Patents

Literature

615 results about "Cobalt naphthenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

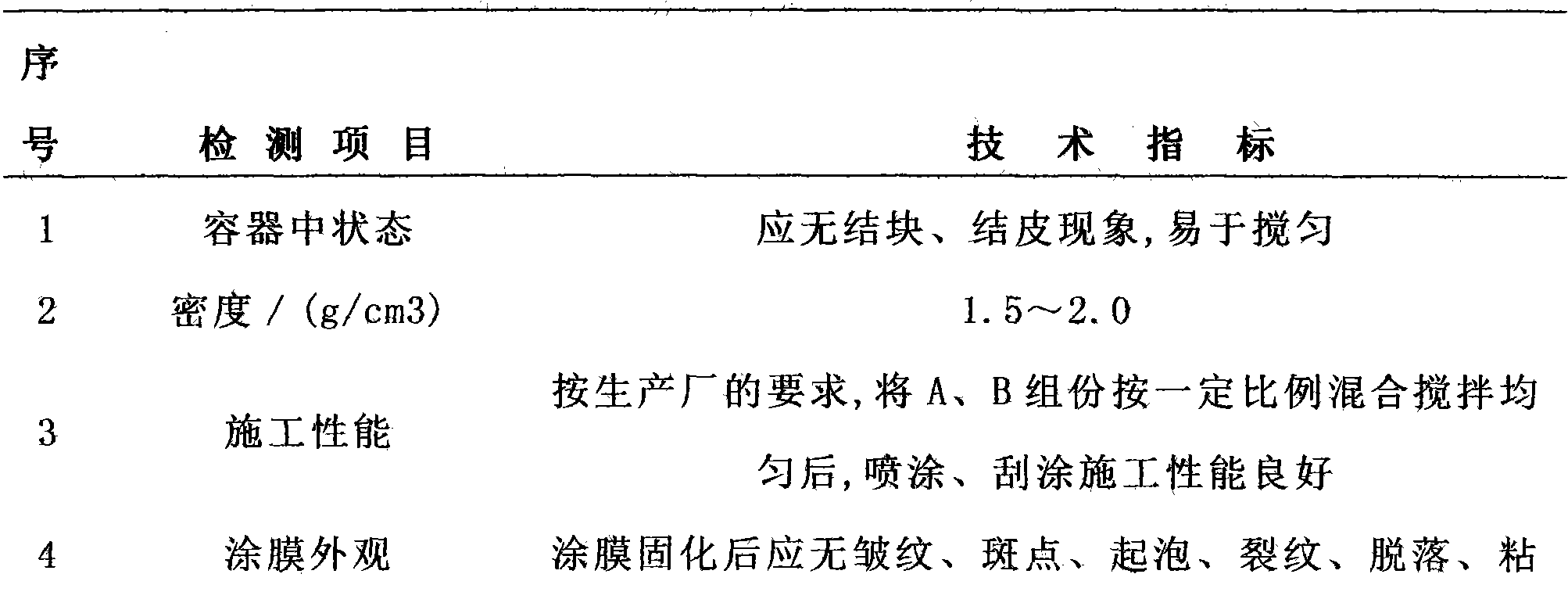

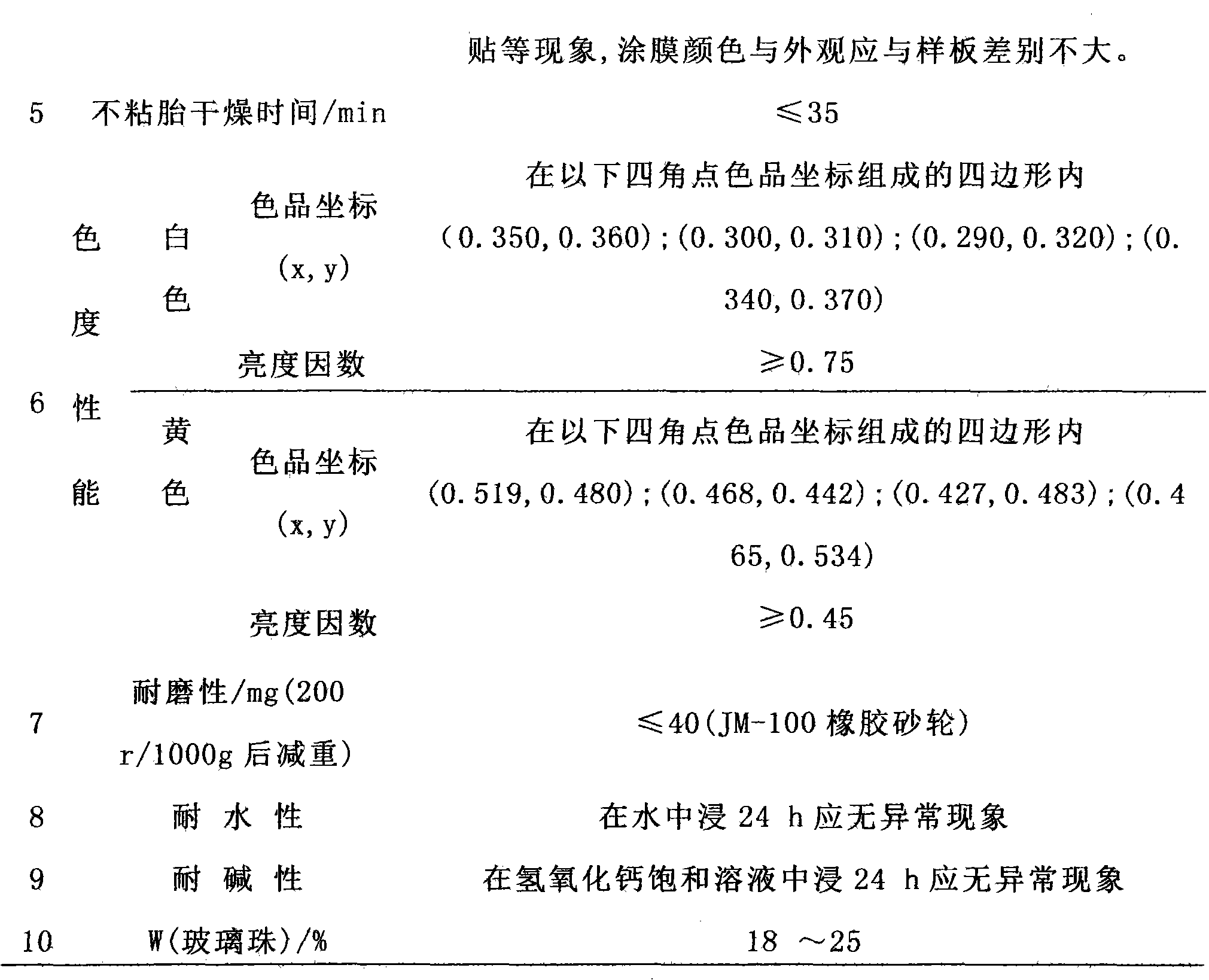

Preparation method of low shrink air dry vinyl ester heavy-duty anti-corrosive paint

InactiveCN101760115AStrong resistance to media penetrationImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsGas phaseSilicon dioxide

The invention discloses a preparation method of low shrink air dry vinyl ester heavy-duty anti-corrosive paint. The anti-corrosive paint comprises a first component of the dry vinyl ester heavy-duty anti-corrosive paint and a second component of the dry vinyl ester heavy-duty anti-corrosive paint, wherein the first component of the dry vinyl ester heavy-duty anti-corrosive pain t comprises vinyl ester resin, titanium pigment, French chalk, mica powder, gas phase silicon dioxide, styrene, BYK-410, BYK-555, glass scales and like, the second component of the dry vinyl ester heavy-duty anti-corrosive paint comprises dibutyl phthalate, methylethyl ketone peroxide and cobalt naphthenate. The defects of low air dry capability and high cure shrinkage of the traditional vinyl ester glass scale heavy-duty anti-corrosive paint are solved by introducing the air dry addition product group to synthesize low shrink air dry resin, and the paint has the advantages of high media penetrability resistance, abrasive resistance and the like. The low shrink air dry vinyl ester heavy-duty anti-corrosive paint has the characteristics of simple preparation process, abundant raw materials and stable performance, and is suitable for large-scale industrial production.

Owner:中昊北方涂料工业研究设计院有限公司

Epoxy modified lacquer putty

An epoxy modified puddy for metallic materials is composed of components A and B. Said component A is prepared from epoxy modified unsaturated polyester resin, functional filler, quinone substance, cobalt naphthenate (or isooctoate), polyvinyl chloride or SiO2 gas, and active diluent. Said component B is vinylamide polymer. Its advantages are long application time (60 min) and high low-temp high-moisture performance.

Owner:ZHUZHOU HUALIAN HI TECH

Room temperature-curing environment-friendly anticorrosive coating for circuit board and preparation method thereof

InactiveCN103305106ASmall smellFast curingAnti-corrosive paintsPolyurea/polyurethane coatingsAromatic solventZircon

The invention discloses a room temperature-curing environment-friendly anticorrosive coating for a circuit board and a preparation method thereof. The anticorrosive coating is prepared through complex formulation of the following raw materials by mass: 50 to 90 parts of a polyurethane modified alkyd resin, 20 to 80 parts of an environment-friendly solvent, 0.01 to 2.0 parts of a main drier, i.e., cobalt naphthenate, 0.01 to 3.0 parts of a secondary drier A which is one or two selected from the group consisting of zinc isocaprylate and zinc naphthenate, 0.01 to 6.0 parts of a secondary drier B which is one or two selected from the group consisting of zircon isocaprylate and zirconium naphthenate, 0.1 to 3.0 parts of a fluorescent agent and 0.01 to 2 parts of a stabilizing agent. The tri-proof coating for the circuit board provided by the invention uses a plant extract as a resin source and is prepared through complex formulation of the resin, the environment-friendly solvent, corresponding metal driers and other auxiliary agents. The prepared coating does not contain aromatic solvents like xylene and ethylbenzene and has the advantages of little smell, a fast curing speed, good adhesion and excellent electrothermal performance.

