Patents

Literature

235 results about "Cement cure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The curing period for concrete is approximately 28 days after placing conventional concrete. New concrete can be wet with soaking hessian, sprinklers or covered with wet hessian or plastic sheets or can be watered with commercially available curing compounds which seal in moisture.

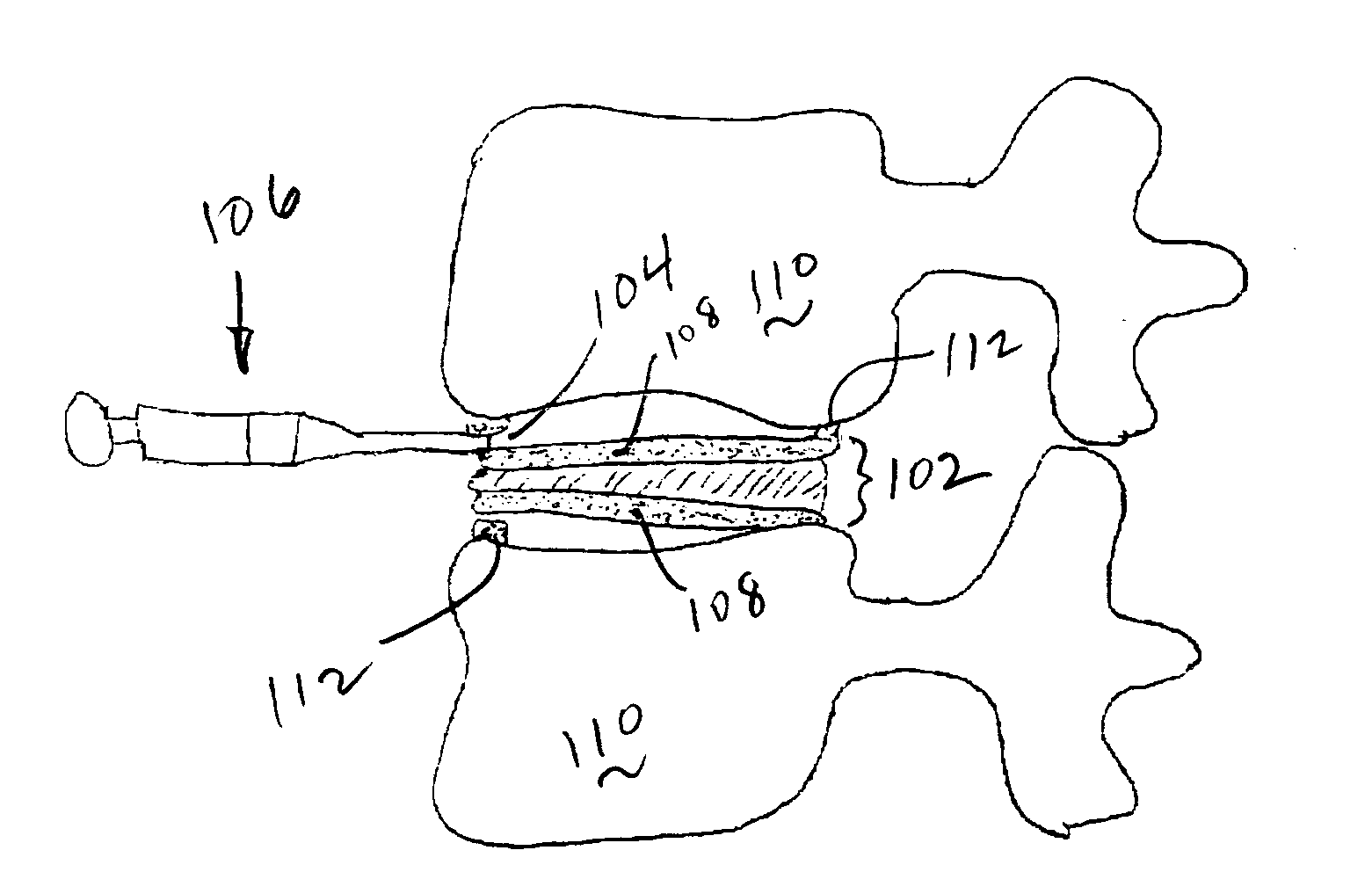

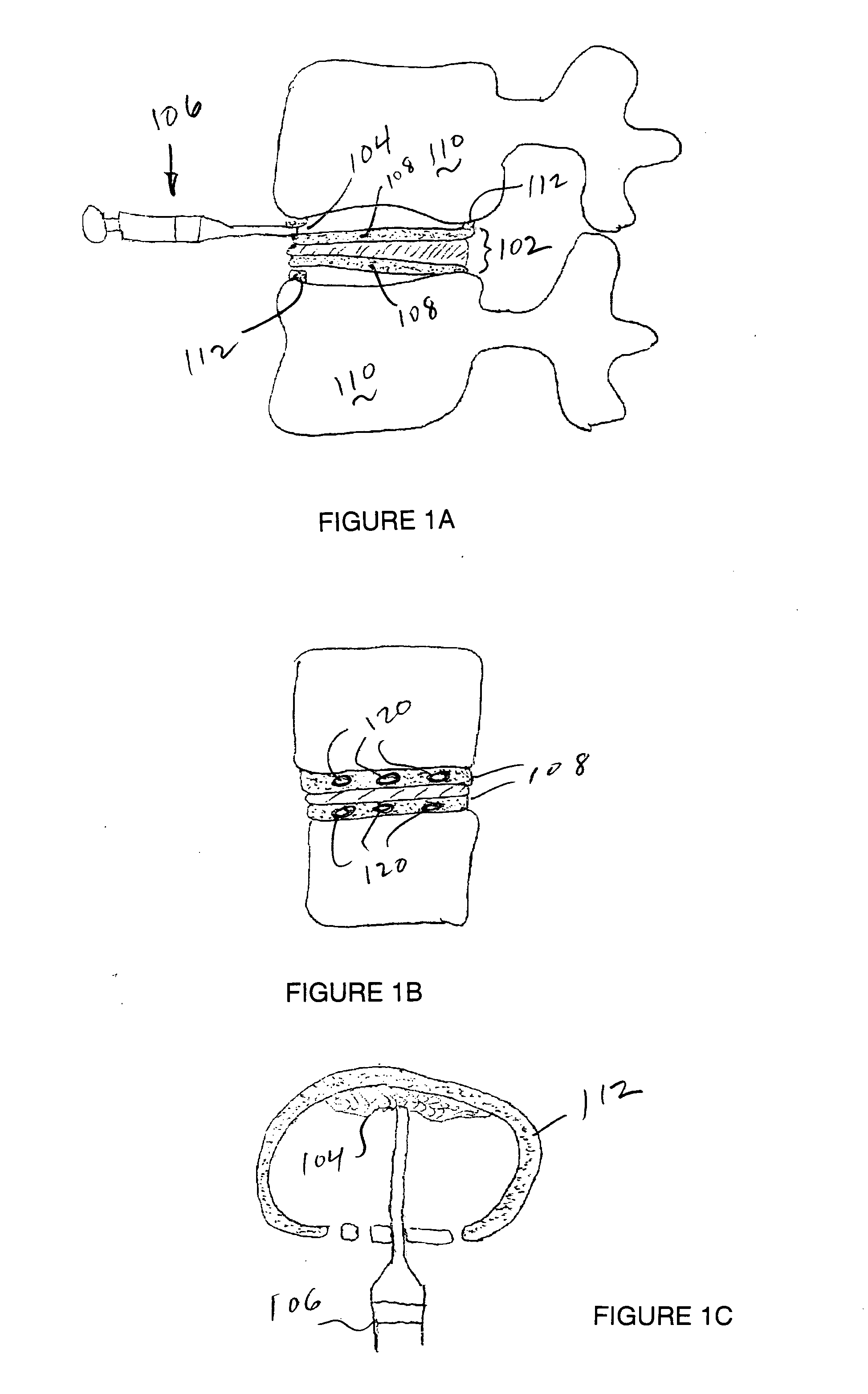

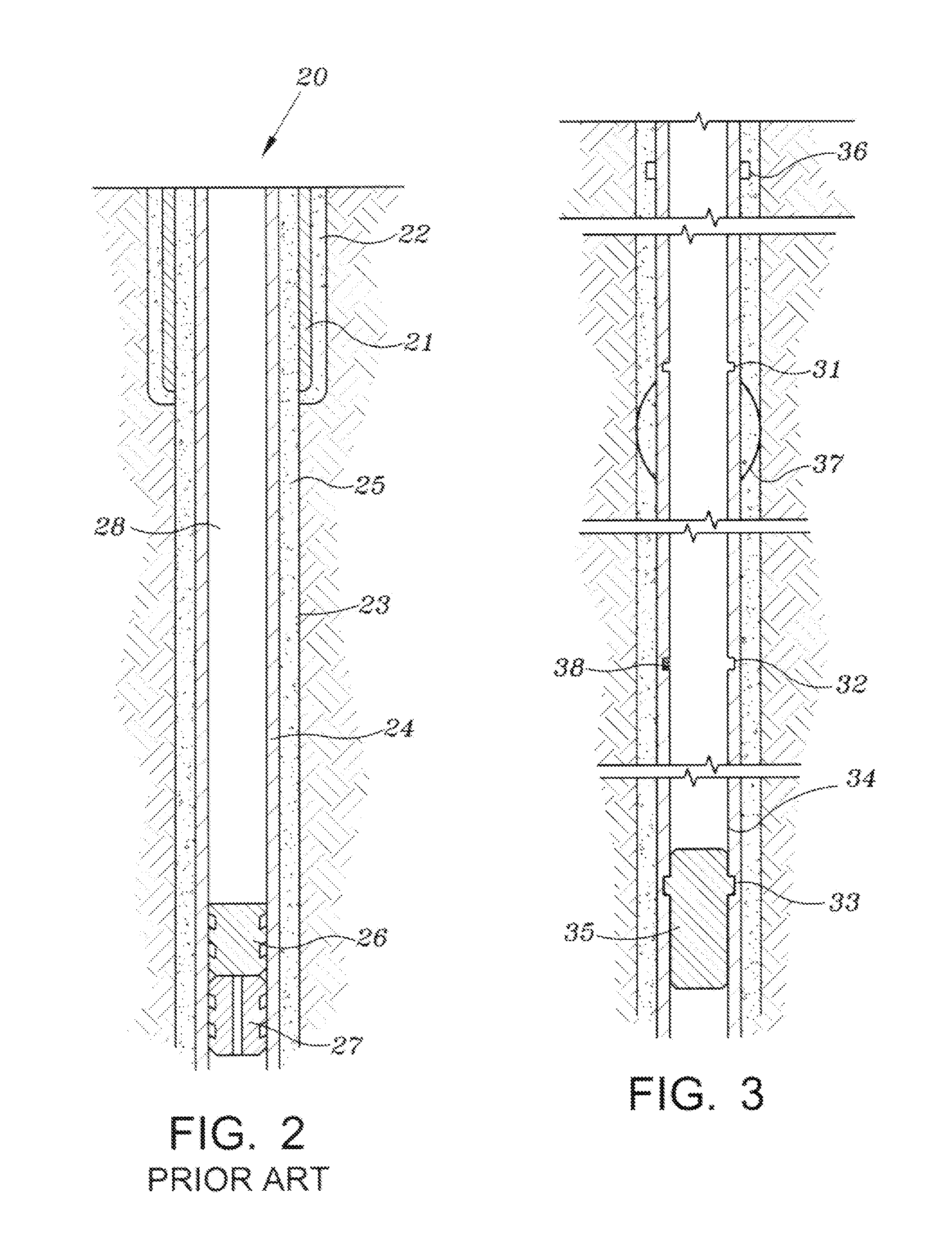

Cemented artificial disc replacements

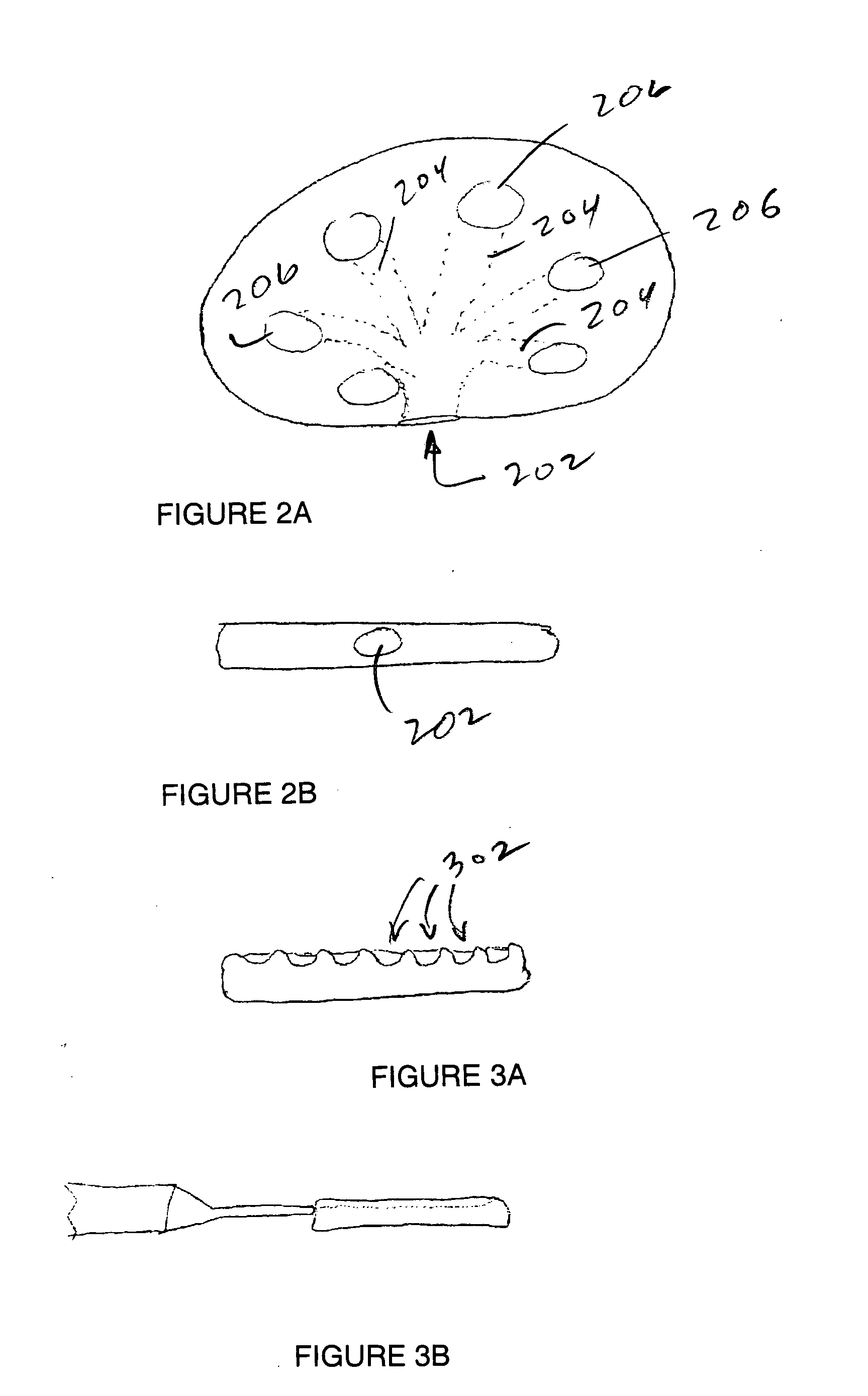

Cementation in place of, or in conjunction with, artificial disc replacements (ADRs) to provide numerous advantages over existing techniques. Methods, instruments, and systems are disclosed. A preferred method of fixing an artificial disc replacement (ADR) to a vertebral endplate according to the invention includes locating a component of the ADR in spaced-apart relation to the vertebral endplate and introducing cement between the component and the vertebral endplate. The “introduction” may be carried out through manual packing or forced injection using inventive instrumentation. The component of the ADR may be a rigid endplate, or it may be constructed of polyethylene or other suitable polymeric material. The component may further articulate with a second component. A system according to the invention involving an artificial disc replacement (ADR) configured for placement between opposing vertebral endplates would comprise a component forming a cavity between the component and one of the vertebral endplates, and a path to fill the cavity with cement. Again, the path may be formed in the component with a channel or groove, with or without a peripheral rim, or the path may be formed through a vertebral body. The system may further include various instruments, including an instrument for urging the component against the vertebral endplate until the cement cures, for injecting the cement prior to insertion of the component, for pressurizing the cement following introduction, or for removing excess, cured cement prior to placement of the ADR.

