Patents

Literature

37 results about "Sodium peroxodisulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

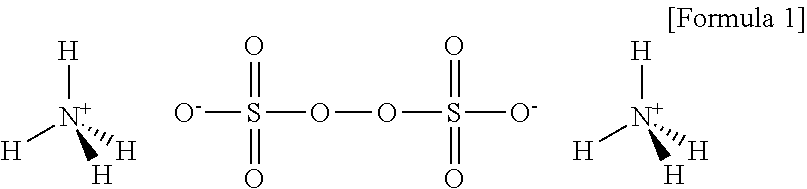

Sodium peroxodisulfate Sodium peroxodisulphate Sodium peroxydisulfate Sodium peroxydisulphate. Identifiers CAS Number. ... Sodium persulfate is the inorganic compound with the formula Na 2 S 2 O 8. It is the sodium salt of peroxydisulfuric acid, H 2 S 2 O 8, an oxidizing agent. It is a white solid that dissolves in water.

Polishing composition and method for producing a memory hard disk

InactiveUS6280490B1High cutting rateSmall surface roughnessPigmenting treatmentOther chemical processesIron sulfateEthylenediamine

A polishing composition for a memory hard disk, which comprises the following components (a) to (d):(a) from 0.1 to 50 wt %, based on the total amount of the polishing composition, of at least one abrasive selected from the group consisting of silicon dioxide, aluminum oxide, cerium oxide, zirconium oxide, titanium oxide, silicon nitride and manganese dioxide,(b) from 0.001 to 10 wt %, based on the total amount of the polishing composition, of at least one iron salt selected from the group consisting of iron nitrate, iron sulfate, ammonium iron sulfate, iron perchlorate, iron chloride, iron citrate, ammonium iron titrate, iron oxalate, ammonium iron oxalate and an iron chelate complex salt of ethylenediaminetetraacetic acid,(c) from 0.01 to 30 wt %, based on the total amount of the polishing composition, of at least one peroxydisulfate salt selected from the group consisting of ammonium peroxydisulfate, potassium peroxydisulfate and sodium peroxydisulfate, and(d) water.

Owner:FUJIMI INCORPORATED

Method of preparing carbon-based high valence silver molecule crystal battery

ActiveCN101058449AEnhance the performance of adsorbing organic toxic and harmful substancesRaise the ratioWater/sewage treatment using germicide/oligodynamic-processChemical reactionPotassium peroxodisulfate

The invention discloses a making method of carbon-based high-valent silver molecular crystal battery, which comprises the following steps: dissolving silver nitrate into pure water; stirring; placing the active carbon in the silver nitrate solution; adsorbing; filtering; drying the active carbon; placing the potassium peroxodisulfate or sodium peroxodisulfate as oxidizer into distilled water; adding sodium hydroxide; diluting; heating; stirring to react with dried active carbon; insulating; filtering; washing four times through pure water; obtaining the product with Ag4O4 distributed evenly on the surface of active carbon; displaying stronger chemical adsorbing ability and chemical reactivity; reinforcing the purifying capacity of organic toxic and harmful material absorbed by active charcoal.