Owner:DONGGUAN BAOHAN LIGHT IND TECH

Preparation method for thermoset high temperature resistant methyl phenyl silicone resin

The invention discloses a preparation method for thermoset high temperature resistant methyl phenyl silicone resin, which relates to the technical field of resin preparation and comprises the steps of utilizing toluene or dimethylbenzene or mixed solution of the toluene and dimethylbenzene to serve as a solvent, utilizing methyl trichlorosilane, dichlorodimethylsilane and methylphenyldichloros as monomer raw materials, dropping mixed solution of acetone and water into the raw materials under the condition of ice-water bath, ensuring that the dropping is finished within 3-5 hours, obtaining a prepolymer of the methyl phenyl silicone resin, performing condensation and curing on the obtained prepolymer above 150 DEG C after pressure of the prepolymer is reduced and the prepolyme is concentrated, the adopted condensation catalyst is caprylate or naphthenate, particularly is stannous octoate, zinc isoocatanoate, cobalt naphthenate and dibutyltin dilaurate. The resin is semi-transparent hard or elastic solid, can not be dissolved or fused, and can be resistant to high temperature above 200 DEG C, and can be used as silicon rubber or a plastic filler.

Owner:JIANGSU UNIV

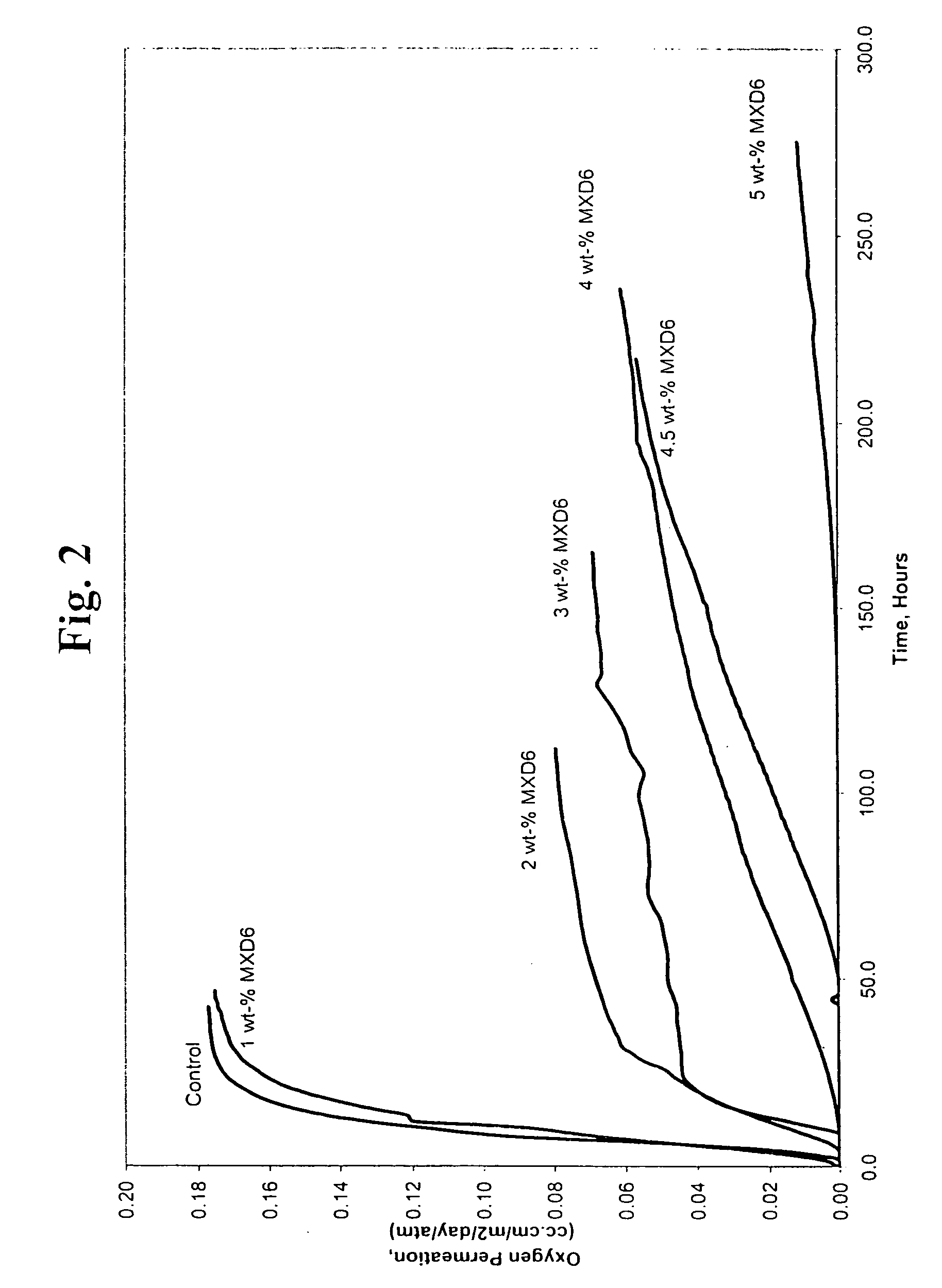

Method to make single-layer pet bottles with high barrier and improved clarity

InactiveUS20060246245A1Reduce yellownessEnvelopes/bags making machineryGroup 4/14 element organic compoundsPolyesterXylylene

The present invention comprises a blend of polyester and a partially aromatic polyamide with an ionic compatibilizer and a cobalt salt. This blend can be processed into a container that has both active and passive oxygen barrier and carbon dioxide barrier properties at an improved color and clarity than containers known in the art. The partially aromatic polyamide is preferably meta-xylylene adipamide. The ionic compatibilizer is preferably 5-sodiumsulfoisophthalic acid or 5-zincsulfoisophthalic acid, or their dialkyl esters such as the dimethyl ester (SIM) and glycol ester (SIPEG). The cobalt salt is selected form the class of cobalt acetate, cobalt carbonate, cobalt chloride, cobalt hydroxide, cobalt naphthenate, cobalt oleate, cobalt linoleate, cobalt octoate, cobalt stearate, cobalt nitrate, cobalt phosphate, cobalt sulfate, cobalt (ethylene glycolate), or mixtures of two or more of these. The partially aromatic polyamide is present in a range from about 1 to about 10 wt. % of said composition. The ionic compatibilizer is present in a range from about 0.1 to about 2.0 mol-% of said composition. The cobalt salt is present in a range from about 20 to about 500 ppm of said composition.

