Patents

Literature

34 results about "Cobalt(II) naphthenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt(II) naphthenate is a mixture of cobalt(II) derivatives of naphthenic acids. These coordination complexes are widely used as oil drying agents for the autoxidative crosslinking of drying oils. Metal naphthenates are not well defined in conventional chemical sense that they are mixtures. They are widely employed catalysts because they are soluble in the nonpolar substrates, such as the alkyd resins or linseed oil. The fact that naphthenates are mixtures helps to confer high solubility. A second virtue of these species is their low cost. A well-defined compound that exhibits many of the properties of cobalt naphthenate is the cobalt(II) complex of 2-ethylhexanoic acid. Often in technical literature, naphthenates are described as salts, but they are probably also non-ionic coordination complexes with structures similar to basic zinc acetate.

Anaerobic adhesive compositions having microencapsulated metal ions

ActiveUS20080242764A1Improve adhesionImprove propertiesSynthetic resin layered productsOrganic non-macromolecular adhesiveCopper naphthenateCobalt(II) naphthenate

An enhanced anaerobic adhesive composition containing microencapsulated metal ions is disclosed. Microencapsulated metal ions, such as iron oxide, copper naphthenate, cobalt naphthenate, ferrocene, and ferrocene derivatives, act as bonding sites in the composition, such that the composition achieves more complete polymerization in a shorter curing time. The curing properties and the cure quality are significantly improved by the inclusion of microencapsulated metal ions. The composition can be used to bond metal and plastic substrates.

Owner:ND IND INC

Method for fabricating artificial stone, and artificial stone with luminescence function, and products

A process for preparing artificial stone and artificial luminous stone includes such steps as proportionally adding phthalate and tetramethyl (or pentamethyl) derivative to unsaturated resin, stirring, adding the vinyl derivative of benzene, stirring, adding MMA, high-speed stirring, adding filler, pigment, modified resin, methylethyl ketone peroxide and cobalt nephthenate, stirring, filling the mixture in mould, vacuumizing, heating at 50-70 deg.C for 1-3 hr, heating at 75-85 deg.C for 1-3 hr, natural cooling, and demoulding. Its products are also disclosed.

Owner:金国华

Anticorrosion primer paint for chimney of electric plant and its uses

InactiveCN101007923AHigh viscositySpeed up the flowAnti-corrosive paintsPolyester coatingsBenzeneAdhesion force

The invention relates to anticorrosion priming paint for power plant chimney, comprising unstaurated polyester base material and curing agent, and the proportion by weight between them is 100: 0.3-3. Said unstaurated polyester base material comprises: chemical-resisting unstaurated resin 20-70 (proportion by weight), cobaltic naphthenate 0.1- 1.0 (proportion by weight), alumina silicate 79.7- 28 (proportion by weight), and gas phase silica dioxide 0.2- 10 (proportion by weight). Said curing agent comprises: methyl-ethyl ketone peroxide 30- 70 (proportion by weight) and butyl benzene o-dicarboxylate 70- 30 (proportion by weight). The anticorrosion priming paint is characterized by fast curing, easy- polishing, little organic solvent discharging, strong adhesion force, simple process, convenient utilization and good corrosion resistance performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Anaerobic adhesive compositions having microencapsulated metal ions

ActiveUS8865794B2Enhanced anaerobicImprove curing effectSynthetic resin layered productsOrganic dyesCopper naphthenateCobalt(II) naphthenate

An enhanced anaerobic adhesive composition containing microencapsulated metal ions is disclosed. Microencapsulated metal ions, such as iron oxide, copper naphthenate, cobalt naphthenate, ferrocene, and ferrocene derivatives, act as bonding sites in the composition, such that the composition achieves more complete polymerizations in a shorter curing time. The curing properties and the cure quality are significantly improved by the inclusion of microencapsulated metal ions. The composition can be used to bond metal and plastic substrates.

Owner:ND IND INC

Highly effective diesel fuel additive and its production method

InactiveCN1546615AGuaranteed cleanlinessEasy dischargeLiquid carbonaceous fuelsManganeseCobalt(II) naphthenate

Highly effective diesel fuel additive and its production method, wherein the components and weight content are, toluene 25-45 parts, diesel fuel 25-50 parts, camphor 4-11 parts, refined naphthalene 10-20 parts, isopropyl alcohol 0.5-2 parts, benzenemethanol 1-3 parts, ferrum naphthenate 12-25 parts, cobaltic naphthenate10-25 parts, manganese naphthenate 45-90 parts, calcium naphthenate 40-90 parts. The preparation process comprises the steps of mixing toluene and diesel fuel, heating camphor and refined naphthalene, charging the mixed liquid of camphor and refined naphthalene into container containing toluene and diesel fuel, mixing with isopropyl alcohol and benzene methanol to obtain concentration liquid, weighing and mixing ferrum naphthenate, manganese naphthenate, cobaltic naphthenate and calcium naphthenate, mixing the concentration liquid with the four raw materials.

Owner:孙怀道

Additive and method for removal of impurities formed due to sulfur compounds in crude oils containing calcium naphthenate

An additive capable of avoiding formation of impurities and capable of removing or dissolving impurities formed and accumulated at the interphase of organic and aqueous layers on reaction between calcium naphthenate and sulfur compound including H2S in presence of water in mixture of crude oils containing calcium naphthenate and sulfur compound or H2S, wherein the additive is glyoxylic acid is provided. A method for avoiding formation of impurities and for removing or dissolving impurities formed and accumulated at the interphase of organic and aqueous layers on reaction between calcium naphthenate and sulfur compound including H2S in presence of water in mixture of crude oils containing calcium naphthenate and sulfur compound including H2S, comprising treating mixture of crude oils containing calcium naphthenate and sulfur compound or H2S with glyoxylic acid is also provided.

Owner:DORF KETAL CHEM (I) PTE LTD

Method for producing benzoic acid

ActiveCN101492368AShort reaction timeShorten distillation timeOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidHigh energy

A benzoic acid production method solves the technical problems of the existing production method such as long reaction time, long rectification separation time, low yield, high energy consumption, high cost, low product output and poor quality. In the production method, cobalt naphthenate is used as a catalyst to oxidize toluene and then the product obtained in the oxidation reaction is rectified to obtain the final product. The oxidization time is 8 to 10 hours, the reaction temperature is 155 to 165 DEG C and the reaction pressure is 0.55 to 0.62MPa; the rectification separation time is 4.5 to 7 hours, the rectification temperature is 177 to 190 DEG C, the rectification pressure is -0.09 to -0.085MPa and the reflux time is 0.5 to 1.5 hours. The invention with simple process, short flow, low energy consumption and no pollution can be used in the large-scale production of benzoic acid.