Owner:TAIYUAN YINXIYUAN TECH CO LTD

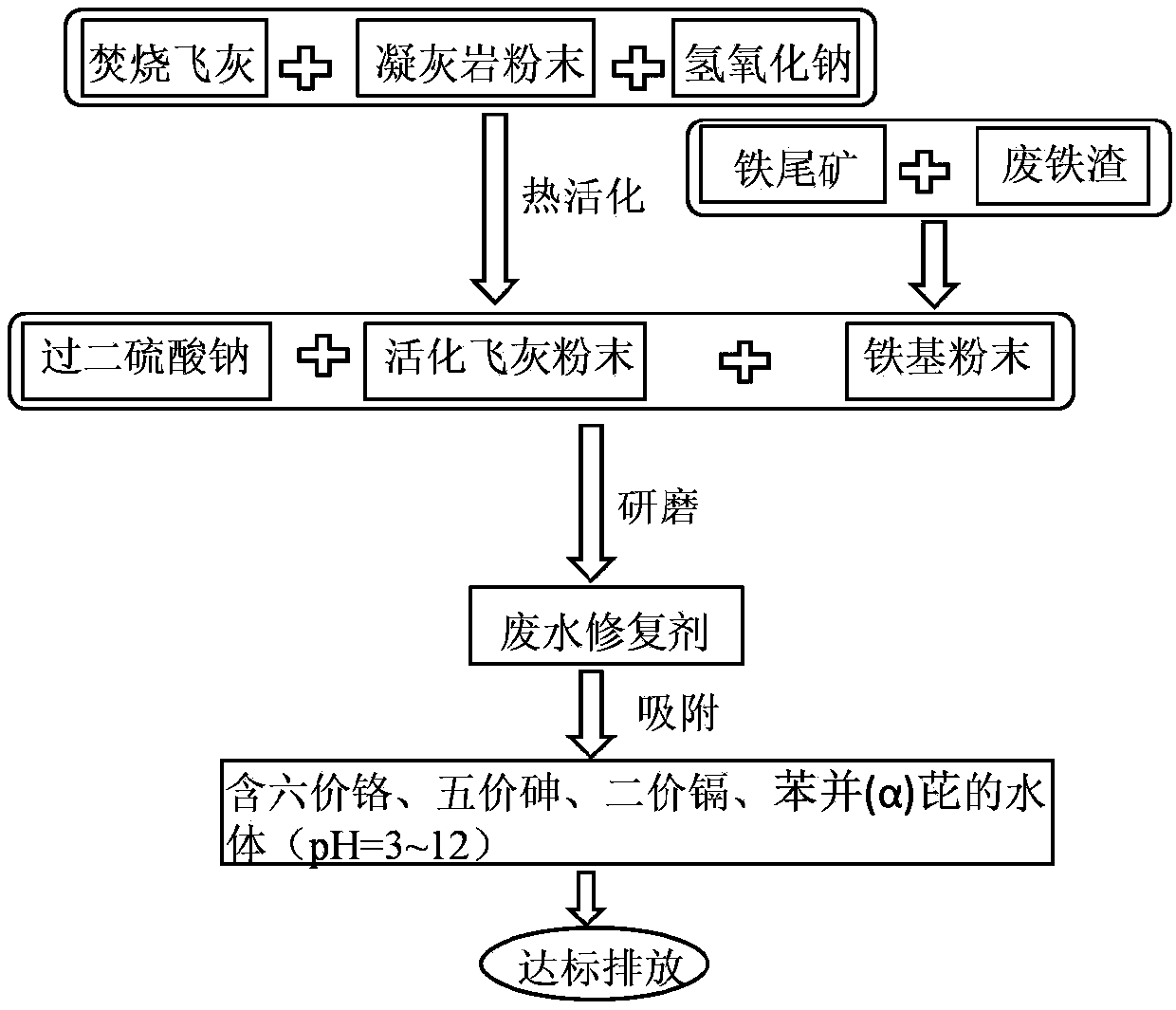

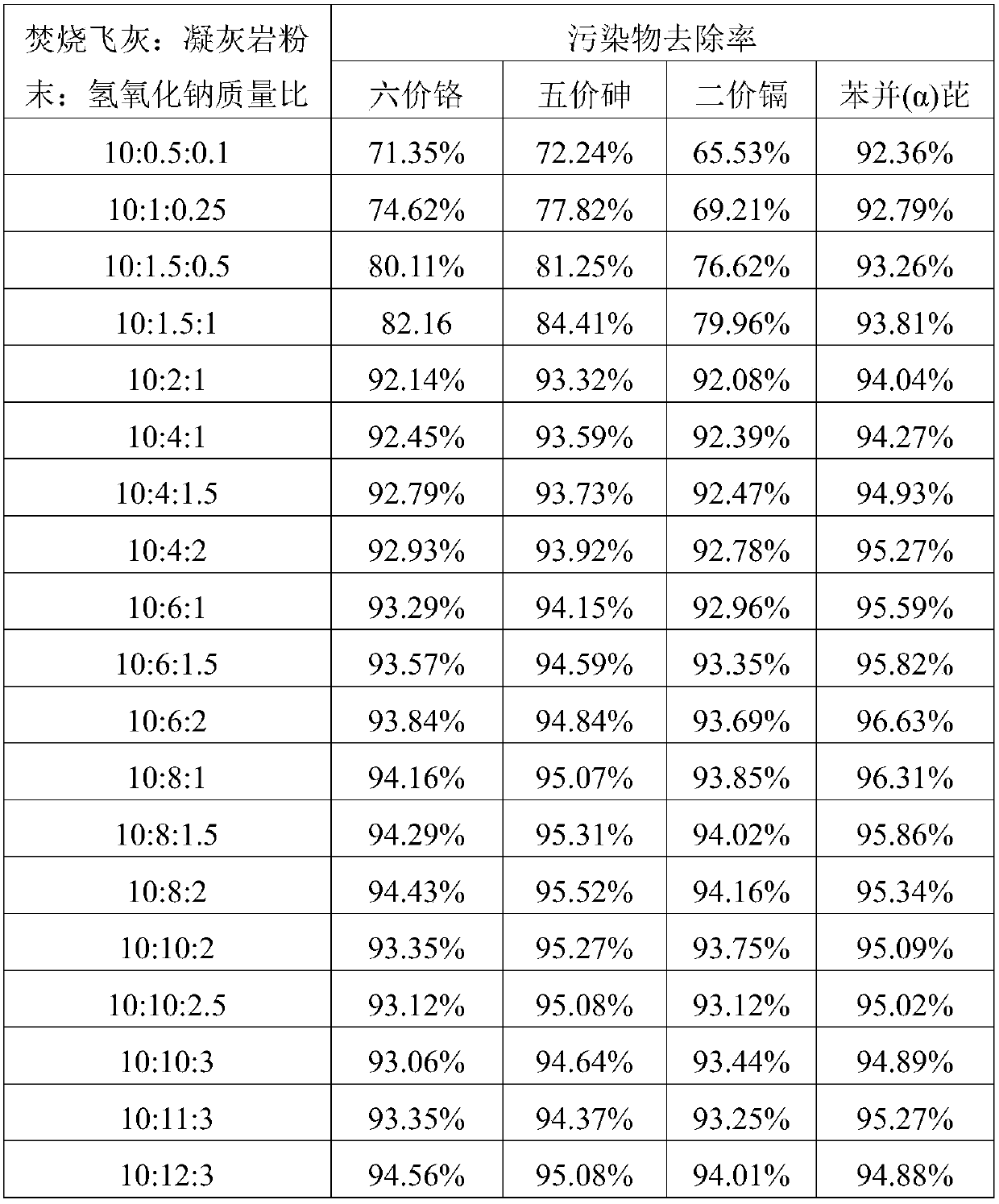

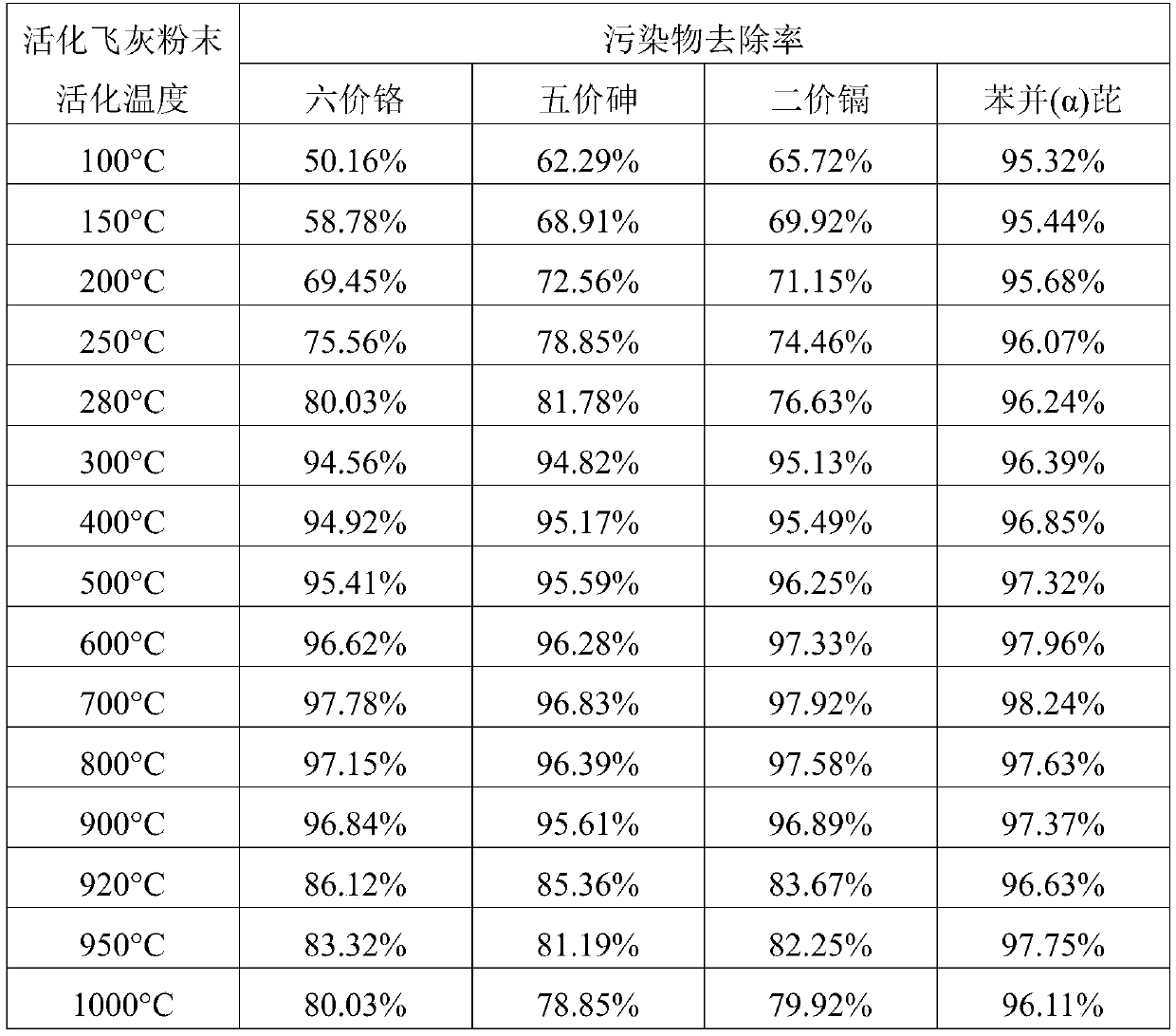

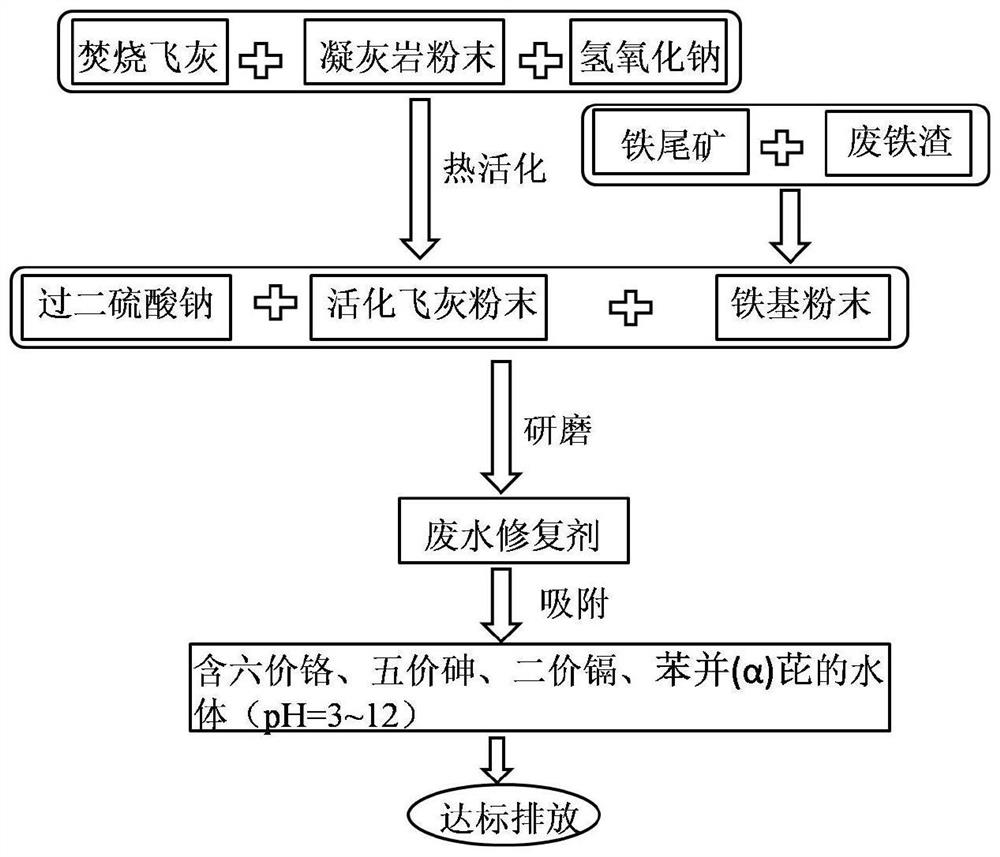

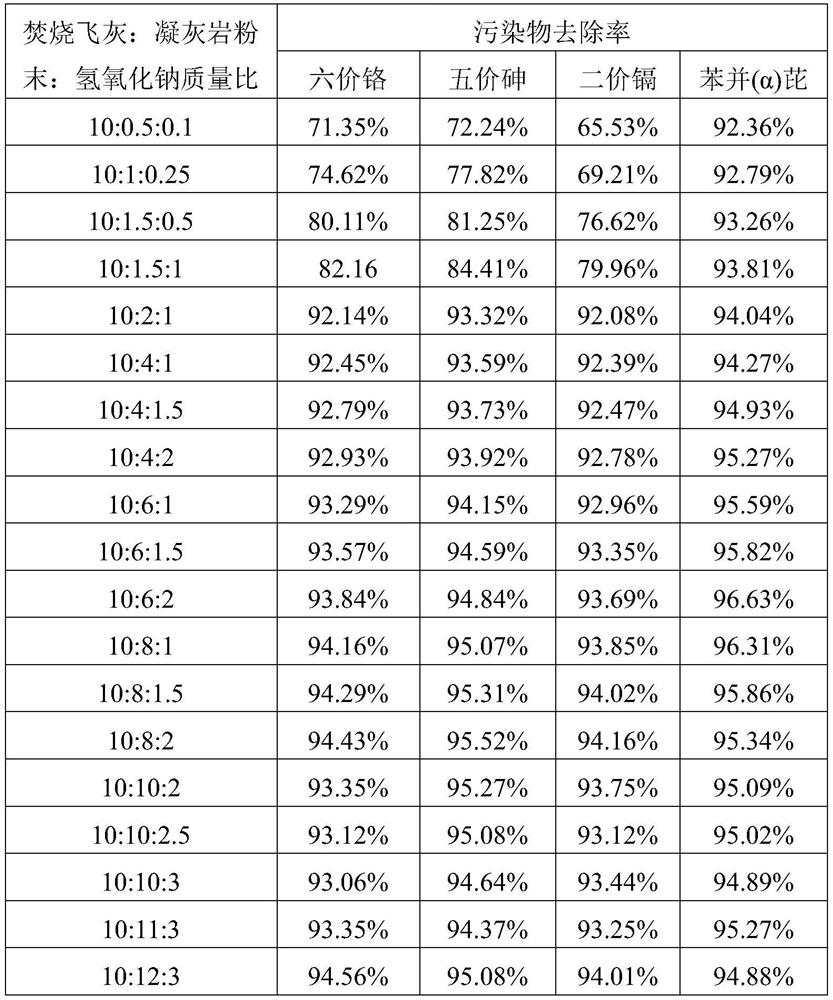

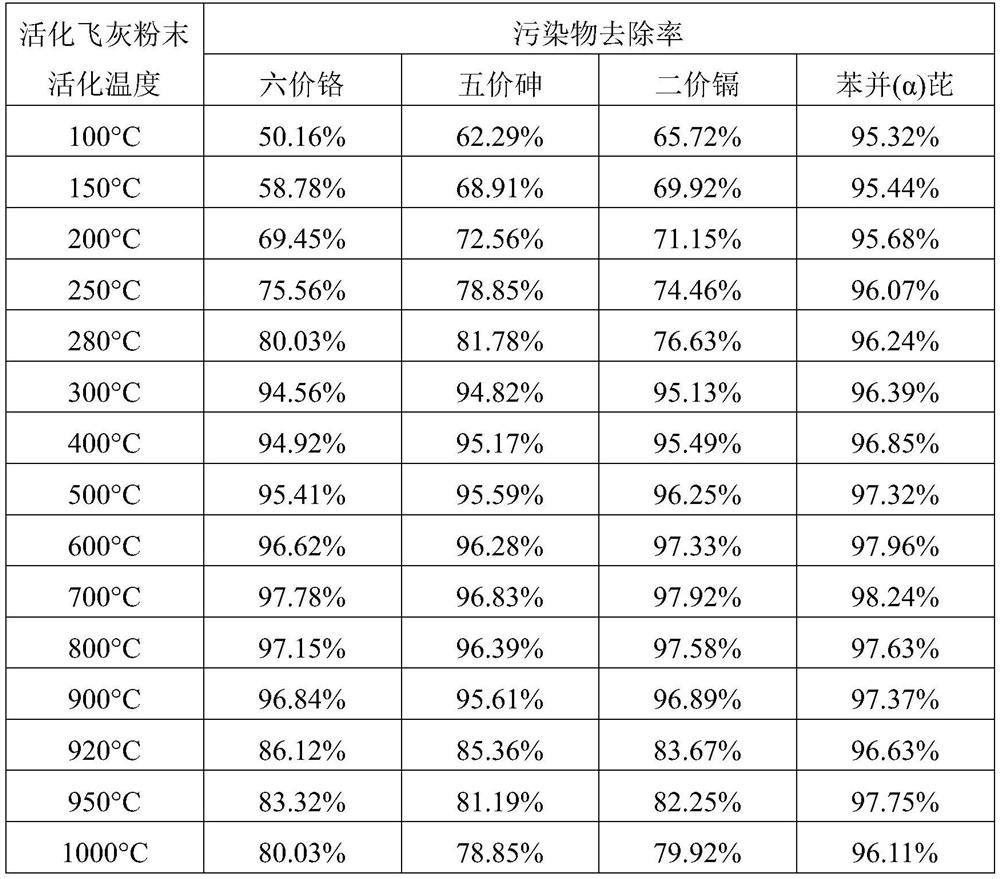

Preparation method of wastewater remediation agent based on incineration fly ash

ActiveCN109592776ADesyncEfficient removalWater treatment compoundsWater contaminantsSlagResource utilization

The invention discloses a preparation method of a wastewater remediation agent based on incineration fly ash. The preparation method comprises the following steps: (1) respectively weighing incineration fly ash, tuff powder and sodium hydroxide, uniformly mixing, and heating for activation, so as to obtain activated fly ash powder; (2) respectively weighing iron tailings and scrap iron slag, uniformly mixing, grinding, and sieving, so as to obtain iron-base powder; and (3) respectively weighing the activated fly ash powder, the iron-base powder and sodium persulfate, uniformly mixing, and grinding, so as to obtain the wastewater remediation agent. By virtue of the combination, mutual complementation and mutual cooperation of an incineration fly ash solidification technique and a techniquefor removing pollutants through an oxidation reduction effect, the synchronous and efficient removal of hexavalent chromium, pentavalent arsenic, divalent cadmium and benzo(alpha)pyrene in a water body with a pH value of 3-12 is realized, and the removal rate reaches up to 98%; pollutants are solidified in particles of the remediation agent, so that the leaching of the pollutants is avoided; a novel application direction is provided for the harmless treatment and resource utilization of the incineration fly ash; and the preparation method of the wastewater remediation agent is simple and low in raw material cost.