Owner:TREVIRA HLDG GMBH

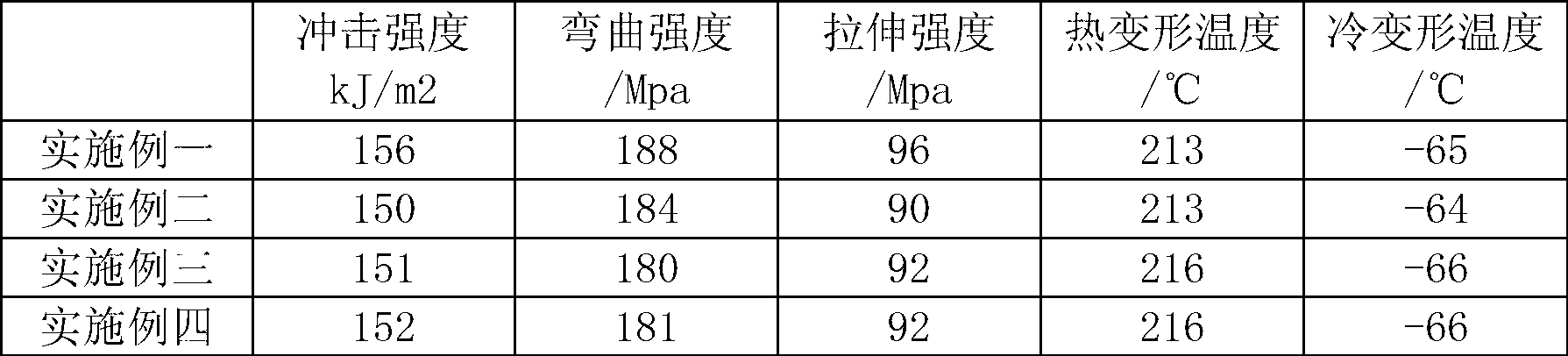

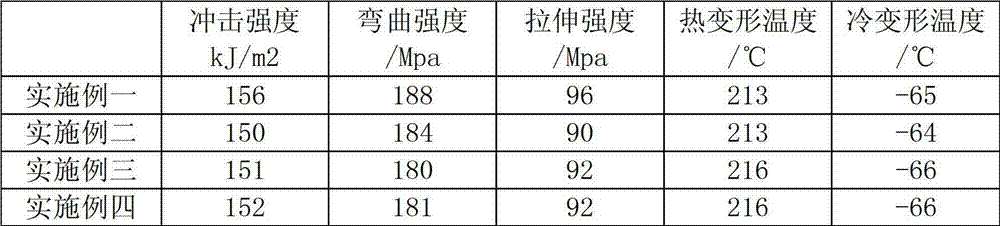

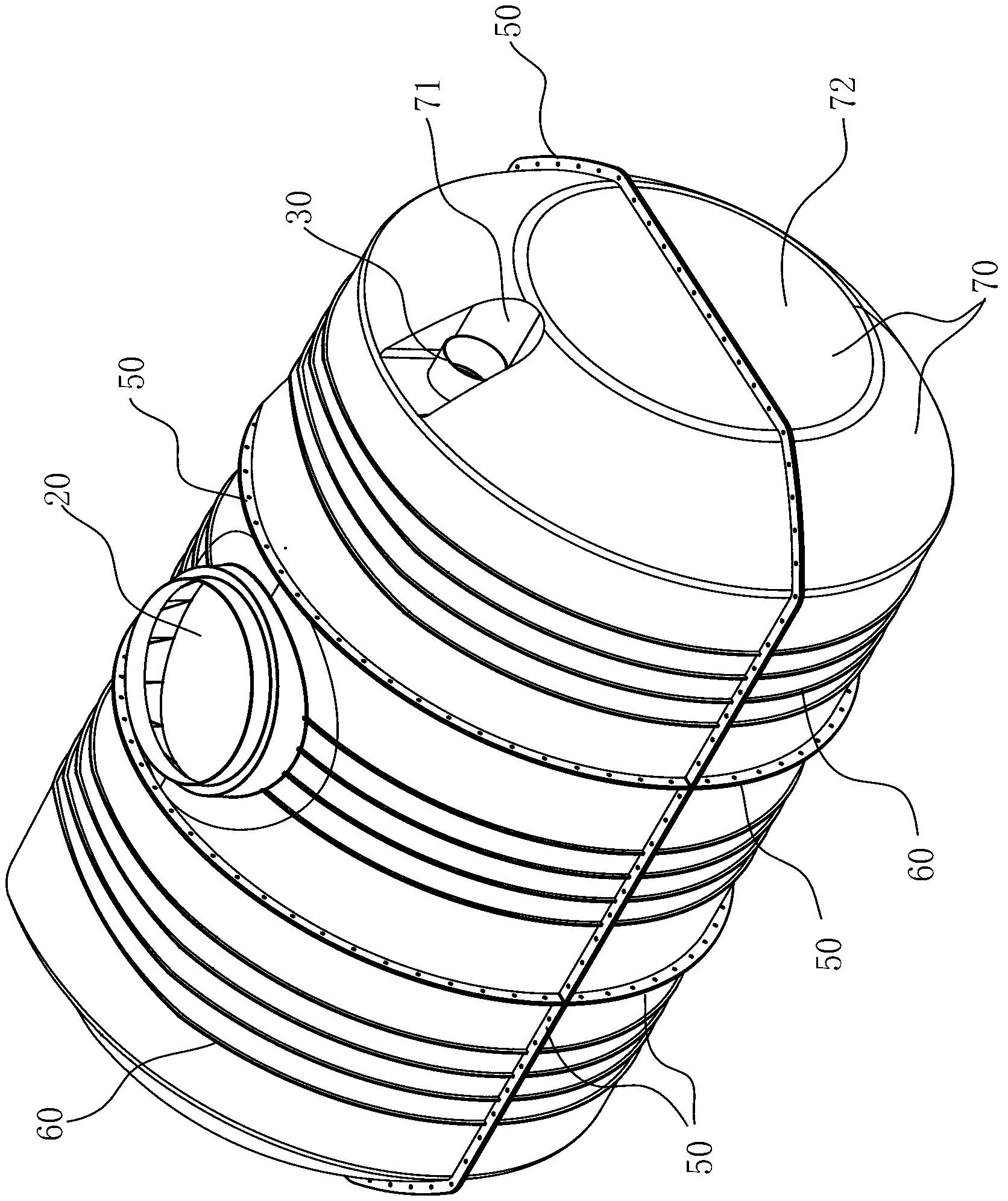

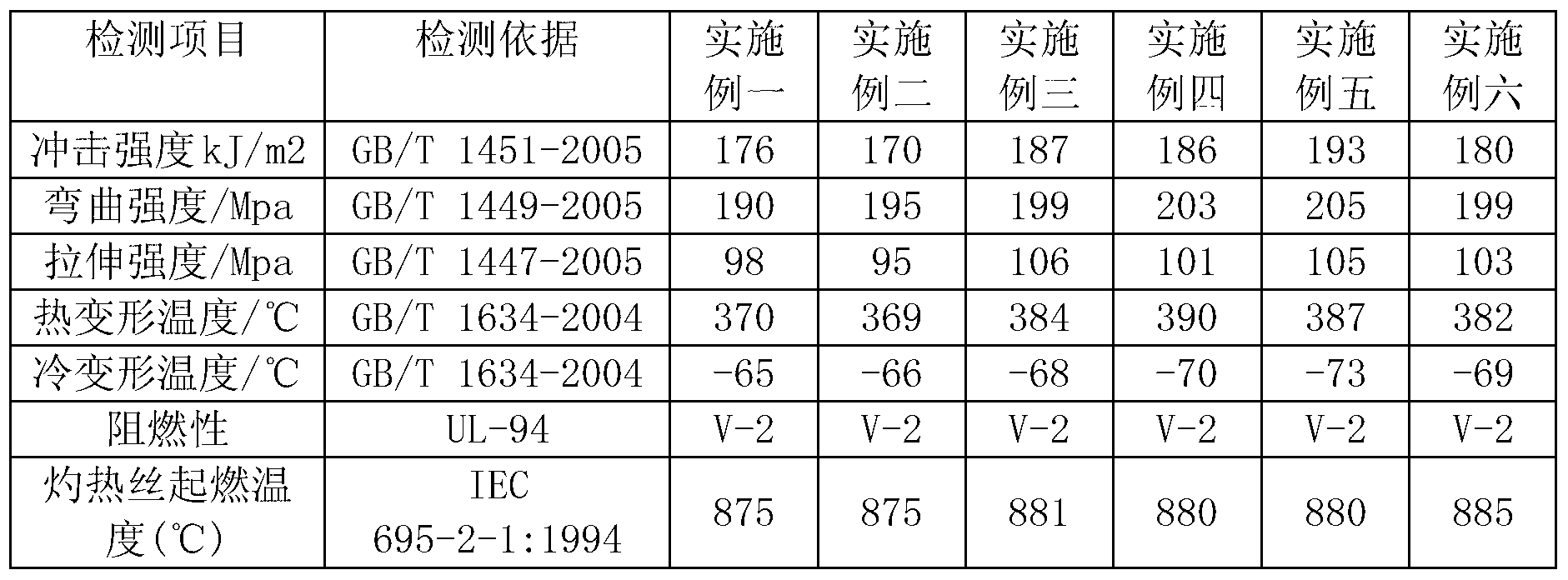

Plastic pipe machined by using bulk molding compounds

The invention relates to a plastic pipeline prepared by using bulk molding compounds. The plastic pipeline comprises the following materials in part by weight: 30-50 parts of unsaturated polyester, 0.3-0.5 part of cobalt naphthenate, 0.2-0.4 part of methyl ethyl ketone peroxide, 25-35 parts of reinforced fibers, 30-40 parts of calcium carbonate, 0.2-0.3 part of anti-static agent, 0.1-0.15 part of antioxidant and 0.2-0.3 part of pentabromo-phenol. According to the invention, the prepared unsaturated polyester fiber reinforced bulk molding compounds have the advantages of high toughness and high strength; the impact strength of the unsaturated polyester fiber reinforced bulk molding compounds is 150 kJ / m<2>, the bending strength of the unsaturated polyester fiber reinforced bulk molding compounds is 180 MPa, and the tensile strength of the unsaturated polyester fiber reinforced bulk molding compounds is 90 MPa. Through adoption of the prepared plastic pipeline, difficult problems in the prior art that the mechanical performance of the plastic material is lower and the prepared plastic pipeline, in particular a large-sized plastic pipeline, is hardly popularized and utilized in practice are solved. The plastic pipeline provided by the invention has the advantages of acid and alkali resistance, anti-corrosion property, low cost and good application prospect in the practice.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

Environment-friendly PE gloss black piano lacquer

ActiveCN101654586ASolve the problem of not being able to transport to the northObvious superiorityPolyester coatingsLacquerOxygen

The invention discloses an environment-friendly PE gloss black piano lacquer, which comprises a main agent, a diluting agent, an accelerating agent and an initiator, wherein the main agent mainly comprises the following components in portion by weight: 75 to 85 portions of unsaturated polyester finishing paint resin, 0.2 to 0.5 portion of wetting dispersing agent, 0.8 to 1.1 portions of carbon black, 4 to 6 portions of hexamethoxymethyl melamine resin, 0.3 to 0.6 portion of anti-sagging agent, 0.02 to 0.04 portion of polymerization inhibitor, 0.2 to 0.4 portion of butanone, 13 to 17 portions of styrene, and 0.2 to 0.4 portion of levelling agent; the diluting agent mainly comprises 100 portions of the styrene; the accelerating agent contains 100 portions of cobalt naphthenate solution with6 percent of Co<2+>; and the initiator contains 100 portions of butanone peroxide solution with 10 percent of active oxygen. The environment-friendly PE gloss black piano lacquer can obtain a bright film coating without polishing, has better mechanical properties and fullness, is difficult to have cooling cracks, can solve the problem of northward transportation of south musical instruments, and simultaneously completely uses active diluting agent and is very favorable for environmental protection.