Owner:BEIJING HONGYUESHUN CHEM FACTORY

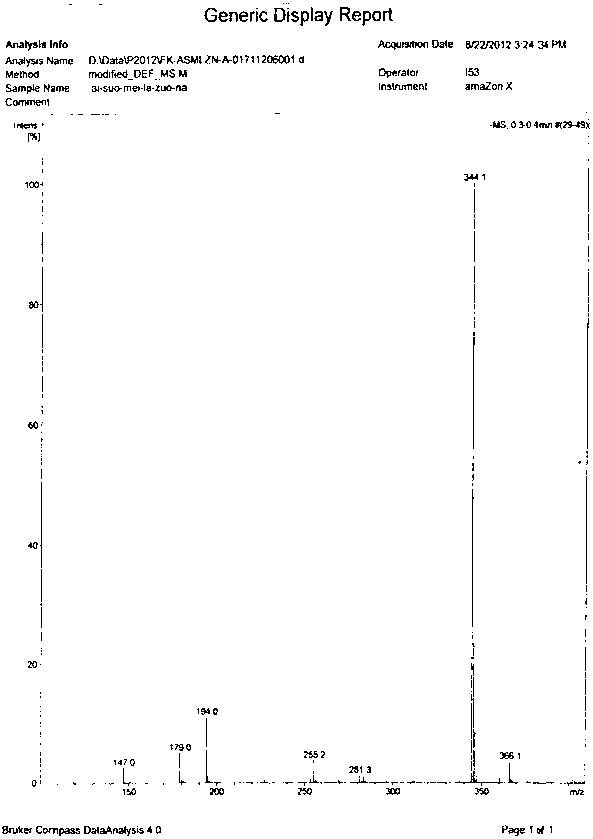

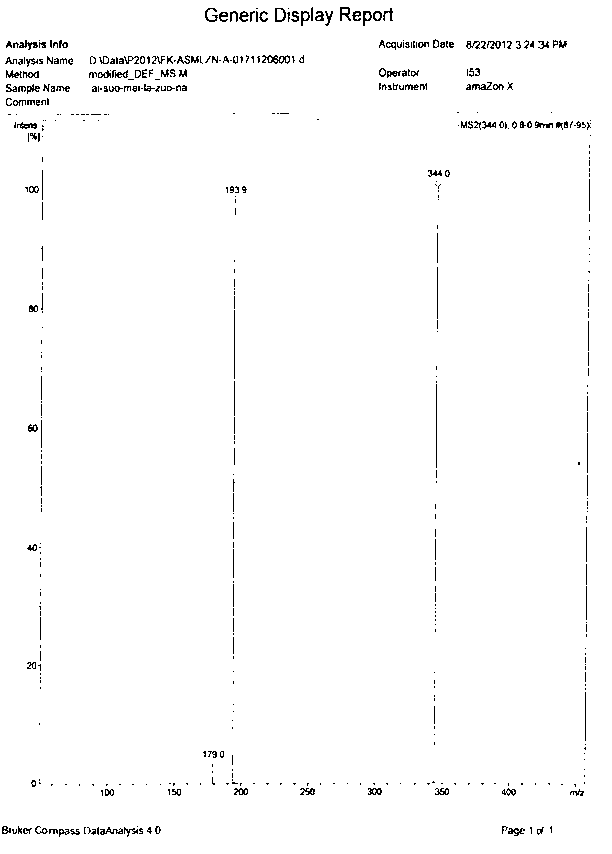

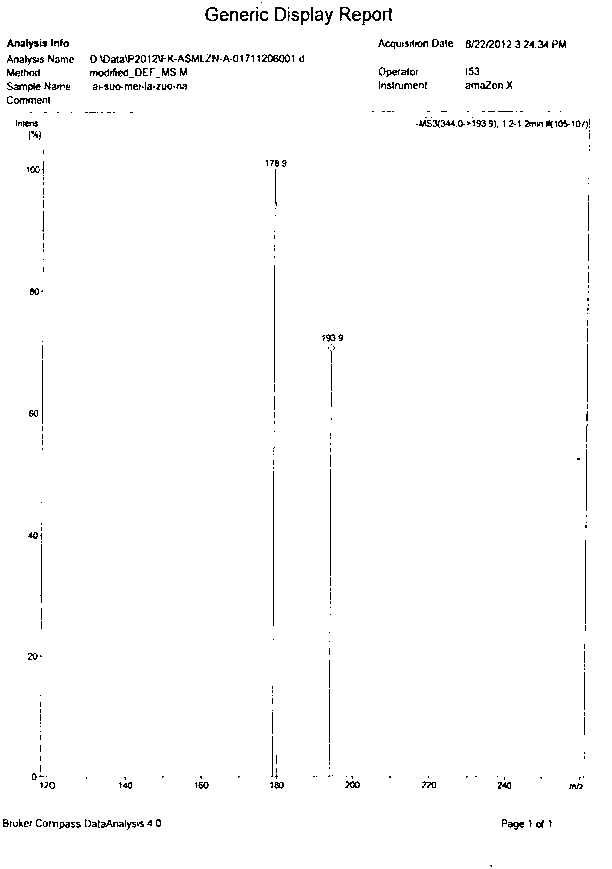

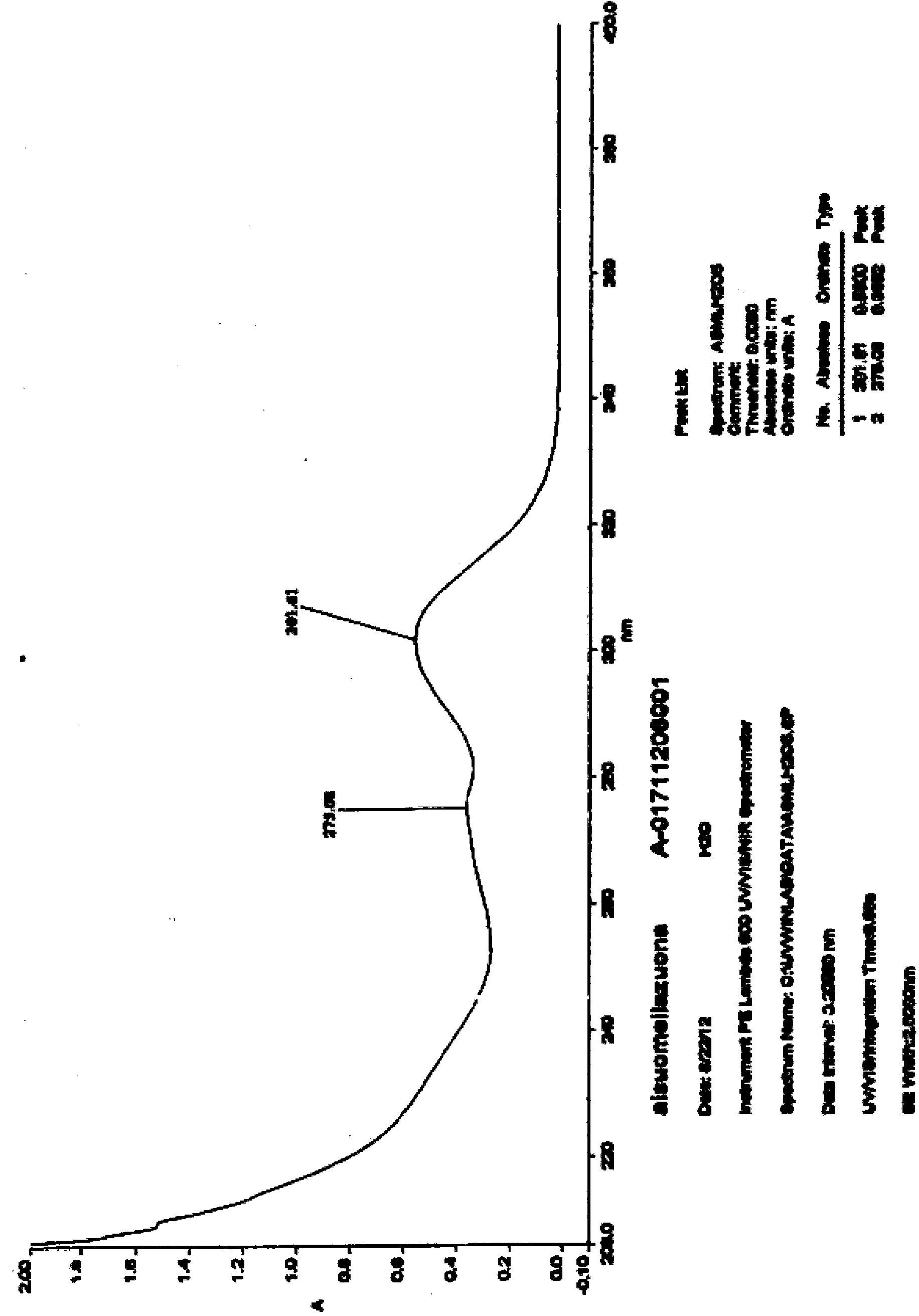

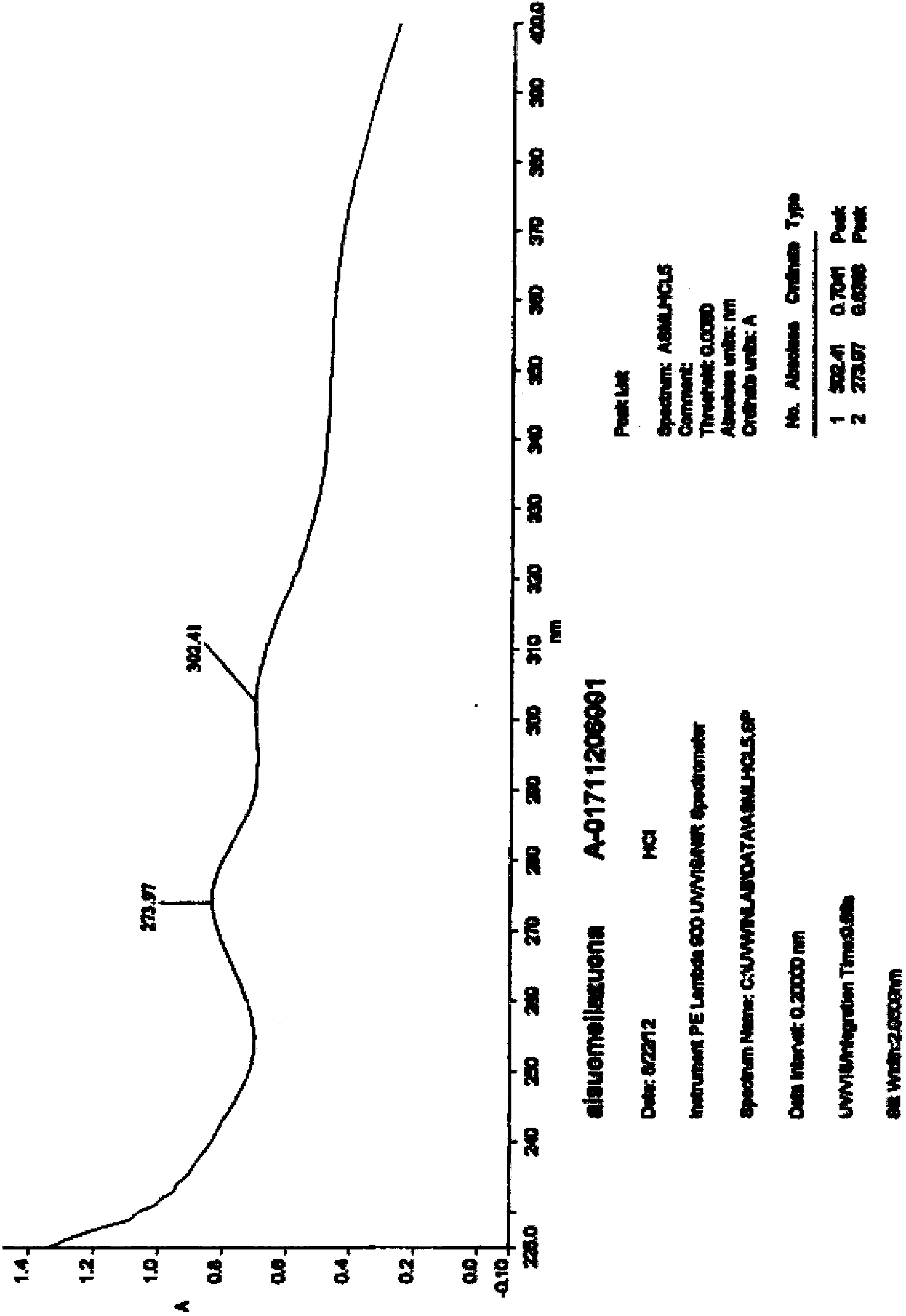

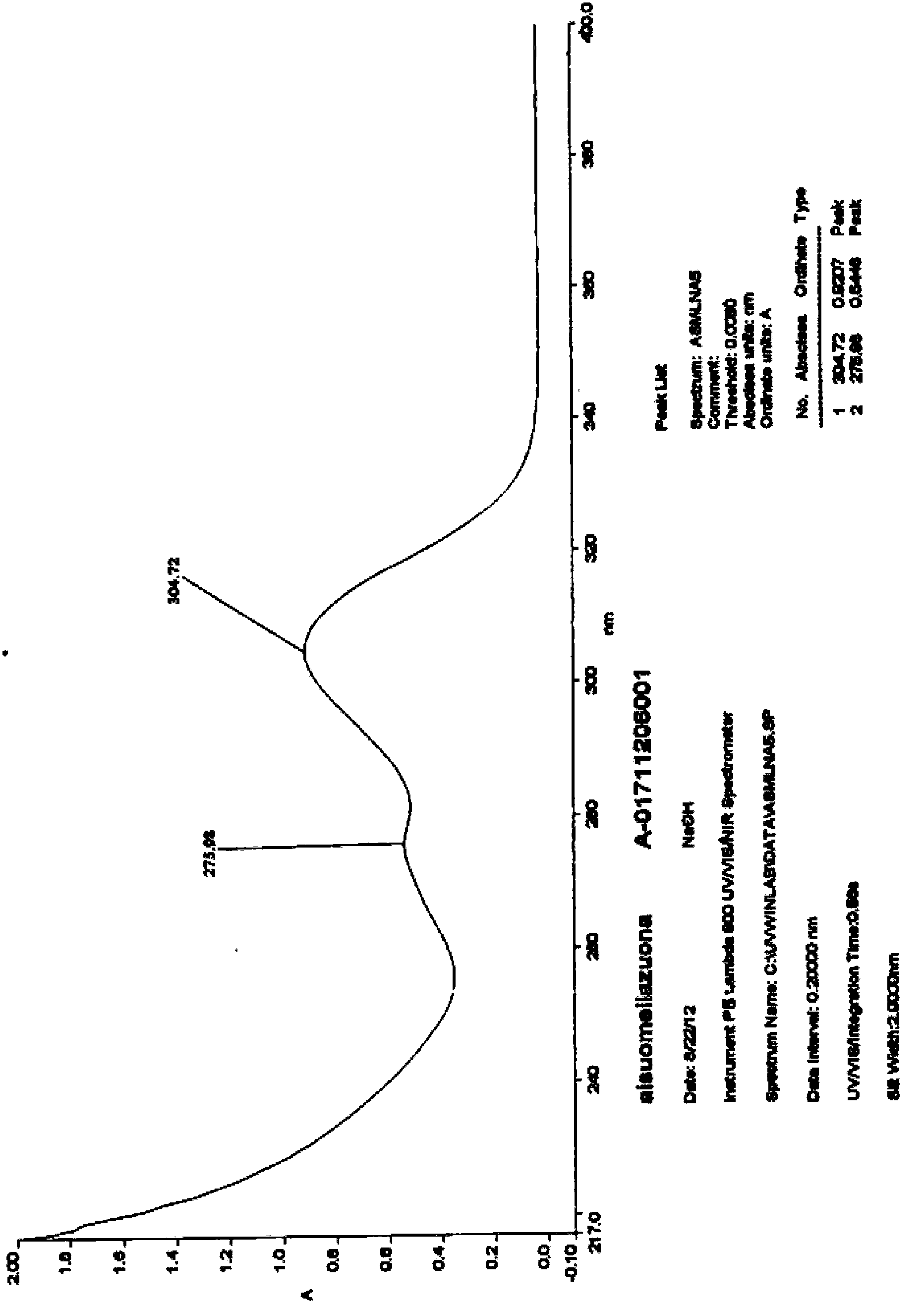

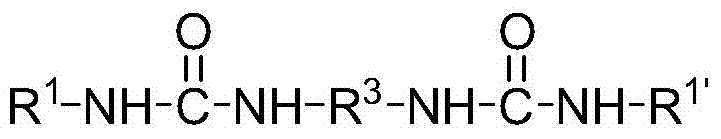

Preparation method of Esomeprazole and preparation method of Esomeprazole sodium

The invention provides a preparation method of Esomeprazole and a preparation method of Esomeprazole sodium, and (1S,2S)-(-)-1,2- hexamethylene diamine-D-tartrate is used as a chiral ligand, cobaltous naphthenate is used as catalyst, and Esomeprazole is prepared by asymmetric oxidation of 2-(((4-methoxy-3,5-dimethyl-2-pyridyl)methyl)sulfur-base)-1H-benzimidazole under the effect of catalyst with catalysis amount, and the prepared Esomeprazole has a better stereoselectivity and generation of peroxide sulfone is avoided. Simultaneously, sodium hypochlorite or sodium peroxide are used as oxidizing agent for preparing Esomeprazole sodium, and the sodium containing compound in the reaction process is used as oxidizing agent and sodium source, thereby the oxidation reaction and the salt forming reaction can be completed in the same reaction system with simple synthesis process.

