Light stability sealant and preparation method thereof

A sealant, light-stabilizing technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low adhesive strength, easy cracking, and inability to take into account the performance of transparent and light-stable sealants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

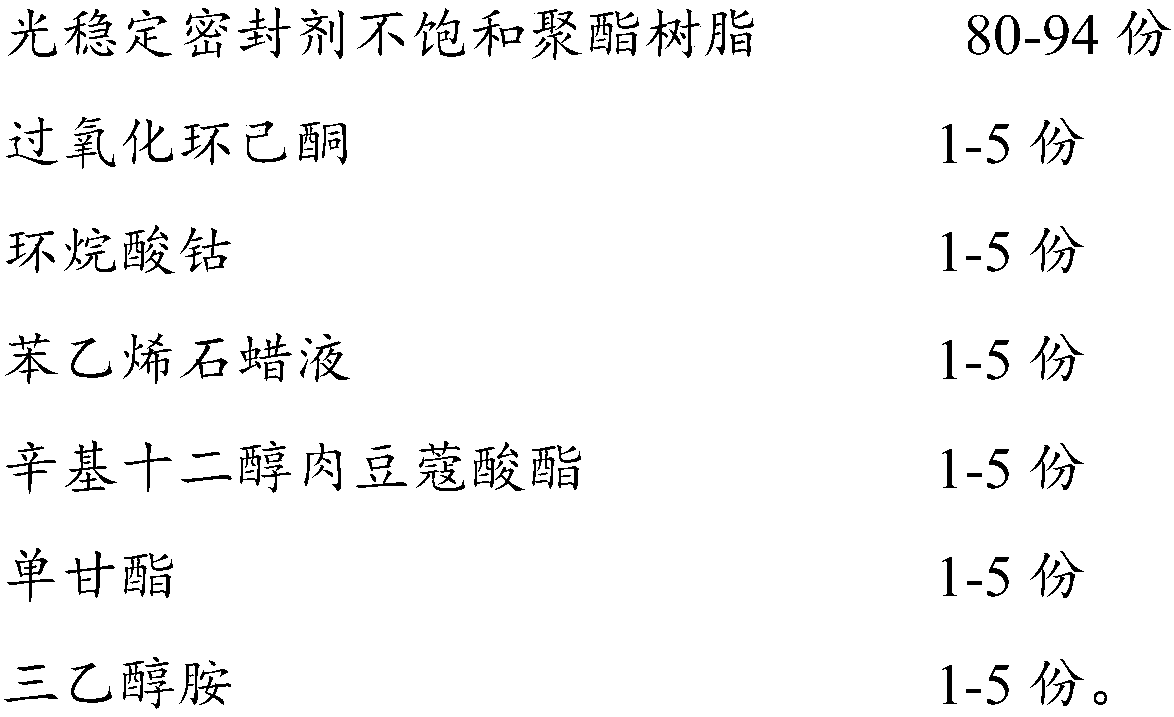

[0030] A light-stable sealant, comprising the following substances calculated in parts by mass:

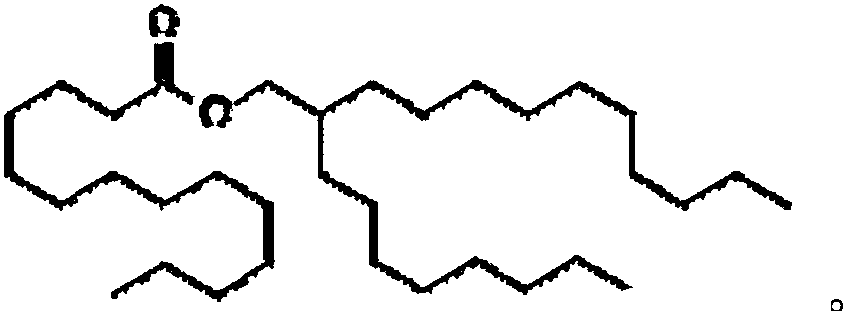

[0031] Light stable sealant unsaturated polyester resin 90 parts, cyclohexanone peroxide solution (35%) 2 parts, cobalt naphthenate solution (2%) 2 parts, styrene paraffin liquid (0.3%) 3 parts, octyl 1 part of lauryl myristate, 1-5 parts of monoglyceride and 2 parts of triethanolamine. Among them, monoglyceride contains saturated fatty acid monoglyceride ≥ 90%, iodine value ≤ 4, freezing point 65°C, and free acid calculated as stearic acid ≤ 2.5%. The acid value of the light-stable sealant unsaturated polyester resin is 45mgKOH / g, and the viscosity is 69pa.s.

[0032] Wherein, the light-stable sealant unsaturated polyester resin includes 5.5 parts by mass of phthalic anhydride, 3.0 parts of maleic anhydride, 16.5 parts of cetyl alcohol, 9 parts of diethylene glycol, 1 part of ultraviolet absorber and benzene Ethylene 500 preparations derived.

[0033] The preparation method of...

Embodiment 2

[0042] A light-stable sealant, comprising the following substances calculated in parts by mass:

[0043] Light stable sealant unsaturated polyester resin 82 parts, cyclohexanone peroxide solution (30%) 5 parts, cobalt naphthenate solution (1%) 5 parts, styrene paraffin liquid (0.1%) 5 parts, octyl 1 part lauryl myristate, 1 part monoglyceride and 1 part triethanolamine. Among them, monoglyceride contains saturated fatty acid monoglyceride ≥ 90%, iodine value ≤ 4, freezing point 60°C, and free acid calculated as stearic acid ≤ 2.5%. The acid value of the light-stable sealant unsaturated polyester resin is 45mgKOH / g, and the viscosity is 69pa.s.

[0044] Wherein, the light-stable sealant unsaturated polyester resin includes 5.5 parts by mass of phthalic anhydride, 3.0 parts of maleic anhydride, 16.5 parts of cetyl alcohol, 9 parts of diethylene glycol, 1 part of ultraviolet absorber and benzene Ethylene 500 preparations derived.

[0045] The preparation method of its light st...

Embodiment 3

[0054] A light-stable sealant, comprising the following substances calculated in parts by mass:

[0055] Light stable sealant unsaturated polyester resin 94 parts, cyclohexanone peroxide solution (50%) 1 part, cobalt naphthenate solution (3%) 1 part, styrene paraffin liquid (0.5%) 1 part, octyl 1 part lauryl myristate, 1 part monoglyceride and 1 part triethanolamine. Among them, monoglyceride contains saturated fatty acid monoglyceride ≥ 90%, iodine value ≤ 4, freezing point 70°C, and free acid calculated as stearic acid ≤ 2.5%. The acid value of the light-stable sealant unsaturated polyester resin is 45mgKOH / g, and the viscosity is 69pa.s.

[0056] Wherein, the light-stable sealant unsaturated polyester resin includes 5.5 parts by mass of phthalic anhydride, 3.0 parts of maleic anhydride, 16.5 parts of cetyl alcohol, 9 parts of diethylene glycol, 1 part of ultraviolet absorber and benzene Ethylene 500 preparations derived.

[0057] The preparation method of its light stabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com