Acid bath washing dust removal device and method

A technology for washing, dust removal and acid bathing, applied in chemical instruments and methods, separation methods, alkali metal sulfites/sulfites, etc., to achieve the effect of increasing recovery routes, reducing sources and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

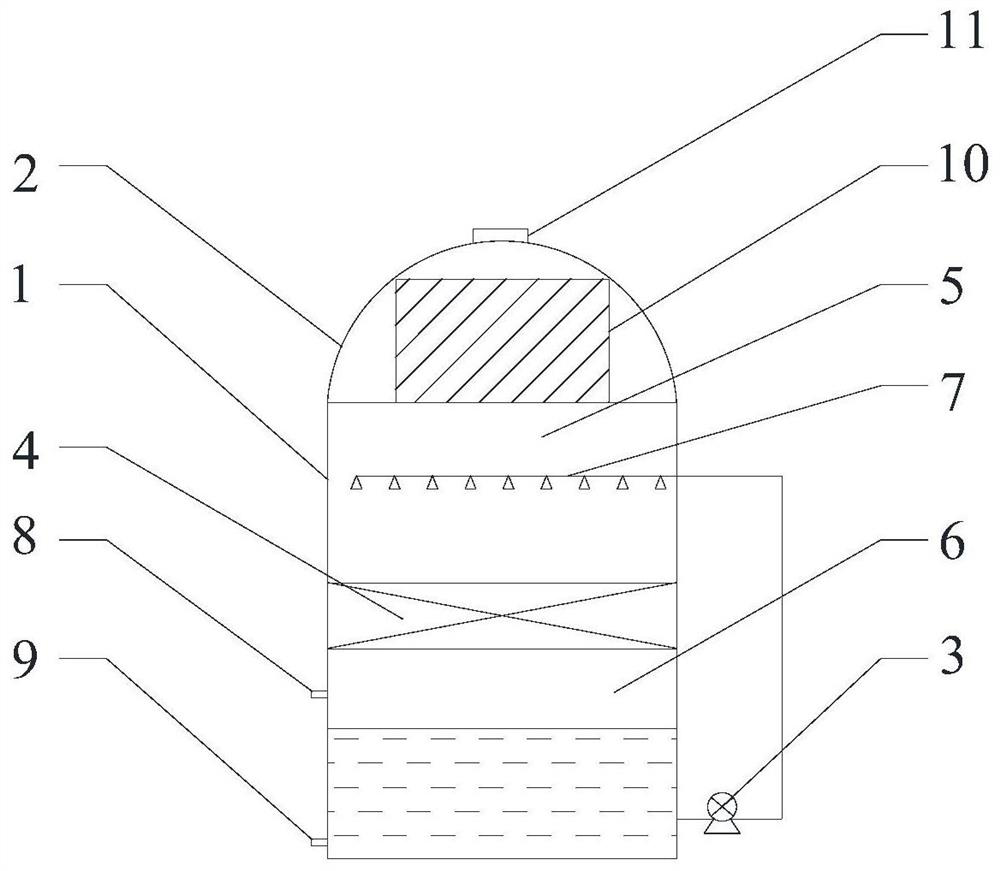

[0037] This embodiment provides an acid bath cleaning and dedusting device, which includes a tank body 1, a cover body 2 that covers the tank body 1, and a circulation device 3 arranged outside the tank body 1;

[0038] The tank body 1 is provided with a liquid-gas distributor 4 in the middle of the vertical direction, and the liquid-gas distributor 4 divides the tank body 1 into an upper tank body 5 and a lower tank body 6;

[0039] The upper tank body 5 is provided with a spray device 7 for spraying acid bath water downward;

[0040] The lower part of the lower tank body 6 is a liquid tank capable of holding acid bath water, and the lower tank body 6 is also provided with a gas inlet 8 for passing into the tank body 1 to dry waste gas of sodium sulfate. The gas inlet 8 is arranged above the liquid level of the acid bath water; the bottom of the lower tank body 6 has a liquid outlet 9 capable of discharging the acid bath water;

[0041] The inlet end of the circulation devic...

Embodiment 2

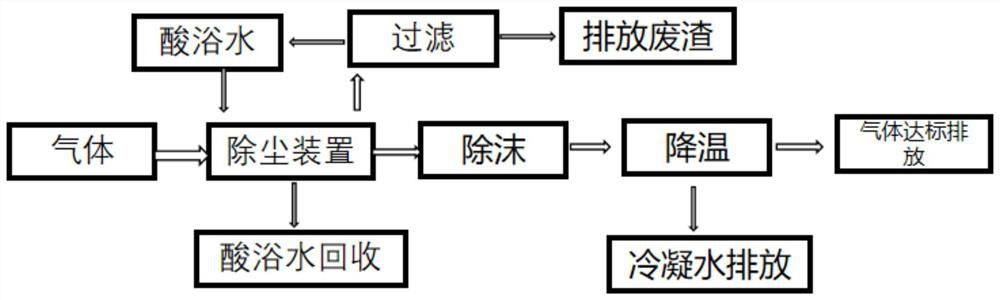

[0046] This embodiment provides an acid bath cleaning and dedusting method, which includes using the acid bath cleaning and dedusting device described in Example 1 to use acid bath water to spray and dedust the waste gas from the drying of sodium sulfate. Specifically, it includes the following steps:

[0047] 1) Add acid bath water into the dust removal device, and make the liquid level of the acid bath water lower than the gas inlet 8, wherein the acid bath water is the acid bath water recovered from viscose fiber production.

[0048] 2) Open the circulation device 3 so that the acid bath water in the lower tank body 6 is delivered to the spray device 7 and sprayed downward;

[0049] 3) Feed Yuanming powder into the tank body 6 through the gas inlet 8 to dry waste gas;

[0050]4) The exhaust gas from drying sodium sulfate and the acid bath water sprayed downward by the spray device 7 fully contacts in the liquid gas distributor 4 so that the dust in the exhaust gas from dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com