Owner:SHOUGUANG FUKANG PHARMA

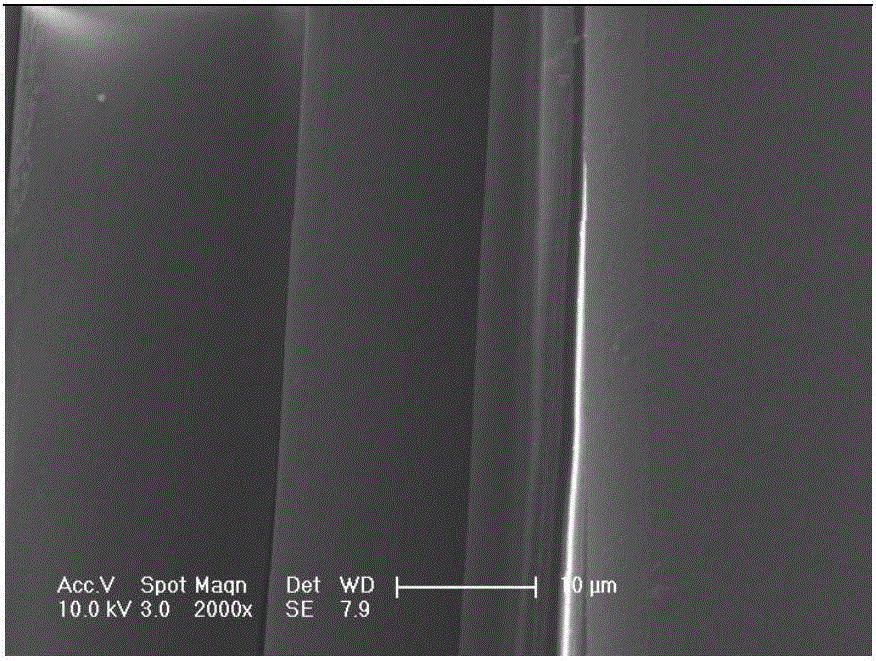

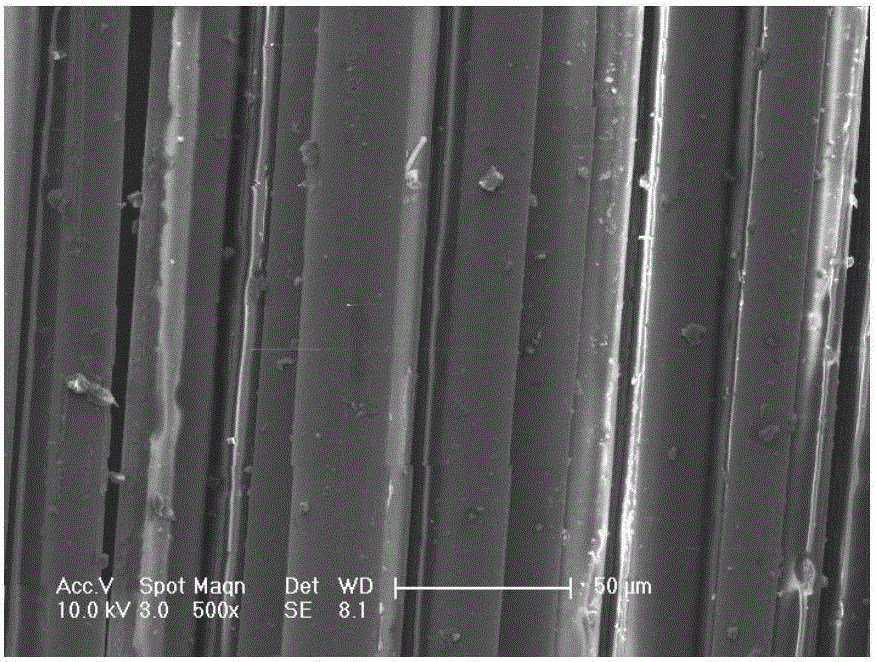

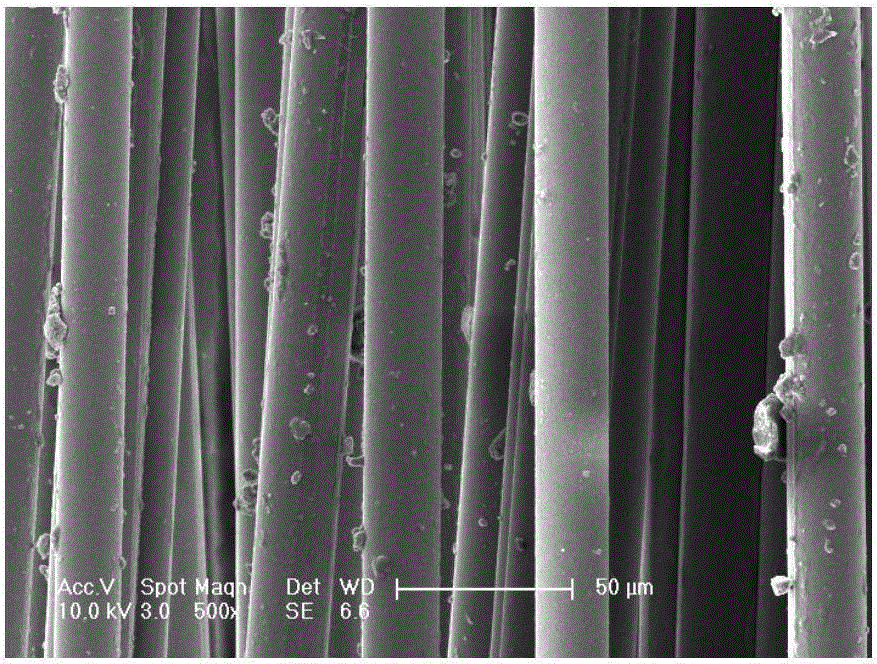

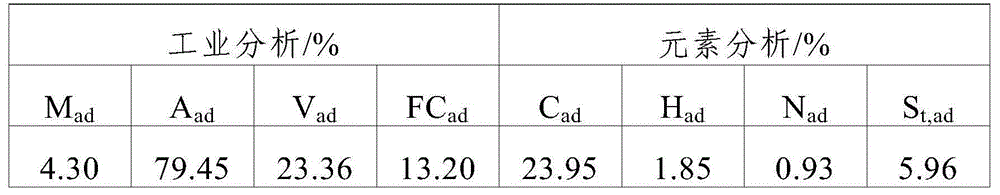

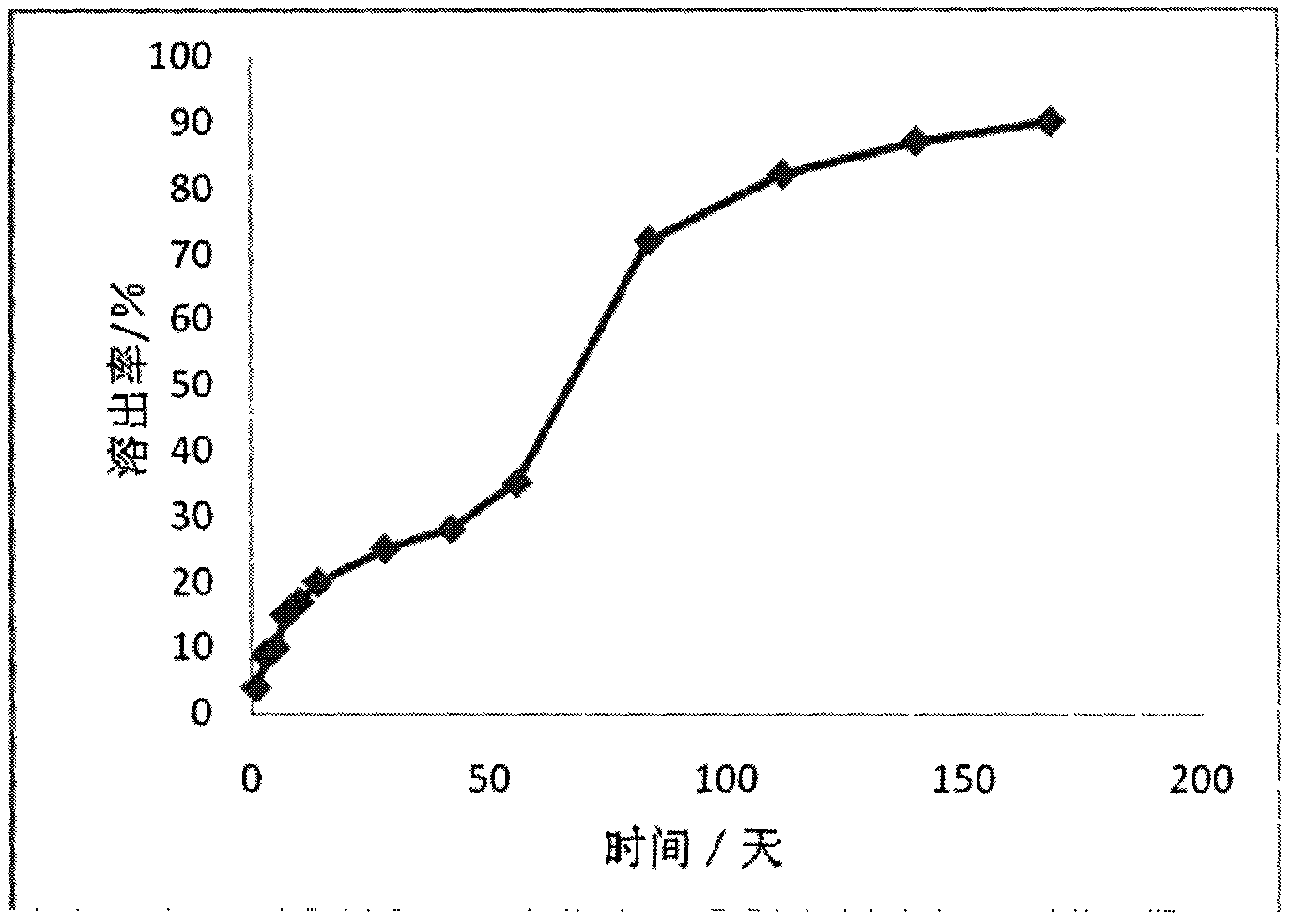

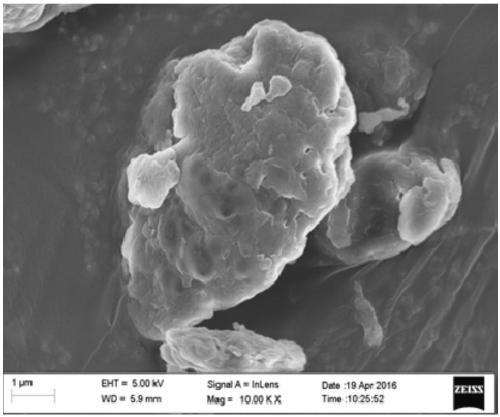

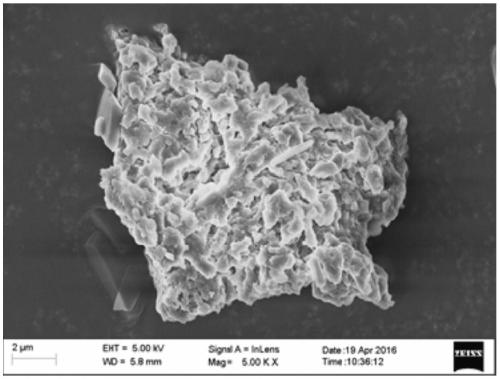

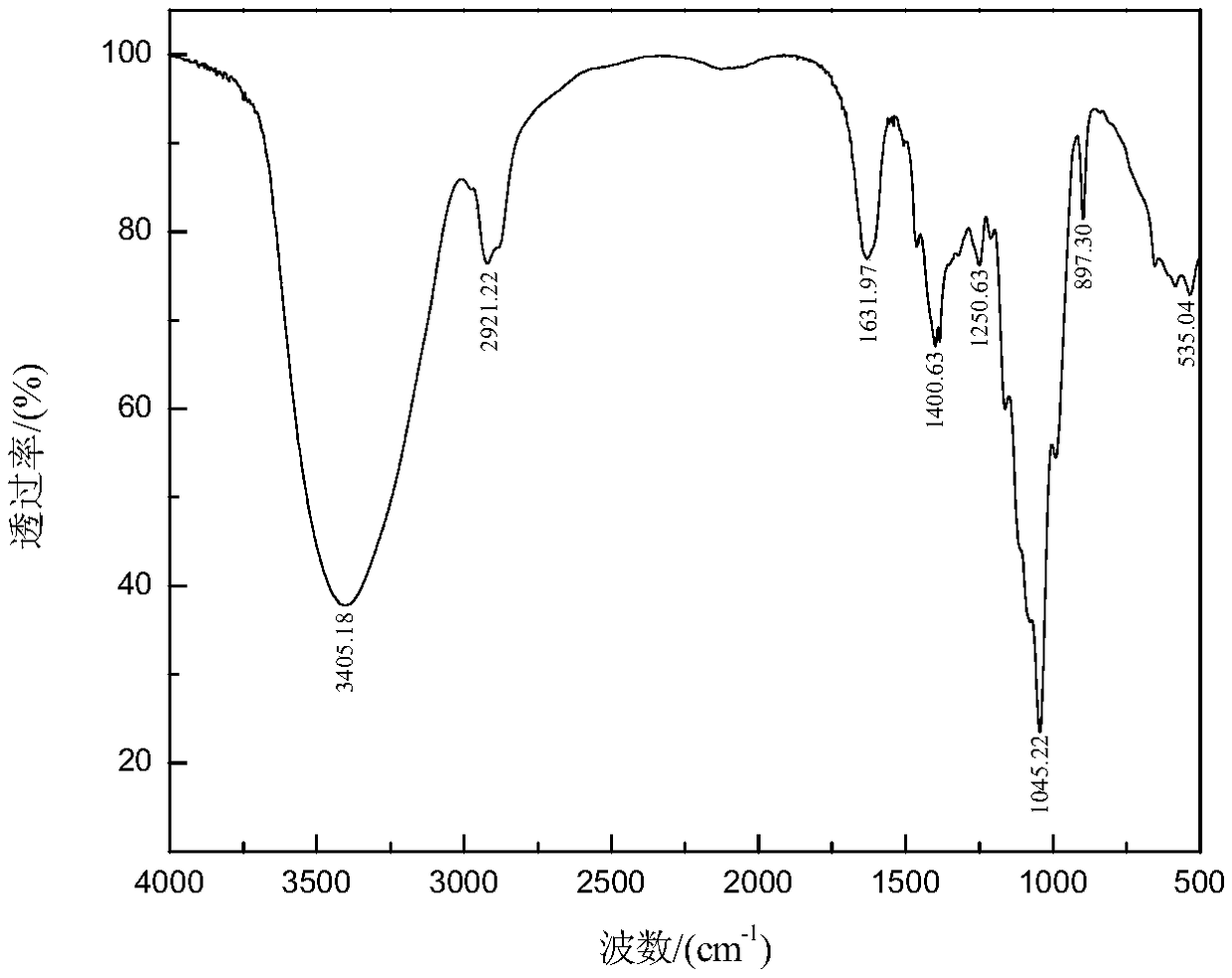

Glass fibre/vinyl ester resin composite material with interface modification by nanometer SiO2 and preparation method thereof

The invention provides a glass fibre / vinyl ester resin composite material with interface modification by nanometer SiO2 and a preparation method thereof. The method comprises the following steps: (1) nanometer SiO2 and a silane coupling agent are dispersed into ethanol, supersonic wave oscillation is carried out for dispersion, stable nanometer SiO2 suspending liquid is formed for standby; (2) glass fibre is immersed with ethanol for cleaning the surface, the nanometer SiO2 suspending liquid is filled in a spray gun, the spray gun sprays the suspending liquid on the prepared glass fibre, the glass fibre is placed at a room temperature, after ethanol is fully volatilized, the nanometer SiO2 modified glass fibre is prepared for standby; (3) methylethyl ketone peroxide, N,N-dimethyl formamide, cobaltous naphthenate are added into vinyl ester resin, vacuum-pumping and uniform stirring are carried out, in order to obtain a vinyl ester resin mixture; (4) the nanometer SiO2 modified glass fibre obtained in the step (2) is placed in a die, the vinyl ester resin mixture prepared in the step (3) is gradually added into the die, and solidification is carried out. The preparation method is simple and has good effects.

Owner:BAOYING COUNTY RUICAI ELECTRIC MATERIAL

PMMA (Polymethyl Methacrylate) type two-component road marking material and preparation method thereof

ActiveCN103254717ASolve weather resistanceSolve chronic drynessCoatingsAntioxidantPolymethyl methacrylate

The invention relates to a PMMA (Polymethyl Methacrylate) type two-component road marking material and a preparation method thereof. The PMMA type two-component road marking material is prepared from the following raw materials in percentage by mass: 40% of liquid PMMA resin, 15% of rutile titanium dioxide, 36% of 325# calcium carbonate, 0.5% of a BASF (Badische Anilin Soda Fabrik) antioxidant, 1.5% of an organic anti-settling agent, 0.5% of a BYK surface wetting agent, 2.5% of organic pigment, 0.3% of a molecular weight regulator, 1.5% of a plasticizer, 0.5% of a permeation aid, 0.2% of an acid value balancing agent and 1.5% of high-cobalt naphthenic acid-containing cobalt. The PMMA type two-component road marking material has the beneficial effects that the problems of poor weather fastness, slowly drying property and initial properties of the materials are solved; the product is green and environment-friendly material; and the PMMA type two-component road marking material as a novel material with low carbon emission is convenient to use, high in construction efficiency, simple to prepare and easy to operate.

Owner:保定市科顺达交通设施有限公司 +2

Phenolic aldehyde varnish

A phenolic aldehyde varnish comprises, by weight, 4-6 parts of light calcium carbonate, 70 parts of phenolic aldehyde paint, 6-8 parts of tung polymerized oil, 6-8 parts of solvent naphtha 200, 0.5-0.6 part of 2% cobaltous naphthenate, 0.5-0.6 part of 2% manganese naphthenate, 0.8-1 part of 10% lead naphthenate and 6-8 parts of pigment scarlet powder. The invention has advantage that the enamel is suitable for surface coating of indoor woodenware in building engineering, traffic tool and machinery equipment, and metal manufacturing; besides the varnish has a good effect and low production cost.

Owner:李之洲

Catalyst for pyrolysis of oil shale, preparation method and application method thereof

InactiveCN103878031BIncrease lytic activityHigh cracking rateOrganic-compounds/hydrides/coordination-complexes catalystsSpecial form destructive distillationCatalytic pyrolysisLiquid fuel

The invention discloses a catalyst for pyrolysis of oil shale. The catalyst is prepared from the following raw materials by weight percentage: 2-8% of a molecular sieve, 1-5% of activated clay, 10-60% of organic cobaltate, 5-20% of metal sulfide, 8-30% of glycerate, and 15-35% of paraffin; the organic cobaltate is one or more of cobalt acetate, cobalt oxalate, cobalt naphthenate and cobalt neocaprate; the metal sulfide is molybdenum sulfide and / or nickel sulfide. The invention further discloses a preparation method of the catalyst and a use method of the catalyst. According to the catalyst disclosed by the invention, the pyrolysis efficiency of the oil shale can be improved, the distribution of pyrolysis products of the oil shale is improved, more light products are produced, and components of gasoline and diesel oil can be separated through rectification. According to the preparation method and use method of the catalyst, which are disclosed by the invention, the catalytic pyrolysis and microwave heating are combined, so that the utilization efficiency of energy source can be improved, the composition and process performance of liquid fuel are improved, and the following processing difficulty is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of polyputty used for wood furniture

InactiveCN102408766AGood construction performanceEasy to useFilling pastesPolyesterDimethylaniline N-oxide

The invention discloses a preparation method of polyputty used for wood furniture, the polyputty is composed of a main agent and a curing agent. The main agent is composed of unsaturated polyester resin, styrene, triallyl phosphate, bentonite, white alundum, gas phase SiO2, attapulgite clay, hydroquinones, copper naphthenate, dimethylaniline, titanium dioxide and cobaltous naphthenate; the curing agent is composed of cyclohexanone peroxide, gas phase SiO2, titanium dioxide and polyvinylpyrrolidone; the preparation method comprises the following steps: the main agent production, curing agent preparation, putty preparation and the like. The polyputty has the advantages of good application property, fine putty membrane, smoothness, flattening, good flexibility and shrinkage resistance, and enable a matching usage with various mainstream wood paints such as acrylic acid, nitro, polyester, polyurethane and the like in market.