Owner:ANOVA

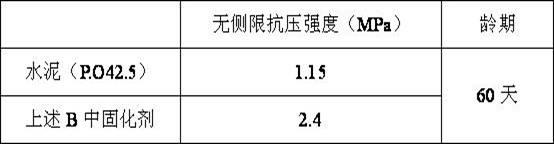

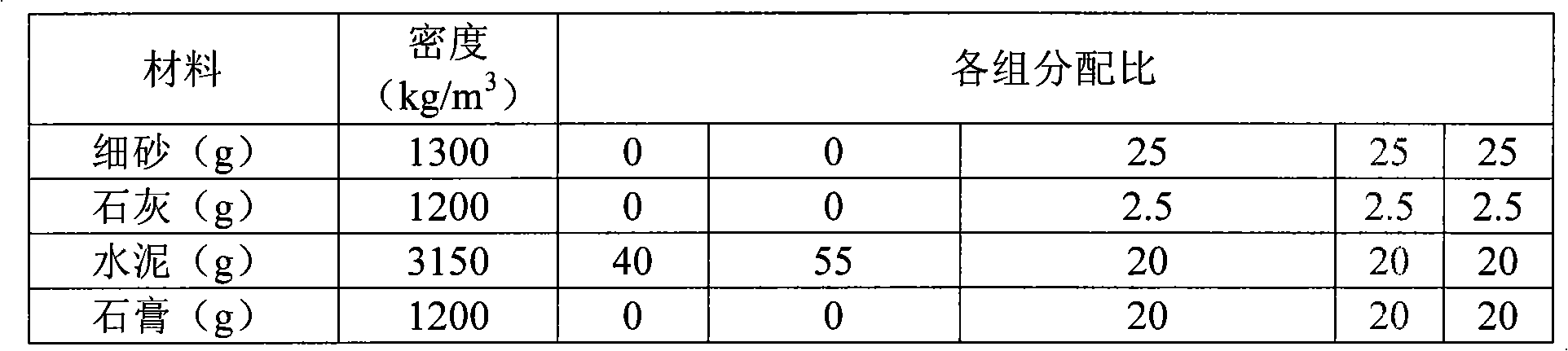

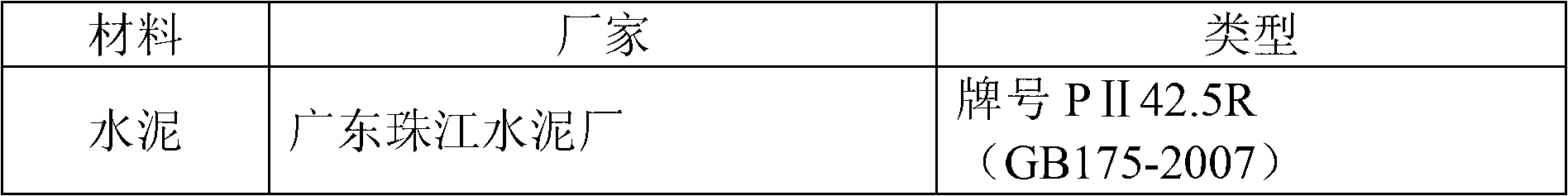

Clay slurry curing agent

The invention discloses a clay slurry curing agent. The curing agent is physically formed by mixing mineral powder and cement which are taken as main gel ingredients with little exciting agent and other auxiliary agents; and under the same condition, compared with the cement with the same mass, the final strength of the prepared slurry consolidation is improved by 100 to 800 percent by adopting the curing agent when the clay slurry with different finenesses is cured by adopting the curing agent. The clay curing slurry formed by adopting the curing agent and the clay slurry can be widely applied to engineering, such as filling and reinforcing of underground cavities, stratum seepage prevention, water plugging and the like.

Owner:湖南宏禹工程集团有限公司

Multiple Mode Accelerating Agent For Cementitious Materials

InactiveUS20080202389A1Accelerate cement hydration reactionSpeedCarbon captureHydration reactionCarrier fluid

A multiple mode cement set accelerating agent is provided. The accelerating agent includes a carrier fluid component having accelerator properties and CO2 gas sequestered in the carrier fluid. The accelerator components of the carrier fluid speed up the cement setting reaction. Additionally, CO2 gas is released from the carrier fluid during cement hydration to further accelerate the hydration reaction. In certain implementations, the carrier fluid is an alkanolamine solution and the cement set accelerating agent operates through a combination of alkali activation and carbonation. The multiple mode cement cure accelerating agent can be applied to pre-selected regions of green shaped cementitious articles to form partially cured zones in the article prior to curing of the green shaped article.

Owner:JAMES HARDIE INT FINANCE BV

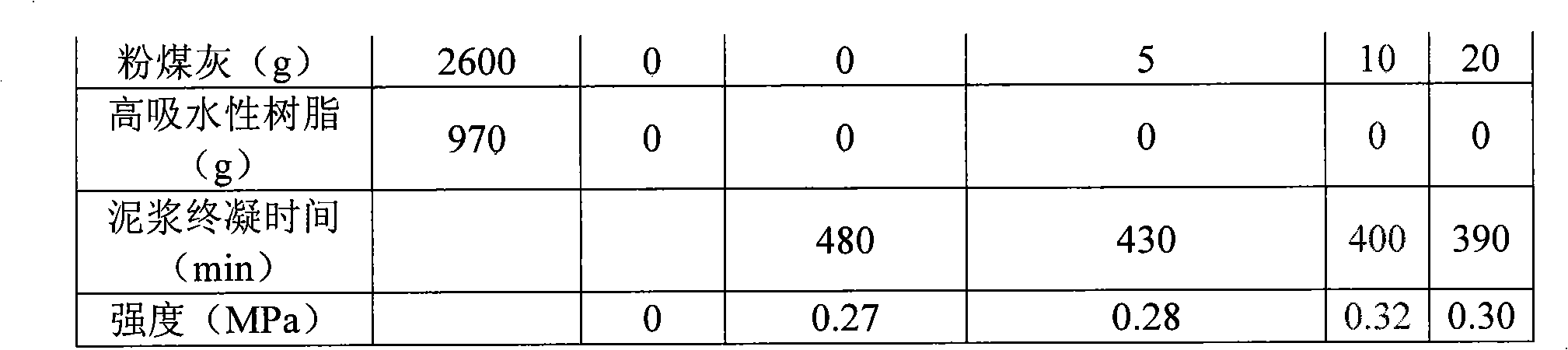

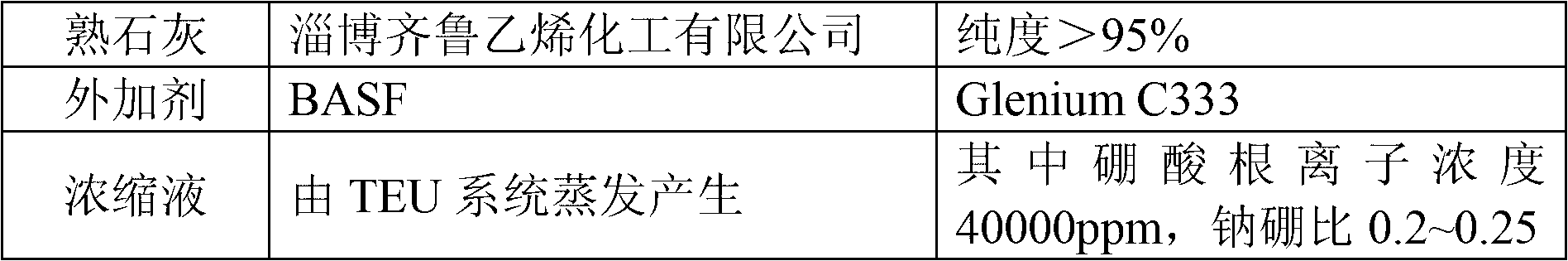

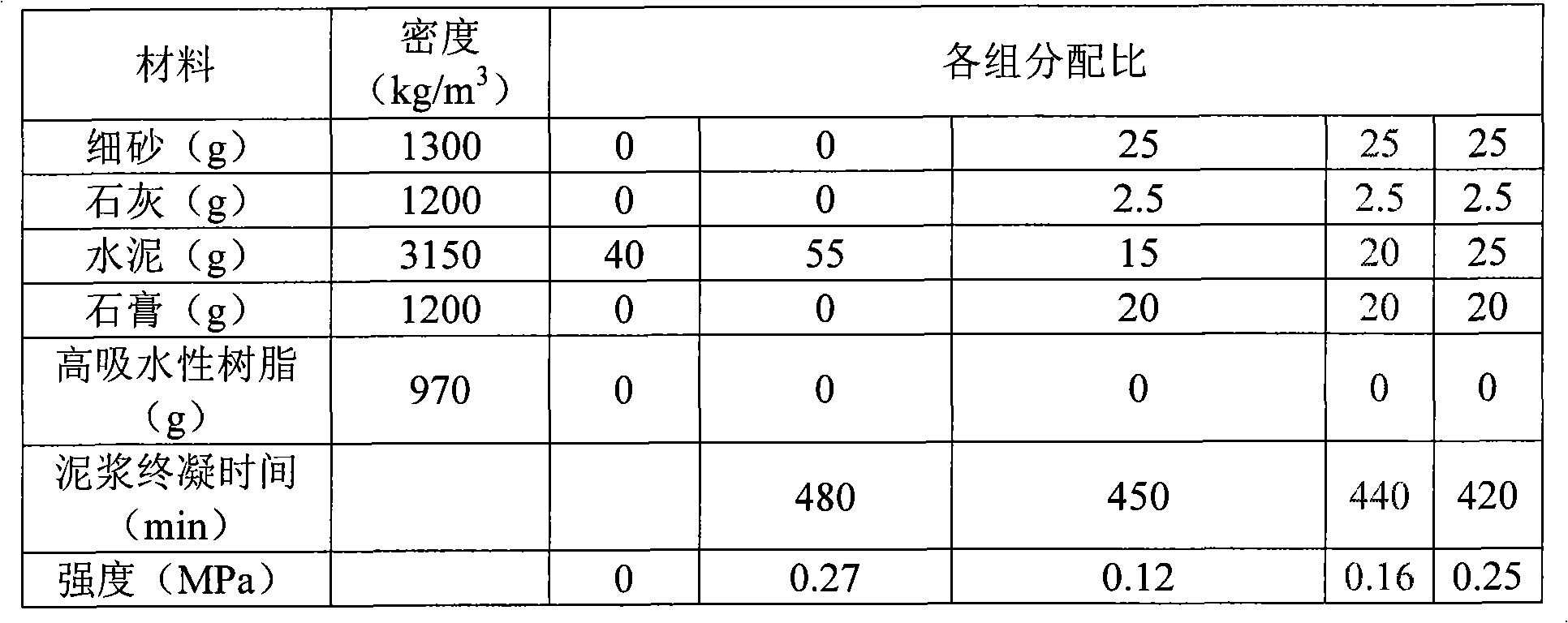

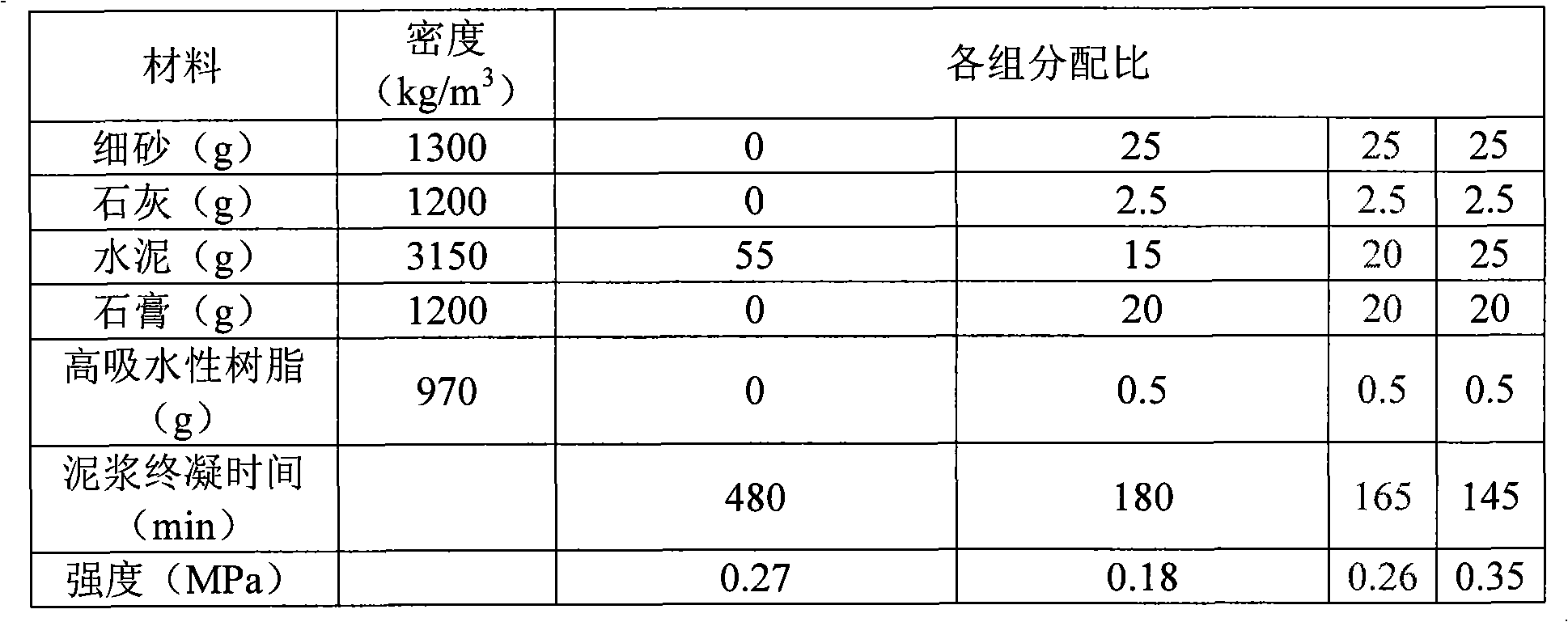

Compound curing agent of high cement slurry

The invention relates to a compound type slurry curing agent for conducting curing treatment on waste slurry generated in geotechnical engineering (for example, investigation drilling, cast-in-place pile, anchorage engineering, trenchless construction and the like), as well as the sludge at the bottom of reservoirs, ditches, ponds, pools and the like. In the invention, the compound type slurry curing agent is prepared by adding and mixing fine sand, lime, industrial waste gypsum, fly ash and super absorbent resin in cement curing agent evenly according to a certain proportion. The slurry curing agent greatly improves the curing effect of slurry, reduces the use amount of cement and lowers the cost. Besides, by doping industrial wastes such as waste gypsum, fly ash and the like in cement, the pollution to the environment is abated, the recycle of wastes is promoted and favorable economic and social benefits are available.

