Patents

Literature

75results about How to "High recycling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mortar recovery technique for cutting single-crystal and polycrystalline silicon wire

InactiveCN101327622APhysical properties unchangedSlicing works wellWorking accessoriesFine working devicesFiltrationWire cutting

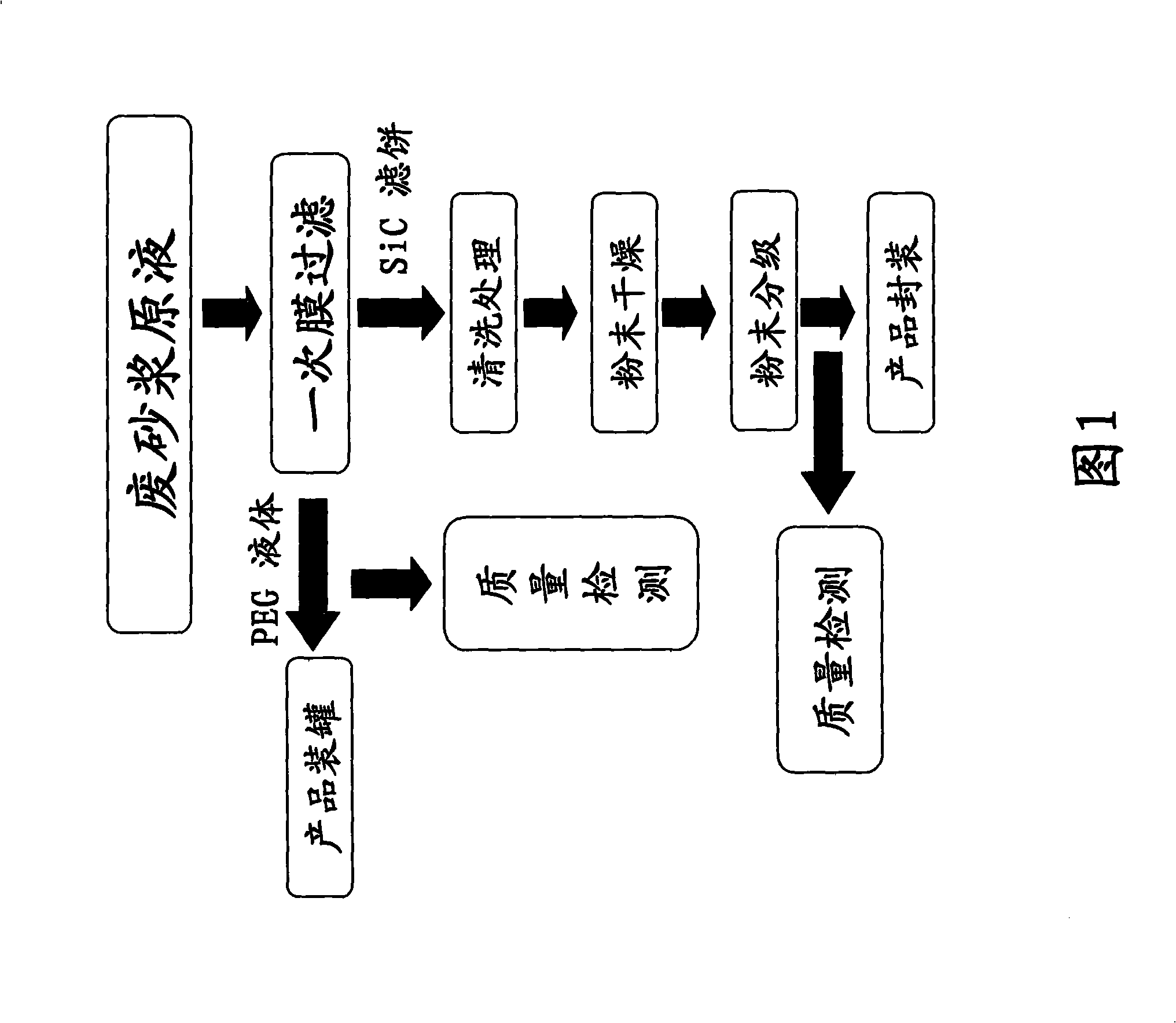

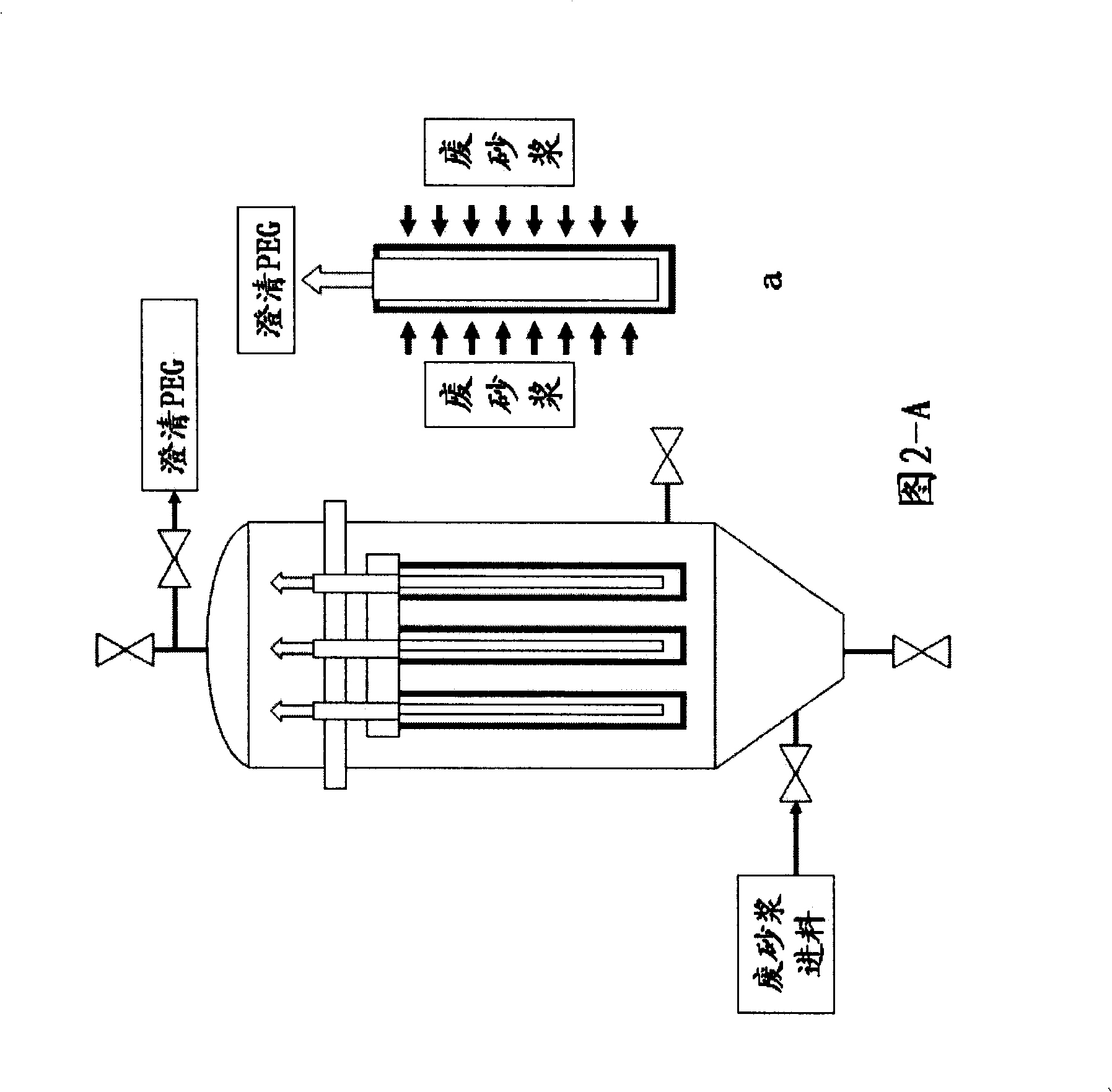

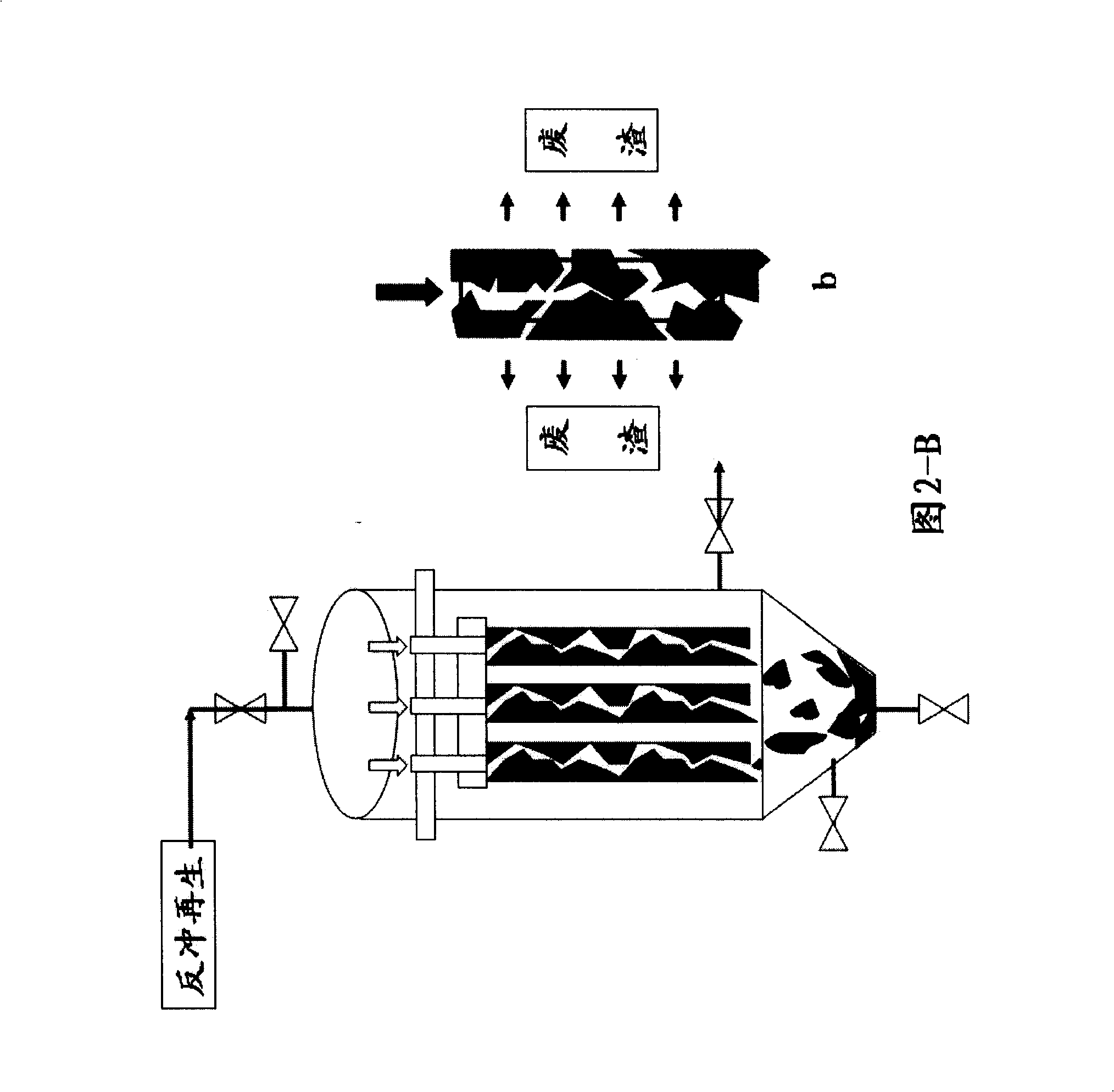

The present invention relates to a technique of recovering mortar used in the wire cutting of monocrystalline silicon or polycrystalline silicon. Silicon is an important material for solar batteries, semiconductors, liquid crystal displays, etc. A silicon rod is cut into silicon wafers by the wire cutting technique, and in the process, a wire-cutting machine needs to be added with cutting liquid mortar, which is mainly composed of liquid phase polyethylene glycol and solid phase silicon carbide powder. When the wire-cutting machine cuts the silicon rod, the solid particles in the mortar are changed into waste mortar as the silicon carbide grinds the silicon rod and a steel wire. If the waste mortar is discharged directly, environment is polluted, and the raw material is wasted. The present invention adopts the mortar-recovering technique to recover the waste mortar, so that the waste mortar can be reused and the discharging of the three wastes can be reduced, so while reducing production cost, the mortar-recovering technique can protect environment. The technique of recovering mortar used in the wire cutting includes the following flow: waste mortar dope, one-step membrane filtration and PEG liquid; waste mortar dope, one-step membrane filtration, cleaning, powder drying, powder classification and SiC powder.

Owner:正申科技(北京)有限公司

Method for recovering valuable metals from cathode materials of waste lithium ion batteries

InactiveCN106848469AEfficient recyclingReduce recycling costsWaste accumulators reclaimingBattery recyclingMetal leachingChloride

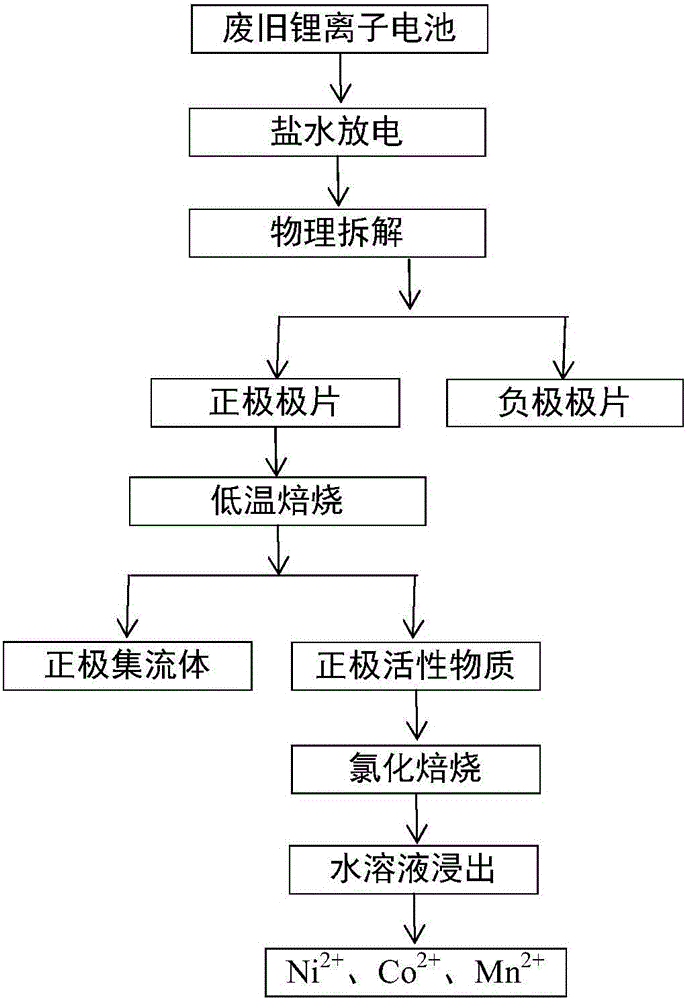

The invention discloses a method for recovering valuable metals from cathode materials of waste lithium ion batteries. The method comprises the following steps: the waste lithium ion batteries are discharged and dismantled, and cathode plates are separated out; the cathode plates are subjected to pyrolysis for glue removal, and current collectors and active materials are separated out; the active materials are mixed with chloride for chloridizing roasting; a solid product of chloridizing roasting is leached with water, and aleachate containing valuable metal ions is obtained. The method overcomes the defect that a large quantity of mineral acids and bases is needed to be consumed in the traditional metal leaching and recovering process of the cathode materials of the waste lithium ion batteries, adopts simple process, is low in cost and environment-friendly and has great industrial application value.

