Patents

Literature

33results about How to "Physical properties unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mortar recovery technique for cutting single-crystal and polycrystalline silicon wire

InactiveCN101327622APhysical properties unchangedSlicing works wellWorking accessoriesFine working devicesFiltrationWire cutting

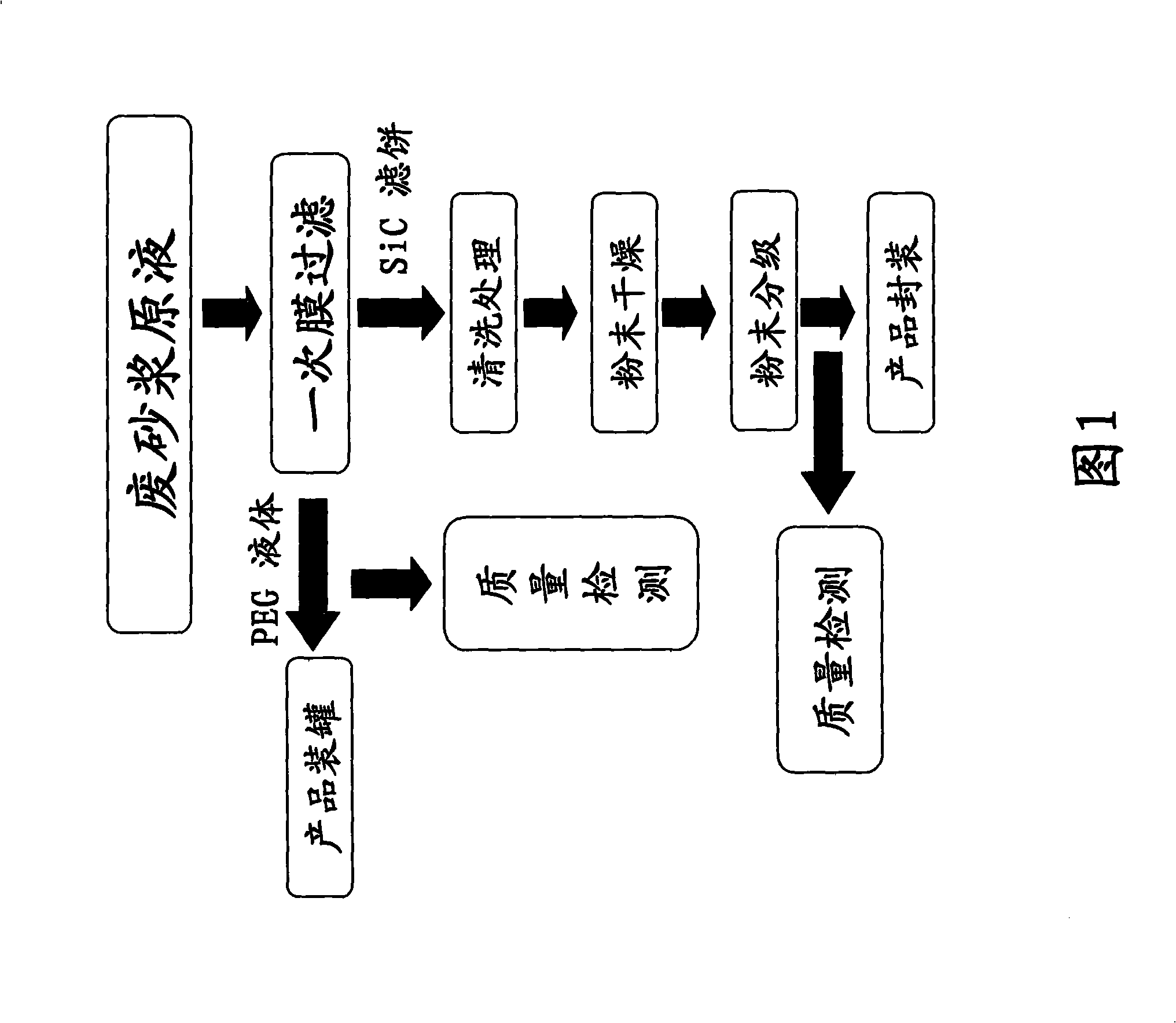

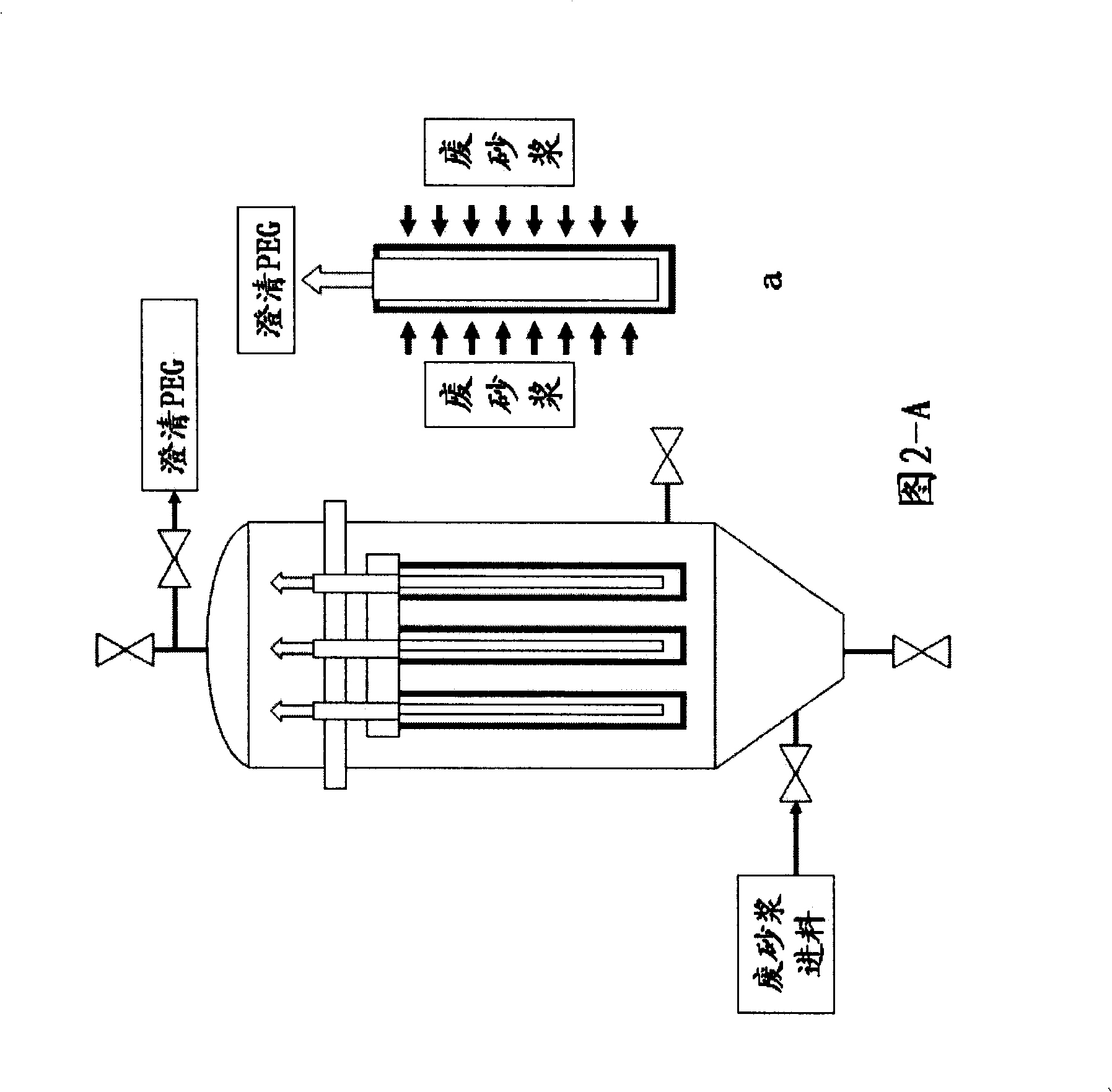

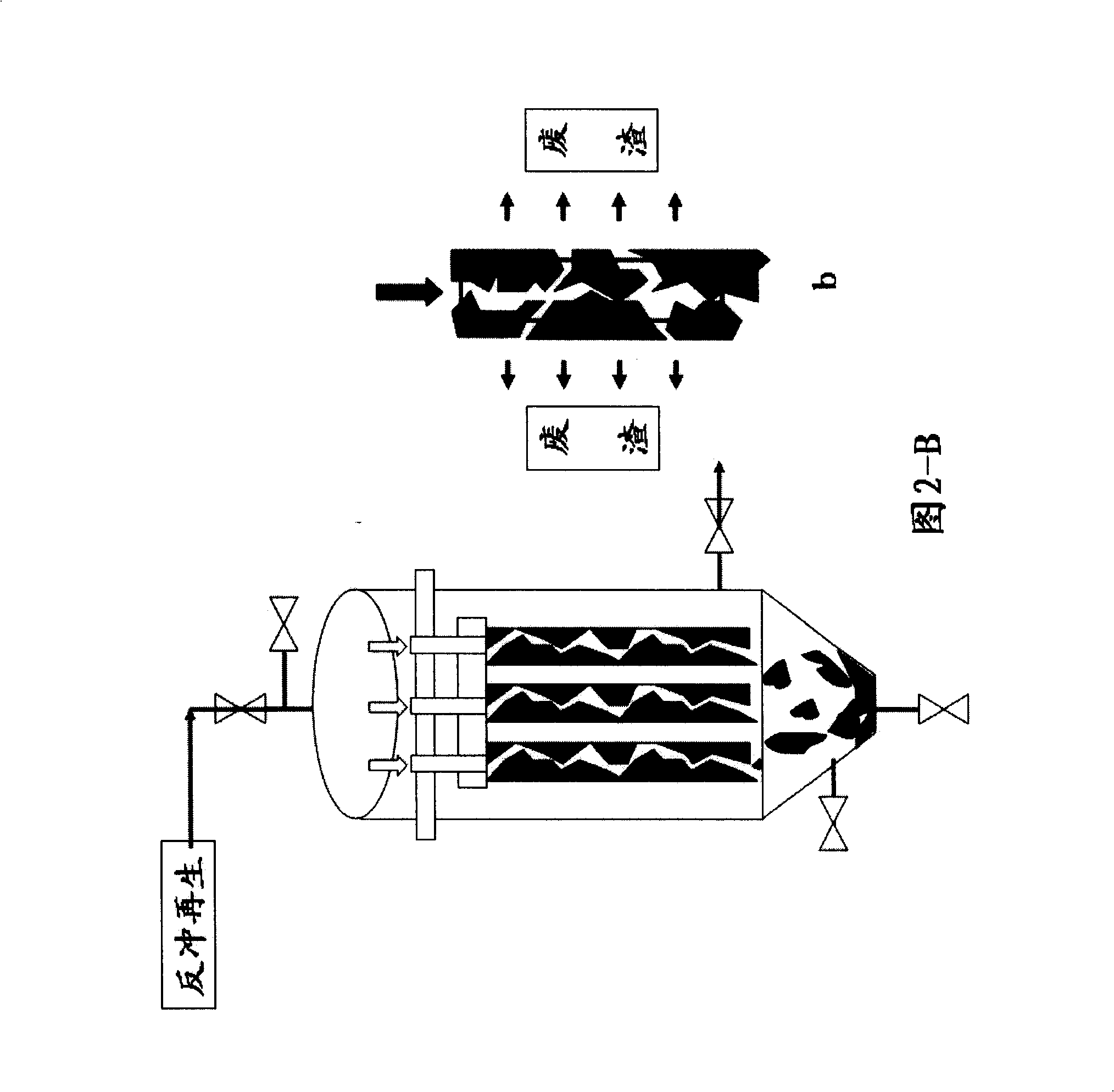

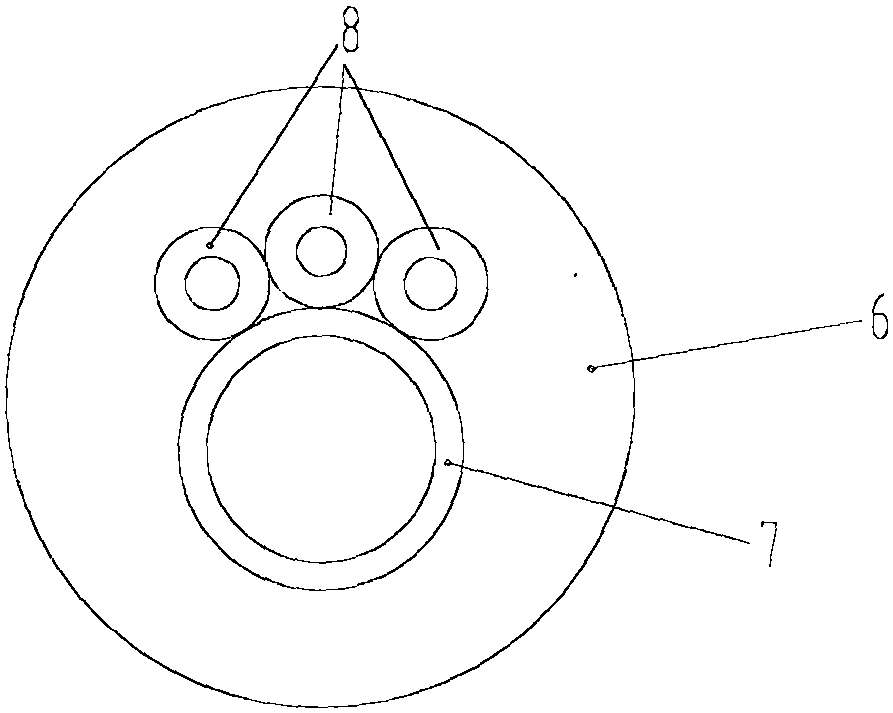

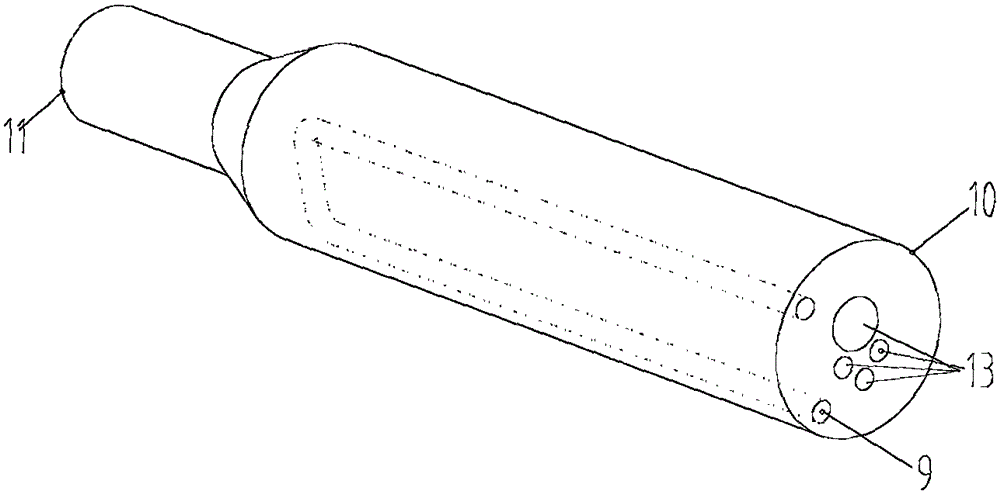

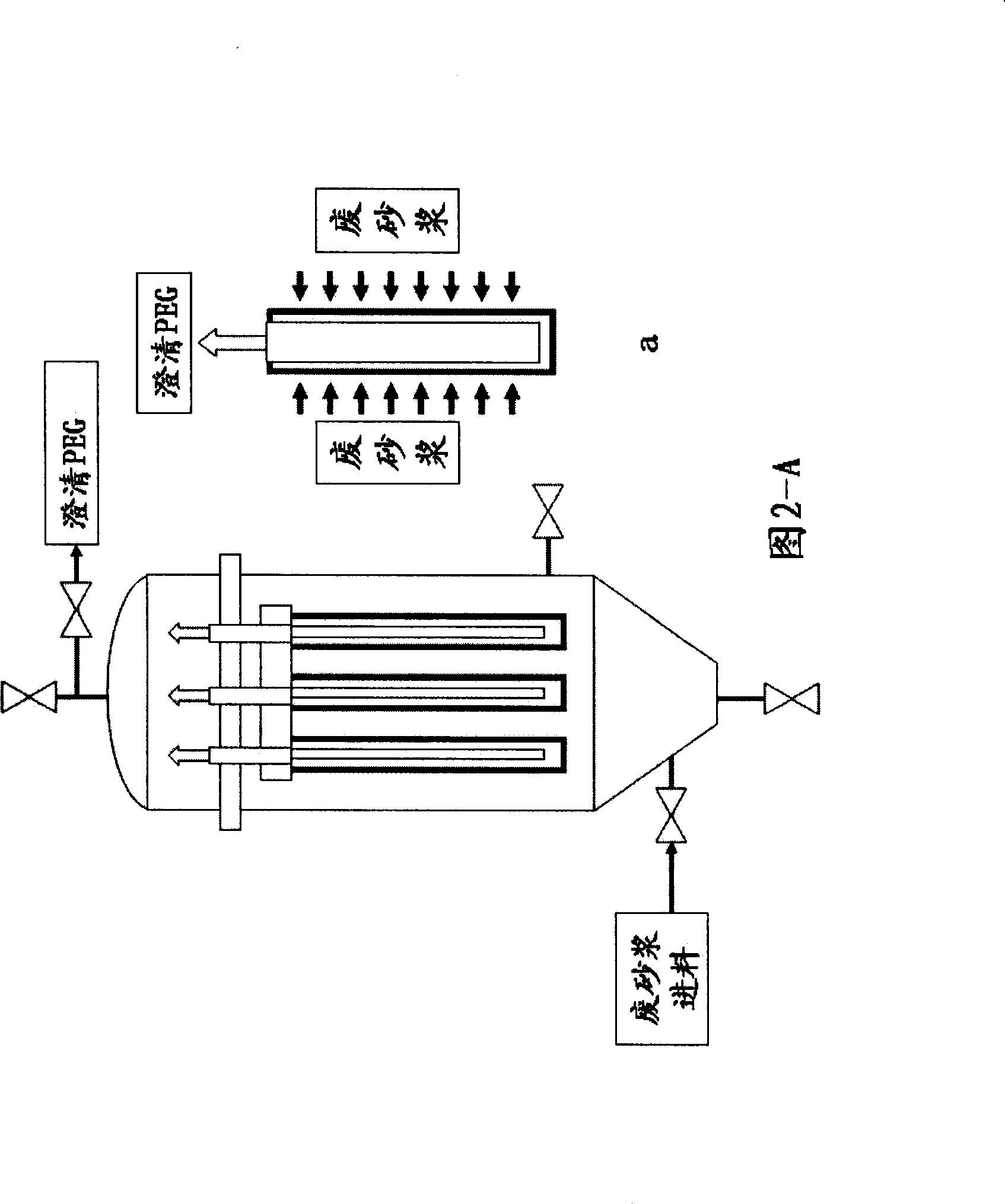

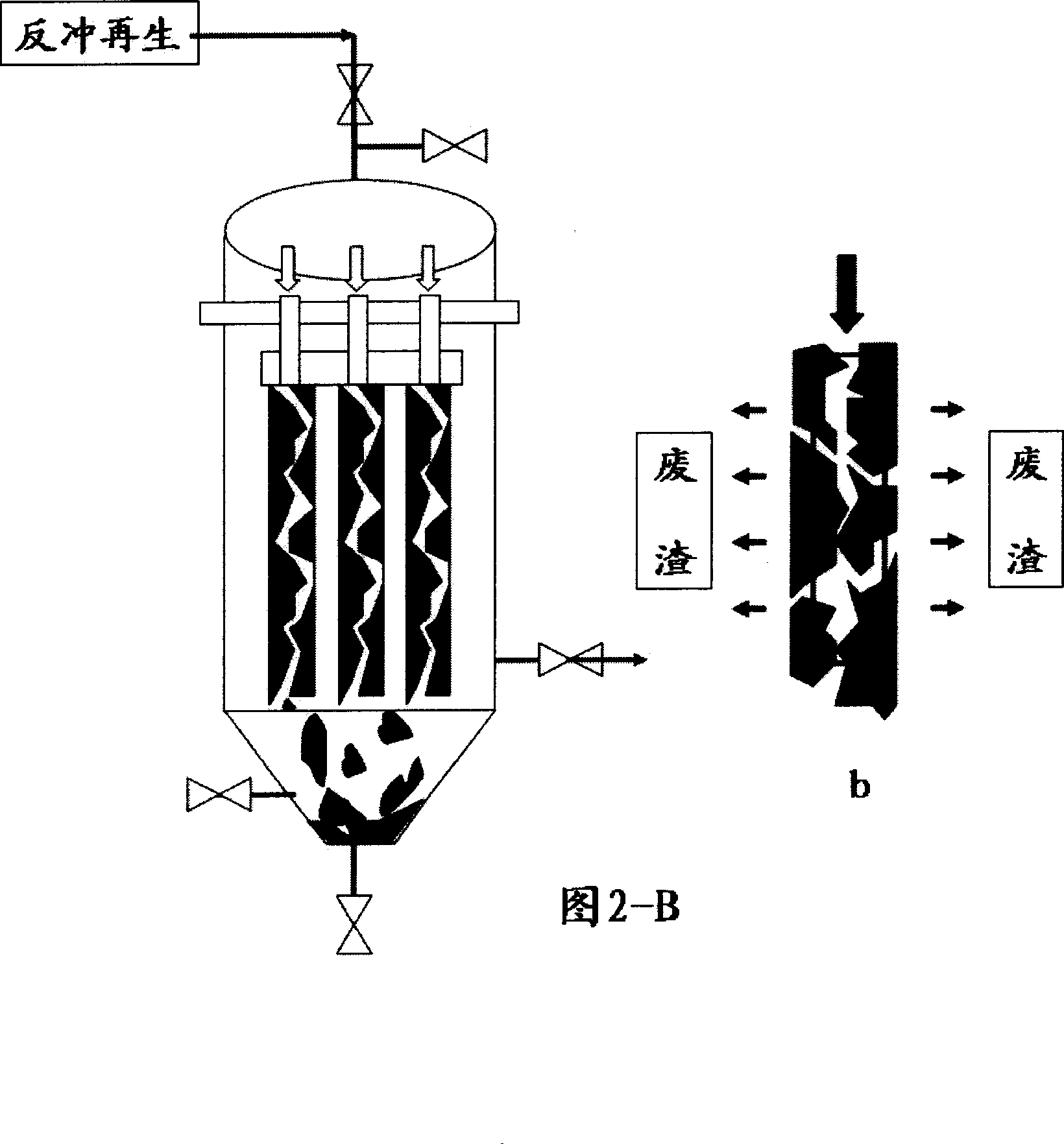

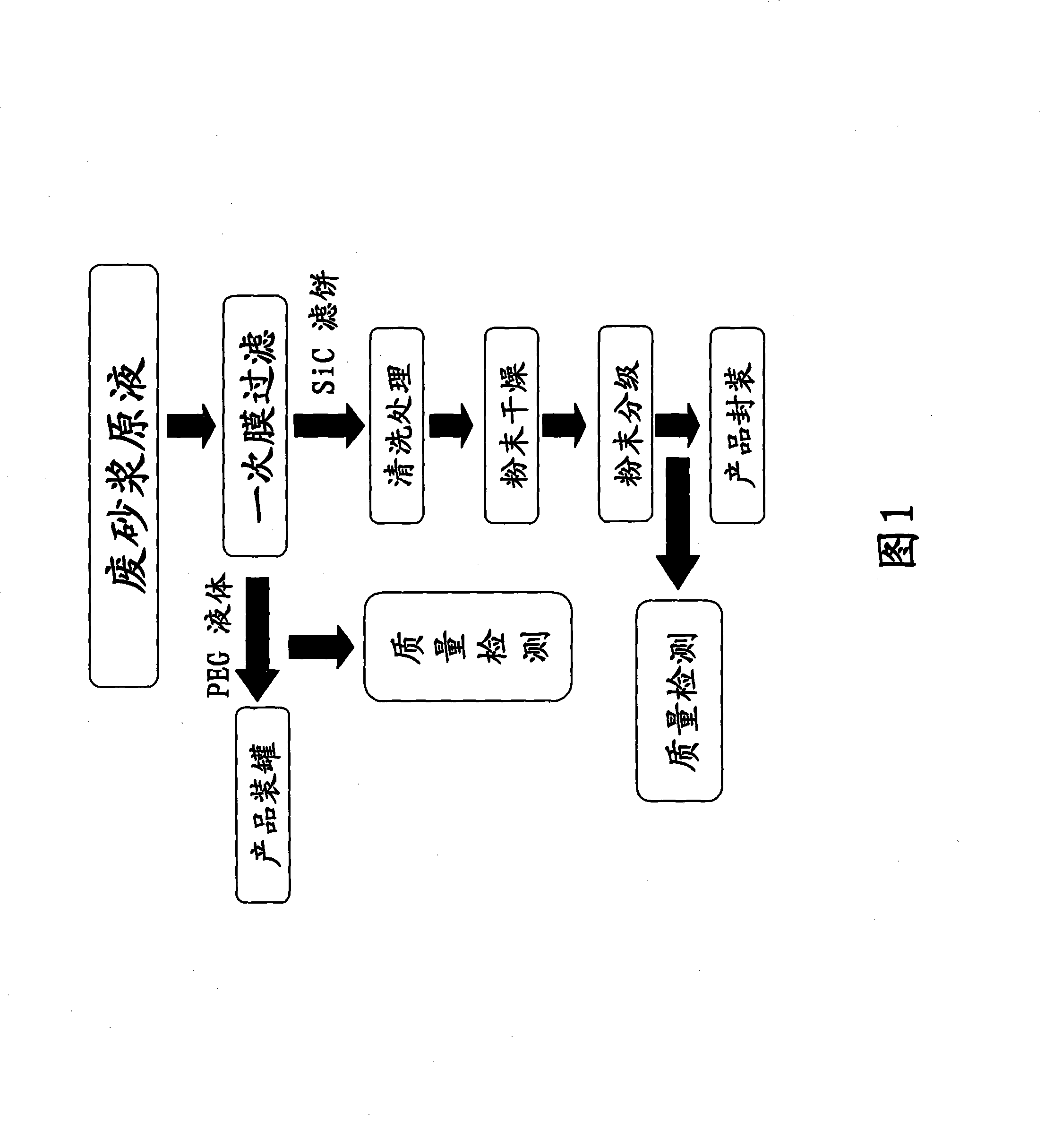

The present invention relates to a technique of recovering mortar used in the wire cutting of monocrystalline silicon or polycrystalline silicon. Silicon is an important material for solar batteries, semiconductors, liquid crystal displays, etc. A silicon rod is cut into silicon wafers by the wire cutting technique, and in the process, a wire-cutting machine needs to be added with cutting liquid mortar, which is mainly composed of liquid phase polyethylene glycol and solid phase silicon carbide powder. When the wire-cutting machine cuts the silicon rod, the solid particles in the mortar are changed into waste mortar as the silicon carbide grinds the silicon rod and a steel wire. If the waste mortar is discharged directly, environment is polluted, and the raw material is wasted. The present invention adopts the mortar-recovering technique to recover the waste mortar, so that the waste mortar can be reused and the discharging of the three wastes can be reduced, so while reducing production cost, the mortar-recovering technique can protect environment. The technique of recovering mortar used in the wire cutting includes the following flow: waste mortar dope, one-step membrane filtration and PEG liquid; waste mortar dope, one-step membrane filtration, cleaning, powder drying, powder classification and SiC powder.