Owner:WENZHOU UNIVERSITY

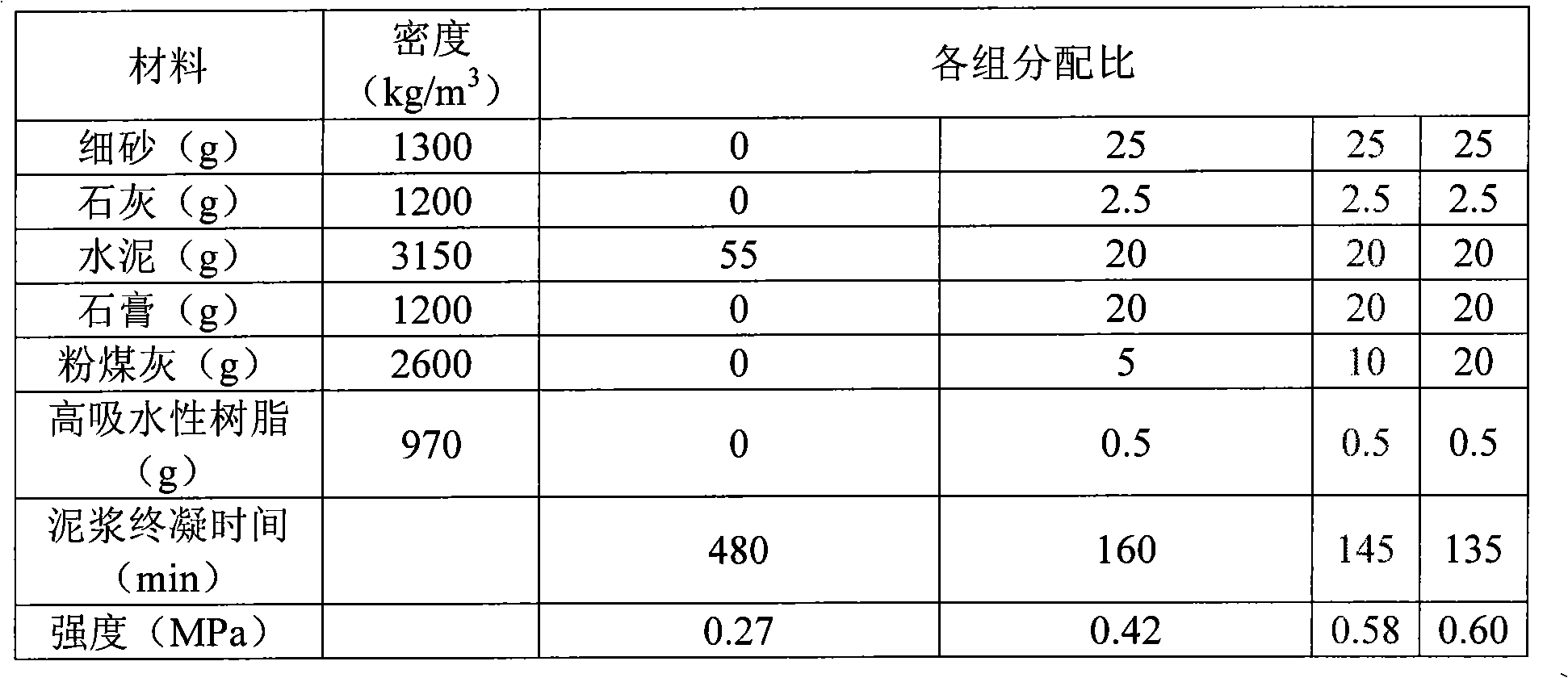

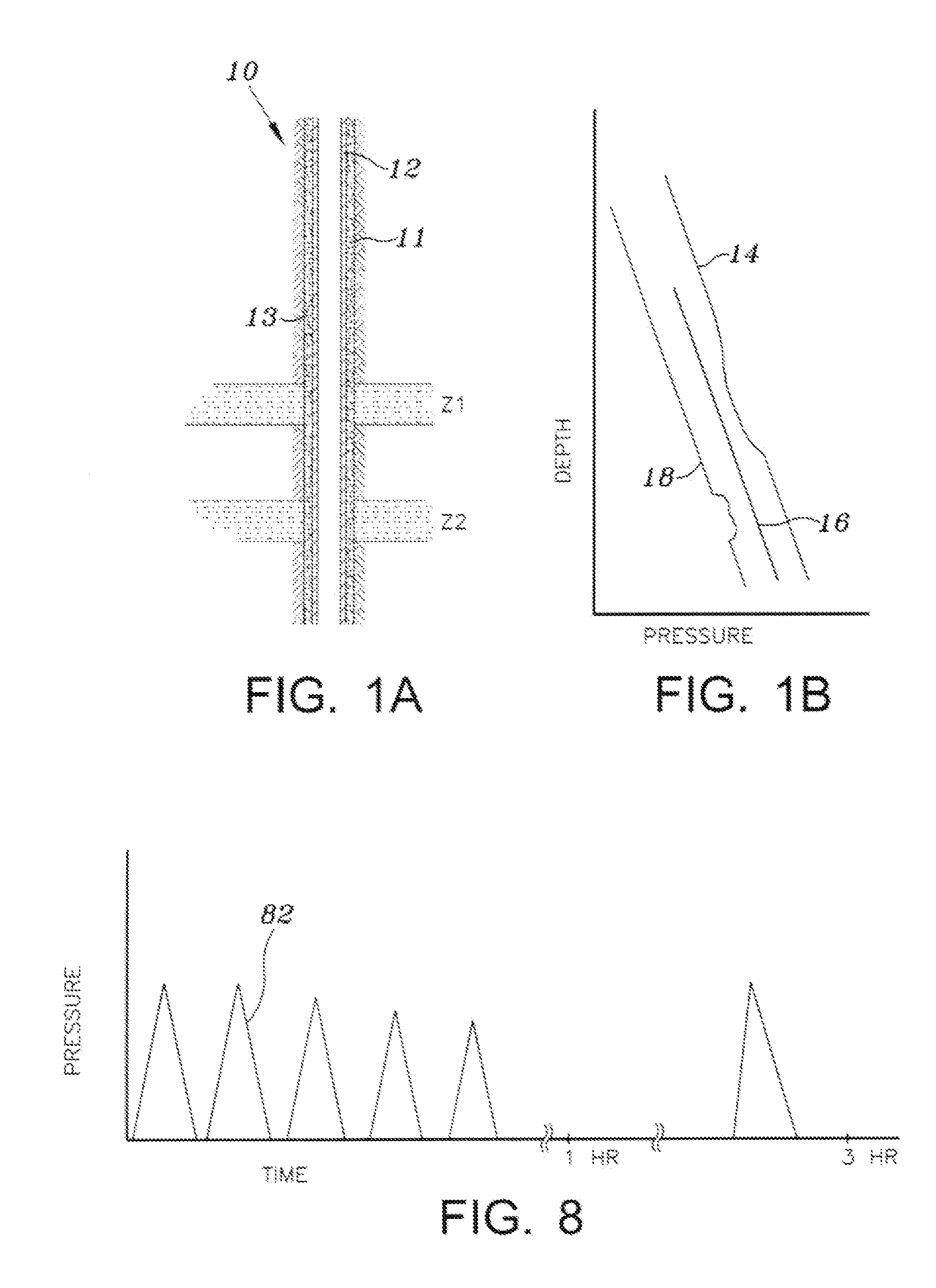

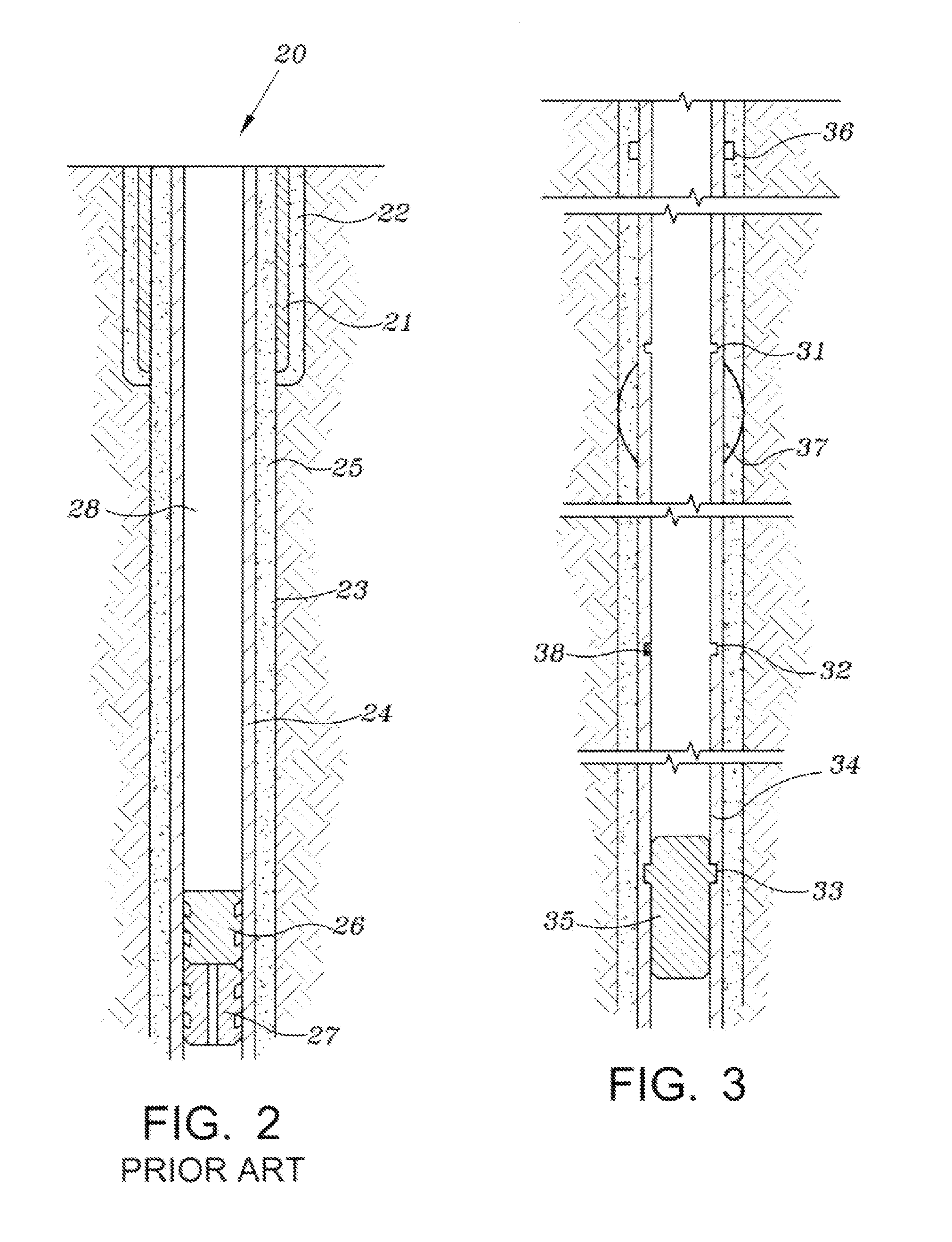

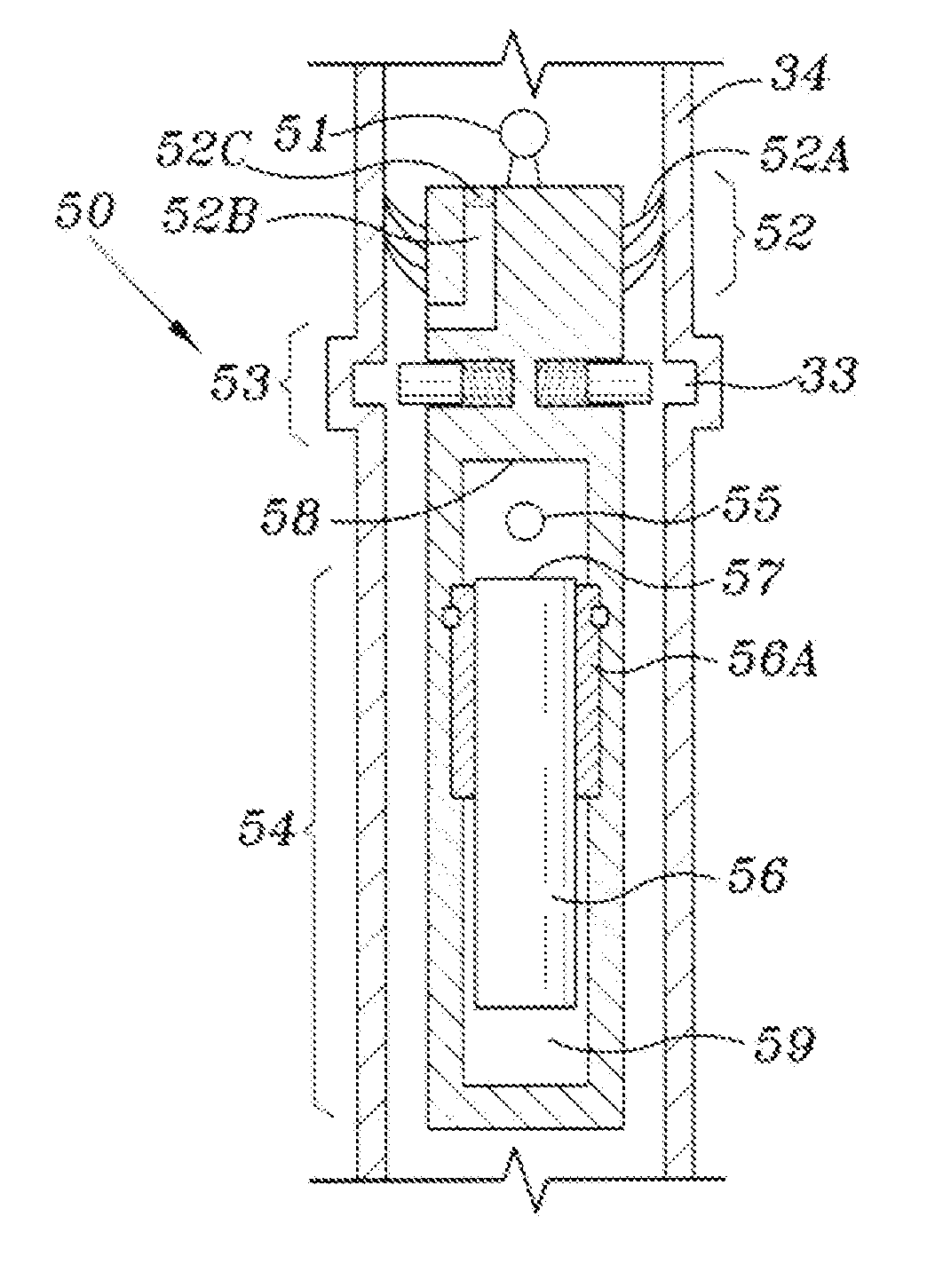

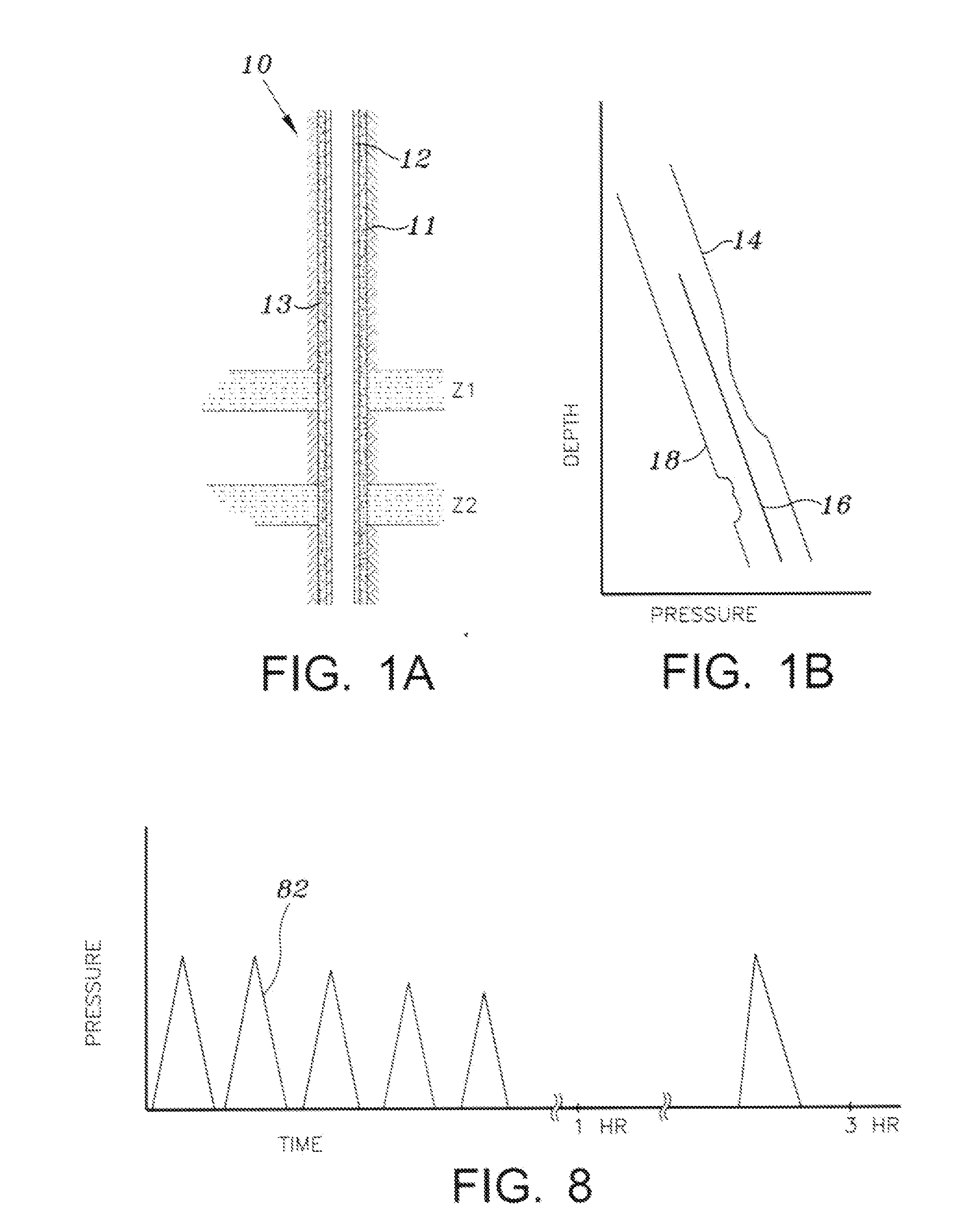

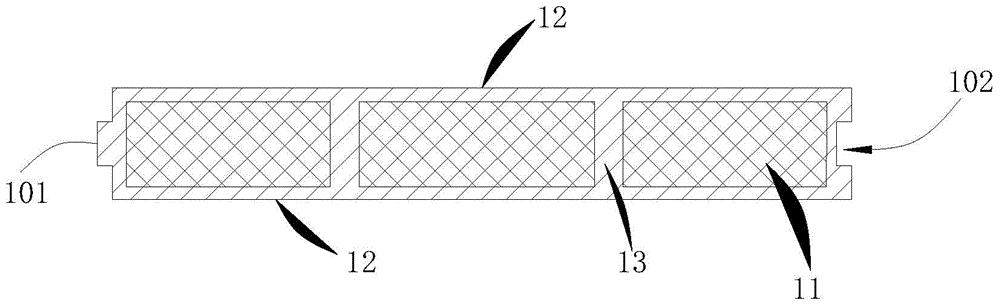

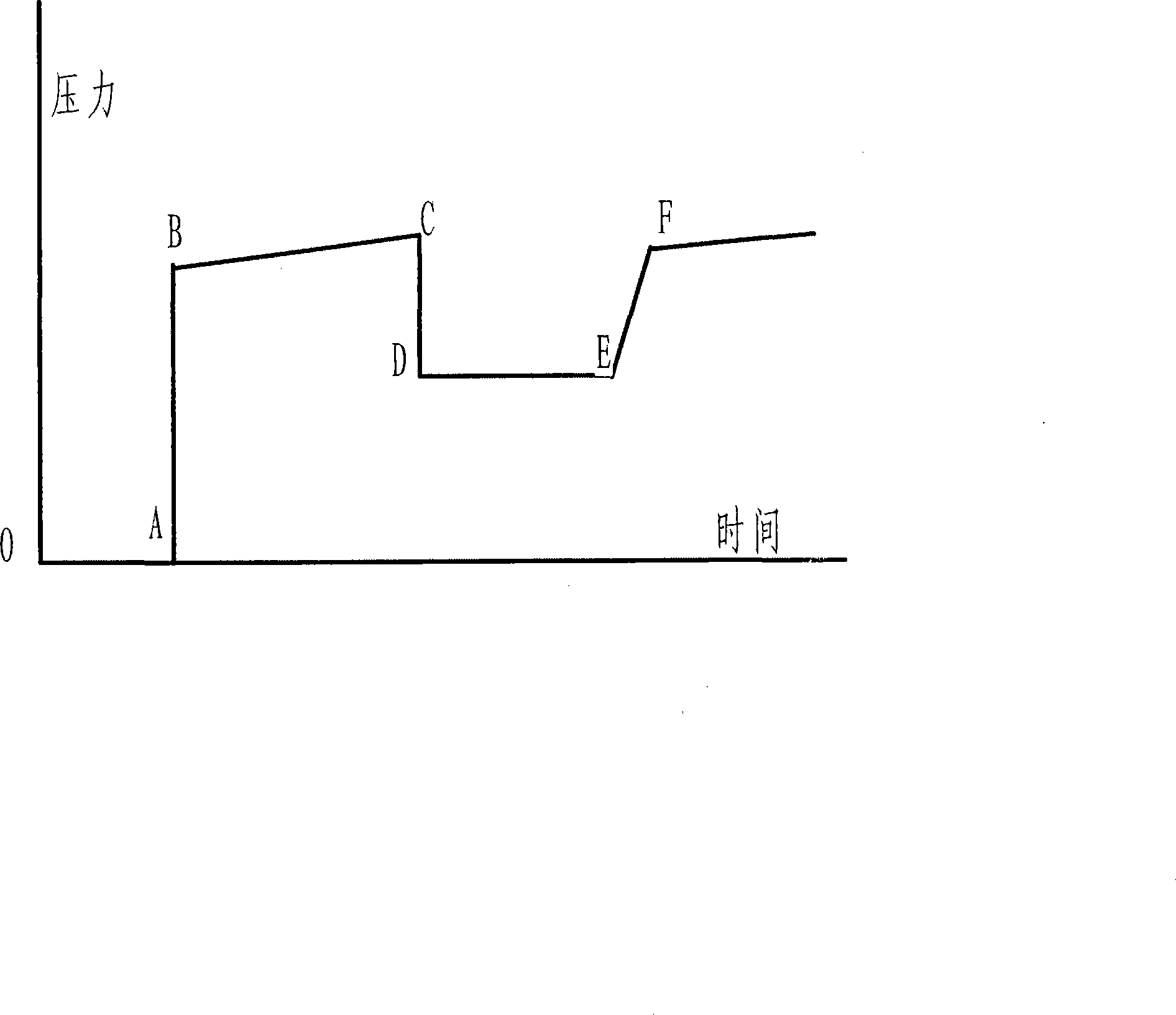

Method and Apparatus for Maintaining Pressure In Well Cementing During Curing

Method and apparatus are provided for cementing wells and preventing fluid entry into the wellbore before the cement cures and increasing radial stress in the cement. Impacts or vibrations are applied to the casing during the time that the cement is curing. The sources of the impacts or vibration are placed in the casing during displacement of the cement slurry and are mechanically coupled to the inside wall of the easing. The sources are later withdrawn from the casing.

Owner:COOKE JR CLAUDE E

Method and Apparatus for Maintaining Pressure In Well Cementing During Curing

InactiveUS20110290485A1Increased radial stressFluid removalVibration devicesRadial stressWell cementing

Method and apparatus are provided for cementing wells and preventing fluid entry into the wellbore before the cement cures and increasing radial stress in the cured cement. Impacts or vibrations are applied to the casing during the time that the cement is curing. The source or sources of the impacts or vibration are placed in the casing during displacement of the cement slurry or soon after placement and are mechanically coupled to the inside wall of the casing. The sources may later be withdrawn from the casing or expendable sources may be used.

Owner:COOKE JR CLAUDE E

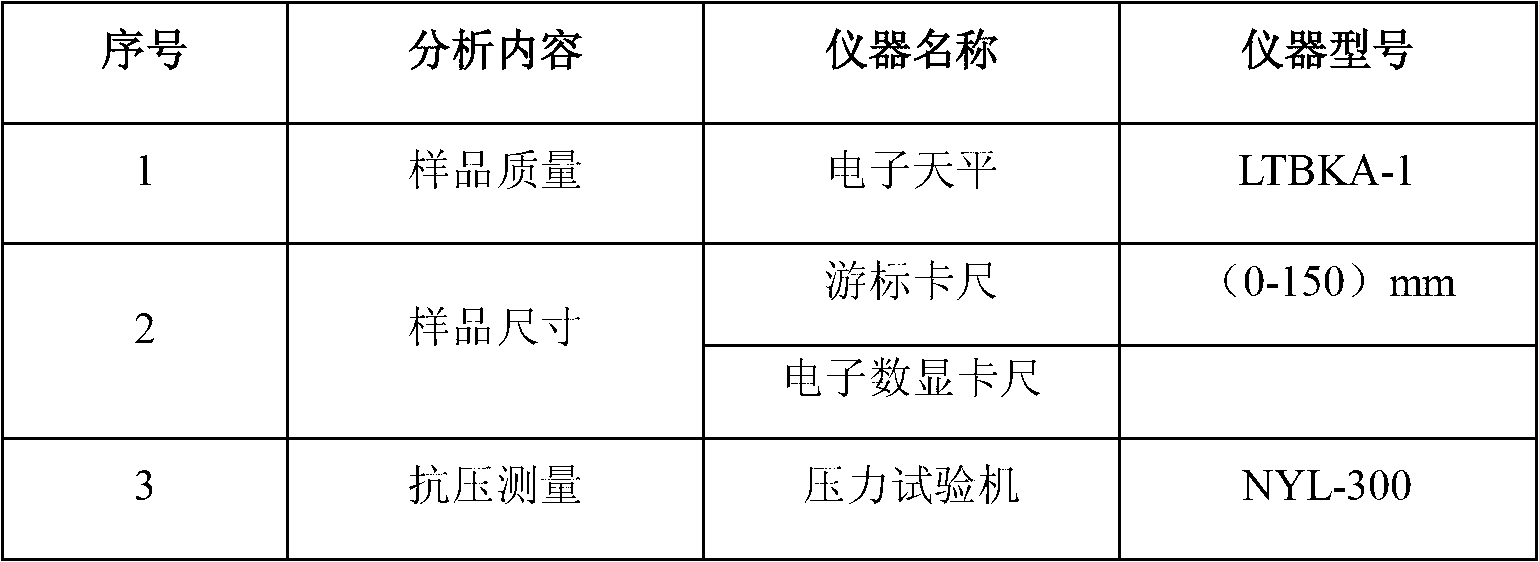

Curing agent for curing radioactive wastes containing borate and method thereof

InactiveCN101935200AAvoid non-condensingAvoid the cracking of the cement solidified body after soaking in waterSolid waste managementRadioactive decontaminationNuclear powerFirming agent

The invention discloses a curing agent for curing radioactive wastes containing borate, belonging to the technical field of a waste treatment. The curing agent is the mixture of cement and sodium silicate, wherein the weight ratio of the cement to the sodium silicate is 100 to (1-15). The invention also discloses a method for curing the radioactive wastes containing the borate