Owner:CENT SOUTH UNIV +1

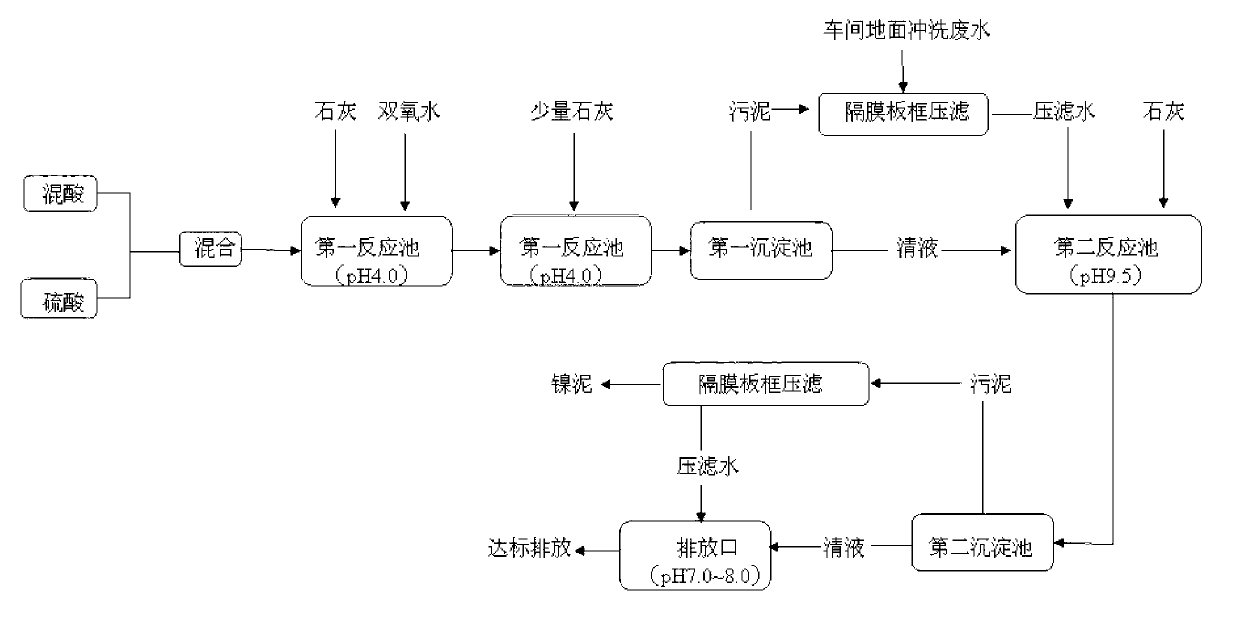

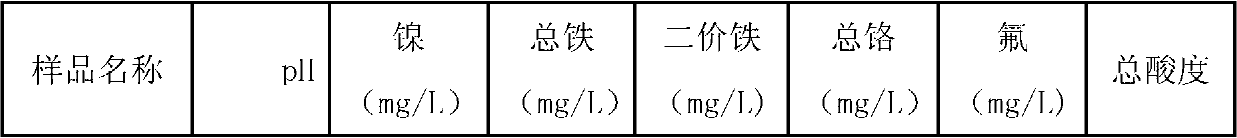

Method for recycling and processing nickel in stainless steel pickling waste acid

InactiveCN102757142AImprove qualityReach recycling methodWater contaminantsMultistage water/sewage treatmentSludgePollution

Disclosed is a method for recycling and processing nickel in a stainless steel pickling waste acid. The potential of hydrogen (pH) value of a mixed waste acid is adjusted to 3.5 to 4.5 by lime, hydrogen peroxide is added, a reaction is performed for 0.5 to 1 hour, then the pH value is adjusted again to 4.0 to 4.5 by the lime, then a flocculating agent is added to enter into a sedimentation tank to obtain a clear liquid and sludges, the clear liquid enters into a second reaction tank, the obtained sludges are subjected to a filter pressing to obtain a filter cake, the filter cake is subjected to a back washing by stainless steel factory workshop ground washing wastewater, and filter pressing water is transferred into the second reaction tank. The lime is added into the second reaction tank to adjust the pH value to 9.0 to 10.0, the flocculating agent is added, a formed solid-liquid mixture is transferred into a second sedimentation tank to be subjected to a solid-liquid separation, solids are subjected to the filter pressing to obtain a nickel mud, a sulfuric acid is added into a filter pressing liquor to adjust the pH of effluent to 7.0 to 8.0, and environmentally acceptable discharge can be achieved. By means of the method, the effective recycling of heavy metal nickel can be achieved, secondary pollutions are reduced, sludge qualities can be improved, and waste acid treatment emission requirements can be met.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

Simplified industrial method for recovering silicon carbide from mortar generated in cutting process of silicon wafers

InactiveCN101875492AAvoid difficult sortingEasy to operateSemiconductor/solid-state device manufacturingLubricant compositionSolid componentDiluent

The invention relates to a simplified industrial method for recovering silicon carbide from mortar generated in cutting process of silicon wafers. The method comprises the steps of: 1. adding diluent in the cutting mortar for reducing system viscosity; 2. carrying out primary separation on the mortar subjected to viscosity reduction by using a precise filter A, and setting and controlling filtering precision according to the requirement of silicon material wire-electrode cutting on the particle size distribution of a silicon carbide abrasive to obtain a solid component S1; 3. carrying out alkali wash, acid wash and rinse on the solid component S1, drying a wet material to directly obtain high-quality silicon carbide which meets the requirement of the silicon material wire-electrode cutting; 4. carrying out secondary separation on the mortar fluid subjected to the primary separation by using a precise filter B, and controlling the filtering precision to ensure that smallest passing particles which can be retained are below 2mu m so as to obtain a solid substance S2, and then separating clear liquid; and 5. carrying out alkali wash, acid wash and rinse on the solid component S2 obtained after secondary separation, drying a wet material to collect and obtain silicon carbide micropowder which has smaller particle size and can be used in other industrial occasions.

Owner:JIANGSU JIAYU RESOURCE UTILIZATION

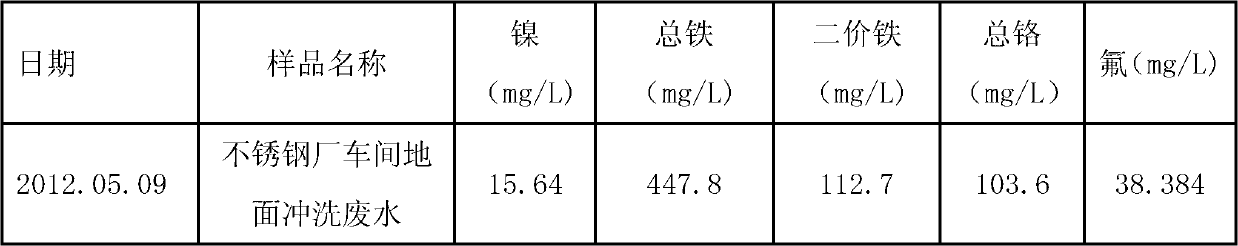

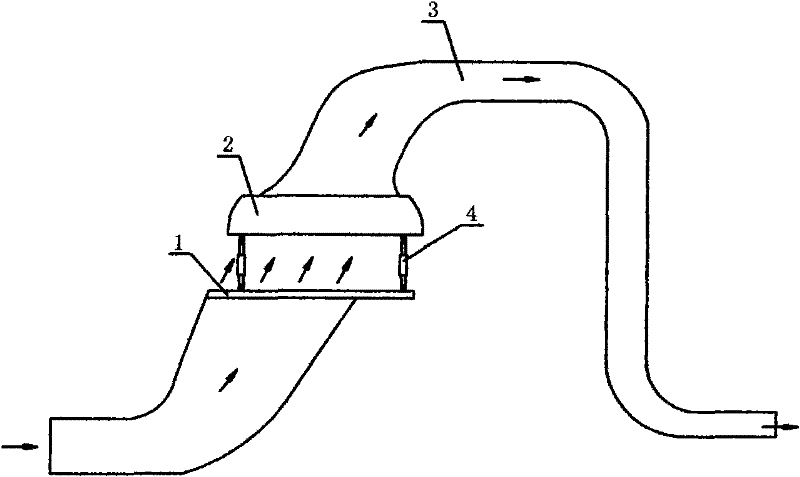

Air preheating and flue gas waste heat utilizing system and method

InactiveCN104807035ASolve the existing disadvantagesRaise the inlet air temperatureFeed water supplyCombustion processAir preheaterFlue gas

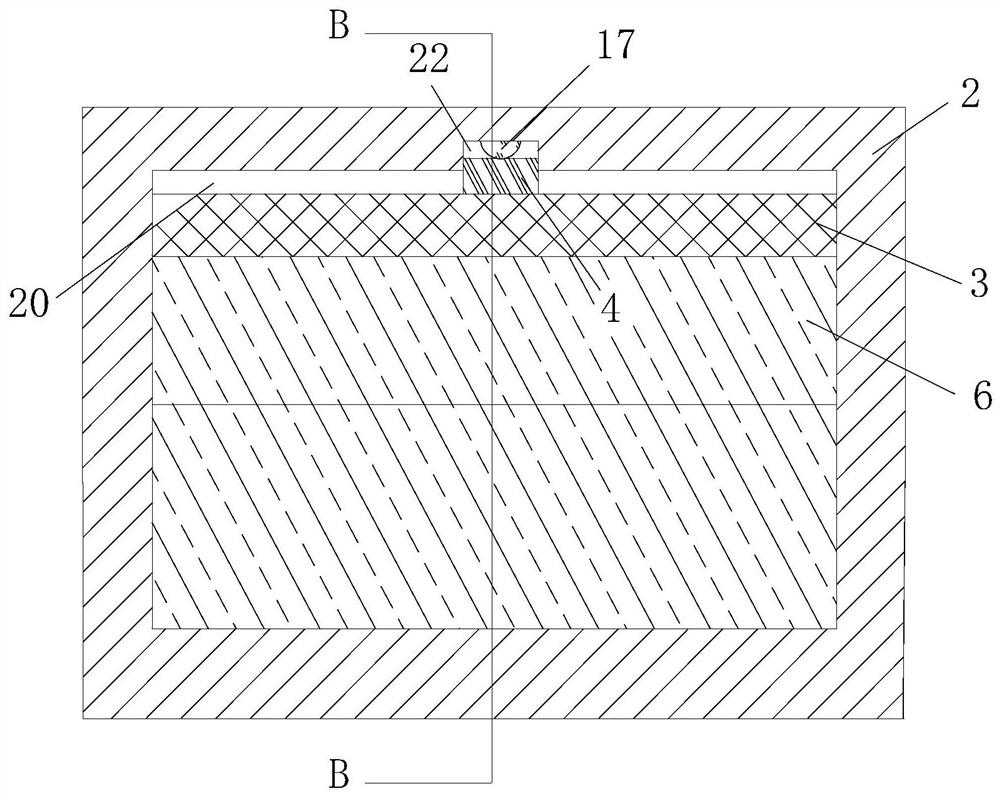

The invention particularly aims to the technical field of boiler air preheating. A disclosed air preheating and flue gas waste heat utilizing system comprises a flue gas channel (17), an air channel (20), an air preheater (9), a condensed water flue heat exchanger (8) and a condensed water air channel heat exchanger (19), and further comprises a condensed water feeding main pipe (15) and a condensed water returning main pipe (12); the flue gas channel (17) and the air channel (20) are connected with the air preheater (9); the condensed water flue heat exchanger (8) is arranged on the flue gas channel (17) at the back of the air preheater (9) in a flue gas flowing direction; the condensed water air channel heat exchanger (19) is arranged on the air channel (20) at the front of the air preheater (9) in an air flowing direction. According to the air preheating and flue gas waste heat utilizing system, flue gas discharge and heat exchange can be automatically adjusted according to change of operation conditions; on the premise of ensuring the safety of a heated surface and the regular operation of the system, the maximization of the heat circulation efficiency and the system economical efficiency is ensured.

Owner:郝江平

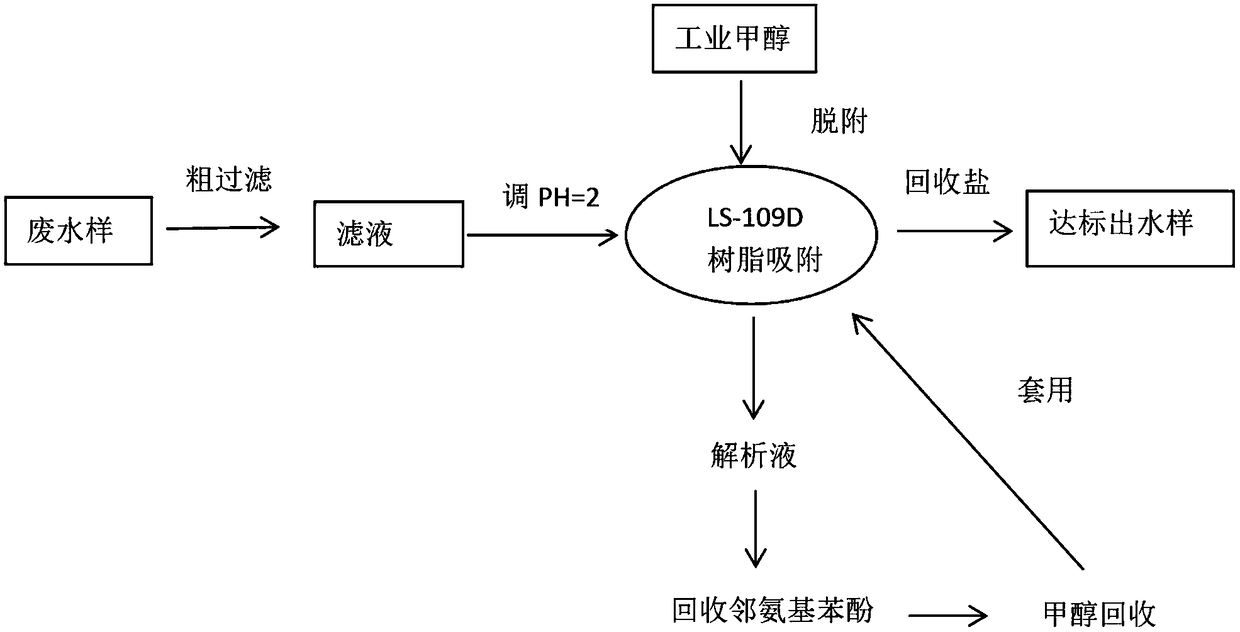

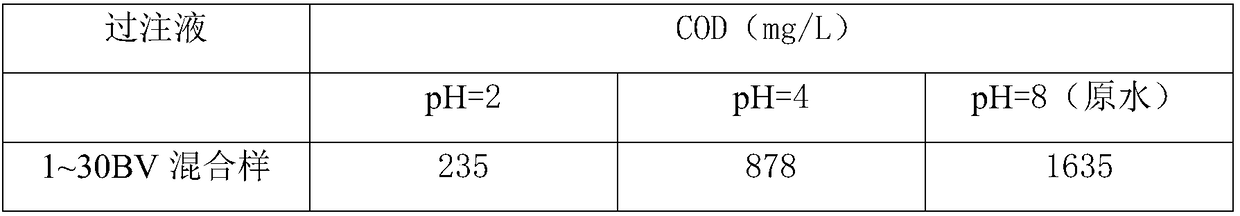

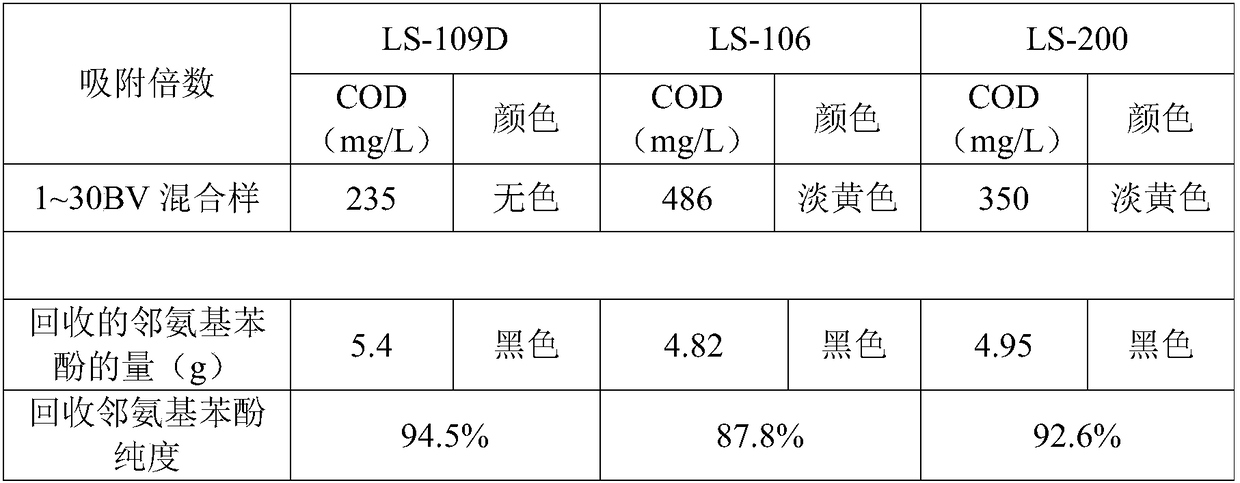

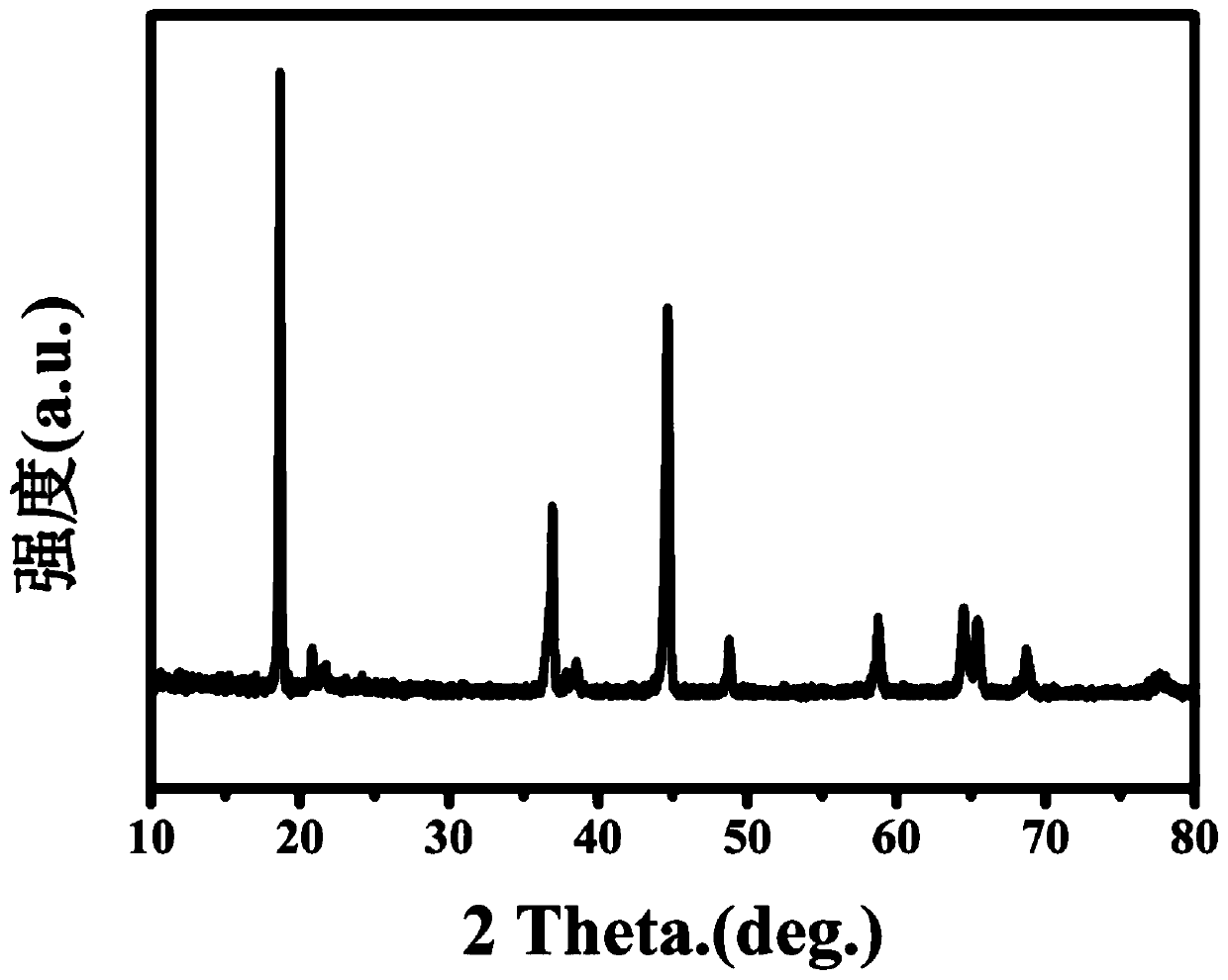

Method for recovering ortho-aminophenol in concentrated brine

InactiveCN108793493AAvoid pollutionHigh recycling efficiencyOrganic compound preparationWater contaminantsHigh concentrationOrganic solvent