Owner:高立波

Coating capable of quick-drying at normal temperature and resisting corrosion and preparation method thereof

InactiveCN101760064ARich textureImprove water resistanceAnti-corrosive paintsCross cutCis-Butenedioic Acid

The method relates to a coating capable of quick-drying at normal temperature and resisting corrosion and a preparation method thereof. The coating comprises the following components by weight ratio: 80 parts of liquid maleate polybutadiene, 10 parts of ethylene glycol dimethacrylate, 10 parts of tetrahydrofurfuryl alcohol, 80 parts of titanium dioxide, 1.0 part of cobalt naphthenate and 2.5 parts of methyl ethyl ketone peroxide. The coating consisting of organic matters is prepared by mixing the components and has the following superior physical properties: the coating is dry-to-touch within 3h and completely cured within 6h with the thickness of the cured coating being mum at room temperature; the pencil hardness of the coating is 2H; the impact strength thereof is higher than 50 according to the Dupont impact tester; the adhesion thereof is 7.5mm according to the Erichsen tester; the coating is qualified according to the cross-cut test; and the coating is corrosion resistant, particularly, no abnormality like rust is detected after 200h, the coating is qualified according to the waterproof test at 40 DEG C after 400h, and no abnormality is detected according to the test in the water solution of sodium hydroxide (5%) at room temperature for 24h. Accordingly, the coating of the invention constituting a low-viscosity high-build coating capable of self-curing at normal temperature is applicable as anti-corrosive and protective coatings in the construction based on the conventional coating construction method.

Owner:刘新光

Teflon-modified vinyl terrace paint

InactiveCN104694009AHigh strengthGood chemical resistanceAnti-corrosive paintsSurface layerCrack resistance

The invention discloses a teflon-modified vinyl terrace paint, which is shortly named as a FVC terrace paint. The paint is composed of a component A, a component B and a component C, wherein the component A is prepared by nine substances such as vinyl resin, teflon resin, pvc resin, and an anionic carboxylic acid polymer dispersant; the component B is methylethyl ketone peroxide and the component C is cobaltous naphthenate, while in use, the teflon-modified vinyl terrace paint is prepared by weight ratio of the component A to the component B to the component C being 100: 1.5-4: 1.5-4. The invention also discloses a formula and a making technology for making anticorrosion terrace by using the teflon-modified vinyl terrace paint. The paint has the characteristics of excellent chemical medium corrosion resistance, weatherability, oiliness resistance, water resistance, and good machinery performance and application property, usage life is long, cracking resistance performance is good, and the paint can be used in the chemical, pharmacy, petroleum and food industries as a protection material for a matrix surface layer of a concrete floor, metope building structure and a member.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Preparation method of polyputty used for wood furniture

InactiveCN102408766BGood construction performanceEasy to useFilling pastesPolyesterDimethylaniline N-oxide

The invention discloses a preparation method of polyputty used for wood furniture, the polyputty is composed of a main agent and a curing agent. The main agent is composed of unsaturated polyester resin, styrene, triallyl phosphate, bentonite, white alundum, gas phase SiO2, attapulgite clay, hydroquinones, copper naphthenate, dimethylaniline, titanium dioxide and cobaltous naphthenate; the curing agent is composed of cyclohexanone peroxide, gas phase SiO2, titanium dioxide and polyvinylpyrrolidone; the preparation method comprises the following steps: the main agent production, curing agent preparation, putty preparation and the like. The polyputty has the advantages of good application property, fine putty membrane, smoothness, flattening, good flexibility and shrinkage resistance, and enable a matching usage with various mainstream wood paints such as acrylic acid, nitro, polyester, polyurethane and the like in market.

Owner:高立波

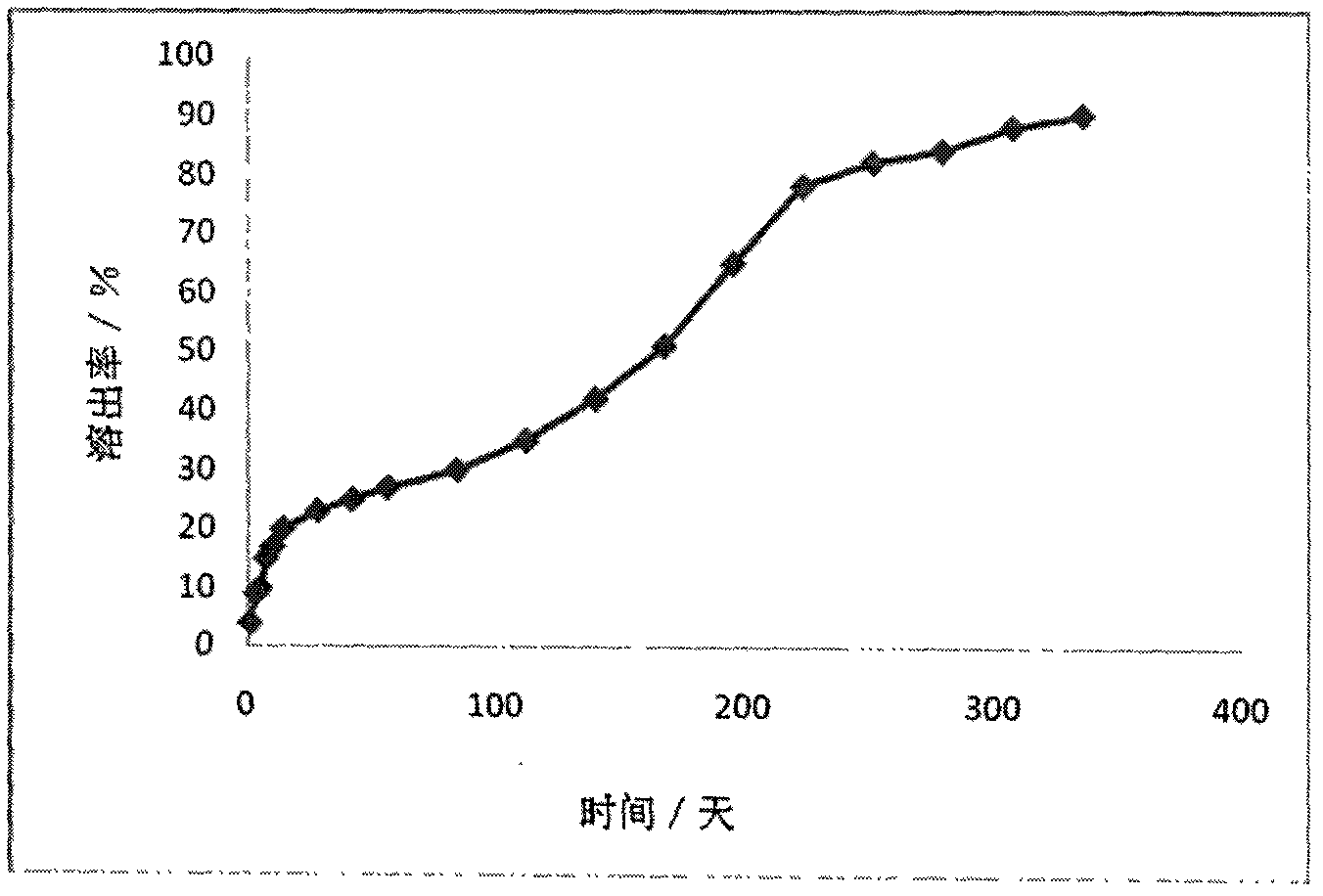

Method for producing sustained-release granular potassium chloride fertilizer

ActiveCN102690142BRound particlesFlat surfacePotassium fertilisersFertilizer mixturesPotassiumHigh heat

The invention relates to a method for producing a sustained-release granular potassium chloride fertilizer and belongs to the technical field of manufacture of fertilizers. The method comprises the specific steps of: preparation of a membrane coating agent and a granular potassium chloride coating membrane; adding linseed oil, glycerin, polyether and calcium naphthenate into a high-temperature reaction kettle, reacting for 2 hours at the temperature of 250 DEG C, putting the materials into a low-temperature reaction kettle, regulating the temperature of the materials to be 60 DEG C, adding toluene diisocynate (TDI-80) to the low-temperature reaction kettle, and simultaneously adding dimethylbenzene in batches; uniformly agitating and mixing, heating to raise the temperature to 80-95 DEG C, reacting for a period of time, cooling to 50-55 DEG C, adding methanol to agitate for a period of time, and adding cobalt naphthenate, lead naphthenate, diacetylmonoxime to uniformly agitate the mixture. A certain amount of granular potassium chloride is added into a fluidized bed coating machine, the air inlet temperature of the fluidized bed coating machine is controlled to be 70-100 DEG C, the wind pressure of an inlet is controlled, the membrane coating agent is sprayed into potassium chloride particles at the ratio to perform membrane coating, the potassium chloride particles are cooled and sieved, and the qualified particles are packaged to obtain the finished product after being coated by the membrane.

Owner:HENAN LEEF FERTILIZER

Preparation method of Esomeprazole and preparation method of Esomeprazole sodium

The invention provides a preparation method of Esomeprazole and a preparation method of Esomeprazole sodium, and (1S,2S)-(-)-1,2- hexamethylene diamine-D-tartrate is used as a chiral ligand, cobaltous naphthenate is used as catalyst, and Esomeprazole is prepared by asymmetric oxidation of 2-(((4-methoxy-3,5-dimethyl-2-pyridyl)methyl)sulfur-base)-1H-benzimidazole under the effect of catalyst with catalysis amount, and the prepared Esomeprazole has a better stereoselectivity and generation of peroxide sulfone is avoided. Simultaneously, sodium hypochlorite or sodium peroxide are used as oxidizing agent for preparing Esomeprazole sodium, and the sodium containing compound in the reaction process is used as oxidizing agent and sodium source, thereby the oxidation reaction and the salt forming reaction can be completed in the same reaction system with simple synthesis process.

Owner:SHOUGUANG FUKANG PHARMA

Method for fabricating artificial stone, and artificial stone with luminescence function, and products

A process for preparing artificial stone and artificial luminous stone includes such steps as proportionally adding phthalate and tetramethyl (or pentamethyl) derivative to unsaturated resin, stirring, adding the vinyl derivative of benzene, stirring, adding MMA, high-speed stirring, adding filler, pigment, modified resin, methylethyl ketone peroxide and cobalt nephthenate, stirring, filling the mixture in mould, vacuumizing, heating at 50-70 deg.C for 1-3 hr, heating at 75-85 deg.C for 1-3 hr, natural cooling, and demoulding. Its products are also disclosed.

