Aldehyde-ketone resin modified unsaturated polyester primer and preparation method thereof

An aldehyde-ketone resin and unsaturated technology, applied in the field of aldehyde-ketone resin modified unsaturated polyester primer and its preparation, can solve the problems of poor adhesion and fullness, increased time and cost, and reduced construction efficiency, etc. Achieve excellent fullness and adhesion, excellent adhesion and fullness, and increase work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

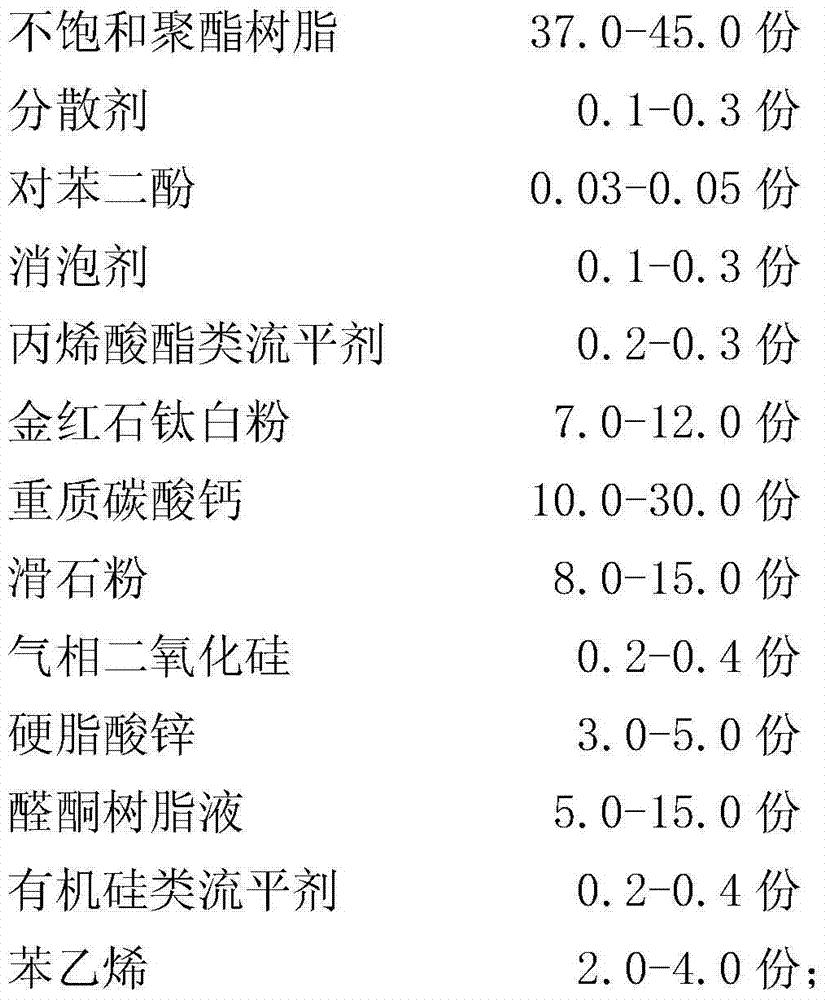

[0039] An aldehyde and ketone resin modified unsaturated polyester primer, which is formed by mixing a main paint, an initiator, and an accelerator in a weight ratio of 100:1.0-1.5:1.2-1.7, wherein the main paint, the initiator, and the accelerator are respectively It is prepared from the following components and weight ratio:

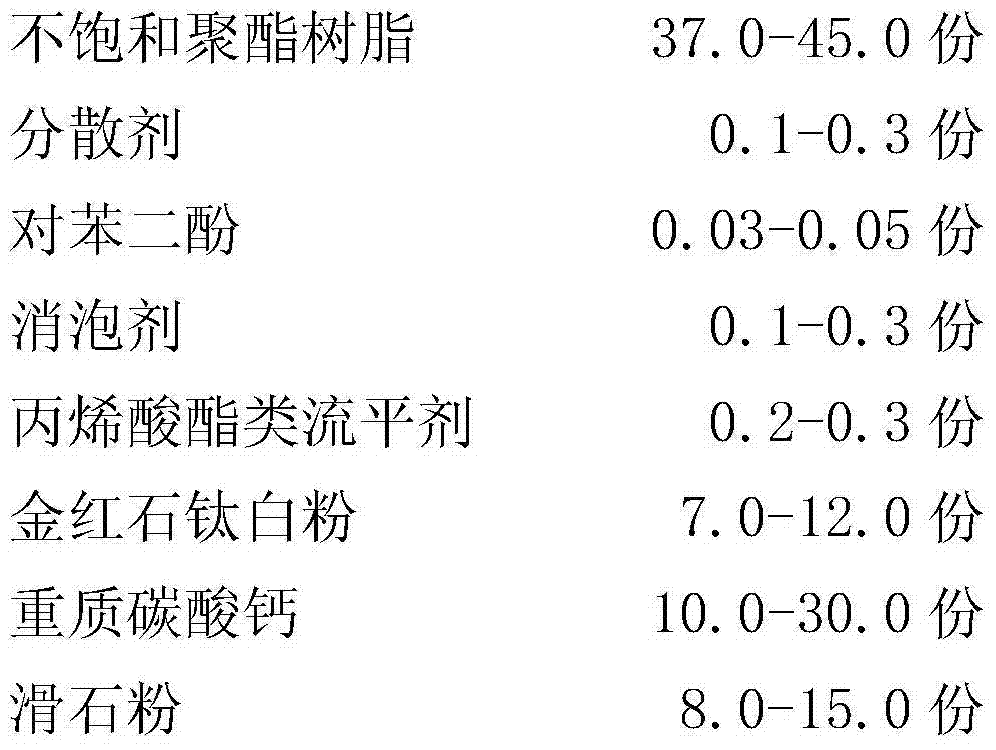

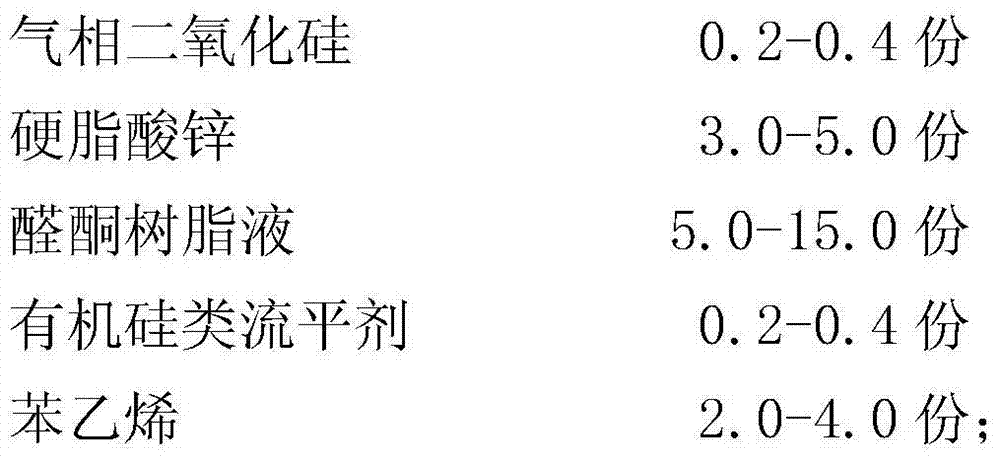

[0040] Wherein the composition and parts by weight of the main paint are as follows:

[0041]

[0042] Accelerator is cobalt naphthenate;

[0043] The initiator is methyl ethyl ketone peroxide.

[0044] A kind of preparation method of aldehyde and ketone resin modified unsaturated polyester primer, comprises the steps:

[0045] (1), the main paint is prepared according to the following preparation method:

[0046] a. Add unsaturated polyester resin, dispersant, defoamer, acrylate leveling agent, and hydroquinone into the container and disperse and stir evenly at a speed of 600-800 rpm;

[0047] b. Add rutile titanium dioxide, talcum powder, heav...

Embodiment 1

[0052] Embodiment 1: A kind of aldehyde and ketone resin modified unsaturated polyester primer is formed by mixing main paint, initiator and accelerator in a weight ratio of 100:1.0:1.2, wherein the main paint, initiator and accelerator are respectively It is prepared from the following components and weight ratio:

[0053] Wherein the composition and parts by weight of the main paint are as follows:

[0054]

[0055] Accelerator is cobalt naphthenate;

[0056] The initiator is methyl ethyl ketone peroxide.

[0057] A kind of preparation method of aldehyde and ketone resin modified unsaturated polyester primer, comprises the steps:

[0058] (1), the main paint is prepared according to the following preparation method:

[0059] a. Add 37.0 parts of unsaturated polyester resin, 0.3 parts of dispersant, 0.1 part of acrylate defoamer, 0.2 part of acrylate leveling agent, and 0.03 part of hydroquinone into the container at a speed of 600 rpm Disperse and stir evenly;

[0060]...

Embodiment 2

[0064] Embodiment 2: A kind of aldehyde and ketone resin modified unsaturated polyester primer is formed by mixing main paint, initiator and accelerator in a weight ratio of 100:1.3:1.5, wherein the main paint, initiator and accelerator are respectively It is prepared from the following components and weight ratio:

[0065] Wherein the composition and parts by weight of the main paint are as follows:

[0066]

[0067]

[0068] Accelerator is cobalt naphthenate;

[0069] The initiator is methyl ethyl ketone peroxide.

[0070] A kind of preparation method of aldehyde and ketone resin modified unsaturated polyester primer, comprises the steps:

[0071] (1), the main paint is prepared according to the following preparation method:

[0072] a. Add 40.0 parts of unsaturated polyester resin, 0.2 parts of dispersant, 0.2 parts of acrylate defoamer, 0.3 part of acrylate leveling agent, and 0.04 part of hydroquinone into the container at a speed of 800 rpm Disperse and stir ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com