Owner:正申科技(北京)有限公司

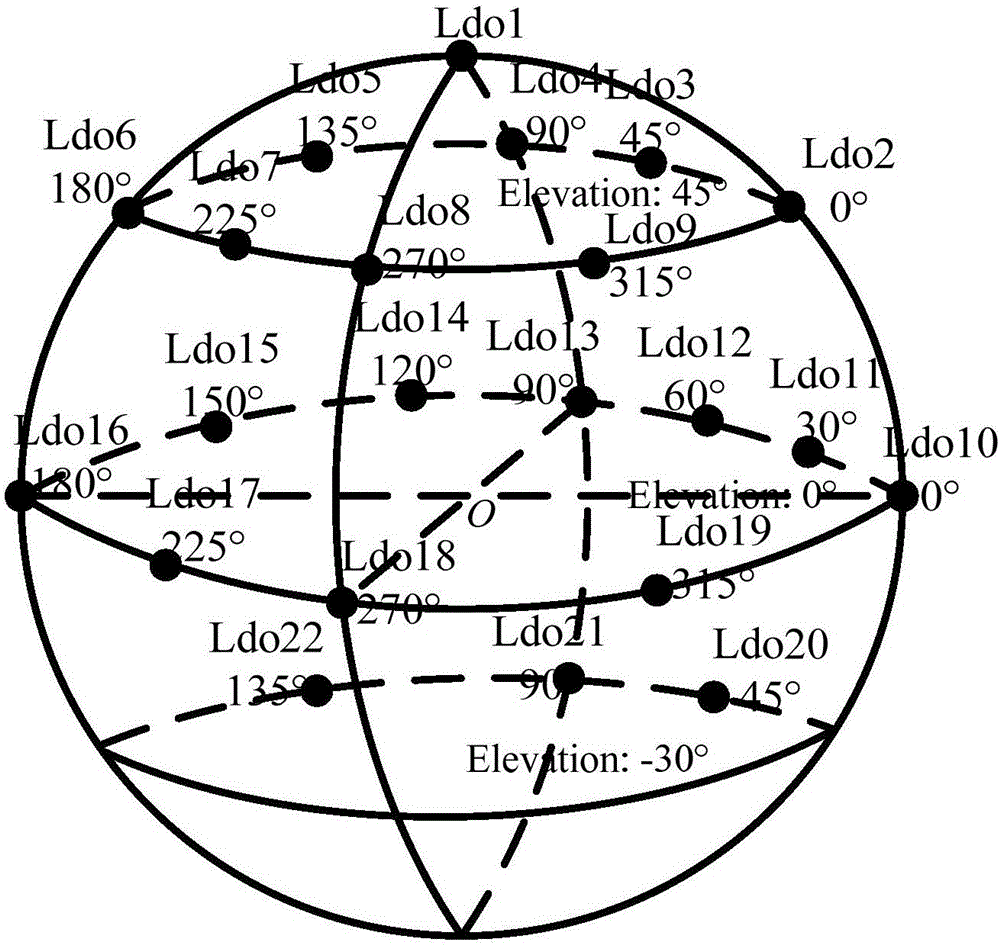

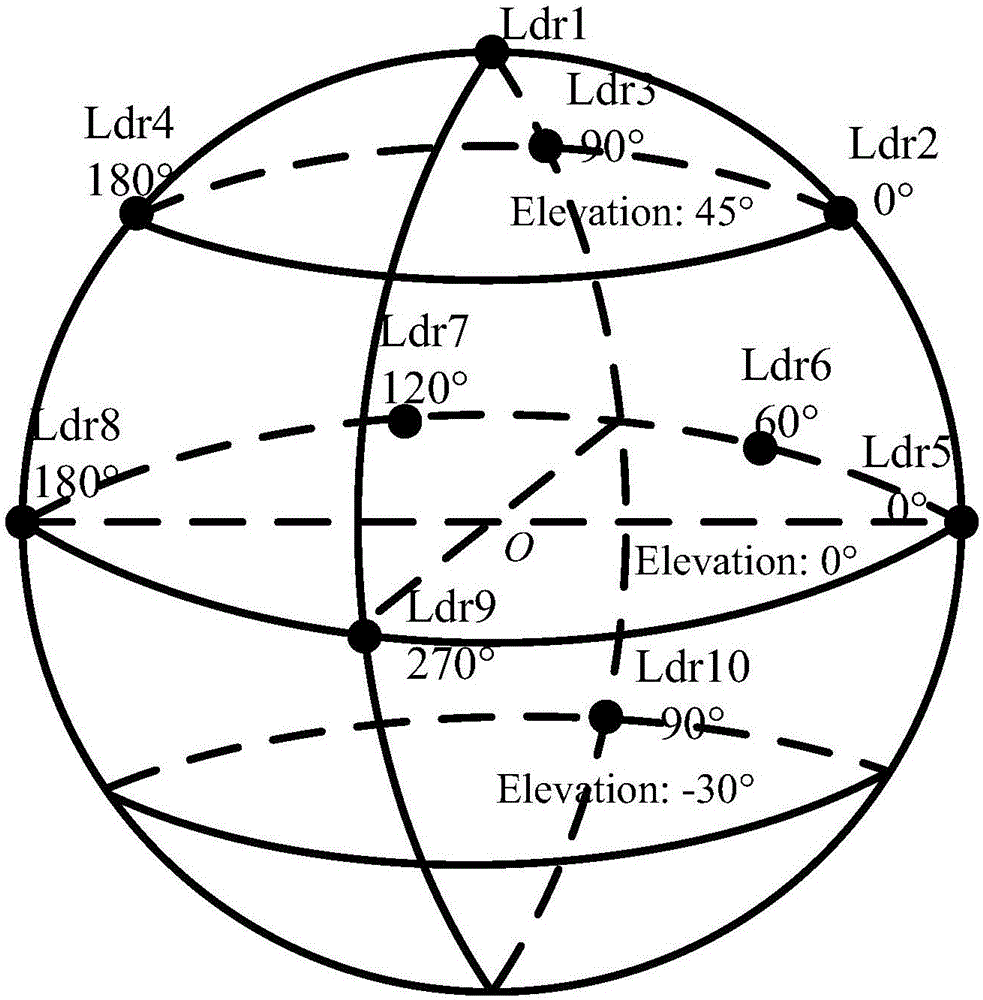

Multichannel system sound field reconstruction method and apparatus

ActiveCN106559730APhysical properties unchangedImprove universalityStereophonic systemsReconstruction methodVocal tract

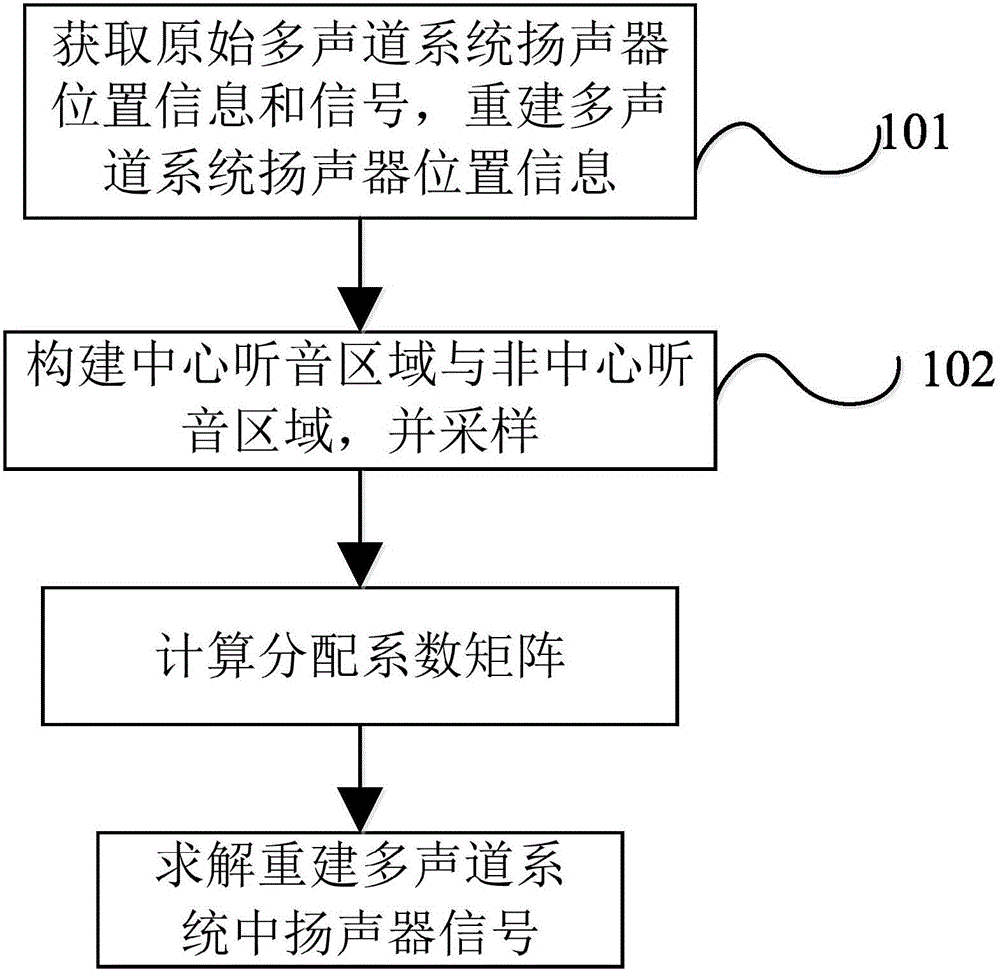

The invention provides a multichannel system sound field reconstruction method and apparatus. The method comprises steps of acquiring loudspeaker set position information in a primary multichannel system and signal information, reconstructing loudspeaker position information in the multichannel system, and listening area sampling point position information, building a central listening area and a non-central listening area, selecting sampling points in these areas, calculating distribution coefficient matrix distributed to all loudspeakers of the reconstructed multichannel system by each loudspeaker in the primary multichannel system, and calculating final distribution signals of all loudspeakers in the reconstructed multichannel system. High-quality 3D sound field can be only displayed in a central listening point or a central listening area by a traditional method, so practical demands of listening in a non-central point cannot be met for people; based on physical features of the sound field, the provided technical scheme enables a listener to acquire optimal listening feeling in any positions in reconstructed sound fields such as the central listening area or the non-central listening area.

