Unsaturated polyester fiber reinforced bulk molding compound and preparation method thereof

A technology of bulk molding compound and polyester fiber, which is applied in the field of unsaturated polyester fiber reinforced bulk molding compound and its preparation, and can solve the problems of low strength and poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

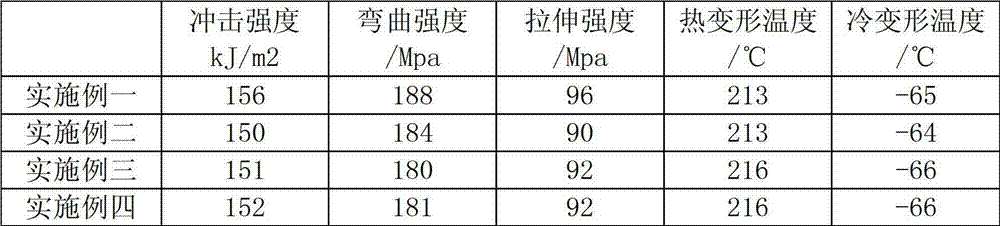

Examples

Embodiment 1

[0017] Formula according to weight ratio: 36 parts of phthalic anhydride-propylene glycol unsaturated polyester, 0.3 part of cobalt naphthenate, 0.2 part of methyl ethyl ketone peroxide, 30 parts of 500 mesh and 200 mesh calcium carbonate mixed at 1:1 by weight, anti 0.2 part of static agent, 0.1 part of antioxidant, and 0.2 part of pentabromophenol were mixed uniformly with a mixer to obtain a resin paste.

[0018] The prepared resin paste is impregnated with 28 parts by weight of non-alkali non-twisted glass roving in a kneader, and the glass roving is added within 5 minutes, kneaded for 15 minutes and mixed evenly.

[0019] Extrude the dough soaked in glass roving with an extruder, seal and pack it with a polyethylene film, and place it in a dry environment at room temperature for 24 hours to obtain an unsaturated fiber-reinforced dough molding compound.

Embodiment 2

[0021] Formula according to weight ratio: 45 parts of phthalic anhydride-propylene glycol unsaturated polyester, 0.4 part of cobalt naphthenate, 0.3 part of methyl ethyl ketone peroxide, 30 parts of 500 mesh calcium carbonate, 0.2 part of antistatic agent, 0.12 part of antioxidant , 0.2 parts of pentabromophenol, and mix it uniformly with a mixer to obtain a resin paste.

[0022] The prepared resin paste is impregnated with 28 parts by weight of non-alkali non-twisted glass roving in a kneader, and the glass roving is added within 5 minutes, kneaded for 15 minutes and mixed evenly.

[0023] Extrude the dough soaked in glass roving with an extruder, seal and pack it with a polyethylene film, and place it in a dry environment at room temperature for 24 hours to obtain an unsaturated fiber-reinforced dough molding compound.

Embodiment 3

[0025] Formula according to weight ratio: 40 parts of isophthalic acid-diethylene glycol unsaturated polyester, 0.4 part of cobalt naphthenate, 0.3 part of methyl ethyl ketone peroxide, 30 parts of 500 mesh calcium carbonate, 0.2 part of antistatic agent, antistatic 0.12 parts of oxygen agent and 0.2 parts of pentabromophenol were mixed uniformly with a mixer to obtain a resin paste.

[0026] The prepared resin paste is impregnated with 30 parts by weight of carbon fiber in a kneader, and the carbon fiber is added within 5 minutes, kneaded for 15 minutes and mixed evenly.

[0027] Extrude the dough impregnated with carbon fiber with an extruder, seal and pack it with a polyethylene film, and place it in a dry environment at room temperature for 24 hours to obtain an unsaturated fiber-reinforced dough molding compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com