Method for recovering ortho-aminophenol in concentrated brine

A technology for o-aminophenol, recovery and treatment, applied in the field of o-aminophenol recovery and treatment in concentrated brine, can solve the problems of economy, difficult operation, complicated process, etc. , avoid environmental pollution, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

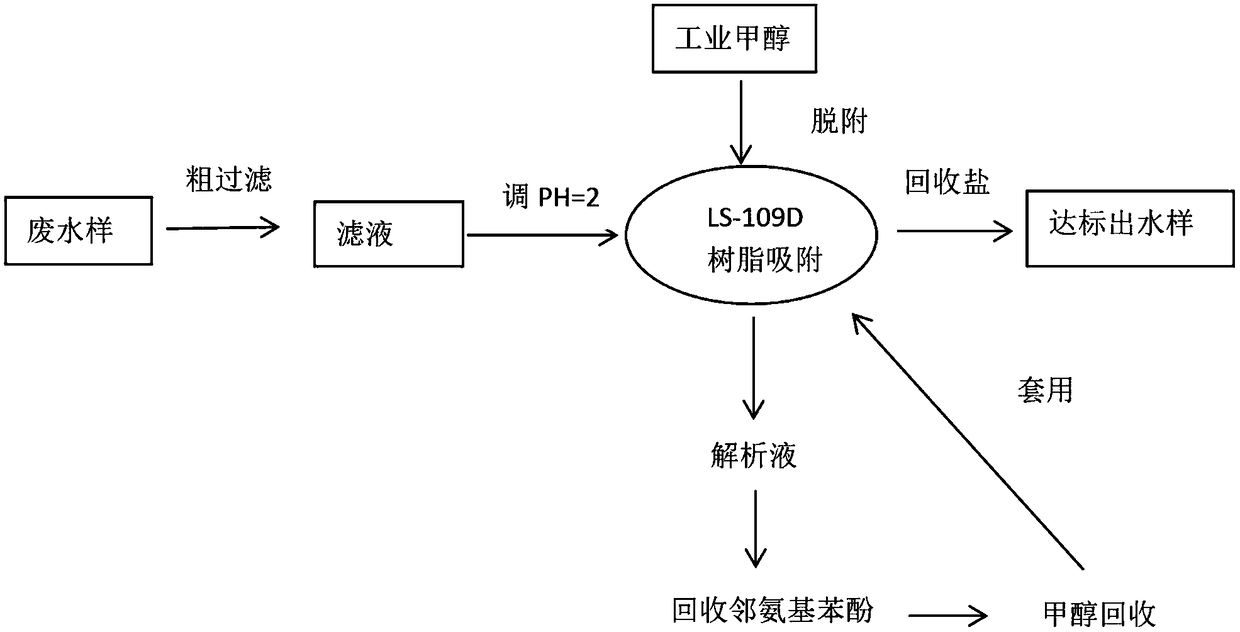

Method used

Image

Examples

Embodiment 1

[0044] The o-aminophenol production wastewater of a fine chemical plant is black with a small amount of suspended solids. CODcr: 9850mg / L, o-aminophenol: 4500mg / L, chloride ion content: 28000mg / L, pH: 7.98, inorganic salt content 6.1%.

[0045] The implementation steps are as follows:

[0046] 1.1. The o-aminophenol production wastewater is preliminarily filtered with fiber balls to remove suspended solids, and the pH of the filtrate is adjusted to 2 with concentrated sulfuric acid.