Owner:浙江中陶环保科技集团有限公司

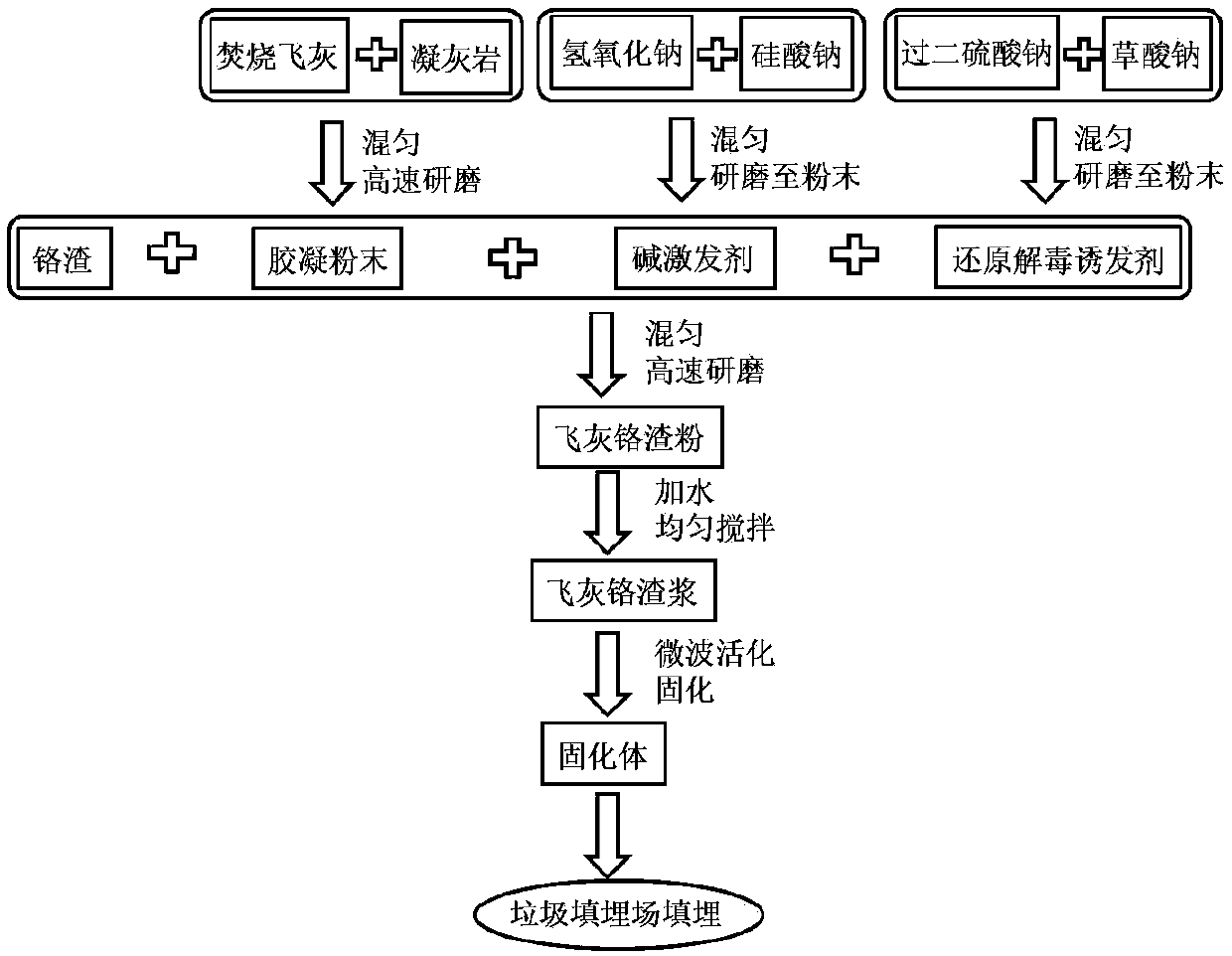

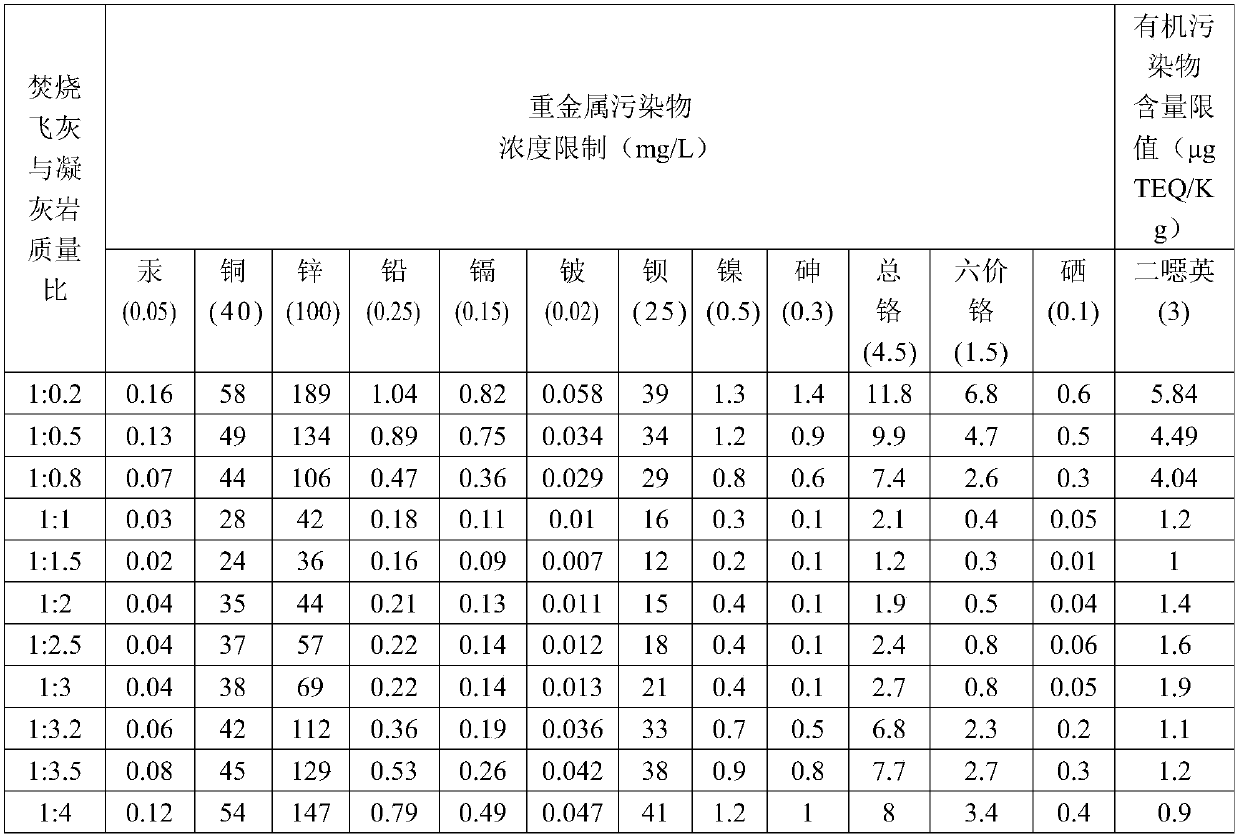

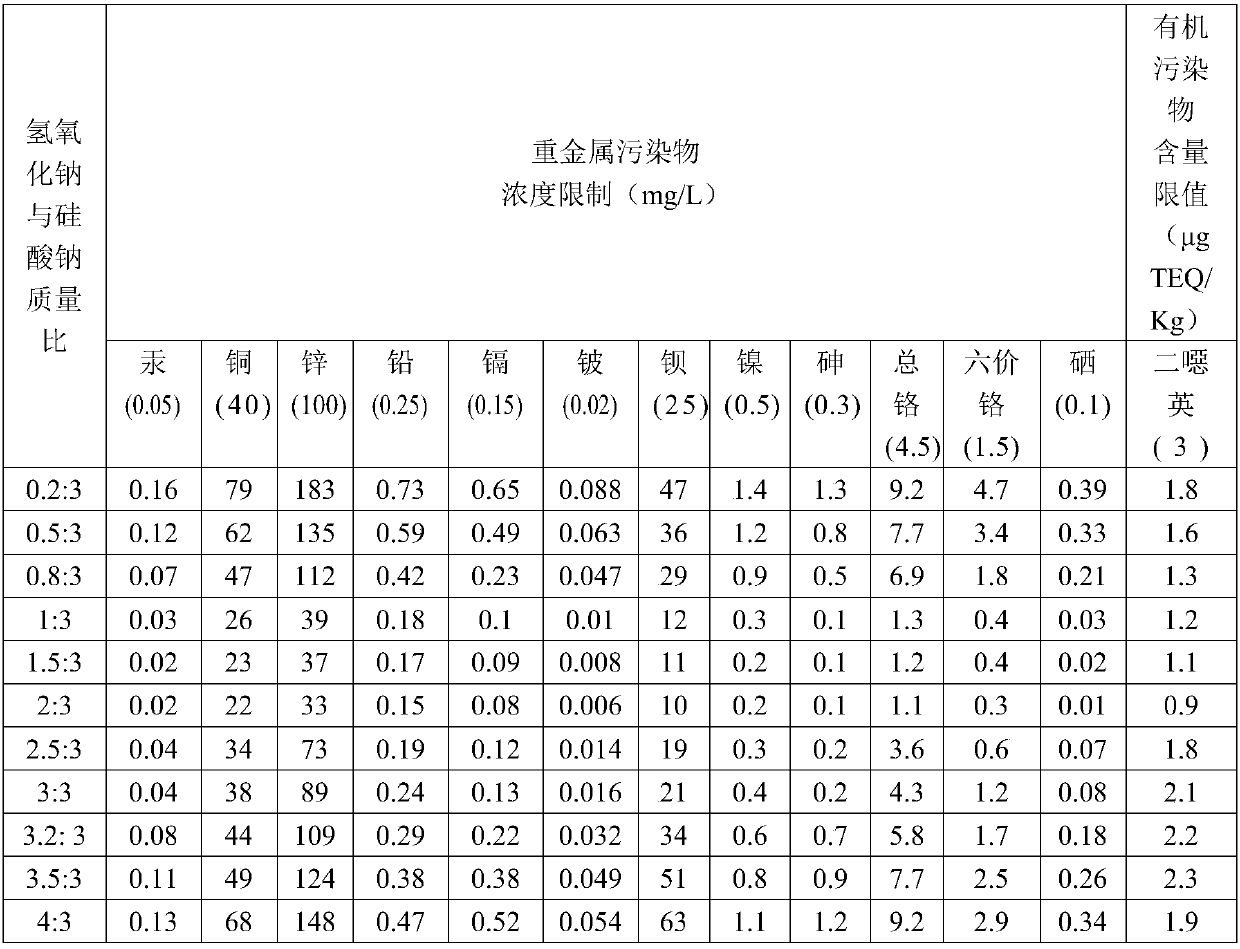

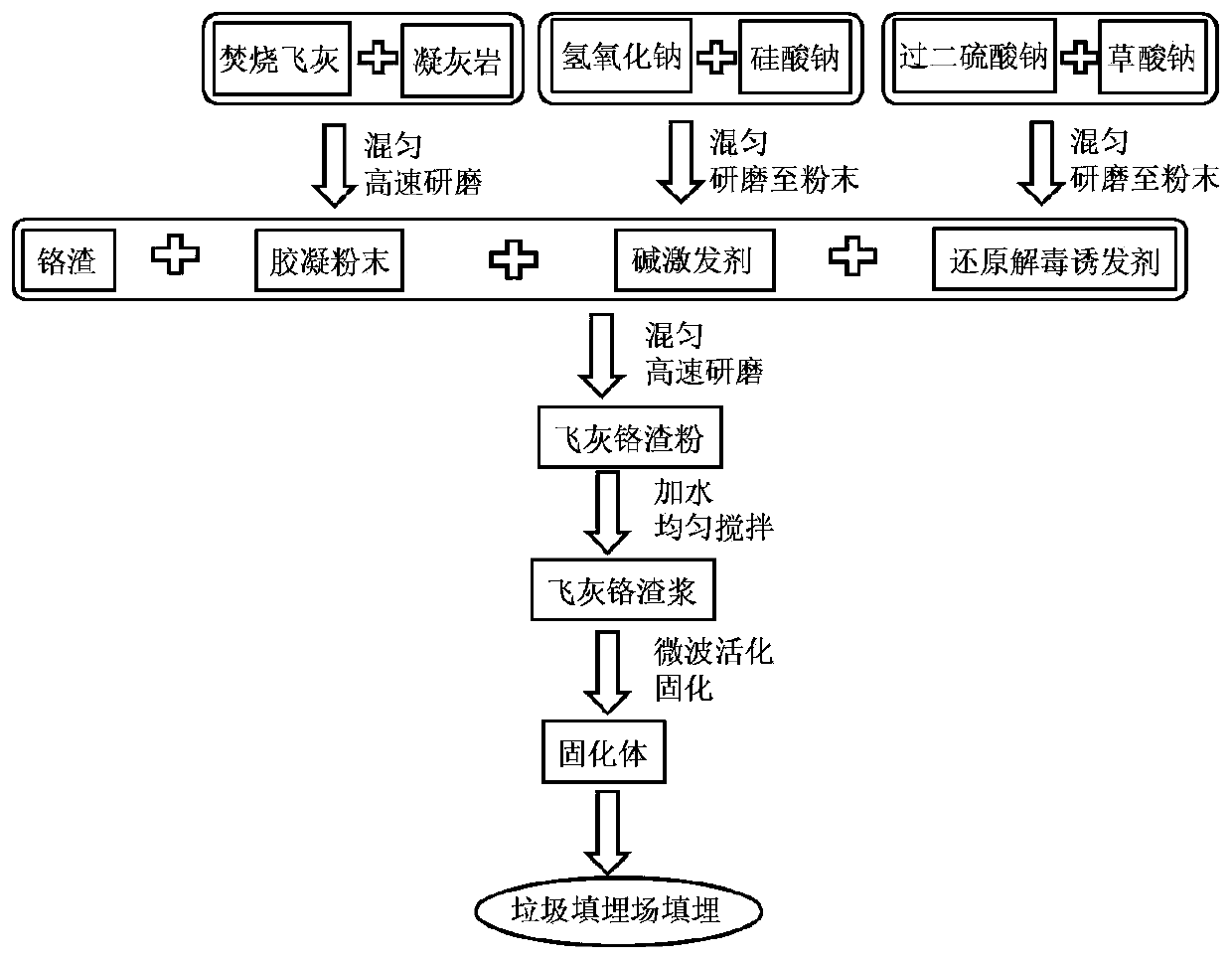

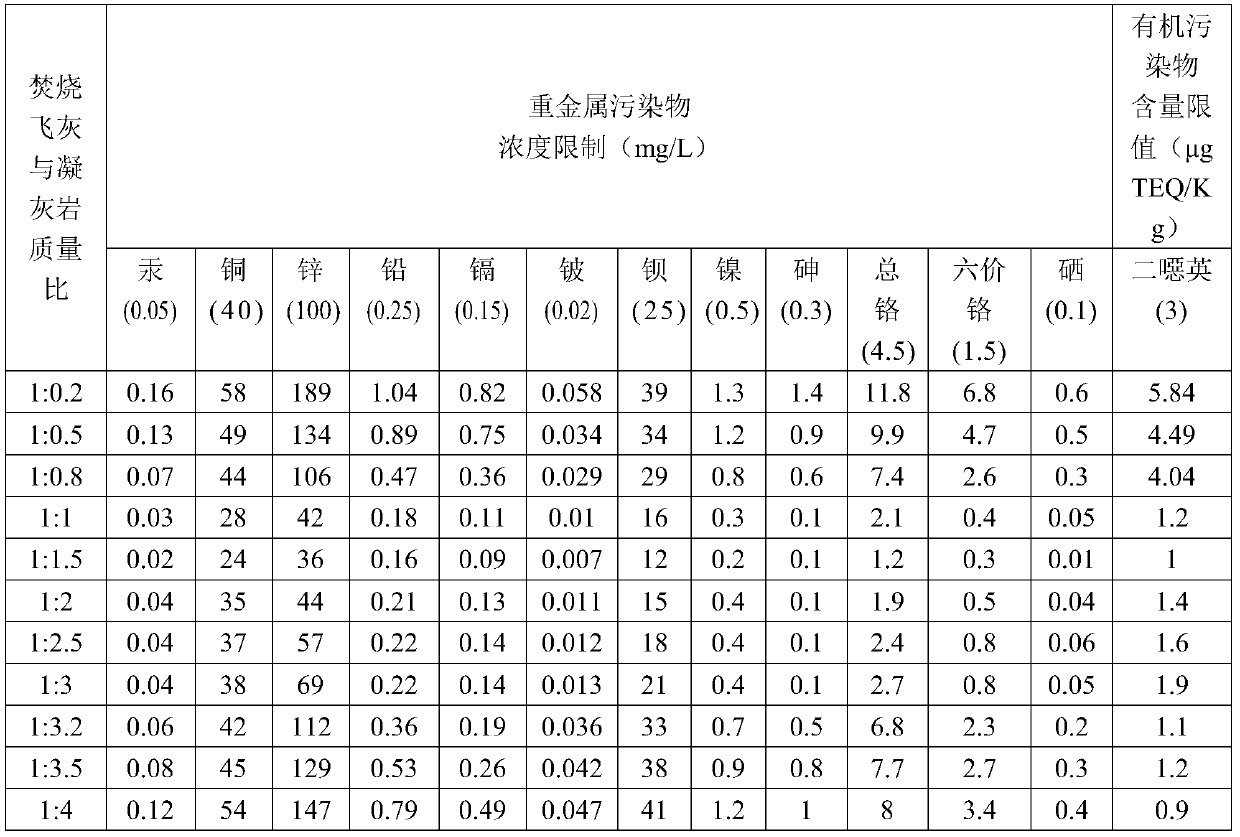

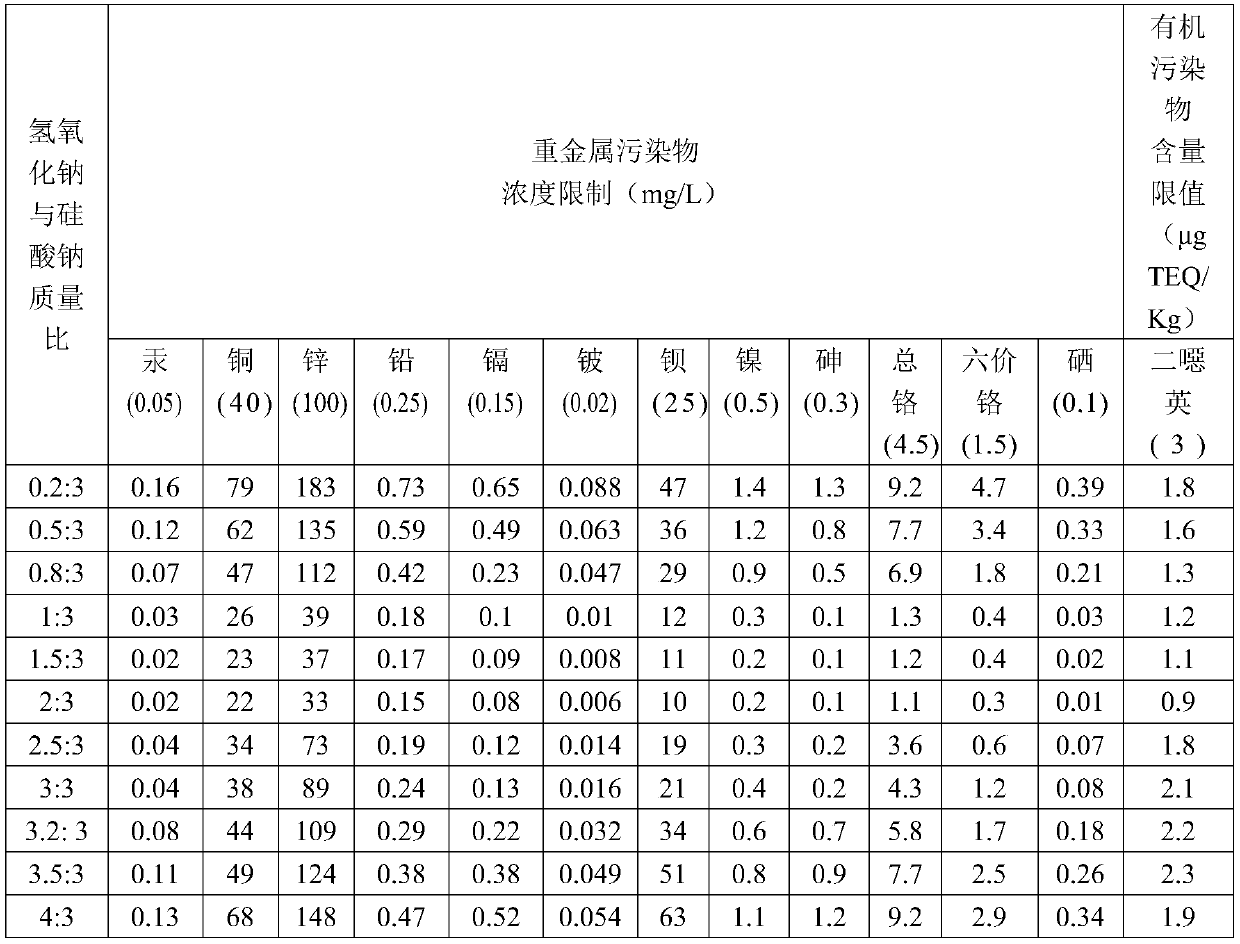

Method for synchronously achieving incineration fly ash detoxification and chromium slag reduction curing

The invention discloses a method for synchronously achieving incineration fly ash detoxification and chromium slag reduction curing. The method includes the following steps that (1), incineration flyash and tuff are weighed, mixed to be uniform and ground, and gelatinized powder is obtained; (2), sodium hydroxide and sodium silicate are weighed, mixed to be uniform and ground, and an alkali activator is obtained; (3), sodium persulfate and sodium oxalate are weighed, mixed to be uniform and ground, and a reductive detoxification inducer is obtained; (4), chromium slag, the gelatinized powder,the alkali activator and the reductive detoxification inducer are weighed, mixed to be uniform and ground, and fly ash and chromium slag powder is obtained; (5), the fly ash and chromium slag powderis weighed and dissolved in water, the materials are mixed to be uniform, and fly ash and chromium slag slurry is obtained; (6), the fly ash and chromium slag slurry is sealed, activated through microwaves, cooled and put in a die to be cured. The leaching concentrations of multiple heavy metals and dioxin in the fly ash and a chromium heavy metal in the chromium slag are all lower than the entrance limiting value of a municipal solid waste landfill. Treated cured bodies have high acid resistance and high constraint capacity for heavy metal inorganic pollutants and organic pollutants.