by utilizing the curing agent. The mixture of the cement and the sodium silicate in the invention can be used for curing the radioactive wastes generated in a nuclear power station, avoiding the phenomenon of non-condensing cement slurry because of the delayed coagulation of the borate adsorbed in the wastes on the cement and cracking of cement curing bodies after being soaked in water, enhancing the capacity, shortening the initial coagulation time of the cement slurry, and ensuring that no crack is generated on the surfaces of the curing bodies and various performance indexes can meet the requirements of the national standard GB14569.1-93.

Owner:TSINGHUA UNIV

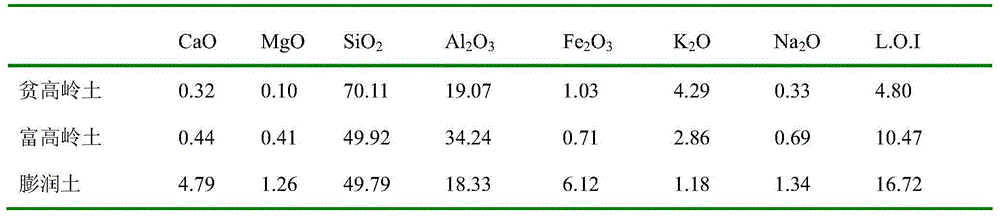

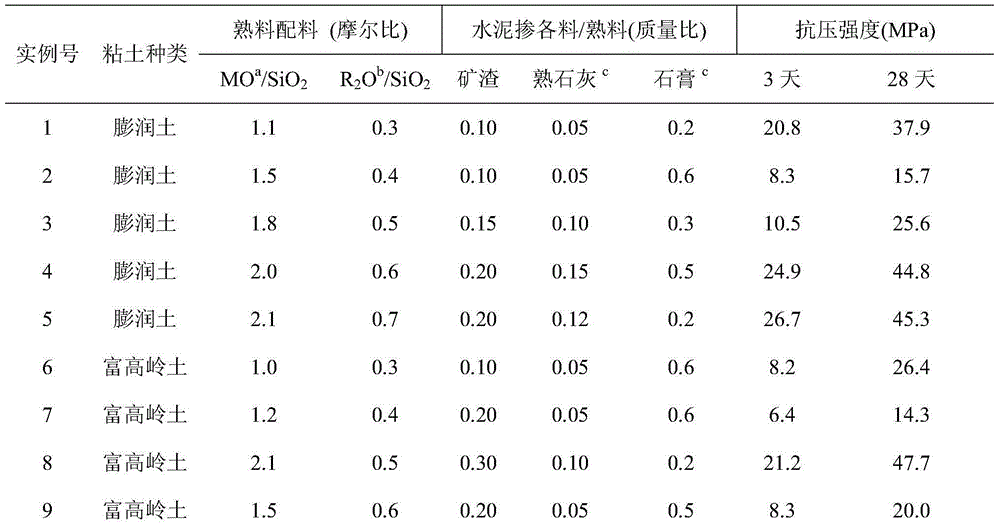

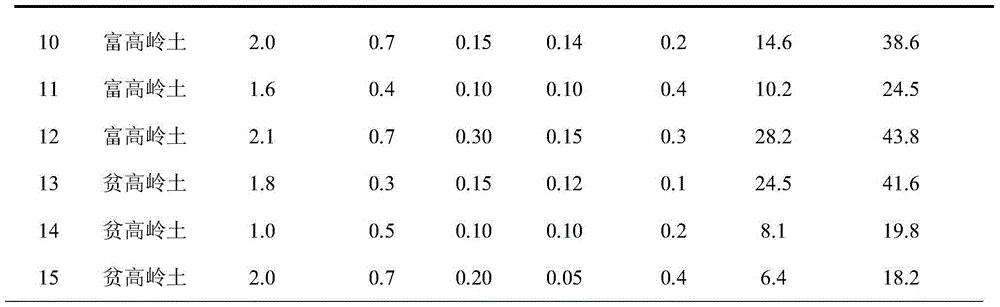

Preparation method of composite single-component alkali-activated cement cured at room temperature

InactiveCN104446040AImprove early strength performanceIncrease late strengthCement productionMeal powderAlkali activated

The invention discloses a preparation method of composite single-component alkali-activated cement cured at room temperature. Raw meal powder is prepared from raw material containing a silicon-aluminum oxide, dolomite sodium carbonate and the like through mixing and ball-milling, wherein the charge ratio meets the conditions that the molar ratio of (CaO+MgO) / SiO2 is 1.0-2.1 and the molar ratio of (Na2O+K2O) / SiO2 is 0.3-0.7; the raw meal powder is calcined at 1100 DEG C for 2-3 hours, thus obtaining a clinker; and 10-30 parts of slag, 5-15 parts of slaked lime and 10-60 parts of gypsum are added to 100 parts of the clinker and the mixture is evenly mixed and ground, thus obtaining the cement. The cement prepared by the method has high early-high-strength, and especially has good long-term strength which is obviously superior to that of the prior art; the cement does not crack after being cured for a long period of time; the problem that the existing cement is easy to crack or break at the later period is solved; the raw materials are available; particularly, the proportions of cheap raw materials are high; the production cost is effectively reduced; and the composite single-component alkali-activated cement is simple in preparation method and convenient to use and maintain, and has good application value.