Owner:珠海展辰新材料股份有限公司

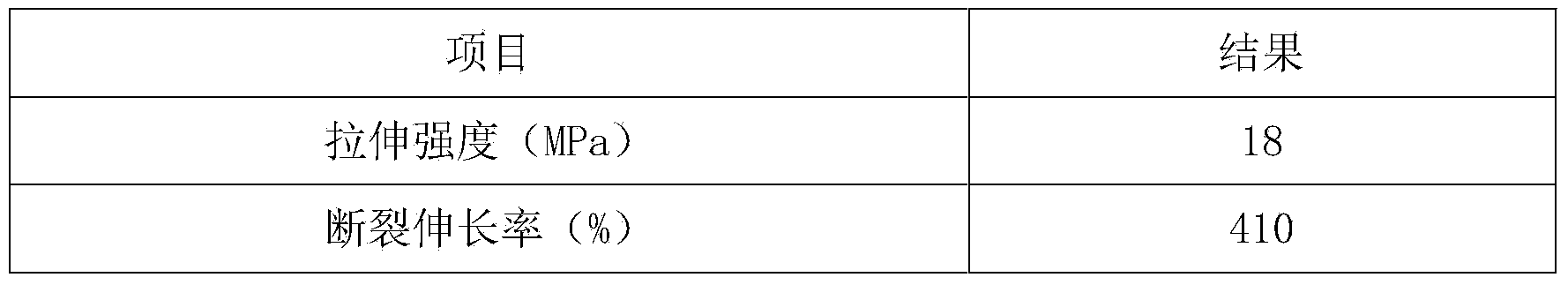

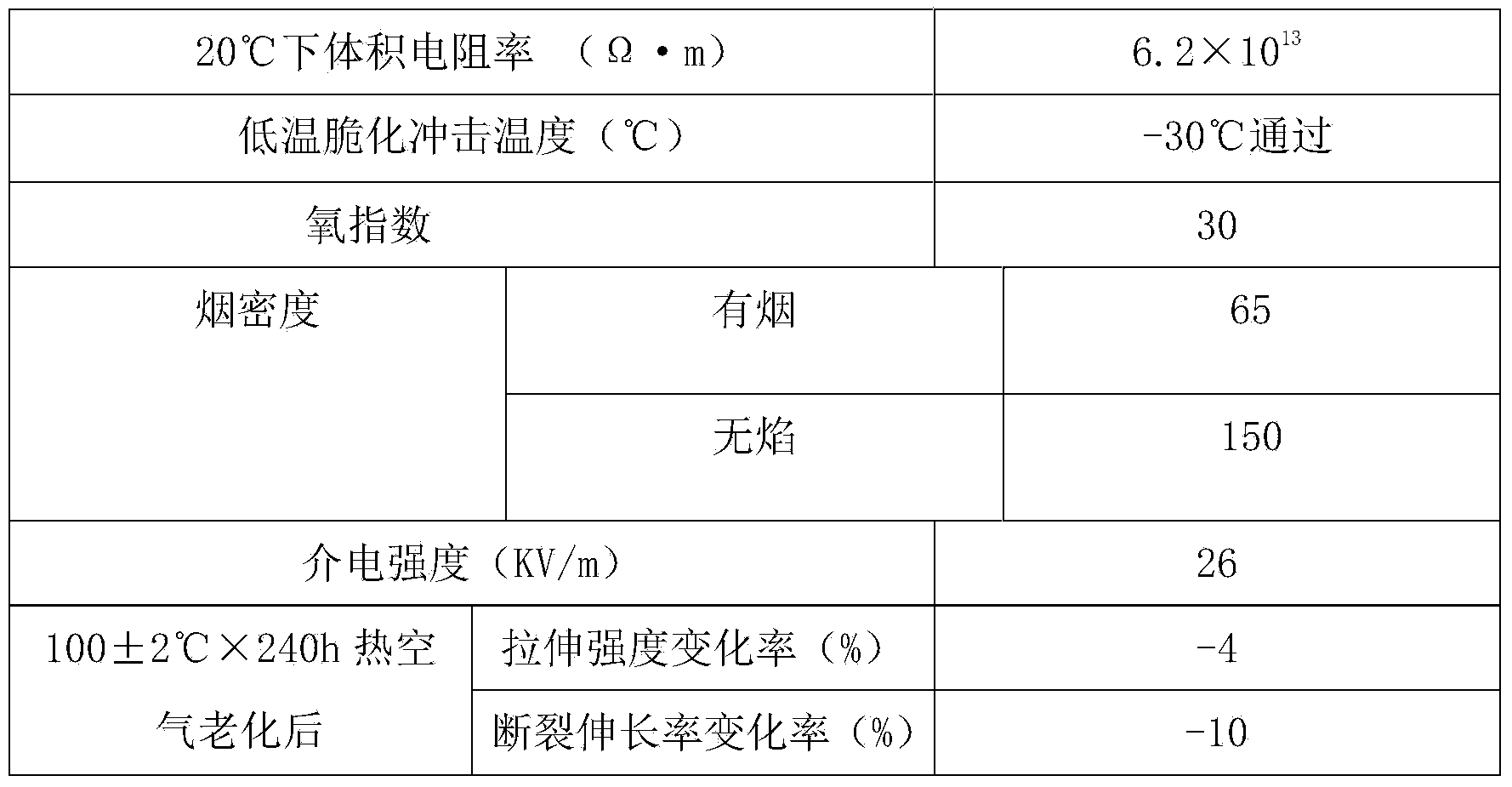

Environment-friendly cold-resistant polyvinyl chloride cable material

InactiveCN103509293AStrong impact resistanceSolve environmental problemsWear resistantDecabromodiphenyl ether

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material. The polyvinyl chloride cable material is prepared with the following components and raw materials by weight: 60-70 parts of polyvinyl chloride, 10-15 parts of polysiloxane, 8-10 parts of silicon rubber, 12-15 parts of dioctyl terephthalate, 5-10 parts of triethylene glycol di-2-ethylhexoate (triglycol dioctate), 3-5 parts of epoxy triglyceride, 8-10 parts of tributyl acetocitrate, 1-2 parts of cobalt naphthenate, 0.2-0.3 part of ethyl silicon oil, 2-5 parts of chlorinated polyethylene, 10-15 parts of aluminum hydroxide, 5-6 parts of triphenyl phosphate, 4-6 parts of decabromodiphenyl ether, 8-10 parts of light activated calcium carbonate, 5-8 parts of bentonite, 1-2 parts of zinc oxide, 1-2 parts of titanium dioxide, 5-6 parts of cinerite, 6-8 parts of highly wear-resistant carbon black, 2-3 parts of Ca-Zn compound stabilizer, 0.1-1 part of antioxidant 1076, 0.1-0.3 part of dicumyl peroxide (DCP), 0.2-0.3 part of butyl stearate, 1-2 parts of barium stearate, 0.1-0.5 part of zinc stearate, and 8-10 parts of modified filler. The cable material is of good shock resistance at low temperature and environment-protection property, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly, and bad in the shock resistance at low temperature.

Owner:东莞虎塑塑胶科技有限公司

Unsaturated polyester fiber reinforced bulk molding compound and preparation method thereof

The invention relates to a preparation method of an unsaturated polyester fiber reinforced bulk molding compound and aims at providing the unsaturated polyester fiber reinforced bulk molding compound that has high strength, impact resistance and high-temperature and low-temperature resistance. The unsaturated polyester fiber reinforced bulk molding compound comprises the following materials in parts by weight: 30-50 parts of unsaturated polyester, 0.3-0.5 parts of cobalt naphthenate, 0.2-0.4 parts of methyl ethyl ketone peroxide, 25-35 parts of reinforced fibers, 30-40 parts of calcium carbonate, 0.2-0.3 parts of antistatic agent, 0.1-0.15 parts of antioxidant agent and 0.2-0.3 parts of pentabromophenol. The unsaturated polyester fiber reinforced bulk molding compound has the advantages of high toughness and high strength; the impact strength is 150kj / m<2>; the bending strength is 180MPa; and the tensile strength is 90MPa.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

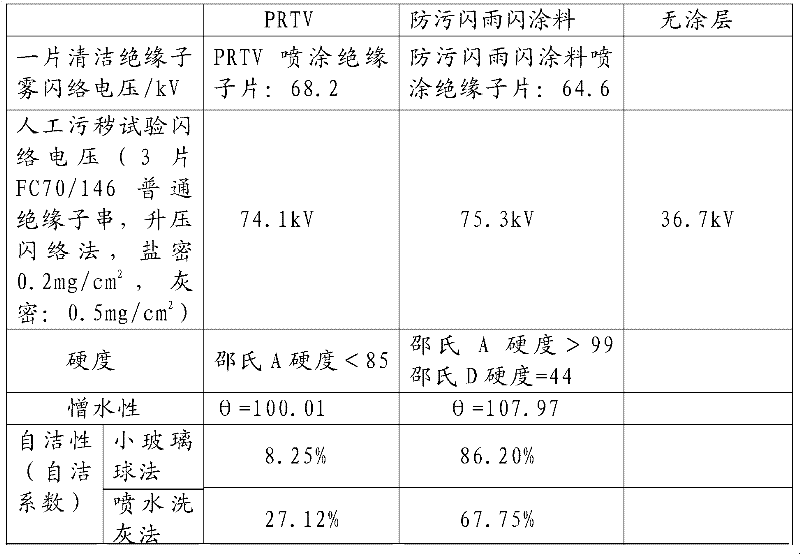

Pollution/rain flashover resistant paint and preparation method thereof

ActiveCN102391752AImprove adhesionImprove wear resistanceAntifouling/underwater paintsPaints with biocidesSilanesOrganotitanium compound

