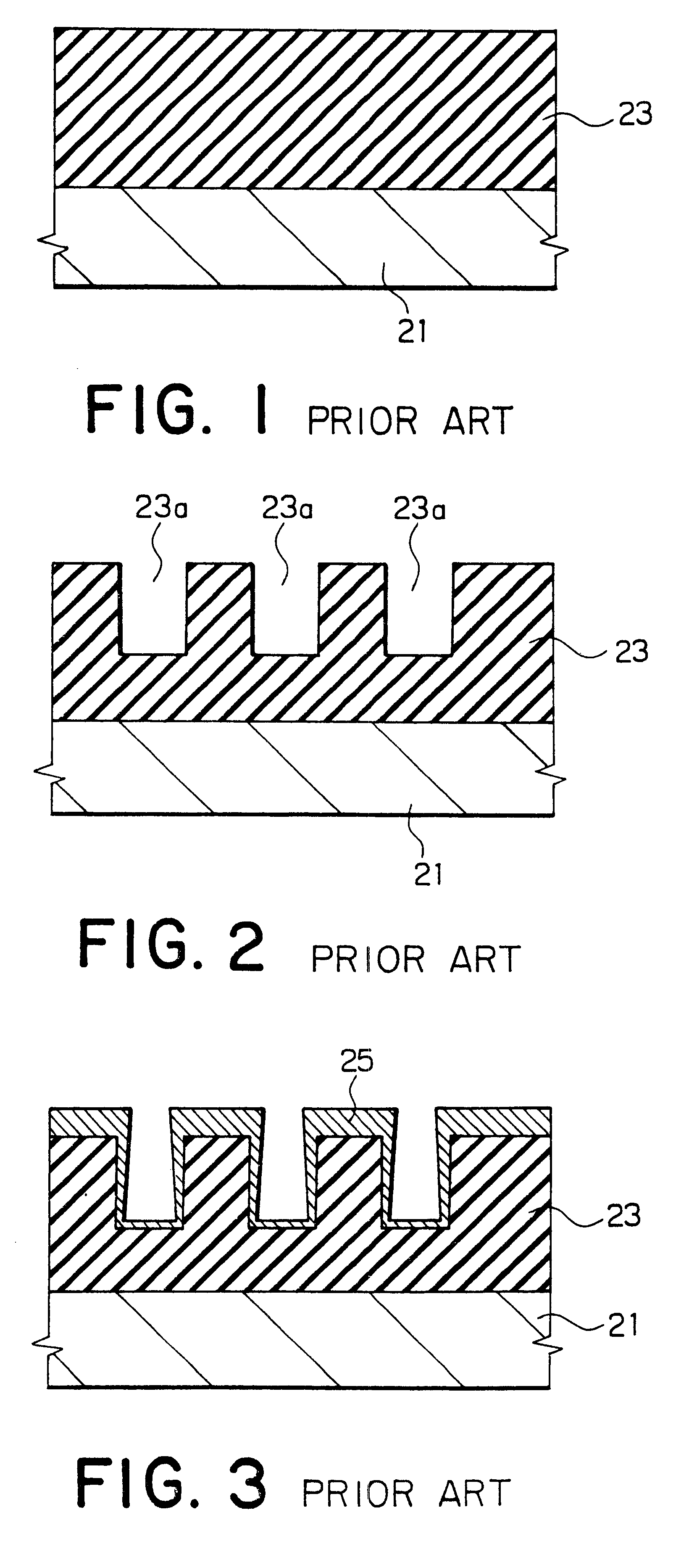

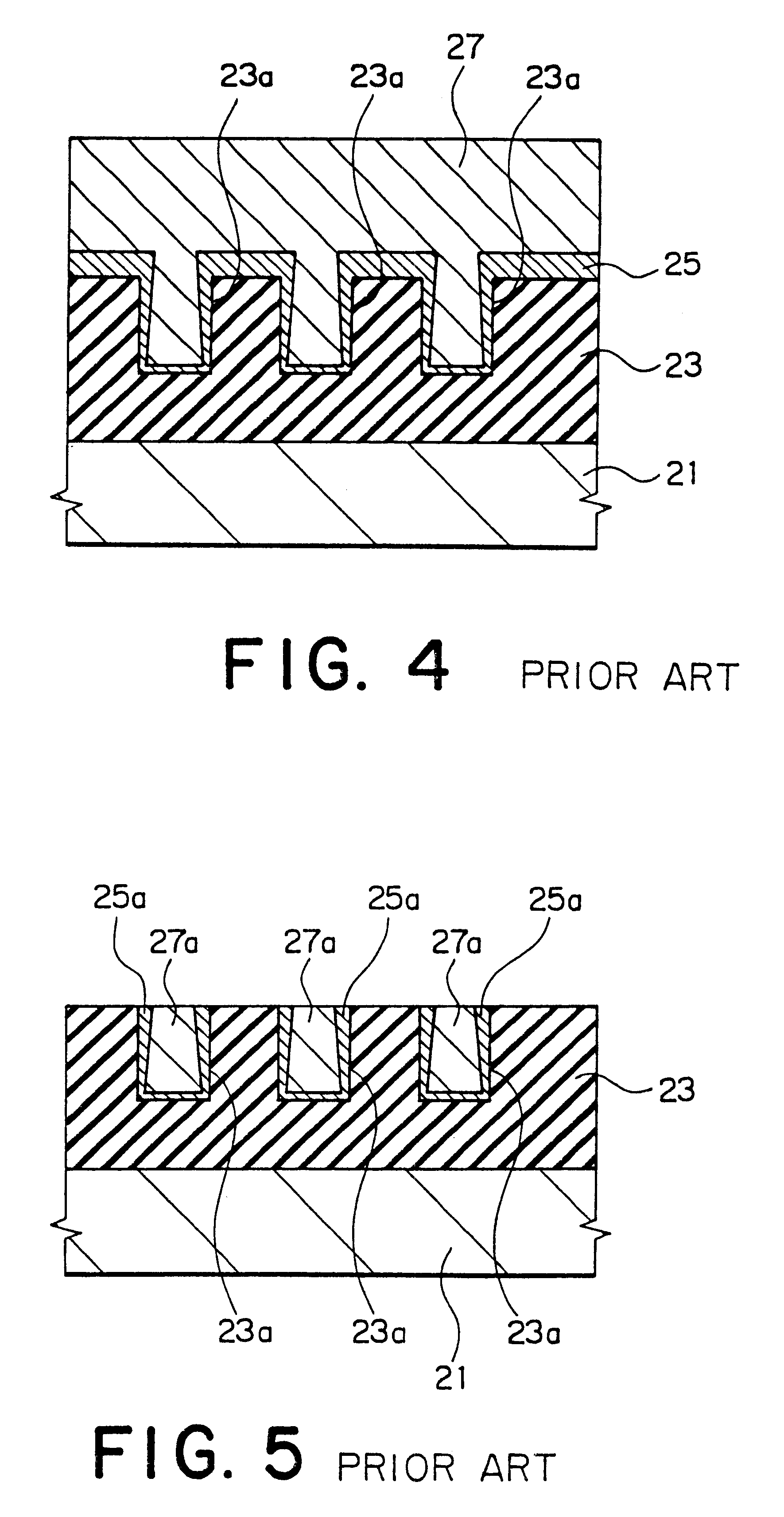

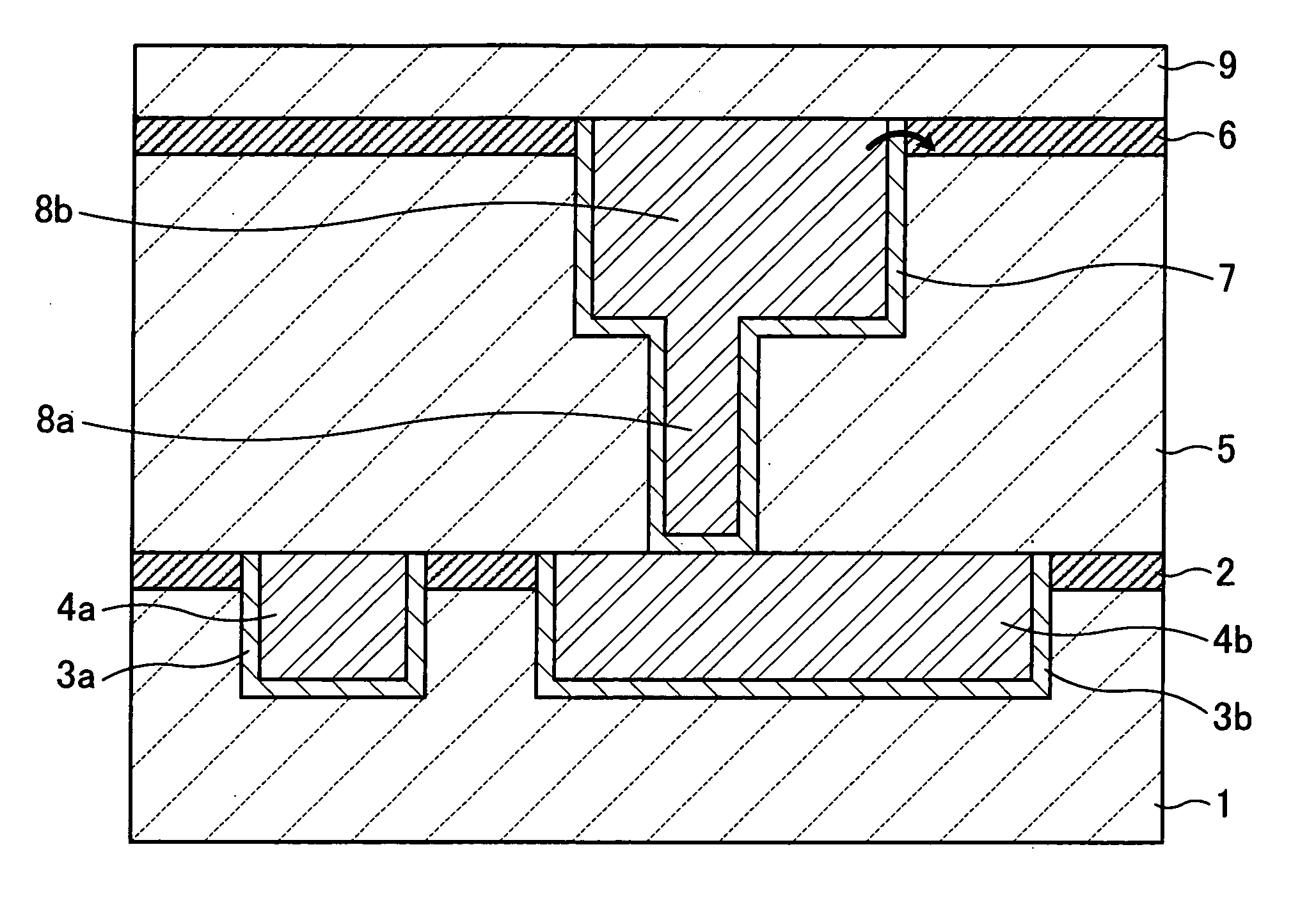

Copper wiring structure comprising a copper material buried in a hollow of an insulating film and a carbon layer between the hollow and the copper material in semiconductor device and method of fabricating the same

InactiveUS6486559B1Improve reliabilityReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesCarbon layerMetallurgy

The object of the present invention is to provide a copper wiring structure in which finely processed copper wiring in a wiring structure in grooves is steadily formed with a high reliability and a method for fabricating the same, wherein an electroconductive carbon layer is formed between the copper material-a copper wiring of a wiring structure in grooves in which the copper material is buried into a wiring groove or holes formed in the organic interlayer film mainly composed of carbon-and the organic interlayer film. This electroconductive carbon layer is formed after forming wiring grooves or holes in the desired region of the organic interlayer film, by a modification of the inner wall of the wiring grooves or holes by plasma irradiation. The copper wiring of the wiring structure in grooves as described above is formed by depositing copper on the electroconductive carbon layer.