Owner:WUHAN UNIV

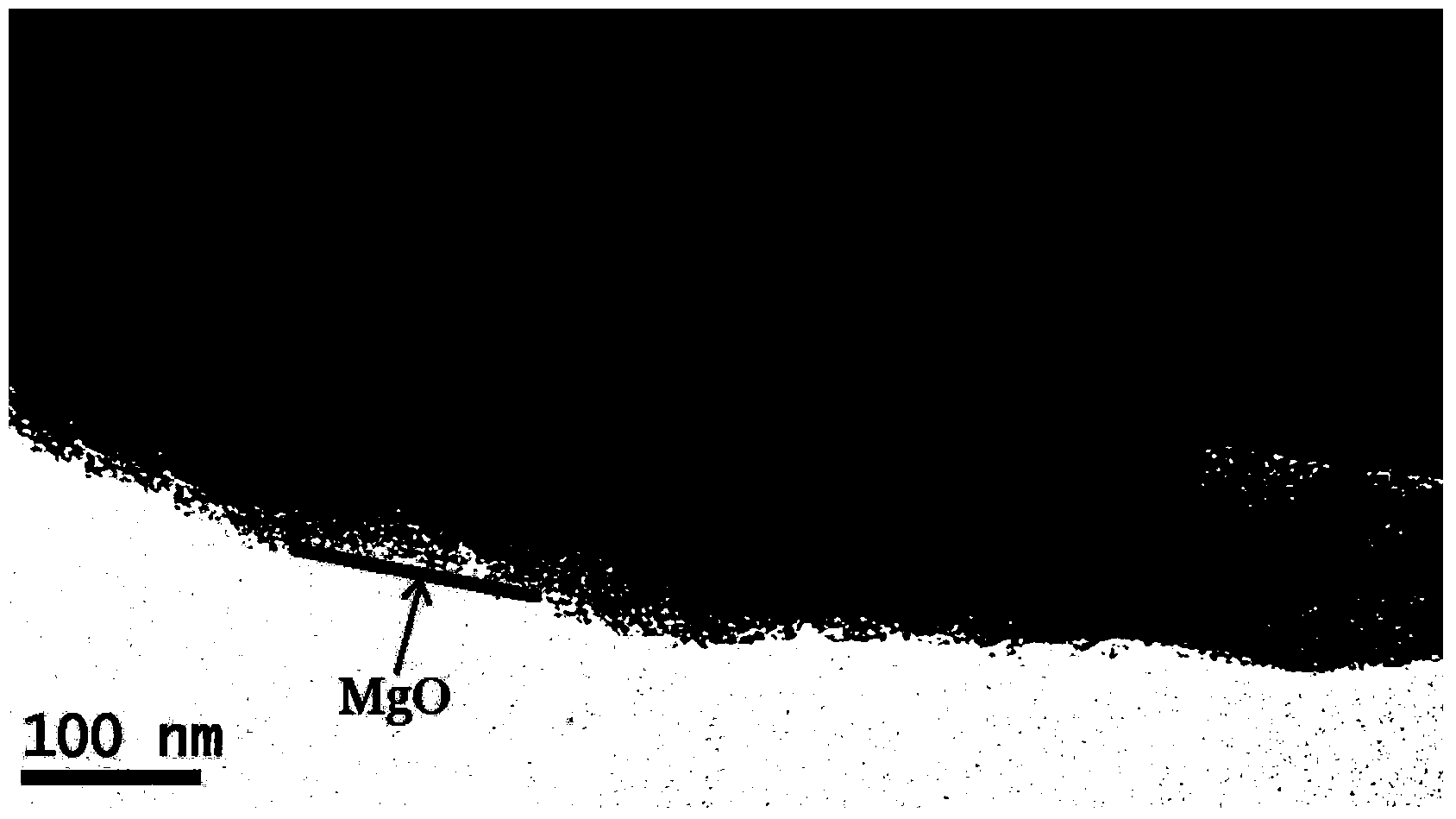

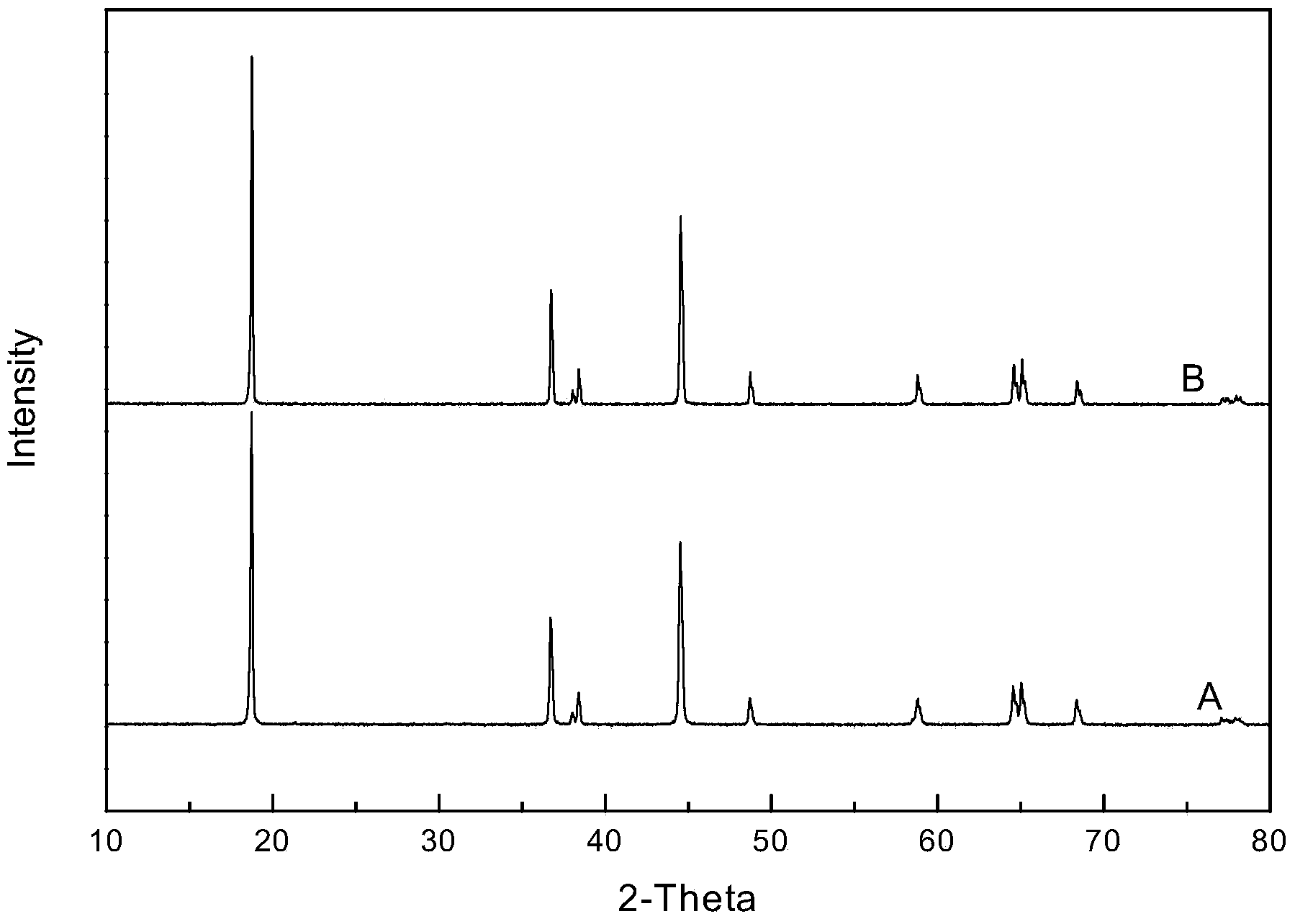

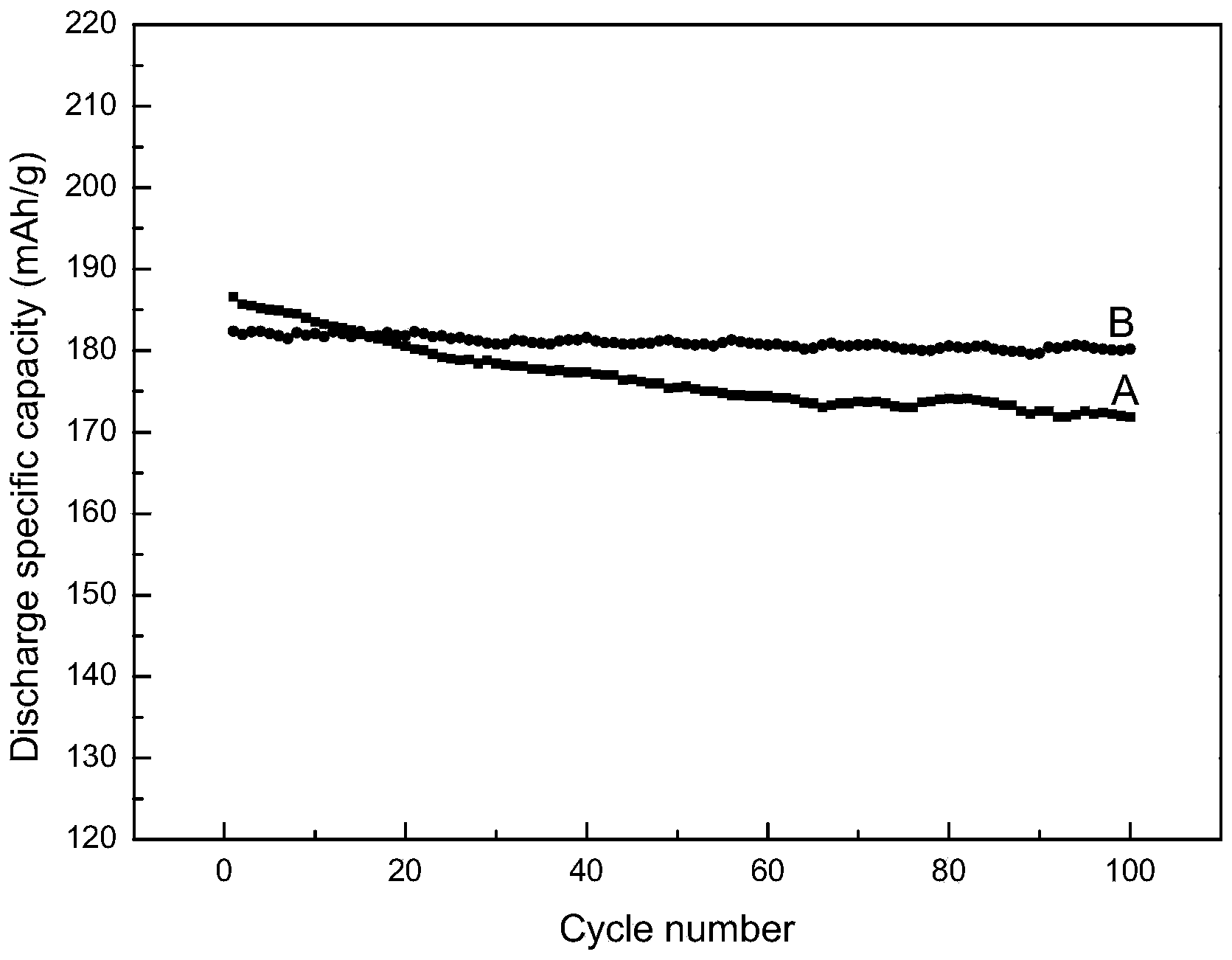

Method for preparing lithium ion battery anode material with core-shell structure

InactiveCN104009209AImprove performancePhysical properties unchangedCell electrodesSecondary cellsOrganic solventThermal treatment

The invention provides a method for preparing a lithium ion battery anode material with a core-shell structure. The method comprises the following steps: dispersing a core shell, namely an anode material, in an aqueous solution of a shell material precursor, adding an organic solvent into the solution, crystallizing and separating the shell material precursor on the surface of the core material, filtering, performing heat treatment, and thus obtaining the lithium ion battery anode material with the core-shell structure. The dissolubility difference of the shell material precursor in an aqueous phase and an organic phase serves as driving force, and the impurity core shell serves as a seed crystal, so that the shell material is uniformly deposited on the surface of the core material, and the lithium ion battery anode material with the core-shell structure is formed. The method has the advantages of uniform coating, simple process, short period, low cost and the like and is suitable for industrial production.

