Patents

Literature

132results about How to "Source of reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

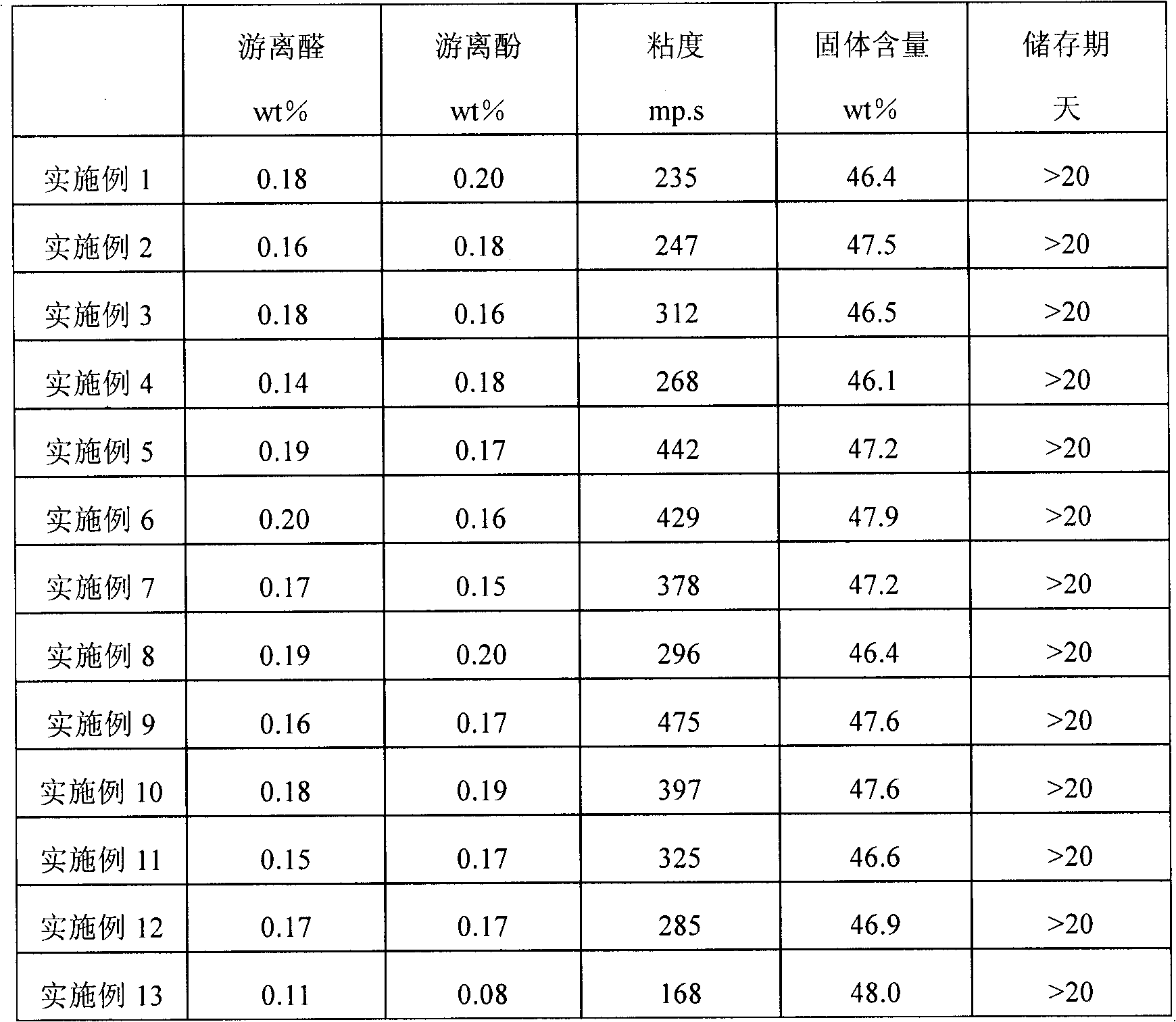