The invention discloses a pollution / rain flashover resistant paint. The paint comprises the following components in parts by weight: 40-50 parts of silicon rubber, 40-50 parts of MQ silicon resin, 50-80 parts of a solvent, 5-20 parts of fillers, 50-70 parts of silicone acrylate resin, 0.5-3 parts of a curing agent and 3-6 parts of catalysts, wherein the silicon rubber is hydroxyl-terminated polydialkylsiloxane; the MQ silicon resin is methyl hydrogen-containing MQ silicon resin with M-Q ratio being 0.6-0.9; the solvent is one or mixture of butyl acetate, ethyl acetate and methyl acetate; the fillers are one or more of nano calcium carbonate, fumed silica, titanium dioxide and silica micropowder, which are subjected to surface modification treatment by silane; the curing agent is zirconiumisooctoate, cobalt isooctoate or cobalt naphthenate; and the catalysts are tin compounds or organic titanium compounds. The invention also discloses a preparation method of the pollution / rain flashover resistant paint.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

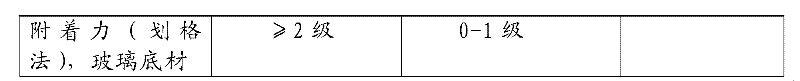

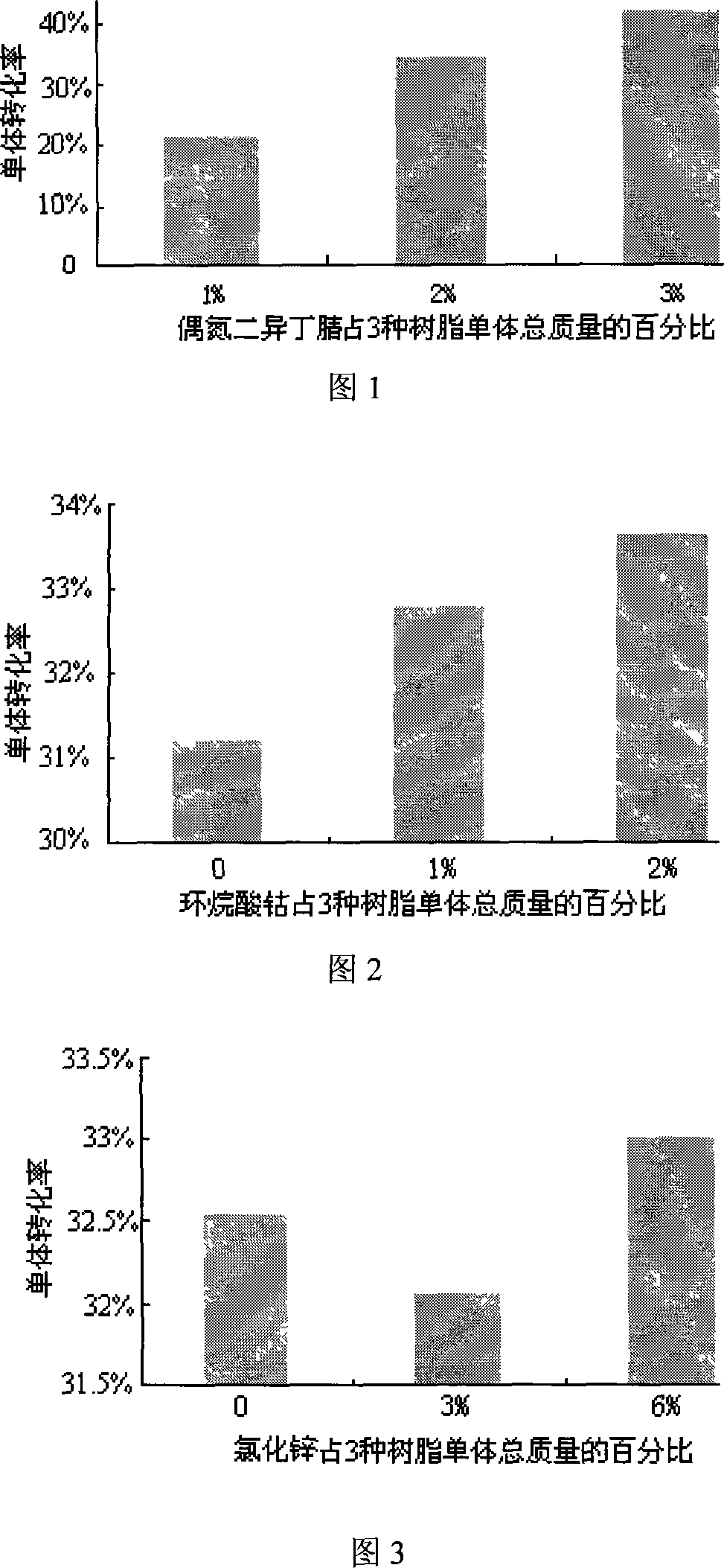

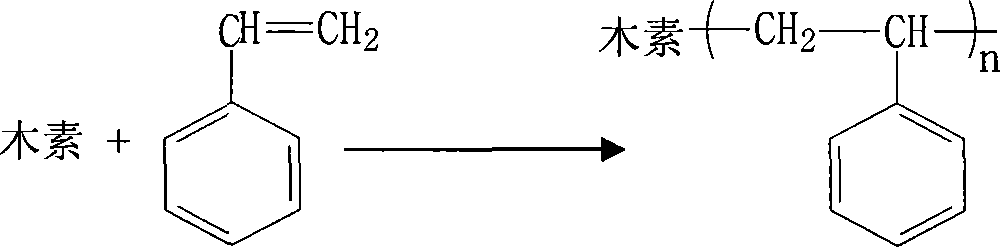

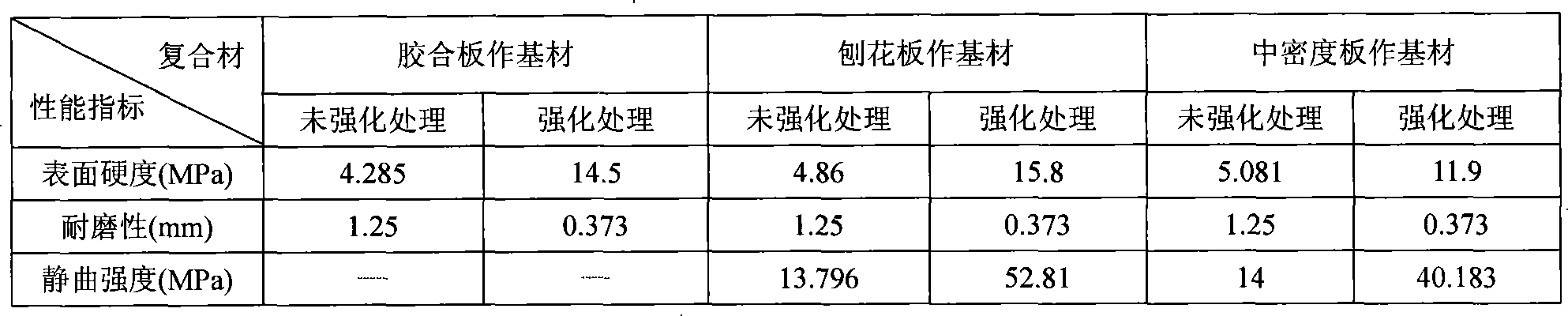

Poplar single ply intensifier and its usage in intensifying poplar single ply

InactiveCN101020326AImprove mechanical propertiesHigh surface hardnessPressure impregnationWood dampingChlorideHardness

The present invention is poplar single ply intensifier and the method of intensifying poplar single ply therewith. The poplar single ply intensifier is prepared with styrene 24-26 weight portions, methyl methacrylate 48-52 weight portions, vinyl acetate 24-26 weight portions, 2azo diisobutyronitrile 2.8-3 weight portions, cobalt naphthenate 1.8-2.2 weight portions and zinc chloride 5.8-6.2 weight portions. The method of intensifying poplar single ply with the intensifier includes the following steps: preparing the intensifier, soaking poplar single ply inside the intensifier, sealing and pressurizing, ageing, and heating before drying. The present invention can raise the surface hardness of poplar single ply by 1.34-2.55 times, wear resistance by 2.35 times and static bending strength by 1.87-2.96 times.

Owner:NORTHEAST FORESTRY UNIVERSITY

Bowlder-imitated artificial stone plate and manufacturing method thereof

InactiveCN102775092ANon-toxicNo radiationCeramic shaping apparatusMethyl ethyl ketone peroxideArtificial stone

The invention discloses a bowlder-imitated artificial stone plate and a manufacturing method thereof. The artificial stone plate comprises the following components in percentage by mass: 28-30% of unsaturated polyester resin, 40-65% of aluminum hydroxide, 5-30% of shells crushed into objects with diameters of 1-5 cm, 0.02-0.04% of cobalt naphthenate, 0.03-0.05% of methyl ethyl ketone peroxide and 1-2% of pigment paste. The bowlder-imitated artificial stone plate disclosed by the invention has the advantages that: the bowlder-imitated artificial stone plate is environmental-friendly, non-toxic and non-radiative; products are diversiform in color, bright in color and translucent; and the bowlder-imitated artificial stone plate can be produced according to various needs of customers, so that the stone plate is agile and changeable and convenient to decorate and collocate, thereby creating colorful life spaces. Compared with ceramic tiles, the product is light in weight and can be arbitrarily cut and processed; and the bowlder-imitated artificial stone plate has various thicknesses, so that the applicable range of the stone plate is wider than that of ceramic tiles in decoration. The production method disclosed by the invention is simple in process and safe and convenient in production, and a produced artificial stone plate has a smooth and non-porous surface, and a situation that dirt infiltrates into the plate does not occur in the process of application, so that the application of the artificial stone plate is cleaner and more sanitary.