The invention discloses a method for recovering ortho-aminophenol in concentrated brine. The method includes adjusting the pH value of high-concentration ortho-aminophenol production wastewater in theconcentrated brine, then introducing into a macroporous styrene series adsorption resin to adsorb the ortho-aminophenol to the macroporous styrene series adsorption resin, utilizing an organic solvent to conduct elution on the saturated macroporous styrene series adsorption resin, and finally recovering the ortho-aminophenol from a solvent desorption solution. According to the method, the problemthat the enterprise water treatment is not up to standard is effectively solved, the economic benefit is improved to the greatest extent, and unification of wastewater treatment and resource recycling is achieved.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD

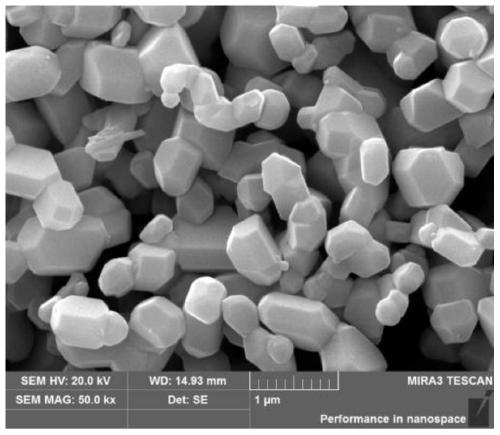

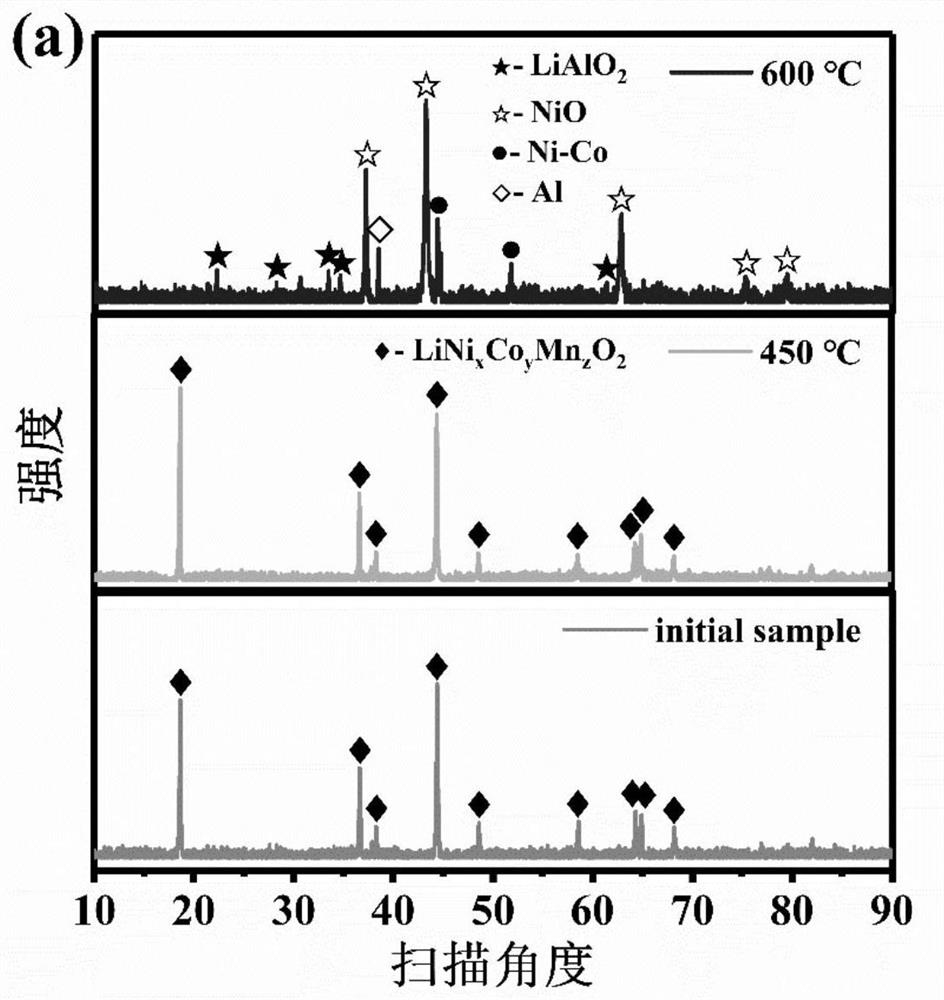

Method for regenerating lithium-rich manganese-based positive electrode material by utilizing waste lithium battery

ActiveCN111082178AAvoid stepwise separation and recyclingIncrease valueCell electrodesWaste accumulators reclaimingLithium carbonatePhysical chemistry

The invention discloses a method for regenerating a lithium-rich manganese-based positive electrode material from a waste lithium battery. The method comprises the steps of carrying out carbon thermalreduction on positive electrode material powder obtained by pretreatment, reducing the waste ternary nickel-cobalt-manganese positive electrode material into a mixture of nickel, cobalt, lithium carbonate and manganese oxide by carbon thermal reduction, carrying out ammonia leaching, then preparing a precursor by a one-step sol-gel method, and finally, calcining to obtain the lithium-rich manganese-based positive electrode material. According to the method, the valuable metal mixed powder is subjected to carbon thermal reduction, so that the process requirement that pressurization must be adopted in the leaching process is avoided, step-by-step separation and recovery of multiple metals are avoided, the technological process is shortened, the operation is easy, the cost is reduced, and the value of recovered and regenerated products is improved.

Owner:兰溪博观循环科技有限公司

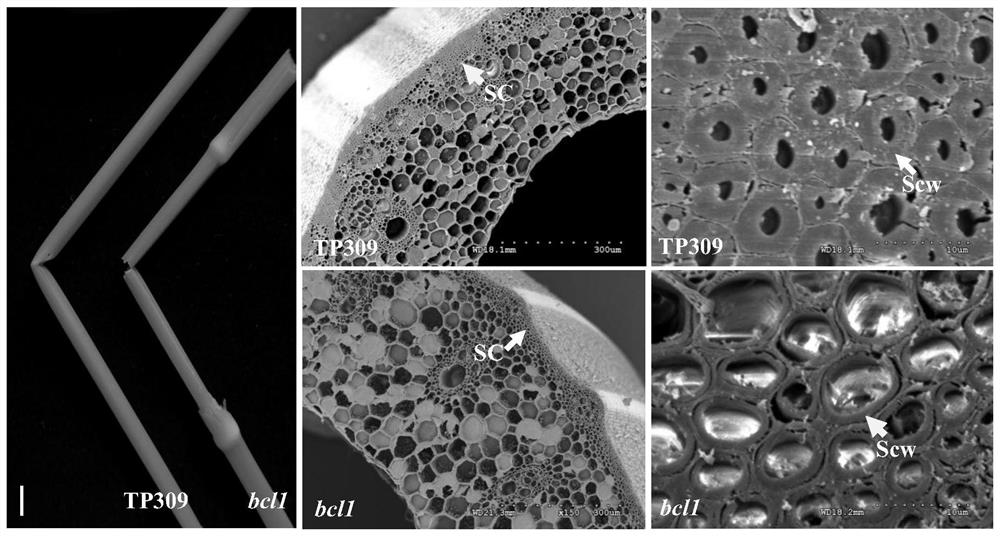

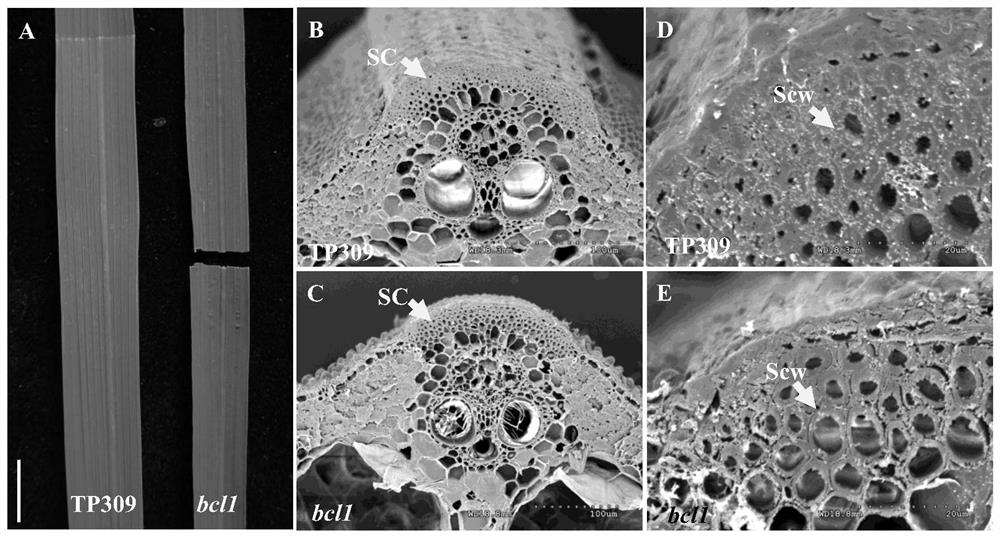

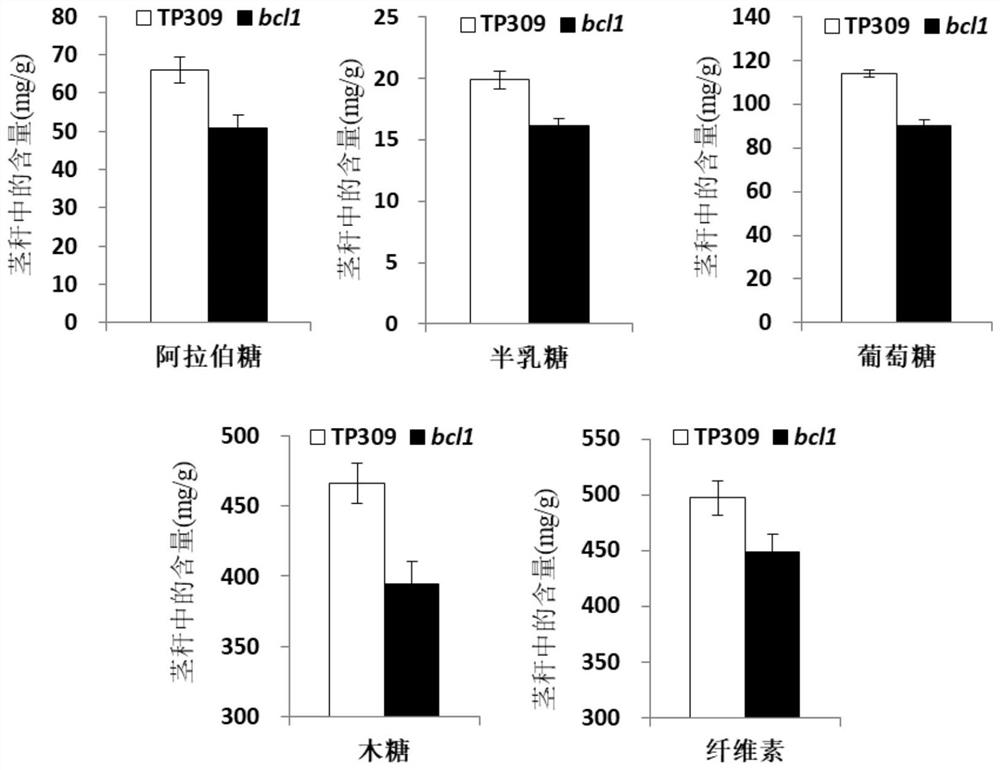

Application of protein and related biological materials thereof to regulation and control on mechanical strength of plants

ActiveCN112250742AReduce contentHigh recycling efficiencyPlant peptidesFermentationBiotechnologyAssociated organism

The invention discloses application of a protein and related biological materials thereof to regulation and control on mechanical strength of plants. The invention firstly discloses application of a BCL1 protein and related biological materials thereof to regulation and control on mechanical strength of plants. The invention further discloses a method for cultivating transgenic plants of which stalks and / or leaves have increased brittleness. The invention not only provides the theoretical basis for cultivating fragile stalk and fragile leaf plant materials and rice varieties of which cell wallcomponents are easy to degrade and which is high in recycling efficiency, but also provides a new gene resource for rice breeding.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Regeneration system and method for positive plate of lithium-ion battery

ActiveCN107611514AHigh level of automationSuitable for large-scale productionWaste accumulators reclaimingBattery recyclingElectrolysisManganese

The invention discloses a regeneration system and method for a positive plate of a lithium-ion battery. The regeneration system comprises a blade crusher, an aluminum separation tank, a reduction roasting segment, a lithium separation tank, an acid dissolving tank, an electrolytic temporary storage tank and an electrolytic tank which are sequentially connected. According to the regeneration method, further separation of three elements, namely nickel, cobalt and manganese in the positive plate of the lithium-ion battery is achieved by using the regeneration system through the processes, such ascrushing, aluminum separation, reduction roasting, lithium separation, acid dissolving and electrolysis in sequence, wherein the cobalt is filtered and separated in a form of a Co3O4 sediment, the nickel is taken down from a negative plate in a form of metal nickel and the manganese is evaporatively crystallized and recovered from remaining electrolyte in a form of manganese sulfate. The regeneration system and method are high in automation degree and suitable for massive production; the system is totally enclosed, and is low in harm to the environment and human body; complete regeneration ofthe battery material is achieved and the recovery benefit is high; and nickel-cobalt-manganese metal separation is achieved through a treatment process without an extraction agent and only electric energy is consumed, so that the process is environment-friendly.