Owner:HUNAN UNIV OF SCI & TECH

Cement solidification method of nuclear power wastes

ActiveCN102800377AReduce volumeHigh inclusion rateSolid waste managementRadioactive decontaminationSulfate radicalsPhosphate ion

The invention discloses a cement solidification method of nuclear power wastes. The cement solidification method comprises the steps of taking cement, lime and an additive as raw materials of a curing agent; detecting the density of concentrated solution, the concentration of boric acid radical ions, total salt content, the concentration of phosphate radical ions, and the concentration of sulfate radical ions in nuclear power waste concentrated solution; determining the weight of the needed cement, additive and lime; sequentially adding the additive, the lime and the cement in the nuclear power waste concentrated solution, and stirring; and standing and curing slurry to obtain the cement solidification body. According to the cement solidification method of the nuclear power wastes provided by the invention, the volume of the cement solidification body is reduced, the containing rate of the nuclear power waste is increased, and the processing process is safe and reliable.

Owner:中广核工程有限公司 +1

Slurry curing formula

The invention relates to a compound type slurry curing agent for conducting curing treatment on waste slurry generated in geotechnical engineering (for example, investigation drilling, cast-in-place pile, anchorage engineering, trenchless construction and the like), as well as the sludge at the bottom of reservoirs, ditches, ponds, pools and the like. In the invention, the compound type slurry curing agent is prepared by adding and mixing fine sand, lime, industrial waste gypsum and super absorbent resin in cement curing agent evenly according to a certain proportion. The slurry curing agent greatly improves the curing effect of slurry, reduces the use amount of cement and lowers the cost. Besides, by doping industrial wastes such as waste gypsum in cement, the pollution to the environment is abated, the recycle of wastes is promoted and favorable economic and social benefits are available.

Owner:WENZHOU DONGOU CONSTR GRP

Method for manufacturing a wood cement board

InactiveUS20050269730A1High curing strengthImprove curingSolid waste managementWood working apparatusAluminium sulfateAdditive ingredient

The object of the present invention is to provide a method for the manufacturing of a wood cement board in which the curing of the cement can be smoothly carried out even if the wood reinforcement used originates from a sort of wood containing a large amount of cement curing inhibitor. To attain said object, the present invention provides a method for the manufacturing of a wood cement board including; scattering an ingredient wherein a sodium alum produced from aluminum sulfate and sodium sulfate, and sodium silicate are added to a mixture containing a cementitious inorganic powder and a wood reinforcement on a base panel to form a mat, then primarily curing the said mat by pressing and heating it under its moist points and, then curing the primarily cured mat at room temperature or in an autoclave. In the method, the aluminum sulfate and sodium silicate in the sodium alum improve the primary curing strength of the mat, with sodium sulfate improving the final curing strength of the mat.

Owner:NICHIHA CORP

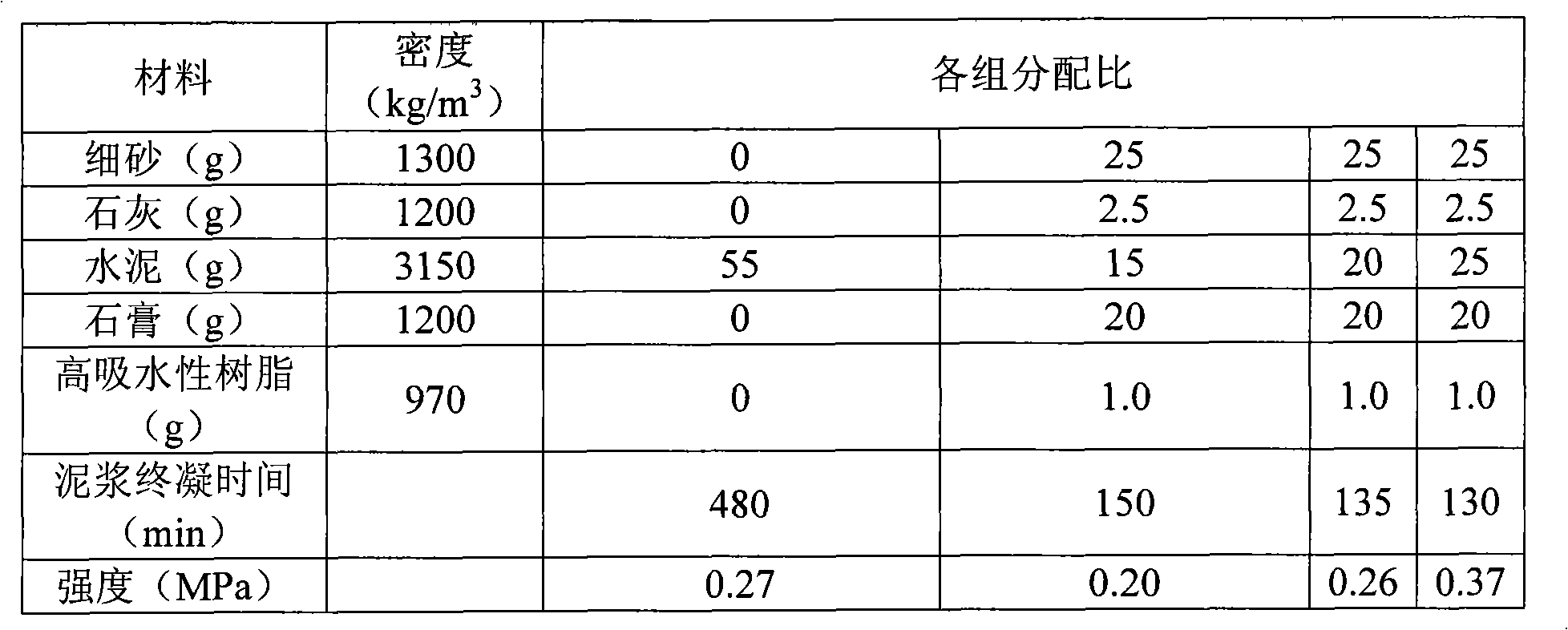

Wall composite insulation board and production method thereof

InactiveCN104369256AImprove insulation effectHigh strengthCeramic shaping apparatusHeat proofingInsulation layerUltimate tensile strength

The invention discloses a wall composite insulation board. The wall composite insulation board comprises a foam cement layer formed by solidification of foam cement and high-strength protection boards respectively arranged on the two outer surfaces of the foam cement layer and used for protecting the same. The foam cement layer forms an insulation layer, and the foam cement is good in insulation, lightweight, high in strength, good in sound insulation, low in water absorption and noninflammable, so that the composite insulation board made of the foam cement is good in insulation, sound insulation and flame retardation.

Owner:天津市滨海新区励胜智成建材科技发展有限公司

Geological cement for radioactive steam residual liquid solidifying and solidifying method thereof

ActiveCN104282353AHigh dry salt contentExcellent indicatorsRadioactive decontaminationLiquid wasteSorbent

The invention provides geological cement for radioactive steam residual liquid solidifying and a solidifying method thereof. The solidifying method includes mixing slag containing aluminosilicate, a compound mineral activator and an absorbent well to prepare the geological cement; stirring the geological cement and concentrated waste liquid in a stirring pan for 7min; transferring a mixture of the geological cement and the concentrated waste liquid into a die for curing. When the method is used to solidify radioactive steam residual liquid, dry salt content of the steam residual liquid is up to 345g / L, the steam residual liquid contained in a solidified body reaches 80%, condensing time is adjustable, final setting time is smaller than 24h, and proper initial setting time is ensured for solidifying operation. After 28h of curing, each indicator of the solidified body is superior to regulations of 'National Requirements on Performance of Low-Medium-Level Radioactive Waste Solidified Bodies-Cement Solidified Bodies', wherein compressive strength is up to more than 15Mpa, and 137Cs 42-th element leaching efficiency is 1.0x10-3cm / d and is lower than the national standard by four times.

Owner:深圳市航天新材科技有限公司

Innocent treatment process for industrial heavy metal waste residue by utilizing treating waste with waste

The invention relates to an innocent treatment process for industrial heavy metal waste residue by utilizing treating waste with waste. In the process provided by the invention, a novel cement curing matrix taking the urban trash firing fly ash as a main component is utilized, wherein the curing matrix comprises following the components in percentage by weight: 60-70% of the urban trash firing fly ash, 10-20% of aluminum-containing additive (aluminum-containing industrial waste residue powder) and 6-20% of calcium controlling agent (lime powder). The process provided by the invention comprises the following components: mixing the trash firing fly ash curing matrix prepared from the components with the industrial heavy metal solid waste residue or sludge to be treated together; adding a proper amount of water, and stirring uniformly; and then preparing a cement curing body; after conserving for five days at normal temperature, embedding in a landfill site. The process provided by the invention is an innocent treatment method of treating waste with waste.

Owner:湖南布鲁斯凯碳资产管理有限公司

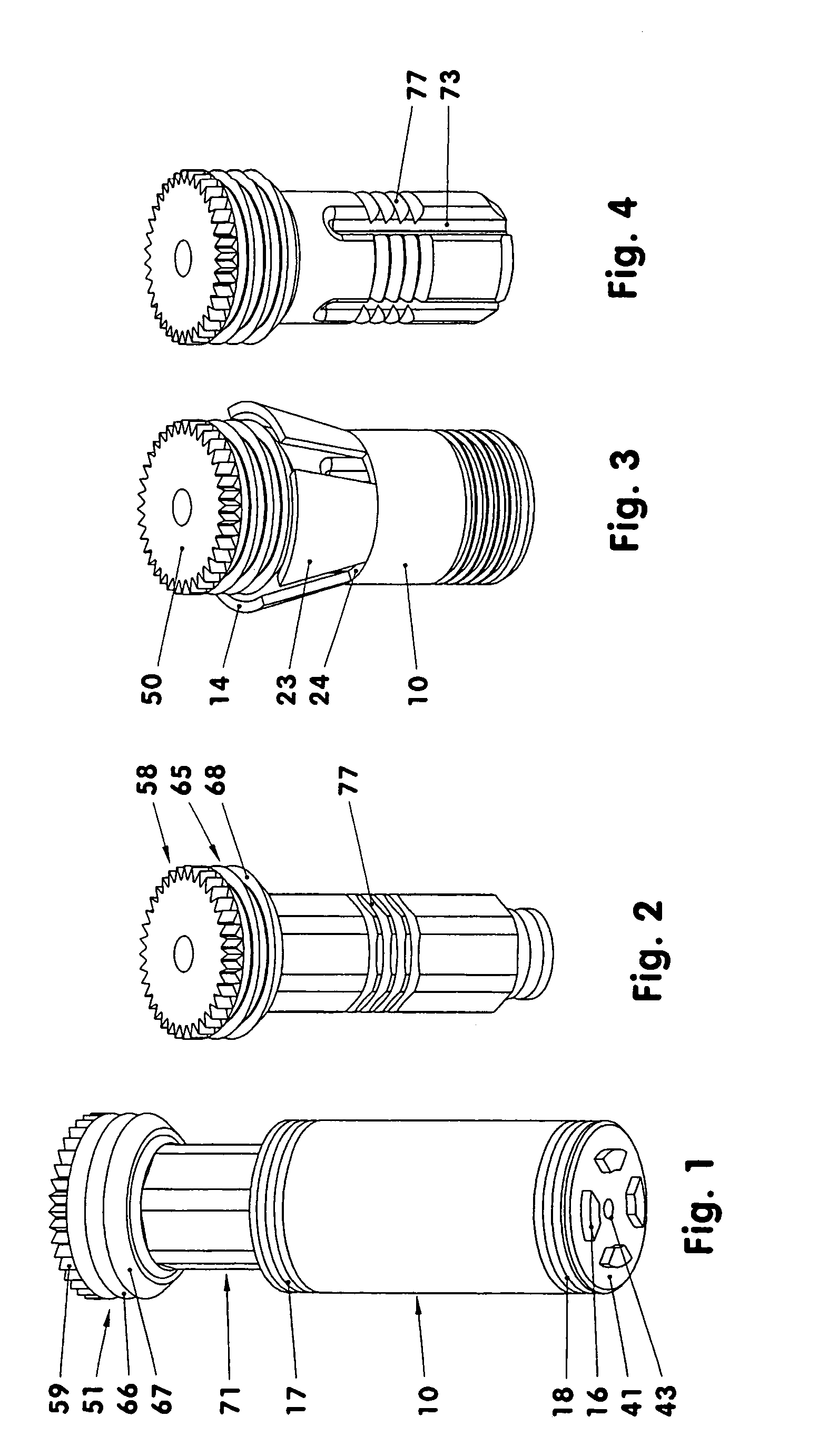

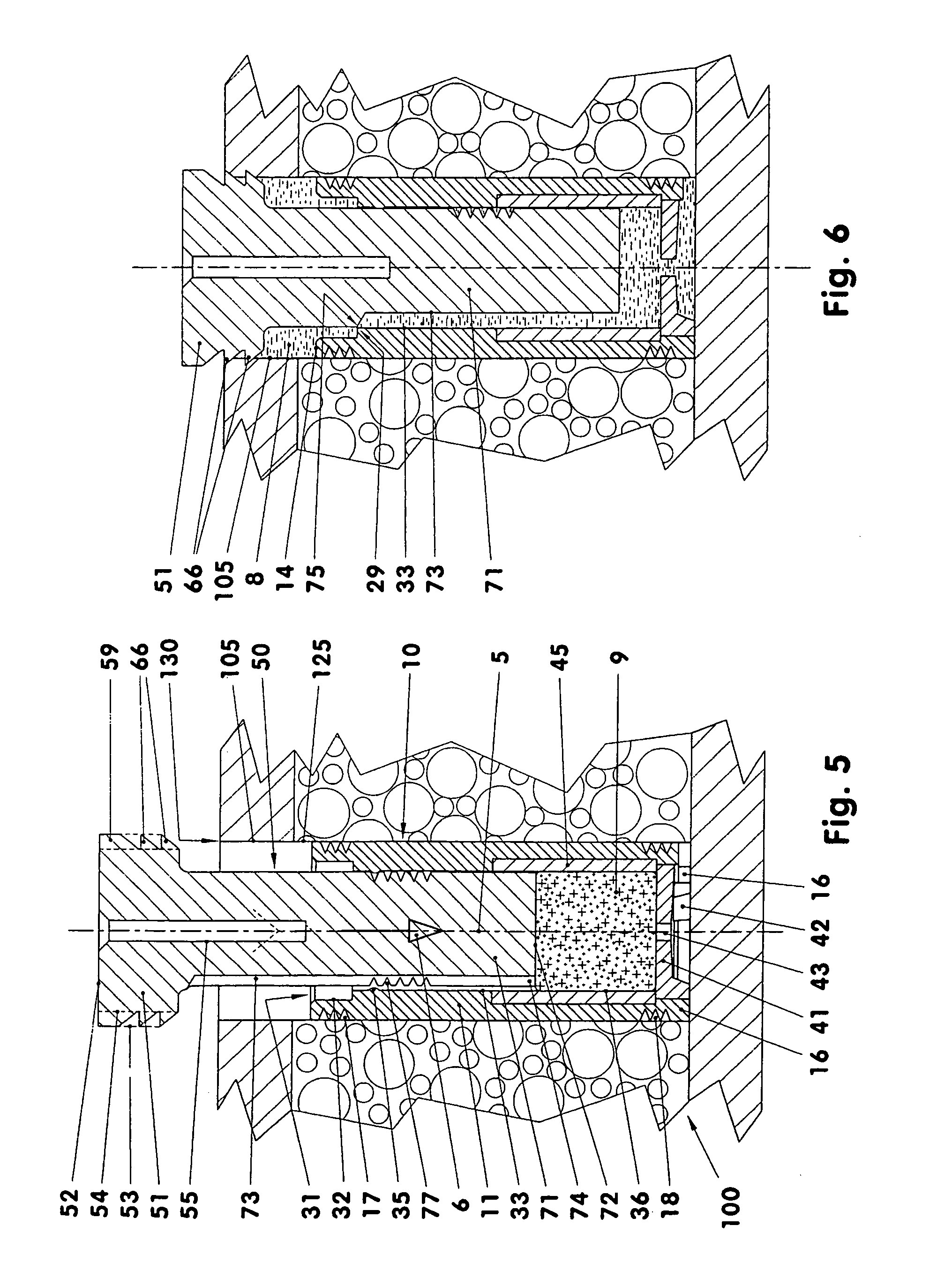

Cement anchor for lightweight construction panels

In a cement anchor for use in connection with lightweight construction panels, wherein the anchor comprises a cylindrical body with at least one piston forming with the cylindrical body a displacement area in which a meltable cement is disposed together with a heatable melt body, the melt body is heated just before the anchor is inserted into a bore in the panel so that the cement is liquefied and, upon compression of the anchor, is displaced from the displacement area into the space around the anchor, so that, upon solidification of the cement, the anchor is firmly connected to the lightweight construction panel.