Owner:ZHOUSHAN OUPOSHI ENVIRONMENTAL PROTECTION TECH DEV

Insulating paint

InactiveCN104387917AEasy to prepare ingredientsHas the function of insulationInsulatorsEpoxy resin coatingsPolyesterPolyvinyl chloride

The invention provides an insulating paint. The insulating paint comprises the following constituents in parts by weight: 40 to 50 parts of organosilicone modified epoxide resin, 20 to 30 parts of metal ceramic particles, 15 to 30 parts of mica powder, 20 to 30 parts of antimonous oxide, 10 to 15 parts of a curing agent, 8 to 10 parts of polysiloxane, 3 to 5 parts of a defoamer, 1 to 1.1 parts of cobalt naphthenate, 4 to 5 parts of butanol, 33 to 34 parts of linoleic acid, 23 to 23.5 parts of oxalic acid polyester, 1 to 8 parts of silica gel powder, 2 to 5 parts of silsesquioxanes compound, 14 to 26 parts of polyvinyl chloride, and 2 to 4 parts of a stabilizing agent. The insulating paint has the advantages that the insulating paint can overcome the deficiencies of common insulating paint, manufacture materials of the paint are simple, the insulating paint has an insulating function, and the production cost of the raw materials is low.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

High-toughness high temperature-resistant modified unsaturated polyester resin and preparation method thereof

InactiveCN106749947AImprove toughnessImprove high temperature resistancePhosphateTemperature resistance

The invention discloses high-toughness high temperature-resistant modified unsaturated polyester resin. Raw materials of the high-toughness high temperature-resistant modified unsaturated polyester resin comprise maleic anhydride, m-phthalic anhydride, o-phthalic anhydride, ethyl acetate, methyl methacrylate, hydroxyhydroquinone, hydroquinone, dicyclopentadiene, cobalt naphthenate styrene, phosphate melamine, methyl ethyl ketone peroxide, dicumyl peroxide, a silane coupling agent KH-550, nano titanium dioxide, nano-silicon dioxide, nano-aluminium trihydrate, modified glass fibres, decabromodiphenyl ethane, silane microcapsule-coated ammonium polyphosphate, ethylene glycol, diethylene glycol and propylene glycol. The invention further provides a preparation method for the high-toughness high temperature-resistant modified unsaturated polyester resin. The unsaturated polyester resin prepared by the preparation method has excellent toughness and high temperature resistance.

Owner:滁州常源新材料有限公司

Graphene heat dissipation coating applied to LED lamps and preparation method of graphene heat dissipation coating

InactiveCN105820736AStrong UV shielding effectGood weather resistancePolyurea/polyurethane coatingsAcrylic resinGraphene

The invention provides a graphene heat dissipation coating applied to LED lamps. The graphene heat dissipation coating applied to LED lamps is prepared from, by weight, 20-40 parts of pure water, 5-15 parts of waterborne acrylic resin, 10-25 parts of waterborne polyurethane resin, 3-6 parts of YH-82 modified amine, 2-3 parts of cobalt naphthenate, 3-8 parts of diamond powder, 4-7 parts of bentonite powder, 3-7 parts of silica powder, 2-6 parts of a titanate coupling agent, 5-15 parts of titanium dioxide, 0.001-20 parts of a graphene material and 5-8 parts of a film-forming aid. The invention further provides a preparation method of the graphene heat dissipation coating applied to LED lamps.

Owner:NINGBO MORSH TECH

Quick-drying unsaturated polyester resin marking coating and preparation method thereof

InactiveCN102140300AIncrease temperatureConvenient timePolyester coatingsCis-Butenedioic AcidMaterials science

The invention discloses a quick-drying unsaturated polyester resin marking coating and a preparation method thereof. The marking coating is prepared from the following raw materials in percentage by weight: 30-50 percent of modified unsaturated polyester resin, 5-12 percent of titanium pigment, 40-50 percent of quartz powder, 2-5 percent of white carbon black, 1-3 percent of kaoline, 0.5-2 percent of titanate coupling agent, 1-3 percent of cobalt naphthenate and 0.5-1.5 percent of methyl ethyl ketone peroxide, wherein the modified unsaturated polyester resin is obtained by the steps of preparing unsaturated polyester resin by performing esterification and condensation on monoester maleate end-capped by dicyclopentadiene and propylene glycol, and adding a methyl methacrylate monomer diluent into the unsaturated polyester resin. The preparation method comprises the following step of: ultrasonically mixing the components with the amount in a formula for 3-7 minutes to obtain a quick-drying unsaturated polyester resin marking coating. During construction, the cobalt naphthenate and the methyl ethyl ketone peroxide are added for curing to form an unsaturated polyester resin marked line, which has the wear resistance superior to that required by a national standard.

Owner:陈希锴

Polytetrafluoroethylene modified vinyl floor coating

ActiveCN101845277AHigh strengthGood chemical resistanceAnti-corrosive paintsChemical industryPolyvinyl chloride

The invention discloses formula components, a preparation process and other contents of a polytetrafluoroethylene modified vinyl floor coating, which is called FVC floor coating for short, the coating comprises three components of A, B and C, wherein the A component is prepared by 9 substances of vinyl resin, polytetrafluoroethylene resin, polyvinyl chloride resin, anionic carboxylic polymer dispersant and the like, the B component is methyl ethyl ketone peroxide, and the C component is cobalt naphthenate. When in use, the A component, the B component and the C component are mixed for preparing the polytetrafluoroethylene modified vinyl floor coating according to the weight ratio of 100: 1.5-4: 1.5-4. The invention simultaneously discloses a formula and the preparation process of producing an anti-corrosion floor by using the polytetrafluoroethylene modified vinyl floor coating, and the polytetrafluoroethylene modified vinyl floor coating is characterized by excellent chemical medium corrosion resistance, weather resistance, oil resistance, water resistance, good mechanical properties, construction performance and the like, as well as long service life, and good anti-cracking performance, and can be used in chemical industry, petroleum, foods, pharmaceutical industry and the like as protective materials of surface layers of basal bodies, such as concrete floors, wall surfaces and other building structures, members and the like.

Owner:ZHEJIANG YONGGUWEIHUA COATING

Alcohol acid ripple finish and preparation method thereof

ActiveCN103468106ASimple production processReduce security risksPolyester coatingsCalcium EDTASkin agent

The invention provides alcohol acid ripple finish and a preparation method thereof. The alcohol acid ripple finish comprises, by weight, 50-60 parts of alcohol acid ripple resin (having solid content of 60+ / -3wt%), 5-10 parts of polymerized oil pattern-adjustment resin, 2-3 parts of carbon black, 20-35 parts of light calcium, 0.5-1.5 parts of bentonite HFGEL-40A, 1-2.5 parts of lead naphthenate having the content of 10%, 2-3.5% of cobalt naphthenate having the content of 4%, 0.1-0.3 parts of an anti-skinning agent and 5-10 parts of toluene. The anti-skinning agent is methyl ethyl ketoxime, butyraldehyde oxime or cyclohexanone-oxime and is obtained by mixing. The film of the alcohol acid ripple finish has excellent characters, realizes a flexible change of ripple patterns according to user demands and can be prepared by a simple method.

Owner:天津灯塔涂料工业发展有限公司

Resin material used for preparing buttons

The invention provides a resin material used for preparing buttons. The material comprises the raw materials of, by weight: 80 parts of unsaturated polyester resin, 20-200 parts of inorganic powder, 2-3 parts of a curing agent, 2-3 parts of an accelerating agent, and 3-8 parts of a monomer diluent. The unsaturated polyester resin is isophthalic-type unsaturated polyester resin or bisphenol A-type unsaturated polyester resin. The inorganic powder is one or a combination of more than two selected from calcium carbonate, talcum powder, silica, and magnesium silicate. The curing agent is methyl ethyl ketone peroxide. The accelerating agent is cobalt naphthenate or cobalt isooctanoate. The monomer diluent is one or a combination of more than two selected from styrene, ethyl methacrylate, and methyl acrylate. Buttons prepared by using the material have the advantages of good mechanical properties and low cost.

Owner:KUNSHAN JIEMING TEXTILE

Catalyst for producing light fuel oil using oily rock as raw material and its method

InactiveCN1786115AGood miscibilityImprove stabilityLiquid hydrocarbon mixture productionLighter fuelParaffin oils

The present invention relates to a catalyst for producing light fuel oil by using oil-bearing rock and its method. Said catalyst raw material composition includes (by wt%) 20-35% of cobalt naphthenate, 30-40% of ethylene glycol monomethyl ether, 3-5% of acidified active clay, 10-20% of stearin and 20-37% of chlorinated paraffin. The described chlorinated paraffin is industrial chlorinated paraffin 70. Said invention also provides the concrete method and steps of utilizing said catalyst to produce light fuel oil.