Owner:金国华

Flexile quick-drying three-proofing paint for printed circuit board

The invention relates to the technical field of printed circuit board protection and concretely relates to flexile quick-drying three-proofing paint for a printed circuit board. Linseed oil-modified polyester resin is subjected to ultrasonic treatment in a solvent so that resin surface performances are improved and the resin has good reactivity and compatibility with other raw materials. Limonene can prevent resin coacervation in ultrasonic treatment. Polyvinylpyrrolidone and cellulose ether as raw materials can improve finished product flexibility, have film formation assistant effects, and provide excellent heat stability and fluidity for paint films. Acetylacetone and cobaltous naphthenate as raw materials accelerate paint curing and shorten curing time. The three-proofing paint has high adhesion and a fast drying rate, can be fast cured at a room temperature, has good paint film toughness, and does not crack easily after spray-coating thereby realizing lasting production.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

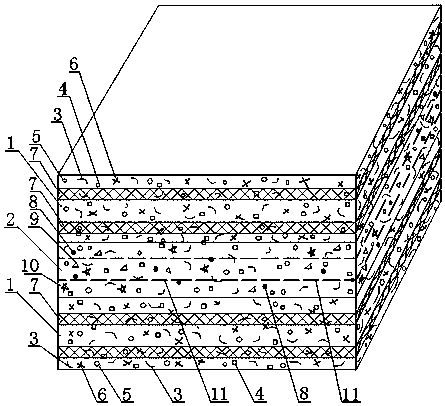

A kind of high-strength antistatic composite material plate and its preparation method

ActiveCN106084705BEasy to produceHigh strengthLaminationLamination apparatusGlass fiberNitrile rubber