Owner:HUNAN INSTITUTE OF ENGINEERING

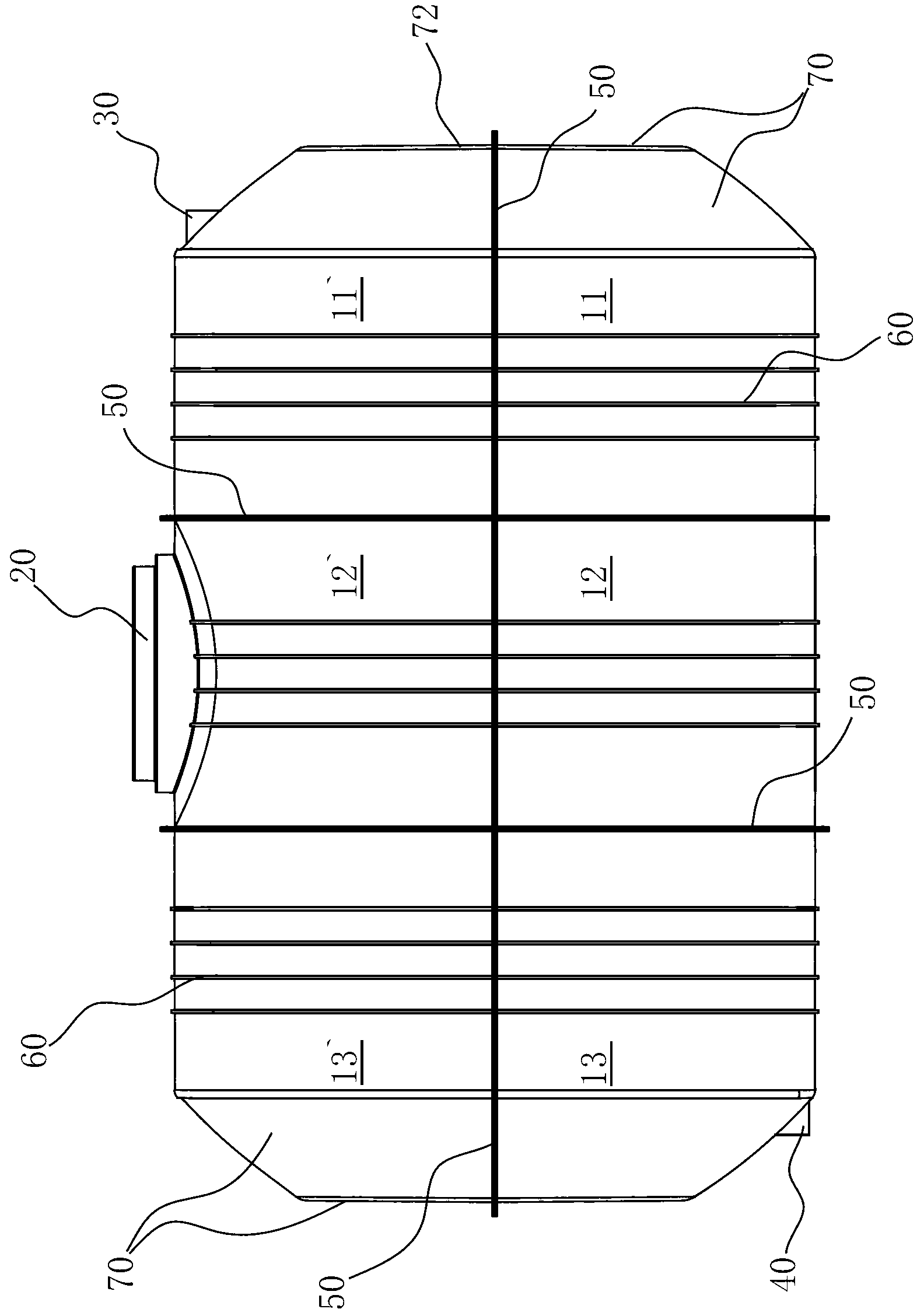

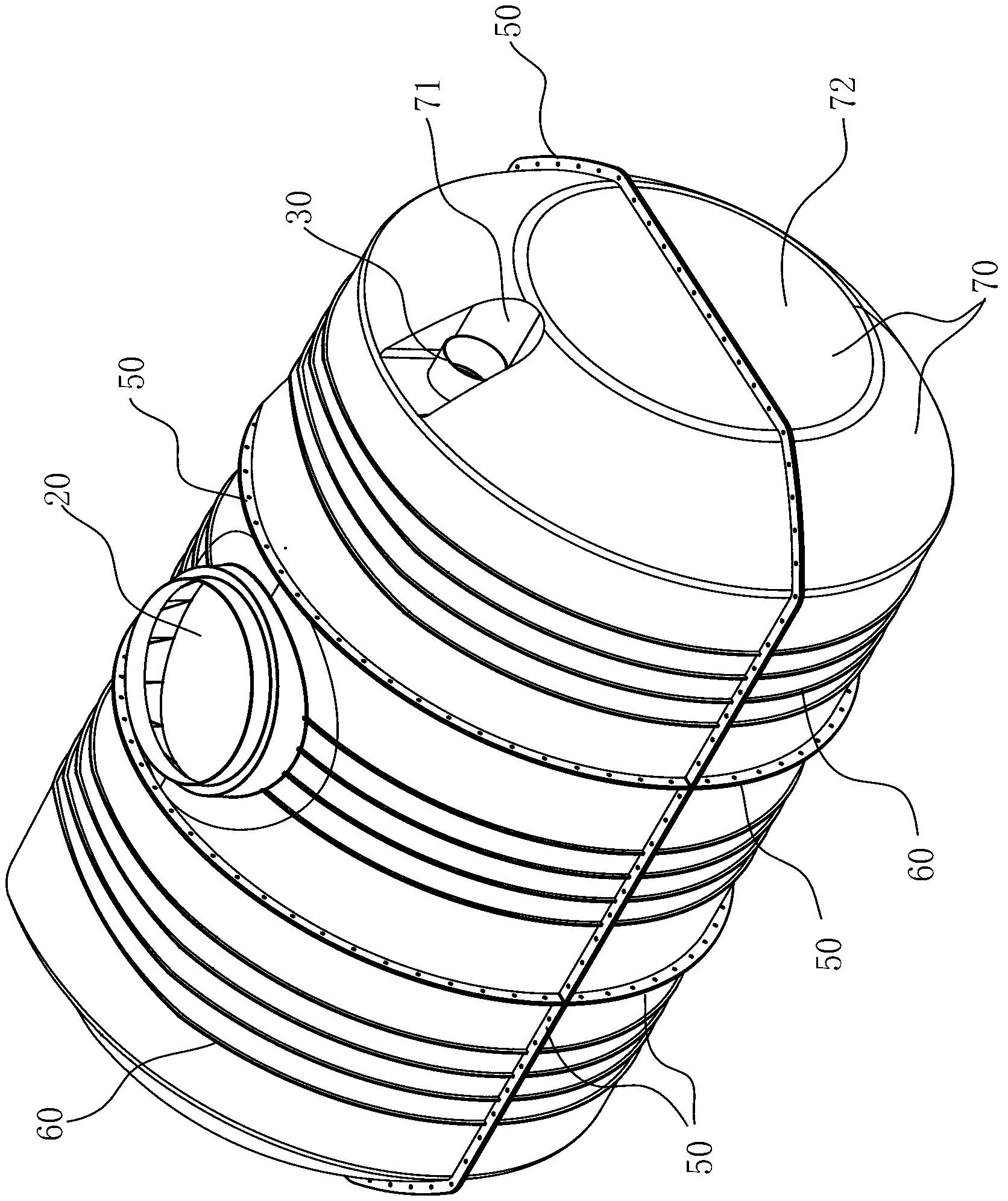

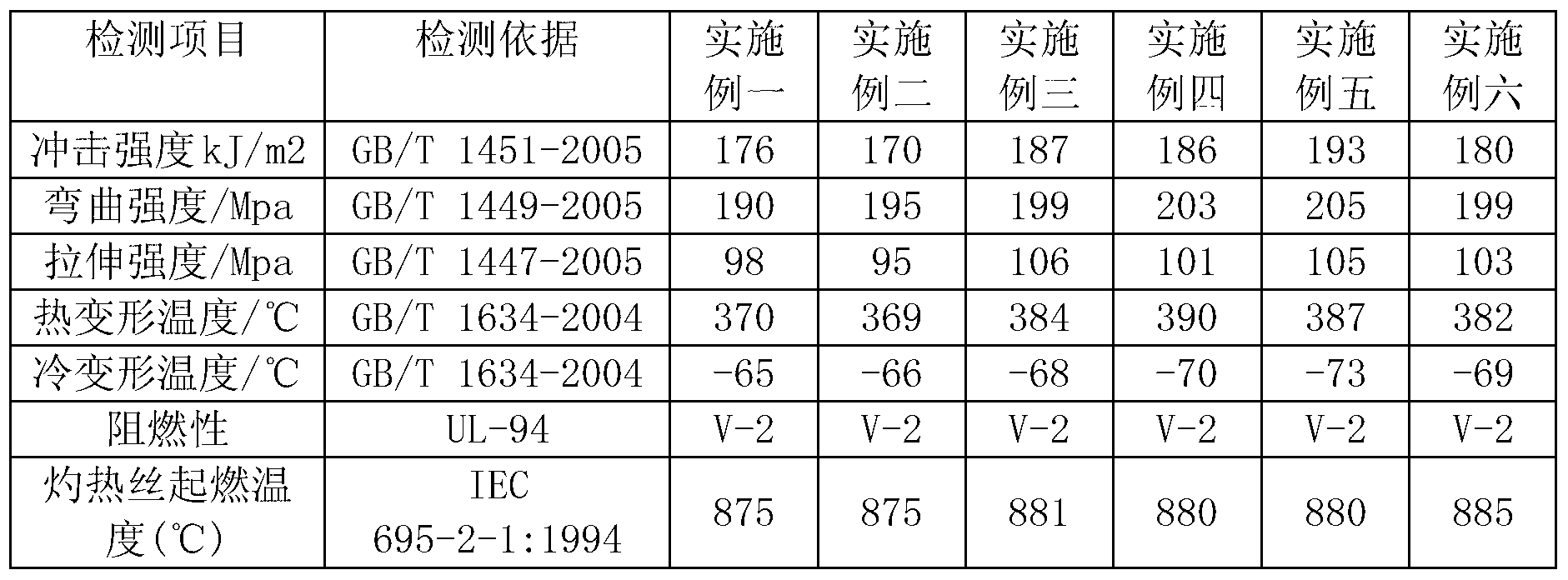

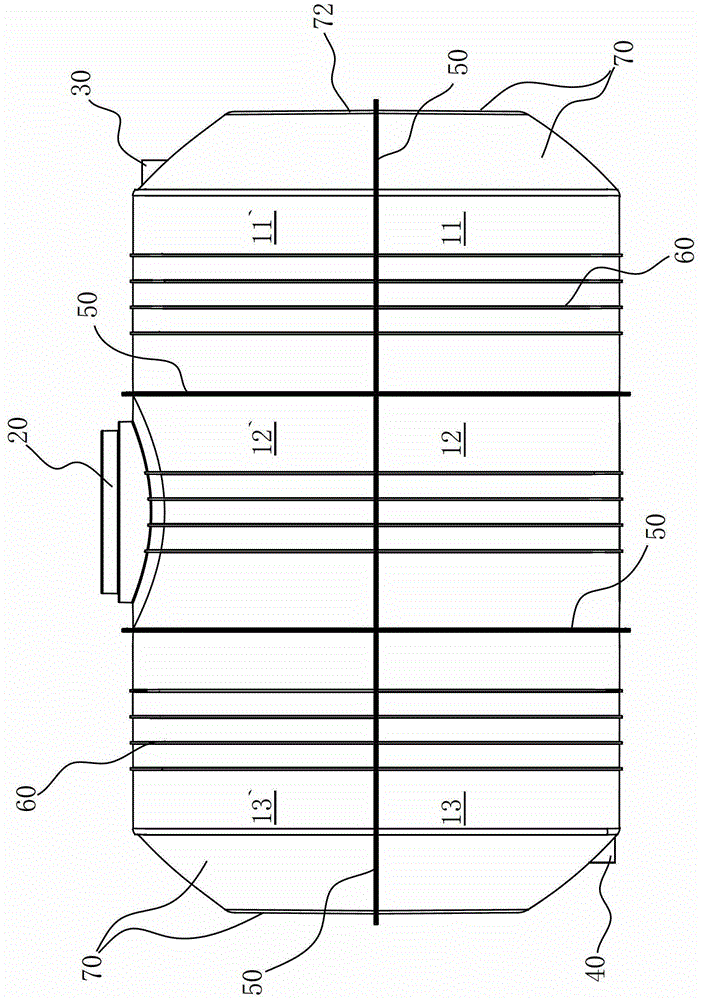

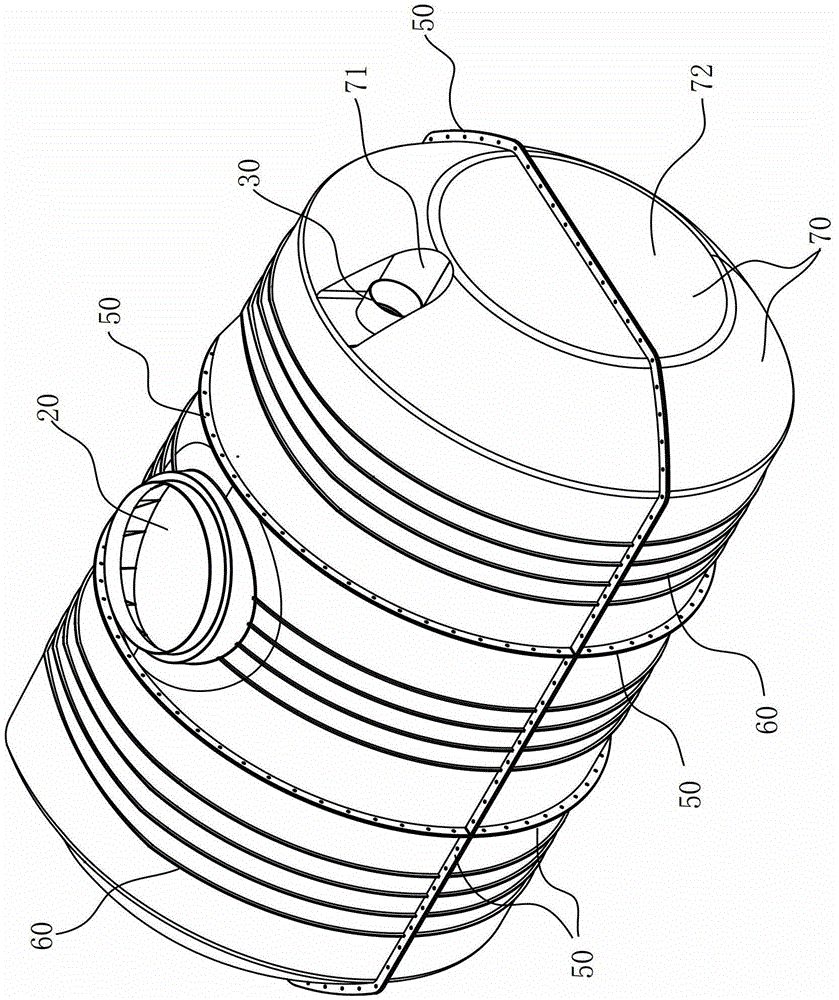

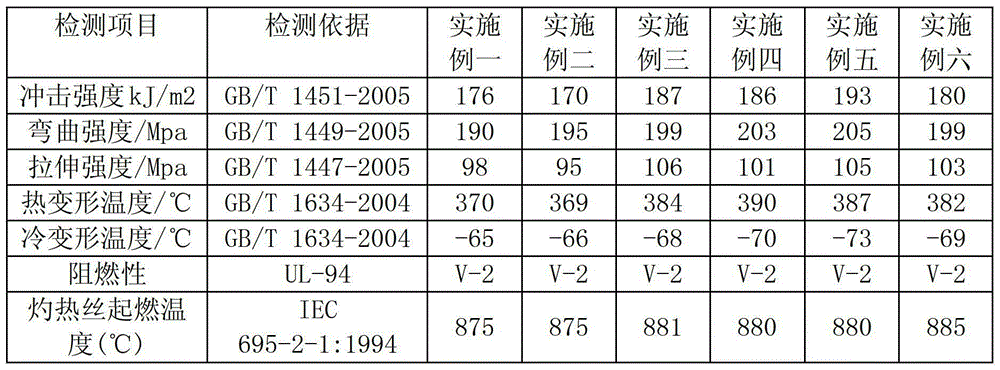

Anti-corrosion, oil-resistant and flame-retardant plastic oil tank

ActiveCN103214806AImprove impact resistancePhysical properties unchangedLarge containersPolyesterFiber

The invention relates to a reinforced plastic and an oil tank, and aims to provide an anti-corrosion, oil-resistant and flame-retardant oil tank which has reliable physical property and is made of reinforced plastic. The technical point is as below: the bulk molding compound comprises the following components in parts by weight: 34-47 parts of unsaturated polyester, 0.3-0.4 part of cobalt naphthenate, 0.3-0.35 part of methyl ethyl ketone peroxide, 45-47 parts of calcium carbonate, 0.1-0.3 part of antistatic agent, 0.1-0.15 parts of antioxygen, 0.1-0.15 part of pentabromo phenol, 0.1-0.3 part of microencapsulation tri-(2,3-dibromopropyl) isocyanuric acid ester, 0.1-0.2 part of melamine, 0.08-0.1 part of nano silica, a proper amount of silane coupling agent and 28-31 parts of reinforced fiber. The plastic can endure the temperature of 360 DEG C and 64 DEG C below zero, has constant physical property and has the advantages of high toughness and strength. The impact resistance of the unsaturated polyester fiber-reinforced bulk molding compounds is effectively improved. The reinforced plastic is anti-corrosion, anti-aging, oil resistant and flame retardant, and is suitable for manufacturing oil tanks.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

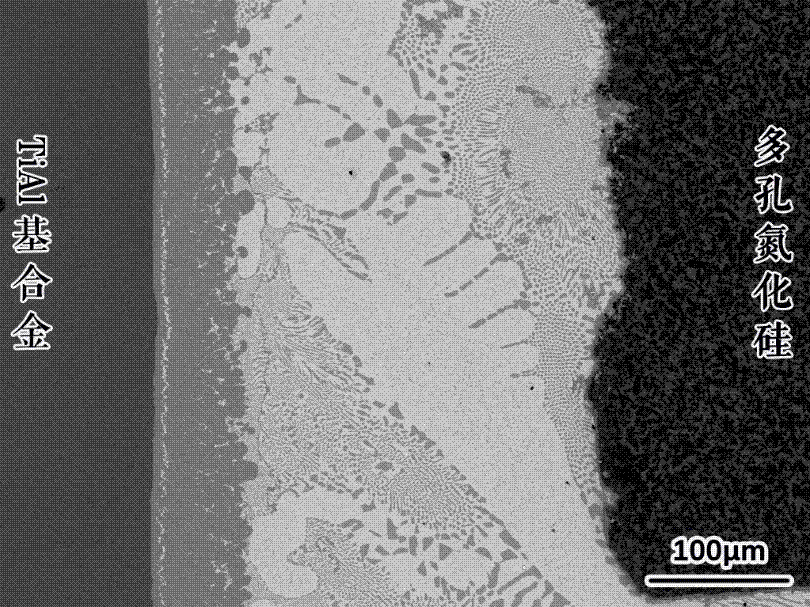

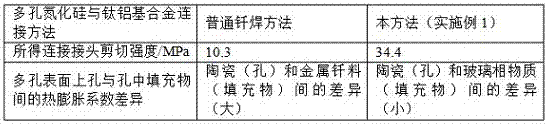

Brazing method for porous ceramic and metal

ActiveCN106944695AGuaranteed performanceEasy to fillSoldering apparatusSilicon oxideMechanical property

The invention discloses a brazing method for porous ceramic and metal. Compacting paint which comprises but not limited to yttrium oxide powder, silicon oxide powder, aluminum oxide powder and nano alpha-Si3N4 particles is uniformly sprayed to a to-be-welded surface of the porous ceramic and is heated to 1400 DEG C-1600 DEG C under the protective atmosphere, and heat preservation is conducted for 30 min-90 min, so that a compacting coating is formed on the sprayed surface; and then vacuum brazing is conducted with corresponding brazing filler metal, and thus better connection between the metal and the porous ceramic can be achieved. The invention aims at providing the vacuum brazing method which can achieve more effective high-strength connection between the porous ceramic and the metal, an obtained brazed joint of the porous ceramic and the metal is good in mechanical property, and the practical application requirement can be met.

Owner:HARBIN INST OF TECH AT WEIHAI

Surface cross-linking treatment method for thermoplastic starch products

The invention relates to a surface cross-linking treatment method for thermoplastic starch products and belongs to the technical field of a solid material surface modifying method. The method comprises the steps of: leading the cross-linking agent into the surface layer of the thermoplastic starch products, performing the cross-linking reaction between the cross-linking agent with the hydroxyl on starch molecule under a condition of heating and forming a cross-linking network between the starch molecule chains on the surface layer of the products. According to the method, the solid cross-linking reaction is utilized to only perform proper cross-linking treatment on hydrophilic hydroxyl on the surface layer of the thermoplastic starch products. Without changing the condition of the main component of the thermoplastic starch products and the treatment property, the sensibility of the products to the environmental humidity is decreased and the water-tolerant property is promoted. After the surface is cross-linked, the sensibility of the products to the environmental humidity is obviously decreased. Under an environment with humidity of 95%, the balanced water content is at least 64.2% of the water content before being modified, namely decreased by 35.8% at most. The anti-solvent dissolubility is also obviously promoted. The solvent which is soluble in dimethyl sulfoxide becomes insoluble.

Owner:JILIN UNIV

Polymer for PP-R high polymer

The invention discloses a master batch of plastic products, in particular to a polymer for PP-R high polymer. The polymer for PP-R high polymer comprises the following raw materials according to the parts by weight: 55-75 of calcium carbonate, 1-3 of lubricant, 0.3-0.8 of polyethylene wax, 0.3-0.8 of polypropylene wax, 5-15 of polyethylene, 3-8 of polypropylene, 1-5 of coupling agent, 0.5-2.5 of zinc stearate, 1-3 of stearic acid and 5-15 of talcum powder. The polymer for PP-R high polymer of the invention fills the gap of the field; the invention has large filling volume, and the original physical properties of the polymer can be kept after being filled; the invention is characterized by high strength and toughness, good sizing and the like and the cost of the manufacturers of PP-R products can be largely decreased. Under the current situation of energy scarcity, a great amount of energy can be saved.