Owner:RENESAS ELECTRONICS CORP

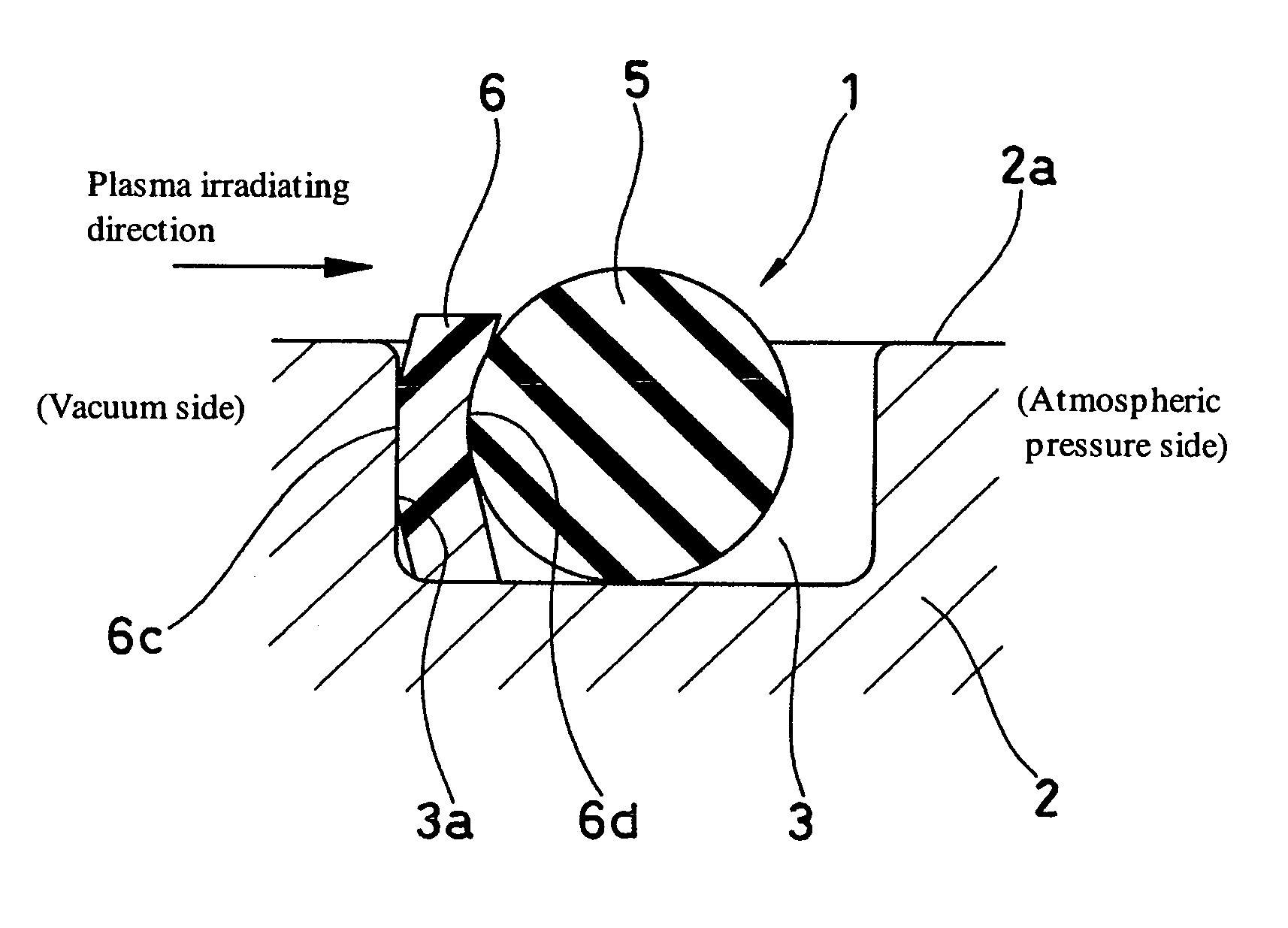

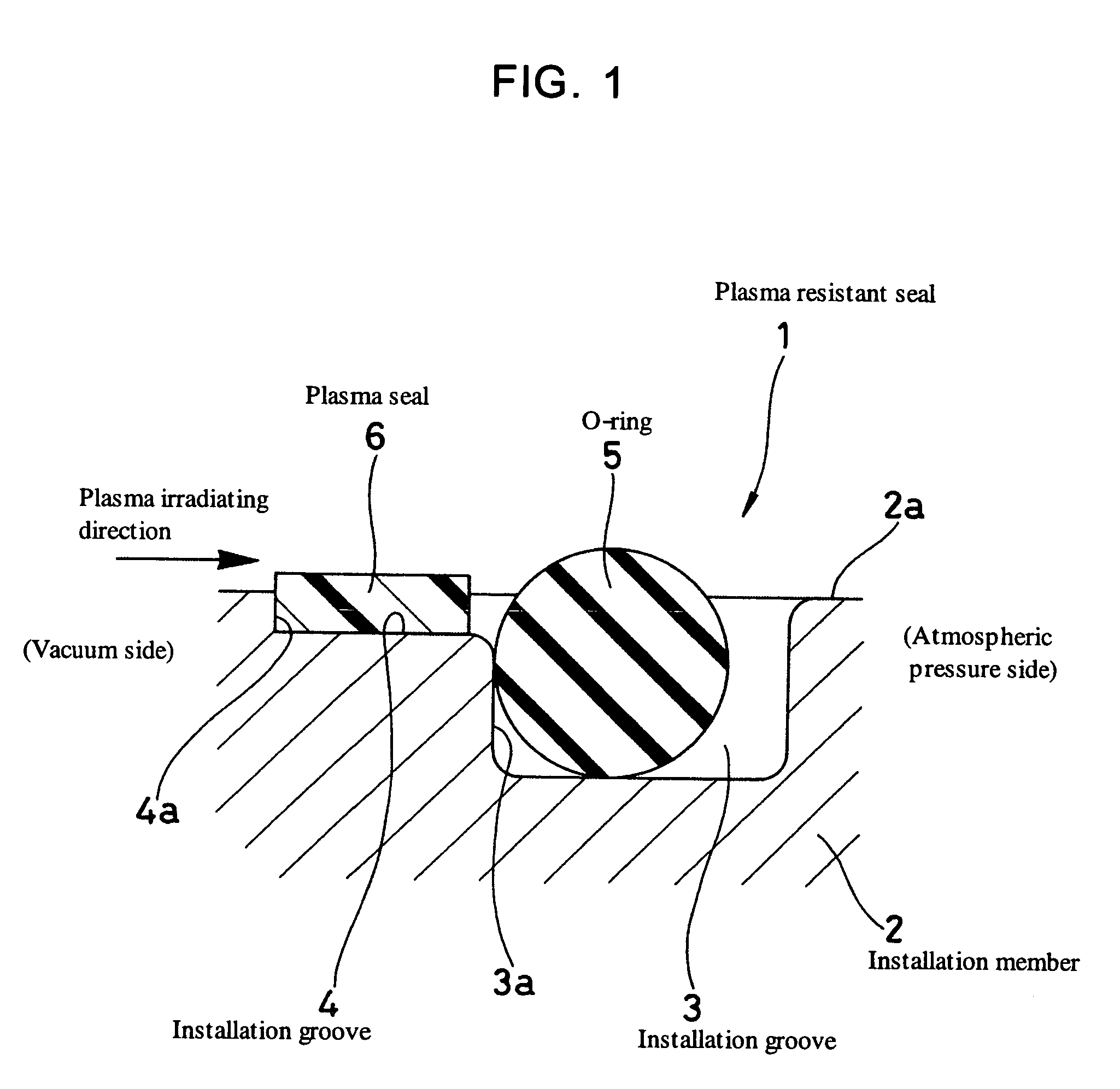

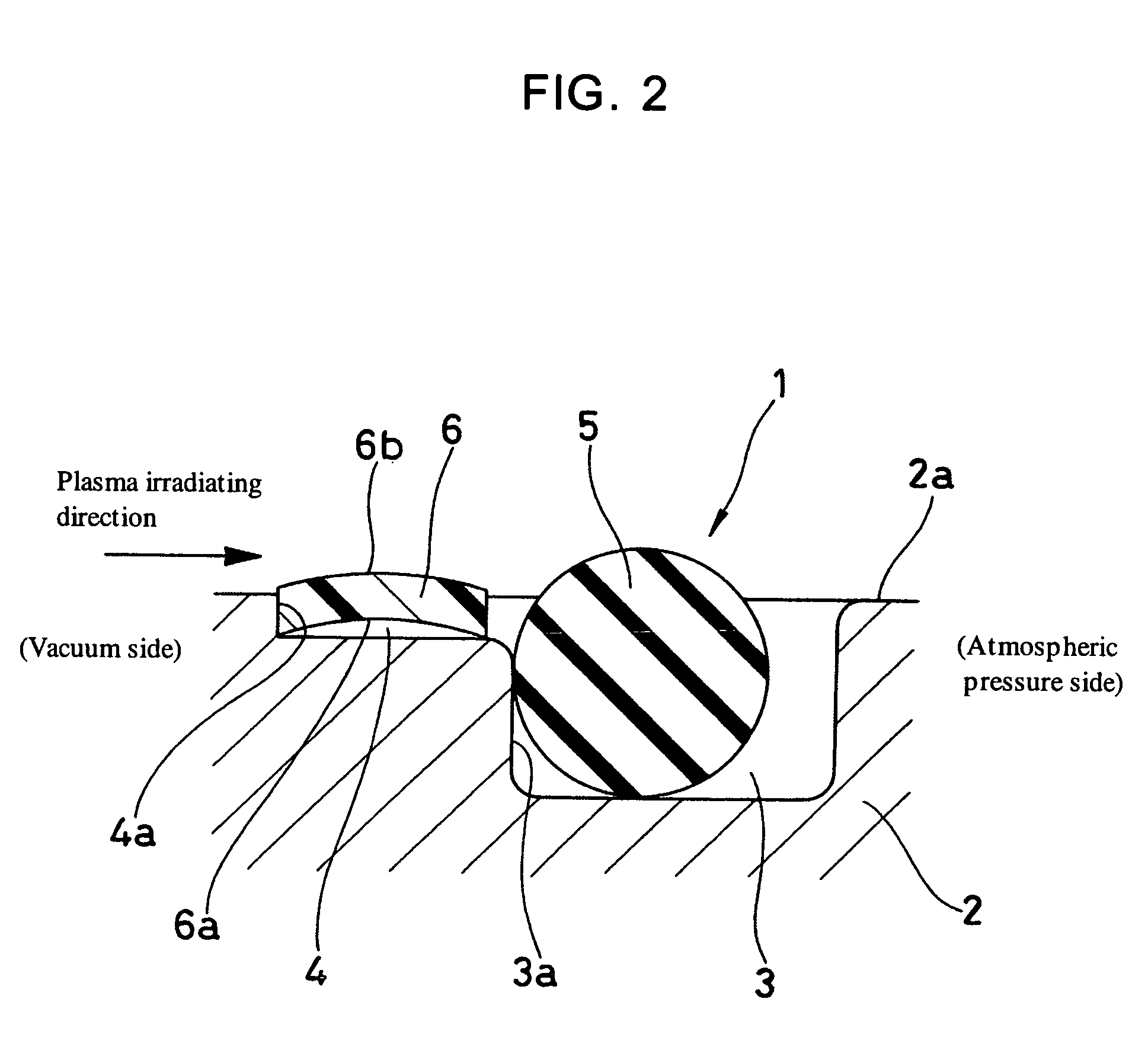

Plasma resistant seal

InactiveUS7942425B2Improve shielding effectPrevent suckingEngine sealsOther chemical processesEngineeringPlasma irradiation

To make a plasma resistant seal excellent in both a plasma resisting performance and a sealing performance, and prevent an O-ring from protruding to a vacuum side gap, a plasma seal (6) made of PTFE having a plasma resisting performance is provided in a plasma irradiating side of an O-ring (5) as a main seal made of a rubber-like elastic material, an installation groove (4) shallower than a depth of an installation groove (3) provided in an installation member (2) is continuously provided in a plasma irradiation side of the installation groove (3), the O-ring (5) is attached to the installation groove (3), and the plasma seal (6) is attached to the installation groove (4) in a compressed state, or the O-ring is attached to the installation groove and the plasma seal is attached to the plasma irradiation side of the same installation groove (3) in a compressed state.

Owner:NOK CORP

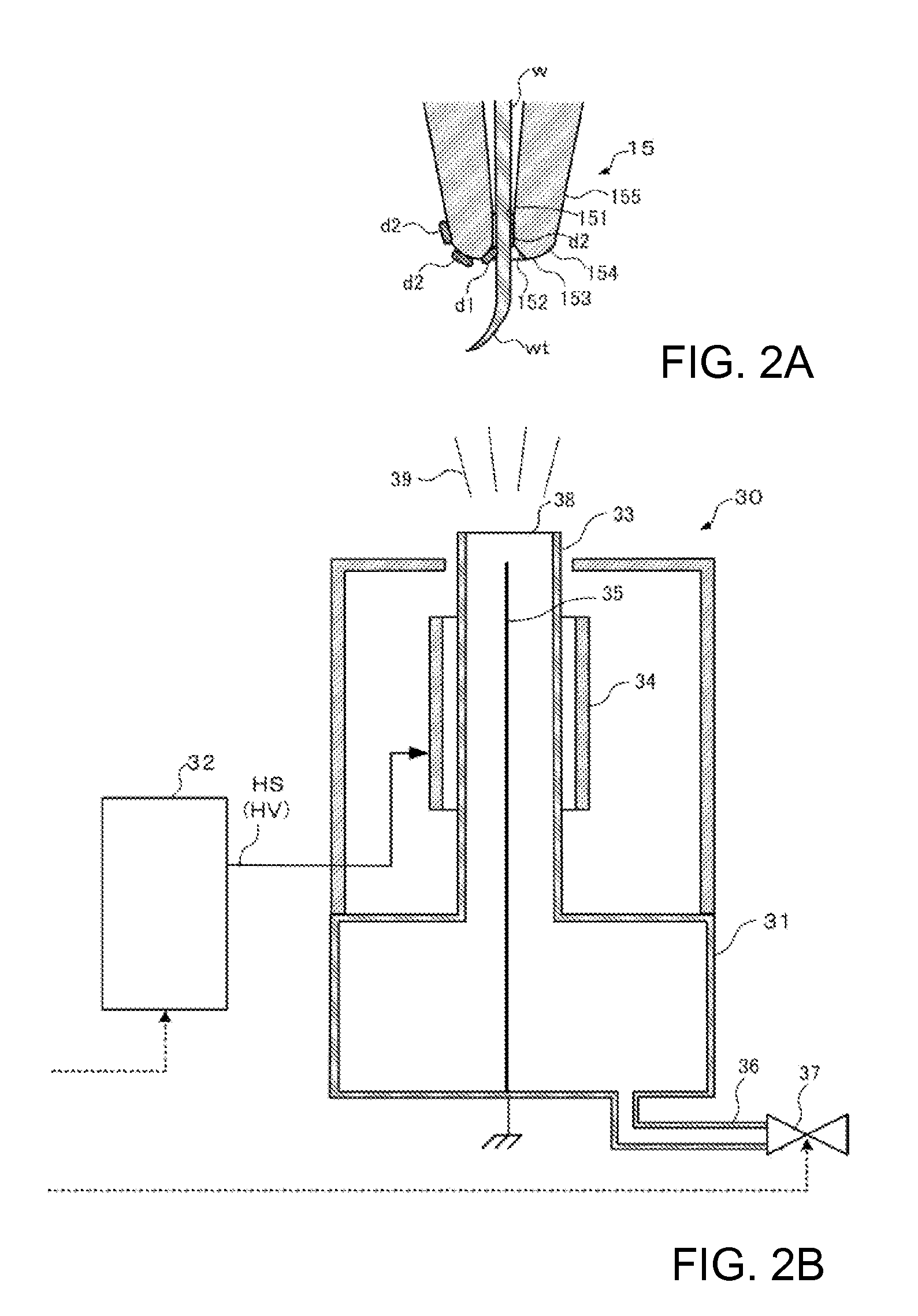

Bonding apparatus and bonding tool cleaning method

InactiveUS20140034712A1Increase the diameterReduce bond strengthWelding/cutting auxillary devicesSolid-state devicesEngineeringCleaning methods

