Mortar recovery technique for cutting single-crystal and polycrystalline silicon wire

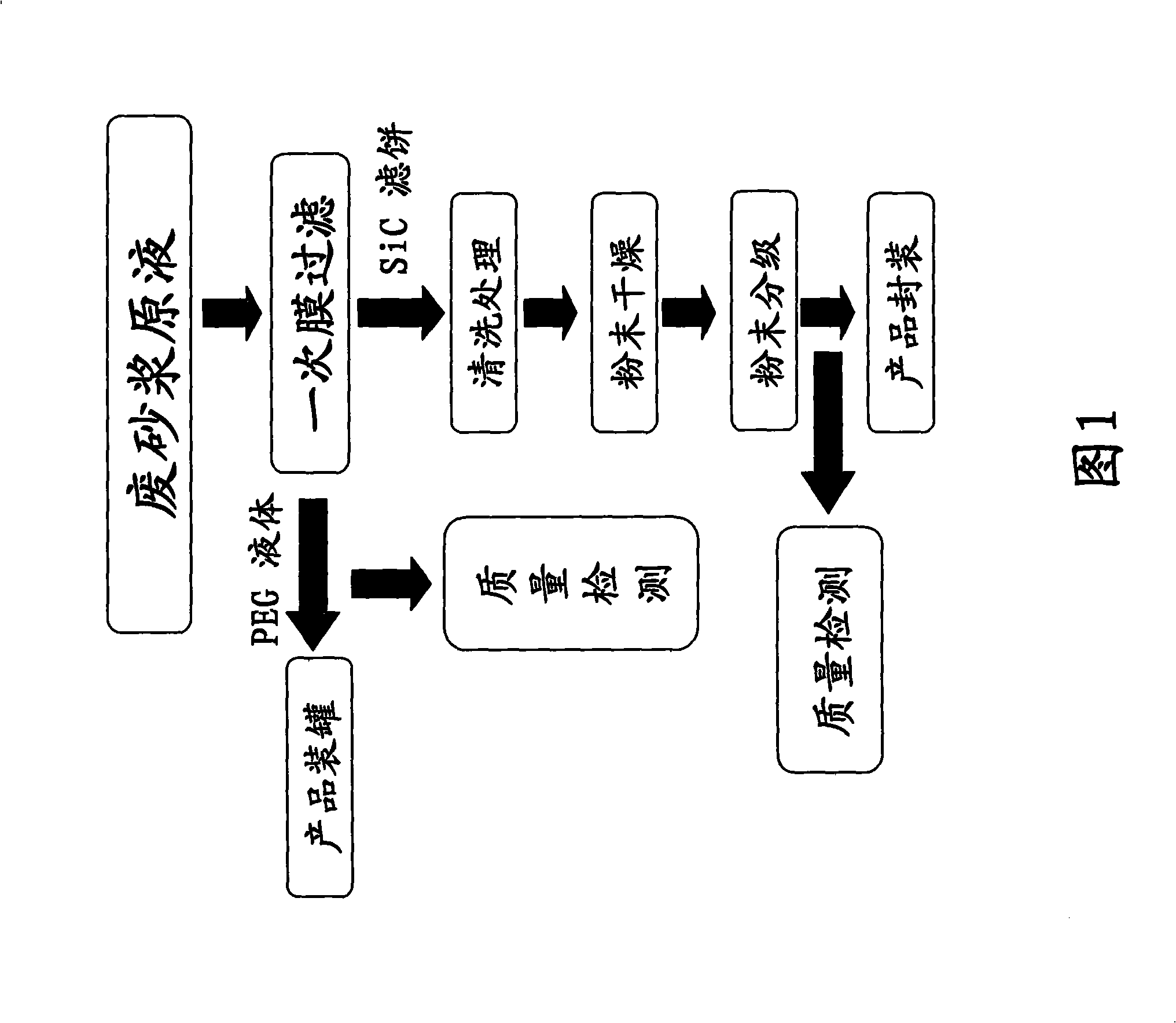

A polysilicon wire and mortar technology, applied in stone processing tools, fine working devices, working accessories, etc., can solve problems such as low efficiency, changes in PEG molecular structure, and decreased quality and efficiency of silicon slices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