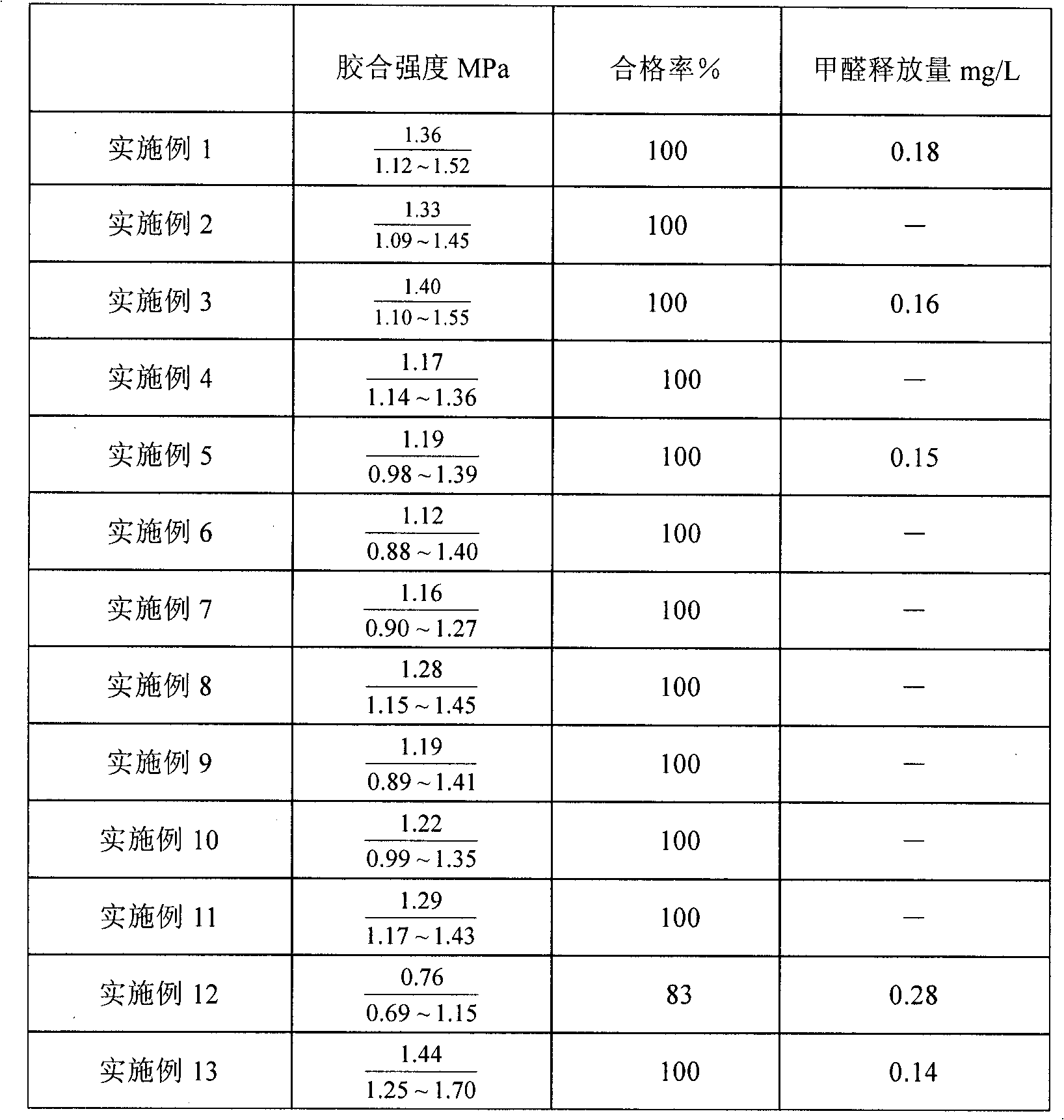

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

Preparation method for sulfur-containing ultra-low titanium high-standard bearing steel

