Quick-drying unsaturated polyester resin marking coating and preparation method thereof

A technology of polyester resin and marking paint, applied in the field of paint, can solve the problems of high cost, high price of two-component paint, environmental pollution, etc., and achieve the effect of low cost and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0199] The modified unsaturated polyester resin that embodiment 1 makes 43.2%

[0200] Quartz powder with a fineness of 350-400 mesh 42.24%

[0201] Titanium dioxide 6.34%

[0202] Silica 2.64%

[0203] Kaolin 1.58%

[0204] Titanate coupling agent 1%

[0205] Cobalt naphthenate 2%

[0206] Methyl ethyl ketone peroxide 1%

[0207] According to this Example 2, the formulation obtains good results in the application of road markings, and has the advantages described in the following "3.4".

[0208] 3.4 Advantages of quick-drying unsaturated polyester resin coatings compared with existing marking paints

[0209] 3.4.1 Use costs are lower

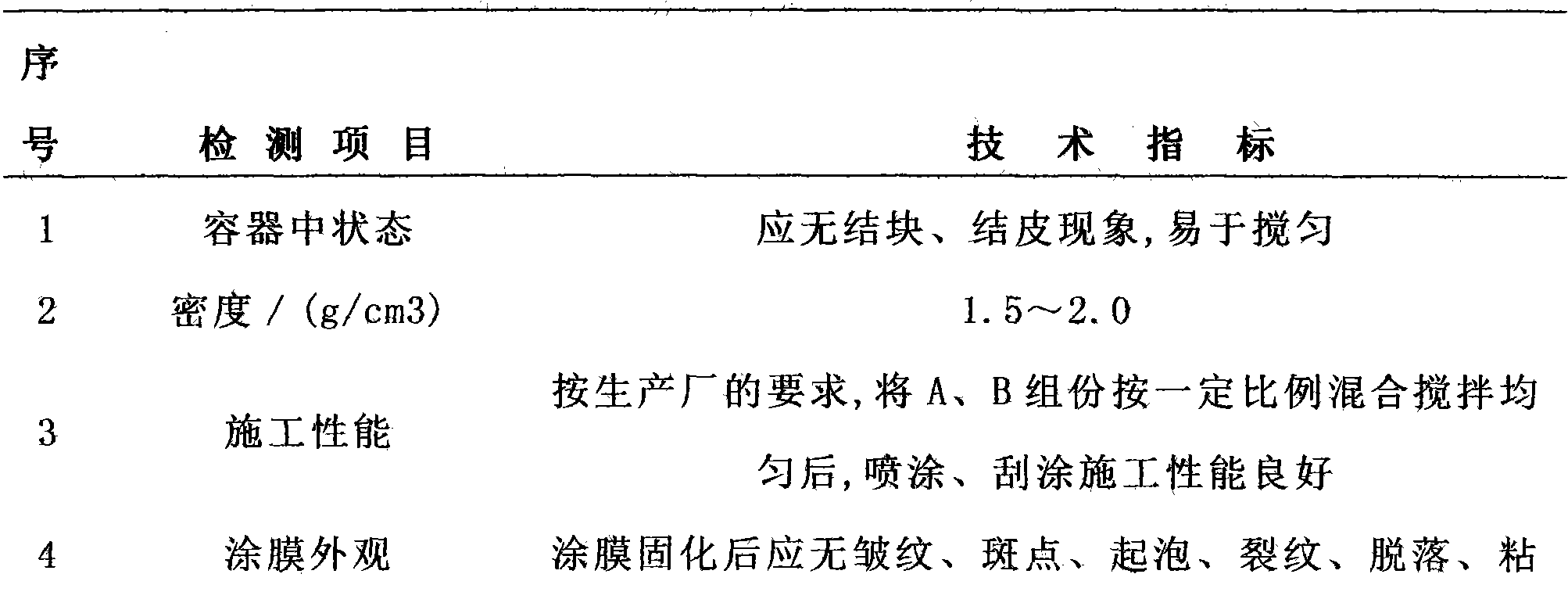

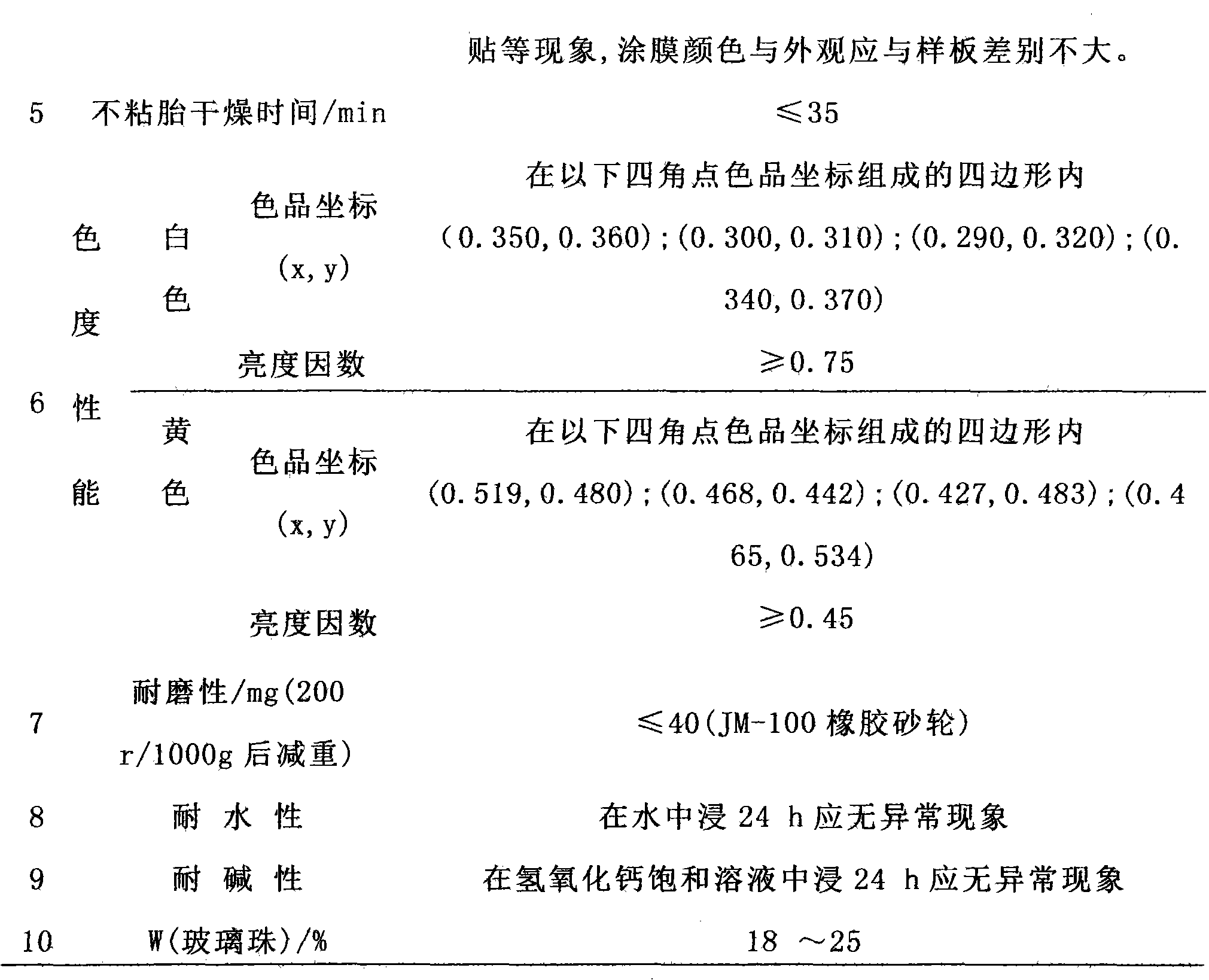

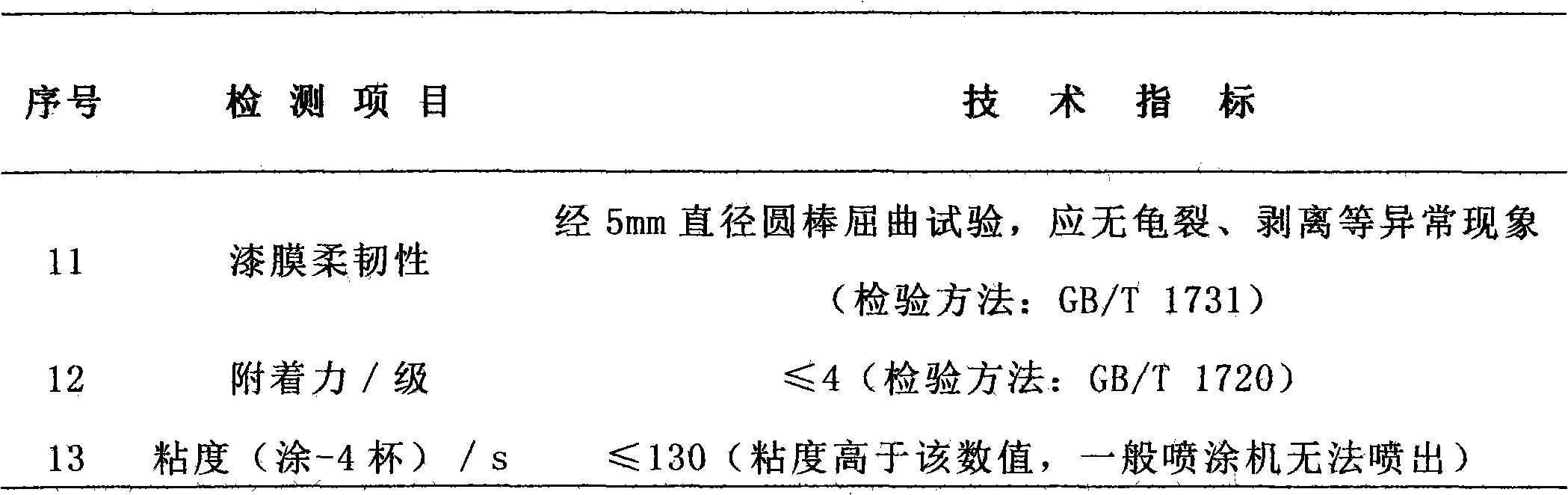

[0210] Table 13 is a comparison of the estimated cost of different coatings calculated in actual road construction. From Table 13, it can be seen that it is more economical to use fast-drying unsaturated polyester resin coatings.

[0211] Table 13 Estimated cost of use

[0212]

[0213] 3.4.2 More stable performance

[0214] The qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com