Curing agent for littoral-facy soft soil

A technology of curing agent and soft soil, applied in the field of civil construction materials, can solve the problems of low strength and unsatisfactory reinforcement effect, and achieve the effects of high early strength, low preparation cost and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

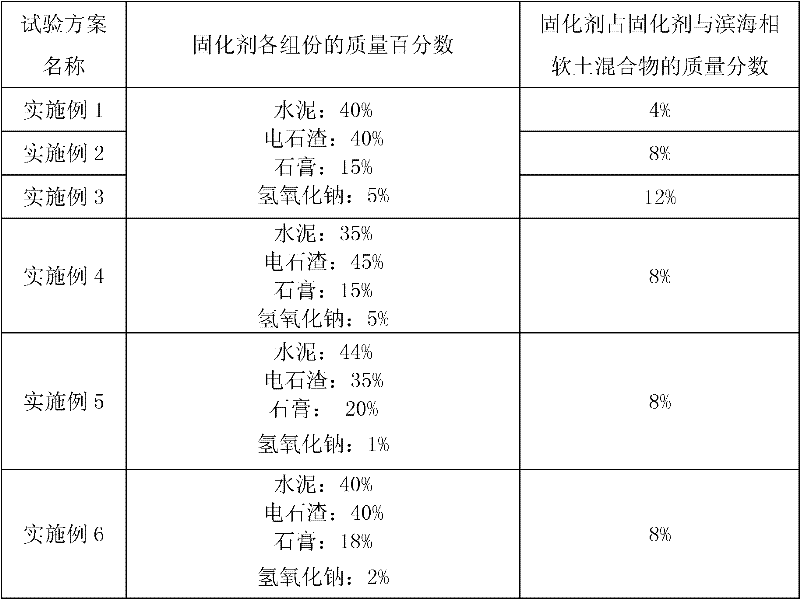

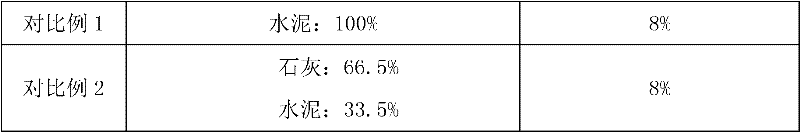

Embodiment 1

[0031] (1) Test material

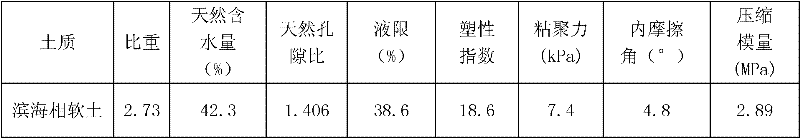

[0032] Coastal facies soft soil: The soil samples used were taken from typical coastal facies soft soil in Lianyungang, Jiangsu Province, and were air-dried before use. The basic physical and mechanical properties are shown in Table 1.

[0033] Table 1 Basic physical and mechanical properties of littoral facies soft soil in Lianyungang area

[0034]

[0035] Cement: "Tianbaoshan brand" 32.5# ordinary Portland cement produced for Nanjing Sanlong Cement Co., Ltd., tested according to the test procedure of GB / T1346-2001, the initial setting time and final setting time are 205min and 260min respectively, and the compressive strength is 12.5Mpa, cement fineness and stability are in line with the quality standard requirements of GB175-1999.

[0036] Carbide slag: produced by Changzhou Acetylene Manufacturing Company in Jiangsu Province, with a CaO content of 68.99% and a loss on ignition of 24.85%.

Embodiment 2

[0048] The mass percentages of each component in the test material and curing agent of this embodiment are the same as in Example 1, except that in the second step of the test method, the mass ratios of curing agent and coastal soft soil are different. In this embodiment, the mass ratio of curing agent to coastal soft soil is 8:92. The experimental results are shown in Table 3.

Embodiment 3

[0050] The mass percentages of each component in the test material and curing agent of this embodiment are the same as in Example 1, except that in the second step of the test method, the mass ratios of curing agent and coastal soft soil are different. In this embodiment, the mass ratio of curing agent to coastal soft soil is 12:88. The experimental results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com