Owner:浙江中陶环保科技集团有限公司

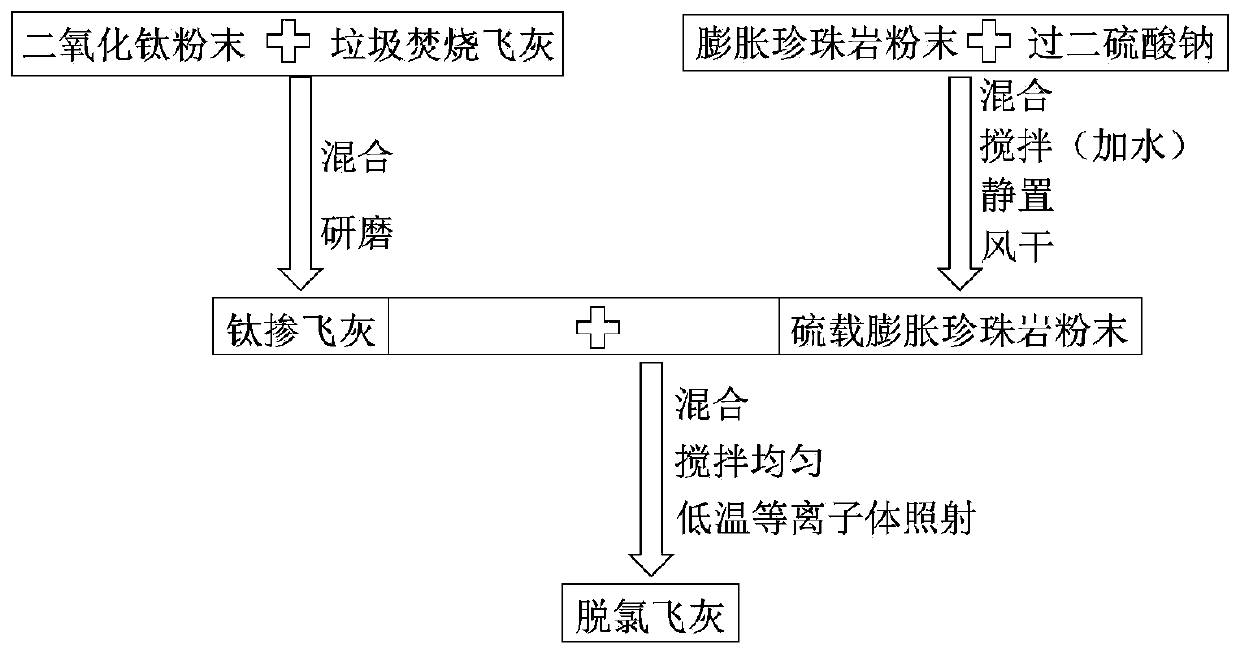

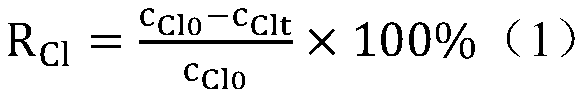

Dry dechlorination process for waste incineration fly ash

The invention discloses a dry dechlorination process for waste incineration fly ash. The process comprises the following steps: (1) mixing titanium dioxide and waste incineration fly ash, and grindingto obtain titanium-doped fly ash; (2) mixing sodium persulfate and expanded perlite powder, dissolving the obtained mixture in water, standing, carrying out solid-liquid separation, and air-drying toobtain sulfur-loaded expanded perlite powder; and (3) mixing the sulfur-loaded expanded perlite powder and the titanium-doped fly ash, and carrying out low-temperature plasma irradiation to obtain the dechlorinated fly ash. Through the simple dry dechlorination process, chloride ions in the waste incineration fly ash are efficiently removed, the removal rate of the chloride ions is as high as 97%, and secondary pollution caused by a traditional water washing method is avoided; and when the chloride ions are removed, the content of dioxin substances in the fly ash is also remarkably reduced, and the removal rate of the dioxin substances reaches up to 96%.

Owner:浙江中陶环保科技集团有限公司

Liquid composition for removing titanium nitride, semiconductor-element cleaning method using same, and semiconductor-element manufacturing method

ActiveUS20160281038A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingDielectricTitanium nitride

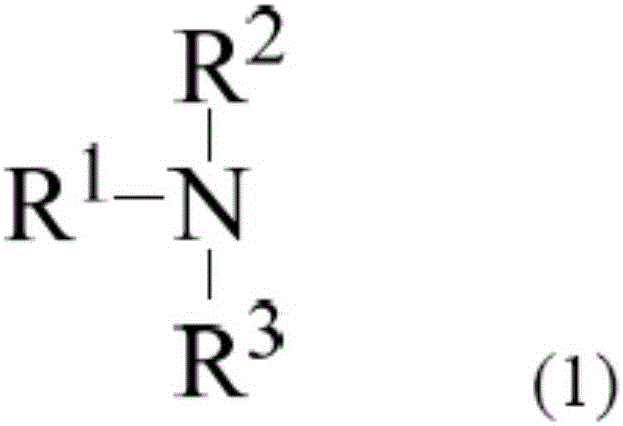

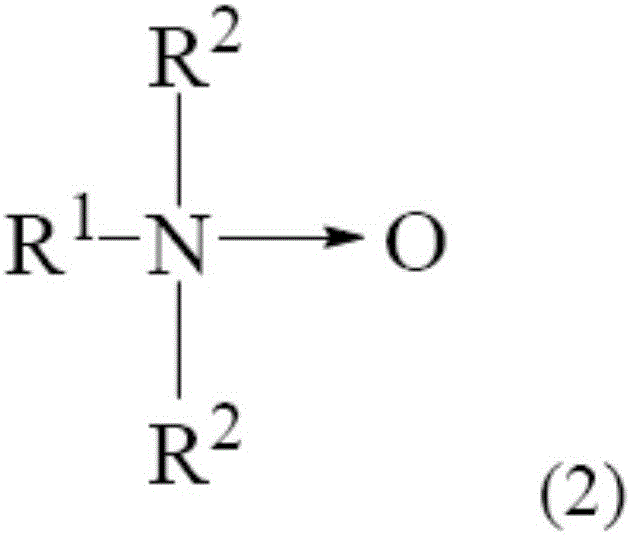

This invention provides a liquid composition that removes titanium nitride from a substrate without corroding tungsten or a low-k interlayer dielectric also present on said substrate. Said liquid composition has a pH between 0 and 4, inclusive, and contains the following: at least one oxidizing agent (A) selected from the group consisting of potassium permanganate, ammonium peroxodisulfate, potassium peroxodisulfate, and sodium peroxodisulfate; a fluorine compound (B); and a tungsten-corrosion preventer (C). The tungsten-corrosion preventer (C) either contains at least two different compounds selected from a group of compounds (C1) consisting of alkylamines, salts thereof, fluoroalkylamines, salts thereof, and the like or contains at least one compound selected from said group of compounds (C1) and at least one compound selected from a group of compounds (C2) consisting of polyoxyalkylene alkylamines, polyoxyalkylene fluoroalkylamines, and the like. The mass concentration of potassium permanganate in the abovementioned oxidizing agent (A) is between 0.001% and 0.1%, inclusive, and the mass concentration of the abovementioned fluorine compound (B) is between 0.01% and 1%, inclusive.

Owner:MITSUBISHI GAS CHEM CO INC

Liquid composition for removing titanium nitride, semiconductor-element cleaning method using same, and semiconductor-element manufacturing method

ActiveCN105981136AInorganic/elemental detergent compounding agentsCationic surface-active compoundsTitanium nitrideAmmonium peroxydisulfate

This invention provides a liquid composition that removes titanium nitride from a substrate without corroding tungsten or a low-k interlayer dielectric also present on said substrate. Said liquid composition has a pH between 0 and 4, inclusive, and contains the following: at least one oxidizing agent (A) selected from the group consisting of potassium permanganate, ammonium peroxodisulfate, potassium peroxodisulfate, and sodium peroxodisulfate; a fluorine compound (B); and a tungsten-corrosion preventer (C). The tungsten-corrosion preventer (C) either contains at least two different compounds selected from a group of compounds (C1) consisting of alkylamines, salts thereof, fluoroalkylamines, salts thereof, and the like or contains at least one compound selected from said group of compounds (C1) and at least one compound selected from a group of compounds (C2) consisting of polyoxyalkylene alkylamines, polyoxyalkylene fluoroalkylamines, and the like. The mass concentration of potassium permanganate in the abovementioned oxidizing agent (A) is between 0.001% and 0.1%, inclusive, and the mass concentration of the abovementioned fluorine compound (B) is between 0.01% and 1%, inclusive.

Owner:MITSUBISHI GAS CHEM CO INC

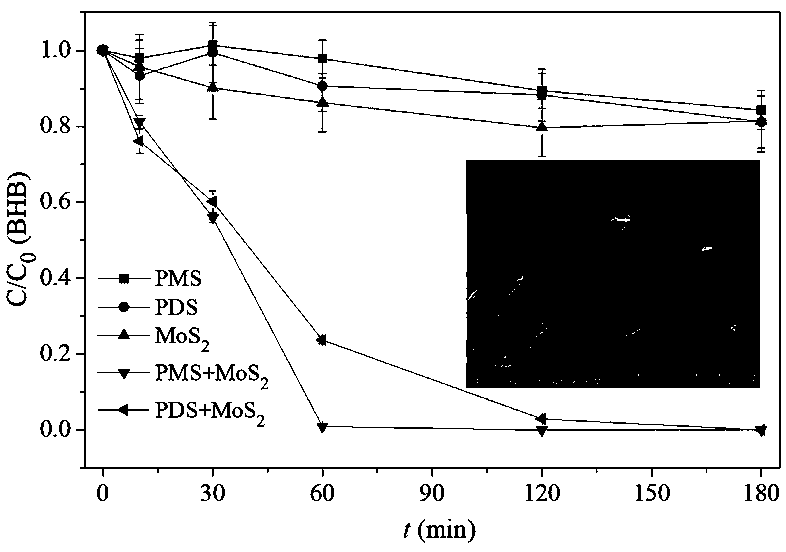

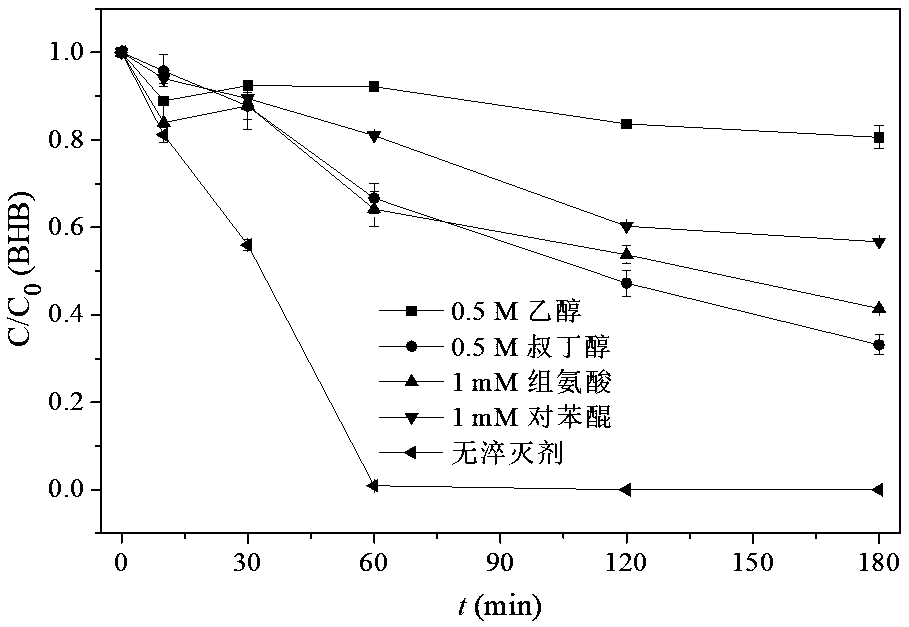

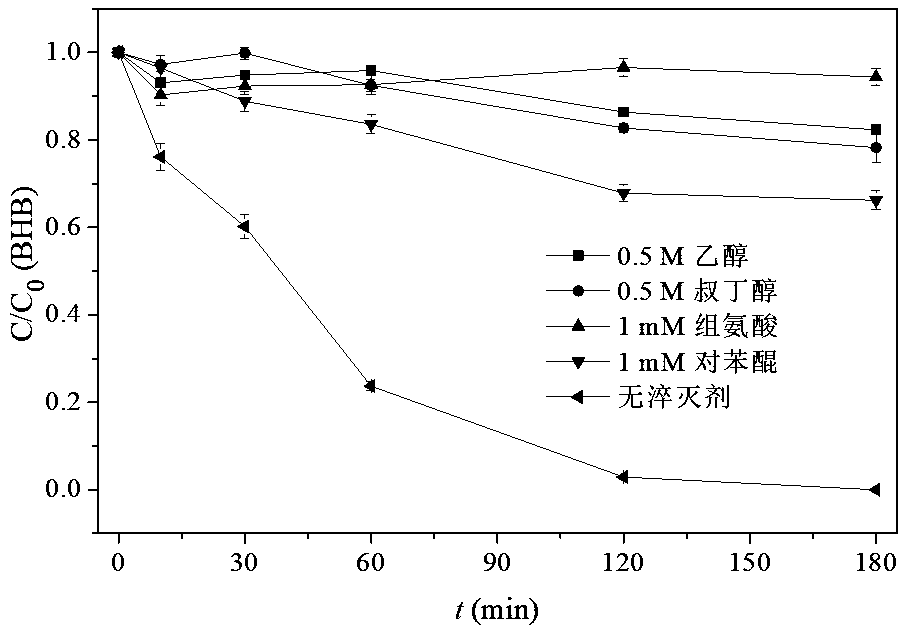

Method for removing butyl p-hydroxybenzoate by activating persulfate with layered MoS2 and application thereof

InactiveCN110217875AEfficient removalEasy to storeWater contaminantsWater/sewage treatment by oxidationExternal energyPotassium peroxomonosulfate

The invention relates to a method for removing butyl p-hydroxybenzoate (BHB) by directly activating potassium peroxymonosulfate (PMS) and sodium persulfate (PDS) with layered MoS2. The method includespreparing a BHB target solution having a pH of 3-10 and a concentration of 5 mg / L; changing experiment conditions, adding a certain amount of commercial MoS2 and PMS / PDS to the BHB target solution respectively, and reacting the mixture under stirring. It is found for the first time that: the layered MoS2 can directly activate persulfate under a condition of no external energy and generate activefree radicals (SO<4><->., .OH and O<2><->.) and non-free radicals (1O2) to achieve synergistic oxidation to remove the BHB. The method is simple in process, easy to operate and low in equipment requirement, and the layered MoS2 is cheap and easily available, and has a wide market application potential in the field of treating newly-developing pollutants in water environment.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