Owner:扬州润友复合材料有限公司

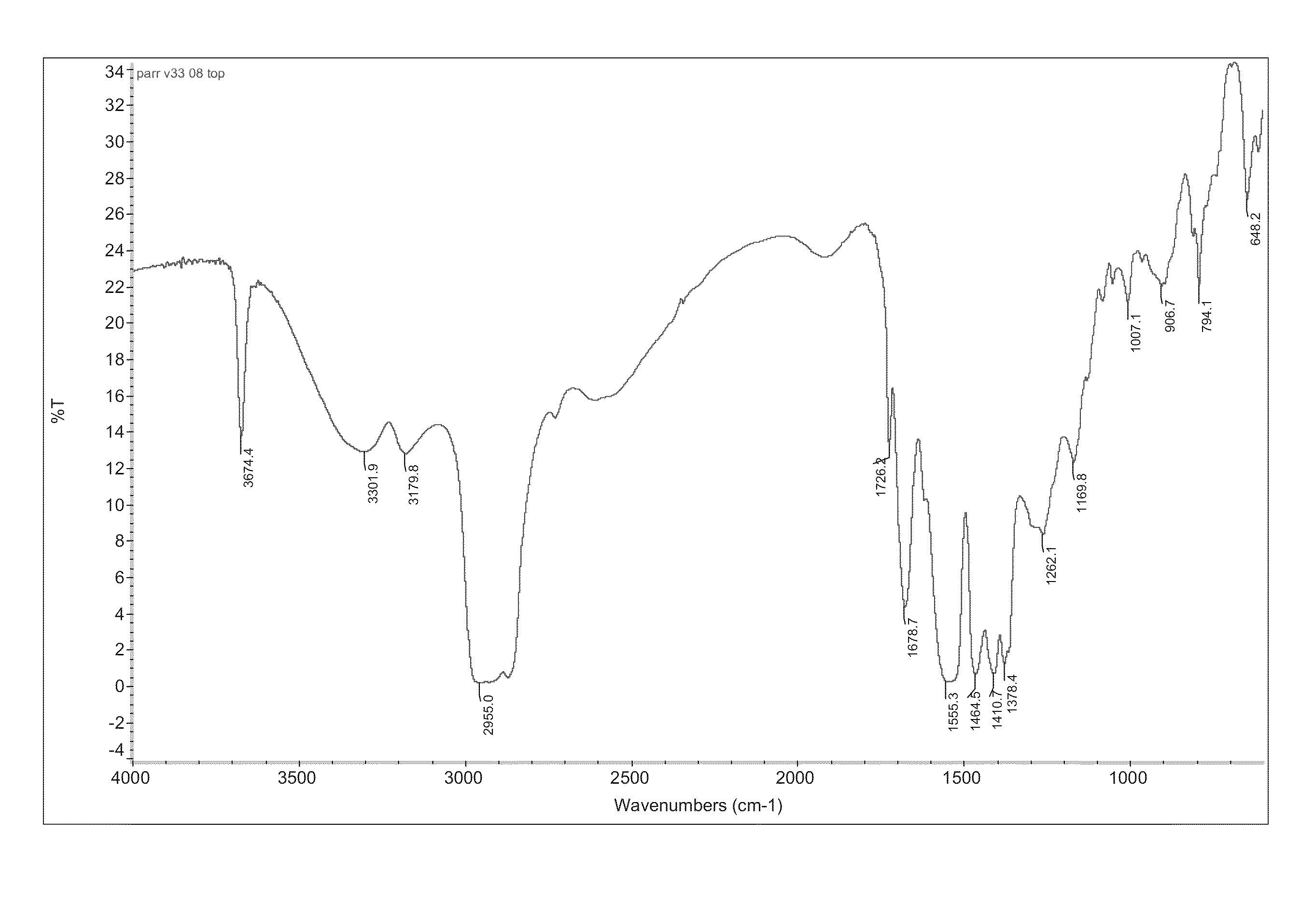

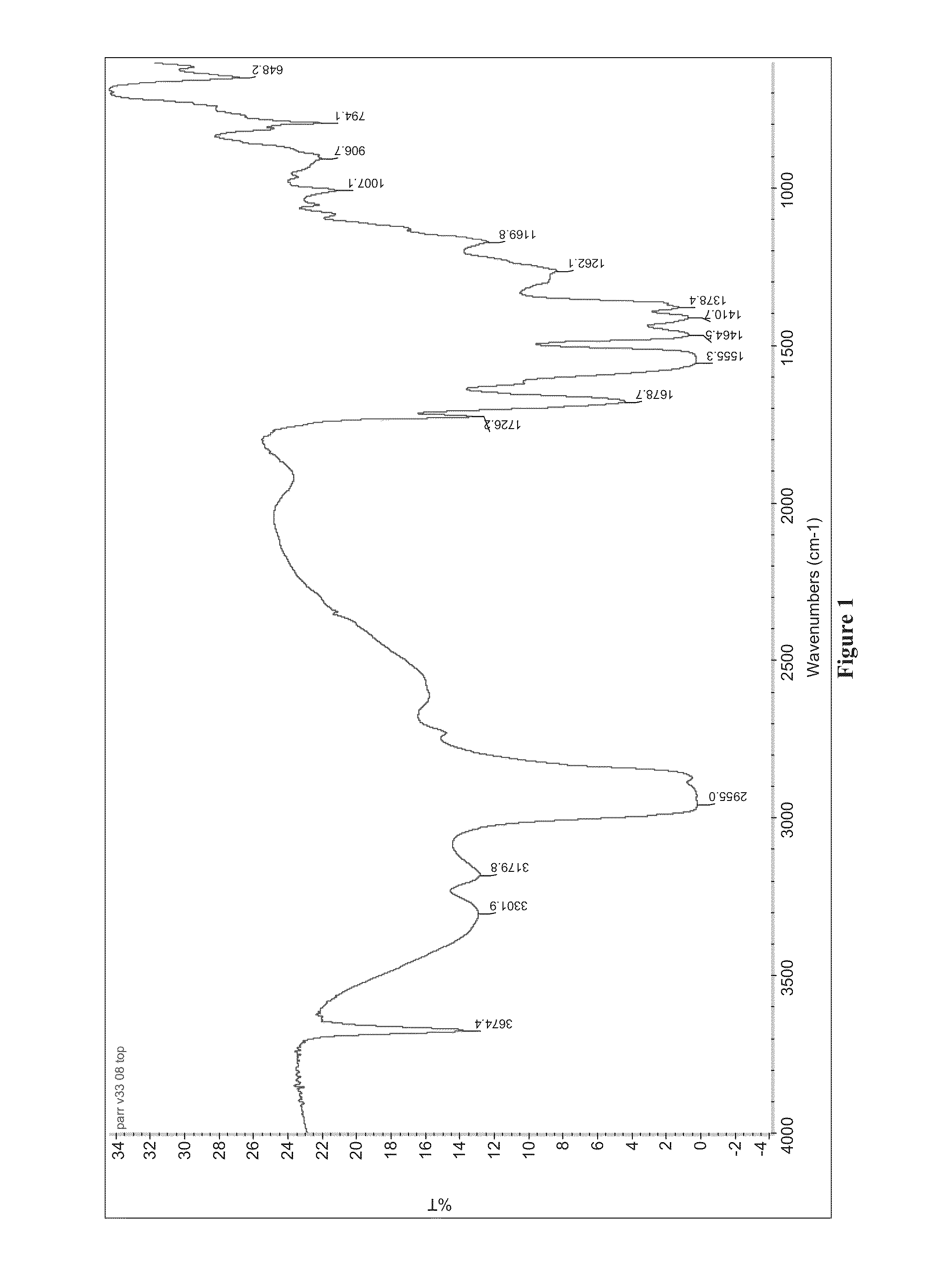

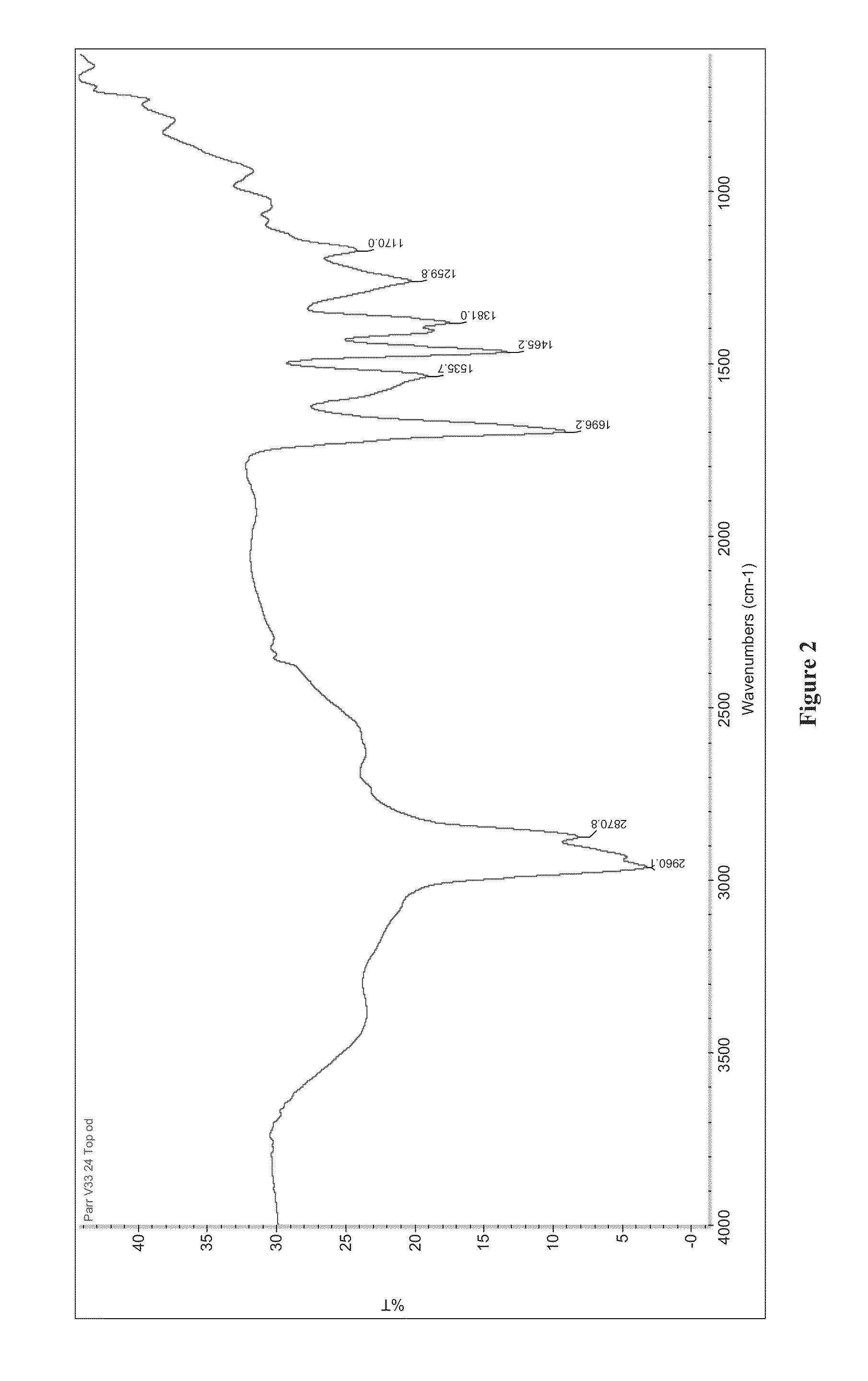

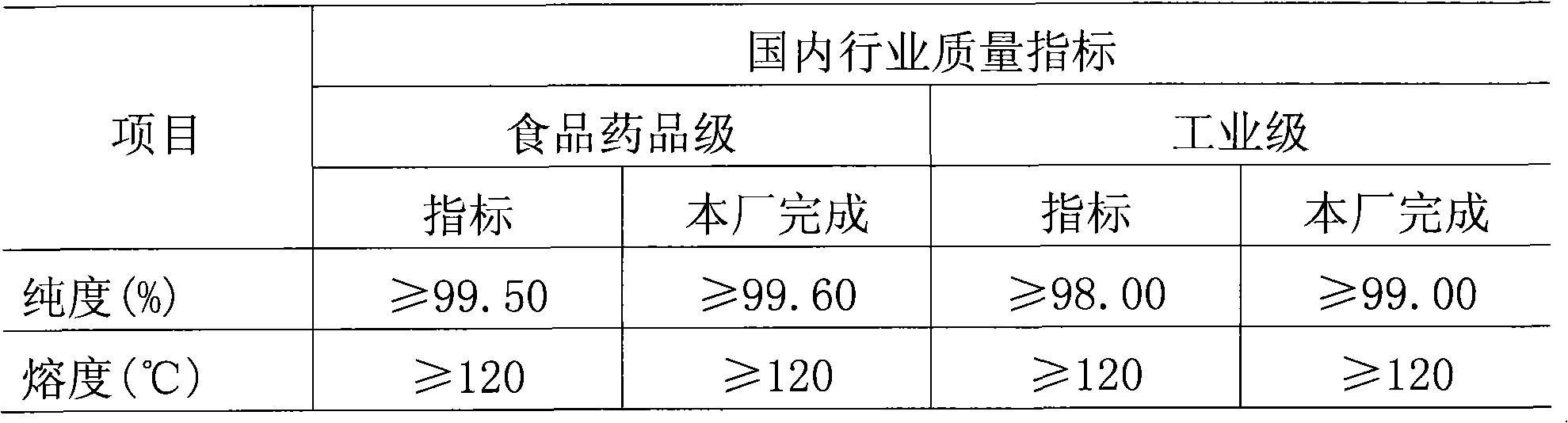

Method of synthesizing solid cobaltic naphthenate

InactiveCN101016238ACarboxylic acid salt preparationCarboxylic compound separation/purificationOrganic solventReaction temperature

The invention discloses a synthesizing method of solid cobaltic naphthenate, which comprises the following steps: dissolving naphthenic acid into polar organic solvent; separating insolubles under lower layer; setting the weight rate of extractant and naphthenic acid at 60: 30-35; transmitting extracting phase into distilling autoclave to distill with reflux rate less than 3; setting the tower floor layer number at 8-10; recycling solvent at 130-150 deg.c; decompressing and rectifying under -0.07-0.09Mpa for 20min; purifying; collecting middle fraction and naphthenic acid at 140-150 deg.c for 16-22h; adding naphthenic acid within 2-4 times.

Owner:谭昌诚

Environment-friendly energy-saving anthracene oil catalyst

InactiveCN108080024AImprove performanceLow costOrganic-compounds/hydrides/coordination-complexes catalystsAnthraceneCombustion