Owner:沈阳大圆天地塑料制品有限公司

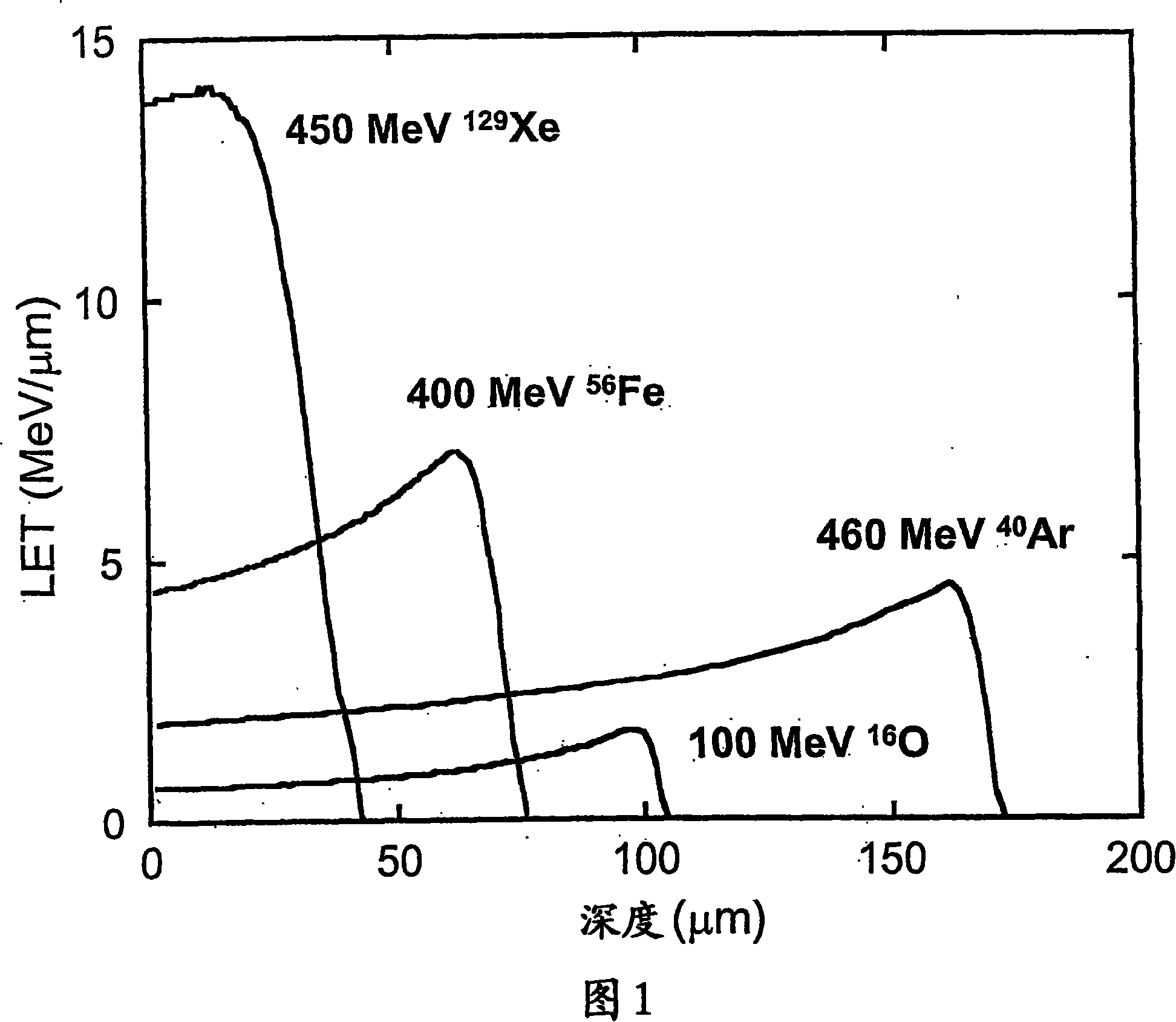

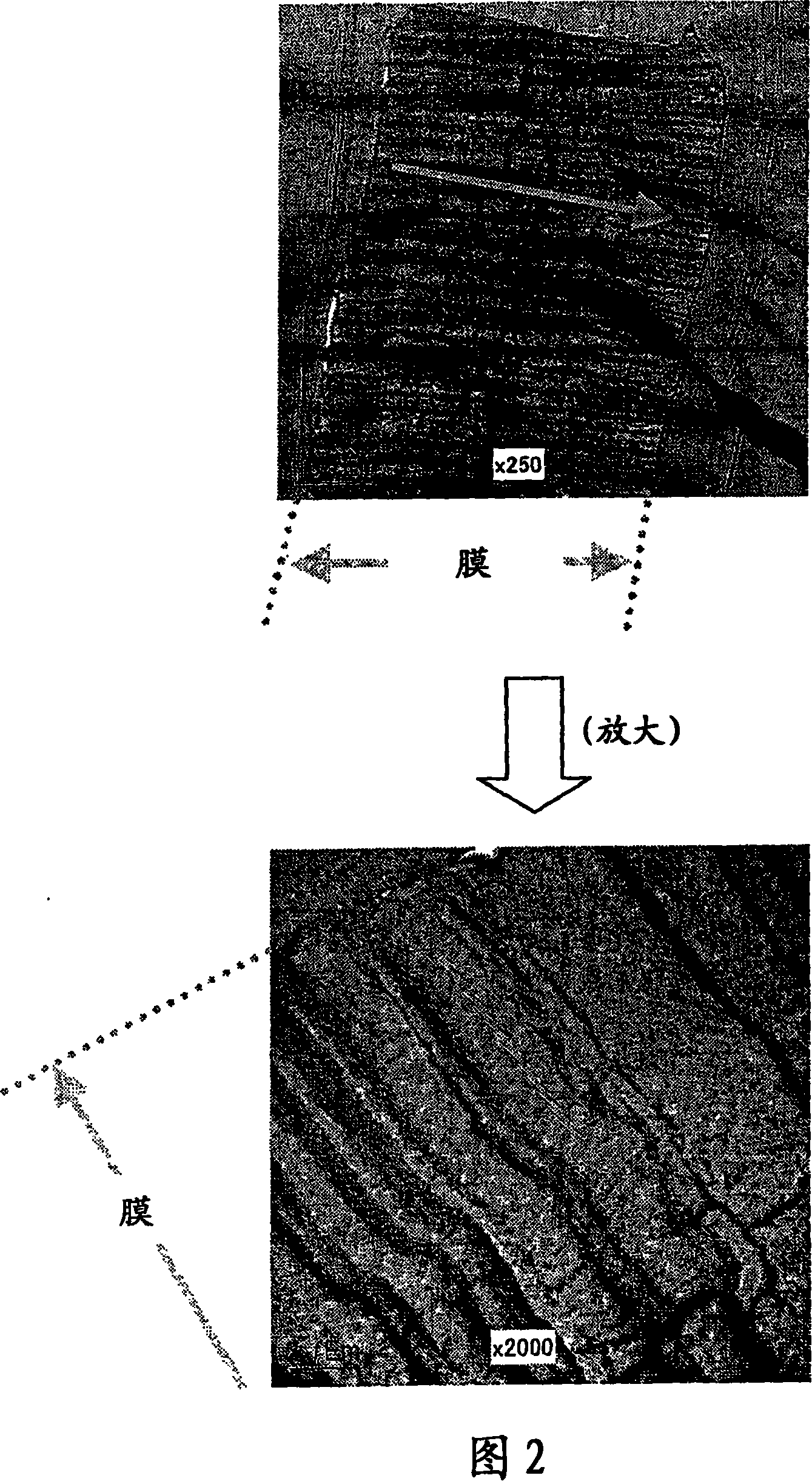

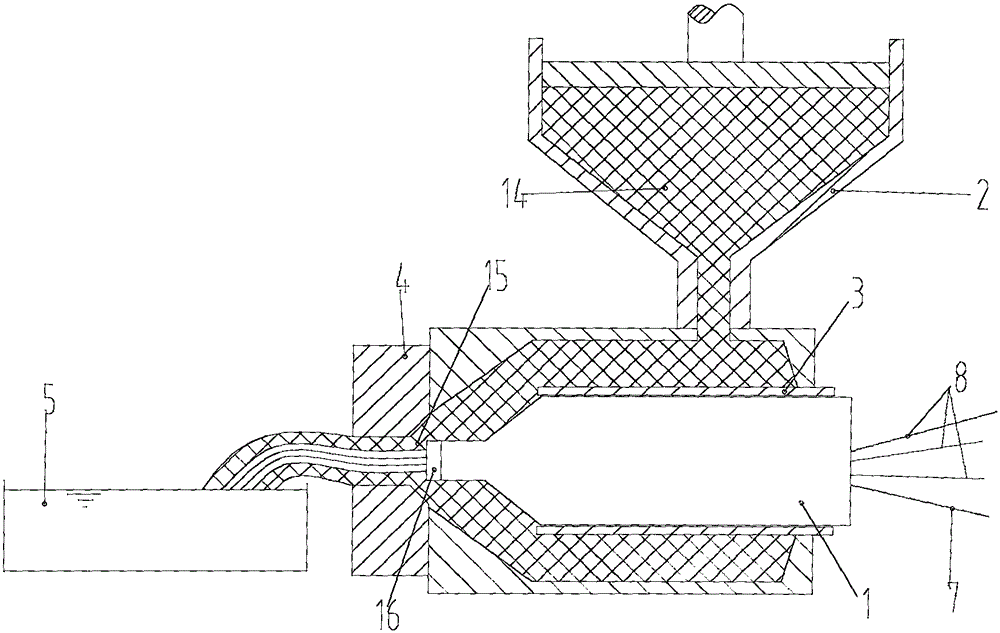

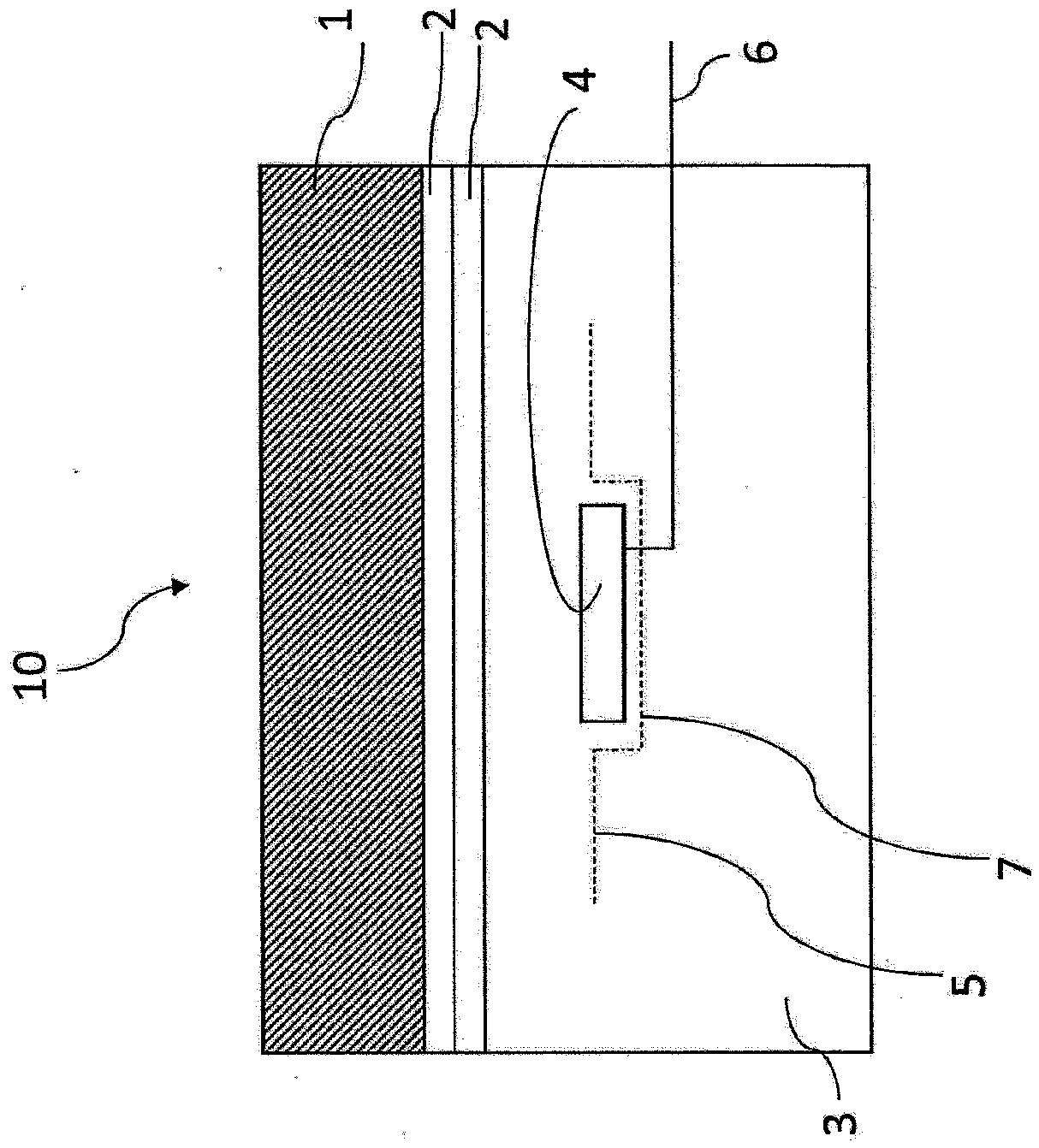

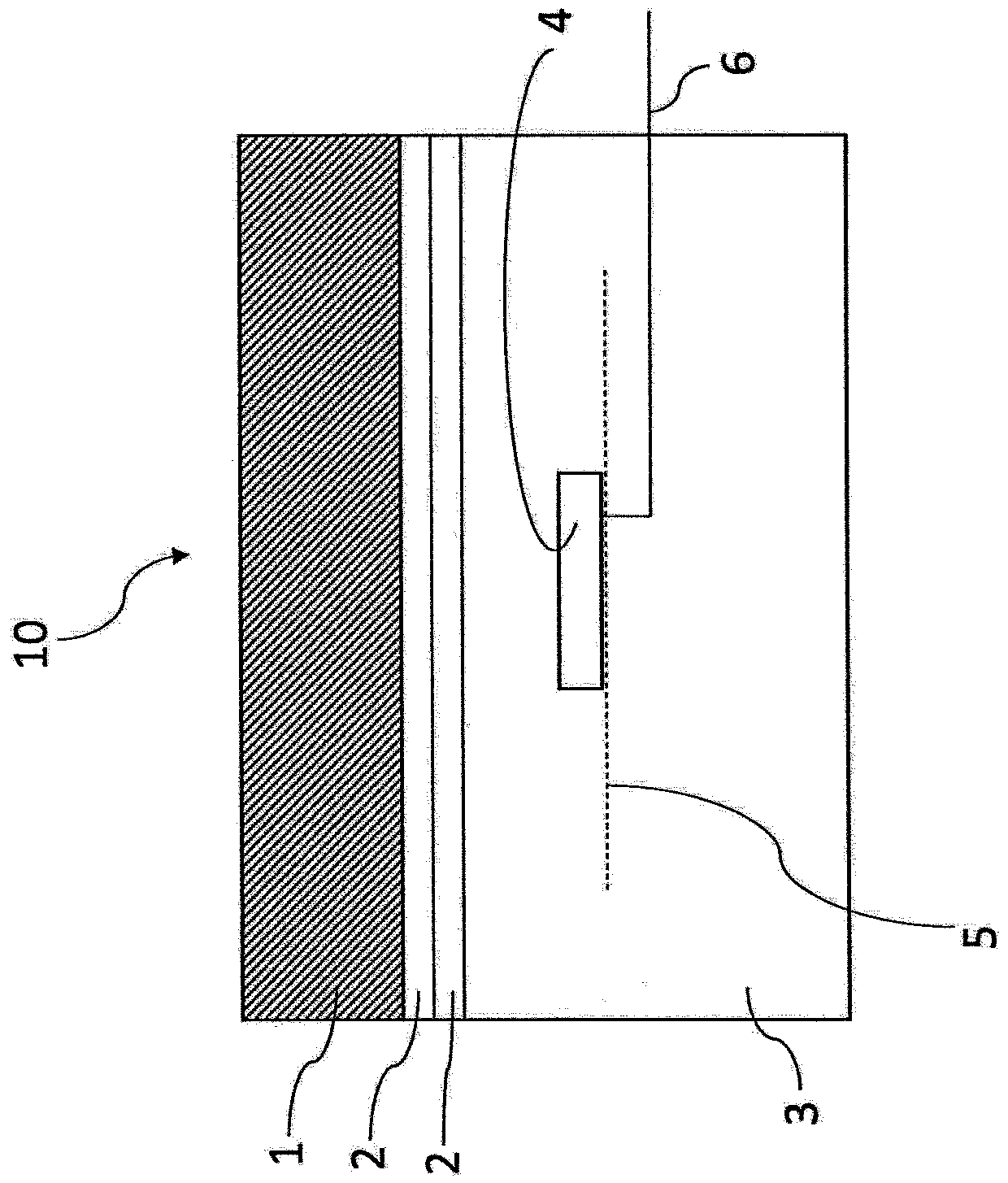

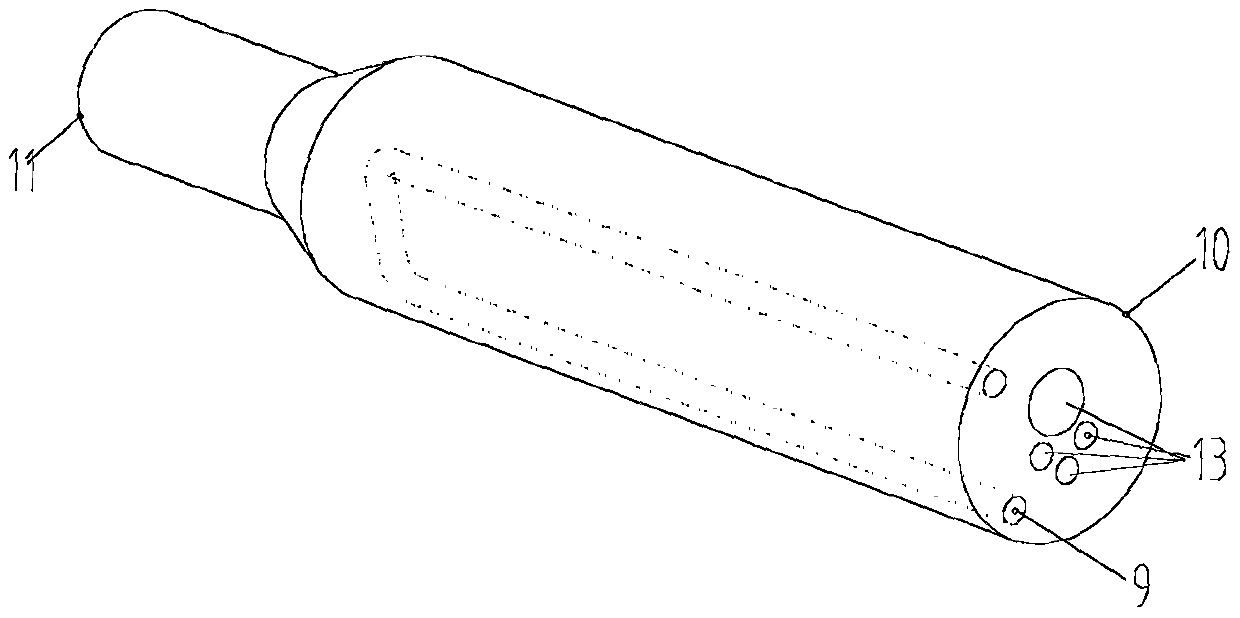

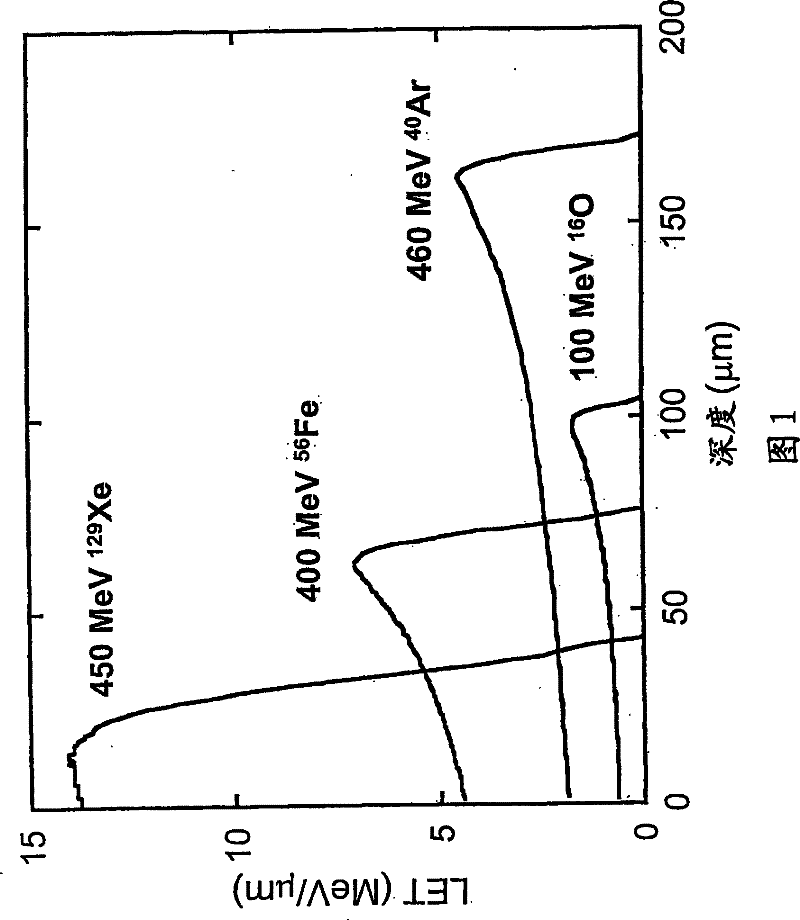

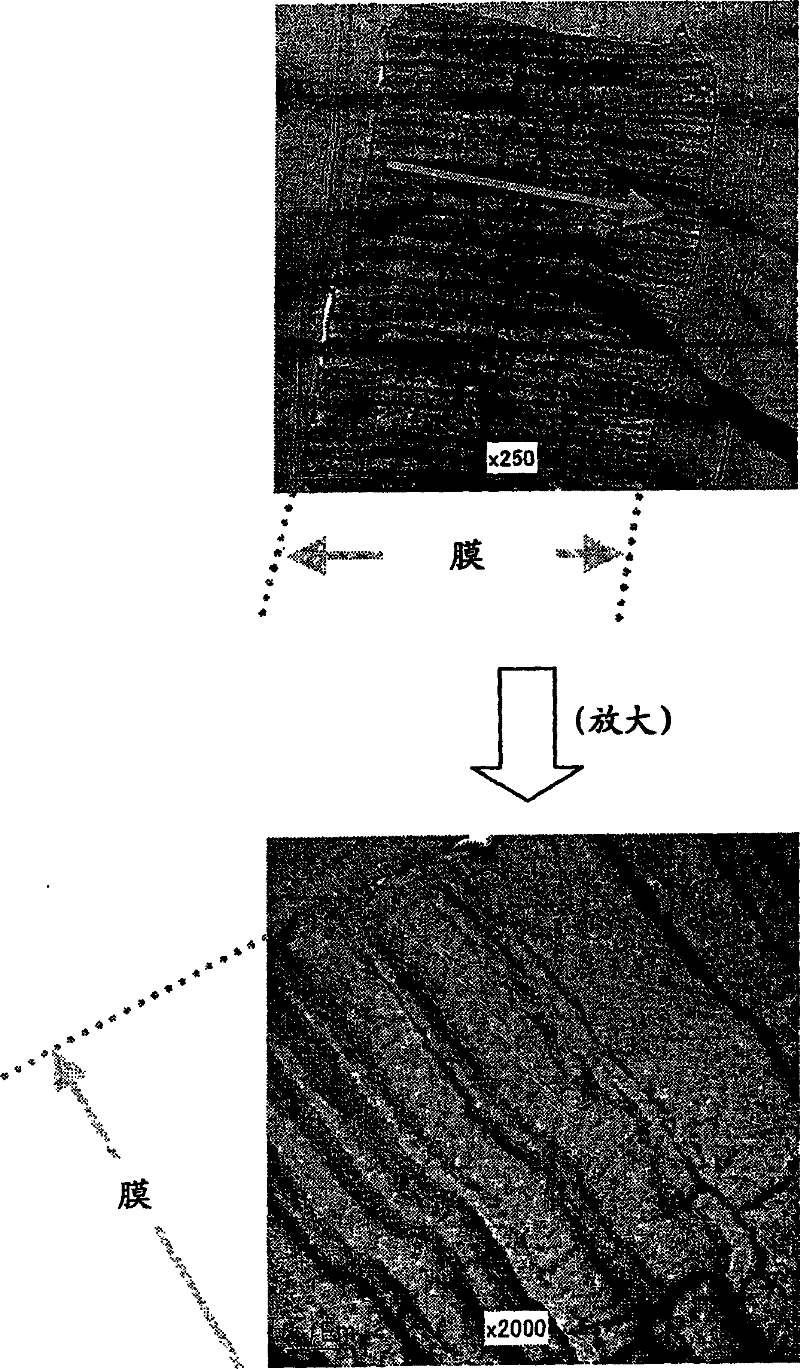

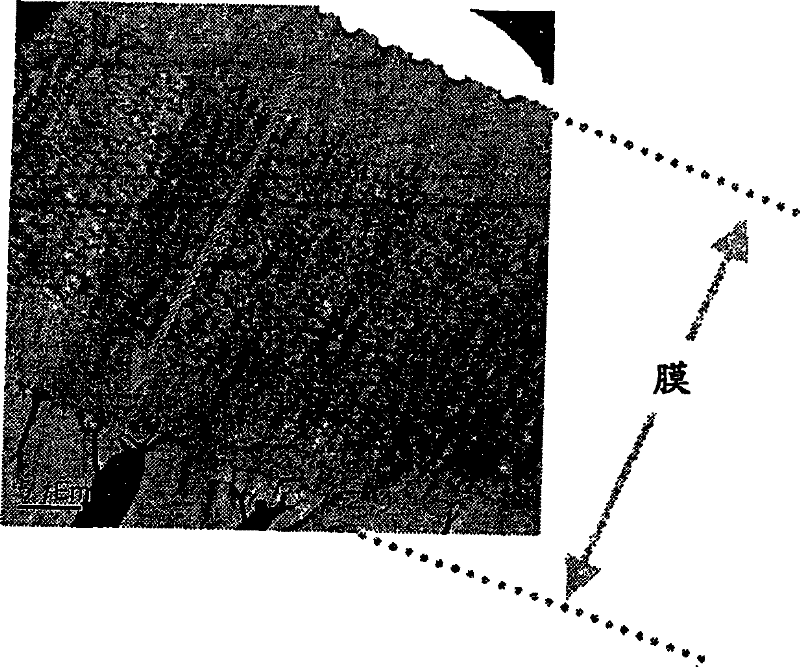

Functional membrane and process for production thereof, and electrolyte membrane for fuel cell and process for production thereof

InactiveCN101128523APosition can be controlledControl positionElectrolyte holding meansNon-metal conductorsFuel cellsHigh energy

A process for producing a functional membrane comprising an ion irradiation step in which a polymeric film base is irradiated with high-energy heavy ions at a density of 104 to 1014 particles / cm2 to generate active species in the film base; and, subsequent to the ion irradiation step, a graft polymerization step in which at least one monomer selected from the members of group A which are monomers each having a functional group and 1 to 80 mol% (based on the total amount of the monomer(s) of group A) of a monomer selected from the members of group B which are crosslinking agents for the monomers of group A are added to the film base and graft polymerization of the film base and the monomers are then performed; and a functional membrane produced by the process.By employing this process, it becomes possible to produce a functional membrane which combines high functionality with gas-barrier property inherent in a polymeric film base. In particular, a polymeric electrolyte membrane having high proton conductivity and good gas barrier property can be produced, which is highly suitable as a polymeric electrolyte membrane for a fuel cell.