In wire bonding in which a bonding tool is cleaned through plasma irradiation, the plasma application to a wire and therefore the formation of an unexpectedly large-sized ball in the following bonding operation is prevented. The cleaning of the bonding tool through plasma irradiation is followed by dummy bonding, the bonding tool is cleaned with a ball formed thereon, or a prohibition period is provided during which ball forming is prohibited until the energy of plasma attenuates after the bonding tool is cleaned to prevent the plasma irradiation from having an impact on the bonding operation so that the ball cannot have an increased diameter.

Owner:SHINKAWA CO LTD

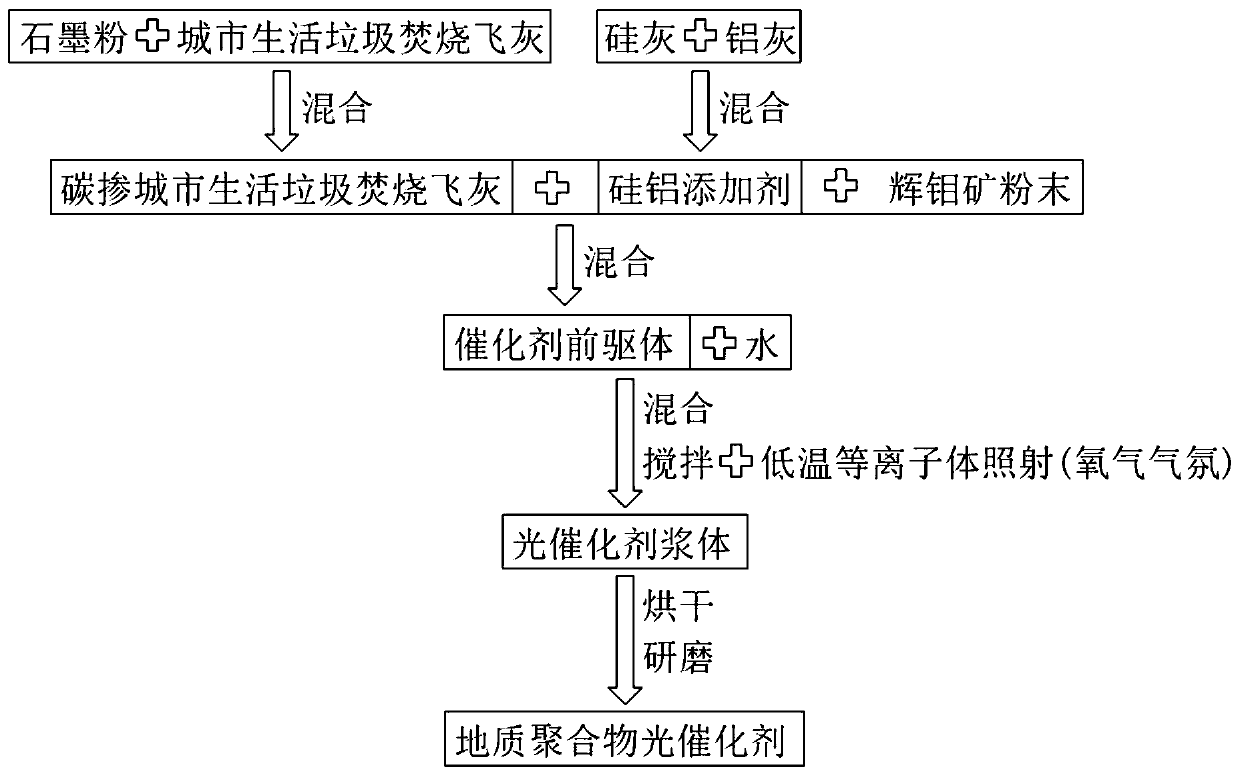

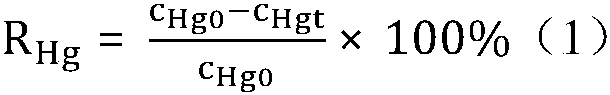

Method for preparing geopolymer photocatalyst from municipal solid waste incineration fly ash

PendingCN111569917AWide variety of sourcesAchieve stabilizationWater/sewage treatment by irradiationWater contaminantsPtru catalystPlasma irradiation

The invention discloses a method for preparing a geopolymer photocatalyst from municipal solid waste incineration fly ash. The method comprises the following steps of: weighing graphite powder and municipal solid waste incineration fly ash, and mixing the graphite powder and the municipal solid waste incineration fly ash to obtain carbon-doped municipal solid waste incineration fly ash; weighing silica fume and aluminum ash, and mixing the silica fume and aluminum ash to obtain a silica-alumina additive; weighing molybdenite powder, the silicon-aluminum additive and the carbon-doped municipalsolid waste incineration fly ash, and mixing the molybdenite powder, the silicon-aluminum additive and the carbon-doped municipal solid waste incineration fly ash to obtain a catalyst precursor material; weighing water and the catalyst precursor material, and performing low-temperature plasma irradiation to obtain photocatalyst slurry; and drying and grinding the photocatalyst slurry to obtain thegeopolymer photocatalyst. The invention also discloses a geopolymer photocatalyst and application thereof. According to the method, the stabilization of heavy metal and the mineralization of dioxin in the fly ash can be achieved, and part of the heavy metal can be converted into a semiconductor material. A molybdenum source and a carbon source are a low-value molybdenite raw material and graphitepowder respectively. The geopolymer photocatalyst can remove 98% of COD, 99% of heavy metal pollutants, 99% of ammonia nitrogen and 98% of total phosphorus at most.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Cross-linked fluorine-containing copolymer moldings

A cross-linked fluorine-containing copolymer moldings applicable to a plasma irradiation step, which is molded as a peroxide cross-linking product of a fluorine-containing copolymer blend comprising a fluorine-containing elastomer copolymer and a fluorine-containing resin copolymer, which is a vinylidene fluoride-tetrafluoroethylene copolymer, both of the copolymers having reaction sites capable of reacting with a common peroxide-based cross-linking agent, respectively, has desired normal state physical properties and compression set value, even if applied to a plasma irradiation step, while reducing particle generation quantity of the fluorine-containing copolymers themselves.

Owner:UNIMATEC CO LTD

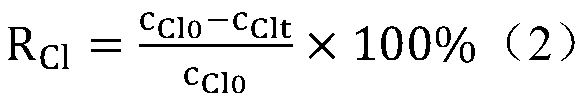

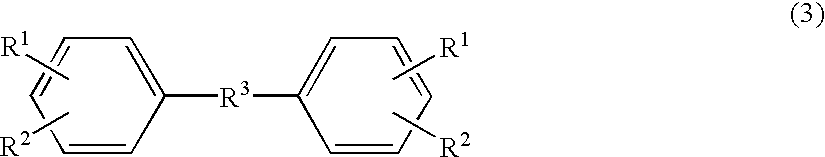

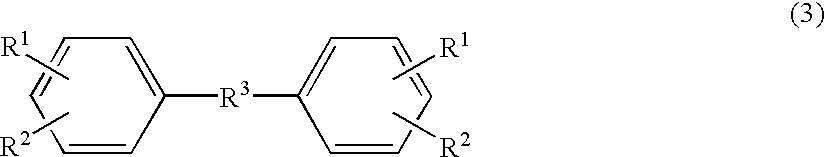

Crosslinkable elastomer composition and formed product comprising the same

InactiveUS7495046B2AmountEasy to processFibre treatmentConductive materialElastomerNon oxide ceramics

The present invention provides a crosslinkable elastomer composition, in which generation of HF under high temperature conditions is reduced, the decrease in weight to both NF3 plasma treatment and O3 treatment in the semiconductor manufacturing process is small and generation of foreign substances (particles) in these treatments is suppressed significantly. Specifically, the present invention relates to a crosslinkable elastomer composition comprising a crosslinkable elastomer and a filler having a specific surface area of at least 0.5 m2 / g and containing a synthetic polymer having a thermally and chemically stable aromatic ring in the main chain, a crosslinkable elastomer composition comprising a crosslinkable elastomer and nonoxide ceramics and a crosslinkable elastomer composition wherein the decrease in weight by NF3 plasma irradiation is at most 0.20%.