The invention relates to an environment-friendly energy-saving anthracene oil catalyst which comprises span-80, glycine betaine, tetrahydrofuran and cobalt naphthenate. Operations are performed in sequence at normal temperature under normal pressure to prepare the catalyst, pollution caused by waste gas, waste water and industrial residue is avoided, and the catalyst is low in cost, high in calorific value, simple in process and convenient to use. Colloid and asphalt in anthracene oil can be thoroughly catalyzed, a nozzle is not coked, combustion is complete, energy is saved, and environmentsare protected.

Owner:绵阳双甘科技有限公司

Smoke-eliminating combustion-supporting additives for fuel oil

The present invention relates to a smoke-eliminating combustion-supporting additive for diesel oil and heavy oil, its composition includes 1-10% of oil soluble nano iron, 5-255 of cobalt naphthenate, 10-30% of barium naphthenate, 5-10% of polyisobutylene succinimide, 1-5% of long-chain fatty acid and the rest is solvent. Said invention also provides its preparation method, and can obtain obvious fuel-saving effect, can be up to 5-20% of can reduce discharge of dust smoke by 30-60%.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

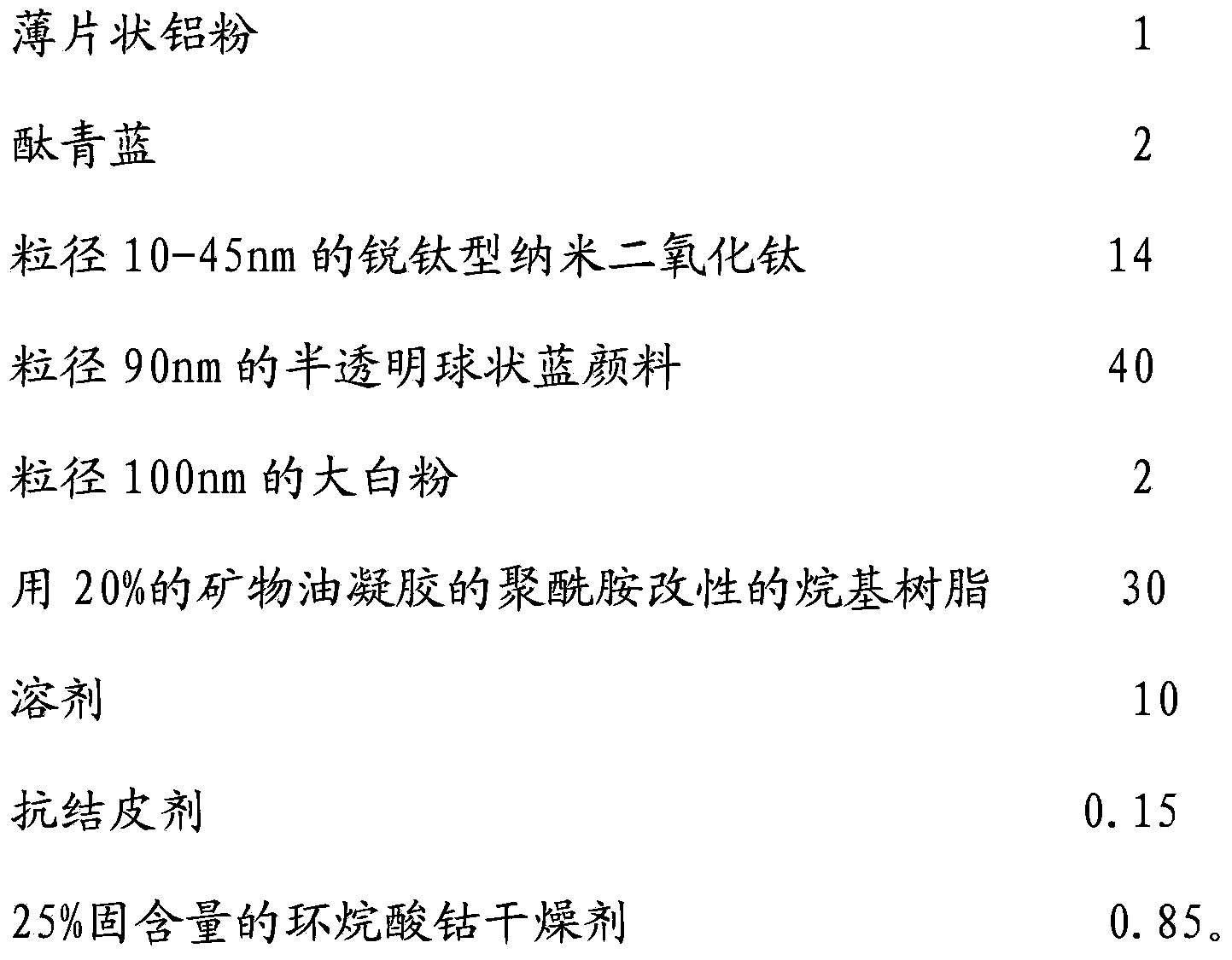

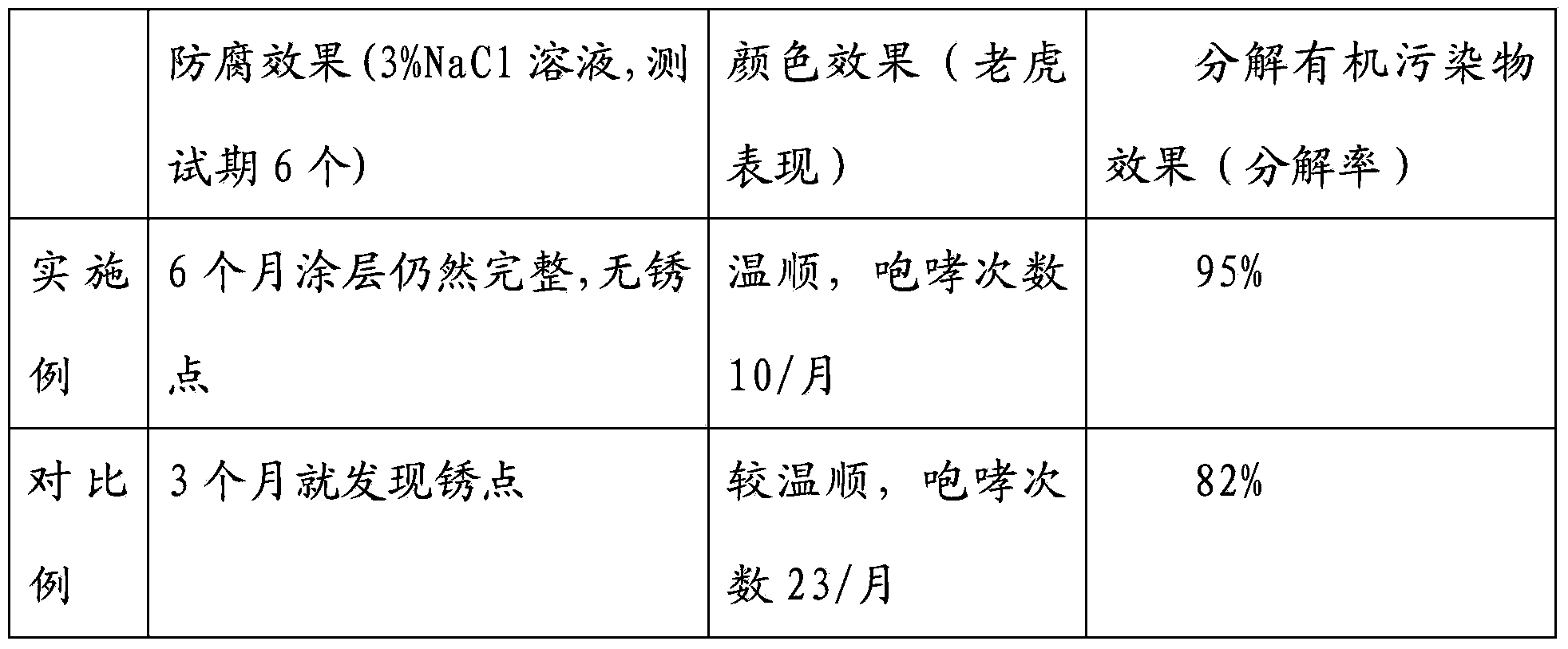

Sky blue-imitated nanometer paint for anticorrosion and organic pollutant decomposition