Owner:KUTTLER AUTOMATION SYST SUZHOU

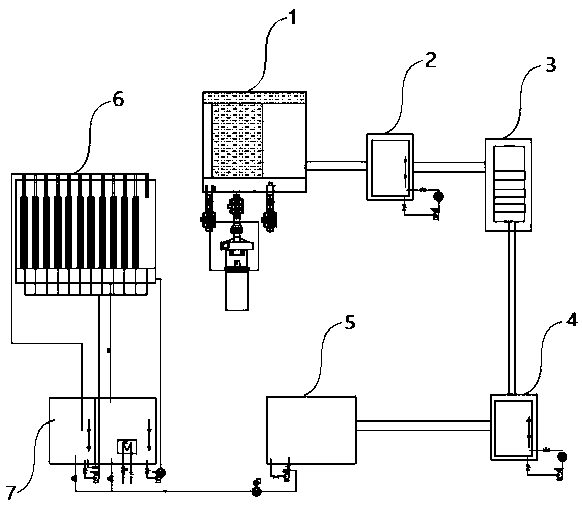

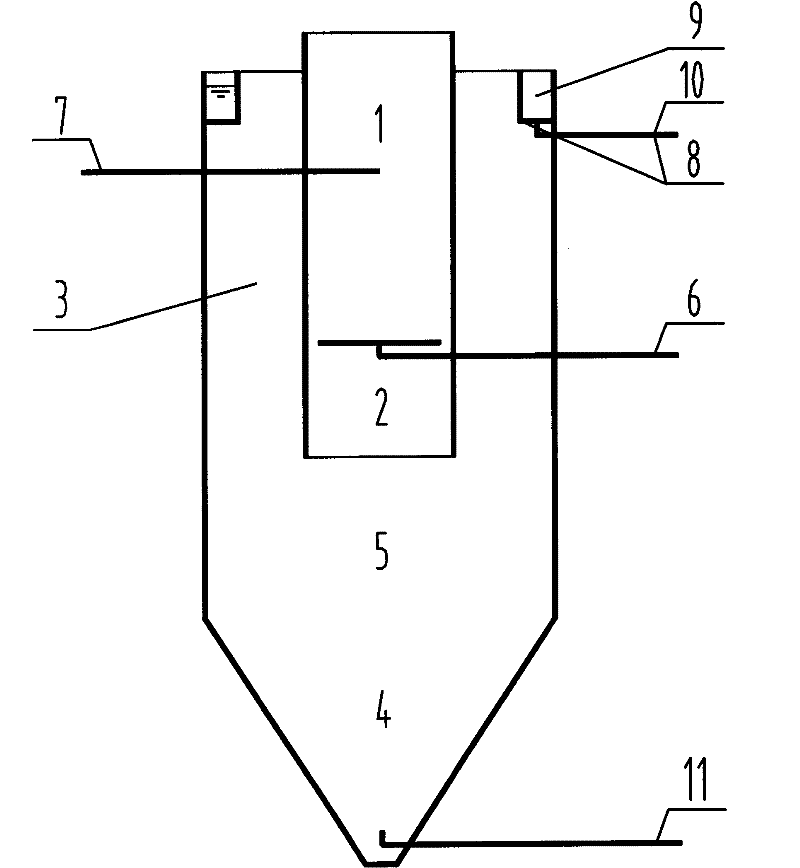

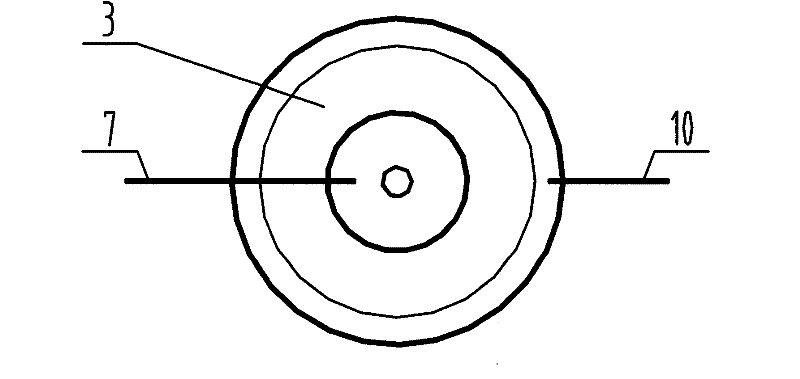

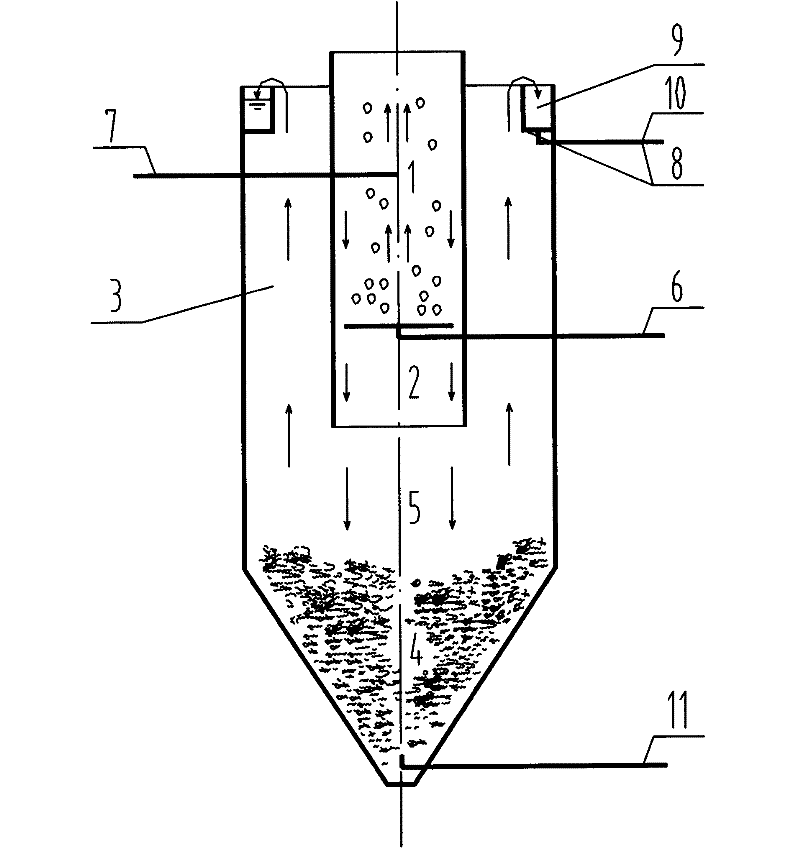

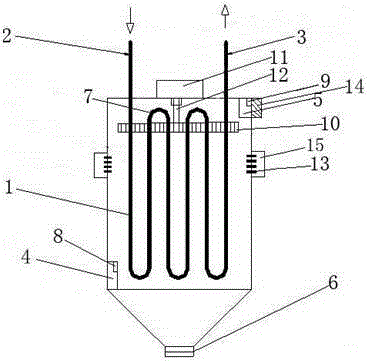

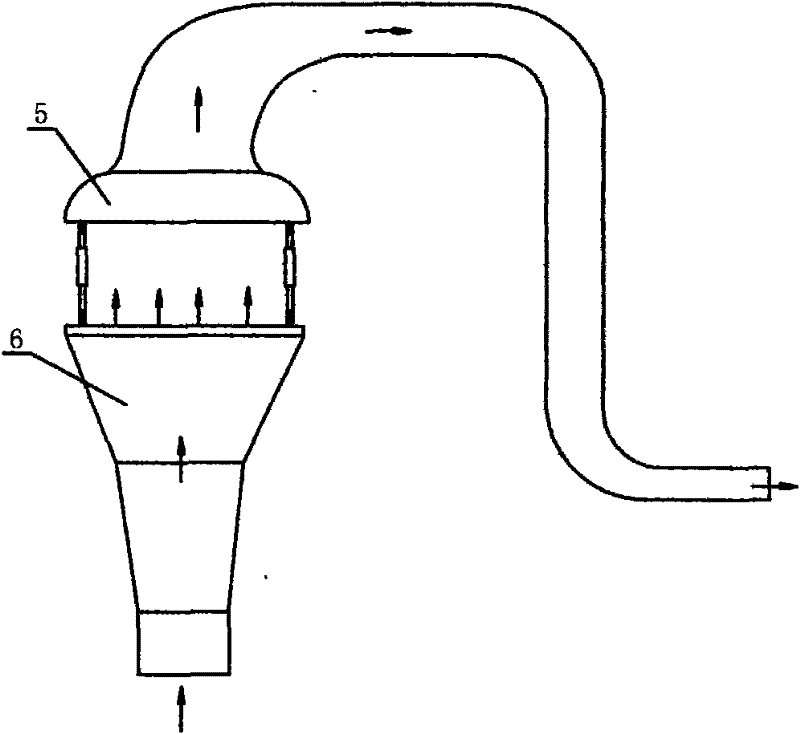

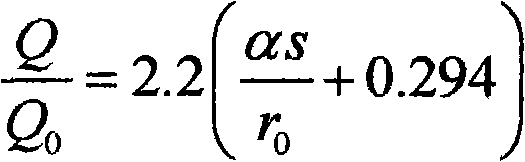

Phosphorus recovery crystallization reactor and phosphorus recovery method

ActiveCN101602535BHigh recycling efficiencyLow costPhosphorus halides/oxyhalidesWater/sewage treatmentRecovery methodHigh concentration

A phosphorus recovery crystallization reactor and a phosphorus recovery method, the reactor is a structure of inner and outer double cylinders, the inner cylinder is located at the center of the outer cylinder of the reactor, and the reactor includes: an aeration stripping zone, a crystallization reaction zone , a precipitation separation area, a high-concentration phosphorus sludge area, and a buffer zone; wherein, the crystallization reaction area and the precipitation separation area are connected through the upper part of the buffer zone, so that the sewage after the crystallization reaction in the crystallization reaction area enters the precipitation The separation area does not affect the high concentration phosphorus sludge area. The present invention fully benefits the effective components in the anaerobic treatment of high-concentration livestock and poultry wastewater, improves the pH value of the anaerobic effluent by means of aeration and blow-off, utilizes the higher concentration of phosphorus and ammonia nitrogen in the livestock and poultry wastewater, and passes the phosphorus through Magnesium ammonium phosphate is removed in the form of crystals, and the removal rate of total phosphorus can reach 50-60%, without adding any chemical agents. The recovered phosphorus is in the form of crystals, which is beneficial to the utilization of recovered phosphorus.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

Method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid

The invention discloses a method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid. Dimethyl phosphite residual liquid is subjected to the steps of filter pressing, acidolysis, secondary acidolysis concentration, crystallization, material washing and the like to obtain phosphorous acid. In the method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid, phosphorous acid is recovered by combination of high-temperature distillation and temperature-lowering crystallization, the recovery efficiency is high, and the existing chloromethane recovering device is utilized for recovering chloromethane during the recovery process of phosphorous acid, and therefore, the recovery benefit is further enhanced.

Owner:HUBEI TAISHENG CHEM

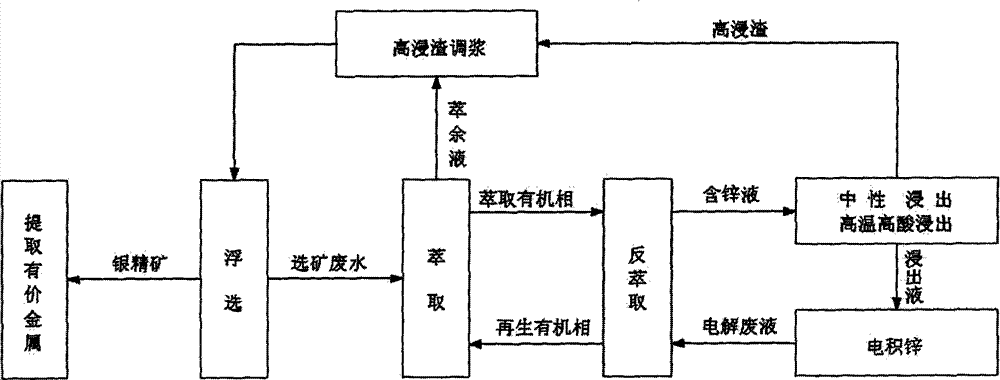

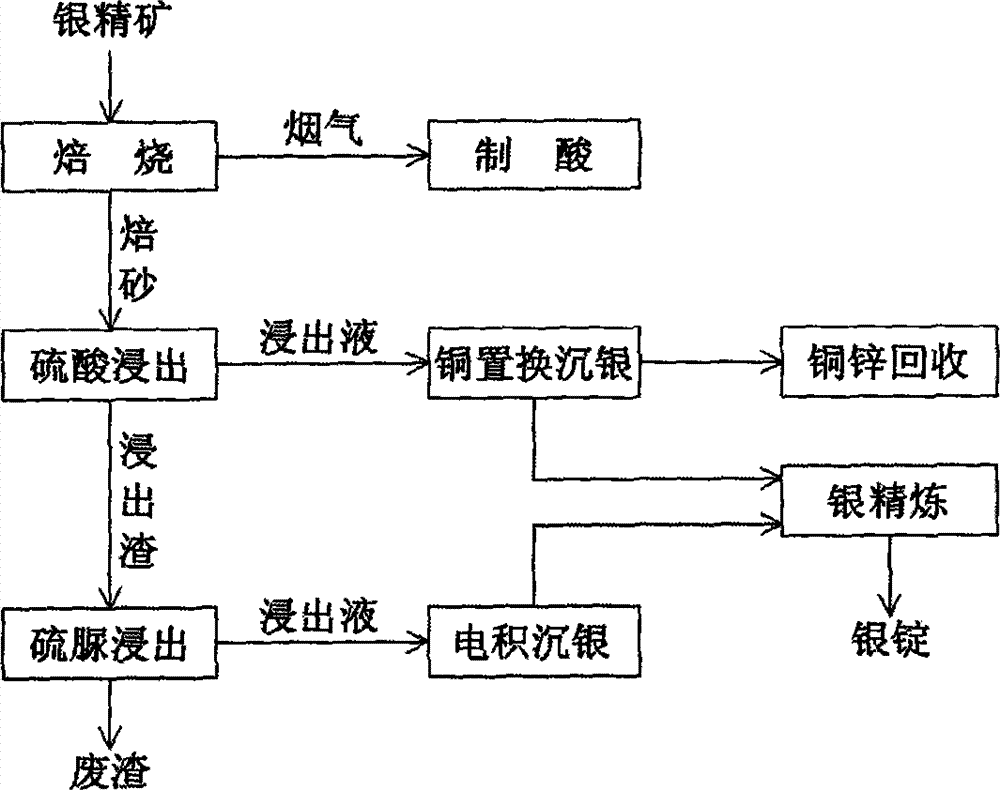

Comprehensive zinc hydrometallurgy recovery system technique

InactiveCN103243349AExtend the industrial chainClean production is environmentally friendlyPhotography auxillary processesProcess efficiency improvementZincBeneficiation

The invention discloses a comprehensive zinc hydrometallurgy recovery system technique which comprises a zinc hydrometallurgy technique, a floatation recovery technique and an extraction recovery technique; high leaching residue is obtained by leaching at high temperature and high acid through the zinc hydrometallurgy technique, and electrolysis waste liquor can be generated by electrodepositing zinc; and according to the floatation recovery technique, floatation is carried out after mixing the high leaching residue size, and silver concentrate and beneficiation wastewater are generated in the floatation process; and the extraction recovery technique consists of an extraction process and a reextraction process, the beneficiation wastewater is extracted in an extraction tank in the extraction process through an extractant, extraction raffinate is used for the high leaching residue size mixing in the floatation recovery technique, the organic extraction phase is reextracted in the reextraction process by the electrolysis waste liquor, regenerative organic phase returns back to the extraction process, and zinc-containing liquid flows in the neutral leaching and high-temperature and high-acid leaching steps in the leaching step of the zinc hydrometallurgy technique. According to the comprehensive zinc hydrometallurgy recovery system technique, the recovery rate of valuable metal is high, the economic benefits are obvious, no hidden safety hazard exists, and the environment pollution can be favorably reduced.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

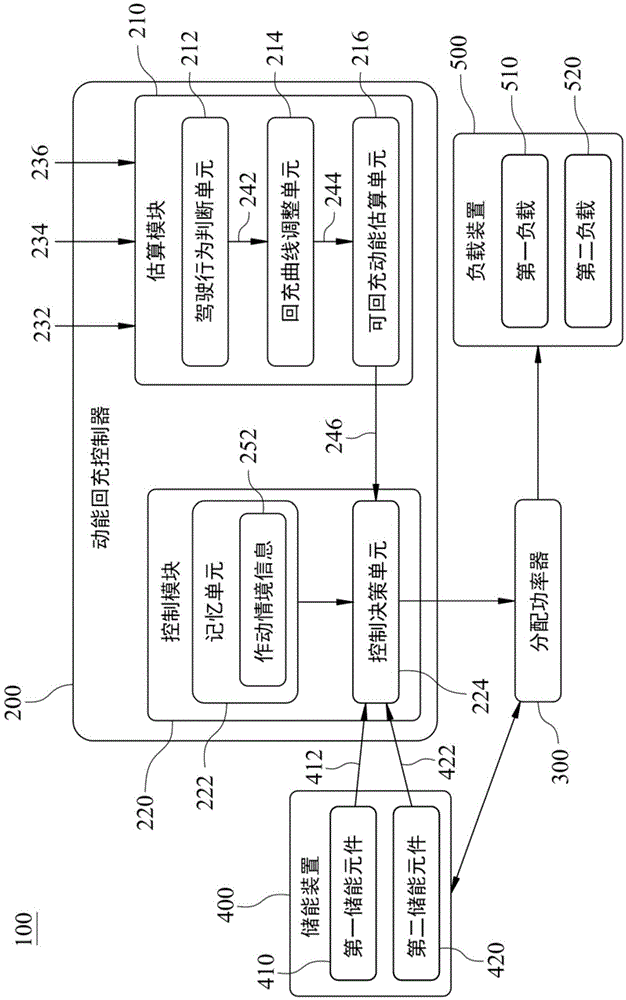

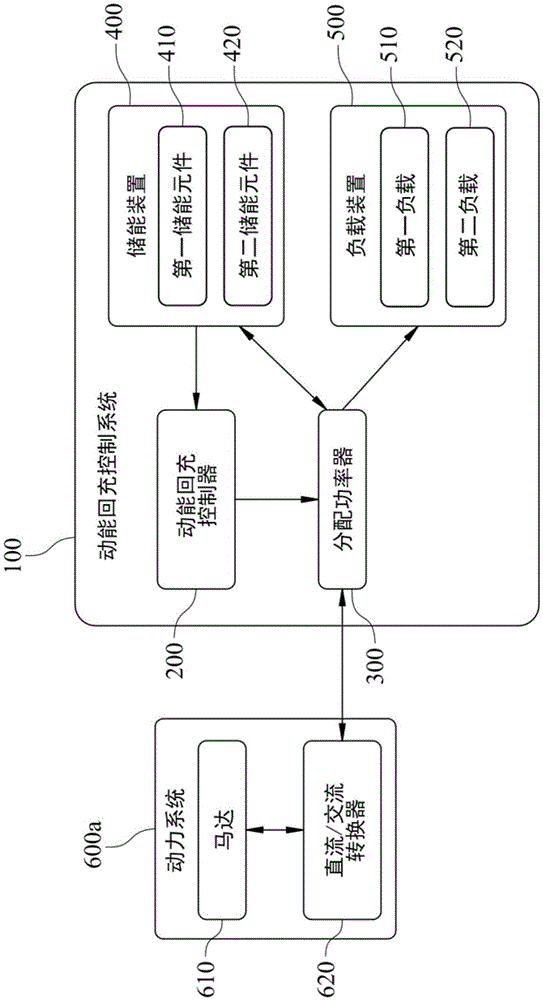

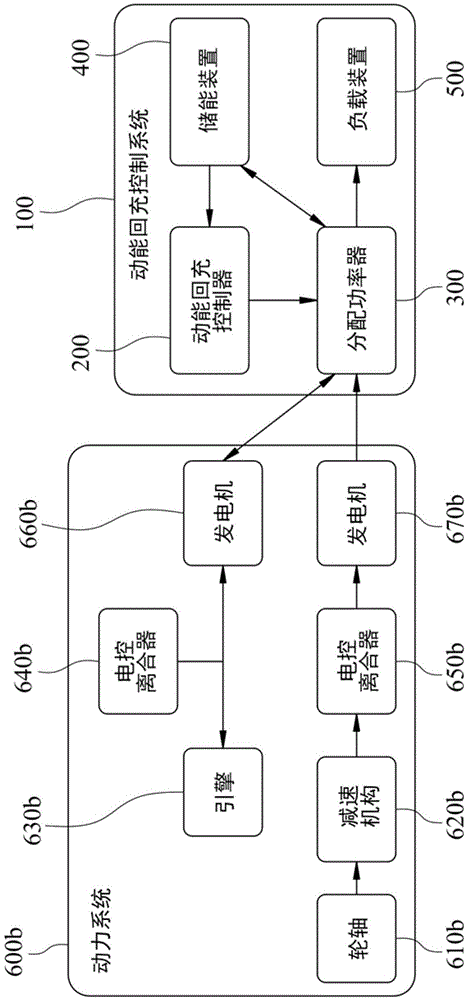

Kinetic energy recharging controller and control method thereof as well as kinetic energy recharging control system

ActiveCN106828114AHigh recycling efficiencyExtend your lifeElectrodynamic brake systemsElectric/fluid circuitStored energyControl system

The invention provides a kinetic energy recharging controller and a control method thereof as well as a kinetic energy recharging control system. The kinetic energy recharging controller comprises an estimation module and a control module. The estimation module comprises a driving behavior judging unit, a recharging curve adjusting unit and a rechargeable kinetic energy estimation unit. The driving behavior judging unit is used for judging a vehicle speed signal, an accelerator pedal signal and a brake pedal signal to generate a driving mode. The recharging curve adjusting unit is used for estimating brake recharging target data according to the driving mode. The rechargeable kinetic energy estimation unit is used for estimating a rechargeable kinetic energy value according to the brake recharging target data and the vehicle speed signal. The control module is used for deciding actuation situation information according to the rechargeable kinetic energy value and a stored energy recyclable power value and outputting the actuation situation information to a vehicle. Therefore, the rechargeable kinetic energy is adjusted through the state of an energy storage element so that the kinetic energy recycling benefit can be increased, the service life of the energy storage element can be prolonged, the full charge endurance can be increased and the oil consumption can be reduced.