Owner:DAIKIN IND LTD

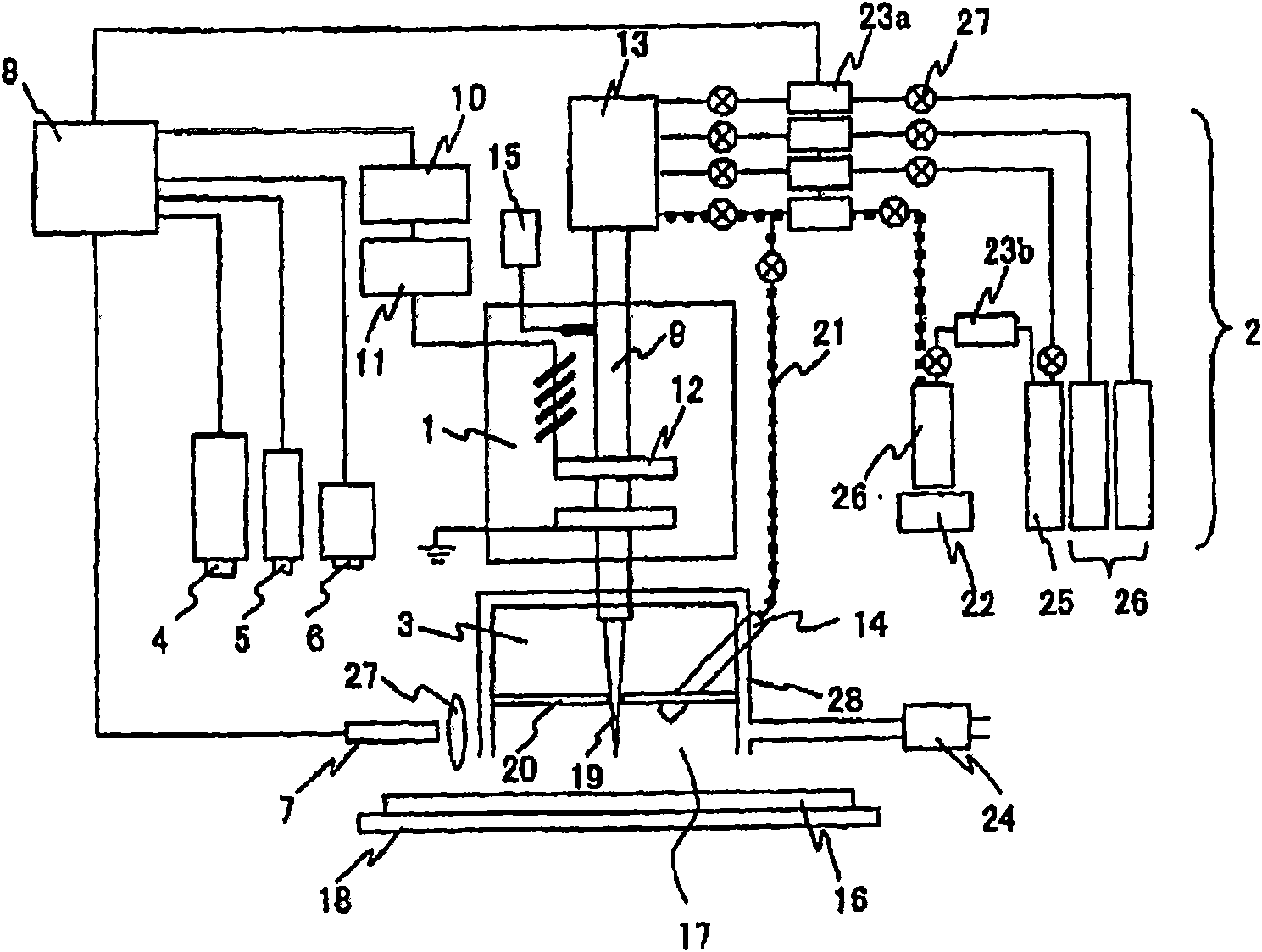

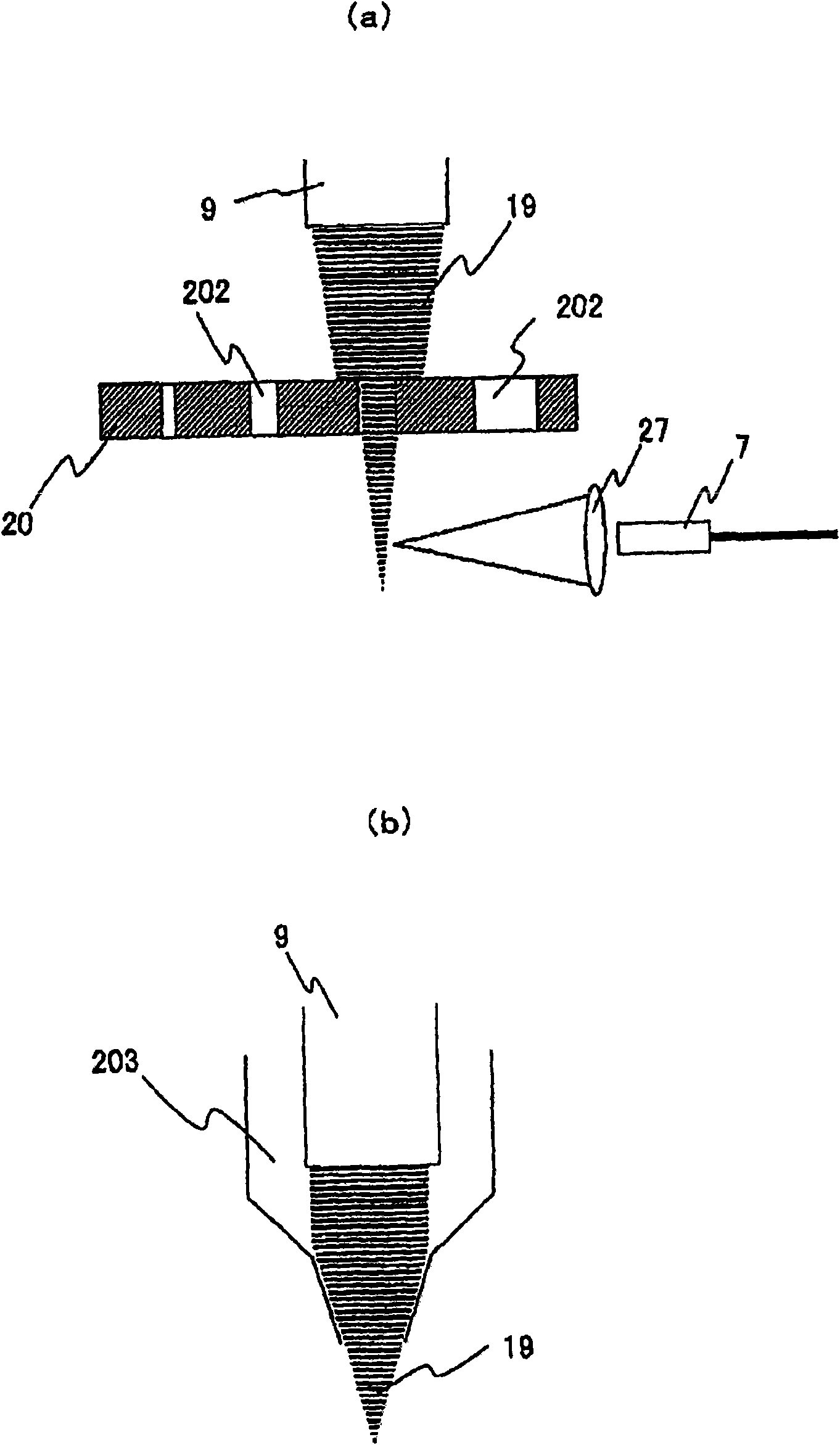

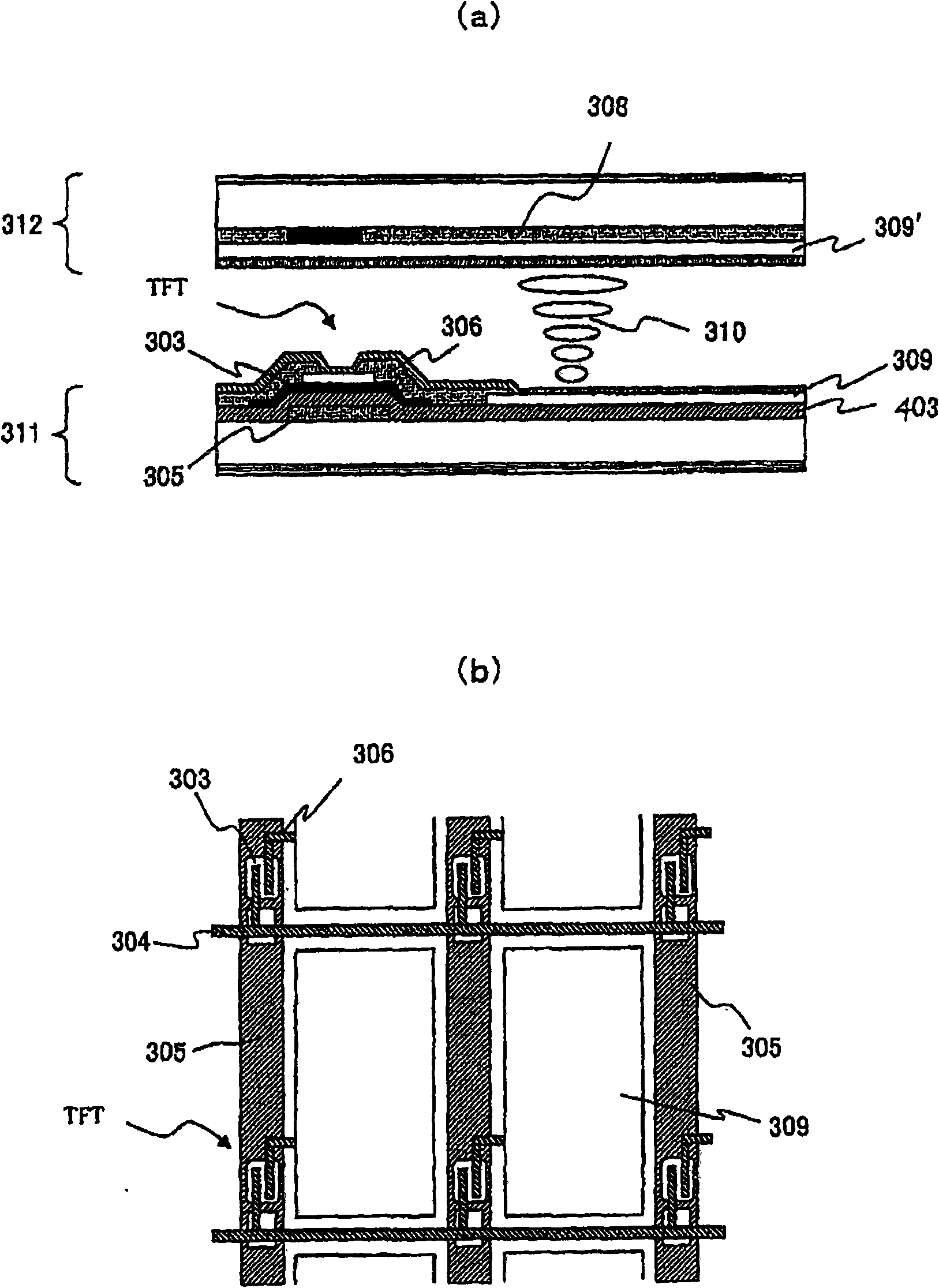

Method for repairing display device and apparatus for same

ActiveCN101667527AReduce quality fluctuationsImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An object of the present invention is to provide a method for repairing a display device according to which a wide variety of regions can be repaired in various ways using various materials, as well as an apparatus for the same. The present invention provides a repairing apparatus for repairing a pattern defect on a surface of a substrate in a display device where an electronic circuit pattern having the above described pattern defect is formed, characterized by having a plasma irradiation means for repairing the above described pattern defect through local irradiation of a region including the above described pattern defect with plasma.

Owner:JAPAN DISPLAY INC

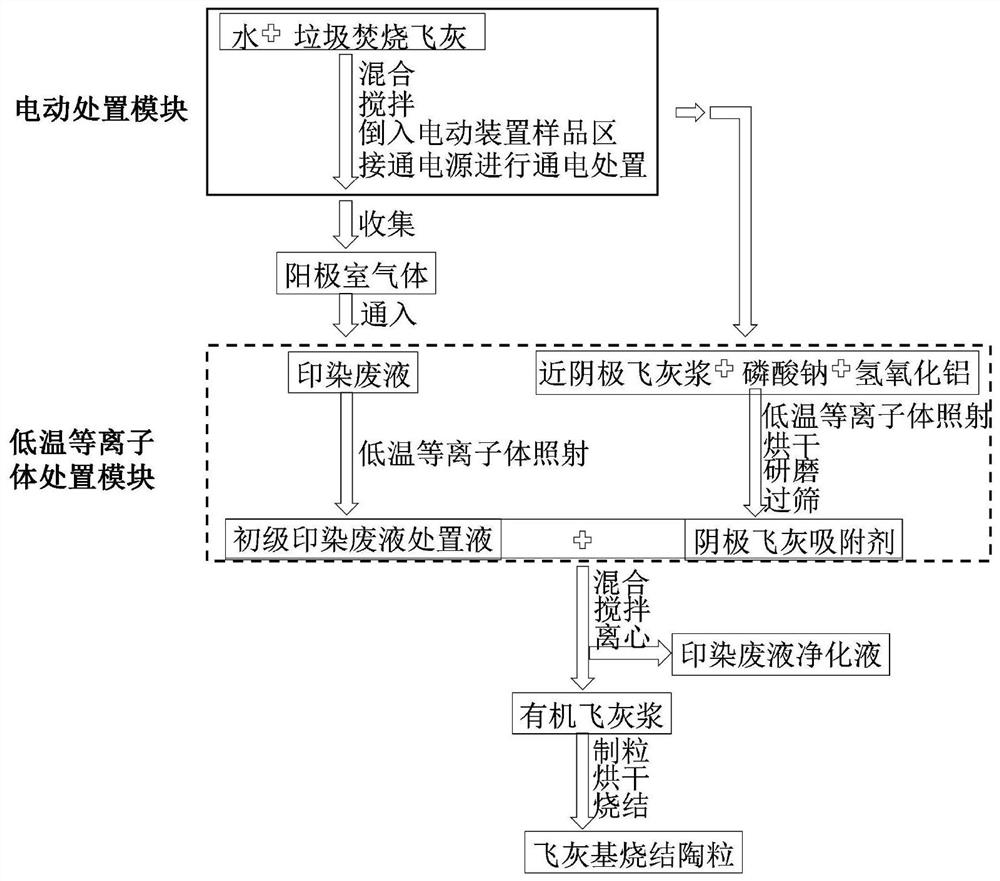

Cooperative treatment method for waste incineration fly ash and printing and dyeing waste liquid

ActiveCN111872027AAchieve transferAchieve conversionWater/sewage treatment by irradiationWater treatment compoundsPlasma irradiationProcess engineering

The invention discloses a cooperative treatment method for waste incineration fly ash and printing and dyeing waste liquid. The method comprises the following steps: (1) mixing and stirring water andwaste incineration fly ash, and pouring a mixture into an electric device for electrifying treatment; (2) collecting gas in an electric anode chamber, introducing the gas into a low-temperature plasmairradiation device as action atmosphere, and carrying out low-temperature plasma irradiation treatment on the printing and dyeing waste liquid to obtain primary printing and dyeing waste liquid treatment liquid; (3) digging out fly ash in a near-cathode sample area of the electric device to obtain near-cathode fly ash slurry, mixing and stirring sodium phosphate, aluminum hydroxide and the near-cathode fly ash slurry, and carrying out low-temperature plasma irradiation, drying, grinding and sieving to obtain a cathode fly ash adsorbent; and (4) mixing and stirring the cathode fly ash adsorbent and the primary printing and dyeing waste liquid treatment liquid, carrying out solid-liquid separation to obtain printing and dyeing waste liquid purification liquid and organic fly ash slurry, andgranulating, drying, sintering and cooling the organic fly ash slurry to obtain fly ash-based sintered ceramsite. According to the cooperative treatment method, purification of the printing and dyeing waste liquid and resource utilization of the waste incineration fly ash can be simultaneously realized.