Owner:ZIMMER GUNTHER +1

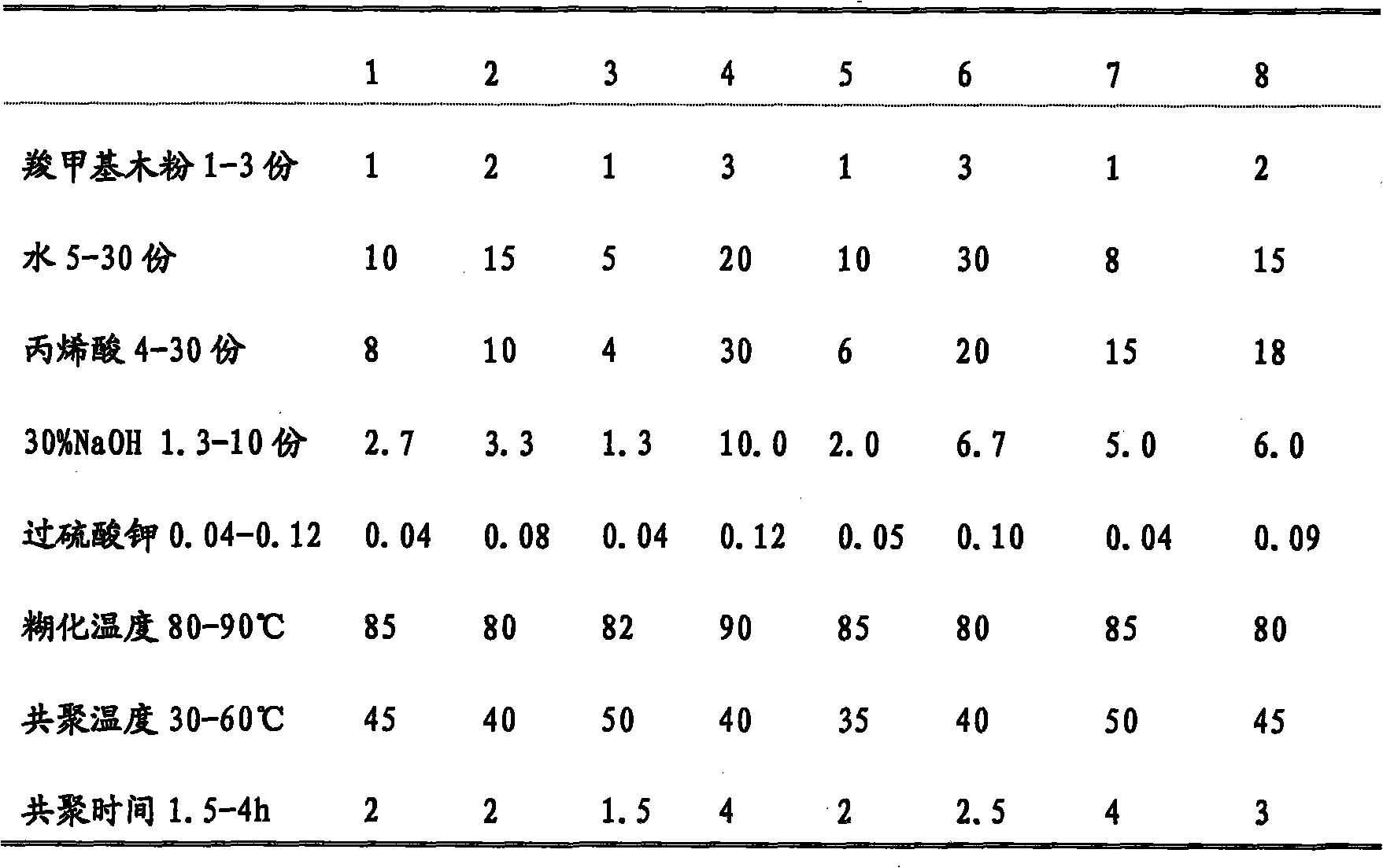

Carboxymethyl wood flour water absorbent and preparation method thereof

The invention provides a carboxymethyl wood flour water absorber, which consists of the following raw materials by weight: 1 to 3 portions of carboxymethyl wood flour, 4 to 30 portions of acroleic acid, 1.3 to 10 portions of sodium hydroxide solution of 30 percent; and 0.04 to 0.12 portion of potassium persulfate. After the raw materials are mixed, the mixture is heated and beaten in nitrogen atmosphere, thus getting high viscosity straw yellow cream through copolymerization; after the cream is dried and pulverized, straw yellow carboxymethyl wood flour with the granularity from 40 meshes to 100 meshes is got; the water absorption rate is 1000 to 1200g / g, and the absorption speed is 30g per minute. The water absorber is prepared through the four steps: preparing the carboxymethyl wood flour, preparing the cream of the carboxymethyl wood flour, preparing a graft copolymer and preparing the water absorber, which is used as a water absorber for aqueous organic solvent, a soil water retention agent, a cement curing compound and so on. The water absorber uses the carboxymethyl wood flour as a raw material, and comprehensively makes use of the carboxy methylation product of cellulose and hemicellulose and lignin in the wood flour as the skeleton and the cross-linking agent of the graft copolymer; the timber utilization rate is high; the cost is low; and the preparation process does not pollute the environment.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Cement additive for curing organic waste and application of cement additive

ActiveCN105417978AAchieve curing stabilizationIncreases the degree of hydrationSolid waste managementActivated carbonFiber

The invention discloses a cement additive for curing organic waste and application of the cement additive and aims to solve the problems that when cement curing treatment is conducted on waste containing organic matter, particularly when cement curing treatment is conducted on organic waste liquid with great harm, due to existence of organic matter, a curing body cannot be formed, or the strength or other performance is poor, organic matter even directly jumps to the upper layer of cement paste, and the curing waste treatment process cannot be conducted. The cement additive comprises coagulant, an oil absorption material, microsilica, activated carbon, wood fibers, coal ash and anti-crack fibers. By means of the cement additive, the problems that when the waste containing organic matter is subjected to curing treatment through cement, curing is not formed, and the strength and other performance of the curing body are poor are solved. The cement additive is low in cost, free of toxin and foul smell, less in consumption, safe and reliable, an existing waste curing treatment process and equipment are not needed to be changed, the compressive strength of the obtained cement curing body is larger than 7 MPa and can reach 13 MPa at the maximum, and the cement additive has good application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

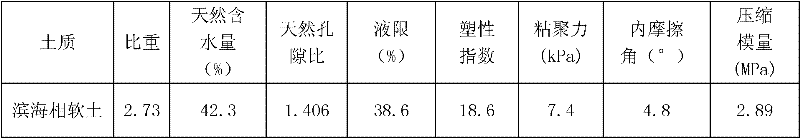

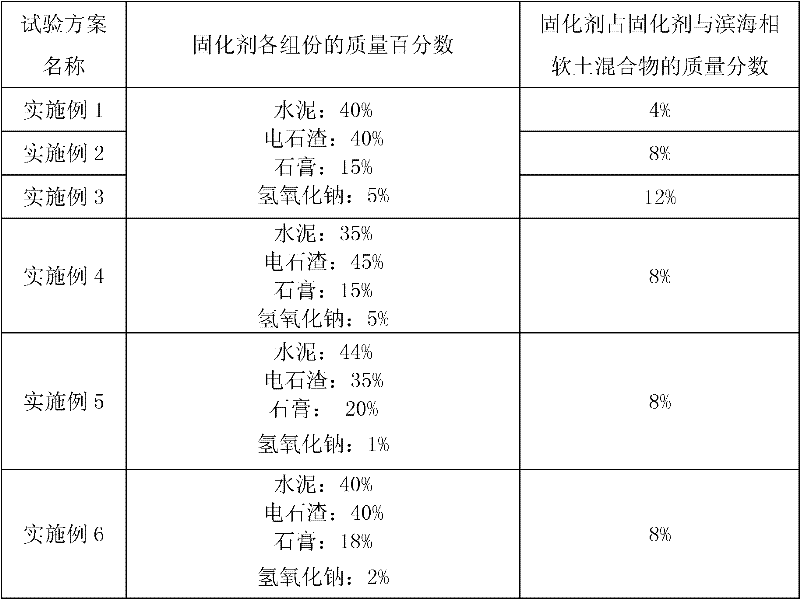

Curing agent for littoral-facy soft soil

The invention discloses a curing agent for littoral-facy soft soil. The curing agent consists of the following components in percentage by mass: 35-45% of cement, 35-45% of carbide slag, 15-20% of gypsum and 1-5% of surfactant. The main components of the curing agent come from industrial waste, and the cost is low; and meanwhile, compared with the cement curing agent, the curing agent disclosed by the invention has a better effect on curing the littoral-facy soft soil, and the engineering properties required for curing the littoral-facy soft soil can be realized.

Owner:SOUTHEAST UNIV

Environment-friendly baking-free brick prepared from sludge and furnace slag and preparation method thereof

The invention discloses an environment-friendly baking-free brick prepared from sludge and furnace slag. Raw materials include: sludge, domestic incinerator slag, cement, a curing agent and water in amass ratio of (35-40): (10-15): (40-50): (5-10). The preparation method comprises the following steps: carrying out pyrohydrolysis and thermophilic anaerobic digestion treatment on raw sludge, and dehydrating to obtain dehydrated sludge; adding a deodorant into the dehydrated sludge, naturally deodorizing and airing, then crushing, sieving with a 100-mesh sieve to obtain sludge powder, and sieving the domestic incinerator slag with a 50-mesh sieve to obtain slag particles; and mixing the sludge powder and the slag particles with Portland cement, a curing agent and water, putting the obtainedmixture into a mold, performing extrusion and compression molding, and performing maintenance in air so as to obtain the environment-friendly baking-free brick. Waste sludge and furnace slag can be used as raw materials to prepare the environment-friendly baking-free brick which is stable in property, free of pollution and capable of meeting the strength requirement.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

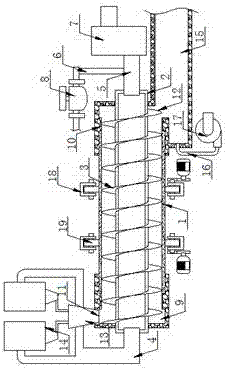

Screw blade type center heating cement curing rotary kiln

InactiveCN107388816AReduce energy consumptionAvoid the phenomenon of agglomerationRotary drum furnacesClinker productionCombustionEngineering

The invention discloses a screw blade type center heating cement curing rotary kiln. The screw blade type center heating cement curing rotary kiln comprises a curing rotary kiln barrel, a gas combustion heating barrel arranged in the curing rotary kiln barrel and a calcination conveying screw blade arranged between the curing rotary kiln barrel and the gas combustion heating barrel. The gas combustion heating barrel and the curing rotary kiln barrel are arranged coaxially. The outer diameter of the calcination conveying screw blade is equal to the inner diameter of the curing rotary kiln barrel, and the inner diameter of the calcination conveying screw blade is equal to the outer diameter of the gas combustion heating barrel. The calcination conveying screw blade is fixedly arranged on the inner side wall of the curing rotary kiln barrel. According to the screw blade type center heating cement curing rotary kiln, when cement mixed raw materials are heated and calcined, no solid waste residues are generated, the cement raw materials can be heated uniformly, and therefore energy consumption of the cement curing rotary kiln is reduced.

Owner:安徽卓煌机械设备有限公司

Method for carrying out cement solidification on radioactive raffinate by using NaAlO2 and Ca(OH)2 coagulant

InactiveCN102254579AHigh compressive strengthShorten final setting timeRadioactive decontaminationSetting timeRaffinate

The invention discloses a method for carrying out cement solidification on radioactive raffinate by using NaAlO2 and Ca(OH)2 coagulant, belonging to the technical field of cement solidification on radioactive raffinate. The method comprises the following steps of: evenly mixing sulphoaluminate cement, a composite mineral additive, NaAlO2 and Ca(OH)2 to obtain a mixture, stirring the mixture and the radioactive raffinate in a stirring pot, moving to a die and curing. When the radioactive raffinate is solidified by using the method disclosed by the invention, the boron concentration of the solidified radioactive raffinate can reach 45g / L, the capacity of the raffinate in the solidified body can reach 60 percent, the final setting time is shortened to be within 24h, the appropriate initial setting time can be ensured for solidification operation, and the solidified body can have higher compressive strength.

Owner:TSINGHUA UNIV

Ultraviolet light-cured glass decorative sheet, and preparation method and applications thereof

InactiveCN105368299ASolve the problem that cannot be directly bondedHigh bonding strengthPolyurea/polyurethane coatingsEpoxy resin coatingsCoated surfaceUltraviolet lights

The invention relates to an ultraviolet light-cured glass decorative sheet, and a preparation method thereof. According to the preparation method, glass surface is coated with a layer of an ultraviolet light-cured adhesive priming paint; the surface of the layer of the ultraviolet light-cured adhesive priming paint is coated with a layer of an ultraviolet light-cured bonding glue; the surface of the layer of the ultraviolet light-cured bonding glue is coated with a layer of an ultraviolet light-cured transfer printing film via transfer printing; and the surface of the ultraviolet light-cured transfer printing film is coated with a layer of an ultraviolet light-cured film upper glue; the surface of the layer of the ultraviolet light-cured film upper glue is coated with a layer of an ultraviolet light-cured finish paint. According to an application method, the surface of the layer of the ultraviolet light-cured finish paint is coated with cement paste, and then the ultraviolet light-cured glass decorative sheet is pasted onto an object directly until cement solidification is realized. Needed production field is small; equipment cost is low; production efficiency is high; energy consumption is low; no pollution is caused; combustion is not easily caused; a problem that glass can not be glued with cement directly is solved; construction is convenient; cost is low; and resources are saved.