Owner:AUTOMOTIVE RES & TESTING CENT

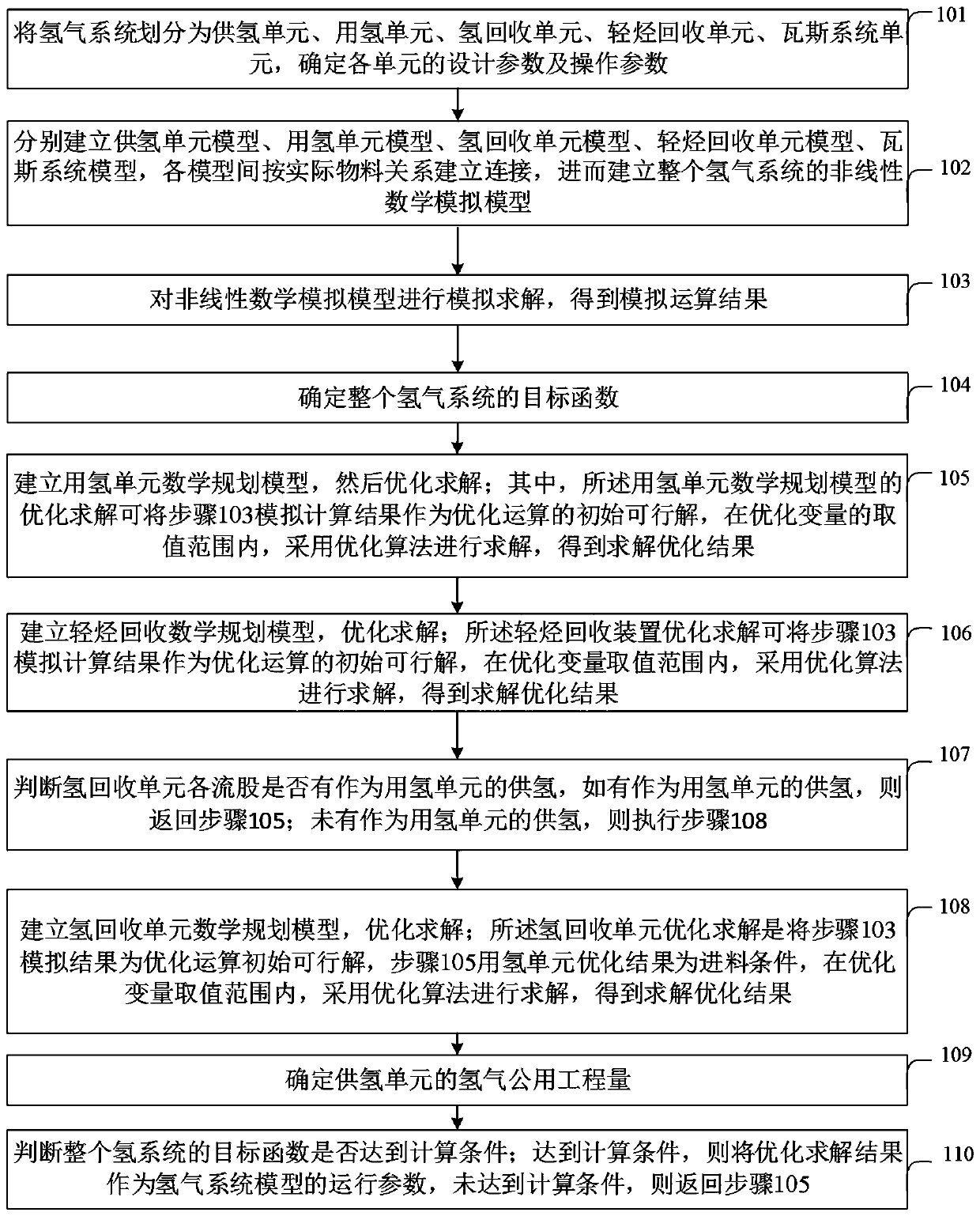

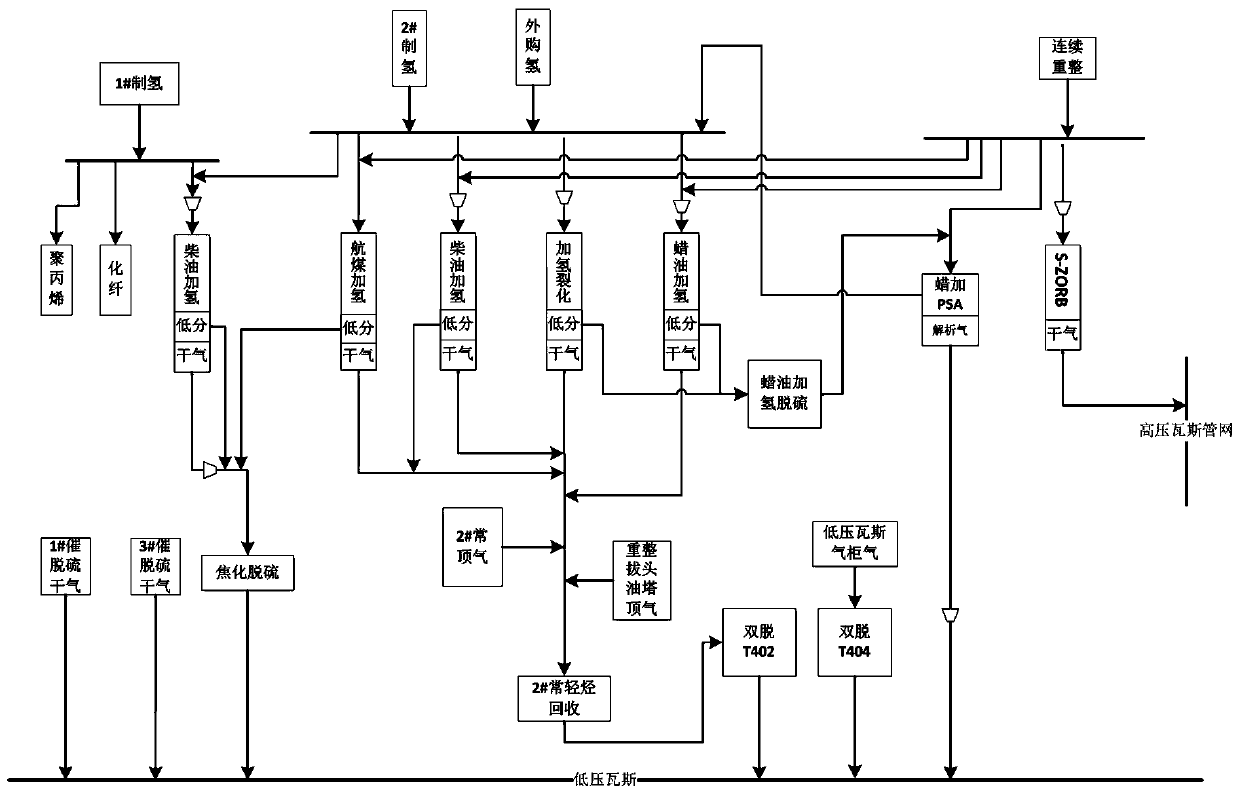

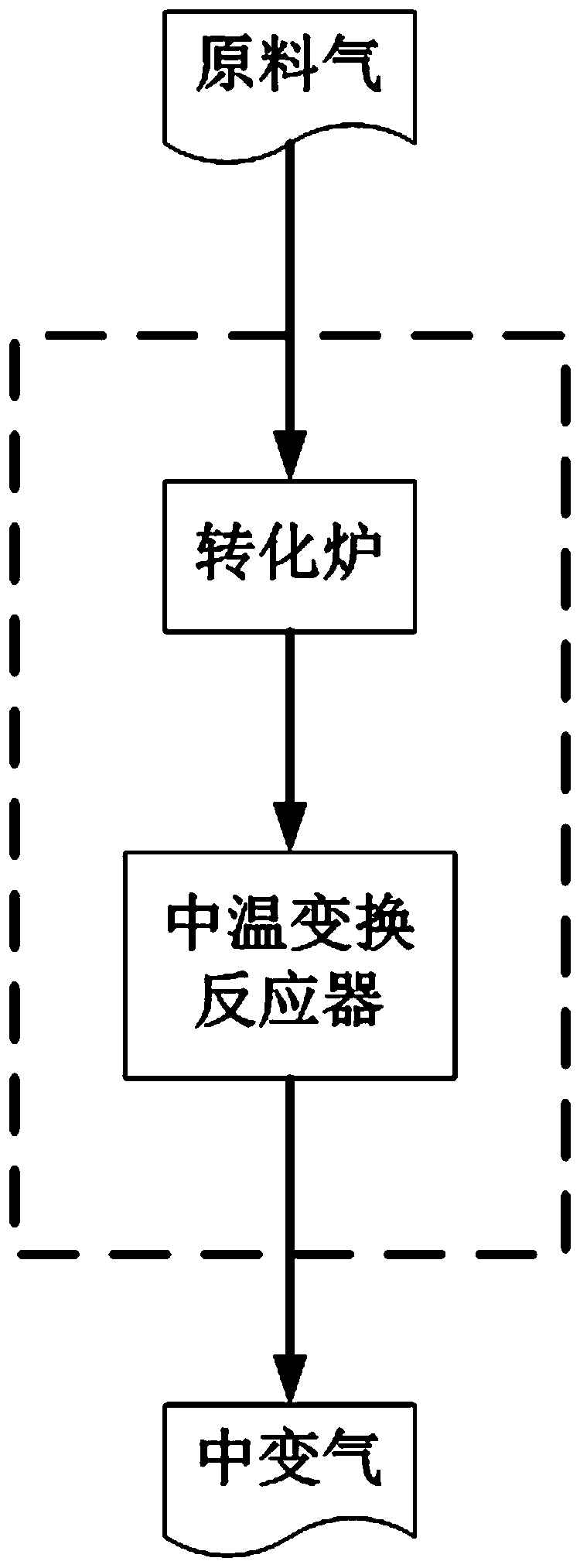

Hydrogen resource optimization method and system

ActiveCN110020444AImprove recycling efficiencyImprove computing efficiencySpecial data processing applicationsMathematical simulationMathematical model

The invention discloses a hydrogen resource optimization method and system. The method comprises the following steps: dividing each unit of a hydrogen system; establishing a nonlinear mathematical simulation model of each unit model and the whole hydrogen system; performing simulation solving on the nonlinear mathematical simulation model; determining an objective function of the whole hydrogen system; establishing a hydrogen using unit mathematical planning model; establishing a light hydrocarbon recovery mathematical planning model; judging whether each flow of the hydrogen recovery unit isused as hydrogen supply of the hydrogen utilization unit or not; establishing a hydrogen recovery unit mathematical planning model; determining the hydrogen public work amount of the hydrogen supply unit; and judging whether the objective function of the whole hydrogen system meets a calculation condition. The method can effectively improve the calculation efficiency of the optimization solution of the hydrogen system under the complex hydrogen system, obtain the optimal solution of the hydrogen system, obtain the optimal matching scheme, improve the comprehensive recovery benefit of hydrogen / light hydrocarbon, and solve the problems of complex mathematical model, difficult convergence and the like caused by the comprehensive optimization of hydrogen and light hydrocarbon of the hydrogen system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiler waste heat collecting and waste gas purifying system

InactiveCN106765257AHigh recycling efficiencyAvoid accumulationCombustion technology mitigationNon-rotary device cleaningPlate heat exchangerRecuperator

The invention relates to a boiler waste heat collecting and waste gas purifying system which comprises a boiler waste heat collecting tubular heat exchanger and a waste gas purifying device, wherein the boiler waste heat collecting tubular heat exchanger communicates with the waste gas purifying device in sequence. Through an electric dust removal brush arranged in the heat exchanger and an ultrasonic atomizer arranged on the side wall of the heat exchanger, smoke is prevented from being accumulated on the heat exchange tube wall, the high heat exchange efficiency can be kept continuously, waste heat recycling is conducted sufficiently, and the recycling benefits of the waste heat system are improved; and by arranging the waste gas purifying device at an air outlet of the boiler waste heat collecting tubular heat exchanger, waste gas exhausted into the air is non-toxic and harmless, and environment pollution is avoided.

Owner:JIANGSU HUAYUE SPECIAL EQUIP

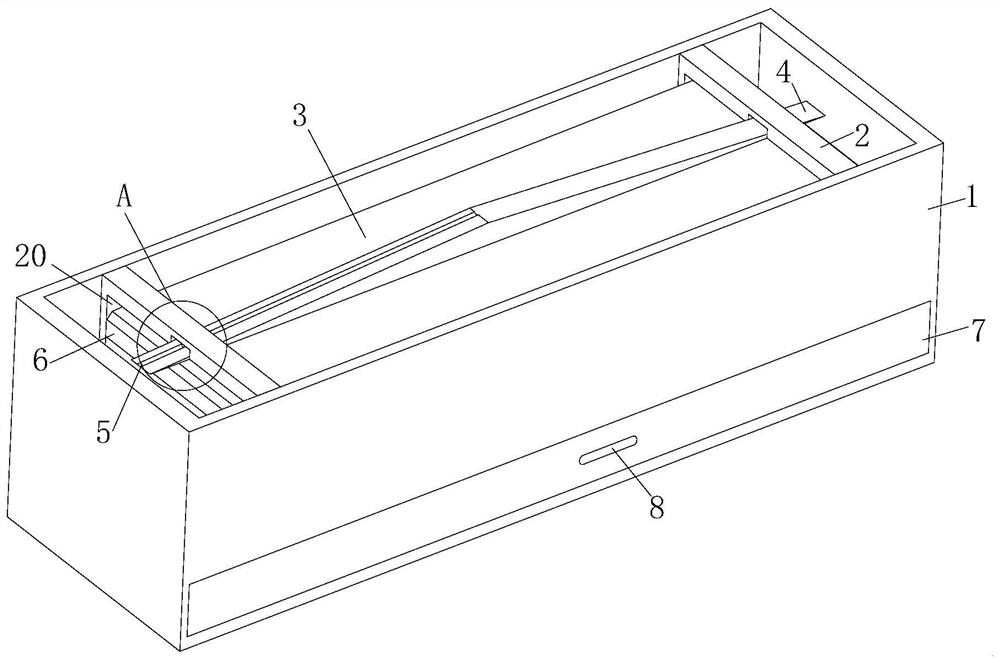

Sand box for copper furnace foundry casting

PendingCN113828738AGuaranteed tightnessFull compaction operationMould handling/dressing devicesMoulding machinesFoundryEngineering

The invention relates to the field of sand boxes, in particular to a sand box for copper furnace foundry casting. The sand box comprises a sand box body, wherein a filter screen is fixedly connected to the position, close to the lower end, in the sand box body through screws, the interior of the sand box body is divided into two parts by the filter screen, the part above the filter screen serves as a sand cavity, and the part below the filter screen serves as a collecting cavity; an opening is formed in the position, close to the bottom of the outer surface of the front end of the sand box body, below the filter screen, a collecting box is arranged in the opening, the collecting box is movably connected into the collecting cavity through the opening and is sealed with the periphery of the opening, and a grip is fixedly connected to the middle of the front end of the outer surface of the collecting box; and a bottom plate is arranged above the filter screen, and rotating shafts are fixedly connected to the left side and the right side of the bottom plate. According to the structure of the device, compaction of the left side and the right side of sand before casting can be achieved, and compaction can be conducted from top to bottom; automatic sand discharging can be conducted when movable plates reset, so that the recovery efficiency is greatly improved; and after casting is completed, caked sand can be smashed, so that the sand recovery benefit is improved.

