Pollution/rain flashover resistant paint and preparation method thereof

A manufacturing method and anti-fouling flashover technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocide, etc., to achieve good self-cleaning, not easy to tear, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

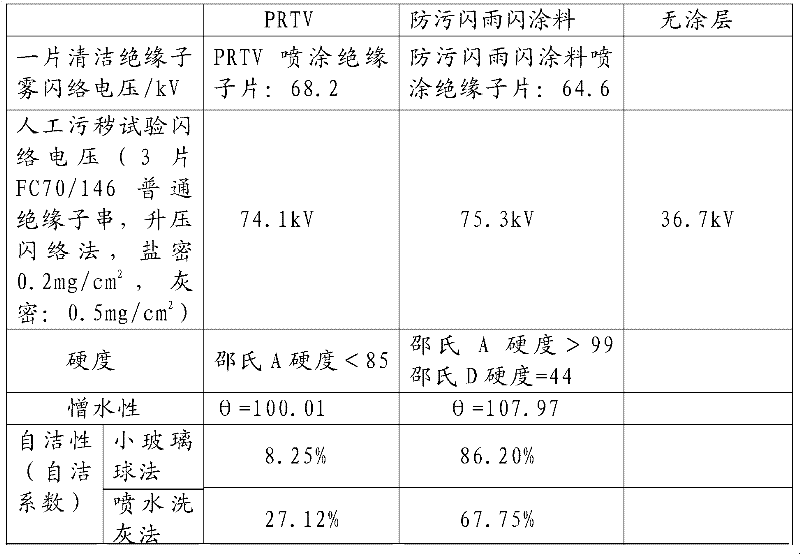

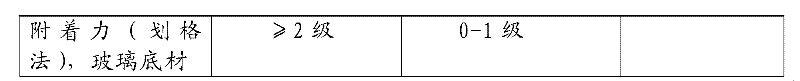

Examples

Embodiment 1

[0019] An anti-fouling flash rain coating, which is composed of the following components by weight: 40 parts of silicone rubber, 40 parts of MQ silicone resin, 50 parts of butyl acetate, 10 parts of nano calcium carbonate treated with silane surface modification, broken 3 parts foam polysiloxane solution, 50 parts silicone acrylic resin, 2 parts curing agent and 3 parts catalyst. Wherein, the silicone rubber is hydroxy-terminated polydialkylsiloxane, for example, hydroxy-terminated polydimethylsiloxane or hydroxy-terminated polymethylvinylsiloxane can be selected. The MQ silicone resin is a methyl hydrogen-containing MQ silicone resin with an M / Q ratio of 0.6 to 0.9, and methyl MQ silicone resin or methyl vinyl MQ silicone resin can be selected. The curing agent is zirconium isooctanoate, cobalt isooctanoate or cobalt naphthenate. The catalyst is a tin compound or organic titanium compound catalyst, and the tin compound can be Bu 2 Sn(OAc) 2 Or Sn(OCOC 7 H 15 ) 2 , Ti(OBu) can...

Embodiment 2

[0026] An anti-pollution flash rain flash paint, which is composed of the following components by weight: 40 parts of silicone rubber, 50 parts of MQ silicone resin, 50 parts of ethyl acetate, 20 parts of fumed silica after surface modification treatment with silane, 6 parts of foam-breaking polysiloxane solution, 60 parts of silicone acrylic resin, 3 parts of curing agent and 5 parts of catalyst. Wherein, the silicone rubber is hydroxy-terminated polydialkylsiloxane, for example, hydroxy-terminated polydimethylsiloxane or hydroxy-terminated polymethylvinylsiloxane can be selected. The MQ silicone resin is a methyl hydrogen-containing MQ silicone resin with an M / Q ratio of 0.6 to 0.9, and methyl MQ silicone resin or methyl vinyl MQ silicone resin can be selected. The curing agent is zirconium isooctanoate, cobalt isooctanoate or cobalt naphthenate. The catalyst is a tin compound or organic titanium compound catalyst, and the tin compound can be Bu 2 Sn(OAc) 2 Or Sn(OCOC 7 H 15...

Embodiment 3

[0033] An anti-fouling and rain-flash paint, which is composed of the following components by weight: 50 parts of silicone rubber, 40 parts of MQ silicone resin, 80 parts of methyl acetate, 15 parts of titanium dioxide with silane surface modification treatment, foam breaking polymer 1 part of siloxane solution, 70 parts of silicone acrylic resin, 0.5 part of curing agent and 6 parts of catalyst. Wherein, the silicone rubber is hydroxy-terminated polydialkylsiloxane, for example, hydroxy-terminated polydimethylsiloxane or hydroxy-terminated polymethylvinylsiloxane can be selected. The MQ silicone resin is a methyl hydrogen-containing MQ silicone resin with an M / Q ratio of 0.6 to 0.9, and methyl MQ silicone resin or methyl vinyl MQ silicone resin can be selected. The curing agent is zirconium isooctanoate, cobalt isooctanoate or cobalt naphthenate. Make the product in the manufacturing process, accelerate the curing. The catalyst is a tin compound or organic titanium compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com