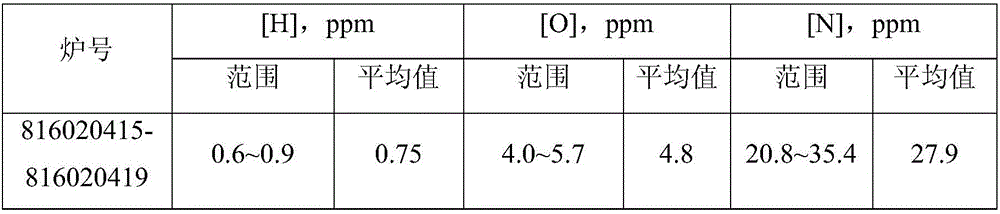

The invention relates to a production method for a round steel, and specifically to a preparation method for a sulfur-containing ultra-low titanium high-standard bearing steel. The preparation method comprises a converter smelting procedure, an LF secondary refining procedure, a VD furnace vacuum refining procedure, a bloom continuous casting procedure, and a rolling procedure. Converter smelting is carried out by means of a double-slag process with an endpoint [C] controlled within a range of 0.15% to 0.25%; a double-slag stopping operation with a slag stopping ball and a sliding plate is performed during tapping; a slag skimming treatment is carried out before feeding into the LF; an operation of forming white slag as soon as possible is performed; an appropriate slag layer thickness is ensured before VD; VD vacuum breaking is followed by feeding of a Fe-S wire; an operation of remaining steel and slag is performed at the final stage of steel ladle casting; cold charging is adopted for rolling of a casting blank; and heating time is prolonged appropriately. The sulfur-containing ultra-low titanium high-standard bearing steel produced by means of the preparation method is good in machinability, and extremely high in purity, and has a titanium content controlled within 10 ppm and an oxygen content controlled within 6 ppm; moreover, the steel is good in castability, and has more than 10 continuous casting heats without feeding of a si-ba wire; therefore, high production efficiency is achieved.

Owner:ZENITH STEEL GROUP CORP +1

Smelting process of Cr-Mn series spring steel

ActiveCN104745765AImprove liquiditySolve the problem of high alkalinity slag and difficult adsorption and inclusionElectric furnaceProcess efficiency improvementNon-metallic inclusionsSmelting process

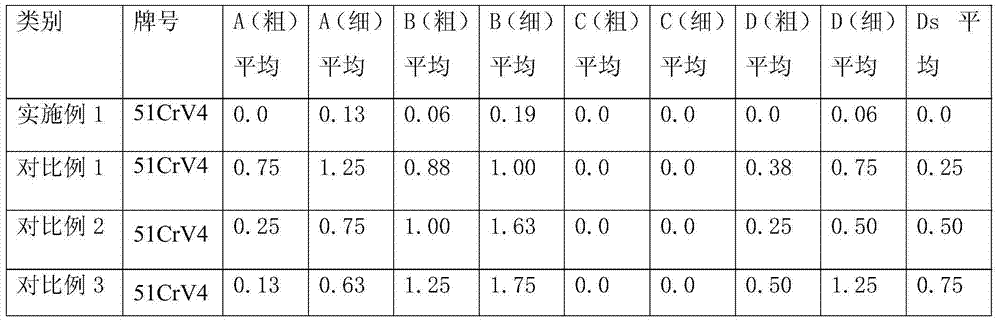

The invention belongs to the field of metallurgy and discloses a smelting process of Cr-Mn series spring steel. The smelting process of Cr-Mn series spring steel comprises the following steps: (1) by taking a low-sulfur molten iron and a high-quality steel scrap as the electric furnace smelting iron and steel materials, controlling the electric furnace end point carbon content to greater than 0.15%; (2) adding active lime and composite refining slag in the electric furnace tapping process, and adding calcium carbide to perform pre-deoxidation in the tapping process; (3) feeding an Al line in an argon station before LF refining; (4) producing high basicity white slag in the refining earlier stage and controlling the basicity of slag in the refining middle and later stages to 1.5-2.5; (5) controlling the ultimate vacuum front argon flow to 15-25 L / min and controlling the ultimate vacuum late argon flow to 30-45 L / min; (6) adding a granular alkaline covering agent and a carbonized rice hull to perform double protection by VD emptying; and (7) stabilizing the speed of continuous casting to 0.8-0.9 m / min, and controlling the degree of superheat to 20-30 DEG C. By adopting the process, the non-metallic inclusion content in the molten steel is reduced.

Owner:ZENITH STEEL GROUP CORP +1

Smelting process for control of spring steel inclusions

ActiveCN105907919AEasy to controlReduce sources of refractory and refractory inclusionsProcess efficiency improvementElectric furnaceSmelting processIntermediate stage

The invention discloses a smelting process for control of spring steel inclusions, wherein the smelting process includes the steps: 1) electric furnace primary smelting; 2) argon blowing; 3) LF refining; 4) VD furnace refining; and 5) continuous casting. In the electric furnace primary smelting steel-tapping process, an Si / Mn Al-free deoxidation process is adopted for pre-deoxidation, and at the same time, active lime, a compound agent and refining slag are adopted; in the earlier stage of the LF refining, an Si / Mn Al-free deoxidation process and active lime are adopted, and the furnace slag basicity is controlled at 1.5-2.5; in the middle stage of the LF refining, refined slag is added, followed by, the Si / Mn Al-free deoxidation process continues to be adopted, deoxidation and desulfuration continues to be carried out, and the furnace slag basicity is guaranteed to be controlled at 0.7-1.4; argon bottom blowing is carried out in the whole process of the LF refining. The Al-free deoxidation process and the low-basicity furnace slag desulfuration process are adopted and are combined with a specific deoxidizing agent, the inclusions in spring steel can be well controlled, and thus the anti-fatigue property of the spring steel is improved.