Owner:TOYOTA JIDOSHA KK

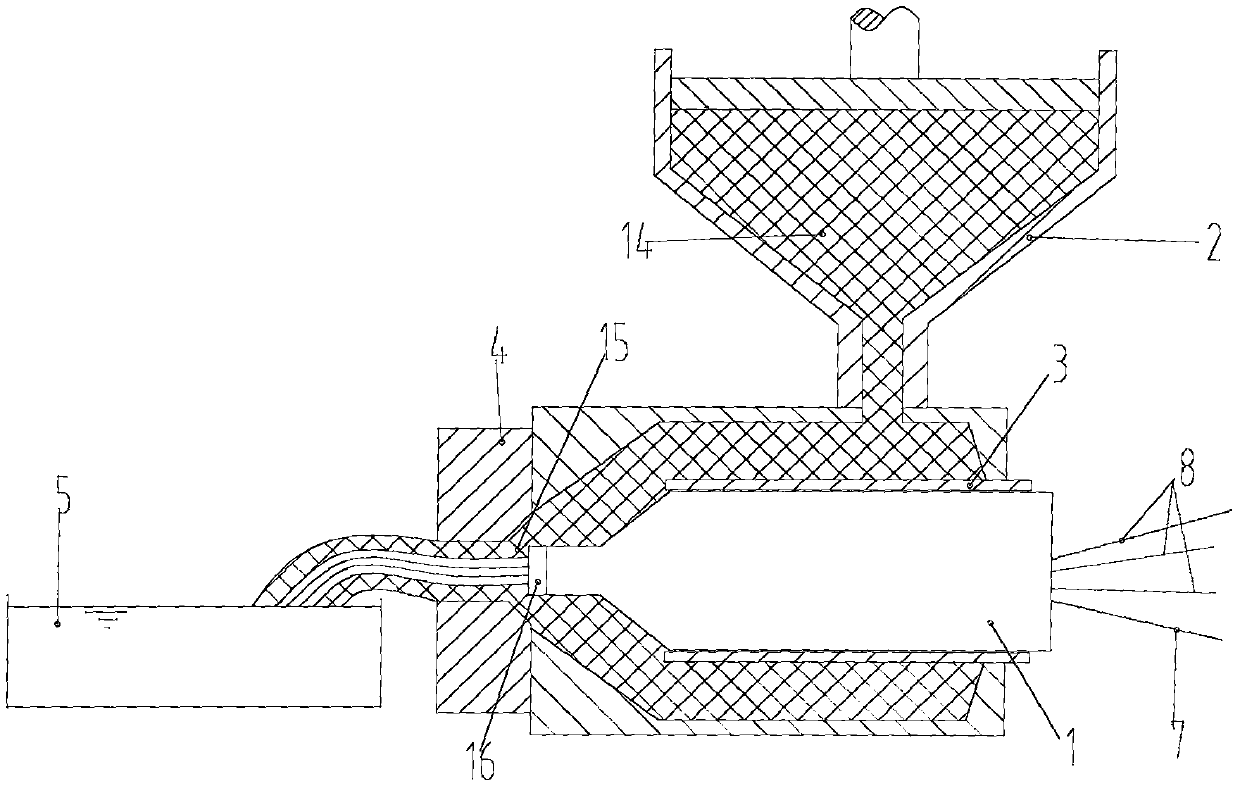

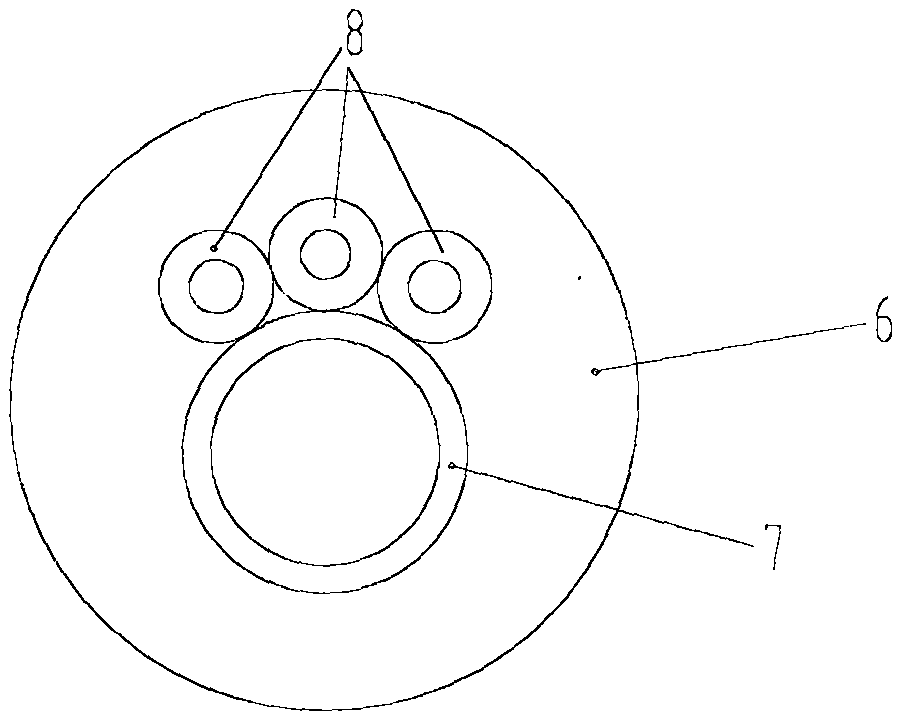

Sterilizing device

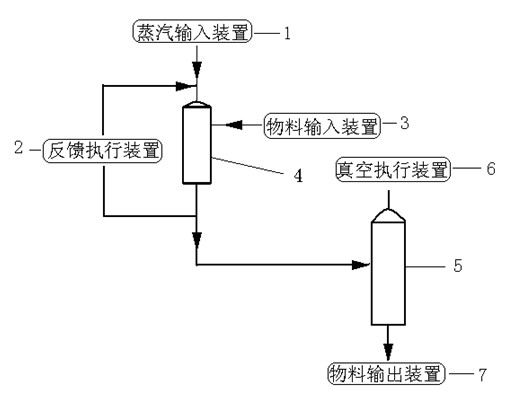

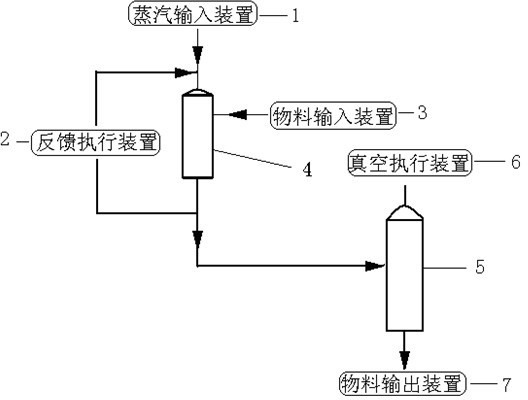

InactiveCN102133411ANutrition is not affectedPhysical properties unchangedHeatOutput deviceEngineering

The invention discloses a sterilizing device, which comprises a first container, wherein a steam input device is connected to the top of the first container; a material input device is connected to the upper part of the lateral surface of the first container; a feedback execution device is connected with the steam input device and the bottom of the first container; the lateral surface of the second container is communicated with the bottom of the first container by a pipeline; a vacuum execution device is connected to the top of the second container; and a material output device is connected to the bottom of the second container. By the sterilizing device, materials can be mixed with steam instantly, fully and uniformly to be sterilized under the condition of not influencing the nutrition of the materials, and redundant moisture can be removed while the sterilized materials can be cooled instantly, so the physical property of the materials remains unchanged, and the materials can be sterilized effectively at high speed.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

Composite pipe and forming process thereof

InactiveCN105042208AQuality improvementTightly boundFlexible pipesRigid pipesMolten stateManufacturing technology

The invention relates to a pipeline and a manufacturing technology thereof, in particular to a multifunctional composite pipe capable of delivering different media simultaneously and a manufacturing process used for manufacturing the composite pipe. The composite pipe comprises wires, a pipe body and a wrapping layer. The wires are parallel to the pipe body. The outer portions of the wires and the outer portion of the pipe body are provided with the wrapping layer in a seamless mode. The wrapping layer is made of high-polymer materials. The core of the composite pipe and the forming process of the composite pipe is that the outer portions of the wires and the outer portion of the pipe body are covered with the high-polymer materials in a molten state, and the physical properties of the wires and the pipe body keep unchanged in the manufacturing process; the relative positions of the wires and the pipe body are maintained through the high-polymer materials, so the composite pipe has good strength and stability.

Owner:WENZHOU NIUNIU PNEUMATIC TECH

A kind of manufacture method of easy-tear polypropylene packaging film

ActiveCN101376270BMechanical properties unchangedPhysical properties unchangedFlat articlesReduction treatmentStretch ratio

The invention discloses a method for manufacturing an easy-to-tear type polypropylene packaging film. The method comprises the following steps: (1) taking a polypropylene thin film meeting the sanitary requirement as a raw material, stretching in a single direction, and specifically, heating the polypropylene thin film to 100DEG C to 160 DEG C, with the stretching ratio being 1.1 to 5, so as to obtain a film material after the positioning stretching; and (2) conducting the temperature reduction treatment for the film material after the positioning stretching, specifically reducing the temperature of the film material after the positioning stretching to the environmental temperature. A packaging bag manufactured through the invention has the advantages of easy tearing, and smooth tearing part, when the packaging bag is torn in the stretching direction.