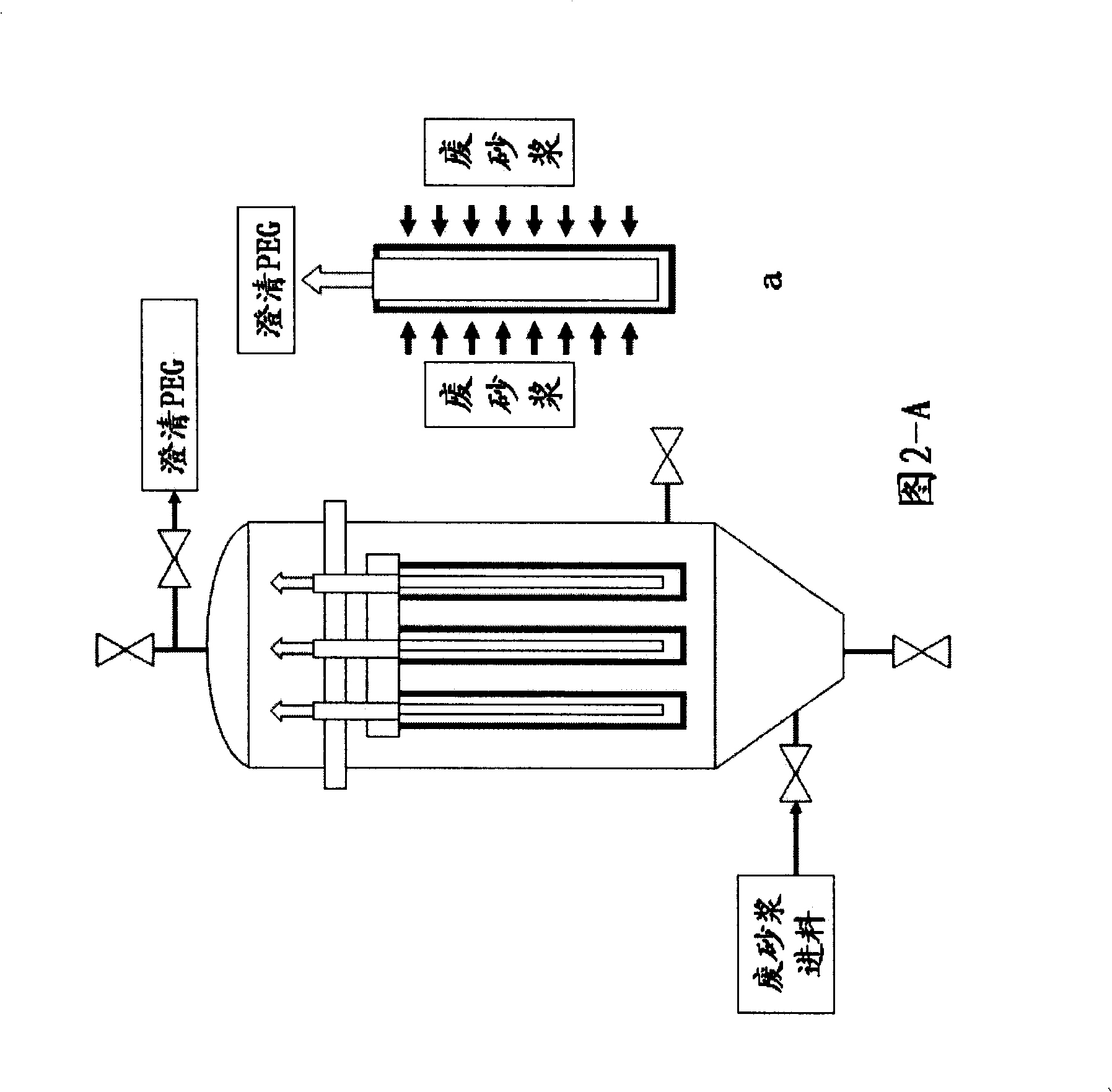

[0092] The waste mortar is put into the microporous filter for a membrane filtration solid-liquid separation. After a period of time, when the filter residue wrapping the filter tube (membrane) in the microporous filter accumulates to a certain thickness, due to gravity, it will flow from the filter tube ( The outer wall of the membrane) falls off. At this time, it is necessary to stop feeding, open the slag discharge hole at the bottom of the microporous filter to discharge the filter residue out of the microporous filter; for different mortar processing volumes and different types of microporous filters, the processing time Not all are the same. Practical note: the filtration area is 30m 2 , Filtration speed is 45~65L / m 2 h microporous filter to filter 4 to 8 tons of mortar and complete a separation of membrane filtrate, it takes 2 to 4 hours.

