Sterilizing device

A technology of sterilization device and input device, which is applied in heating and other directions, can solve the problems of long sterilization time, large influence of particle and viscosity of plate sterilization device, and large influence on physical properties of materials, etc., so as to achieve high sterilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific embodiment, further set forth the present invention:

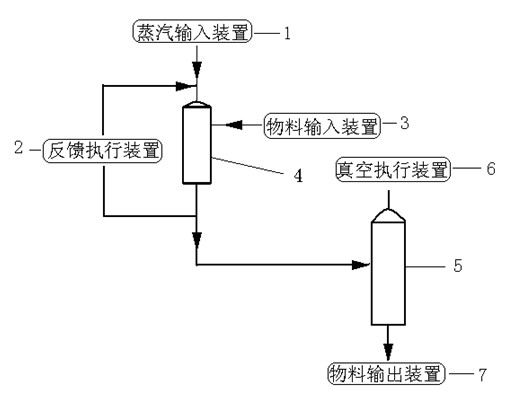

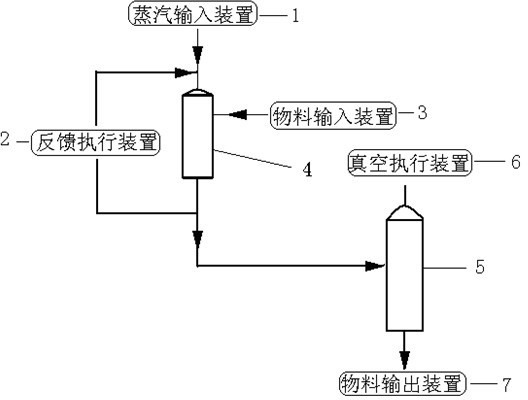

[0014] like figure 1 As shown, a sterilizing device includes a first container 4, a steam input device 1 is connected to the top of the first container 4, a material input device 3 is connected to the upper side of the first container 4, a feedback actuator 2 and the steam input device 1 is connected to the bottom of the first container 4, the side of a second container 5 communicates with the bottom of the first container 4 through pipes, the top of the second container 5 is connected to a vacuum actuator 6, and the bottom of the second container 5 is connected to a material output device 7.

[0015] The feedback actuator 2 includes a controller and a regulating valve. The controller controls and connects a temperature sensor and a regulating valve. The temperature sensor can sense the temperature of the material flowing out from the bottom of the first container 4 and transmit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com