Dry dechlorination process for waste incineration fly ash

A technology for waste incineration fly ash and dechlorination, which is applied in the direction of protection devices against harmful chemicals, can solve the problems of a large number of harmful waste liquids, increase the types and quantities of hazardous wastes, etc., to avoid secondary pollution, reduce content, and achieve high efficiency. removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Effect of Mass Ratio of Titanium Dioxide Powder and Waste Incineration Fly Ash on Removal Efficiency of Chlorine and Dioxins

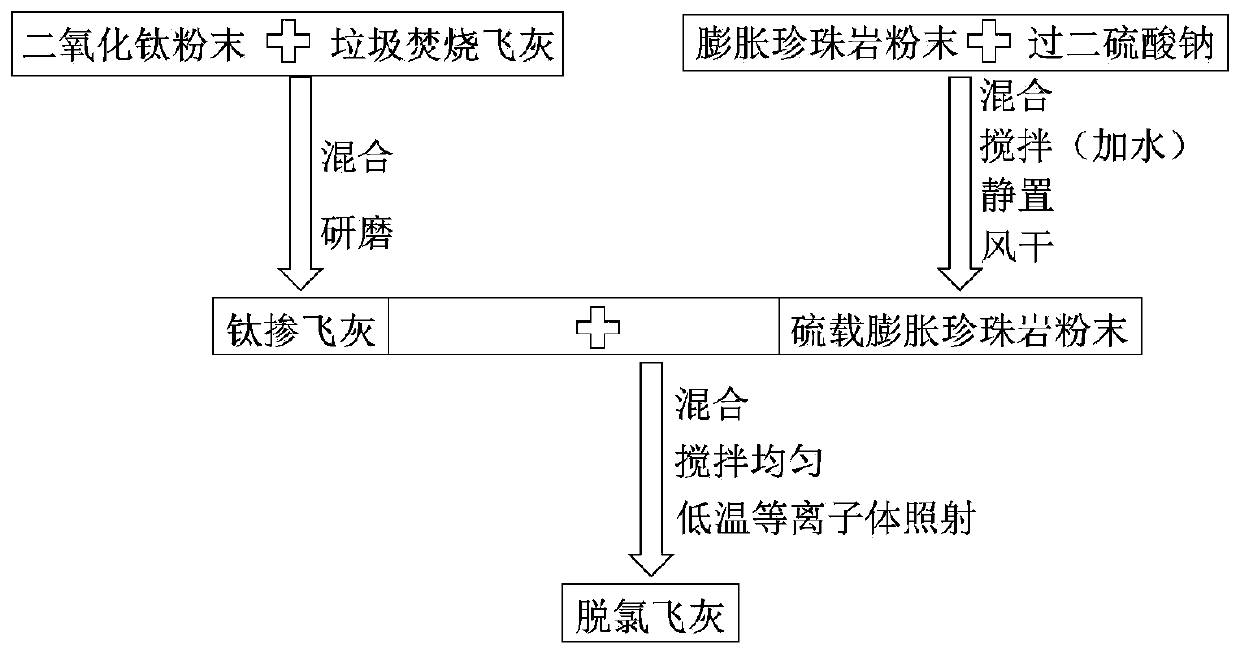

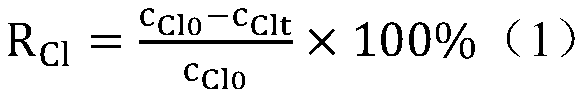

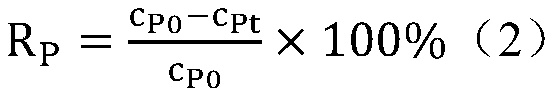

[0018] Dechlorination treatment of waste incineration fly ash: such as figure 1 As shown, according to the mass ratio of titanium dioxide powder and waste incineration fly ash 0.5:1000, 0.7:1000, 0.9:1000, 1:1000, 3:1000, 5:1000, 5.5:1000, 6:1000, 7:1000 respectively Take titanium dioxide powder and waste incineration fly ash, mix them, and grind them at 200rpm for 1 hour to obtain titanium-mixed fly ash; grind expanded perlite and pass through a 200-mesh sieve to obtain expanded perlite powder; Powder mass ratio 5:100 Weigh sodium persulfate and expanded perlite powder respectively, mix and dissolve in water, stir until sodium persulfate is completely dissolved, let stand for 3 hours, separate solid and liquid, air-dry at room temperature to obtain sulfur Loaded expanded perlite powder; according to the mass ratio of sulfur-loaded expanded per...

Embodiment 2

[0028] Effect of mass ratio of sodium persulfate to expanded perlite powder on the removal rate of chlorine and dioxins

[0029] Dechlorination treatment of waste incineration fly ash: Weigh titanium dioxide powder and waste incineration fly ash according to the mass ratio of titanium dioxide powder and waste incineration fly ash of 5:1000, mix them, and grind them for 2 hours at a rate of 600 rpm to obtain titanium-doped fly ash; Perlite is ground and passed through a 300-mesh sieve to obtain expanded perlite powder; according to the mass ratio of sodium persulfate to expanded perlite powder: 2.5:100, 3.5:100, 4.5:100, 5:100, 10:100, 15:100 , 15.5:100, 16.5:100, 17.5:100 Weigh sodium persulfate and expanded perlite powder respectively, mix and dissolve in water, stir until sodium persulfate is completely dissolved, let stand for 3 hours, separate solid and liquid, room temperature Air-dried under the conditions to obtain sulfur-loaded expanded perlite powder; according to the...

Embodiment 3

[0035] Effect of mass ratio of sulfur-loaded expanded perlite powder to titanium-doped fly ash on the removal rate of chlorine and dioxins

[0036] Dechlorination treatment of waste incineration fly ash: Weigh titanium dioxide powder and waste incineration fly ash according to the mass ratio of titanium dioxide powder and waste incineration fly ash of 5:1000, mix them, and grind them for 3 hours at a rate of 1000rpm to obtain titanium-doped fly ash; Grind perlite and pass through a 400 mesh sieve to obtain expanded perlite powder; weigh sodium peroxodisulfate and expanded perlite powder respectively according to the mass ratio of sodium peroxodisulfate and expanded perlite powder at 15:100, dissolve in water after mixing, and stir Dissolve completely to sodium peroxodisulfate, leave standstill 6 hours, separate solid and liquid, air-dry under room temperature condition, obtain sulfur-loaded expanded perlite powder; 100, 2.5:100, 3:100, 9:100, 15:100, 16:100, 17:100, 18:100 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com