Owner:浙江中陶环保科技集团有限公司

Method for physical and chemical combined modification of surface of polydimethylsiloxane

InactiveCN102093586AImprove surface hydrophilicityGood biocompatibilityAnodisationNanotechnologyPolyvinyl alcoholPlasma irradiation

Owner:ZHEJIANG UNIV

Crosslinked fluorocopolymer moldings

A cross-linked fluorine-containing copolymer moldings applicable to a plasma irradiation step, which is molded as a peroxide cross-linking product of a fluorine-containing copolymer blend comprising a fluorine-containing elastomer copolymer and a fluorine-containing resin copolymer, which is a vinylidene fluoride-tetrafluoroethylene copolymer, both of the copolymers having reaction sites capable of reacting with a common peroxide-based cross-linking agent, respectively, has desired normal state physical properties and compression set value, even if applied to a plasma irradiation step, while reducing particle generation quantity of the fluorine-containing copolymers themselves.Crosslinked fluorocopolymer moldings which are obtained by subjecting a fluorocopolymer blend comprising both a fluoro- elastomer copolymer and a fluororesin copolymer consisting of a vinylidene fluoride / tetrafluoroethylene copolymer which each have reaction sites reactive with a common peroxide-type crosslinking agent to molding and crosslinking and which are subjectable to plasma irradiation. The moldings are reduced in the quantity of particles generated from the fluorocopolymer itself when subjected to plasma irradiation, and exhibit normal-state physical properties and compression set favorable to sealing material.

Owner:UNIMATEC CO LTD

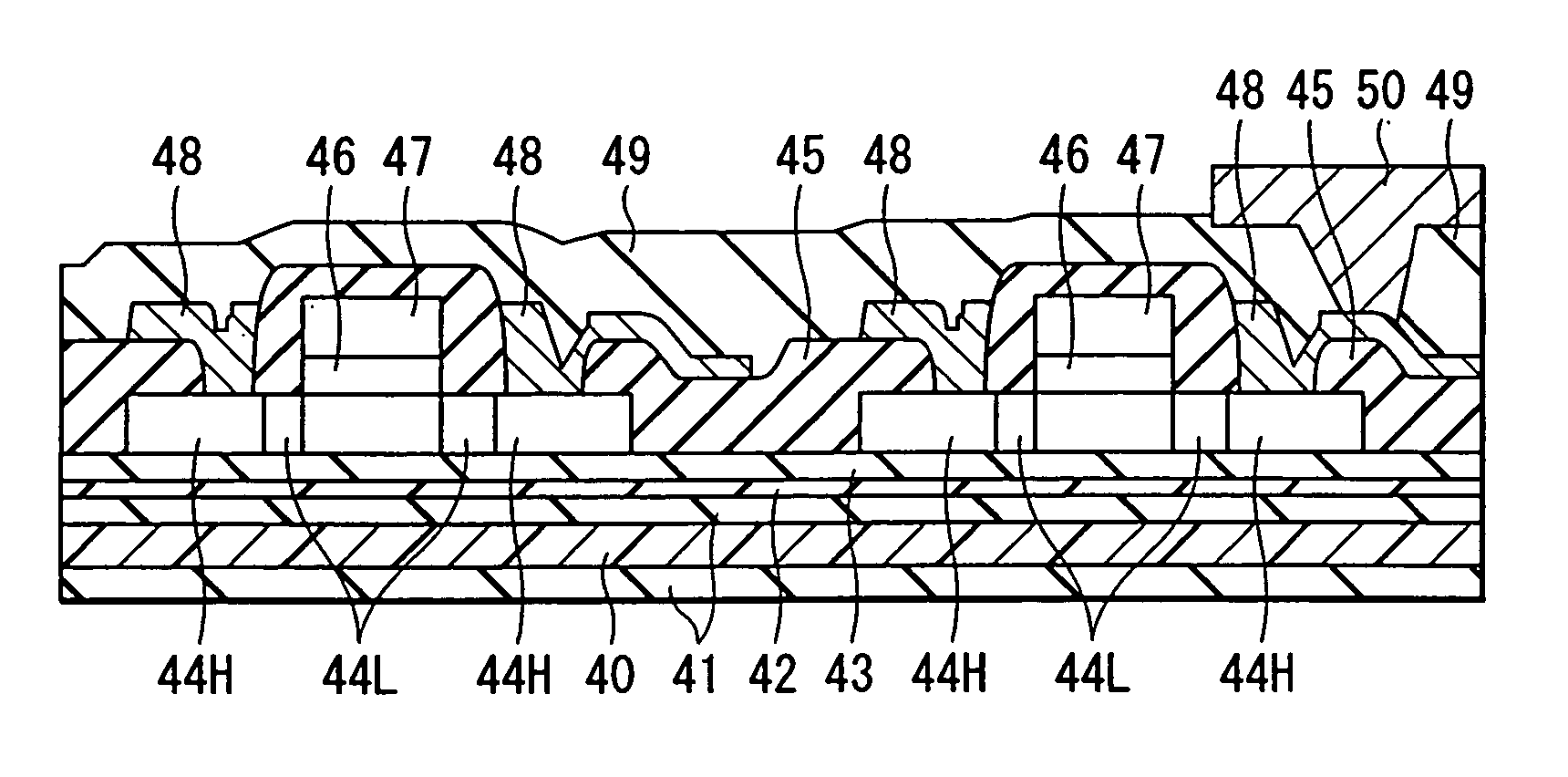

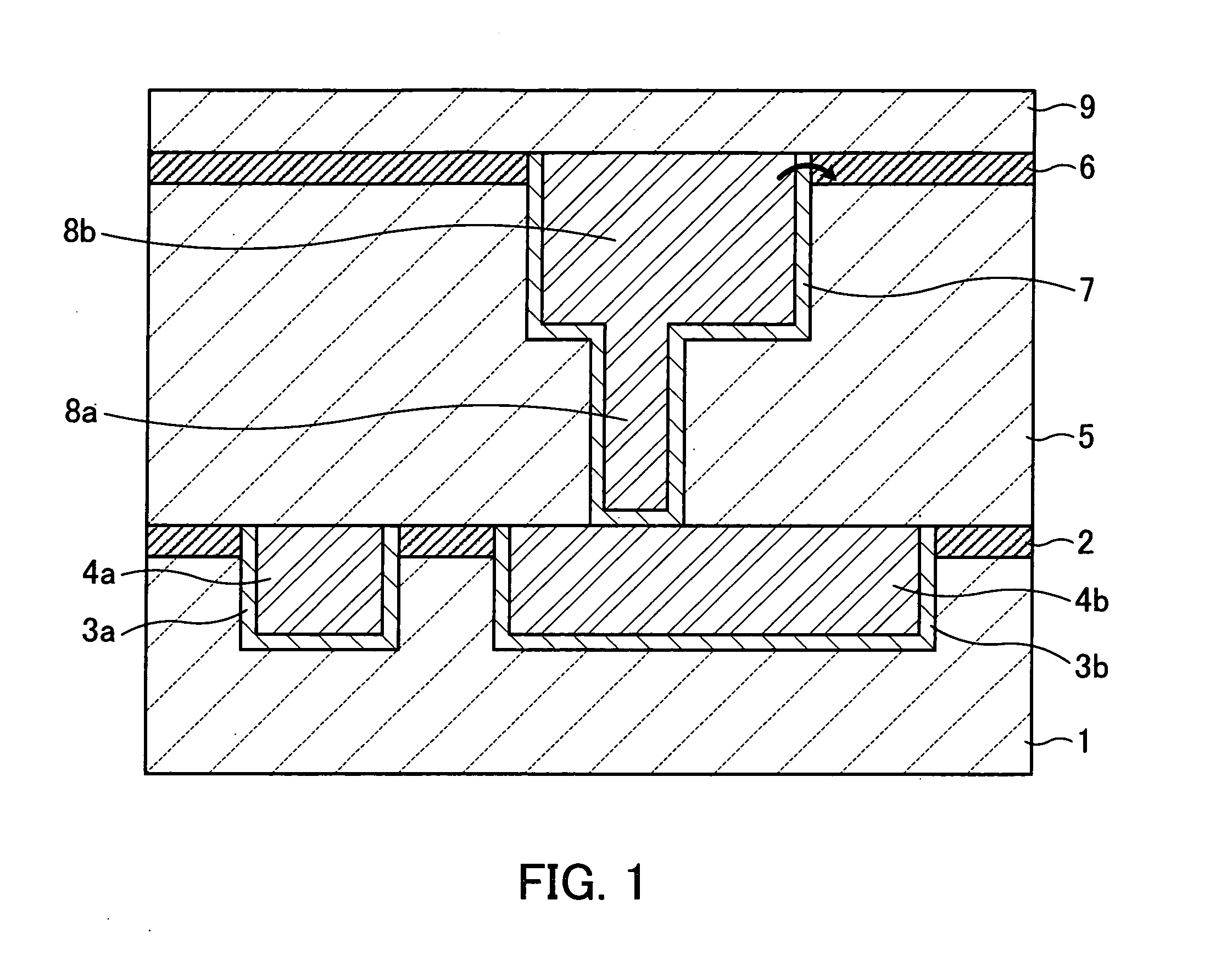

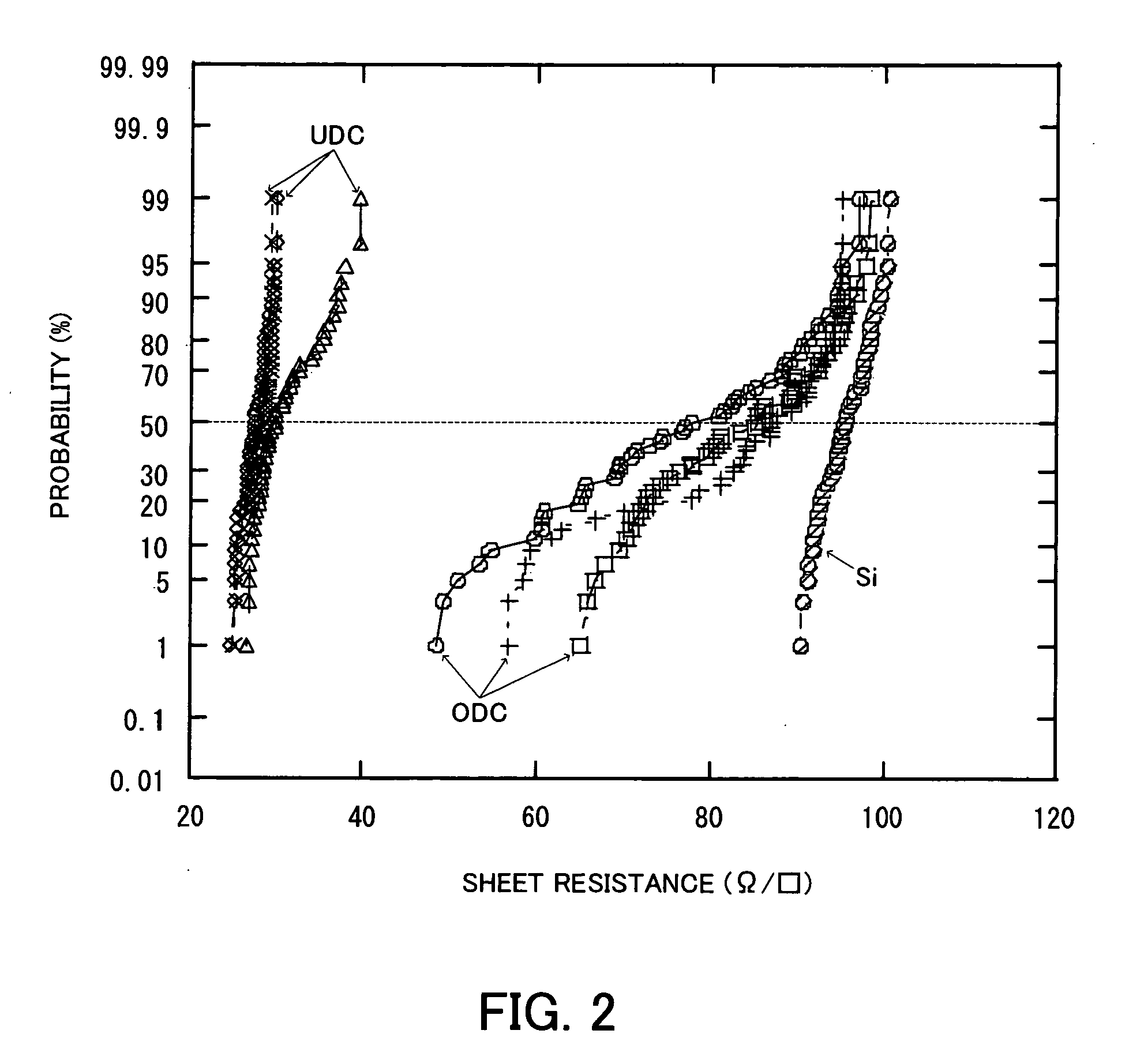

Semiconductor device and method for fabricating the same

ActiveUS20070197032A1Improve reliabilitySemiconductor/solid-state device detailsSolid-state devicesHydrogenCrystal structure

A semiconductor device in which the diffusion of copper from a wire is prevented and a method for fabricating such a semiconductor device. For example, a via groove and a wire groove are formed in a multilayer structure including a UDC diffusion barrier film, a porous silica film, a middle UDC stopper film, a porous silica film, a UDC diffusion barrier film, and the like, and the surfaces the UDC diffusion barrier film, the middle UDC stopper film, and the UDC diffusion barrier film that get exposed in the via groove and the wire groove are irradiated with hydrogen plasma, thereby making the surface of each exposed SiC film silicon-rich. After the plasma irradiation, a Ta film is formed in the via groove and the wire groove and copper is embedded in these grooves. By making the surface of each SiC film which is to touch the Ta film silicon-rich in advance, the crystal structure of the Ta film can be controlled so that copper cannot pierce through the Ta film. This prevents copper from diffusing from a wire.