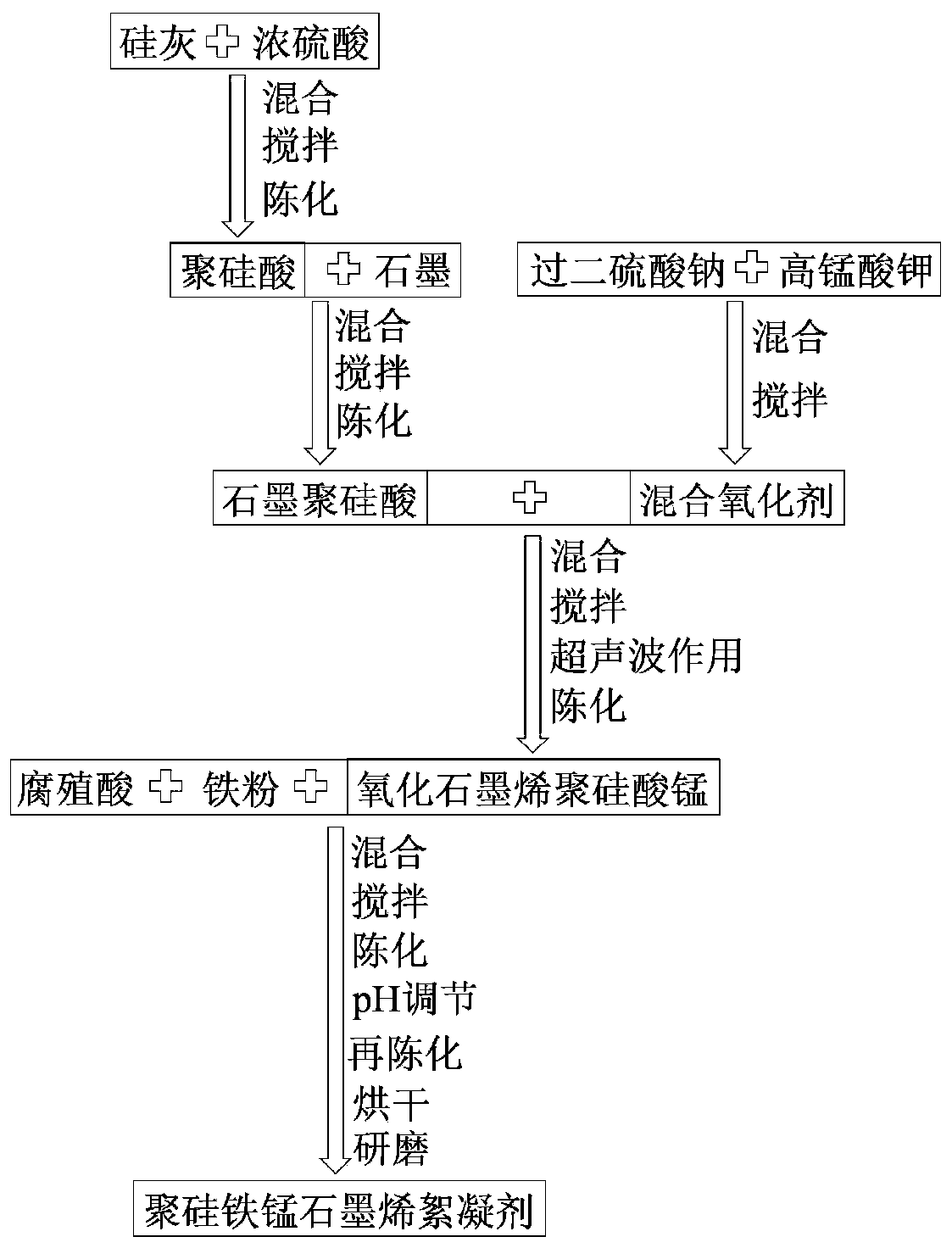

Preparation method of poly-silicon iron manganese graphene flocculant

ActiveCN110818047AImprove stabilityImprove adsorption capacityWater treatment parameter controlWater contaminantsSilicic acidManganese

The invention discloses a preparation method of a poly-silicon iron manganese graphene flocculant. The preparation method comprises the following steps: (1) uniformly mixing silica fume with concentrated sulfuric acid, and aging to obtain polysilicic acid; (2) adding graphite powder into polysilicic acid, uniformly mixing, and aging to obtain graphite polysilicic acid; (3) uniformly mixing sodiumpersulfate and potassium permanganate to obtain a mixed oxidant, adding the mixed oxidant into graphite polysilicic acid, uniformly mixing, carrying out ultrasonic treatment, and aging to obtain graphene oxide polysilicic acid manganese; and (4) uniformly mixing humic acid, iron powder and graphene oxide polysilicic acid manganese, aging, adjusting the pH value to be lower than 7, continuing aging, drying, and grinding to obtain the poly-silicon iron manganese graphene flocculant. The poly-silicon iron manganese graphene flocculant can capture various pollutants at the same time, the flocculant recovery efficiency is high, and the applicable pH range of the flocculant is wide; the preparation process is simple, the preparation condition requirement is low, the preparation process is easy to realize, and the required raw material source is wide.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Production process for leaching of cobalt from cobalt-containing water-quenched slag

The invention provides a production process for leaching of cobalt from cobalt-containing water-quenched slag. The process comprises the following steps: respectively subjecting powdered coal and cobalt-containing water-quenched slag to drying, grinding, crushing, sieving, etc., then carrying out uniform mixing, adding water and carrying out granulation, wherein lime is added as a binder in the process of granulation; carrying out drying, then putting an obtained substance into a graphite crucible for roasting, carrying out a reaction for a period of time, taking a resultant out and cooling the resultant at room temperature; and triturating and grinding the resultant, taking a small amount of the ground resultant, transferring the ground resultant into an autoclave, adding a certain amount of ammonium sulfate, sodium persulfate, ammonia water and water, carrying out sealed heating with continuous stirring, introducing cooling water to cool the autoclave after completion of a reaction, opening the autoclave after cooling, subjecting an obtained material to filtering and separating by using a rotary-vane vacuum pump, washing leached slag with ammonia water and carrying out drying.

Owner:赖世权

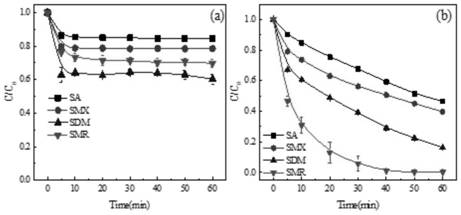

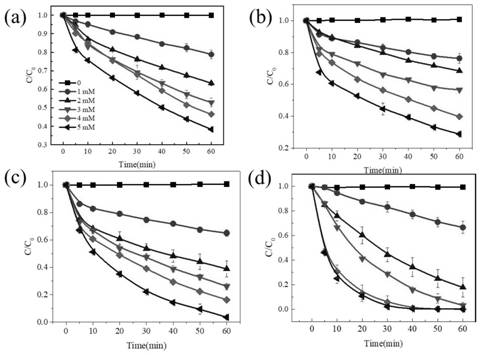

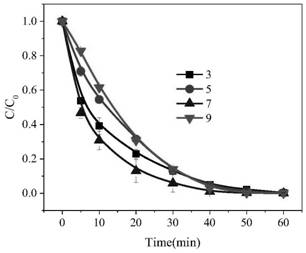

Method for removing antibiotics in water body by activating peroxydisulfate without catalyst under visible light

PendingCN111977740AReduce energy consumptionLow costWater/sewage treatment by irradiationWater treatment compoundsPeroxydisulfateSulfate radicals

The invention belongs to the technical field of sewage treatment and recycling, and relates to a method for removing antibiotics in a water body by activating peroxydisulfate without a catalyst undervisible light. The method comprises the following specific operation steps: adding PS into the water body containing the antibiotics, and activating the PS under the irradiation of the visible light to generate free radicals to remove the antibiotics, wherein the mass ratio of the antibiotics to the PS is 1: (27-135), the antibiotics are sulfonamide antibiotics, and the PS refers to a salt capableof providing peroxydisulfate ions and mainly comprises one or a mixture of more of potassium peroxydisulfate, sodium peroxydisulfate and ammonium peroxydisulfate. The method does not need additionalenergy consumption, needs a simple reaction device, is low in cost, simple in process flow and easy to operate, and thus has a wide application prospect.

Owner:CHONGQING UNIV

Agent for bleaching hair with an initially red or red-blonde hair color

A subject of the present disclosure is a cosmetic agent to lighten keratinous fibers containing—relative to its total weight—(A) from about 12.0 to about 23.0 wt. % potassium peroxodisulfate and(B) from about 10.0 to about 20.0 wt. % ammonium peroxodisulfate and(C) from about 5.0 to about 15.0 wt. % sodium peroxodisulfate.A second subject of the present disclosure is a method for lightening keratinous fibers, particularly red and / or reddish-blond keratinous fibers, wherein an agent of the first subject of the present disclosure is mixed with at least one additional component containing hydrogen peroxide and applied to the hair.

Owner:HENKEL KGAA

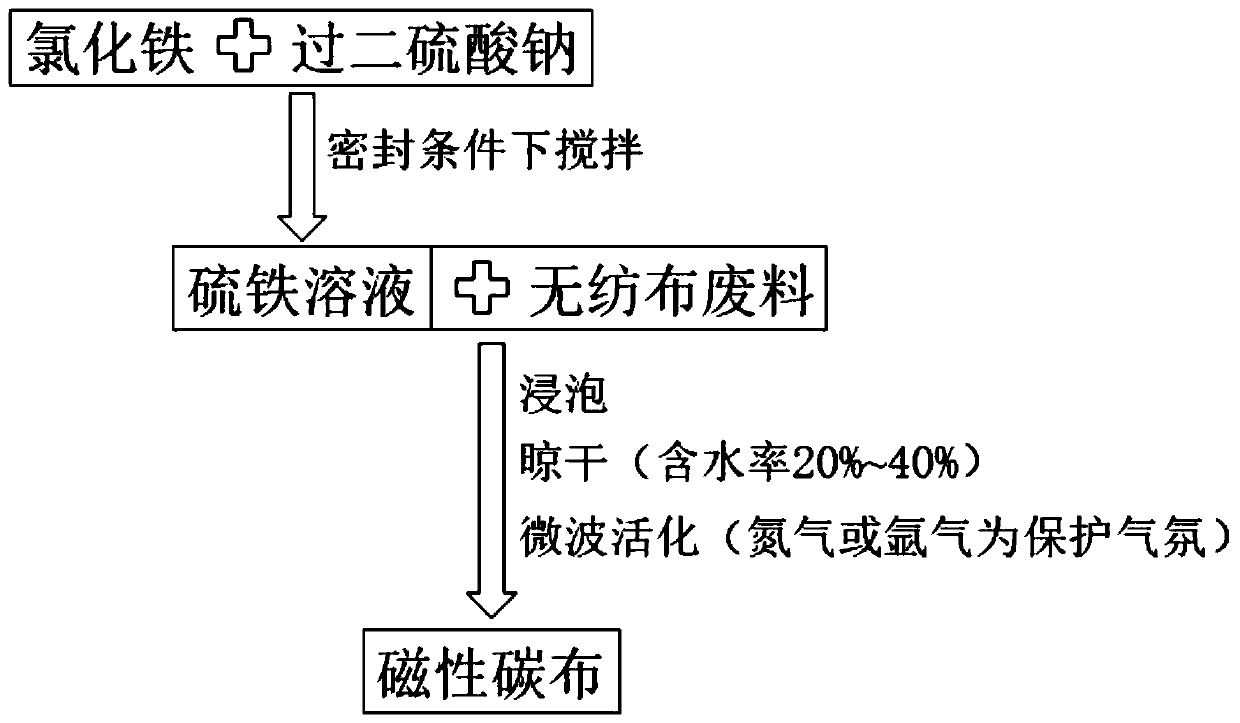

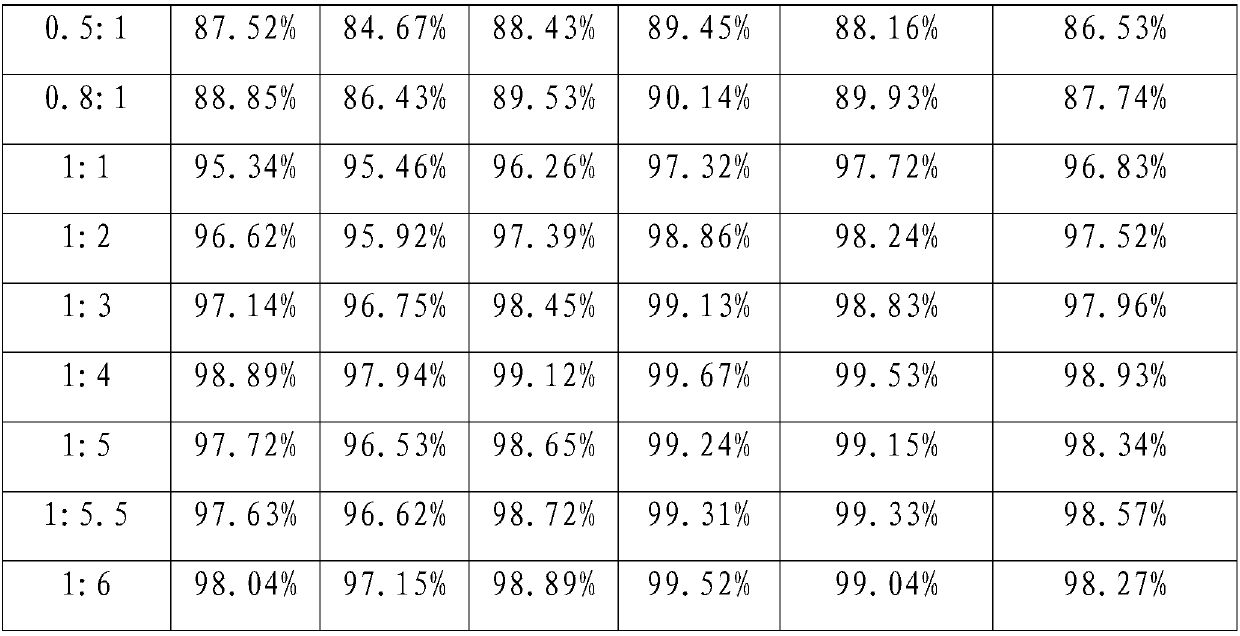

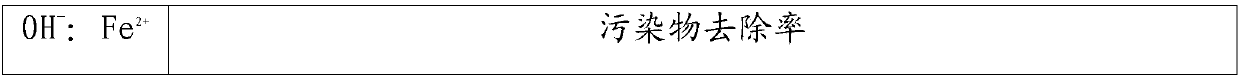

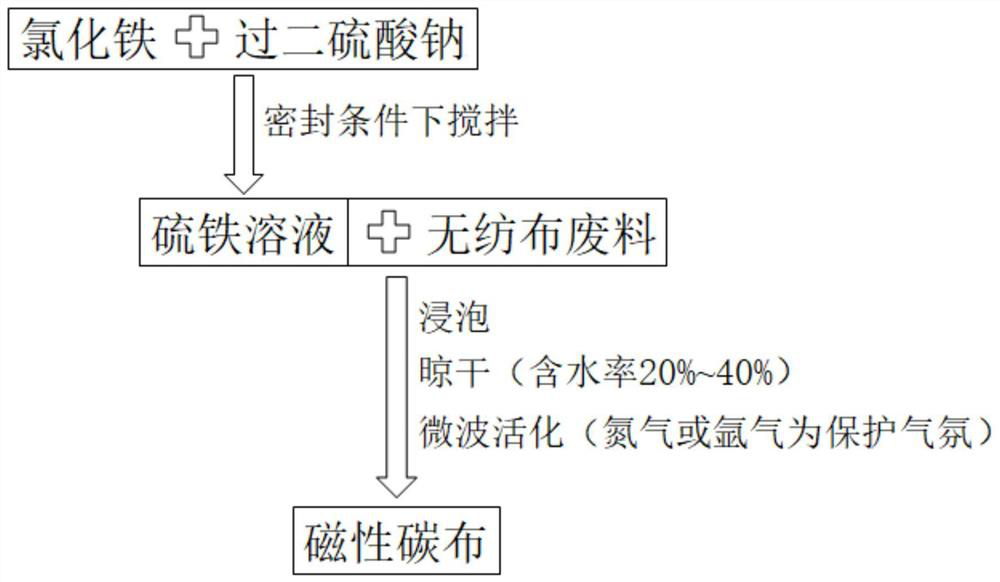

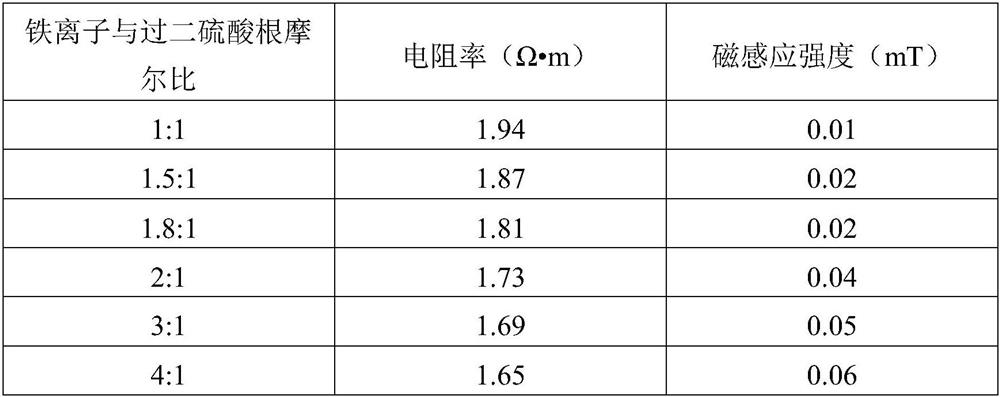

Method for preparing magnetic carbon cloth by utilizing non-woven fabric waste, magnetic carbon cloth prepared through method and application of magnetic carbon cloth