Owner:ZHUHAI DONGSHENG TECH CO LTD

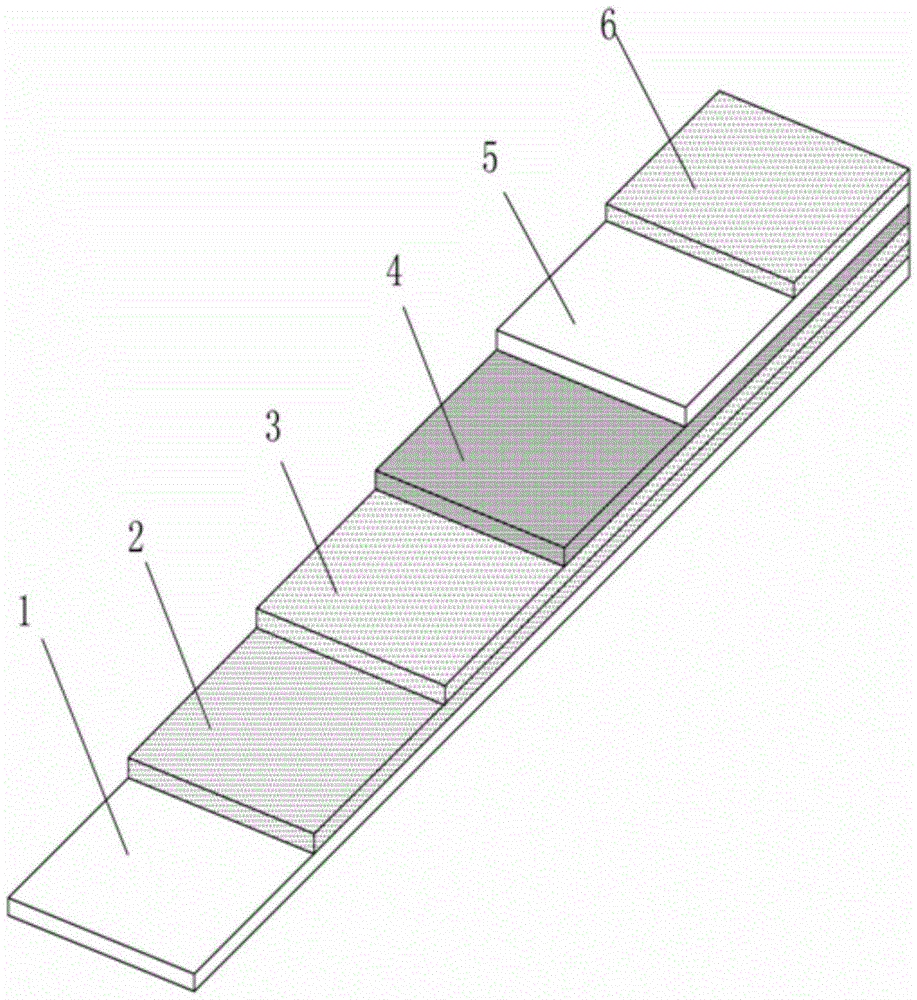

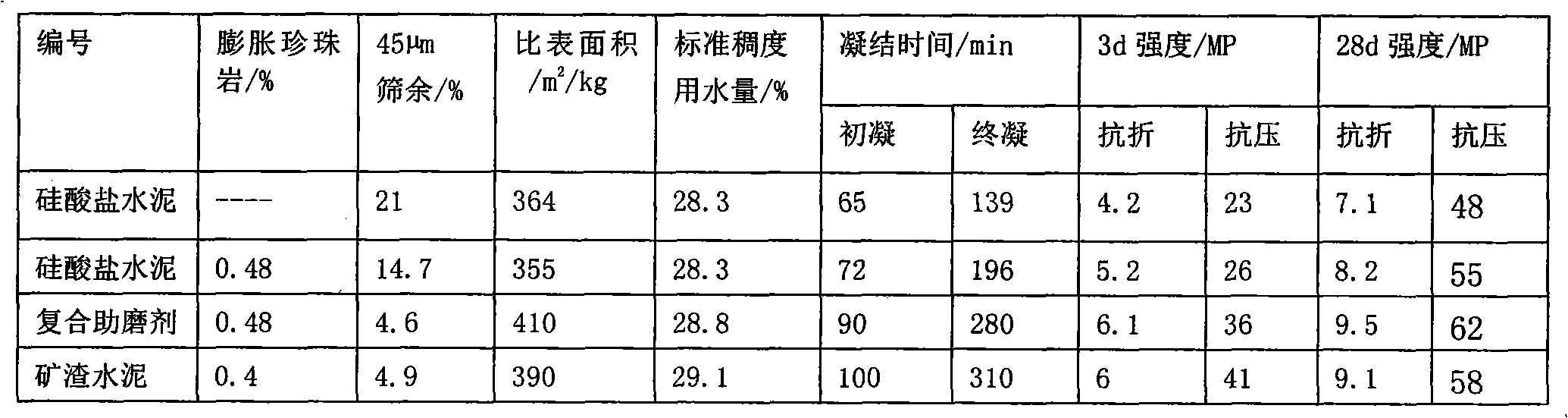

Multi-functional environment-friendly grinding aid

The invention discloses a multi-functional environment-friendly grinding aid, and relates to a cement grinding aid. The invention mainly aims to solve the problems that the energy consumption is high, the grinding efficiency is low, use safety of the grinding aid is low and the like in the cement grinding process. Light and porous expanded perlite is adopted to serve as the grinding aid, can be separately doped or compounded, and has good grinding aiding effect on clinker, slag, flyash and the like. The content of a portland cement grinding aid is 0.2 to 0.5 percent; and the content of a slag cement grinding aid is 0.3 to 0.4 percent. A compound grinding aid comprises 0.48 percent of expanded perlite, 0.001 percent of triethanolamine and 0.003 percent of sodium hexametaphosphate. The multi-functional environment-friendly grinding aid has the advantages that: phenomena of segregation, bleeding and powder enrichment cannot happen in the mortar stirring process; the activity of glass contributes to improving the strength of cement concrete, components harmful to cement and concrete are not contained, and the grinding air is convenient to use, low in price, safe, environment-friendly, high-efficiency and high in applicability; the fine powder content is effectively increased, and the strength of cement cured for 28 days is improved; and the aims of increasing yield, saving energy and reducing consumption are fulfilled.

Owner:YANTAI UNIV

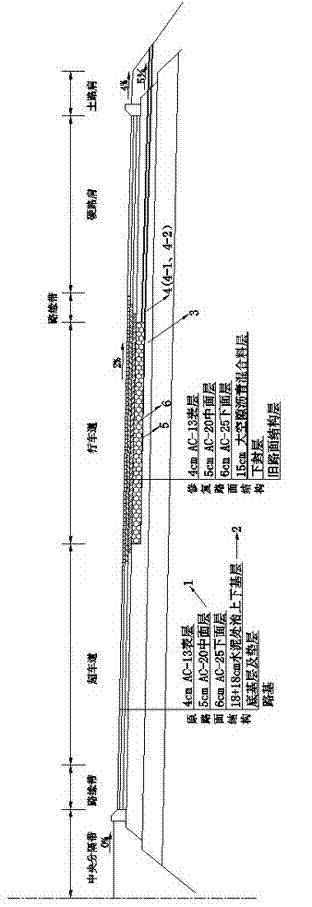

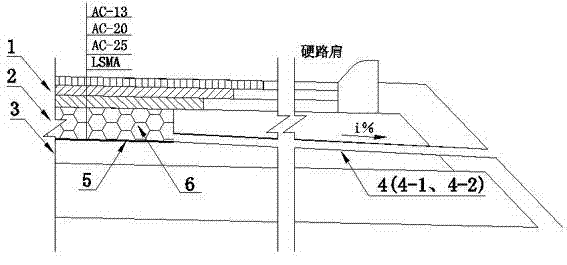

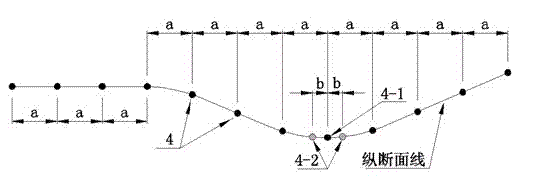

Repair method of structural water damage of asphalt pavement with cement-cured base layer

InactiveCN102900002AAvoid damageSolve drainage problemsIn situ pavingsGround-workEnvironmental resistanceStructural water

The invention discloses a repair method of a structural water damage of an asphalt pavement with a cement-cured base layer, belonging to the field of maintenance and repair of road works. The method comprises the following repair steps: a) milling damaged surface layer and base layer structure and arranging transverse drainpipe; b) arranging lower sealing layer; and c) paving macroporous asphalt mixture layer, dense-graded asphalt mixture surface layer, etc. Compared with prior art, the method provided by the invention is environmentally friendly and highly efficient, can maintain a long-term and continuous use of the pavement structure, and has a good application value.

Owner:山东省交通科学研究所

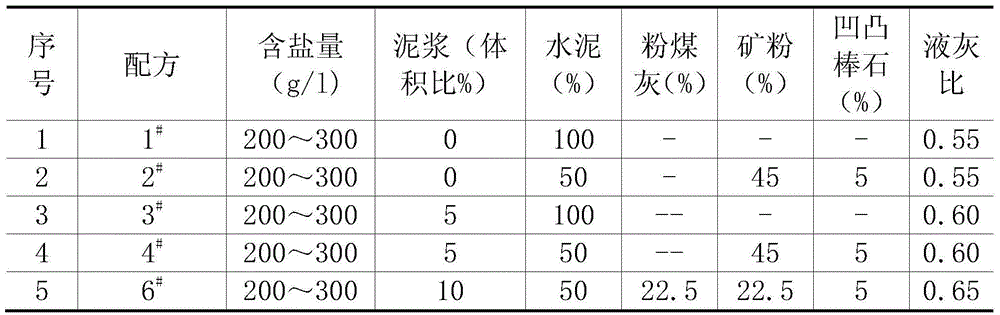

High-salt high-alkali low and intermediate level radioactive waste solution cement solidification formula

The invention discloses high-salt high-alkali low and intermediate level radioactive waste solution cement solidification formula which is used for low and intermediate level waste solution with salt content of 200g / l to 300g / l and 80 percent of sodium nitrate. The low and intermediate level radioactive waste solution with 80 percent of sodium nitrate contains the following components: 0 to 5 percent by volume of slurry, 50 to 100 percent by mass of cement, 0 to 22.5 percent by mass of coal ash, 0 to 22.5 percent by mass of mineral powder and 0 to 5 percent by mass of attapulgite, wherein the ratio of liquid to ash is 0.55 to 0.65. The high-salt high-alkali low and intermediate level radioactive waste solution cement solidification formula is already proved in the commissioning and continuous operation of a cement solidification engineering solidification line, and the performance of solid prepared by utilizing the formula not only can meet the national standard requirement, but also can promote the deployment of the solidification of high-salt high-alkali low and intermediate level radioactive waste solution (containing alpha slurry) and can accelerate the transformation of basic application scientific research to the engineering application.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

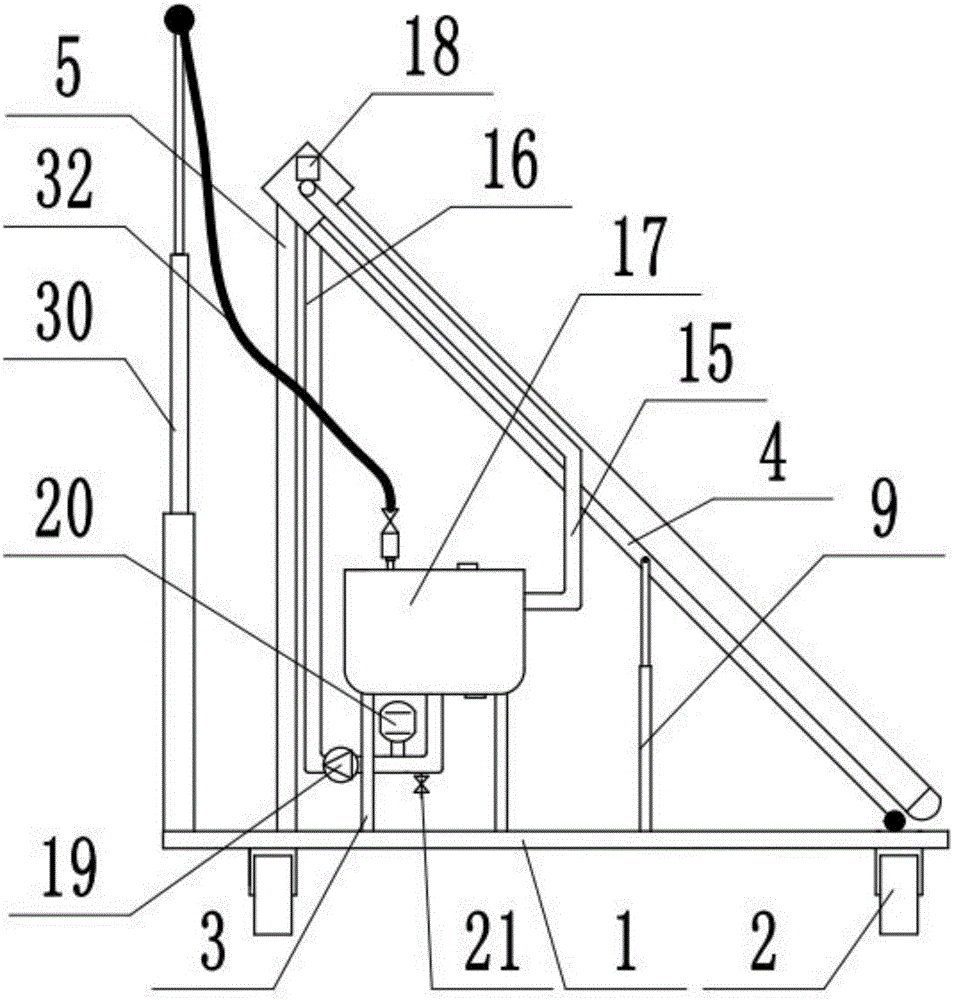

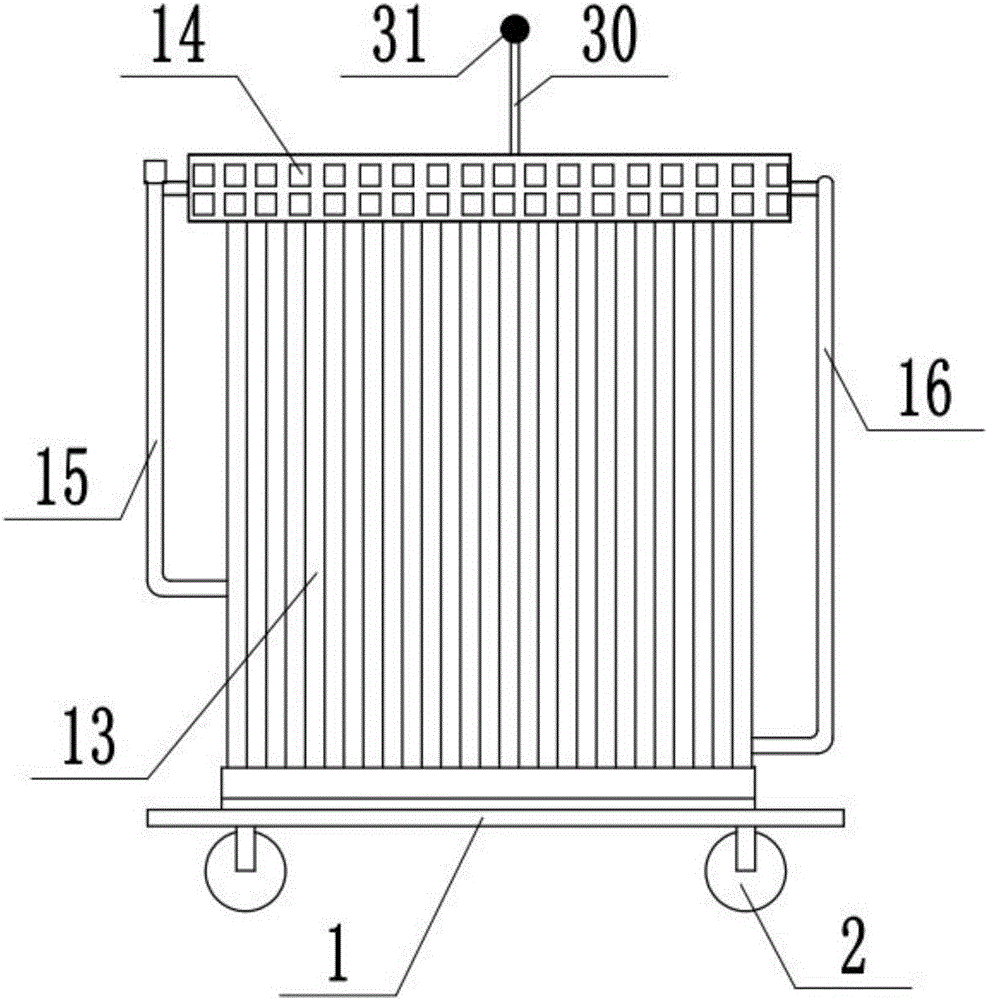

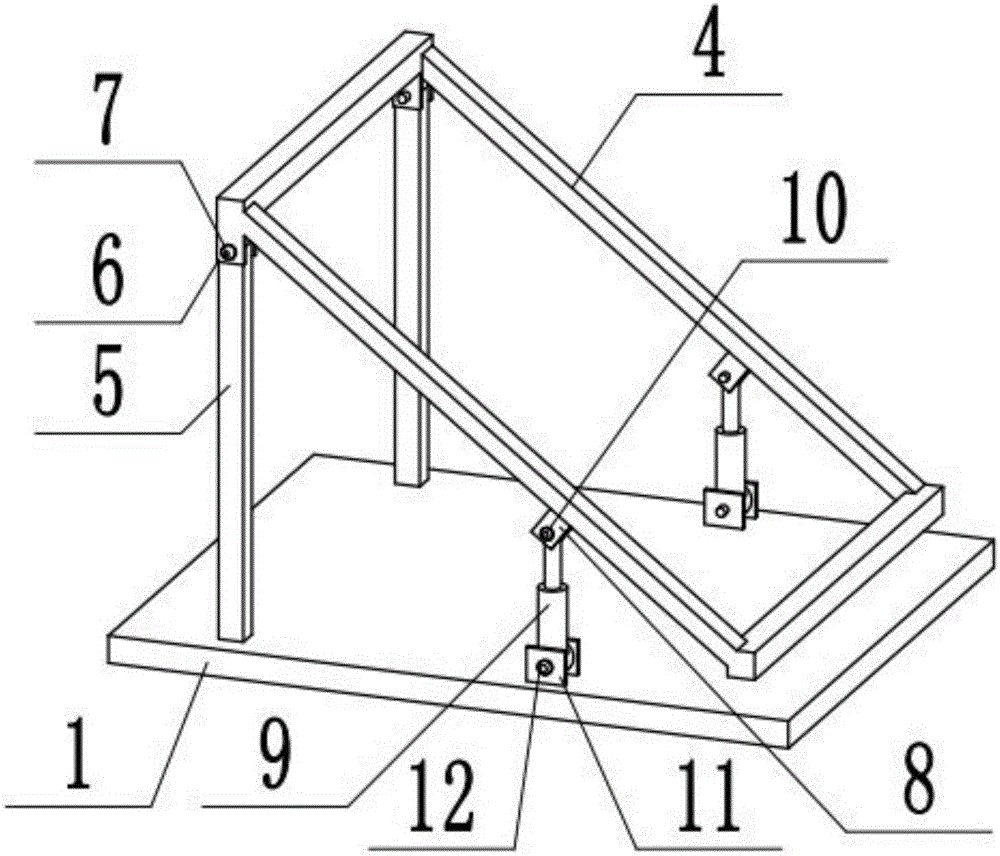

Solar steam cement curing device

ActiveCN106426537AFast startupImprove heat collection efficiencySolar heating energySolar heat devicesExpansion tankExhaust valve