Owner:FUJITSU SEMICON LTD

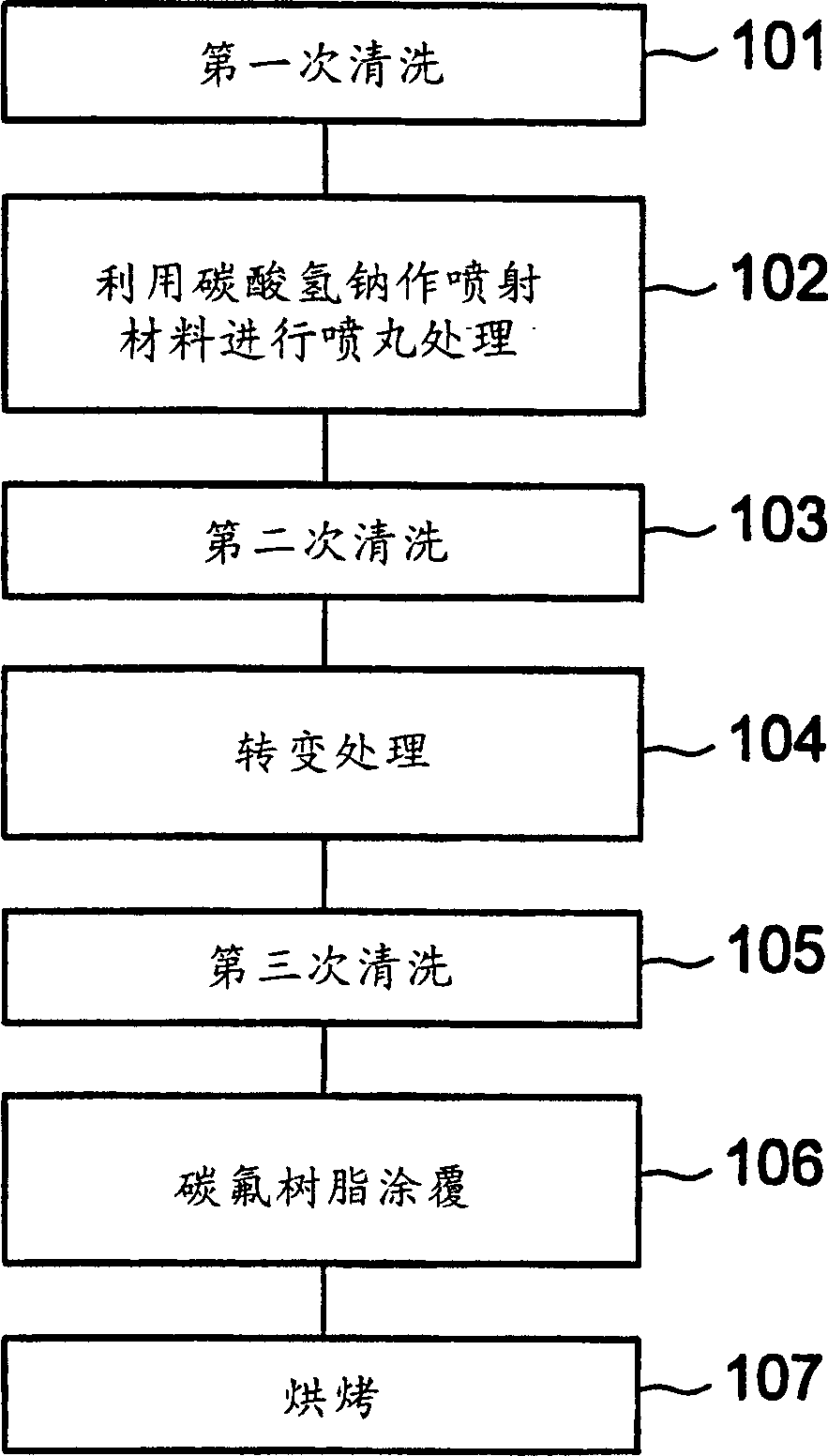

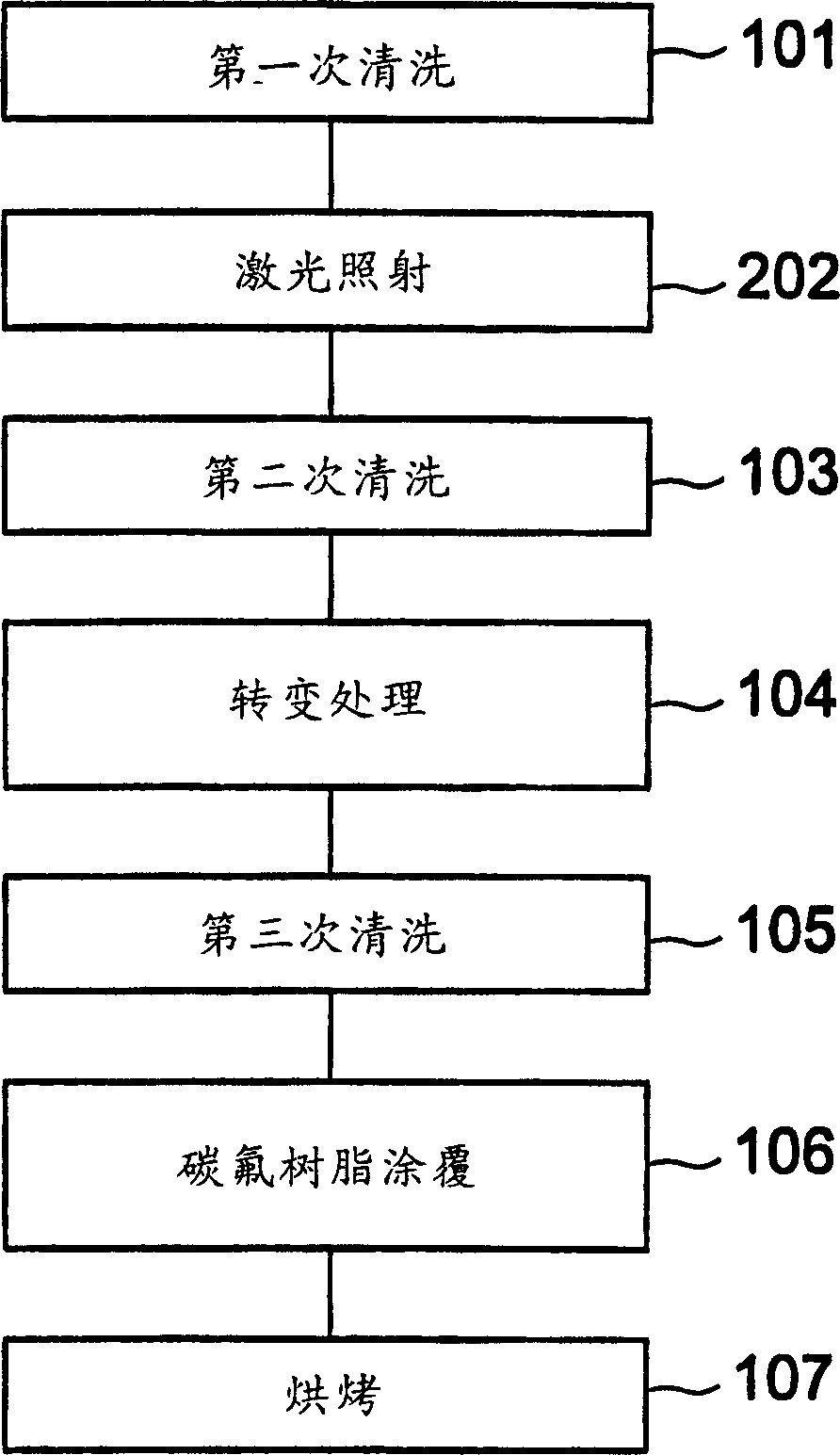

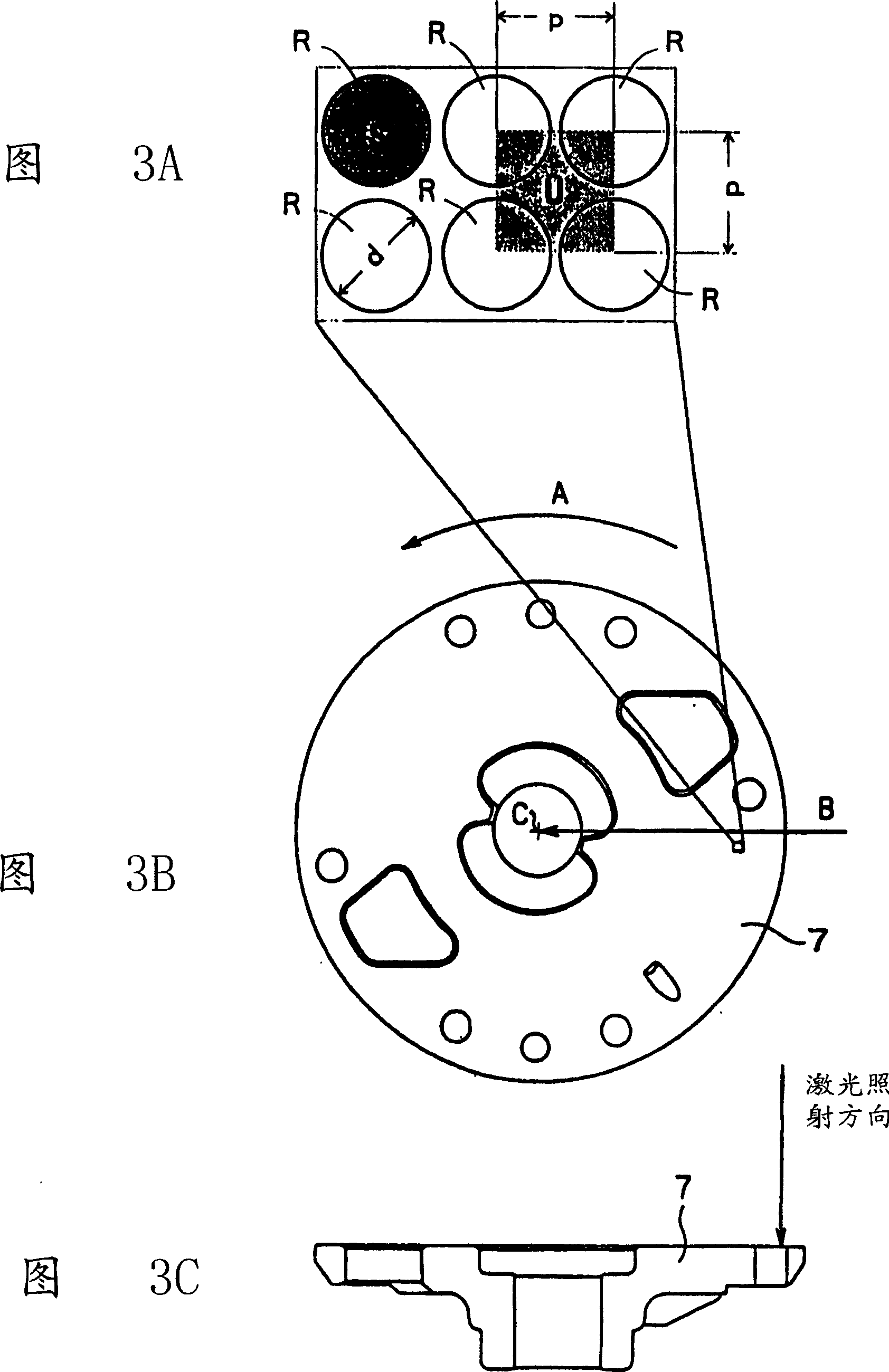

Method of coating fluorocarbon resin and sliding part and gas compressor using said method

InactiveCN1442617AImprove adhesionInternal combustion piston enginesPretreated surfacesGas compressorWater soluble

A method of coating a fluorocarbon resin comprising roughening the surface to be coated by shot blasting with a water-soluble blasting material or an evaporable blasting material or by laser or plasma irradiation. This method provides a high-quality fluorocarbon resin having good contact and adhesion properties without peeling off even when performing a sliding motion under severe load conditions. In addition, the blasting material used in the coating base treatment does not remain in the base material made of aluminum alloy or the like in the vicinity of the coating. In this way, there is no possibility of residual blasting material damaging the coating or the like.