ActiveCN110512411AWide variety of sourcesEfficient use ofRadio/micro wave fibre treatmentFibre typesCarbonizationMicrowave shielding

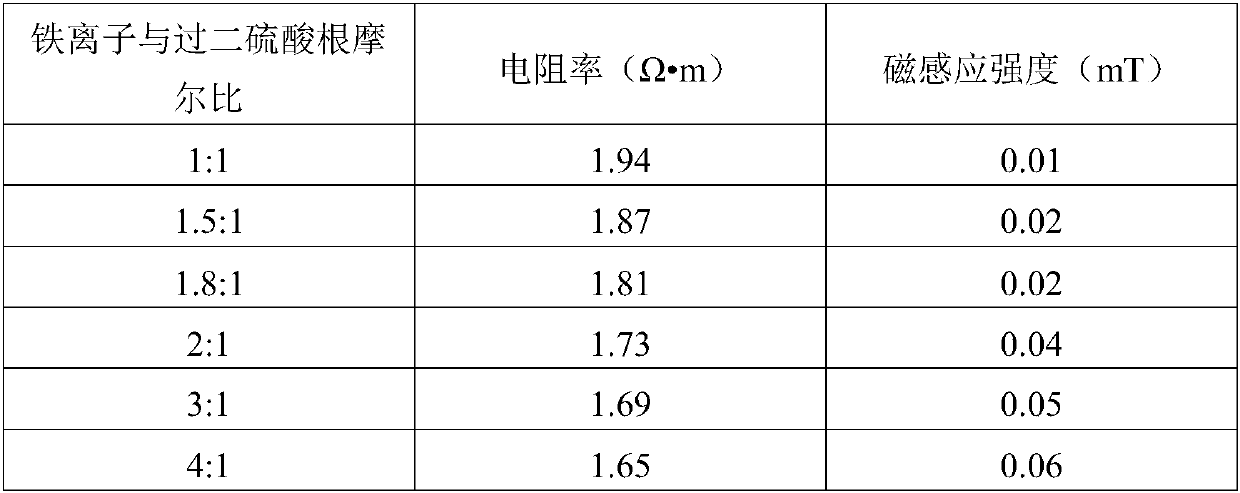

The invention discloses a method for preparing magnetic carbon cloth by utilizing non-woven fabric waste. The method comprises the following steps that ferric chloride and sodium persulfate are weighed separately, then dissolved in water, and stirred under the sealing condition until being dissolved completely, and a ferrous sulfide solution is prepared; a non-woven fabric is soaked in the ferroussulfide solution for 30-60 minutes under the sealing condition, and then taken out and dried until the water content is 20-40%; the obtained non-woven fabric is subjected to microwave activation in microwave shielding gas; after preset time is reached, microwave activation is ended, the non-woven fabric is cooled to the room temperature and then taken out, and the magnetic carbon cloth is obtained. The invention further includes the magnetic carbon cloth prepared through the method and application thereof. According to the method, iron ions and perbisulfate strengthen the carbonization process of the non-woven fabric waste, and magnetic ferrites are generated on the surface of the carbon cloth and effectively loaded; the minimum electrical resistivity of the magnetic carbon cloth preparedby utilizing the non-woven fabric waste is 1.37 omiga m, and the magnetic induction intensity is 0.12 mT.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Method of preparing carbon-based high valence silver molecule crystal battery

ActiveCN100491266CEnhance the performance of adsorbing organic toxic and harmful substancesRaise the ratioWater/sewage treatment using germicide/oligodynamic-processChemical reactionPotassium peroxodisulfate

The invention discloses a making method of carbon-based high-valent silver molecular crystal battery, which comprises the following steps: dissolving silver nitrate into pure water; stirring; placing the active carbon in the silver nitrate solution; adsorbing; filtering; drying the active carbon; placing the potassium peroxodisulfate or sodium peroxodisulfate as oxidizer into distilled water; adding sodium hydroxide; diluting; heating; stirring to react with dried active carbon; insulating; filtering; washing four times through pure water; obtaining the product with Ag4O4 distributed evenly on the surface of active carbon; displaying stronger chemical adsorbing ability and chemical reactivity; reinforcing the purifying capacity of organic toxic and harmful material absorbed by active charcoal.

Owner:TAIYUAN YINXIYUAN TECH CO LTD

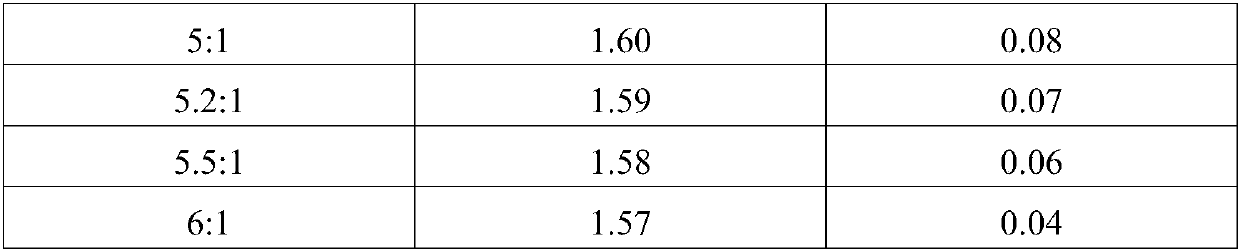

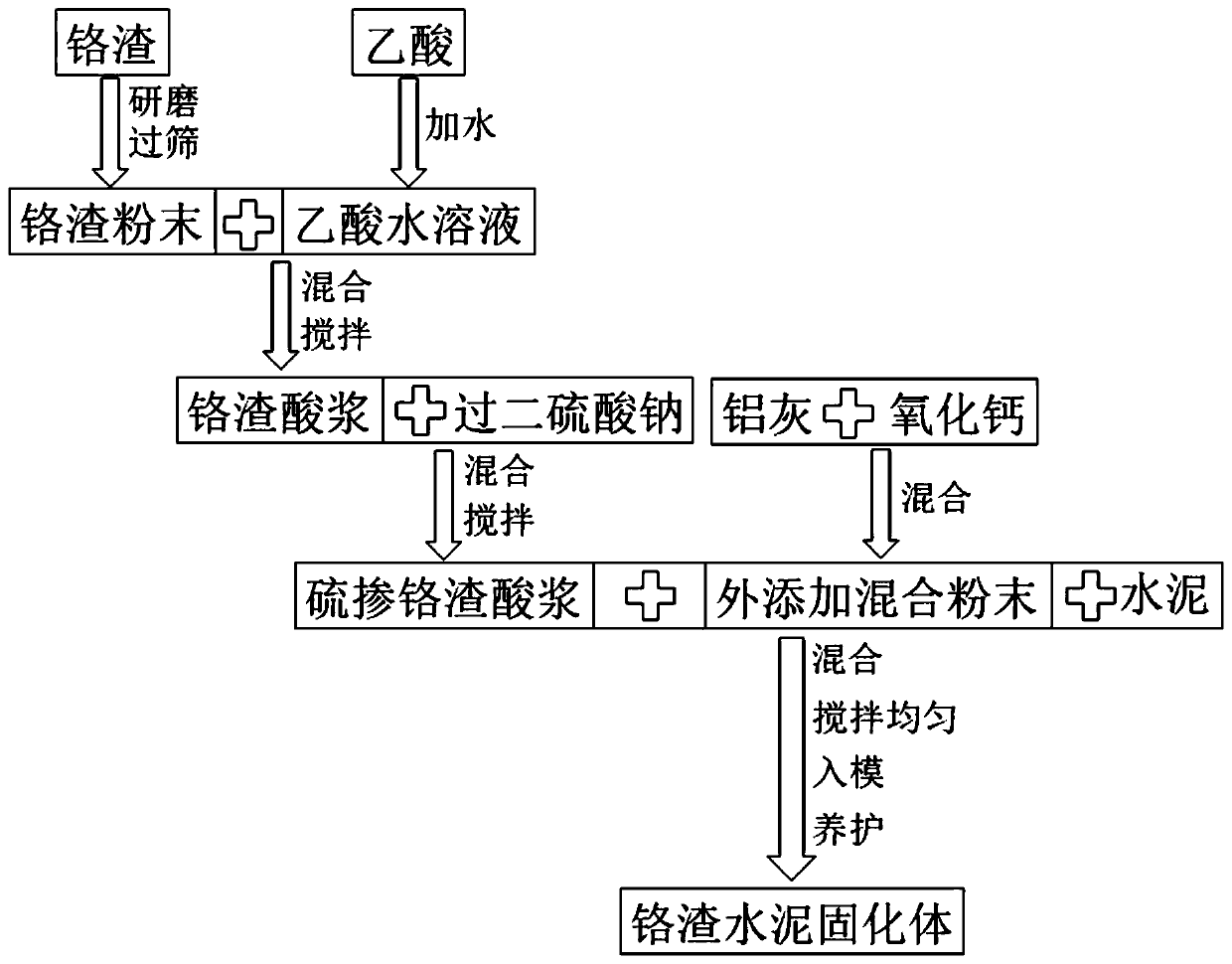

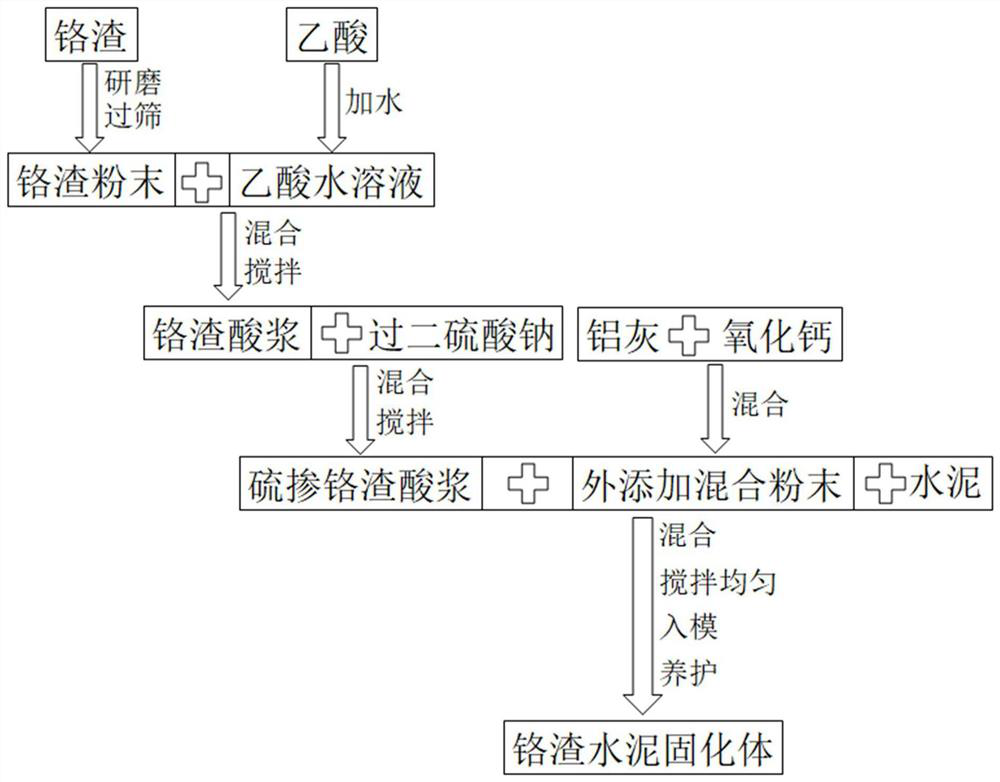

Method for improving cement solidified chromium slag and product thereof

ActiveCN111348881APackage completelyHigh uniaxial compressive strengthCalcium silicatePeroxydisulfate

The invention discloses a method for improving cement solidified chromium slag, which comprises the following steps: grinding and sieving chromium slag to obtain chromium slag powder; mixing an aceticacid aqueous solution with the chromium slag powder, and stirring to obtain chromium slag acid slurry; mixing sodium peroxydisulfate into the chromium slag acid slurry, and stirring until the sodiumperoxydisulfate is completely dissolved to obtain sulfur-doped chromium slag acid slurry; weighing aluminum ash and calcium oxide, and mixing to obtain externally added mixed powder; and respectivelyweighing the sulfur-doped chromium slag acid slurry, an externally added mixed powder and cement, mixing, uniformly stirring, putting an obtained mixture into a mold, and curing to obtain a chromium slag cement solidified body. The invention further discloses the chromium slag cement solidified body. By means of the method, reduction detoxification of chromium in the acid-leached state in the chromium slag can be achieved, and the chromium slag can be fully wrapped by generating ettringite, calcium acetate and chromium hydroxide to strengthen the hydrated calcium silicate hardening process. The uniaxial compressive strength of the chromium slag cement solidified body prepared through the method is 67.35% higher than that of a traditional chromium slag cement solidified body, and the leaching toxicity of hexavalent chromium is lower than that of the domestic waste landfill pollution control standard (GB16889-2008).

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

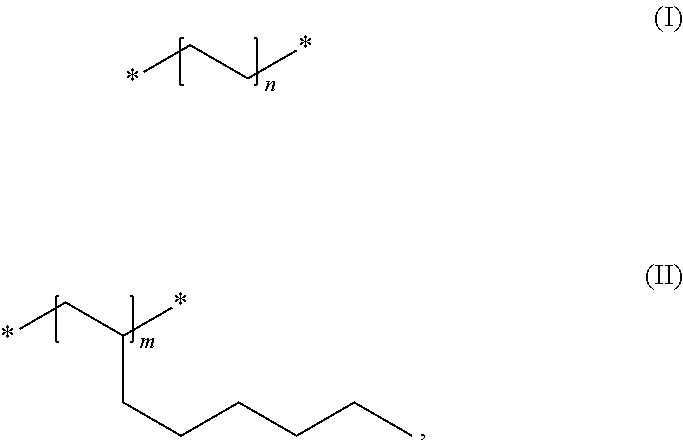

Bleaching agents having reduced oil-separation tendency

Bleaching agents with improved resistance to oil separation and better miscibility with dye-containing formulations comprise—in relation to their weight—from about 0.015 to about 10 wt.-% ethylene octene copolymer(s), from about 5 to about 70 wt.-% oil component(s), from about 1 to about 70 wt.-% peroxydisulfate(s) chosen from the group of sodium peroxodisulfate and / or potassium peroxodisulfate and / or ammonium peroxodisulfate, and ≦1 wt.-% free water.