The invention discloses a sky blue-imitated nanometer paint for anticorrosion and organic pollutant decomposition. The paint comprises the following components: 1 part of laminar aluminum powder, 2 parts of phthalocyanine blue, 14 parts of anatase nanometer titanium dioxide, 40 parts of a semitransparent spherical blue pigment with the particle size of 90nm, 2 parts of calcium carbonate with the particle size of 100nm, 30 parts of an alkyl resin modified with polyamide containing 20% of mineral oil gel, 10 parts of a solvent, 0.15 parts of an antiskinning agent, and 0.85 parts of a drying agent cobaltous naphthenate with the solid content of 25%. The paint of the present invention which provides a visual relax for humans allows efficacies of anticorrosion and organic pollutant decomposition to be simultaneously reached.

Owner:ANHUI MEIJIA NEW MATERIAL

Calcium naphthenate-zirconium-based polyurea grease and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyphenylene sulfide modified coating

InactiveCN106479234AOptimizing Air Drying PerformanceHigh hardnessAnti-corrosive paintsPhosphatePolymer

A polyphenylene sulfide modified coating is characterized in that the polyphenylene sulfide modified coating is made of raw materials in parts by mass, 60-90 parts of polyphenylene sulfide polymer, 16-25 parts of acid phosphate, 6-10 parts of pentaerythritol, 1-4 parts of cobaltous naphthenate, 2-6 parts of titanium dioxide, 0.3-0.8 part of a levelling agent, and 15-25 parts of acrylic acid. The cobaltous naphthenate and the titanium dioxide are fully crushed and added to a mixture liquid made of the polyphenylene sulfide polymer, the acid phosphate, the pentaerythritol and the acrylic acid. Then high-speed homogeneous dispersion is performed after the cobaltous naphthenate, the titanium dioxide, and the levelling agent are added. The air seasoning performance after the coating is painted is optimized. The formula is reasonable. Coating layers are dense and the flatness is high after the anticorrosion painting is carried out on steel structures. The hardness of the coating layers is improved too, and the coating layers have good high temperature resistant and rust resistant capacities. The damage and local rust do not appear easily. The service life of the coating layers is prolonged, and the use range is wide.

Owner:闫杰

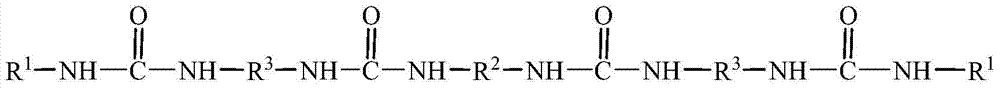

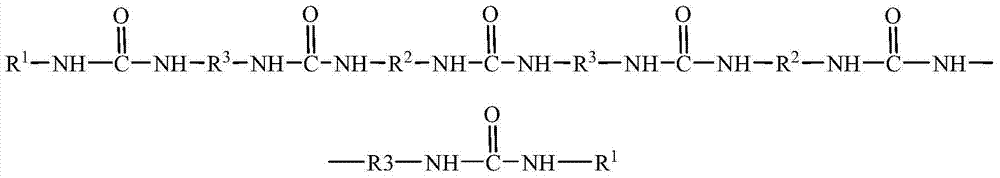

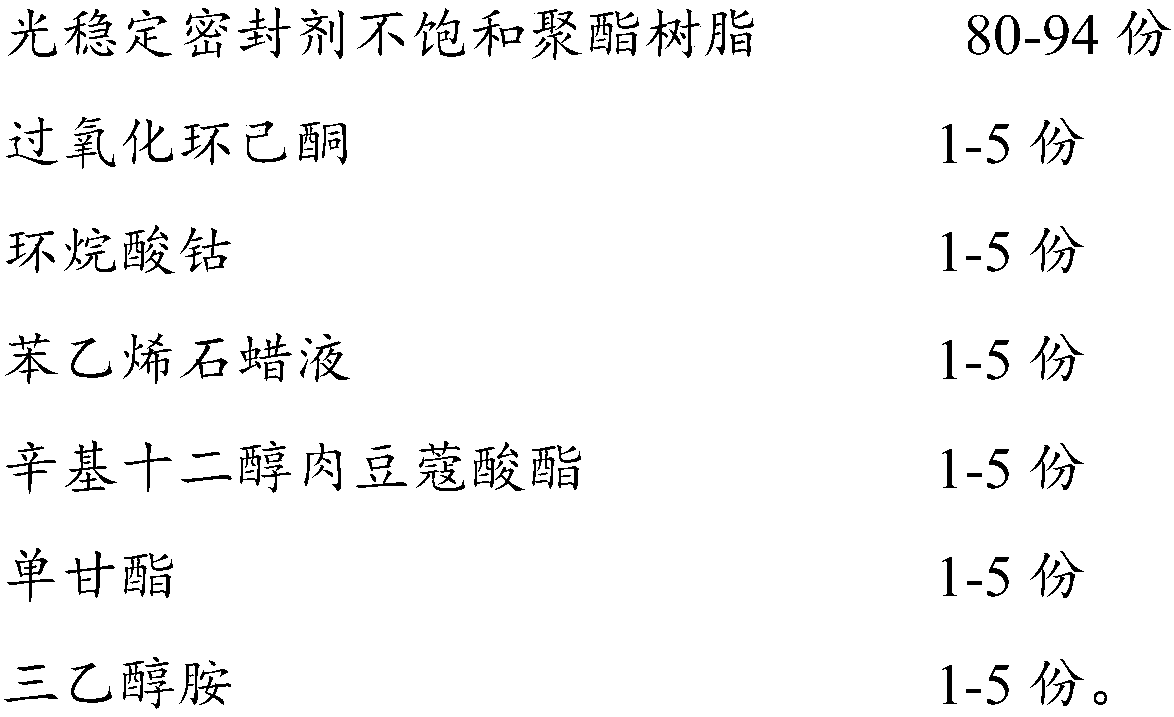

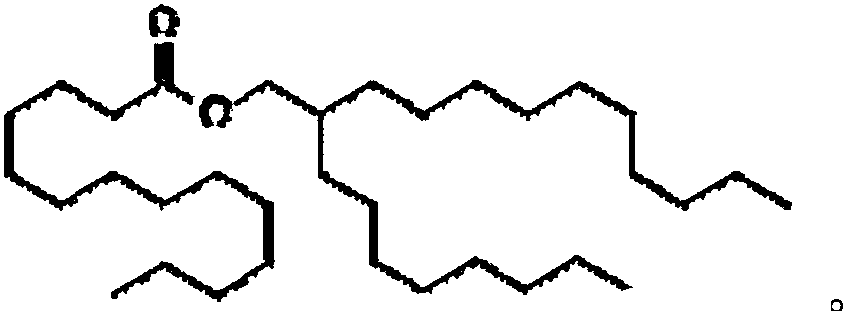

Light stability sealant and preparation method thereof

The invention belongs to the technical field of an adhesive, and concretely relates to a light stability sealant used for glass fiber reinforced plastic and a preparation method thereof. The light stability sealant comprises light stability sealant unsaturated polyester resin, cyclohexanone peroxide, cobaltous naphthenate, styrene paraffin liquid, octyldodecyl myristate, monoglyceride and triethanolamine according to a certain ratio; a unsaturated polyester resin acid value of the light stability sealant is 45 mg KOH / g, the viscosity is 69 pa.s, and the light stability sealant is specially prepared. The light stability sealant is transparent, and the adhesive property is good.

Owner:袁林林

Synthesis method of bagasse xylan gallic acid trimesic acid diesterified derivative

InactiveCN109320632AProcess conditions are easy to controlImprove biological activityGallic acid esterSynthesis methods

The invention discloses a synthesis method of a bagasse xylan gallic acid trimesic acid diesterified derivative. Bagasse xylan is used as raw materials; N, N-dimethylformamide is used as a solvent; ammonium persulfate is used as a catalyst; firstly, catalytic esterification reaction is performed with triacetyl gallate chloride to synthesize the bagasse xylan gallate; then, in the N, N-dimethylformamide solvent, with the existence of dewatering agents of N, N-dicyclohexylcarbodiimide, second step of catalytic esterification reaction is performed with trimesic acid under the catalysis effect ofcobalt naphthenate; the bagasse xylan gallic acid trimesic acid diesterified derivative is synthesized. The bagasse xylan diesterified derivative has the dual activity of the bagasse xylan gallate andthe bagasse xylan trimesic acid ester. The dual-active bagasse xylan derivative subjected to chemical modification has certain effects in aspects of anti-HIV activity, anticoagulant activity, platelet aggregation resistance and the like; high application values are realized in the fields of medicine, food, fine chemical engineering and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Corrosion-resistant two-dimensional code steel fiber braided rope for braiding machine

InactiveCN107641894AImprove corrosion resistancePlay the role of protecting the braided ropeRubber derivative coatingsAnti-corrosive paintsEpoxyCyclohexanone

The invention discloses a corrosion-resistant two-dimensional code steel fiber braided rope for a braiding machine. The corrosion-resistant two-dimensional code steel fiber braided rope for the braiding machine is braded by steel fibers, a corrosion-resistant coating layer is arranged on the surfaces of the steel fibers, a corrosion-resistant coating coats the surfaces of the steel fibers and thenis dried to form the corrosion-resistant coating layer. The corrosion-resistant coating is prepared by the following steps: (1) carrying out heat treatment on organic silicon resin, epoxy resin, castor oil, zinc phosphate, cyclohexanone, cobalt naphthenate, alumina silicate fibers and ethylene glycol to obtain a component I; (2) carrying out heat treatment on chlorinated rubber, mannitol, ethane-acetate emulsion, expanded graphite, nano cerium oxide, nano silicon oxide and propylene glycol to obtain a component II; and (3) under the condition of pressurizing, mixing the component I with the component II to obtain the corrosion-resistant coating. The corrosion-resistant two-dimensional code steel fiber braided rope for the braiding machine has excellent corrosion resistance.

Owner:WUHU PINDU ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com