Owner:ZHEJIANG GOLDSTONE PACKING

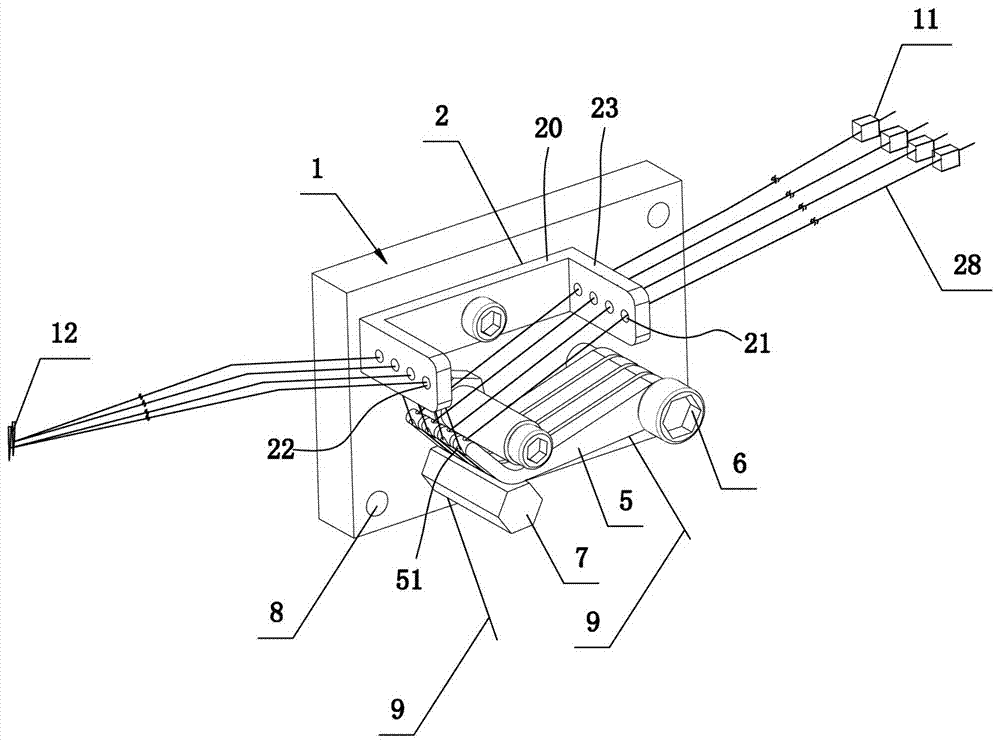

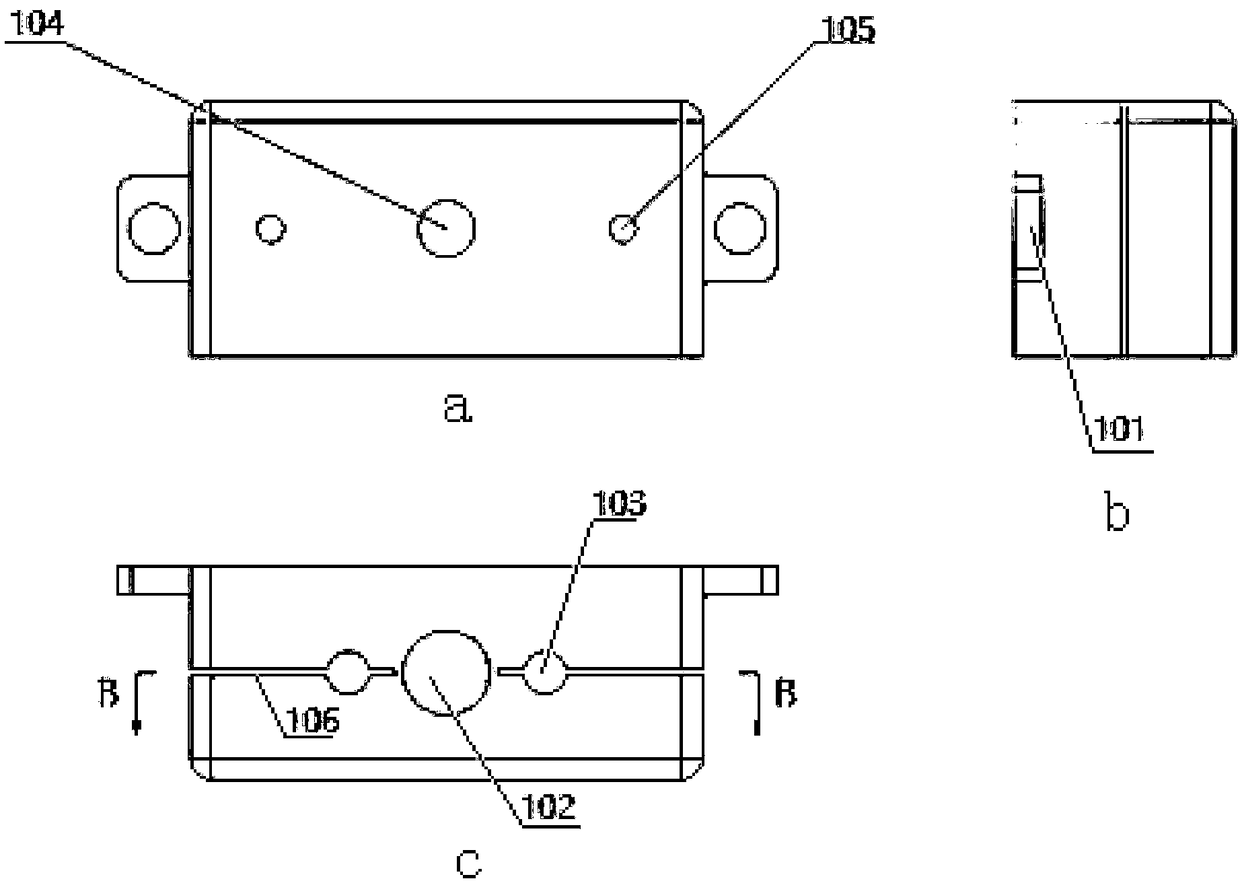

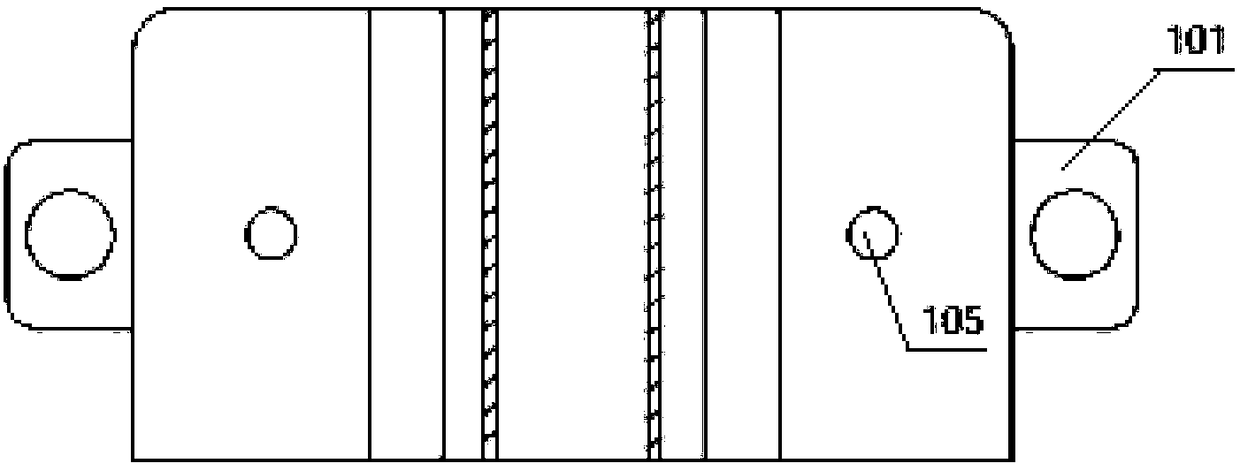

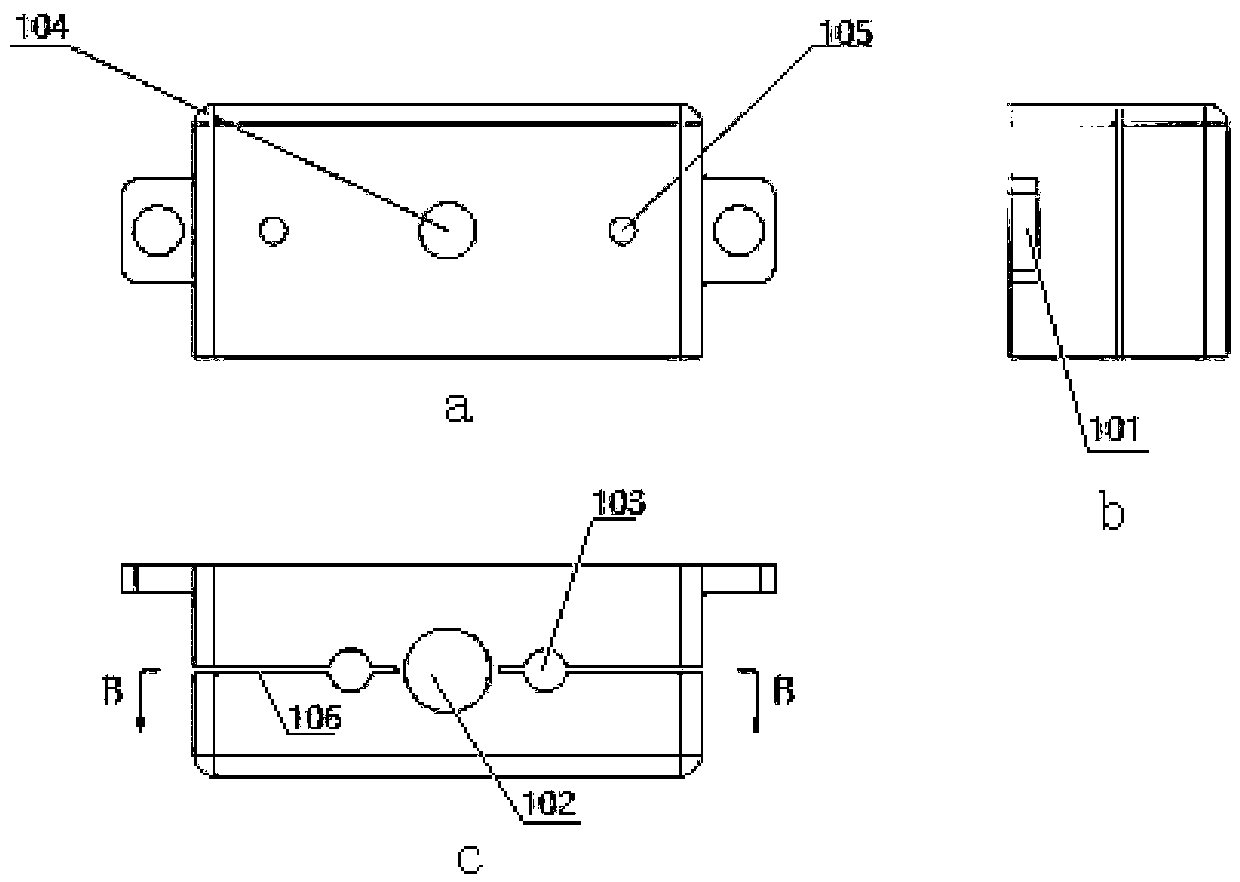

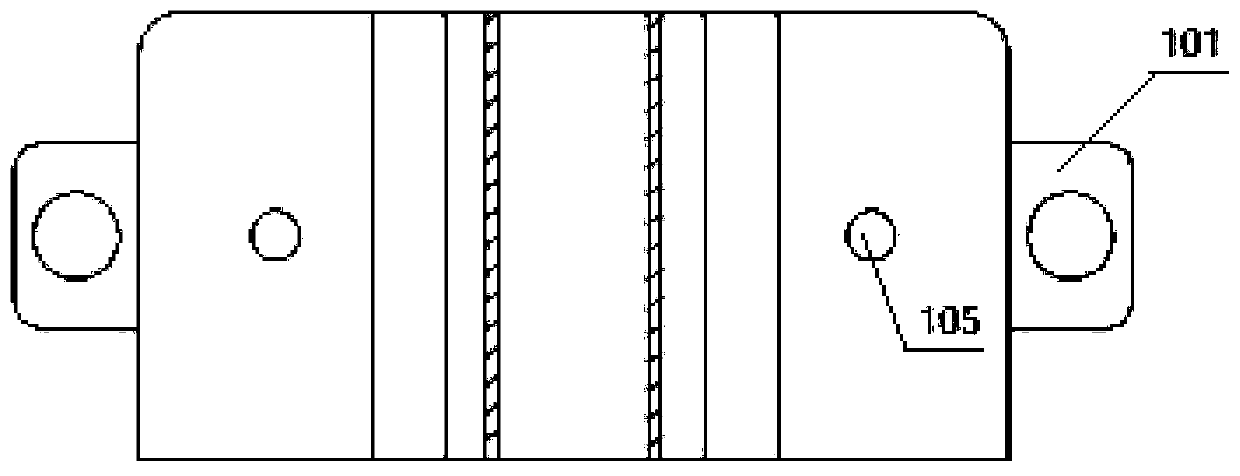

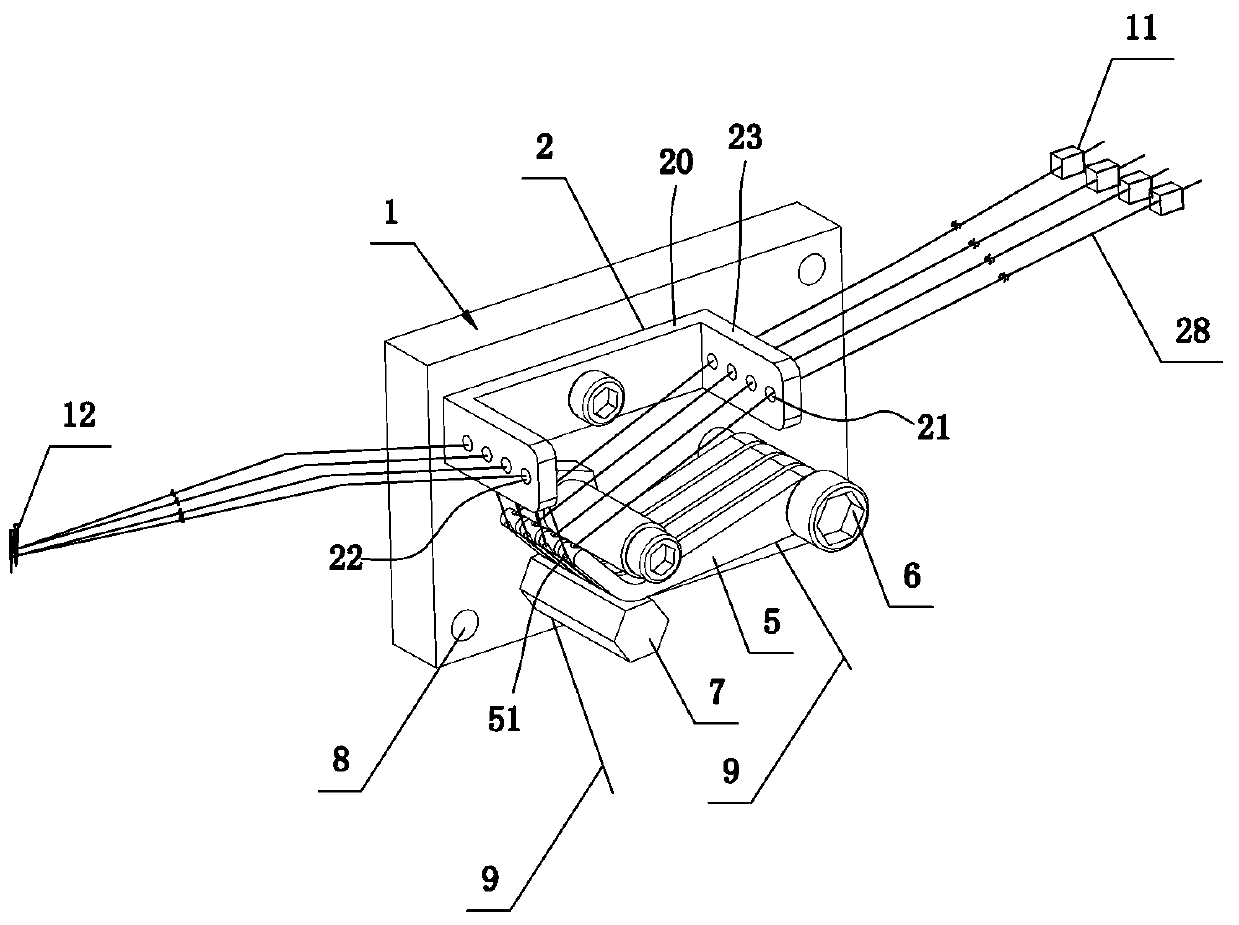

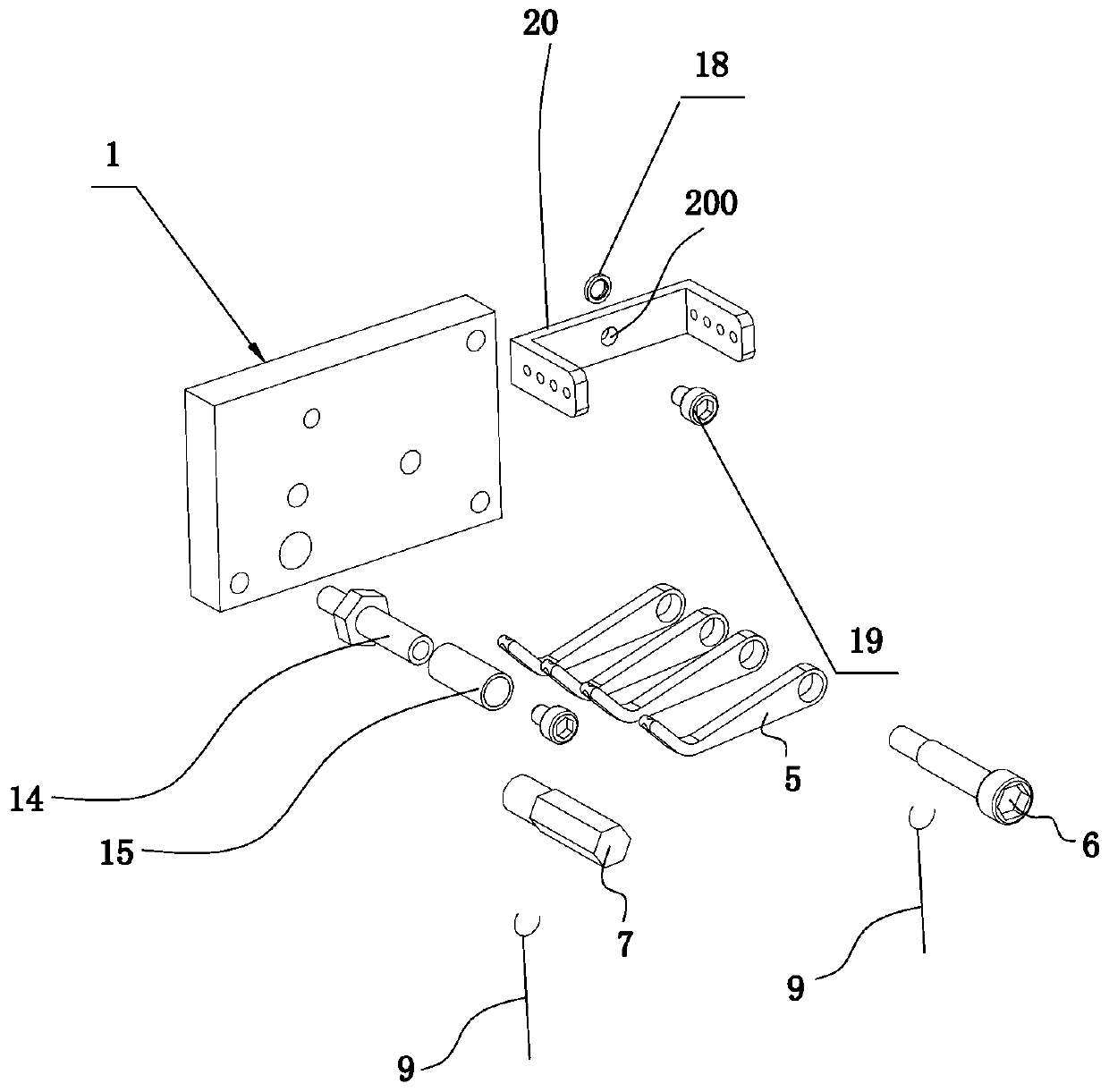

Yarn break switch for nylon zipper stitching machine

A yarn break switch for a nylon zipper stitching machine comprises a fixing plate, a yarn passing board mounted on the fixing plate, at least one induction block, a fixing bar and a conductive bar, wherein at least one yarn inlet hole is formed in one side of the yarn passing board, at least one yarn outlet hole is formed in the other side, a fixed end of the induction block is rotatablly arranged on the fixing bar in a sleeving manner, and yarn arranging holes are formed in a free end of the induction block, and are located below the yarn inlet hole and the yarn outlet hole; the conductive bar is located below the induction block; yarn passes through the yarn inlet hole, the yarn arranging holes and the yarn outlet hole in sequence to be fed and conveyed, when the yarn is broken, the induction block falls by own gravity, and abuts against the conductive bar, so that the fixing bar and the conductive bar are electrically connected. The yarn break switch can detect whether the yarn (which can be subdivided into bottom yarn and upper yarn) in production of the nylon stitching machine is broken constantly, and stopping can be performed timely in case of yarn breaking; therefore, accuracy is high, and product quality is stabilized.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

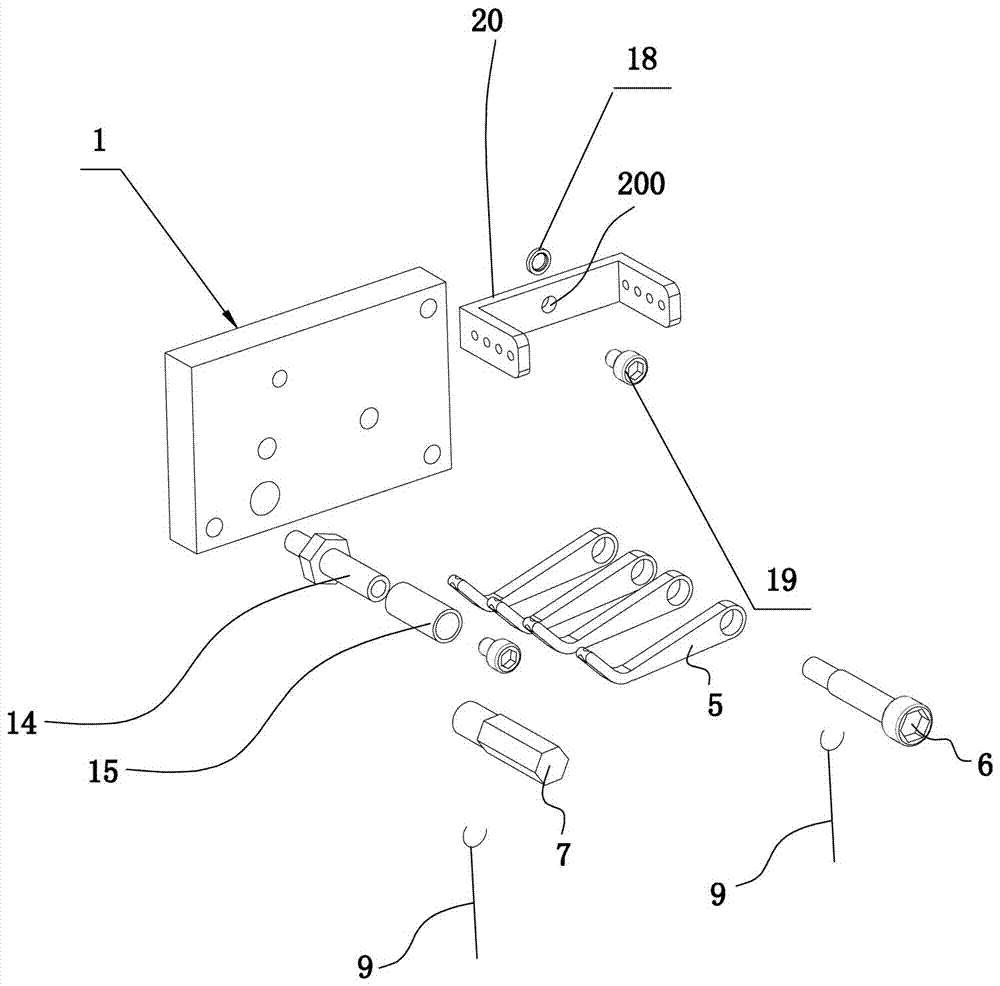

High-temperature solid foam draining agent and preparation method

The invention relates to the technical field of oil production engineering for oil fields, provides a high-temperature solid foam draining agent for drainage gas recovery for gas wells and a preparation method of the foam draining agent and is researched to solve the problems that high-temperature deep gas well foam draining agents have reduced performance, are poor in draining effect and inconvenient to store and fill in winter and the like. The high-temperature solid foam draining agent is prepared from, in percentage by weight, 20%-30% of alkyl sulfate, 10%-15% of ammonium lauryl sulfate C12H25SO4NH4, 25%-35% of stearic acid C18H36O2, 8%-12% of sodium carbonate Na2CO3 and the balance of water. The invention further provides the preparation method of the foam draining agent. The foam draining agent is suitable for deep gas wells with the well temperatures larger than or equal to 120 DEG C or the well depths larger than or equal to 3,500 m, is particularly applied to continuous production and intermittent draining gas wells and has the advantages of being good in foaming performance and high in foam stability at the high temperature, convenient to store and transport, small in pollution and the like.

Owner:PETROCHINA CO LTD +1

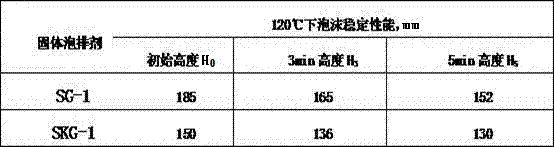

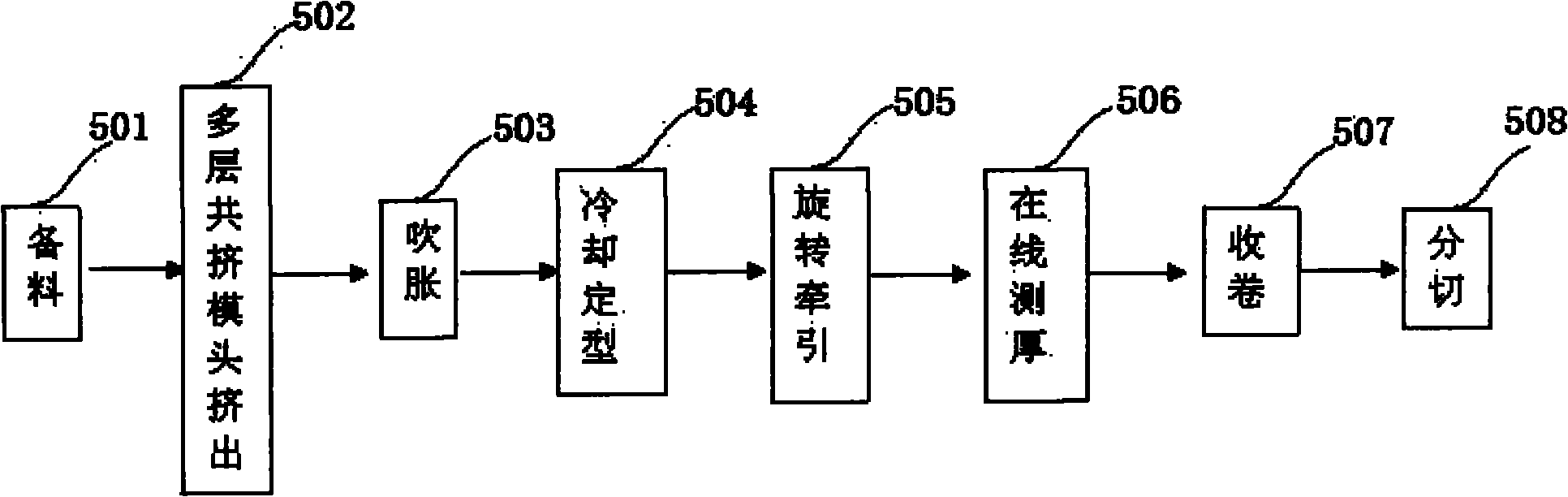

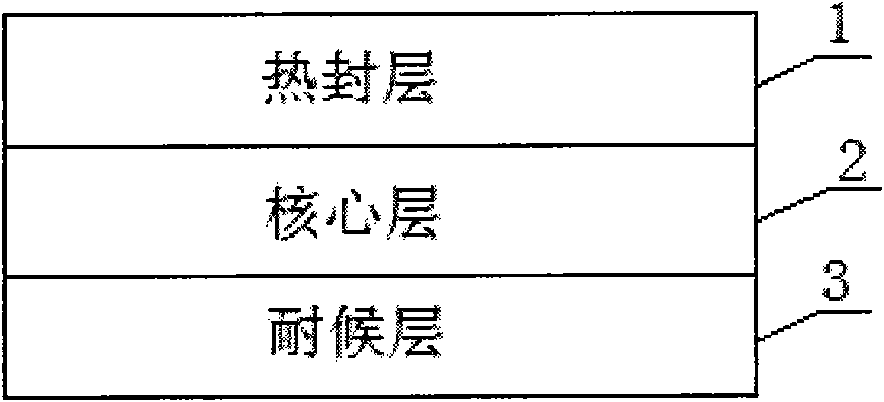

Packaging film for multilayer co-extruding urine bag and production method thereof

InactiveCN102371738AImprove toughnessPhysical properties unchangedSynthetic resin layered productsMedical treatmentEthylene

The invention discloses a packaging film for a multilayer co-extruding urine bag. The packaging film comprises a heat sealing layer, a core layer and a weather-resisting layer, which are arranged in turn, wherein the heat sealing layer, the core layer and the weather-resisting layer are modified ethylene-vinyl acetate copolymer layers. The invention also discloses a method for producing the packaging film for the multilayer co-extruding urine bag. The method comprises the following steps: preparing materials, extruding a multilayer co-extruding film head, blowing up, cooling and shaping, rotating and dragging, measuring thickness on line, coiling and cutting. The packaging film for the multilayer co-extruding urine bag provided by the invention is the packaging film which is excellent in comprehensive property, especially separating property, is suitable for various devices and interfaces, is excellent in properties for sealing and protecting urine, and is used as a urine packaging material applied to the medical field.

Owner:SUZHOU HAISHUN PACKAGING MATERIAL

Anti-corrosion, oil-resistant and flame-retardant plastic oil tank

ActiveCN103214806BImprove impact resistancePhysical properties unchangedLarge containersPolyesterFiber

The invention relates to a reinforced plastic and an oil tank, and aims to provide an anti-corrosion, oil-resistant and flame-retardant oil tank which has reliable physical property and is made of reinforced plastic. The technical point is as below: the bulk molding compound comprises the following components in parts by weight: 34-47 parts of unsaturated polyester, 0.3-0.4 part of cobalt naphthenate, 0.3-0.35 part of methyl ethyl ketone peroxide, 45-47 parts of calcium carbonate, 0.1-0.3 part of antistatic agent, 0.1-0.15 parts of antioxygen, 0.1-0.15 part of pentabromo phenol, 0.1-0.3 part of microencapsulation tri-(2,3-dibromopropyl) isocyanuric acid ester, 0.1-0.2 part of melamine, 0.08-0.1 part of nano silica, a proper amount of silane coupling agent and 28-31 parts of reinforced fiber. The plastic can endure the temperature of 360 DEG C and 64 DEG C below zero, has constant physical property and has the advantages of high toughness and strength. The impact resistance of the unsaturated polyester fiber-reinforced bulk molding compounds is effectively improved. The reinforced plastic is anti-corrosion, anti-aging, oil resistant and flame retardant, and is suitable for manufacturing oil tanks.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

Hanging drop protection cover automatic separation device and method

ActiveCN108458877AReduce heat transferAchieve evaporationInternal-combustion engine testingGlass coverEvaporation

Owner:JIANGSU UNIV OF SCI & TECH

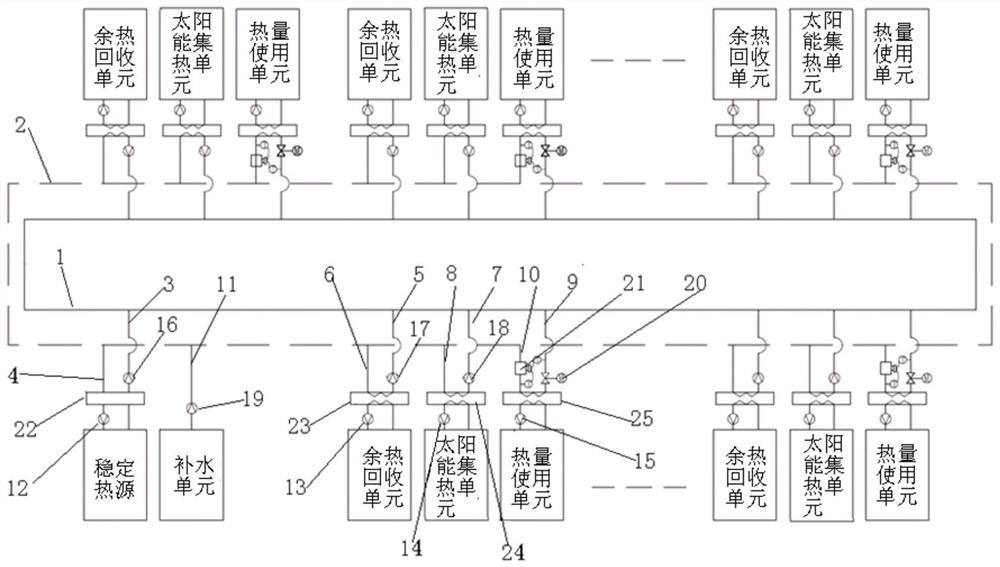

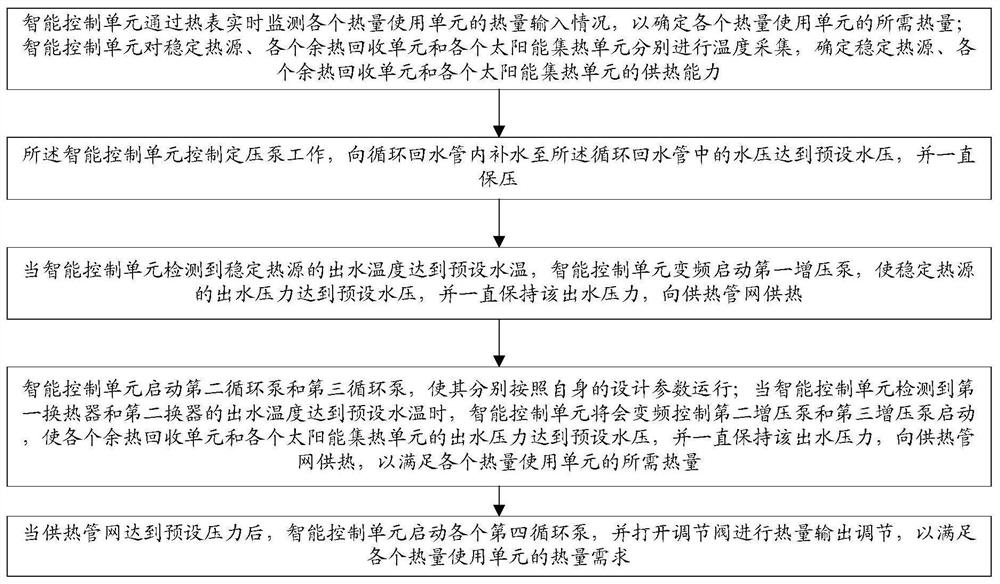

Green low-carbon comprehensive energy utilization system and method

ActiveCN111947226ARealize the purpose of useRealize process production needsHeating fuelLighting and heating apparatusWaste heat recovery unitThermodynamics

The invention discloses a green low-carbon comprehensive energy utilization system and method. The green low-carbon comprehensive energy utilization system comprises a heat supply pipe network, a setof intelligent control unit, a set of water supplementing unit, a plurality of heat utilization units and a heat supply heat source unit, the heat supply heat source unit comprises a stable heat source, a plurality of waste heat recovery units and a plurality of solar heat collection units, the stable heat source, the waste heat recovery units, the solar heat collection units and the heat utilization units are connected into the heat supply pipe network in parallel, the intelligent control unit is connected into and uniformly dispatches the heat supply heat source unit, the heat utilization units and the water supplementing unit, and the water supplementing unit is arranged close to the stable heat source and connected with the heat supply pipe network. The system is advantageous in that the plurality of waste heat recovery units, the plurality of solar heat collection units and the plurality of heat utilization units are arranged around the heat supply pipe network without position limitation, and the heat supply heat source unit and the plurality of heat utilization units are used in cooperation so that the waste heat utilization rate and the clean energy utilization rate are increased, heat energy is saved, and the usage requirement of users can be met.