Owner:HENKEL KGAA

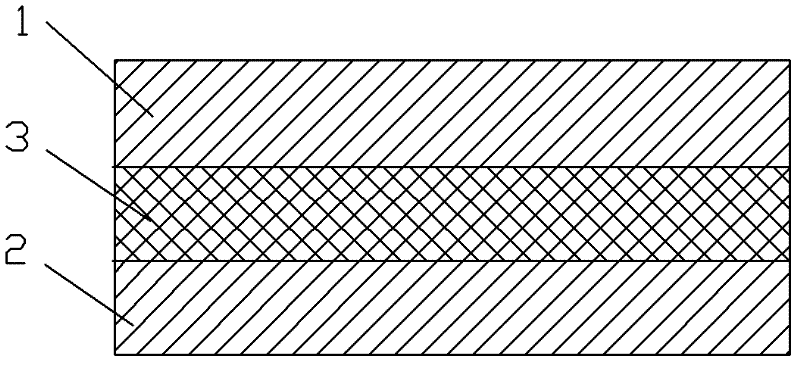

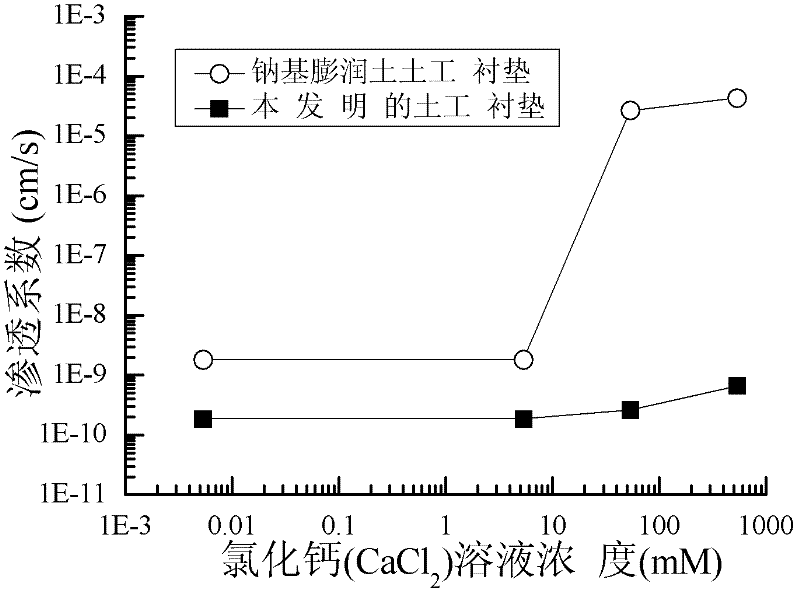

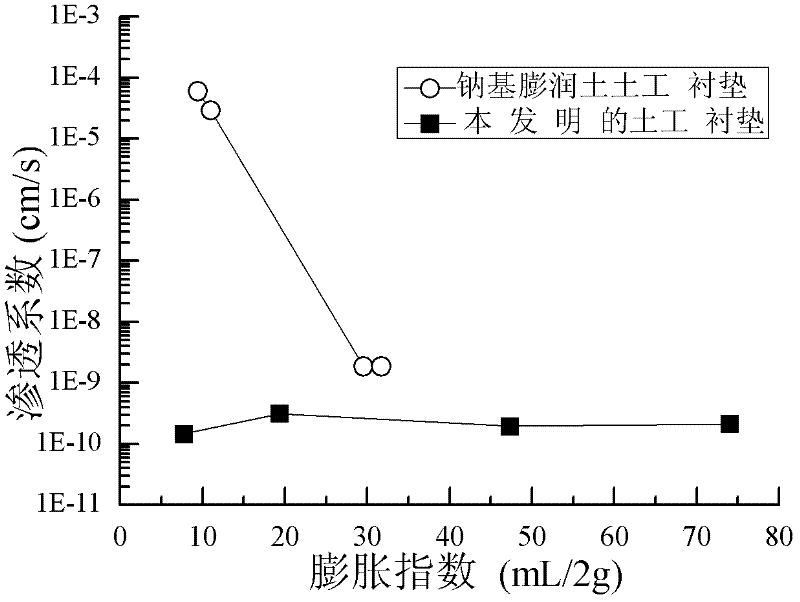

Soil engineering gasket suitable for environment containing multivalent cation mineral and preparation method thereof

InactiveCN102518151AImprove permeabilityGood expansion performanceProtective foundationClay processing apparatusSodium BentoniteDiluent

The invention discloses a soil engineering gasket suitable for an environment containing multivalent cation mineral and a preparation method thereof. The soil engineering gasket is fixedly connected between a first soil engineering layer and a second soil engineering layer by a nano bentonite composite material. The preparation method of the soil engineering gasket comprises: step 101, preparing the nano bentonite composite material: diluting acrylic acid to obtain acrylic acid diluent; adding sodium bentonite powder into the acrylic acid diluent to form bentonite grinding fluid; adding sodium persulfate solution into the bentonite grinding fluid, and adding sodium hydroxide powder to form composite bentonite slurry; and drying the composite bentonite slurry and grinding to obtain the nano bentonite composite material; and step 102, connecting the nano bentonite composite material between the first soil engineering layer and the second soil engineering layer. The soil engineering gasket is used in an environment containing multivalent cation mineral, and has stable permeability coefficient and good anti-seepage performance. The preparation method has a simple process and a short period.

Owner:SOUTHEAST UNIV

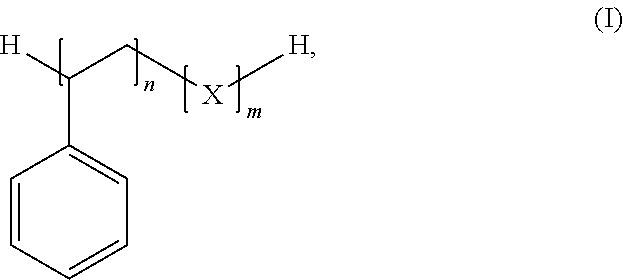

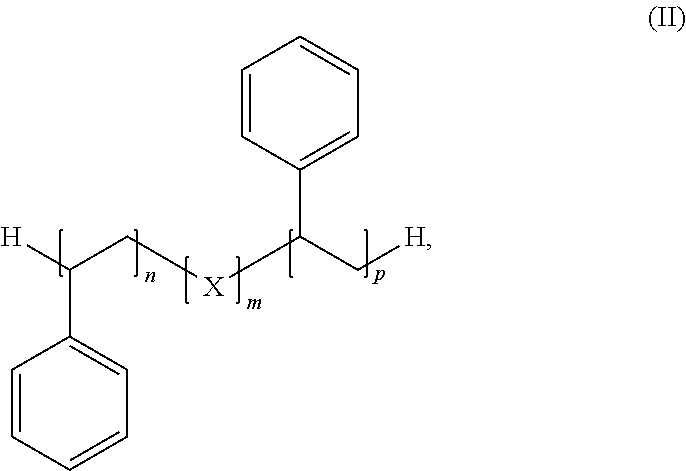

Foaming bleach-blonding compositions

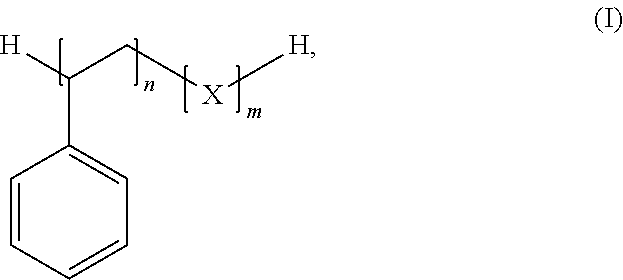

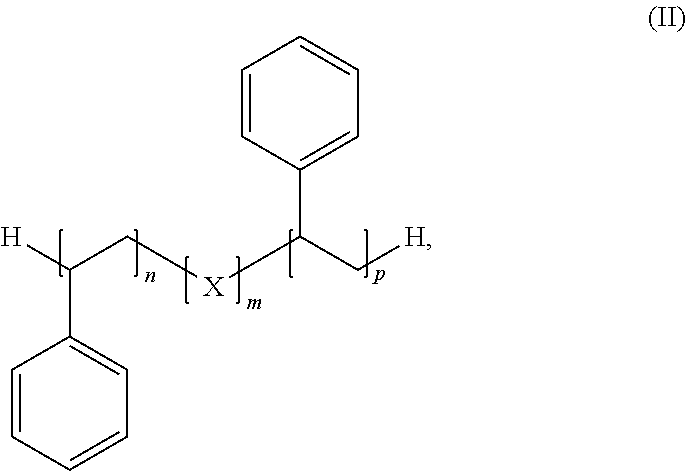

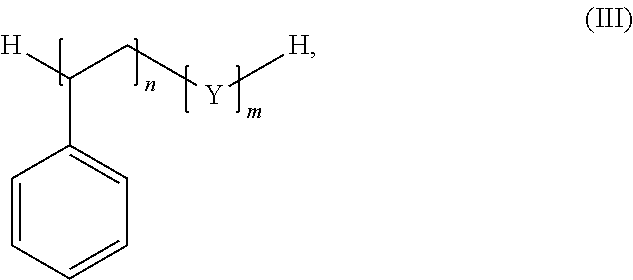

Agents for lightening keratinic fibers, which include, based on their weight, 20 to 75% by weight of oil(s), 0.05 to 5% by weight of polymer(s) from the group of ethylene / propylene / styrene copolymers and / or butylene / ethylene / styrene copolymers and / or butylene / propylene / styrene copolymers, and 1 to 70% by weight of peroxydisulfate(s), whereby the weight ratio of sodium peroxydisulfate in the agent to the total amount of peroxydisulfates in the agent is at least 0.2, possess increased storage stability, the improvement being not only in physical stability (sedimentation, phase separation) but also in chemical stability (degradation of the persalts). There are also improvements in product yield, spreadability of the application mixture, and the bleaching effect.

Owner:HENKEL KGAA

A kind of preparation method of waste water remediation agent based on incineration fly ash

ActiveCN109592776BDesyncEfficient removalWater treatment compoundsWater contaminantsSlagSodium sulfate

Owner:浙江中陶环保科技集团有限公司

A method for improving cement solidified chrome slag and its product

ActiveCN111348881BPackage completelyHigh uniaxial compressive strengthCalcium silicateChromium(III) hydroxide

The invention discloses a method for improving cement solidification of chromium slag, which comprises the following steps: grinding and sieving chromium slag to obtain chromium slag powder; mixing acetic acid aqueous solution and chromium slag powder, and stirring to obtain chromium slag slurry; Sodium sulfate is mixed into the chromium slag slurry, and stirred until the sodium peroxodisulfate is completely dissolved to obtain the sulfur-doped chromium slag slurry; the aluminum ash and calcium oxide are weighed and mixed to obtain an externally added mixed powder; the sulfur-doped chromium slag is weighed separately Physalis, externally added mixed powder and cement, mixed, stirred evenly, molded, cured, to obtain chromium slag cement solidified body. The invention also discloses a chromium slag cement solidified body. The method of the invention can not only realize the reduction and detoxification of chromium in the acid leachable state in the chromium slag, but also strengthen the hardening process of the hydrated calcium silicate by generating ettringite, calcium acetate and chromium hydroxide, so as to fully wrap the chromium slag. The uniaxial compressive strength of the chromium slag cement solidified body prepared by the present invention is 67.35% higher than that of the traditional chromium slag cement solidified body, and the leaching toxicity of hexavalent chromium is lower than "Standards for Pollution Control of Domestic Garbage Landfill Sites" (GB16889-2008 ).

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

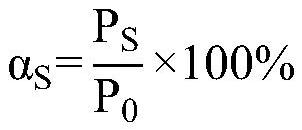

Method for preparing cerium phosphate by utilizing tetravalent cerium-containing waste liquid

ActiveCN111204727ANo effect on reduction efficiencyImprove reduction efficiencyPhosphorus compoundsCerium phosphateO-Phosphoric Acid

The invention discloses a method for preparing cerium phosphate by using tetravalent cerium-containing waste liquid, which comprises the following steps: 1) respectively weighing sodium persulfate andacetic acid, mixing, and stirring until the sodium persulfate is completely dissolved to obtain a reduction preparation solution; 2) mixing the tetravalent cerium-containing waste liquid with the reduction preparation liquid to obtain a cerium to-be-reduced liquid; and 3) adding phosphoric acid into the cerium to-be-reduced solution, fully stirring, heating, cooling, carrying out solid-liquid separation, and carrying out vacuum drying to obtain cerium phosphate. According to the method, the tetravalent cerium-containing waste liquid can be efficiently treated, the cerium recovery rate is as high as 99%, and the cerium phosphate yield is as high as 98%. Meanwhile, cerium phosphate is obtained in the process of treating the tetravalent cerium-containing waste liquid by applying the method,the generated waste liquid only contains sodium sulfate and sodium carbonate, the environmental friendliness is obvious, and secondary treatment is not needed.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