Owner:徐永上

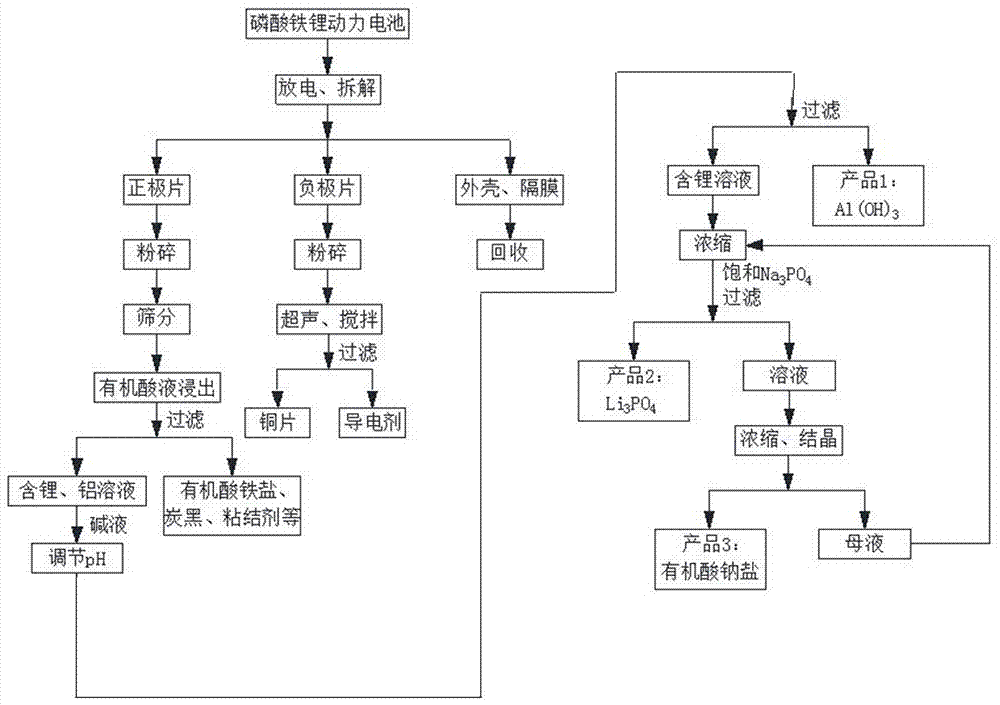

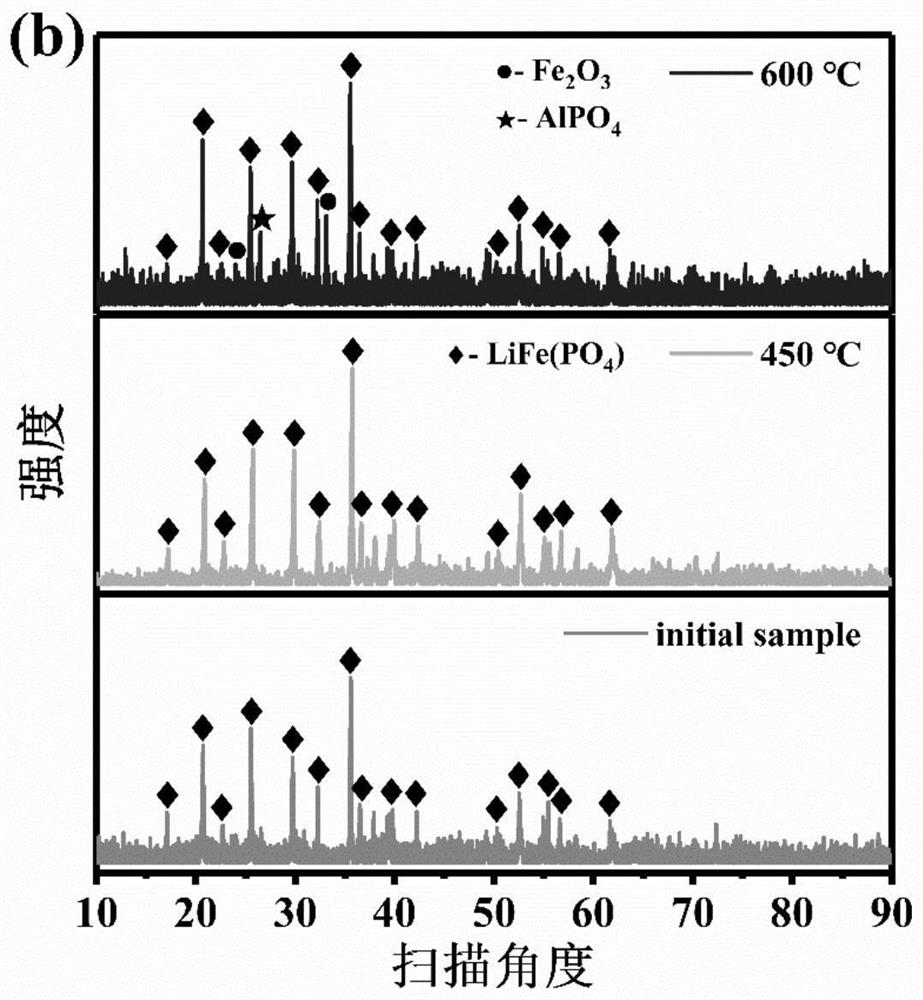

A kind of recycling method of lithium iron phosphate power battery

ActiveCN105244564BAchieve separationSimple processWaste accumulators reclaimingProcess efficiency improvementSodium saltRaw material

The invention provides a method for recycling a lithium iron phosphate power battery. The method comprises the steps that discharging and disassembling of the lithium iron phosphate power battery are performed for separating out positive and negative electrode plates, a membrane and a shell, and the membrane and the shell are directly recycled; the negative electrode plate is smashed for ultrasonic and stirring treatment, filtering is performed and a copper sheet is recycled; after the positive electrode piece is smashed and screened, organic acid is used for performing a leaching reaction, filtering is performed to separate a solution containing lithium and aluminum from filter residues including organic acid ferric salt, carbon black, binding agents and the like; alkali liquor is added into the filtrate to obtain Al(OH)3 sediments which are separated from the solution containing lithium; the solution containing lithium is treated and then lithium can be recycled; after the lithium is recycled from the solution, the crystallization step is performed to obtain an organic acid sodium salt product. According to the method, the organic acid liquor is used for directly leaching iron and the like in the lithium iron phosphate positive electrode piece, the recycling technology is simplified, conventional equipment and raw materials are adopted, lithium, aluminum and copper of the lithium iron phosphate battery positive electrode material are economically, easily and conveniently recycled, and the organic acid sodium salt product with the high added value is obtained.

Owner:FUZHOU UNIV

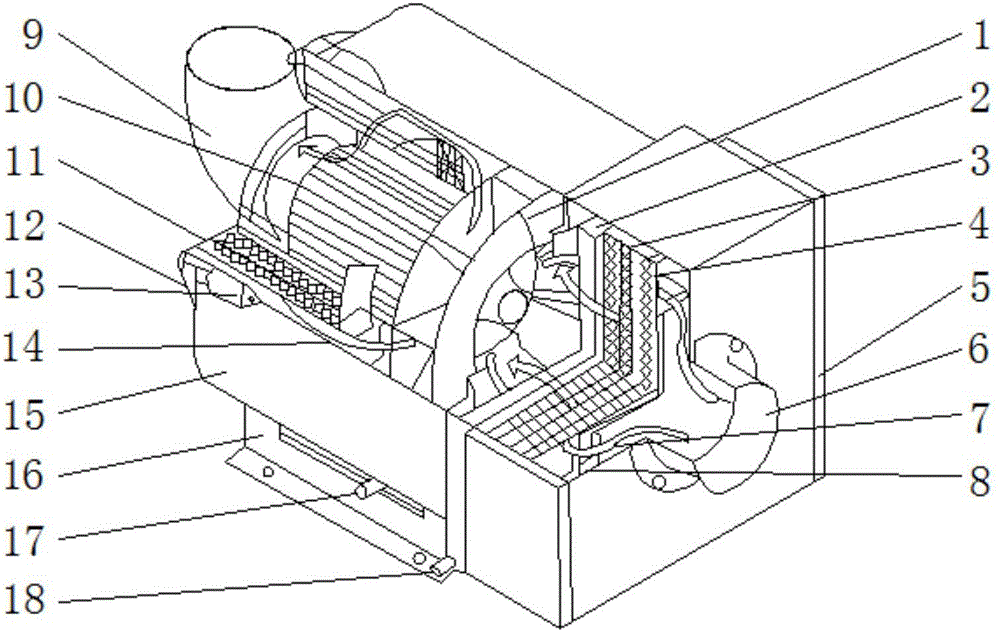

Machine tool oil mist purifier

InactiveCN106422561AReduce spendingComfortable working environmentDispersed particle filtrationTransportation and packagingImpellerMachine utilization

The invention discloses a machine tool oil mist purifier which comprises a front air distribution device, an air inlet, a filtering box, a third filter, a silencer, a box and fixed support legs. An impeller is mounted on the left side of the front air distribution device, a second filter is connected with the inside of a first filter, an air outlet is formed in the left side of the filtering box, a collision filter is mounted in the air outlet and connected between the second filter and the first filter, an air outlet is formed in left side of the box, a rear end cover and a buckle are connected between the third filter and the box, the silencer is connected with the third filter, and the box is connected with the fixed support legs. According to the machine tool oil mist purifier, layer-by-layer secondary filter is achieved, production cost is saved, benefits are expanded, the silencer is arranged, working environments of workers are more comfortable, use ratio of a whole machine is high, and the machine tool oil mist purifier is reasonable and humanized in design and has high recycling benefits.

Owner:王铭

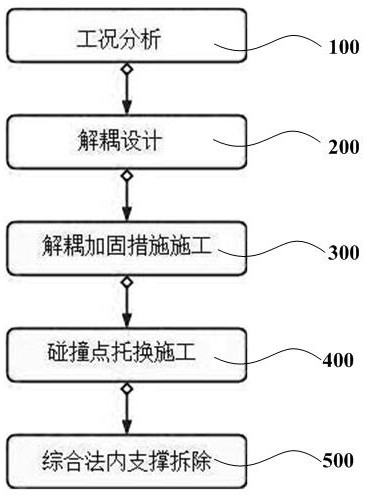

Asynchronous decoupling construction method for large foundation pit coupling inner supporting system

The invention relates to the technical field of building construction, in particular to an asynchronous decoupling construction method for a large foundation pit coupling inner supporting system. The asynchronous decoupling construction method comprises the following steps of working condition analysis, specifically, analyzing the structural working condition of a basement according to a building construction solution; decoupling design, specifically, correspondingly setting decoupling models according to the supporting systems at different positions; decoupling reinforcement measure construction, specifically, conducting reinforcement construction on the weak position of a supporting structure stress system; collision point underpinning construction, specifically, conducting collision inspection of the basement structure and an inner supporting latticed column through a BIM technology, proposing an underpinning construction solution according to the collision inspection result of the latticed column and the structural beam, and conducting construction according to the underpinning construction solution; and dismantling the inner support by a comprehensive method. According to the asynchronous decoupling construction method, many factors restricting the construction period during dismantling of the coupling inner support are overcome, the construction efficiency is improved, energy conservation and environmental protection are achieved, and the resource recovery benefit is improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

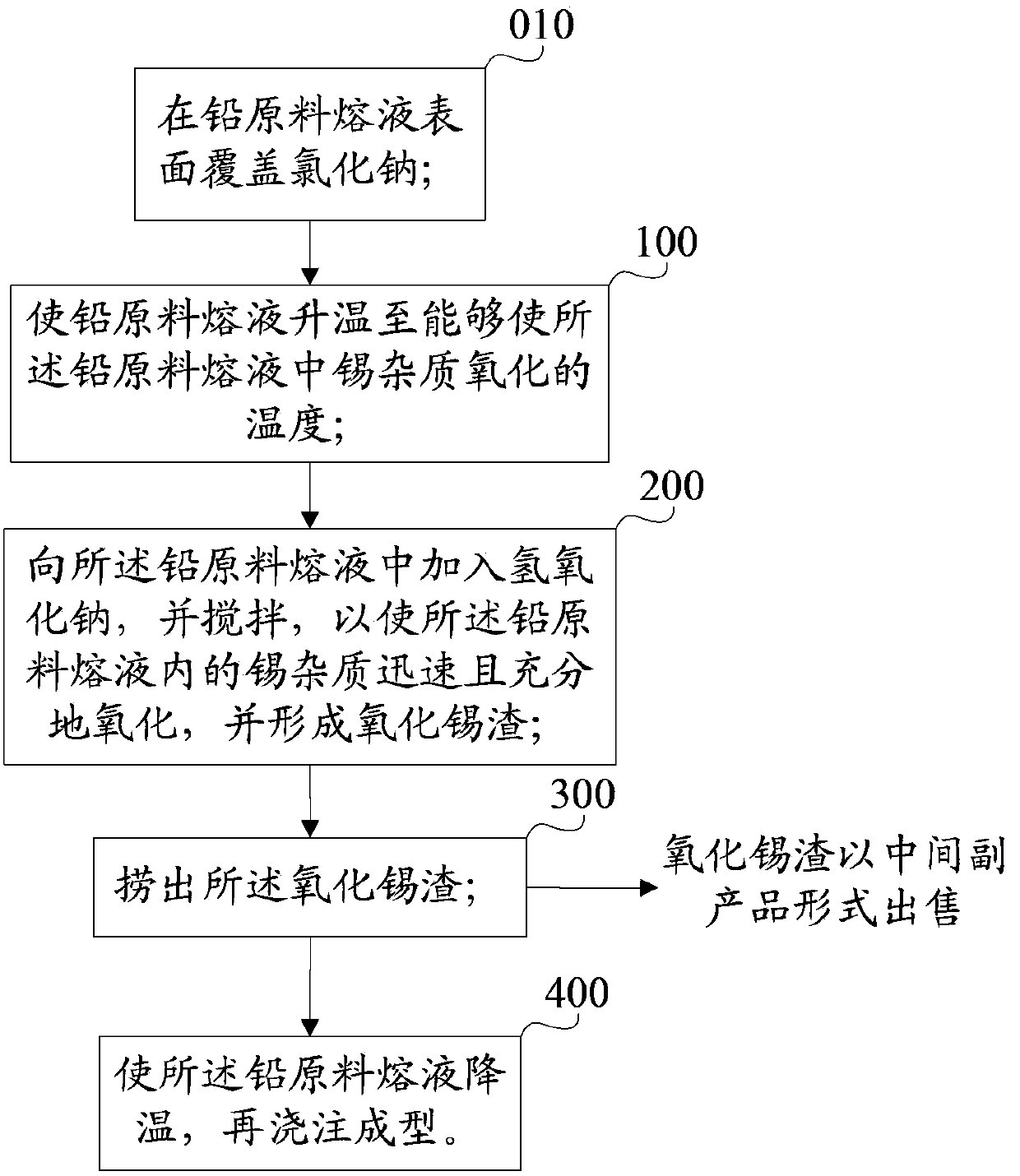

Refining method of tin-containing lead bullion and lead refining production method

InactiveCN103849780AAvoid close electrolytic potentialsImprove current efficiencyProcess efficiency improvementElectrolysisSlag

The invention discloses a refining method of tin-containing lead bullion. The refining method of the tin-containing lead bullion comprises the following steps: (1) heating a molten lead raw material to a temperature which can ensure that tin impurities in the molten lead raw material are oxidized; (2) adding sodium hydroxide to the molten lead raw material, and stirring so as to ensure that the tin impurities in the molten lead raw material are rapidly and fully oxidized to form stannic oxide slag; (3) fishing out the stannic oxide slag. The refining method of the tin-containing lead bullion has the advantages that tin in the lead raw material can be removed, the problem that as the electrolytic potential of tin is close to the electrolytic potential of lead, tin is dissolved in a positive pole and separated out in a negative pole in an electrolytic refining production process, is avoided, the current efficiency is improved, and the electric energy is saved. The invention also discloses a lead refining production method by applying the refining method of the tin-containing lead bullion. The power consumption can be reduced during electrolytic refining.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