Owner:曹志德

Anti-corrosion, oil-resistant and flame-retardant plastic oil tank

ActiveCN103214806AImprove impact resistancePhysical properties unchangedLarge containersPolyesterFiber

The invention relates to a reinforced plastic and an oil tank, and aims to provide an anti-corrosion, oil-resistant and flame-retardant oil tank which has reliable physical property and is made of reinforced plastic. The technical point is as below: the bulk molding compound comprises the following components in parts by weight: 34-47 parts of unsaturated polyester, 0.3-0.4 part of cobalt naphthenate, 0.3-0.35 part of methyl ethyl ketone peroxide, 45-47 parts of calcium carbonate, 0.1-0.3 part of antistatic agent, 0.1-0.15 parts of antioxygen, 0.1-0.15 part of pentabromo phenol, 0.1-0.3 part of microencapsulation tri-(2,3-dibromopropyl) isocyanuric acid ester, 0.1-0.2 part of melamine, 0.08-0.1 part of nano silica, a proper amount of silane coupling agent and 28-31 parts of reinforced fiber. The plastic can endure the temperature of 360 DEG C and 64 DEG C below zero, has constant physical property and has the advantages of high toughness and strength. The impact resistance of the unsaturated polyester fiber-reinforced bulk molding compounds is effectively improved. The reinforced plastic is anti-corrosion, anti-aging, oil resistant and flame retardant, and is suitable for manufacturing oil tanks.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

Bamboo strip softener and preparation process thereof

InactiveCN104526808AWood treatment detailsReed/straw treatmentPotassium persulfateDimethylaniline N-oxide

The invention provides a bamboo strip softener and a preparation process thereof. The bamboo strip softener is prepared by the following steps: weighing glycerol, alkylethoxyglucoside, polyoxyethylene ether and a surfactant, putting into a stirring tank, stirring for 30 minutes with the stirring temperature to be 80 DEG C, then adding potassium persulfate, formaldehyde and ammonium persulfate, simultaneously adding cobalt naphthenate, dimethylaniline and calcium carbonate, rapidly stirring for 3 minutes with the stirring temperature to be 130 DEG C, finally adding stearyl alcohol, stearic acid, stearic acid, urethane and paraffin, stirring for 1h, and cooling at room temperature. The bamboo strip softener has the beneficial effects that the prepared softener is good in softening effect without corrosion and good in effect, is capable of strengthening the strength and the toughness of the softening part and is convenient in popularization and using.

Owner:界首市祥雨竹编专业合作社

High-temperature-resistant corrosion-resistant modified unsaturated polyester resin fiberglass-reinforced plastic grille

InactiveCN105907070AExtended service lifeImprove high temperature resistanceTemperature resistanceUnsaturated polyester

The invention discloses a high-temperature-resistant corrosion-resistant modified unsaturated polyester resin fiberglass-reinforced plastic grille. The fiberglass-reinforced plastic grille is prepared from the raw materials in parts by weight: 50-150 parts of modified unsaturated polyester resin, 20-60 parts of phenol-formaldehyde resin, 5-15 parts of acrylic acid modified alkyd resin, 2-5 parts of silicon carbide, 1-4 parts of aluminum hydroxide, 3-9 parts of magnesium hydroxide, 2-6 parts of talcum powder, 1-4 parts of paraffin, 2-5 parts of zinc oxide, 3-5 parts of fiberglass, 1-4 parts of hydroxy silicone oil, 1-6 parts of wetting dispersant BYK-W940, 2-8 parts of anti-aging agent D, 1-4 parts of ammonium polyphosphate, 2-5 parts of hydroxyethyl methacrylate, 1-5 parts of tin dibutyl dilaurate, 1-4 parts of dicumyl peroxide, 3-5 parts of propenyl ether glycol peroxide, 1-5 parts of silane coupling agent KH-570, 2-5 parts of methylethyl ketone peroxide and 3-6 parts of cobalt naphthenate. The fiberglass-reinforced plastic grille disclosed by the invention has excellent high-temperature resistance and corrosion resistance.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

Insulating coating

InactiveCN104031438AStrong adhesionHigh mechanical strengthFireproof paintsPolyesterElectrical conductor

The invention relates to an insulating coating which is characterized by comprising the following components by weight parts: 20-30 parts of silica-gel powder, 20-30 parts of phenyl trichlorosilane, 10-20 parts of cobalt naphthenate, 10-20 parts of linoleic acid, 8-16 parts of butanol, 2-8 parts of p-phenylenediamine, 10-20 parts of oxalic acid polyester, 6-10 parts of zinc oxide, 5-15 parts of a silsesquioxane compound, 6-10 parts of polyvinyl chloride and 6-10 parts of a stabilizer. Compared with the prior art, the insulating coating has the advantages of strong adhesion power, high mechanical strength, good high temperature resistance, excellent corrosion resistance and moisture resistance, high low-temperature drying speed, good storage stability and excellent flame resistance, electrical insulation property and ultraviolet resistance, and can be used in the field of flame-retardant insulating coatings for surfaces of conductors in various electrical devices.

