Slurry curing formula

A formula and slurry technology, applied in the field of civil construction materials, can solve the problems of slow setting and hardening, waste of resources, low curing strength, etc., and achieve good economic and social benefits, reduce cement consumption, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

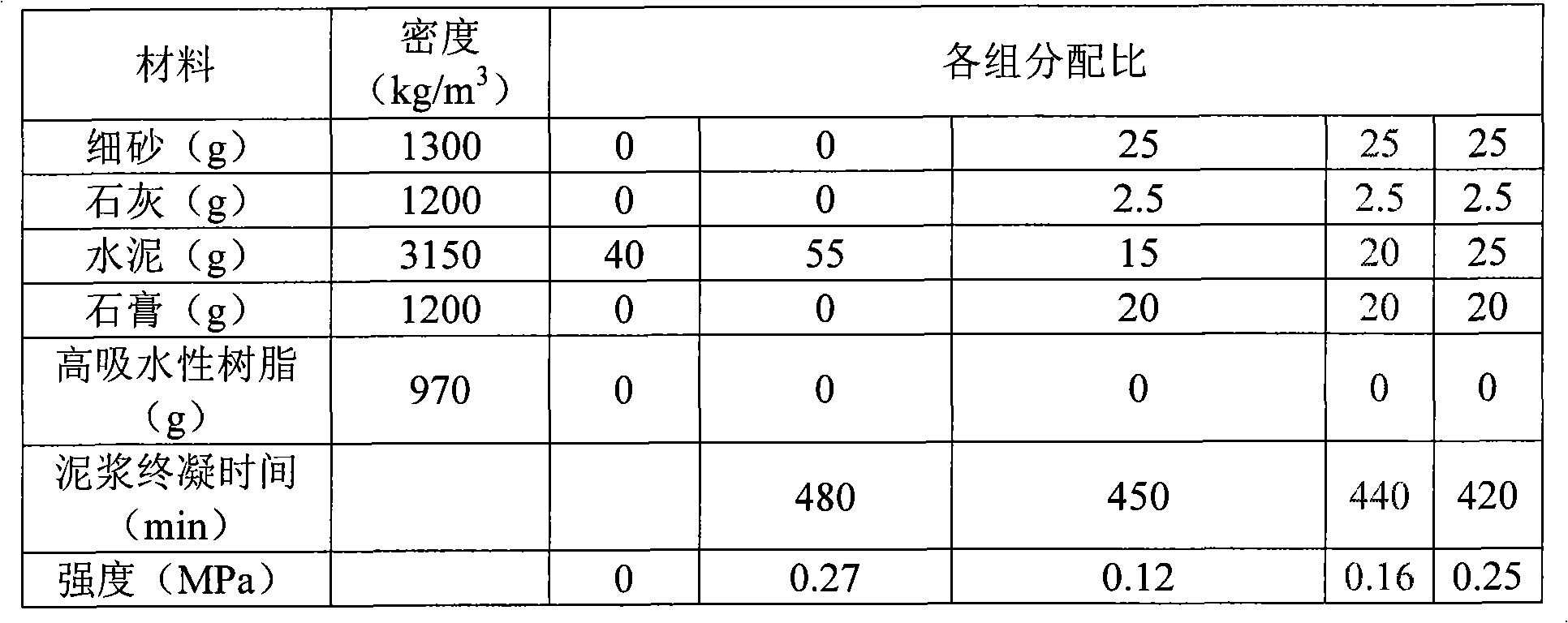

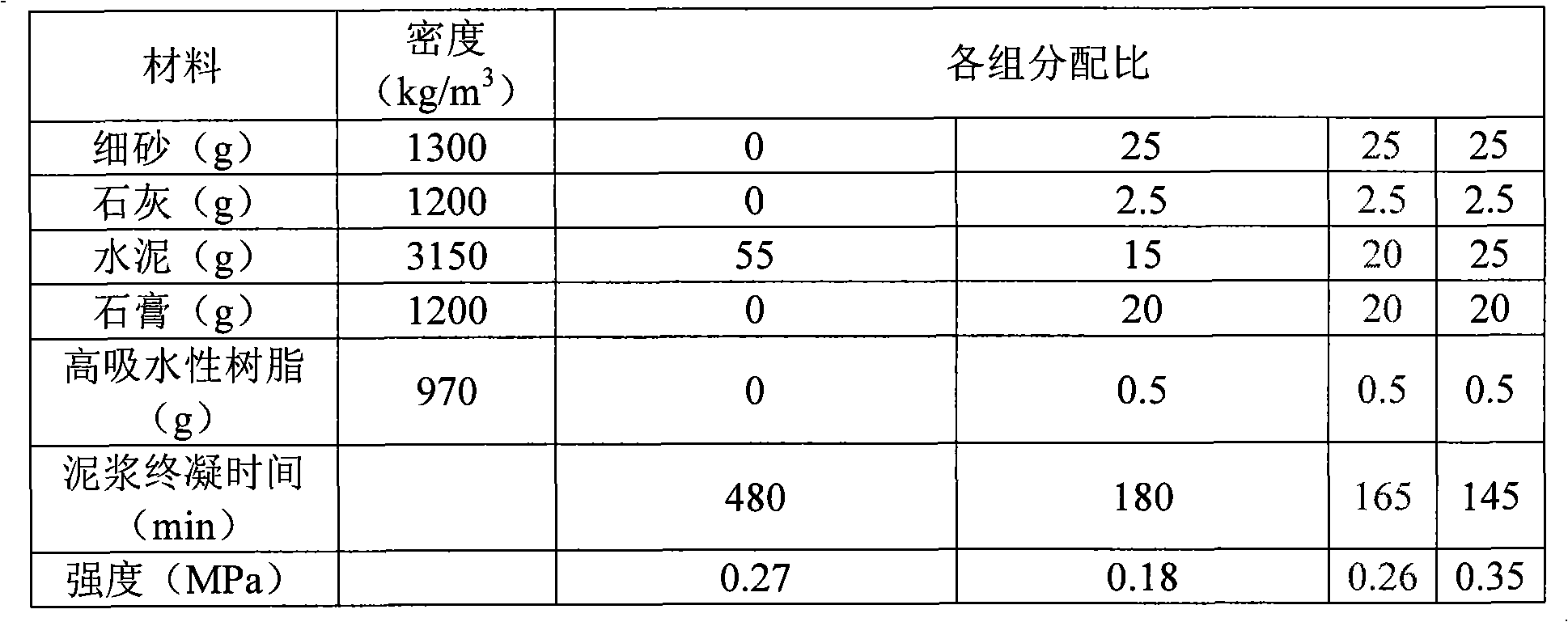

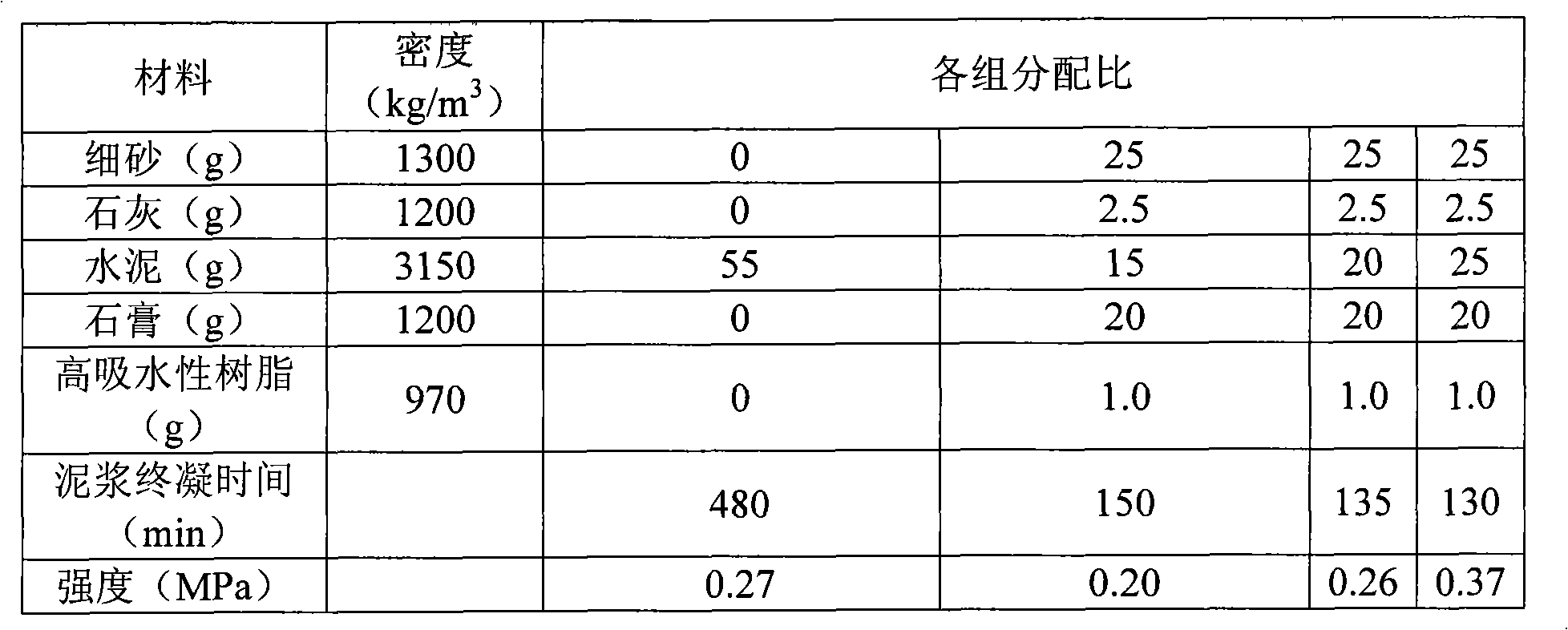

Embodiment 1

[0014] The conventional size of the mortar test is adopted, and the sample size is 70.7mm×70.7mm×70.7mm. The mud to be solidified is the mud for bored piles at a construction site, with a moisture content of 200% and a density of 1.36g / cm 3 . Mix the curing agent and the mud evenly and pour it into the test mold, insert and tamp it manually so that the mud surface is 3-5mm higher than the test mold, lift one end of the test mold and vibrate 5-10 times, then lift the other end of the test mold to vibrate 5-10 times , to smooth the surface. After the test block was formed, it was cured at 20°C for 24 hours to be demoulded, and then placed in a standard curing room for curing. The unconfined compressive strength of the mud solidified body was measured at the age of 7 days. The raw materials for curing agent preparation are: the cement used is ordinary portland cement with the label of 425; the fine sand used is sand with a fineness modulus of 1.7; the lime used is slaked lime ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com