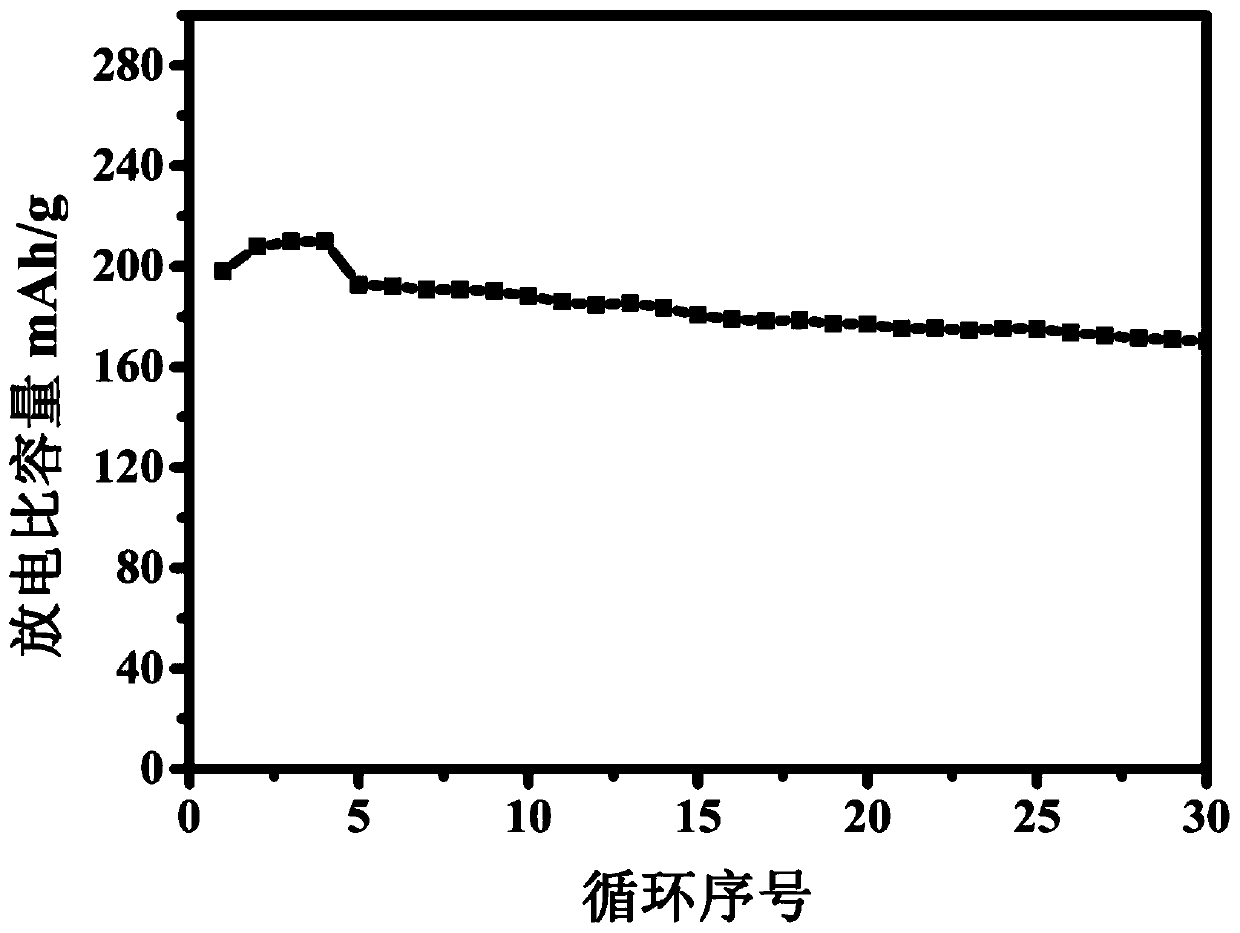

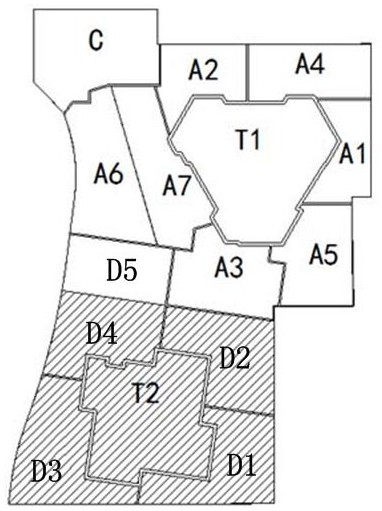

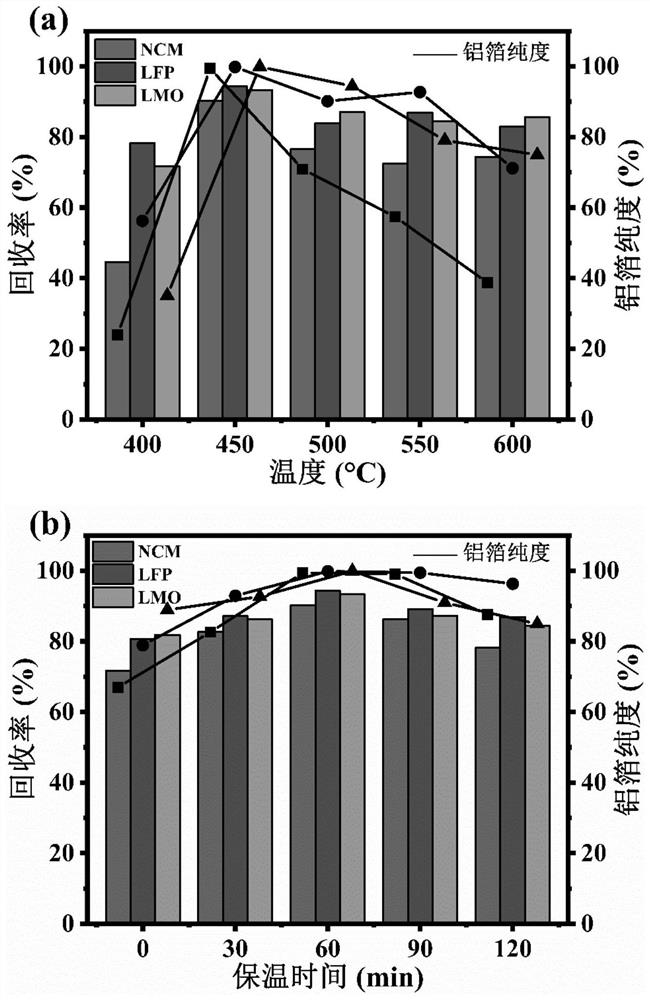

Method for separating and recycling aluminum foil and positive active substances in retired lithium ion power battery

InactiveCN112713328AEfficient separationHigh purityWaste accumulators reclaimingBattery recyclingPower batteryResource recovery

The invention belongs to the technical field of retired lithium ion power battery resource recovery and discloses a method for separating and recovering an aluminum foil and a positive electrode active substance in a retired lithium ion power battery. The method comprises the following steps (1) carrying out discharge treatment on the retired lithium ion power battery, and disassembling to obtain a positive electrode material; (2) carrying out pyrolysis treatment on the positive electrode material obtained in the step (1) under an inert gas condition; and (3) carrying out physical oscillation on the pyrolyzed positive electrode material obtained in the step (2) to obtain an aluminum foil and a positive electrode active substance. For the mixed type retired lithium ion power battery, recovery efficiency of the positive electrode active substance reaches 94.33%, the purity of the aluminum foil reaches 99.92%, and the recovered positive electrode active substance has a complete crystal structure and good electrochemical activity, and can be directly used for secondary utilization without leaching extraction. The method is simple in process, low in investment cost, environmentally friendly, efficient, capable of avoiding metal loss and wastewater generation and suitable for large-scale recovery.

Owner:SOUTH CHINA UNIV OF TECH

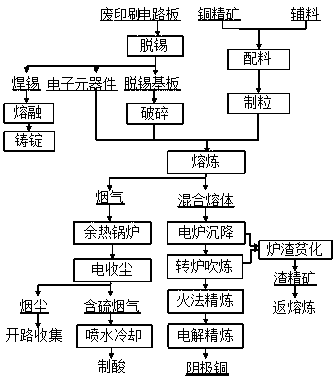

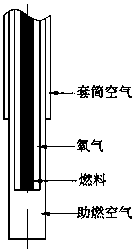

Oxygen-enriched top-blown copper smelting combined with a method for treating waste printed circuit boards

The invention provides a method for treating waste printed circuit boards with combination of oxygen-enriched top-blown copper smelting. The method comprises the following steps: (1) heating and removing tin; (2) crushing; (3) mixing and smelting; (4) treating melts; (5) treating smoke in a furnace; and (6) treating the smoke out of the furnace. According to the method, copper concentrates are used as the main raw materials and cooperate with part of waste printed circuit boards; the treatment of the waste circuit boards is combined with oxygen-enriched top-blown copper smelting; organic matters are effectively decomposed in a high-temperature smelting tank; the organic matters and sulphide ore are oxidized to generate heat and achieve self-heating smelting; high-concentration SO2 smoke is used for inhibiting generation of dioxin; secondary air is blown for decomposing residual compounds; the smoke enters an acid production system after being subjected to waste heat recovery, electric dust collection and water-injection cooling. The method is low in energy consumption and high in comprehensive recovery rate of valuable metals, is capable of recycling the waste circuit boards and can solve the problems of serious pollution, generation of hypertoxic dioxin and low metal recovery rate of the existing waste circuit board treatment process.

Owner:CENT SOUTH UNIV +1

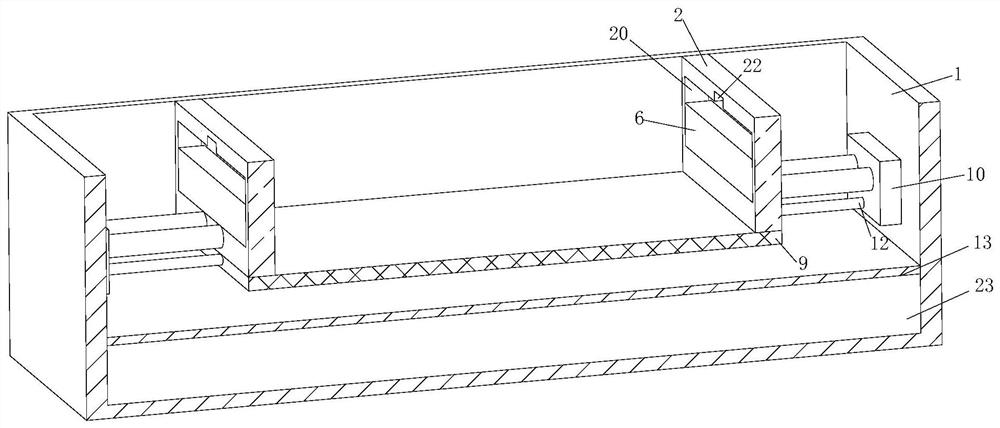

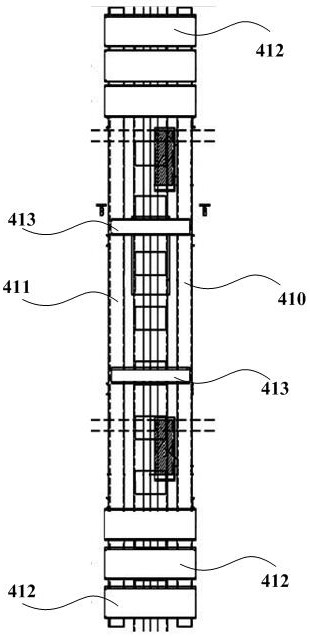

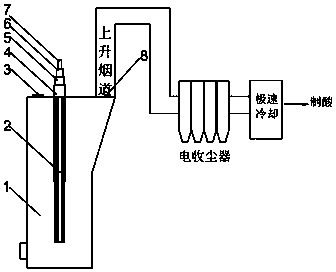

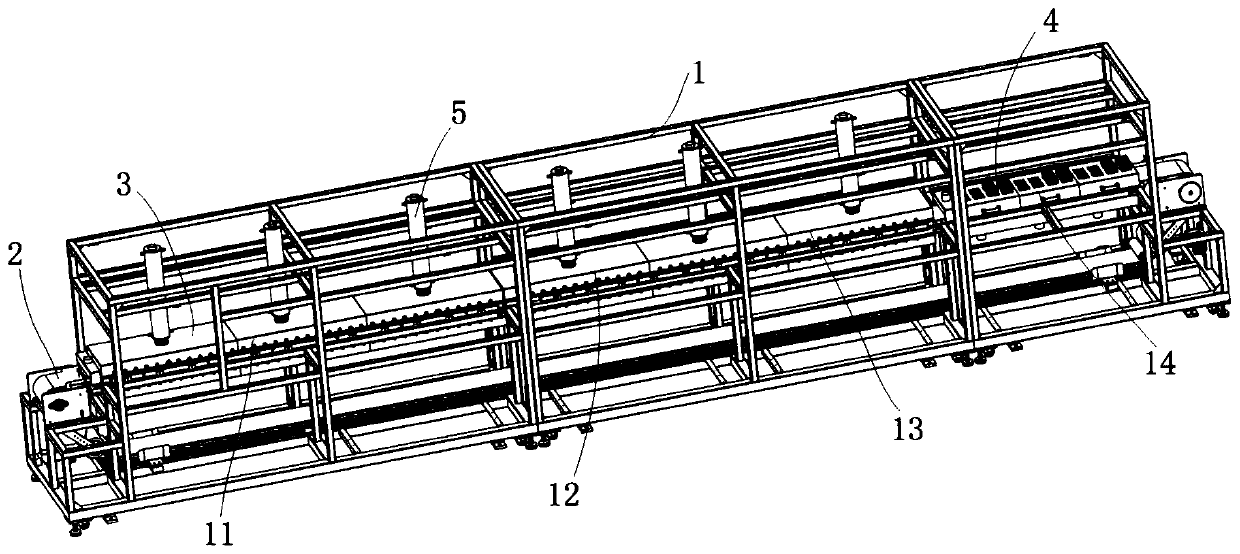

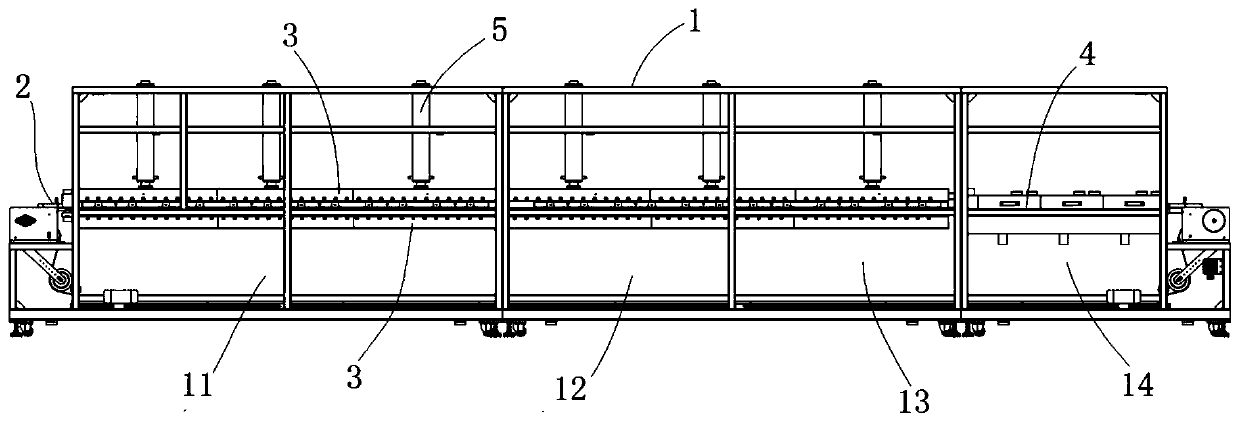

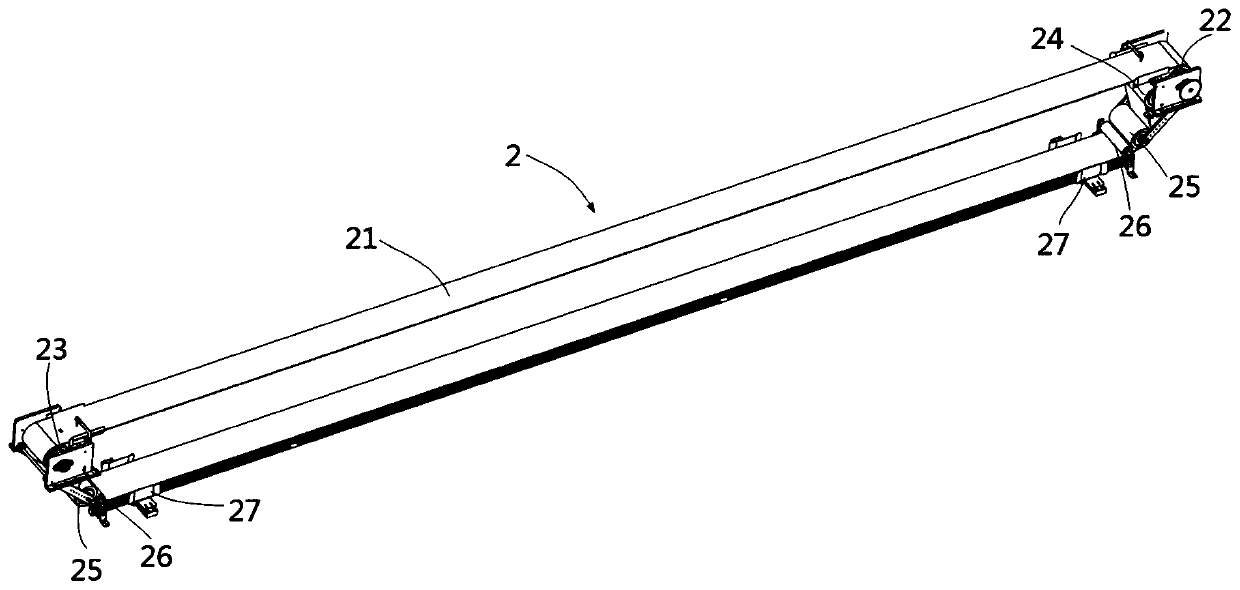

Pyrolysis equipment and battery pack heat treatment method

PendingCN111151555AShort timeHigh recycling efficiencyTransportation and packagingSolid waste disposalExhaust fumesProcess engineering

The invention discloses pyrolysis equipment and a battery pack heat treatment method. The pyrolysis equipment and the battery pack heat treatment method are used for carrying out pyrolysis treatment on a packaging material of a battery pack. The pyrolysis equipment comprises a pyrolysis furnace, a conveying device, a heating device and a plurality of air interchangers. The conveying device includes a conveying belt for conveying the battery pack, and the conveying belt extends from an inlet of the pyrolysis furnace to an outlet of the pyrolysis furnace; the heating device comprises a heating pipe and a heating cover, wherein the heating pipe is used for heating the battery pack on the conveying belt, and the heating cover covers the side, away from the conveying belt, of the heating pipe;and the air interchangers are arranged at intervals along the conveying direction of the conveying belt, each air interchanger is arranged to be capable of introducing nitrogen or air to the battery pack so as to generate a pyrolysis reaction with the packaging material of the battery pack, and leading out exhaust gas generated by the pyrolysis reaction of the packaging material in the heating cover. According to the technical scheme, the packaging material of the battery pack is removed in a pyrolysis mode, the time consumption is short, and the recovery processing efficiency is high.

