Catalyst for pyrolysis of oil shale, preparation method and application method thereof

An oil shale and catalyst technology, applied in the field of oil shale pyrolysis catalyst and its preparation, can solve the problems of difficult to realize industrialization, complicated process, low pyrolysis efficiency, etc. Reaction progress, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The catalyst of the present embodiment is made of the following raw materials in mass percentage: 5% molecular sieve, 3% activated clay, 45% organic cobaltate, 10% metal sulfide, 12% glyceride, and 25% paraffin; The organic cobaltate is cobalt acetate; the metal sulfide is nickel sulfide; the molecular sieve is 5A molecular sieve; the glyceric acid ester is glyceryl stearate; and the paraffin is industrial paraffin.

[0031] The preparation method of the catalyst in this example is as follows: after mixing the raw materials, heat it to 70° C. under stirring condition, then continue stirring for 40 minutes, and obtain the catalyst for oil shale pyrolysis after natural cooling.

[0032] The method of using the catalyst of this embodiment to catalyze pyrolysis of oil shale:

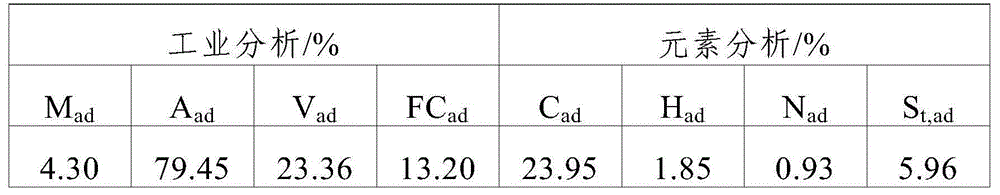

[0033] Step 1, crushing and screening the oil shale minerals, collecting oil shale with a particle size not greater than 25 mm; testing the used oil shale, the results are shown in Table 1;

[0034] ...

Embodiment 2

[0046] This embodiment is the same as Example 1, except that the molecular sieves used are Y-type molecular sieves, ZSM molecular sieves, 13X-type molecular sieves, ZSM molecular sieves loaded with potassium salts, ZSM molecular sieves loaded with sodium salts, ZSM molecular sieves loaded with cobalt salts, 13X molecular sieve loaded with potassium salt, 13X molecular sieve loaded with sodium salt or 13X molecular sieve loaded with cobalt salt, or 5A molecular sieve, Y-type molecular sieve, ZSM molecular sieve, 13X molecular sieve, ZSM molecular sieve loaded with potassium salt, ZSM molecular sieve loaded with sodium salt , at least two of ZSM molecular sieves loaded with cobalt salts, 13X molecular sieves loaded with potassium salts, 13X molecular sieves loaded with sodium salts, and 13X molecular sieves loaded with cobalt salts; the organic cobaltates used are cobalt oxalate, cobalt naphthenate or neodecyl cobalt acid, or at least two of cobalt acetate, cobalt oxalate, cobalt...

Embodiment 3

[0048] The catalyst of the present embodiment is made of the following raw materials in mass percentage: molecular sieve 2%, activated clay 1%, organic cobaltate 60%, metal sulfide 5%, glyceride 17%, paraffin 15%; The organic cobaltate is cobalt neodecanoate; the metal sulfide is molybdenum sulfide; the molecular sieve is Y-type molecular sieve and ZSM-5 molecular sieve (mass ratio 2:1); the glyceric acid ester is glyceryl stearate ; The paraffin is chlorinated paraffin.

[0049] The preparation method of the catalyst in this example is as follows: after mixing the raw materials, heat to 80° C. under stirring condition, then continue to stir for 30 minutes, and obtain the catalyst for oil shale pyrolysis after natural cooling.

[0050] The method of using the catalyst of this embodiment to catalyze pyrolysis of oil shale:

[0051] Step 1, crushing and screening the oil shale minerals, collecting oil shale with a particle size not greater than 25mm, the industrial analysis and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com