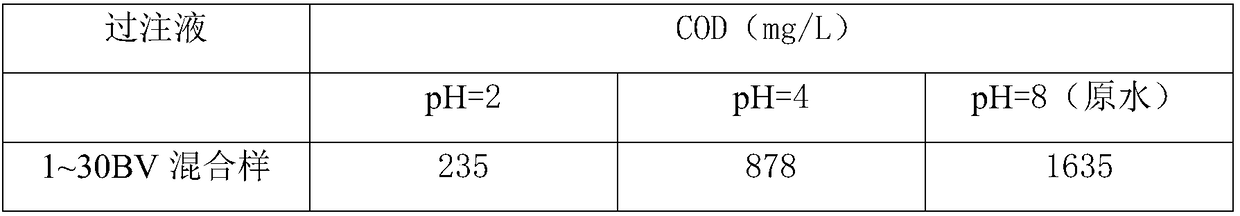

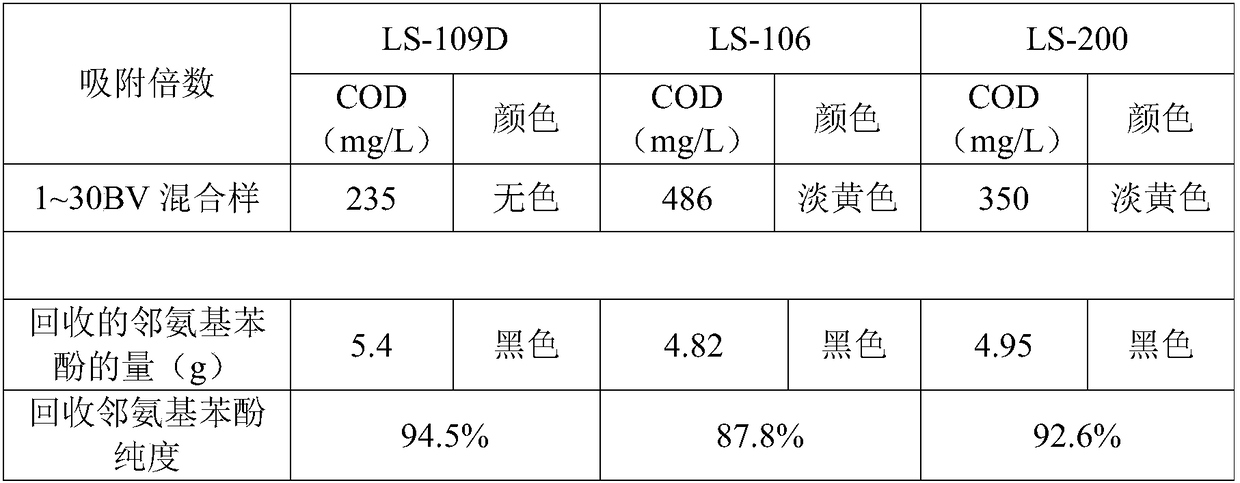

[0047] 1.2. Put 40ml LS-109D resin into a resin column (Φ25ⅹ300mm) fixed with iron clamps, and pass the water sample treated in 1.1 through the resin bed at a flow rate of 1BV / h at room temperature. When the column is adsorbed by 30BV , The CODcr of the adsorbed effluent drops below 300mg / L, o-aminophenol is not detected, and the effluent is colorless and transparent.

[0048] 1.3. 2.5BV methanol is used for resin desorption at a flow rate of 0.5BV / h. After the desorbed resin is washed with water at 15°C...

Embodiment 2

[0051] An environmental protection company provided o-aminophenol production wastewater with black color, clear water, CODcr: 10520mg / L, o-aminophenol: 4620mg / L, chloride ion content: 26800mg / L, pH: 7.56, inorganic salt content 6.5%.

[0052] The implementation steps are as follows:

[0053] 1.1. Adjust the pH of o-aminophenol production wastewater to 2 with concentrated sulfuric acid.

[0054] 1.2. Put 40ml LS-109D resin into a resin column (Φ25ⅹ300mm) fixed with iron clamps, and pass the water sample treated in 1.1 through the resin bed at a flow rate of 1BV / h at room temperature. When the column is adsorbed by 32BV , The CODcr of the adsorbed effluent drops below 300mg / L, o-aminophenol is not detected, and the effluent is colorless and transparent.

[0055] 1.3. 3BV methanol performs resin desorption at a flow rate of 0.5BV / h. After the desorbed resin is washed with water at 25°C, it is washed with water until the methanol content is less than 5%, and the resin can be reused after ...

Embodiment 3

[0058] A dye intermediate chemical company provided o-aminophenol production wastewater in black, slightly turbid water quality, CODcr: 9650mg / L, o-aminophenol: 4475mg / L, chloride ion content: 30800mg / L, pH: 8.0, and inorganic salt content 7.5% .

[0059] The implementation steps are as follows:

[0060] 1.1. The o-aminophenol production wastewater is preliminarily filtered with fiber balls to remove suspended solids, and the filtrate is adjusted to pH 2 with concentrated sulfuric acid.

[0061] 1.2. Put 40ml LS-109D resin into a resin column (Φ25ⅹ300mm) fixed with iron clamps, and pass the water sample treated in 1.1 through the resin bed at a flow rate of 1BV / h at room temperature. When the column is adsorbed by 30BV , The CODcr of the adsorbed effluent drops below 300mg / L, o-aminophenol is not detected, and the effluent is colorless and transparent.

[0062] 1.3. 3BV methanol performs resin desorption at a flow rate of 0.5BV / h. After the desorbed resin is washed with water at 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com