Owner:WUXI AUTOWELL TECH

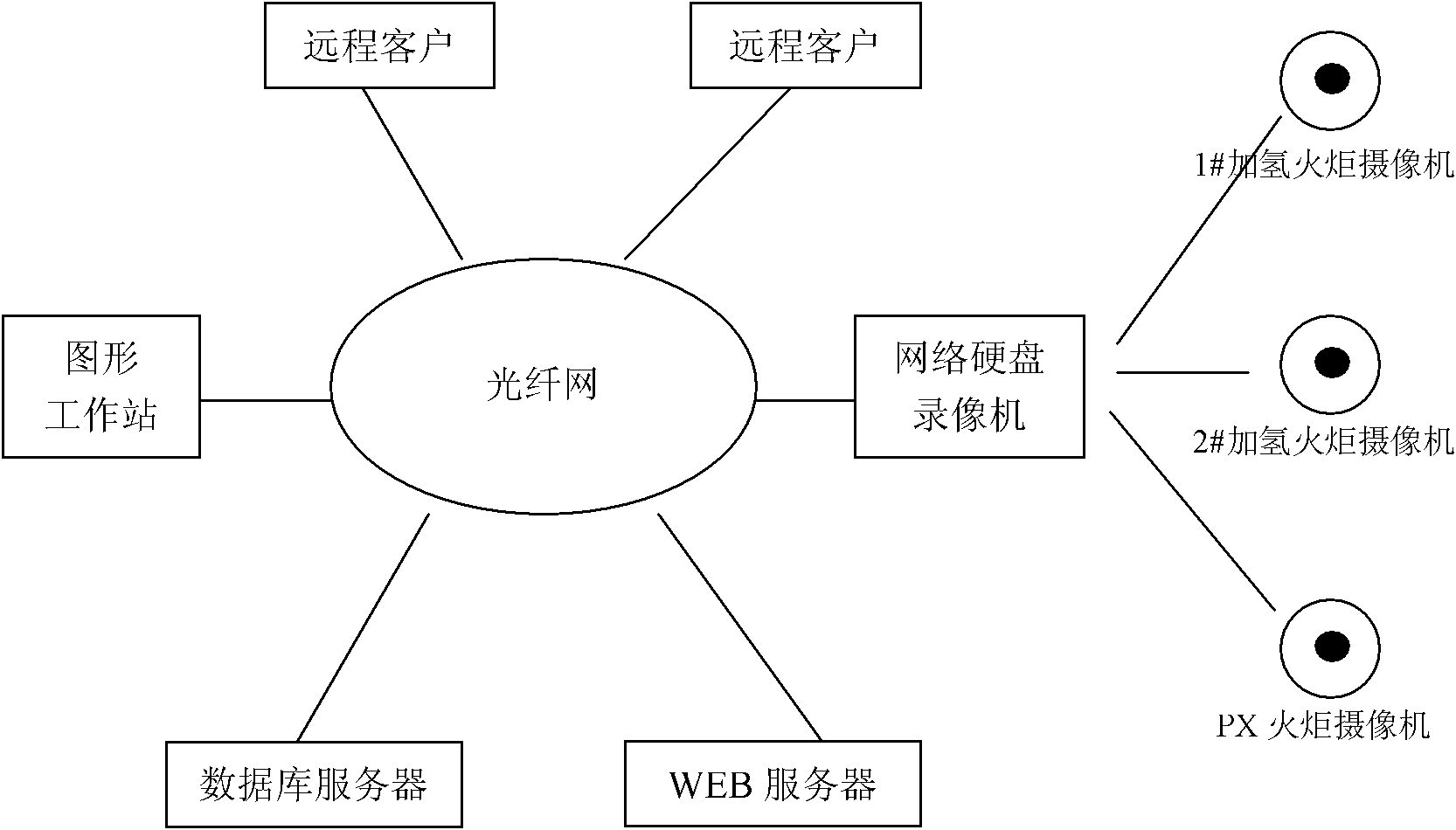

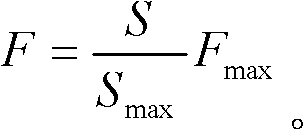

Method for real-time measurement of torch flow rate of torch discharge system based on torch videos

ActiveCN102645246ASolving difficult problems that cannot be directly and effectively measuredHigh recycling efficiencyVolume/mass flow measurementTorchActive measurement

The invention relates to a method for real-time measurement of the torch flow rate of a torch discharge system based on torch videos. A dynamic image mode recognition technology is used, a high-definition camera is used for picking up the flame core of the torch, the pickup target is converted into image signals to be transmitted into a graphic work station, the flow rate of exhausted gas is judged and calculated according to the flame core shape size, and the practical torch flow rate discharge data is measured through monitoring the flame size in the torch discharge system. The method has the advantages that the problem that the torch discharge cannot be directly and effectively measured for many years is solved, the measurement precision can reach a value within 10 percent, a good supervisory effect is realized on the device discharge through the torch discharge history trend, and the unnecessary discharge is reduced; and the production process operation condition and the practical condition of the torch discharge are conveniently known, and extremely high reference effects are reached for stabilizing the production and improving the safe, stable, long, full and excellent operation of devices.

Owner:CHINA PETROLEUM & CHEM CORP

Method and device for collecting ventilation air methane on top of diffuser of main fan of coal mine

InactiveCN102392675AImplement recollectionAchieve reuseTunnel/mines ventillationGas removalAtmospheric airNew energy

The invention discloses a method and a device for collecting ventilation air methane on the top of a diffuser of a main fan of a coal mine. The device comprises an air-collecting hood, an air-collecting pipeline and connecting supports, the air-collecting hood is fixed on the extension line of the air flow direction of the outlet of the top of the diffuser of the main fan of the coal mine by the connecting supports, and the air-collecting pipeline is connected with the outlet of the air-collecting hood. The air-collecting hood utilizes the loss of the kinetic energy of ventilation to fulfill the process of ventilation air methane collection, the normal working condition of the fan of the coal mine cannot be affected, new energy consumption is not generated as well, the coal mine methane utilization rate is increased, and the atmospheric environment is protected. The structure of the collecting device is simple and practical, the device is convenient to mount, the collection cost is low, the benefit of recovery is high, and the device is applicable to both common centrifugal fans and axial fans in coal mines.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

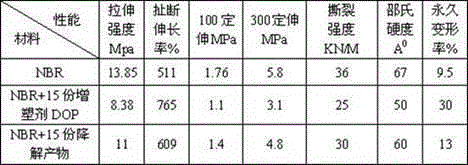

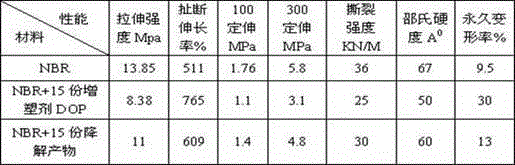

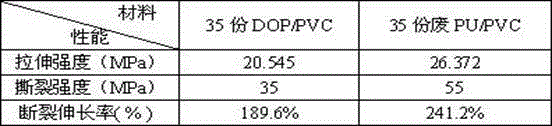

Method for preparing novel plasticizer by using waste polyurethane

InactiveCN104151602AContinuous automated productionHigh recycling efficiencyPlastic recyclingPolymer scienceOligomer

The invention provides a method for preparing novel plasticizer by using waste polyurethane. The method comprises the following orders and steps: (1) the waste polyurethane is crushed and put in a degradation reaction kettle, and degradation agents and catalysts are added; (2) in a stage of high temperature degradation, a high polymer is turned into an oligomer, mainly, the cross bonds and a part of main chains of the waste polyurethane are controlled to be cracked, so that discharging can be performed, the obtained novel plasticizer is a high molecular weight plasticizer which has the advantages that the novel plasticizer does not volatilize, does not migrate, does not reduce the intensity of plasticized materials basically and has low cost, wastes are converted into useful materials, and new pollution is not generated; (3) a degradation reaction is performed once again without additionally adding the degradation agents, degraded products can be used, and the production cost is reduced.

Owner:青岛三瑞节能环保技术有限公司 +1

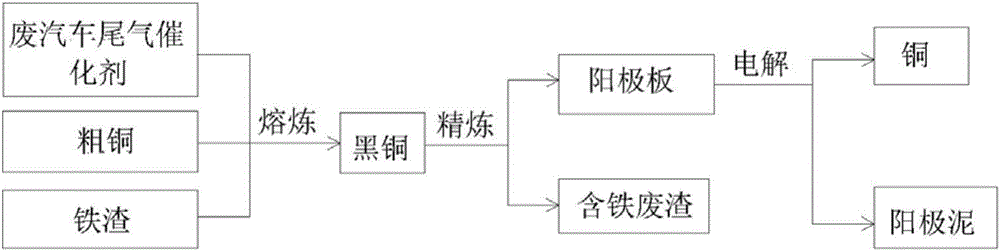

Method for separating iron and precious metals from iron residue

InactiveCN106756033AAvoid churnGuaranteed purityPhotography auxillary processesProcess efficiency improvementEconomic benefitsCarbon dust

The invention discloses a method for separating iron and precious metals from an iron residue. The method comprises the following steps of smelting the iron residue of an iron separator, copper-containing carbon dust obtained by cracking a waste circuit board and a waste auto-exhaust catalyst to obtain a compound of black copper and iron and separating the compound of the black copper and the iron. According to the method for separating the iron and the precious metal from the iron residue, resourceful treatment can be carried out on multiple wastes in the technical field of automobile disassembling and recycling, so that, on the one hand, the iron and other precious metals in an iron separator residue can be removed, the purity of the recycled iron is ensured and losses of the previous metals are avoided; and on the other hand, the auto-exhaust catalyst can be subjected to resourceful treatment and the copper in the copper-containing carbon dust obtained by cracking the circuit board is comprehensively extracted, the recovery benefits are improved, the cost is reduced and the economic benefits are improved.

Owner:JINGMEN GEM NEW MATERIAL

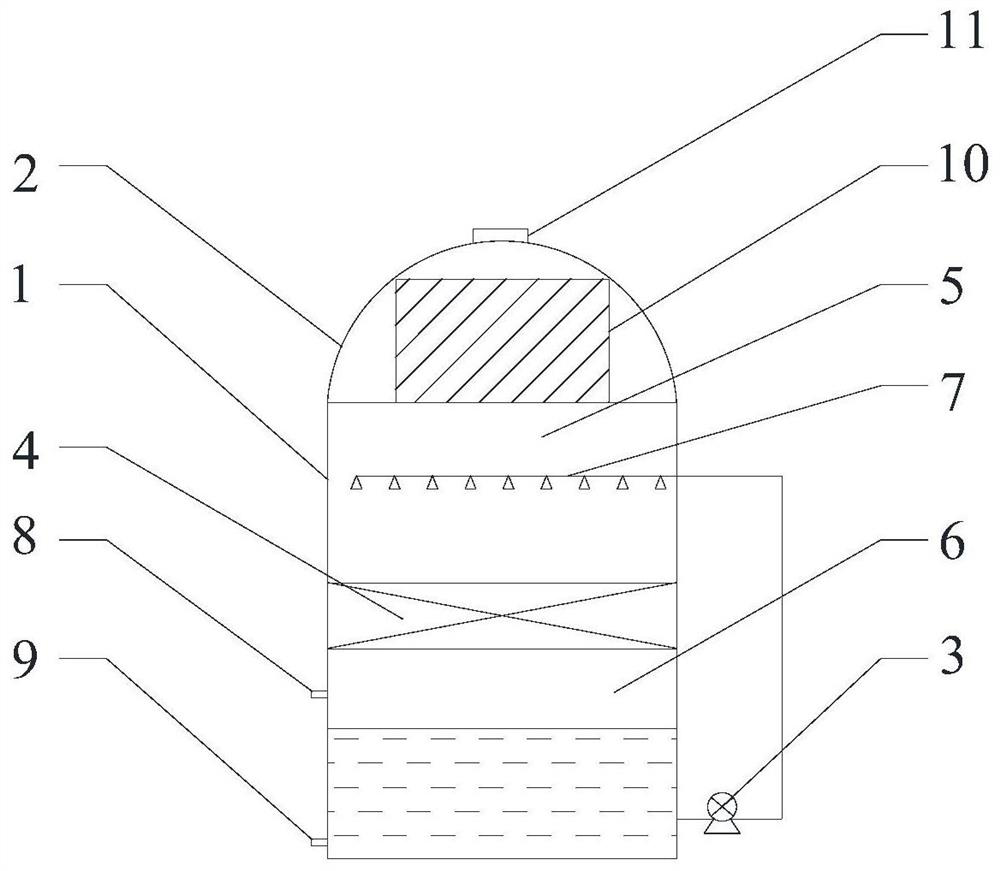

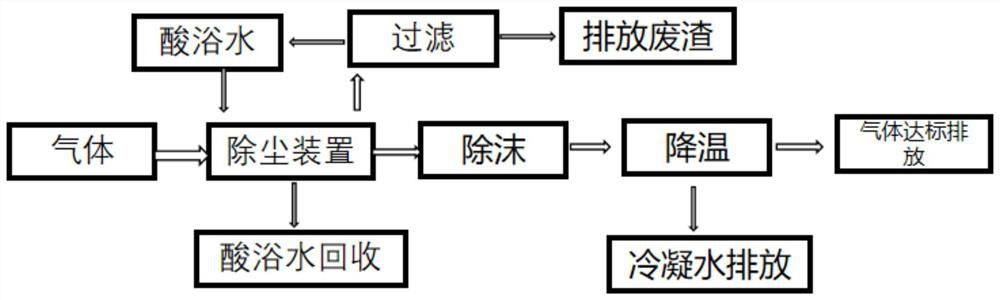

Acid bath washing dust removal device and method

ActiveCN112473288AHigh recovery rateAvoid emissionsUsing liquid separation agentAlkali metal sulfites/sulfatesPhysical chemistryDust control

The invention relates to the technical field of waste gas treatment, in particular to an acid bath washing dust removal device and method, and the device comprises a tank body, a cover body covering the tank body and a circulating device arranged outside the tank body; a liquid-gas distributor is arranged in the middle of the tank body in the vertical direction and divides the tank body into an upper tank body and a lower tank body; a spraying device for spraying acid bath water downwards is arranged in the upper tank body; a liquid containing groove capable of containing acid bath water is formed in the lower portion of the lower tank body, wherein a gas inlet used for introducing anhydrous sodium sulphate drying waste gas into the tank body is further formed in the lower tank body, and the gas inlet is formed above the liquid level of the acid bath water; a liquid outlet capable of discharging the acid bath water is formed in the bottom of the lower tank body; and the inlet end of the circulating device is communicated with the lower tank body through a pipeline. By means of the technical scheme, the problem of anhydrous sodium sulphate roasting waste gas treatment in the prior art can be solved.

Owner:SATERI JIUJIANG FIBER CO LTD

Manufacturing method of lead brass extracted from valve waste copper

PendingCN108165753AGood broad-spectrum reducibilityAvoid the limitations caused by a singleProcess efficiency improvementSurface cleaningSlag

The invention discloses a manufacturing method of lead brass extracted from valve waste copper. The lead brass extracted from the valve waste copper is equivalent in weight and chemical component in new manufacturing of an original valve; reduction and purification are performed mainly through microbial activities after surface cleaning; then, electric slag is remolten in vacuum; and finally, recovery is performed. The lead brass extracted from the valve waste copper is higher in recovery rate; and the recovered lead brass is high in quality, convenient to recover, low in cost and wide in application range.

Owner:NINGBO HUACHENG VALVE

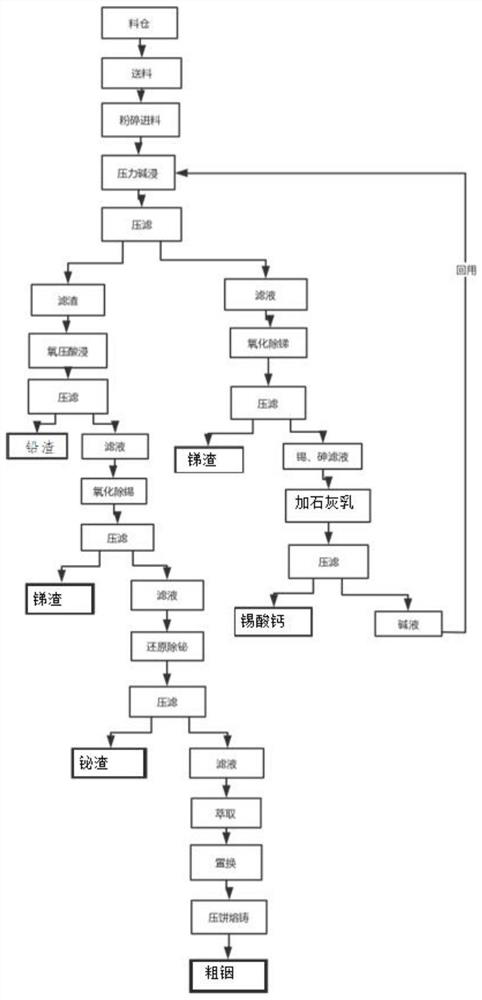

Comprehensive recovery method for oxygen pressure alkaline leaching calcium salt tin precipitation of tin-containing material

PendingCN112410578AHigh recovery rateHigh recycling efficiencyProcess efficiency improvementPregnant leach solutionSlag

The invention discloses a comprehensive recovery method for oxygen pressure alkaline leaching calcium salt tin precipitation of a tin-containing material. The method is characterized by comprising thefollowing steps of: 1, crushing the tin-containing material to obtain a crushed material; 2, adding bottom water, the crushed material and caustic soda flakes into a slurrying kettle to form a leachate, and performing a reaction for 1 hour to obtain a reaction material; 3, adding the reaction material in the slurrying kettle into an autoclave for reaction; 4, carrying out filter pressing to obtain a filtrate and filter residues; 5, after rinsing the filter residues, leaching and extracting indium in the filter residues by using an acid method; 6, adding hydrogen peroxide into the filtrate tooxidize and remove antimony; and 7, making antimony-containing slag into antimony white to recover antimony; and adding lime into the tin-containing filtrate, and carrying out filter pressing to obtain calcium stannate filter residues and alkaline filtrate. According to the method, the comprehensive recovery rate and the comprehensive recovery benefit of the tin-containing material are improved, so that valuable metals in the tin-containing material are productized, the product income is increased, and the environmental pollution is reduced.

Owner:刘罗平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com