Embodiment 2

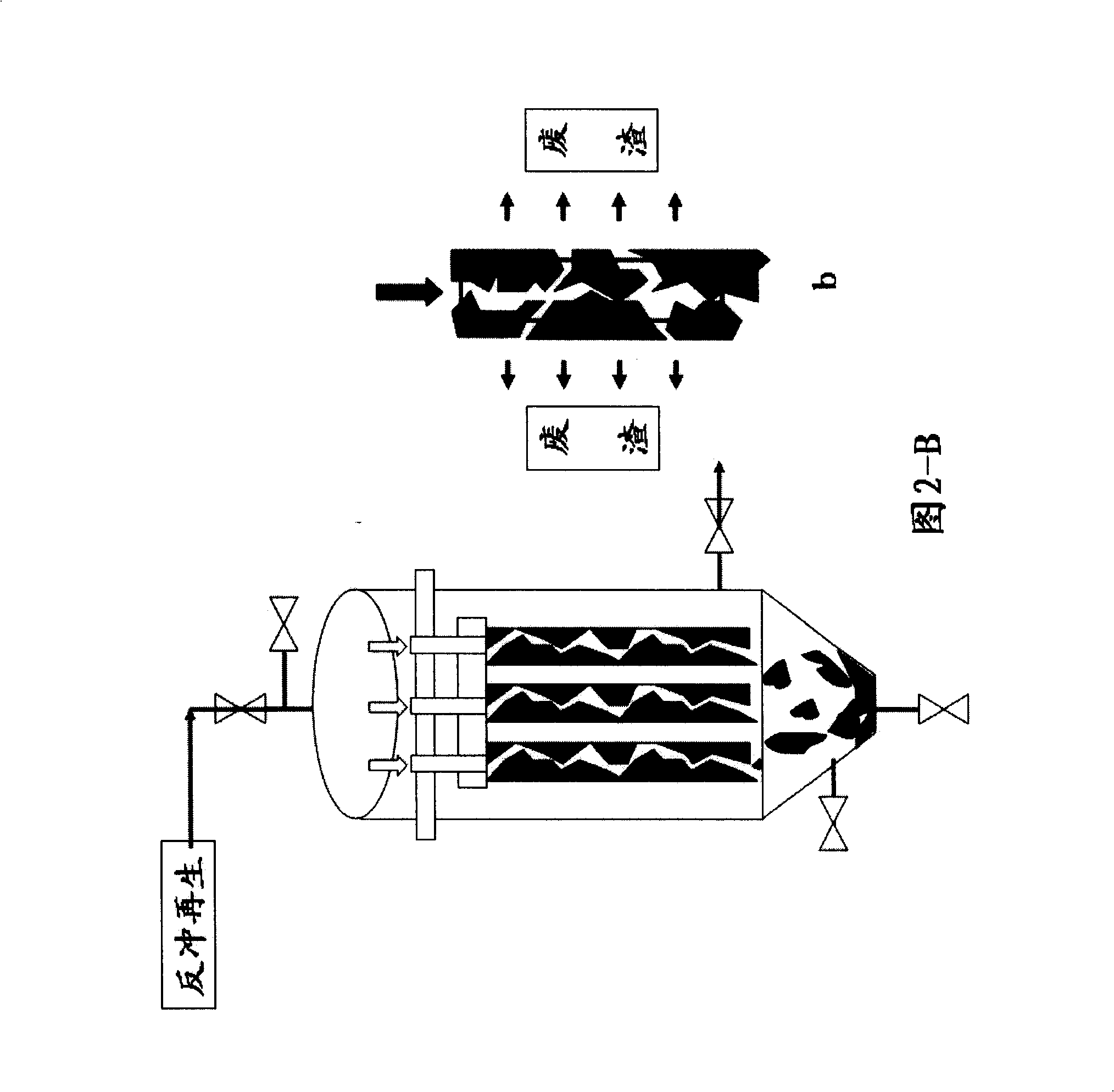

[0094] Use a pump to drive the SiC aqueous solution in the pool into the filter press, and perform solid-liquid separation by means of filter press. Filtration area is 125m 2 , There are 48 filter chambers, the filter cake volume is 2m 3 It takes 15-35 minutes to press filter the aqueous solution of 2 tons of SiC solids, and 10-25 minutes to unload; when drying, use an electric rotary drying furnace with a processing capacity of 200kg / h to dry materials containing about 2 tons of SiC , It takes 8 to 10 hours.

Embodiment 3

[0096] Using negative pressure self-distributing gas sorting technology for SiC, it has high precision and high production efficiency, and the classification efficiency can be 250-500kg / h. If 200 tons of SiC are processed per month, calculated on the basis of 16h / day work, only one set is needed. Moreover, it occupies a small area, has high efficiency, and saves labor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com