The invention provides a solar steam cement curing device. The device comprises a vehicle body, a heating device, a circular device and a spraying device; the vehicle body comprises a chassis and steering wheels, a water storage tank supporting base is arranged on the upper end face of the chassis, the heating device comprises a supporting frame, a solar heat collector and a solar photovoltaic cell, the circular device comprises a first circular pipeline, a second circular pipeline and a water storage tank, an automatic exhaust valve is arranged between the upper end of the first circular pipeline and the solar heat collector, a direct-current circular pump, an expansion tank and a liquid injection valve are arranged on the second circular pipeline, and the spraying device comprises a telescopic rod, a nozzle and a steam conveying pipeline; and the upper end of the telescopic rod is connected with the nozzle, the lower end of the telescopic rod is connected with the chassis, a steam spraying switch is arranged between the lower end of the steam conveying pipeline and the water storage tank, a temperature pressure safety valve is arranged between the steam spraying switch and the water storage tank, and a temperature sensor is arranged at the upper end of the side wall of the water storage tank. The solar steam cement curing device is suitable for field operation, and is energy-saving, environment-friendly and low in energy consumption.

Owner:山东嘉宇项目管理有限公司

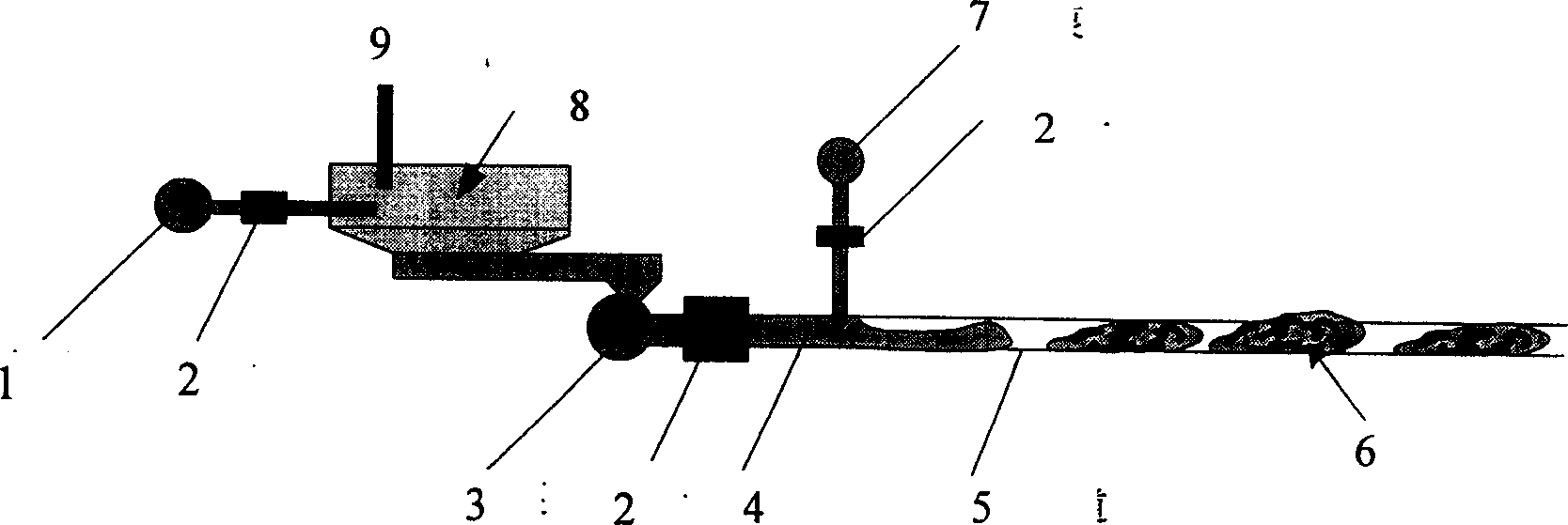

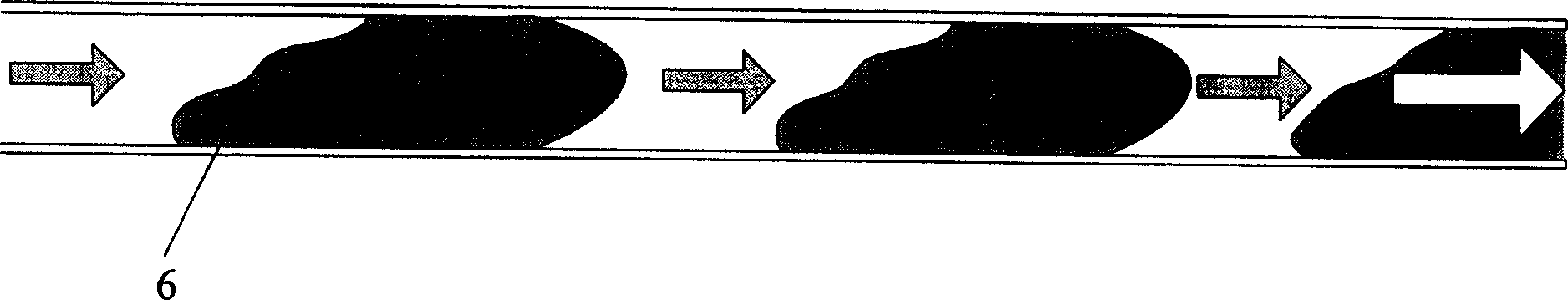

Pipeline sludge solidification treatment method

InactiveCN1830850AEasy constructionEasy to operateSludge treatment by de-watering/drying/thickeningSolid waste managementSludgeCement slurry

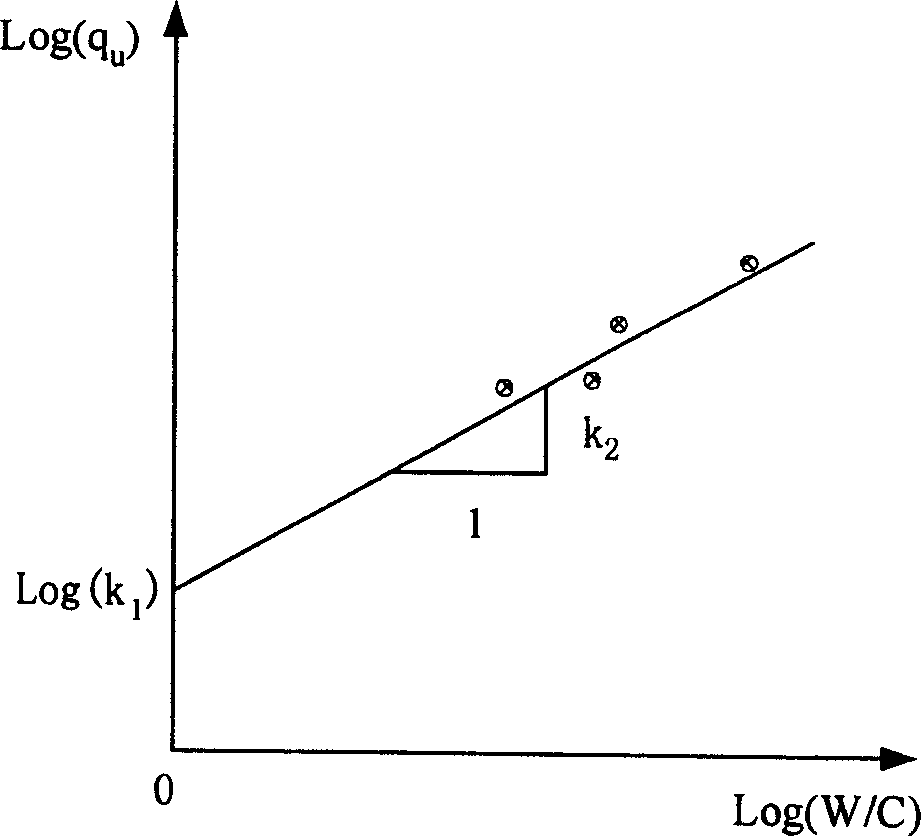

A pipeline delivering method for treating and solidifying the sludge to obtain a building filler includes such steps as indoor solidifying experiment of the sludge to be solidified to determining the relation between its compression strength and total water / cement ratio, sieving the dredged sludge by 1-cm sieve, measuring its content of water, filling cement slurry in pipeline while regulating its water / cement ratio, and using high-pressure air to mix the cement slurry with said sludge and drive the mixture to flow to obtain the solidified sludge.

Owner:SOUTHEAST UNIV

Autoclaved sand-lime brick and preparation method thereof

The invention provides an autoclaved sand-lime brick and a preparation method thereof. The autoclaved sand-lime brick is prepared from the following raw materials: fly ash, calcium carbide powder, tailings, an aggregate, a modifier 1 and a modifier 2; the aggregate is composed of construction waste, coarse slag ash and industrial sludge. In the cement solidification process of industrial solid waste, due to a strong alkaline medium formed by cement hydration, heavy metal ions generate insoluble hydroxide precipitates, oxide precipitates and the like, so that the leaching amount of the industrial solid waste is reduced, an autoclaved lime-sand wall material is prepared, and the influence of the autoclaved lime-sand wall material on human bodies and the ecological environment is effectivelyreduced. Besides, in the production process of the autoclaved brick, the modifier is added besides the industrial solid waste, so that the autoclaved brick with high strength can be produced at lowervapor pressure and temperature, the cost is saved, the energy consumption is reduced, the safety production can be further guaranteed, and the production hidden danger caused by over-high vapor pressure is avoided.

Owner:中盐安徽红四方新型建材科技有限公司

Squeezing cement plugging technical skill for thick oil absorption well

The invention relates to the thick oil absorption well squeeze cementing leakage sealing process technology. The process technology performs the adjustment and controlling according to the pressure difference of the well head oil and the sleeve during the process of the squeeze cementing displacement, in addition, the leakage stoppage, the re-washing of liquid cement and the moving of a pipe column are inexistent during the whole construction process, and the nonpressurized cement curing is adopted. The invention has novel conception, and the adjustment and controlling is easy to be executed, because the invention adopts the leakage stoppage free, the liquid cement re-washing free and the pipe column moving free and the nonpressurized cement curing squeezing cementing methods to construct, the re-washing of the liquid cement, the moving of the pipe column can not be used and the well can be directly shut off to perform cement curing when the cement mortar displacement is positioned, thereby, the time of the squeezing cementation can be shortened, the working risk and the ground pollution are reduced, the invention is favor of saving the cost and shortening the well repairing time, the technology is suitable for the thick oil well layer sealing and the leakage seal, and is particularly effective to the leakage sealing and the strengthening of the outer cement mantle of a sleeve pipe.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

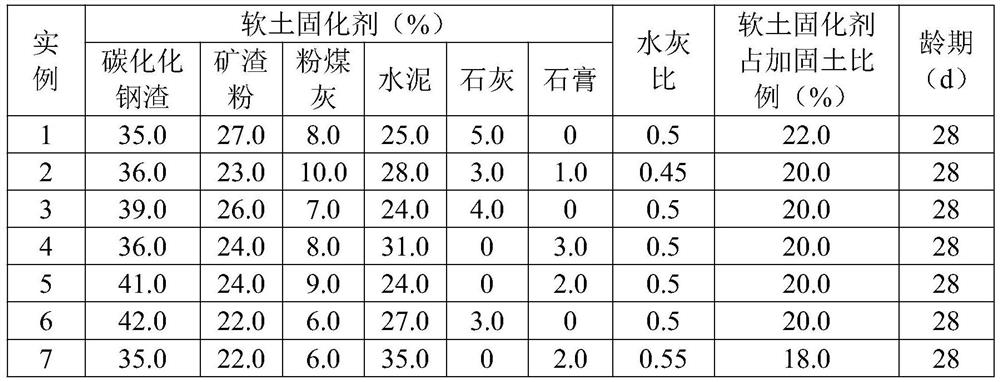

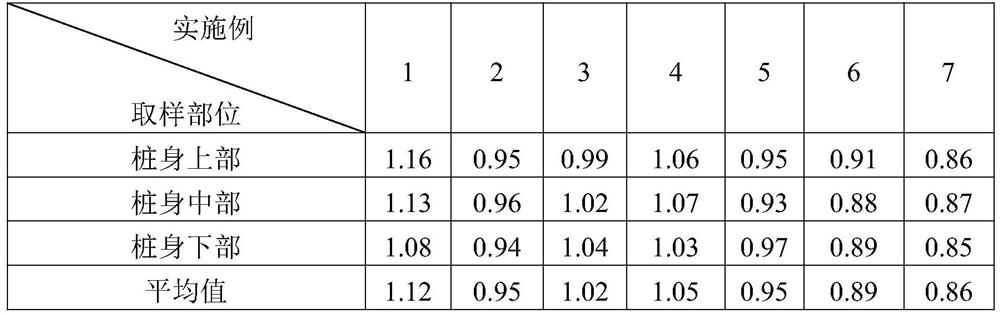

Method for reinforcing soft soil foundation by taking industrial solid waste as main raw material

InactiveCN112921945ASolve the problem of low utilization rate of solid wasteReduce reinforcement costsBuilding constructionsOrganic fertilisersSoil scienceSlag

The invention discloses a method for reinforcing a soft soil foundation by taking industrial solid waste as a main raw material. The raw material of a soft soil curing agent comprises the following components according to mass percent: 35.0% to 42.0% of carbonated steel slag, 22.0% to 27.0% of slag powder, 6.0% to 10.0% of fly ash, 24.0% to 35.0% of cement and 2.0% to 5.0% of lime, gypsum or a mixture of lime and gypsum in any proportion. When the sum of the mass of soft soil, the mass of water and the mass of the soft soil curing agent is 100%, the mixing ratio of the soft soil curing agent is 12.0% to 20.0%; and according to the method, water is added according to the water cement ratio of 0.45 to 0.55, the mixture is stirred so as to prepare soft soil curing agent slurry, and the soft soil curing agent slurry is injected into the soft soil foundation. According to the method, the carbonated steel slag, the slag powder and the fly ash are used for replacing a cement curing agent, so that the problem of low utilization rate of industrial solid waste is solved, the reinforcing cost of a mixing pile of the soft soil foundation is greatly reduced, the treatment problem of the soft soil foundation in urban development and construction is also solved, and the requirements of technical regulations of a reinforcing method of the mixing pile of the soft soil foundation (YBJ225-91) are met.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com