Owner:CALSONIC COMPRESSOR INC

Production method of fluoride-free waterproof woven fabric

InactiveCN104878617AEfficient water repellencyImprove washabilityPhysical treatmentFibre typesPlasma generatorPlasma irradiation

The invention relates to a production method of a fluoride-free waterproof woven fabric. The production method comprises the following processes in sequence: (a) pre-treatment process; (b) dyeing process; (c) cleaning process; (d) plasma process; and (e) fluoride-free waterproof heat setting process. The production method is characterized in that plasma beams emitted by a plasma generator are utilized to irradiate the woven fabric to ensure that a concave-convex coarse structure is formed on the surface of the treated fabric and then fluoride-free finishing liquid is padded on the coarse surface of the fabric. The coarse structure on the surface of the plasma irradiated fabric can form a lotus effect so as to enhance the water repellency of the fabric. Meanwhile, after the plasma irradiation, reactive free radicals can be generated on the fiber surface so that the combination of the subsequent fluoride-free waterproof finishing agent and the fiber surface is steady and the fabric still has water repellency after repeated washing. According to the production method, the technical problems of low water repellency and washing intolerance in present fluoride-free waterproof finishing are solved.

Owner:ANTA CHINA

Elastomer molded article and crosslinkable fluorine-containing elastomer composition for semi-conductor production apparatuses

Elastomer molded article for semiconductor production apparatuses which is obtained by crosslinking and molding a crosslinkable fluorine-containing elastomer composition comprising a crosslinkable fluorine-containing elastomer component and fine particles of aluminum oxide having an average particle size of not more than 0.5 mum. The elastomer molded article is excellent in plasma resistance and an amount of micro particles generated after irradiation of plasma is very small and therefore a very clean molded article for semiconductor production apparatuses, particularly a sealing material to be used in an environment of plasma irradiation is provided.

Owner:DAIKIN IND LTD

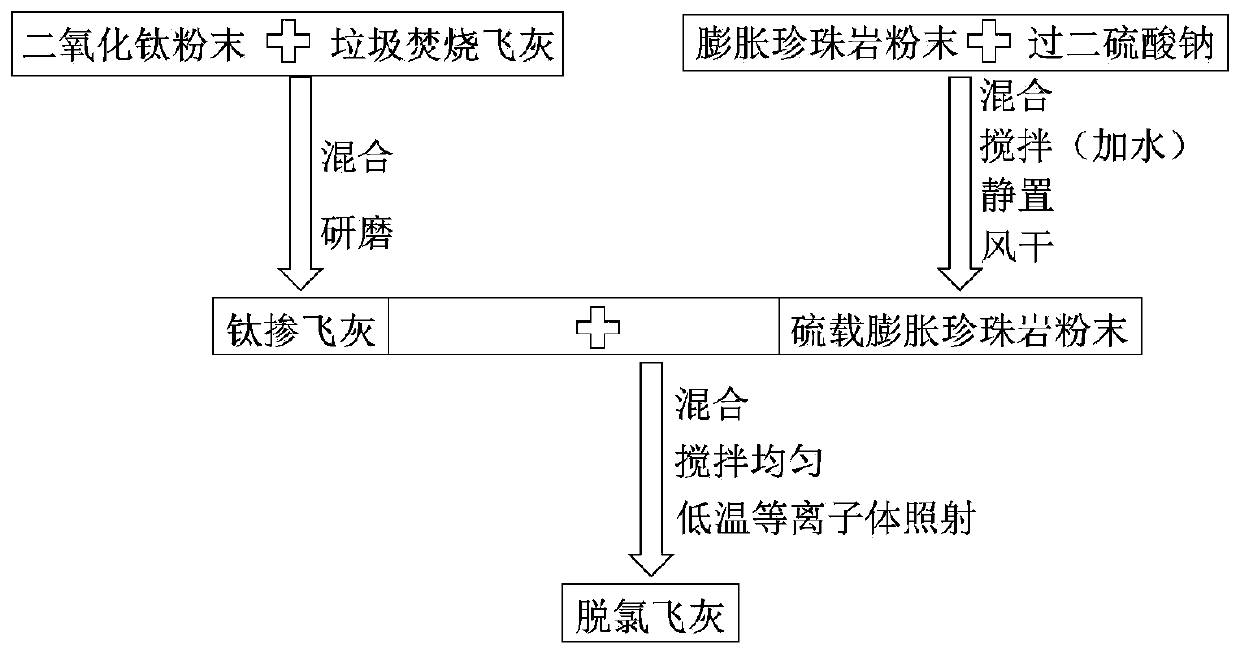

Dry dechlorination process for waste incineration fly ash

The invention discloses a dry dechlorination process for waste incineration fly ash. The process comprises the following steps: (1) mixing titanium dioxide and waste incineration fly ash, and grindingto obtain titanium-doped fly ash; (2) mixing sodium persulfate and expanded perlite powder, dissolving the obtained mixture in water, standing, carrying out solid-liquid separation, and air-drying toobtain sulfur-loaded expanded perlite powder; and (3) mixing the sulfur-loaded expanded perlite powder and the titanium-doped fly ash, and carrying out low-temperature plasma irradiation to obtain the dechlorinated fly ash. Through the simple dry dechlorination process, chloride ions in the waste incineration fly ash are efficiently removed, the removal rate of the chloride ions is as high as 97%, and secondary pollution caused by a traditional water washing method is avoided; and when the chloride ions are removed, the content of dioxin substances in the fly ash is also remarkably reduced, and the removal rate of the dioxin substances reaches up to 96%.