Owner:中竞同创能源环境科技集团股份有限公司

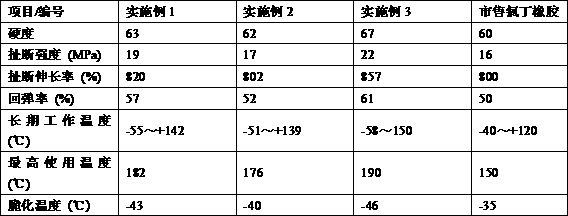

High temperature resistant chloroprene rubber and preparation method thereof

InactiveCN108084530APhysically stableGood high temperature resistanceTemperature resistanceMagnesium

The invention belongs to the technical field of rubber materials and relates to high temperature resistant chloroprene rubber and a preparation method thereof. The high temperature resistant chloroprene rubber is prepared from the following raw materials in parts by weight: 80 to 120 parts of chloroprene rubber, 4-6 parts of magnesium oxide, 0.3-0.7 part of stearic acid, 3-6 parts of a vulcanizingagent, 1-3 parts of a vulcanization retarder, 0.3-0.4 part of an accelerant, 1-3 parts of an antioxidant and 1-3 parts of a plasticizer. The high temperature resistant chloroprene rubber is physically stable, can maintain the physical properties unchanged in harsh environment, is especially good in high temperature resistance, and is suitable for use in high temperature environment.

Owner:SHENYANG SAIYA RUBBER PRODS

Corrosion resistant chemical pump casing

The invention discloses a corrosion resistant chemical pump casing which is made by adopting the following components: PET powder, modified UV glue, silicon carbide whisker, reinforced fibers, alanine, nanometer aluminium oxide, modified lignocelluloses and a compatilizer. The chemical pump casing disclosed by the invention is light in weight, high in strength, excellent in high and lower temperature resistance, good in physical performance, high in oil resistance and acid-base corrosion resistance, reliable in flame retardant property, and low in deformation rate, and has good ageing resistance, excellent chemical stability and electrical insulating property; the material formula of the chemical pump casing is simple, the compatibility is reasonable, the cost is low, and the components have good compatibility and dispersibility; and the manufacture method of the chemical pump casing is simple in procedures, low in cost, easy to implement, low in price, high in rate of finished products, and excellent in performance, has great development prospect and can meet difference requirements of customers.

Owner:HEFEI HUAYUN MACHINERY MFG CO LTD

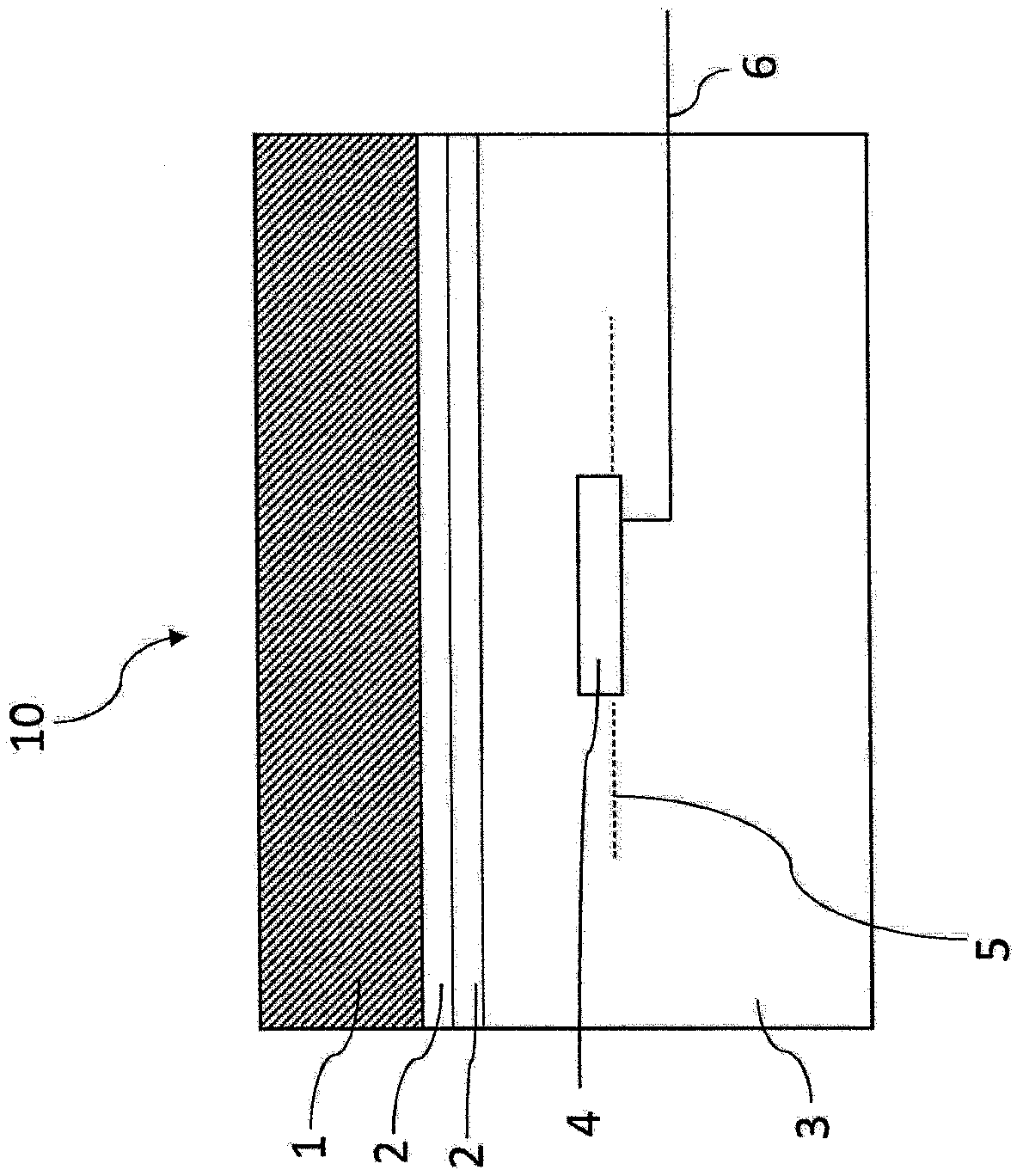

A decorative panel

InactiveCN108778720APhysical properties unchangedFree from destructionBatteries circuit arrangementsSpecial ornamental structuresPolymer scienceEngineering

The present invention relates to a decorative panel, comprising a core layer provided with a decor layer, said decor layer comprising a substrate layer provided with at least one coating, wherein within said decorative panel at least one induction coil is located. The present invention furthermore relates to the use of such a decorative panel in indoor and / or outdoor furniture and in interior and / or exterior decoration.

Owner:TRESPA INT

Polymer for PP-R high polymer

The invention discloses a master batch of plastic products, in particular to a polymer for PP-R high polymer. The polymer for PP-R high polymer comprises the following raw materials according to the parts by weight: 55-75 of calcium carbonate, 1-3 of lubricant, 0.3-0.8 of polyethylene wax, 0.3-0.8 of polypropylene wax, 5-15 of polyethylene, 3-8 of polypropylene, 1-5 of coupling agent, 0.5-2.5 of zinc stearate, 1-3 of stearic acid and 5-15 of talcum powder. The polymer for PP-R high polymer of the invention fills the gap of the field; the invention has large filling volume, and the original physical properties of the polymer can be kept after being filled; the invention is characterized by high strength and toughness, good sizing and the like and the cost of the manufacturers of PP-R products can be largely decreased. Under the current situation of energy scarcity, a great amount of energy can be saved.

Owner:沈阳大圆天地塑料制品有限公司

An automatic separation device and method for a suspended droplet protection cover

ActiveCN108458877BReduce heat transferAchieve evaporationInternal-combustion engine testingGlass coverEvaporation

Owner:JIANGSU UNIV OF SCI & TECH

Mortar recovery technique for cutting single-crystal and polycrystalline silicon wire

InactiveCN101327622BPhysical properties unchangedSlicing works wellWorking accessoriesFine working devicesRecovery methodFiltration

Owner:正申科技(北京)有限公司

Mechanical regeneration method for rubber burrs

InactiveCN101602236BHigh strengthImprove performancePlastic recyclingPolymer scienceEconomic benefits

The invention discloses a mechanical regeneration method for rubber burrs. A mechanical method is adopted to treat the rubber burrs and destroy molecular chains of the rubber burrs, and has no pollution in the treating process; and the reclaimed rubber after the treatment can be processed into new rubber products. The method comprises the following steps of sorting classification of the burrs, crushing of the burrs, mechanical treatment of the burrs and regenerative utilization processing of the burrs. When the reclaimed rubber of the rubber burrs is processed into the new products, the reclaimed rubber can account for 20 to 50 percent of a total rubber mixing material, so that production cost of the products is effectively saved, the loss that the rubber burrs are directly used as waste is avoided, and great economic benefit is brought to rubber manufacturers.

Owner:厦门市金汤橡塑有限公司

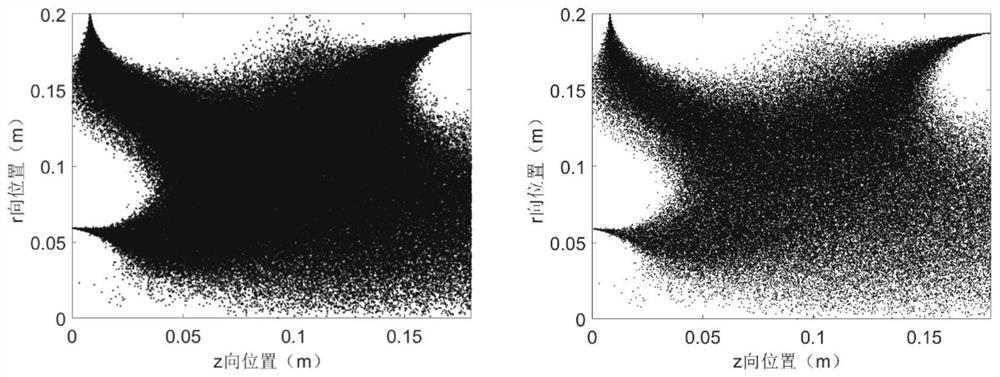

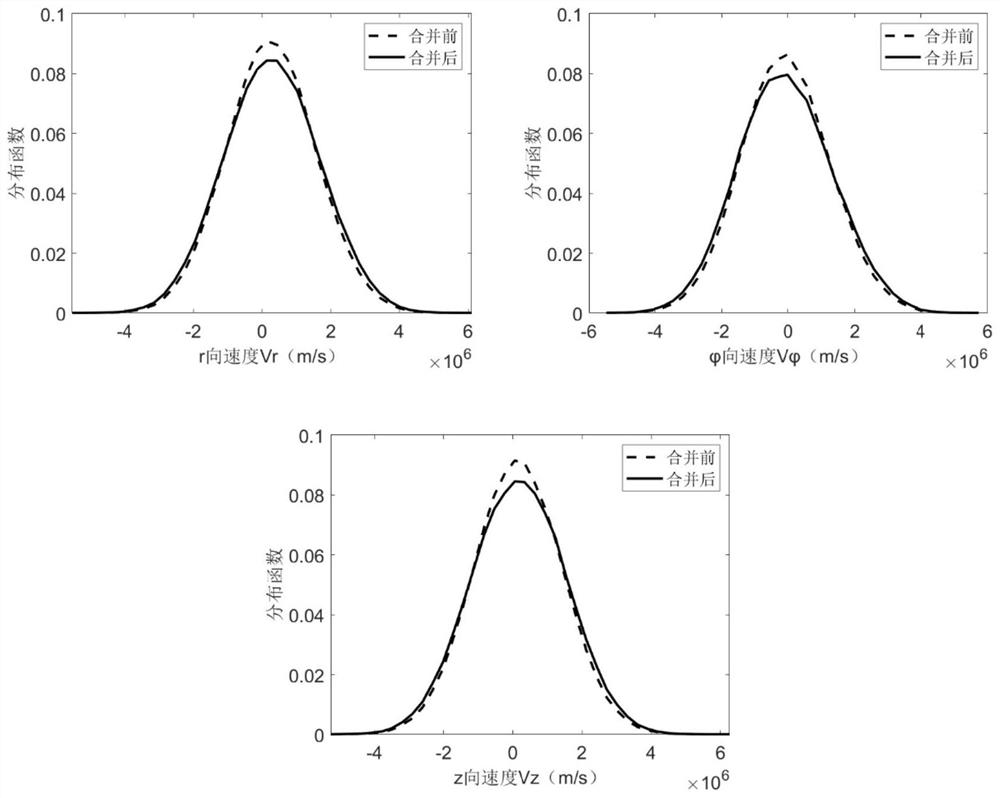

Voronoi diagram particle combination algorithm of based on particle simulation

ActiveCN111967148AEasy to adjustFast constructionSustainable transportationDesign optimisation/simulationTheoretical computer scienceComputation process

The invention relates to the field of particle simulation numerical simulation and particularly relates to a Voronoi diagram particle combination algorithm based on particle simulation. According to the method, a particle list is preprocessed before combination, particles with large weights are screened out, large numerical noise caused by the fact that the weights of the combined particles are too large is avoided, and meanwhile the speed of the whole calculation process is increased; selection of the expected weight is more reasonable through the selection of the preprocessing rule, so a purpose of quickly finding out similar particle groups is achieved, and calculation efficiency of the Voronoi graph particle merging algorithm is improved. According to the method, the limitation that the number of particles is too large in the simulation process of the PIC method is overcome, the algorithm ensures that the physical characteristics before and after merging are unchanged while the scale of the simulated particles is reduced, calculation efficiency is greatly improved, and user input parameters can be conveniently adjusted to control the final merging error and the number of remaining particles expected by a user.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Composite pipe and its forming process

InactiveCN105042208BFast heat conductionChanges in physical propertiesFlexible pipesRigid pipesMolten stateManufacturing technology

The invention relates to a pipeline and a manufacturing technology thereof, in particular to a multifunctional composite pipe capable of delivering different media simultaneously and a manufacturing process used for manufacturing the composite pipe. The composite pipe comprises wires, a pipe body and a wrapping layer. The wires are parallel to the pipe body. The outer portions of the wires and the outer portion of the pipe body are provided with the wrapping layer in a seamless mode. The wrapping layer is made of high-polymer materials. The core of the composite pipe and the forming process of the composite pipe is that the outer portions of the wires and the outer portion of the pipe body are covered with the high-polymer materials in a molten state, and the physical properties of the wires and the pipe body keep unchanged in the manufacturing process; the relative positions of the wires and the pipe body are maintained through the high-polymer materials, so the composite pipe has good strength and stability.

Owner:WENZHOU NIUNIU PNEUMATIC TECH

Surface cross-linking treatment method for thermoplastic starch products

The invention relates to a surface cross-linking treatment method for thermoplastic starch products and belongs to the technical field of a solid material surface modifying method. The method comprises the steps of: leading the cross-linking agent into the surface layer of the thermoplastic starch products, performing the cross-linking reaction between the cross-linking agent with the hydroxyl onstarch molecule under a condition of heating and forming a cross-linking network between the starch molecule chains on the surface layer of the products. According to the method, the solid cross-linking reaction is utilized to only perform proper cross-linking treatment on hydrophilic hydroxyl on the surface layer of the thermoplastic starch products. Without changing the condition of the main component of the thermoplastic starch products and the treatment property, the sensibility of the products to the environmental humidity is decreased and the water-tolerant property is promoted. After the surface is cross-linked, the sensibility of the products to the environmental humidity is obviously decreased. Under an environment with humidity of 95%, the balanced water content is at least 64.2% of the water content before being modified, namely decreased by 35.8% at most. The anti-solvent dissolubility is also obviously promoted. The solvent which is soluble in dimethyl sulfoxide becomes insoluble.

Owner:JILIN UNIV

Functional membrane and process for production thereof, and electrolyte membrane for fuel cell and process for production thereof

InactiveCN101128523BPhysical properties unchangedImprove proton conductivityNon-metal conductorsElectrolyte holding meansFuel cellsFilm base

A process for producing a functional membrane comprising an ion irradiation step in which a polymeric film base is irradiated with high-energy heavy ions at a density of 104 to 1014 particles / cm2 to generate active species in the film base; and, subsequent to the ion irradiation step, a graft polymerization step in which at least one monomer selected from the members of group A which are monomers each having a functional group and 1 to 80 mol% (based on the total amount of the monomer(s) of group A) of a monomer selected from the members of group B which are crosslinking agents for the monomers of group A are added to the film base and graft polymerization of the film base and the monomers are then performed; and a functional membrane produced by the process. By employing this process, it becomes possible to produce a functional membrane which combines high functionality with gas-barrier property inherent in a polymeric film base. In particular, a polymeric electrolyte membrane having high proton conductivity and good gas barrier property can be produced, which is highly suitable as a polymeric electrolyte membrane for a fuel cell.

Owner:TOYOTA JIDOSHA KK

A kind of high-temperature solid foaming agent and preparation method thereof

The invention relates to the technical field of oil production engineering for oil fields, provides a high-temperature solid foam draining agent for drainage gas recovery for gas wells and a preparation method of the foam draining agent and is researched to solve the problems that high-temperature deep gas well foam draining agents have reduced performance, are poor in draining effect and inconvenient to store and fill in winter and the like. The high-temperature solid foam draining agent is prepared from, in percentage by weight, 20%-30% of alkyl sulfate, 10%-15% of ammonium lauryl sulfate C12H25SO4NH4, 25%-35% of stearic acid C18H36O2, 8%-12% of sodium carbonate Na2CO3 and the balance of water. The invention further provides the preparation method of the foam draining agent. The foam draining agent is suitable for deep gas wells with the well temperatures larger than or equal to 120 DEG C or the well depths larger than or equal to 3,500 m, is particularly applied to continuous production and intermittent draining gas wells and has the advantages of being good in foaming performance and high in foam stability at the high temperature, convenient to store and transport, small in pollution and the like.

Owner:PETROCHINA CO LTD +1

Yarn break switch for nylon zipper sewing machine

A yarn break switch for a nylon zipper stitching machine comprises a fixing plate, a yarn passing board mounted on the fixing plate, at least one induction block, a fixing bar and a conductive bar, wherein at least one yarn inlet hole is formed in one side of the yarn passing board, at least one yarn outlet hole is formed in the other side, a fixed end of the induction block is rotatablly arranged on the fixing bar in a sleeving manner, and yarn arranging holes are formed in a free end of the induction block, and are located below the yarn inlet hole and the yarn outlet hole; the conductive bar is located below the induction block; yarn passes through the yarn inlet hole, the yarn arranging holes and the yarn outlet hole in sequence to be fed and conveyed, when the yarn is broken, the induction block falls by own gravity, and abuts against the conductive bar, so that the fixing bar and the conductive bar are electrically connected. The yarn break switch can detect whether the yarn (which can be subdivided into bottom yarn and upper yarn) in production of the nylon stitching machine is broken constantly, and stopping can be performed timely in case of yarn breaking; therefore, accuracy is high, and product quality is stabilized.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com