Insulating coating

A technology of insulating coatings and components, applied in fire-resistant coatings, coatings, etc., can solve the problems of aging and powdering of coatings, insulating paints without flame retardant function, and easy breakage of ether bonds, etc., to achieve strong adhesion, anti-corrosion and moisture-proof. The effect of excellent performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

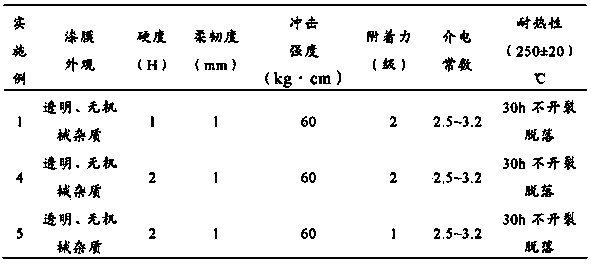

Examples

Embodiment 1

[0009] An insulating coating, consisting of the following components in parts by weight: silica gel powder 20, phenyltrichlorosilane 30, cobalt naphthenate 20, linoleic acid 20, butanol 16, p-phenylenediamine 8, ethylene diamine Acid polyester 20, zinc oxide 10, silsesquioxane compound 15, polyvinyl chloride 10, stabilizer 10.

Embodiment 2

[0011] An insulating coating, consisting of the following components in parts by weight: silica gel powder 30, phenyltrichlorosilane 20, cobalt naphthenate 10, linoleic acid 10, butanol 8, p-phenylenediamine 2, ethylene diamine Acid polyester 10, zinc oxide 6, silsesquioxane compound 5, polyvinyl chloride 6, stabilizer 6.

Embodiment 3

[0013] An insulating coating, consisting of the following components by weight: silica gel powder 23, phenyltrichlorosilane 27, cobalt naphthenate 17, linoleic acid 17, butanol 14, p-phenylene diamine 6, ethylene diamine Acid polyester 17, zinc oxide 9, silsesquioxane compound 12, polyvinyl chloride 9, stabilizer 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com