Owner:HUZHOU BAISHENG PAINT

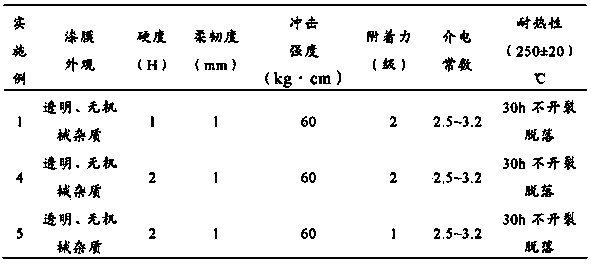

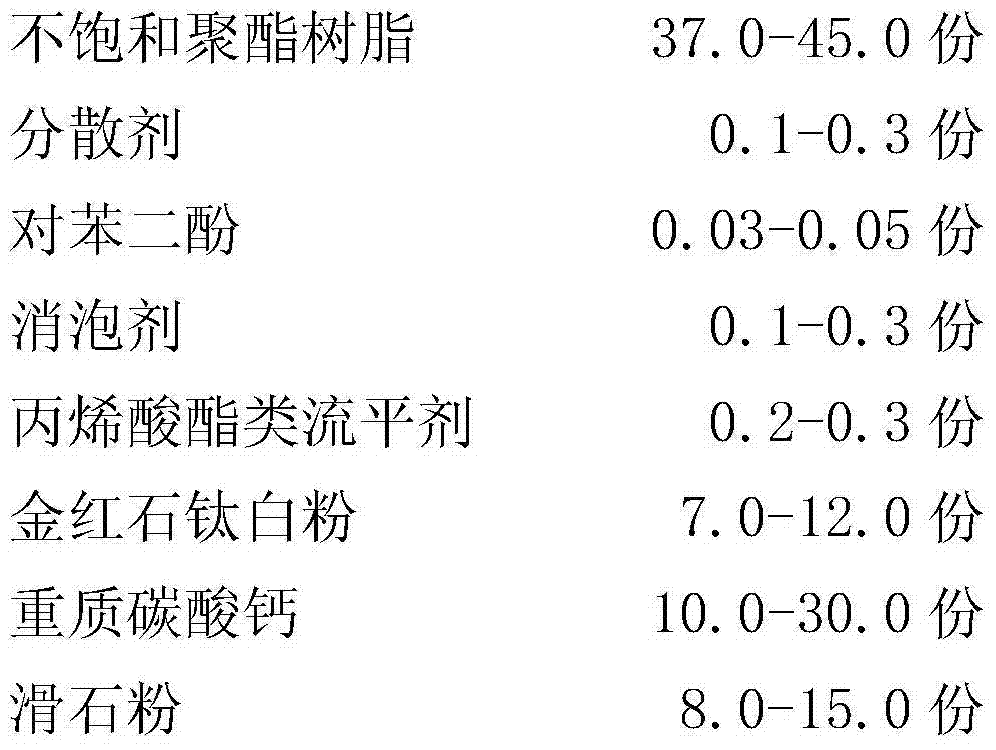

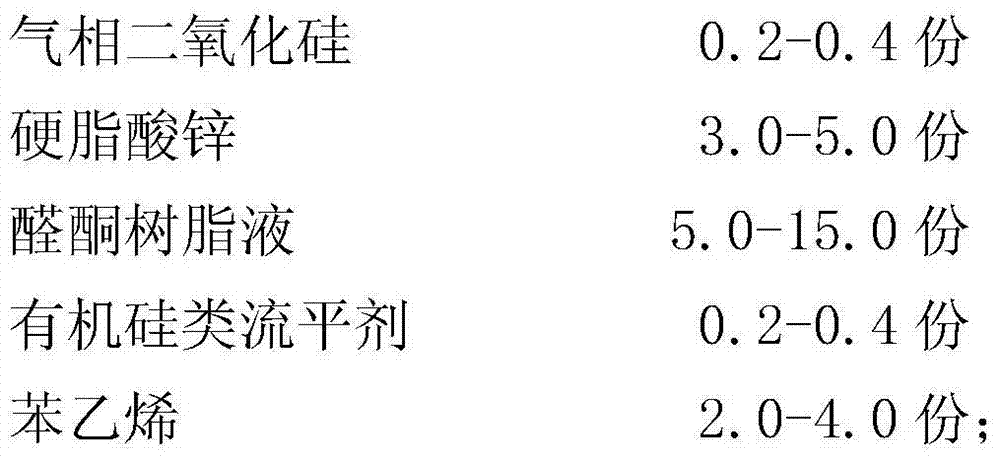

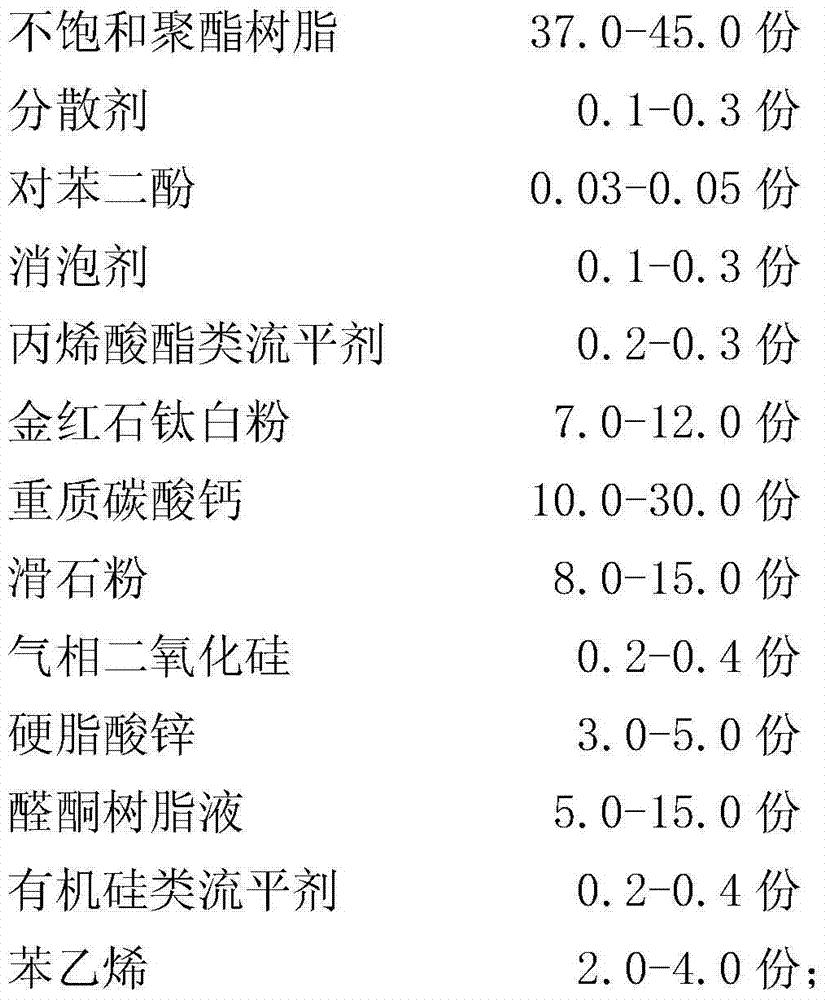

Aldehyde-ketone resin modified unsaturated polyester primer and preparation method thereof

InactiveCN104497814AStrong adhesionImprove mechanical propertiesPolyester coatingsKetoneFumed silica

The invention relates to an aldehyde-ketone resin modified unsaturated polyester primer and a preparation method thereof. The aldehyde-ketone resin modified unsaturated polyester primer is prepared by mixing a main paint, an initiator and an accelerator at a weight ratio of 100:(1.0-1.5):(1.2-1.7), wherein the main pain is prepared from the following components in parts by weight: unsaturated polyester resin, a dispersing agent, hydroquinone, a defoaming agent, a leveling agent, a toner, heavy calcium carbonate, talc powder, fumed silica, zinc stearate, aldehyde-ketone resin solution and styrene, the accelerator is cobalt naphthenate, and the initiator is methyl ethyl ketone peroxide. The aldehyde-ketone resin modified unsaturated polyester primer prepared by adopting the preparation method can be directly sprayed on the substrate of a fiberboard without the necessity of polishing the substrate, and the aldehyde-ketone resin modified unsaturated polyester primer presents excellent adhesion and fullness after being sprayed on the substrate of the fiberboard.

Owner:SKSHU PAINT

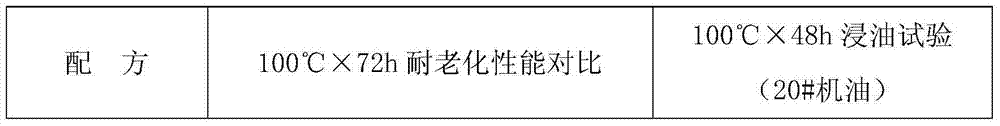

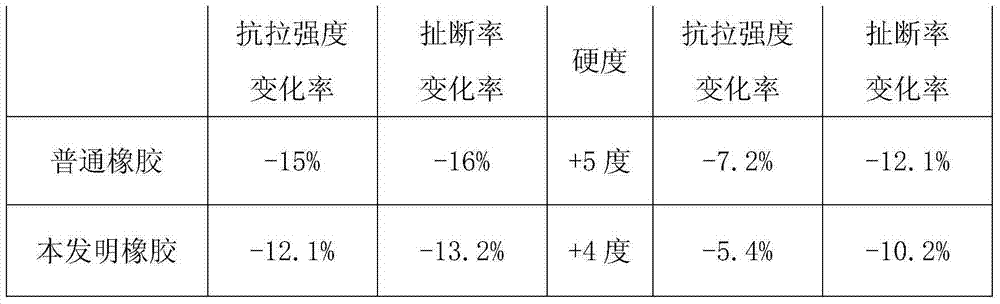

Rubber sealing pad material with wear resistance and sealing performance and preparation method of material

The invention discloses a rubber sealing pad material with wear resistance and sealing performance. The rubber sealing pad material is characterized by comprising the following materials in parts by weight: 70-75 parts of acrylate rubber, 20-25 parts of chloroprene rubber (CR121), 24-28 parts of N330 carbon black, 12-18 parts of nano mica, 2-3 parts of benzotriazole, 2-3 parts of polyethylene glycol, 1-2 parts of cobalt naphthenate, 1-2 parts of calcium stearate, 10-15 parts of N660 carbon black, 20-25 parts of nano clay, 1-2 parts of aluminate coupling agent DL-411, 1-2 parts of accelerant, 1-2 parts of sulphur, 2-3 parts of zinc oxide and 10-12 parts of modified attapulgite. The rubber sealing pad material disclosed by the invention has the advantages that due to addition of the modified attapulgite, the process properties of rubber are improved; due to use of an environment-friendly compounding agent, the toxic and side effects and the pollution to the environment are reduced; the formula is reasonable, the process is simple, the cost is low, the sealing performance and the wear resistance are good and the ageing resistance is good.

Owner:马鞍山市中澜橡塑制品有限公司

Insulating paint

InactiveCN104341828AEasy to prepare ingredientsHas the function of insulationCoatingsPolyesterLinoleic acid

The invention provides an insulating paint. The paint comprises the following raw materials in parts by weight: 1.5 parts of cobalt naphthenate, 6 parts of butanol, 38 parts of linoleic acid, and 26 parts of oxalic acid polyester. The insulating paint has the beneficial effects of being capable of overcoming the deficiencies of the common insulating paint, simple in raw materials for production, having an insulating function, and being low in production cost of raw materials.

Owner:QINGDAO YIQUN PANT GRP

Hollow glass bead and polyurethane cooperated-modified unsaturated polyester composite material and preparation method thereof

The invention discloses a hollow glass bead and polyurethane cooperated-modified unsaturated polyester composite material and a preparation method thereof. The composite material is prepared from the following ingredients in parts by weight: 100 parts of unsaturated polyester resin, 15-40 parts of hollow glass bead-polyurethane prepolymer, 5-10 parts of diluent styrene, 1.5-3 parts of initiator methylethyl ketone peroxide, 0.3-0.6 part of accelerant cobalt naphthenate and 0.3-0.6 part of antifoamer simethicone. The prepared composite material has good mechanical strength and toughness while the density is effectively lowered, and meanwhile, the composite material further has special properties such as heat insulation, heat preservation and silencing.

Owner:WUHAN UNIV OF TECH

Formula and preparation method of anti-ultraviolet ray quartz stone plate

The present invention discloses a formula and a preparation method of an anti-ultraviolet ray quartz stone plate. The anti-ultraviolet ray quartz stone plate comprises, by weight, 65-75 parts of quartz sand, 15-25 parts of quartz powder, 8-10 parts of an unsaturated resin, 0.5-1 part of titanium dioxide powder, 0.1-0.3 part of an anti-ultraviolet ray agent, 0.5-1.5 parts of a silane coupling agent, 0.2-0.4 part of tert-butyl peroxy-2-ethylhexanoate, and 0.2-0.3 part of cobalt naphthenate, wherein the particle size of the quartz sand is 10-300 mesh, the particle size of the quartz powder is 325 mesh, and the anti-ultraviolet ray agent is benzophenone or benzotriazole or iron oxide red or zinc oxide. The preparation method comprises: completely stirring the materials, uniformly distributing the material, pumping vacuum, carrying out high pressure pressing molding, baking for 4-6 h with a baking oven, and carrying out thicknessing polishing. The variable quartz stone plate has advantages of ultraviolet ray resistance, color change resistance, aging resistance and the like.

Owner:ZAOZHUANG KEJIA PHOTOELECTRIC TECH CO LTD

Water resistance and high-temperature resistance polyvinyl acetate emulsion coating

InactiveCN105153836AGood compatibilityImprove low temperature resistanceFireproof paintsAnti-corrosive paintsPhosphateTemperature resistance

The invention discloses a water resistance and high-temperature resistance polyvinyl acetate emulsion coating which is prepared from raw materials comprising polyvinyl acetate emulsion, organosilicon-modified acrylate mulsion, nano alumina sol, silicon dioxide, hexamethyldisilazane, organo-modified montamorillonite, expanded vermiculite, nano calcium carbonate, rutile titanium dioxide, ferric oxide, nano silicon nitride, nano silicon carbide, polyarmide fibers, aluminum hydroxide, zinc borate, hexamethylene diisocyanate, 2-hydroxyethyl methacrylate phosphate, cobalt naphthenate, triethylene tetramine, coalescing agents, thickening agents, preservatives, antifreeze agents and deionized water. The water resistance and high-temperature resistance polyvinyl acetate emulsion coating is good in water resistance and high-temperature resistance, good in adhesive force with base materials and high in adhesive strength.

Owner:TIANCHANG YINHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com