A method for improving cement solidified chrome slag and its product

A technology of cement solidification and chrome slag, which is applied in the field of harmless disposal of hazardous solid waste, and can solve problems such as the reduction of solidified body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

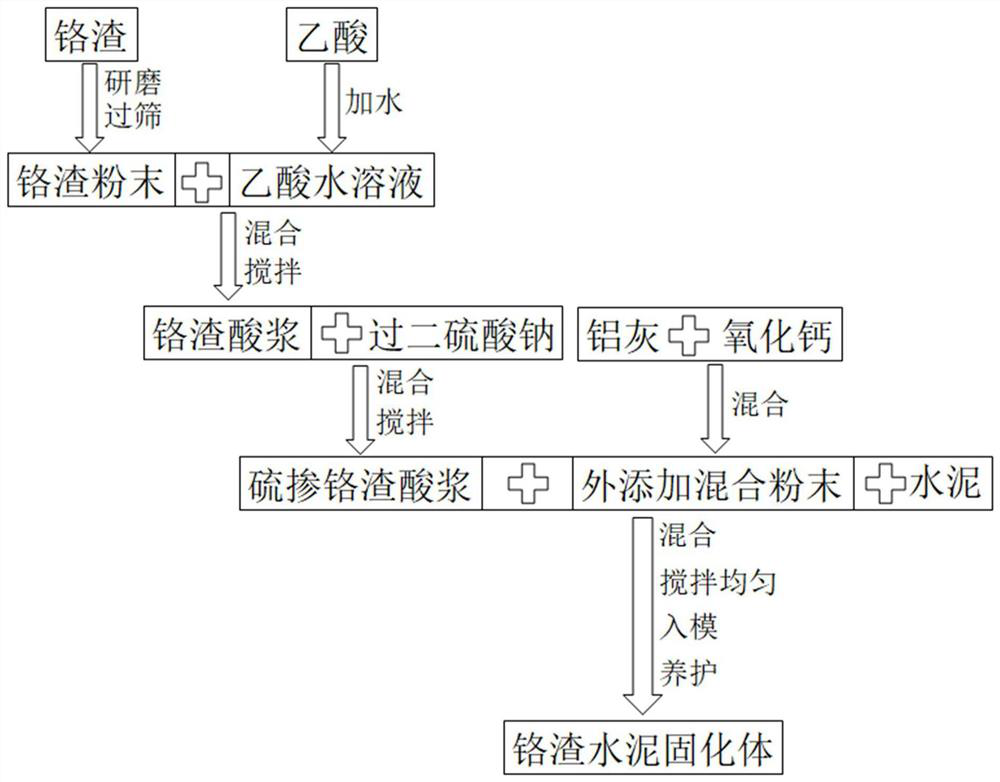

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Effect of acetic acid concentration on cured body curing chromium residue

[0025] The chromium residue is ground, and the 200 mesh sieve is obtained. A acetic acid solution was formulated in water, 0.05 m, 0.07 m, 0.09 m, 0.1 m, 0.15 m, 0.2 m, 0.21 m, 0.23 m, 0.25 M, a acetic acid solution. The aqueous solution of acetic acid and chromium residue powder was mixed according to liquid solid ratio of 0.8: 1 mL / g, stirred for 30 minutes, and the nine-group chromium slag acid pulp was obtained. Following sodium sodium sodium sulfate and chromium slabs were mixed into chromium slabs in 3:100, stirred until the sodium sulfate was completely dissolved, and the nine sets of sulfur droolite delate. Aluminum ash and calcium oxide, mixed, and mixed with aluminum oxide, mixed, and additionally added mixed powders. According to the sulfur drooprogen: additional mixed powder: cement mass rather than 40:5: 100 Group chrome slag cement cured body.

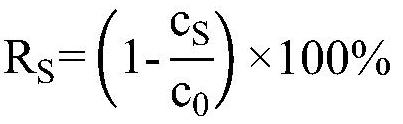

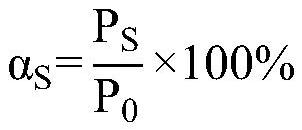

[0026] Single-axial compress...

Embodiment 2

[0037] Example 2 Effect of sodium hyperodaryate and chromium residue mass compared to cured body solidified chrome

[0038] The chromium residue was ground, and the 300 mesh sieve was obtained, and the chrome slag powder was obtained. The acetic acid was added to water, and 0.2 M a aqueous solution was formulated. The aqueous solution of acetic acid and chromium residue powder was mixed according to liquid solid ratio of 1: 1 ml / g, stirred for 45 minutes, and chrome slabs. According to the mass of sodium sodium sulfate and chromium slag, 2:100, 2:100, 2.5:100, 3:100, 5:100, 7:100, 7.5:100, 8:100, 9:100 will pass two Sodium sulfate is mixed into the chromium slabs, stirred to sodium sulfate is completely dissolved, and the nine sets of sulfur bleed chromery. Aluminum ash and calcium oxide, mixed, and mixed with aluminum oxide, mixed, and additionally added mixed powders. According to the sulfur drooprogen: additional mixed powder: cement mass rather than 60:10: 100 Group chrome s...

Embodiment 3

[0043] Example 3 Effect of aluminum ash and calcium oxide mass compared to cured body solidified chrome

[0044] The chromium residue is ground, and the 400 mesh sieve is obtained. The acetic acid was added to water, and 0.2 M a aqueous solution was formulated. The aqueous solution of acetic acid and chromium residue powder was mixed according to liquid solid ratio of 1.2: 1 ml / g, stirred for 60 minutes, and chrome slabs. According to sodium sodium sulfate, sodium sodium sodium sodium sodium sulfate is mixed into chromium slabs, stirred to sodium sulfide, and sulfur drooproid. Co-aluminum ash and oxidation Calcium, mixed, adding a mixed powder addition in nine groups. According to the sulfur droopolymeral tester: additional mixed powder: cement mass rather than 80:15: 100 Group of chrome slag cement solidification blocks.

[0045] Uniaxial compressive strength detection, chromium immersion toxicity detection, chromium curing ratio, cured body corrosion resistance test, corrosion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com