Owner:浙江中陶环保科技集团有限公司

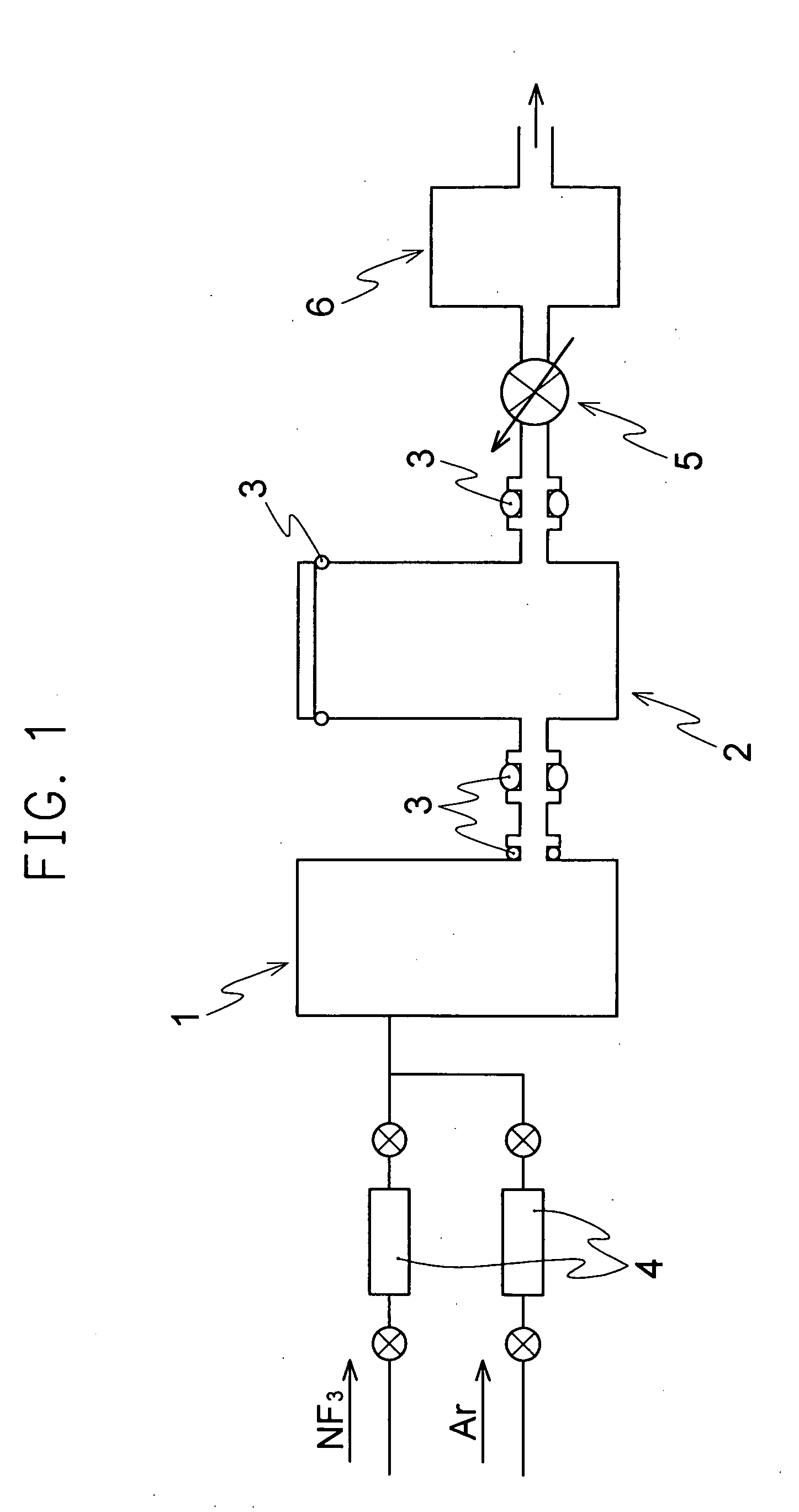

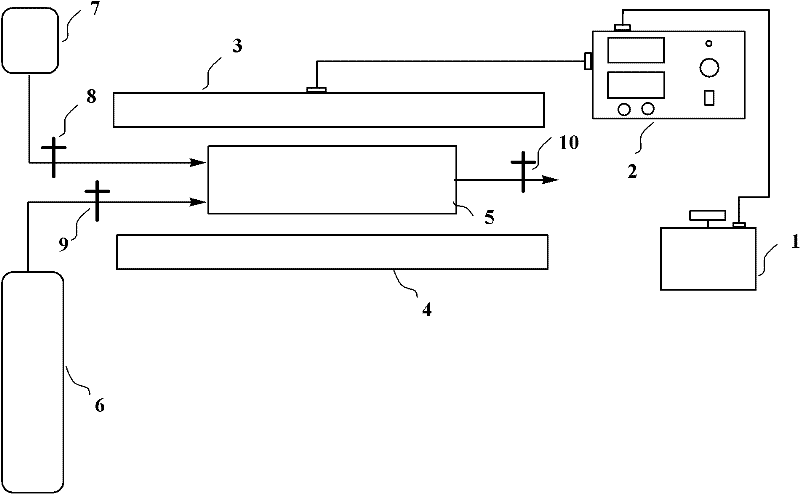

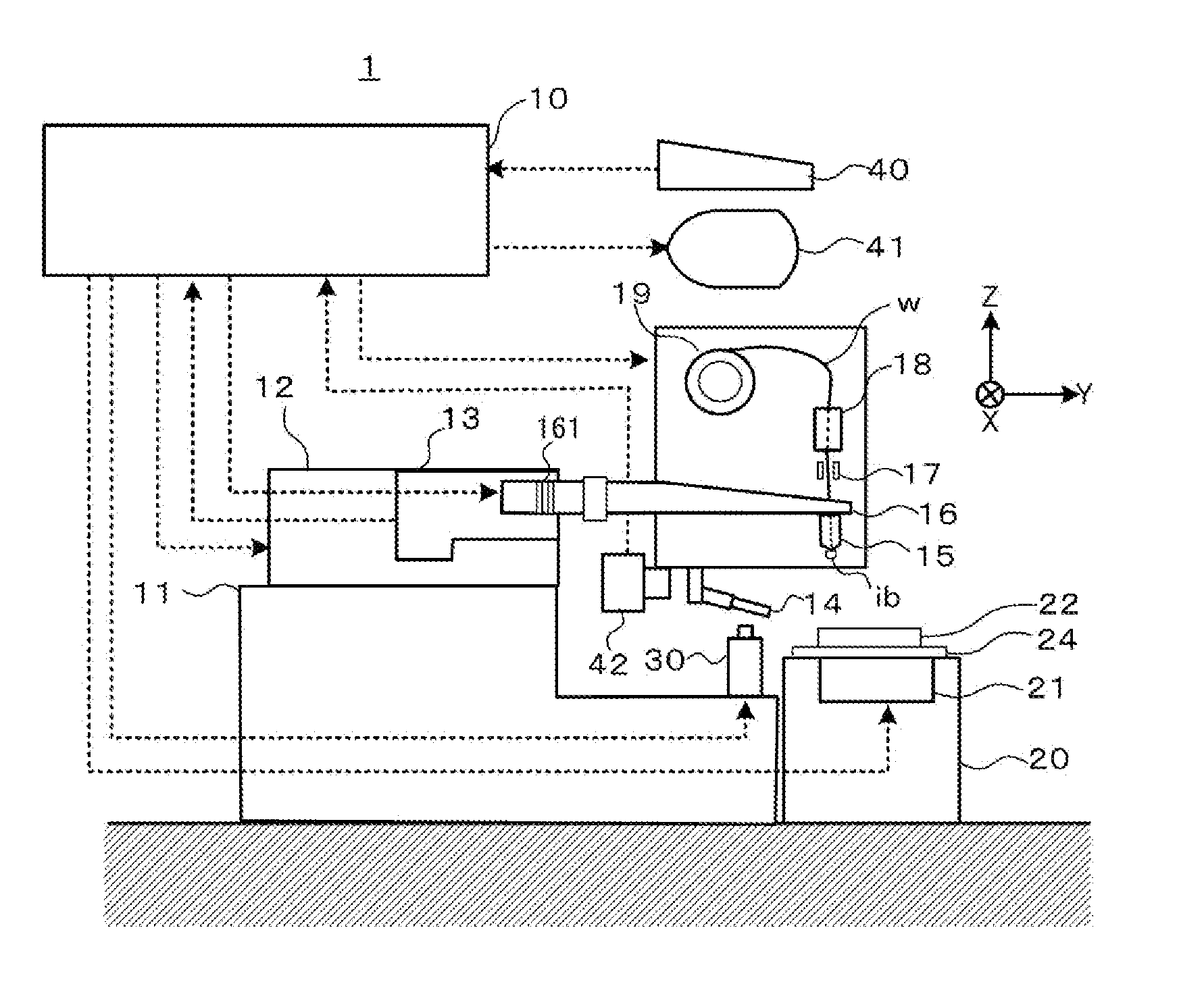

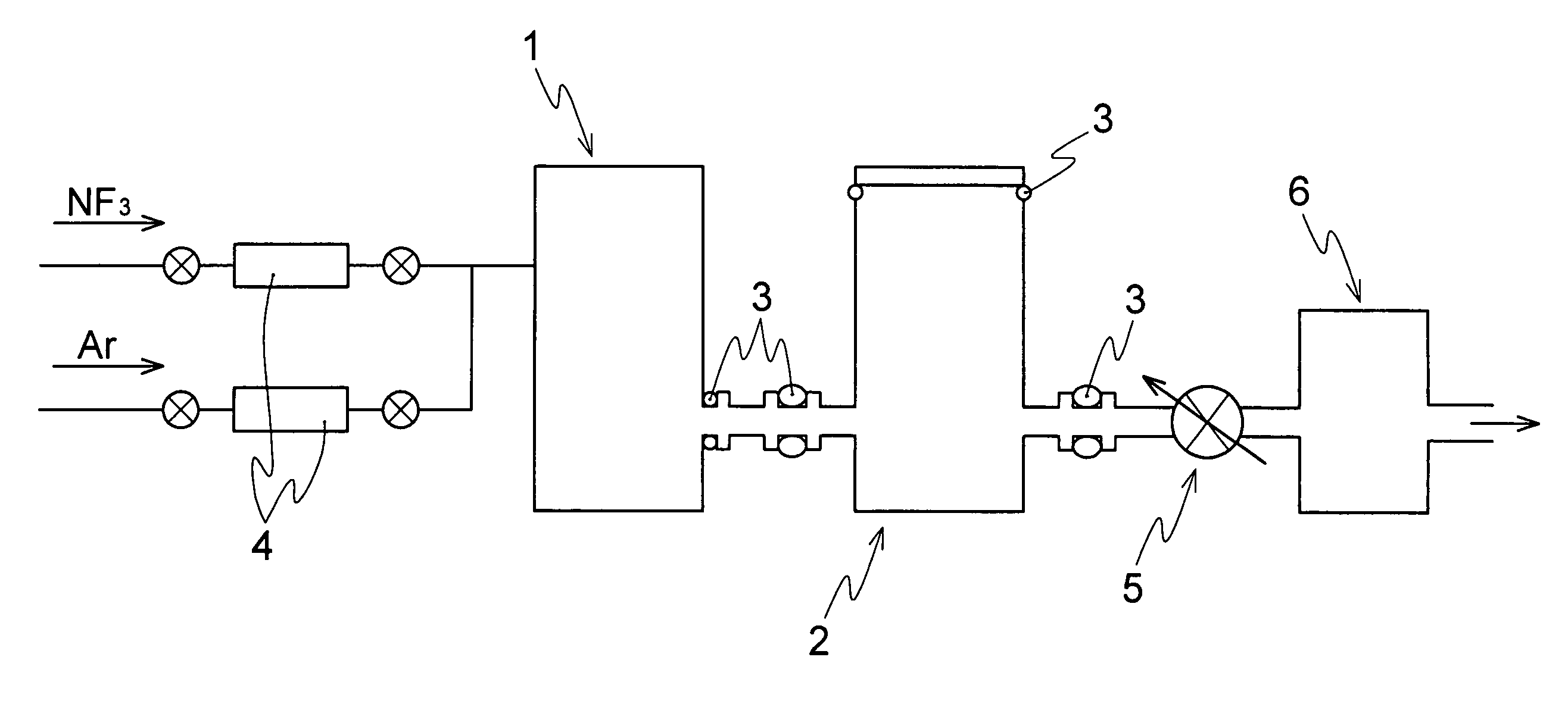

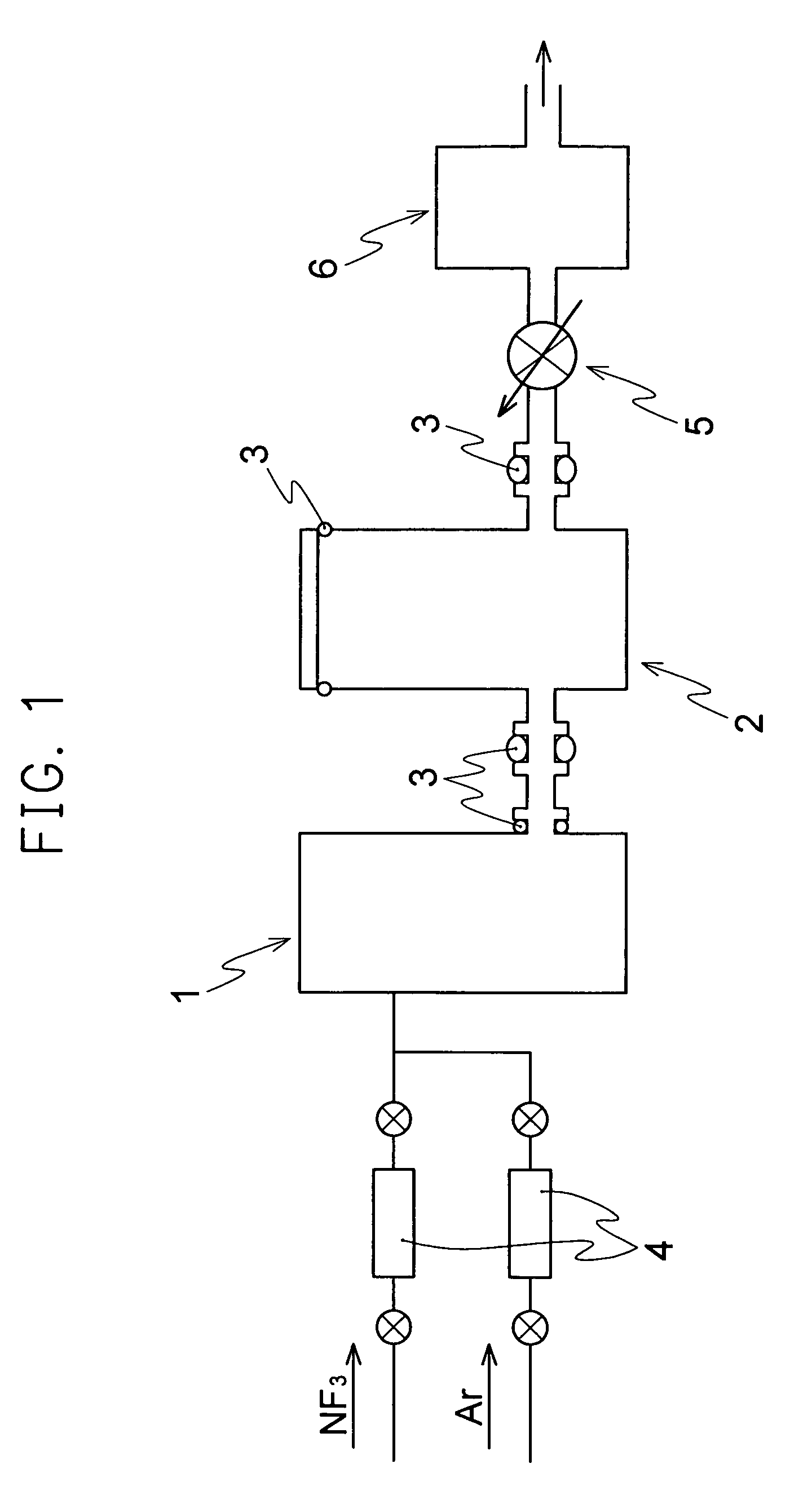

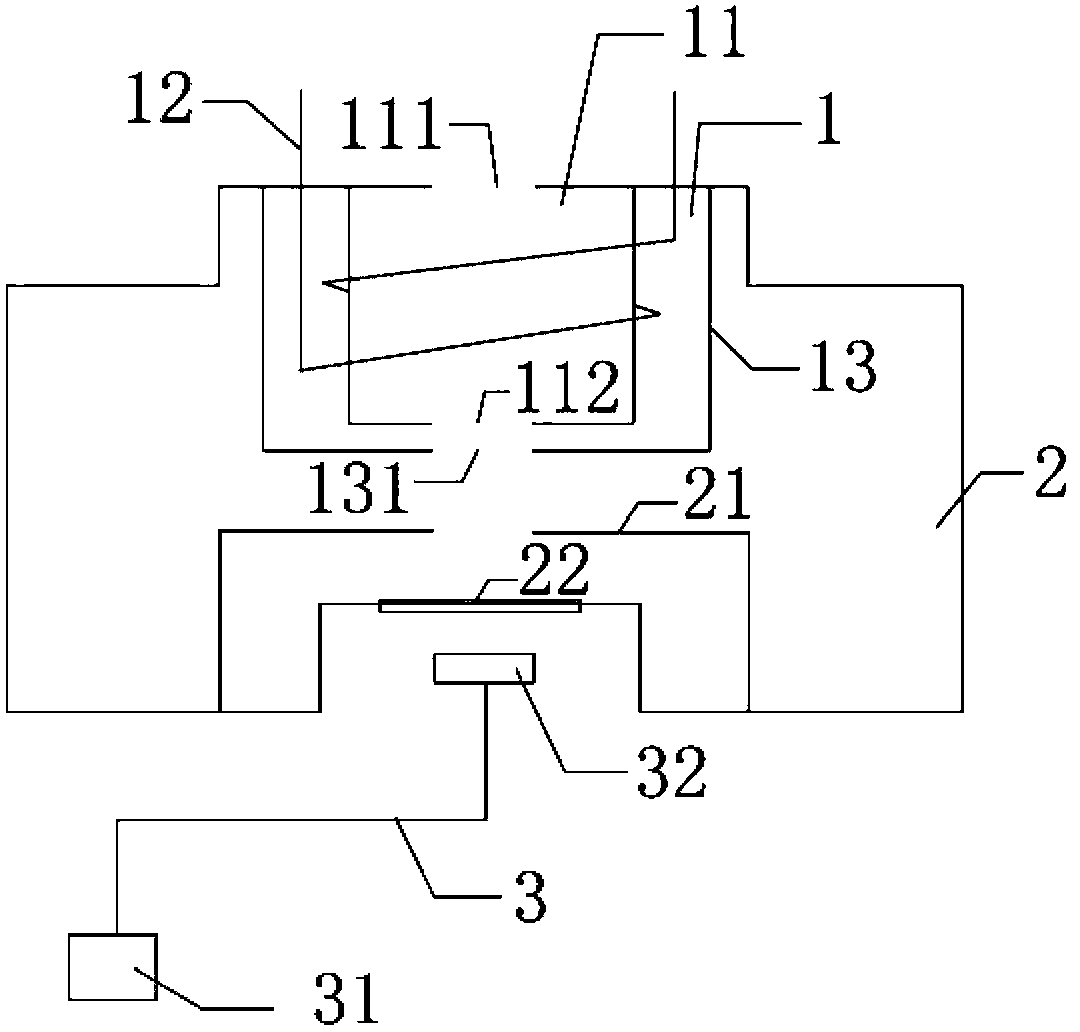

Plasma irradiation platform

InactiveCN103258581ALow costShort experiment cycleIrradiation devicesPlasma irradiationLaser heating

The invention relates to a plasma irradiation platform, and belongs to the technical field of application of plasma. The plasma irradiation platform comprises an ion source, a cavity and a laser heating system, wherein the ion source is sealed inside the cavity, and the laser heating system is arranged outside the cavity. The ion source comprises a quartz tube, a copper tube and a shielding cover, wherein the copper tube is wound on the outer wall of the quartz tube, the shielding cover is used for shielding a radio frequency electric field, and the quartz tube and the copper tube wound on the outer wall of the quartz tube are arranged inside the shielding cover. An air inlet is arranged at the upper end of the quartz tube, an ion spraying port is arranged at the lower end of the quartz tube, two ends of the copper tube are connected with two ends of a radio frequency power supply outside the cavity, a through hole is formed at the bottom of the shielding cover, a sample platform arranged inside the cavity is located under the ion source, and a quartz window arranged under the sample platform is in seal connection with the cavity. The laser heating system comprises a combination type laser which is fixed under the quartz window. The plasma irradiation platform has the advantages of being simple in equipment, low in cost, short in experimental period, and high in experimental efficiency.

Owner:DALIAN NATIONALITIES UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com