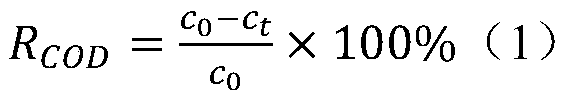

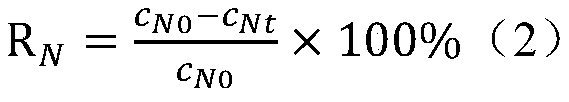

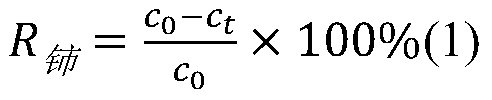

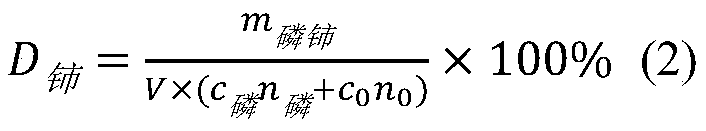

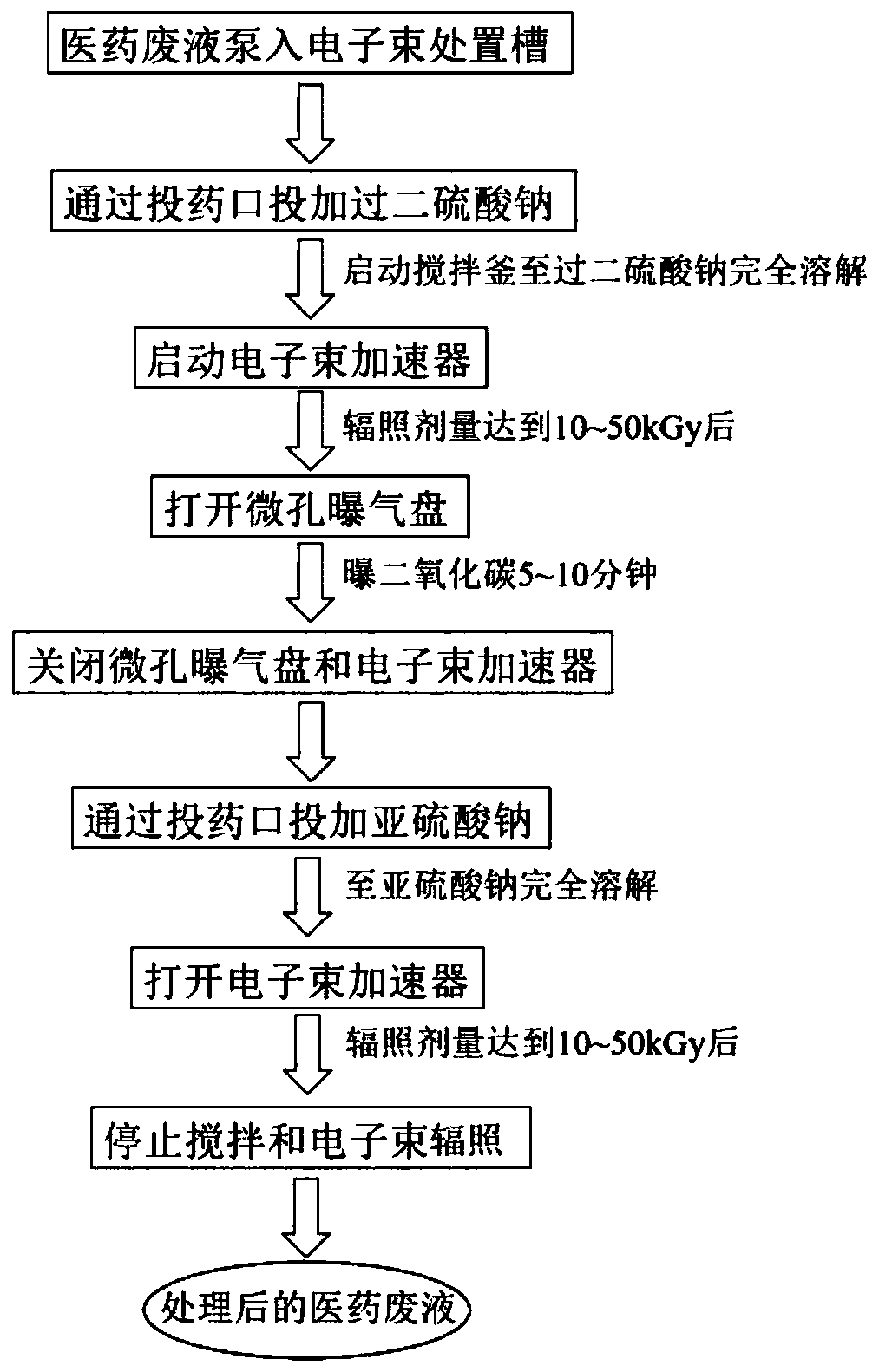

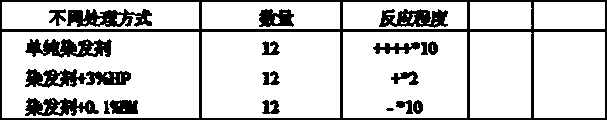

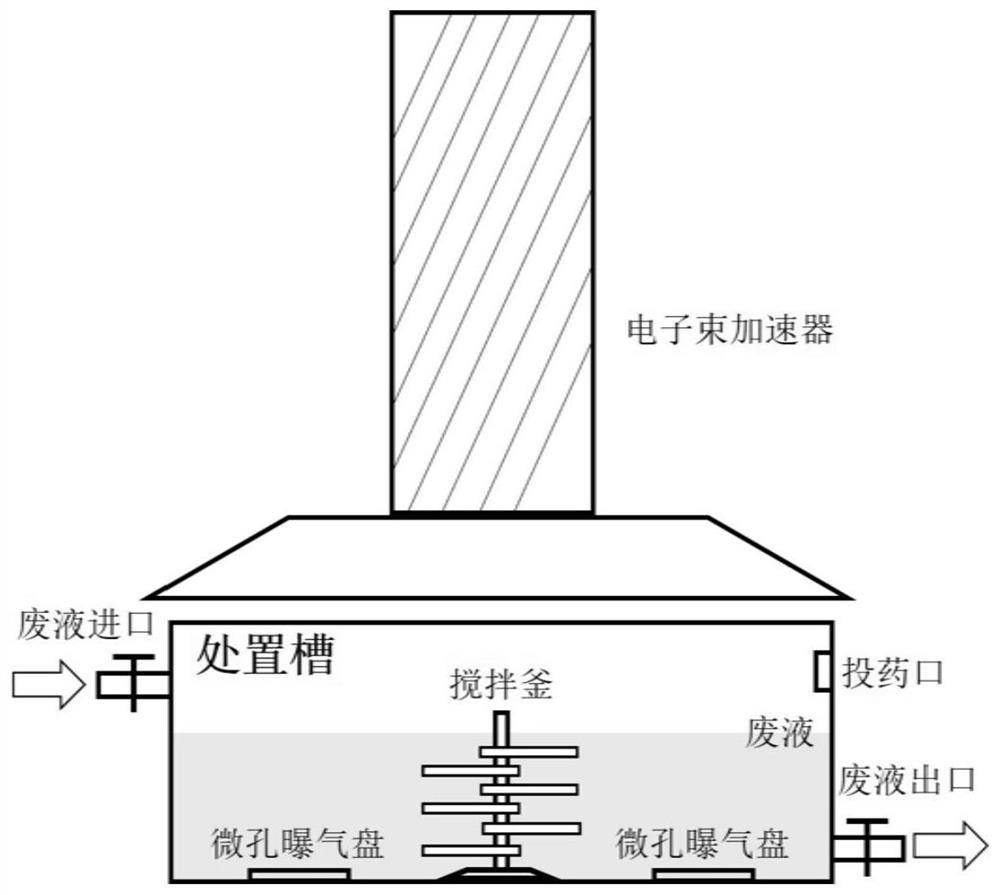

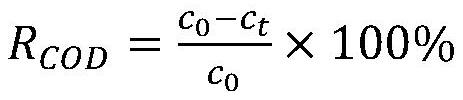

Method for treating medical waste liquid by utilizing electron beam irradiation technology

ActiveCN110372064AHigh removal rateSimple processing methodWater treatment parameter controlWater/sewage treatment by irradiationElectronElectron beam accelerator

The invention discloses a method for treating a medical waste liquid by utilizing an electron beam irradiation technology. The method comprises the following steps: introducing the medical waste liquid into an electron beam treatment groove, adding sodium persulfate into the treatment groove, carrying out stirring until the sodium persulfate is completely dissolved, starting an electron beam accelerator for irradiation treatment of medical wastewater, and aerating carbon dioxide into the treatment groove at the same time; stopping carbon dioxide aeration and irradiation treatment, then addingsodium sulfite into the treatment groove, carrying out stirring until the sodium sulfite is completely dissolved, starting the electron beam accelerator again for irradiation treatment of the medicalwastewater, and stopping stirring and irradiation treatment so as to complete one-time electron beam irradiation oxidation-reduction alternate reinforcement treatment. According to the invention, on the basis of a traditional electron beam irradiation wastewater treatment process, through addition of the sodium persulfate and the sodium sulfite, additional arrangement of a stirring kettle, aeration of the carbon dioxide and alternate reinforcement of oxidation effect and reduction effect in an electron beam irradiation stage, high COD removal rate of the medical waste liquid is realized; and the treatment method is simple.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

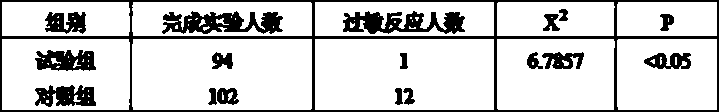

Protective method for blocking hair dye absorption and hair dye allergy

InactiveCN107753327AAvoid absorptionEasy to useCosmetic preparationsHair cosmeticsSodium bicarbonatePotassium persulfate

The invention discloses a protective agent and a protective method for blocking hair dye absorption. The protective agent comprises purified scutellaria baicalensis, purified astragalus membranaceus,sodium hydroxymethyl starch, sodium hydrogen carbonate, potassium persulfate, sodium peroxodisulfate, tartaric acid and the like. The blocking agent includes crystals thereof and configured various dosage forms. Through the protective agent and the protective method, occurrence of allergization and absorption poisoning when people use a hair dye can be reduced and prevented; effective therapeuticmeasures for p-phenylenediamine-allergized dermatitis are supplied to clinicians; disease conditions of hair dye allergic contact dermatitis patients can be significantly relieved, and the disease courses are shortened; allergic reactions of hair dye-sensitive users do not occur or seldom occur during and after dyeing; the hair dye containing the protective agent can also significantly shorten thehair dyeing time, the effect after hair dyeing is natural, and unsafe hair dyeing becomes safe. The protective agent is safe, convenient to use and reliable in effect, and can be applied to shampoos,matched hair dye boxes, external preparations for treating hair dyeing allergization, anti-allergic fur, wig dyes and the like.

Owner:刘全忠

A method for treating medical waste liquid by using electron beam irradiation technology

ActiveCN110372064BHigh removal rateSimple processing methodWater treatment parameter controlWater/sewage treatment by irradiationSulfite saltMedical waste

The invention discloses a method for treating medical waste liquid by electron beam radiation technology, which comprises the following steps: introducing the medical waste liquid into an electron beam disposal tank, adding sodium peroxodisulfate into the disposal tank, stirring until the sodium peroxodisulfate is completely Dissolve, start the electron beam accelerator to irradiate the medical wastewater, and at the same time expose carbon dioxide to the disposal tank; stop the exposure to carbon dioxide and irradiation treatment, then add sodium sulfite to the disposal tank, stir until the sodium sulfite is completely dissolved, and start the electron beam again The accelerator irradiates medical wastewater, stops stirring and irradiating treatment, and completes an electron beam irradiation oxidation-reduction alternate strengthening treatment. On the basis of the traditional electron beam irradiation wastewater treatment process, the present invention adds sodium peroxodisulfate and sodium sulfite respectively, adds stirring tank and carbon dioxide aeration, alternately strengthens the oxidation and reduction in the electron beam irradiation stage, and realizes the treatment of medical waste. Higher COD removal rate; simple treatment method.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

A method for synchronously realizing the detoxification of incineration fly ash and the reduction and solidification of chromium slag

The invention discloses a method for synchronously achieving incineration fly ash detoxification and chromium slag reduction curing. The method includes the following steps that (1), incineration flyash and tuff are weighed, mixed to be uniform and ground, and gelatinized powder is obtained; (2), sodium hydroxide and sodium silicate are weighed, mixed to be uniform and ground, and an alkali activator is obtained; (3), sodium persulfate and sodium oxalate are weighed, mixed to be uniform and ground, and a reductive detoxification inducer is obtained; (4), chromium slag, the gelatinized powder,the alkali activator and the reductive detoxification inducer are weighed, mixed to be uniform and ground, and fly ash and chromium slag powder is obtained; (5), the fly ash and chromium slag powderis weighed and dissolved in water, the materials are mixed to be uniform, and fly ash and chromium slag slurry is obtained; (6), the fly ash and chromium slag slurry is sealed, activated through microwaves, cooled and put in a die to be cured. The leaching concentrations of multiple heavy metals and dioxin in the fly ash and a chromium heavy metal in the chromium slag are all lower than the entrance limiting value of a municipal solid waste landfill. Treated cured bodies have high acid resistance and high constraint capacity for heavy metal inorganic pollutants and organic pollutants.

Owner:浙江中陶环保科技集团有限公司

Manufacturing method of a glass substrate for a magnetic disk

InactiveUS20130008463A1Efficient removalIncrease roughnessBase layer manufactureMagnetic disksSodium peroxodisulfate

Owner:HOYA CORP

Liquid composition for removing titanium nitride, semiconductor-element cleaning method using same, and semiconductor-element manufacturing method

ActiveUS9777251B2Anionic surface-active compoundsDetergent mixture composition preparationDielectricTitanium nitride

This invention provides a liquid composition that removes titanium nitride from a substrate without corroding tungsten or a low-k interlayer dielectric also present on said substrate. Said liquid composition has a pH between 0 and 4, inclusive, and contains the following: at least one oxidizing agent (A) selected from the group consisting of potassium permanganate, ammonium peroxodisulfate, potassium peroxodisulfate, and sodium peroxodisulfate; a fluorine compound (B); and a tungsten-corrosion preventer (C). The tungsten-corrosion preventer (C) either contains at least two different compounds selected from a group of compounds (C1) consisting of alkylamines, salts thereof, fluoroalkylamines, salts thereof, and the like or contains at least one compound selected from said group of compounds (C1) and at least one compound selected from a group of compounds (C2) consisting of polyoxyalkylene alkylamines, polyoxyalkylene fluoroalkylamines, and the like. The mass concentration of potassium permanganate in the abovementioned oxidizing agent (A) is between 0.001% and 0.1%, inclusive, and the mass concentration of the abovementioned fluorine compound (B) is between 0.01% and 1%, inclusive.

Owner:MITSUBISHI GAS CHEM CO INC

Foaming bleach-blonding compositions

Agents for lightening keratinic fibers, which include, based on their weight, 20 to 75% by weight of oil(s), 0.05 to 5% by weight of polymer(s) from the group of ethylene / propylene / styrene copolymers and / or butylene / ethylene / styrene copolymers and / or butylene / propylene / styrene copolymers, and 1 to 70% by weight of peroxydisulfate(s), whereby the weight ratio of sodium peroxydisulfate in the agent to the total amount of peroxydisulfates in the agent is at least 0.2, possess increased storage stability, the improvement being not only in physical stability (sedimentation, phase separation) but also in chemical stability (degradation of the persalts). There are also improvements in product yield, spreadability of the application mixture, and the bleaching effect.

Owner:HENKEL KGAA

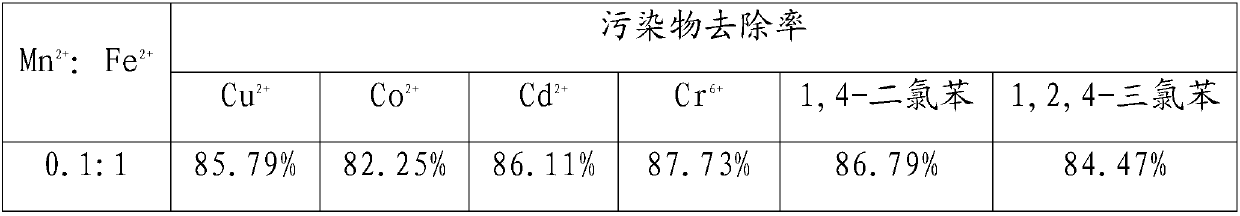

Preparation method of ferrous-per-disulfide-based composite remover

InactiveCN109607665AEasy to prepareReduce manufacturing costWater contaminantsWater/sewage treatment by magnetic/electric fieldsSodium peroxodisulfateMineralogy

The invention provides a preparation method of a ferrous-per-disulfide-based composite remover, and belongs to the technical field of waste water treatment. A mixed ferro-manganese solution is prepared, alkali liquor is prepared, the alkali liquor is mixed in the mixed ferro-manganese solution, and ferro-manganese two-phase hydroxide ore pulp is obtained; the ore pulp is vacuum-dried to achieve constant mass, the ore pulp is ground, and ferro-manganese two-phase hydroxide is obtained; sodium per-disulfide is added, the materials are ground, and ferro-manganese disulfide hydroxide powder is obtained; complexing iron powder is added into the ferro-manganese disulfide hydroxide powder, and the finished ferrous-per-disulfide-based composite remover is obtained. The composite remover is appliedto water body treatment, and the requirements of treatment of an acidic water body, an alkaline water body and a neutral water body can be simultaneously met.

Owner:SHAOXING ENVIRONREM ENVIRONMENTAL TECH CO LTD

Method for preparing magnetic carbon cloth from non-woven fabric waste, magnetic carbon cloth and application thereof

ActiveCN110512411BWide variety of sourcesEfficient use ofRadio/micro wave fibre treatmentFibre typesMagnetic carbonIron chloride

The invention discloses a method for preparing magnetic carbon cloth from non-woven fabric waste, which comprises the following steps: respectively weighing ferric chloride and sodium peroxodisulfate, then dissolving them in water, stirring until they are completely dissolved under sealed conditions, and preparing iron sulfur solution ; Immerse the non-woven fabric in the iron sulfur solution, and soak it for 30-60 minutes under sealed conditions, then take out the non-woven fabric and dry it until its moisture content is 20%-40%; Microwave activation is carried out in the middle; after the preset time is reached, the microwave activation is terminated, and the magnetic carbon cloth is obtained after cooling to room temperature. The content of the present invention also includes the magnetic carbon cloth prepared by the method and its application. The invention strengthens the carbonization process of non-woven fabric waste through iron ions and peroxodisulfate radicals, simultaneously generates and effectively loads magnetic ferrite on the surface of the carbon fabric. The resistivity of the magnetic carbon cloth prepared by using the non-woven fabric waste in the invention is at least 1.37Ω•m, and the magnetic induction intensity is 0.12mT.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com