Owner:HANGZHOU IRON & STEEL GRP

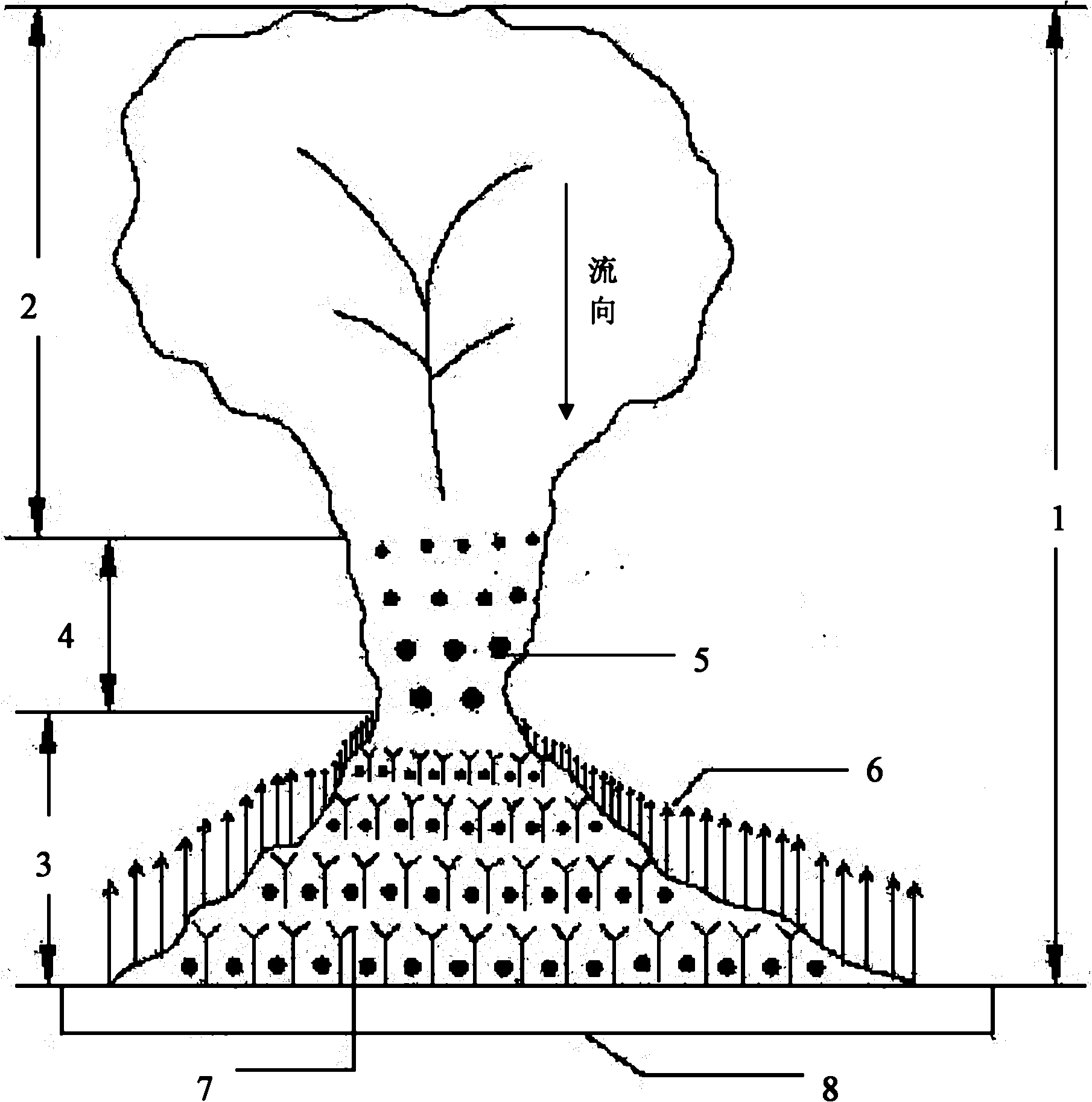

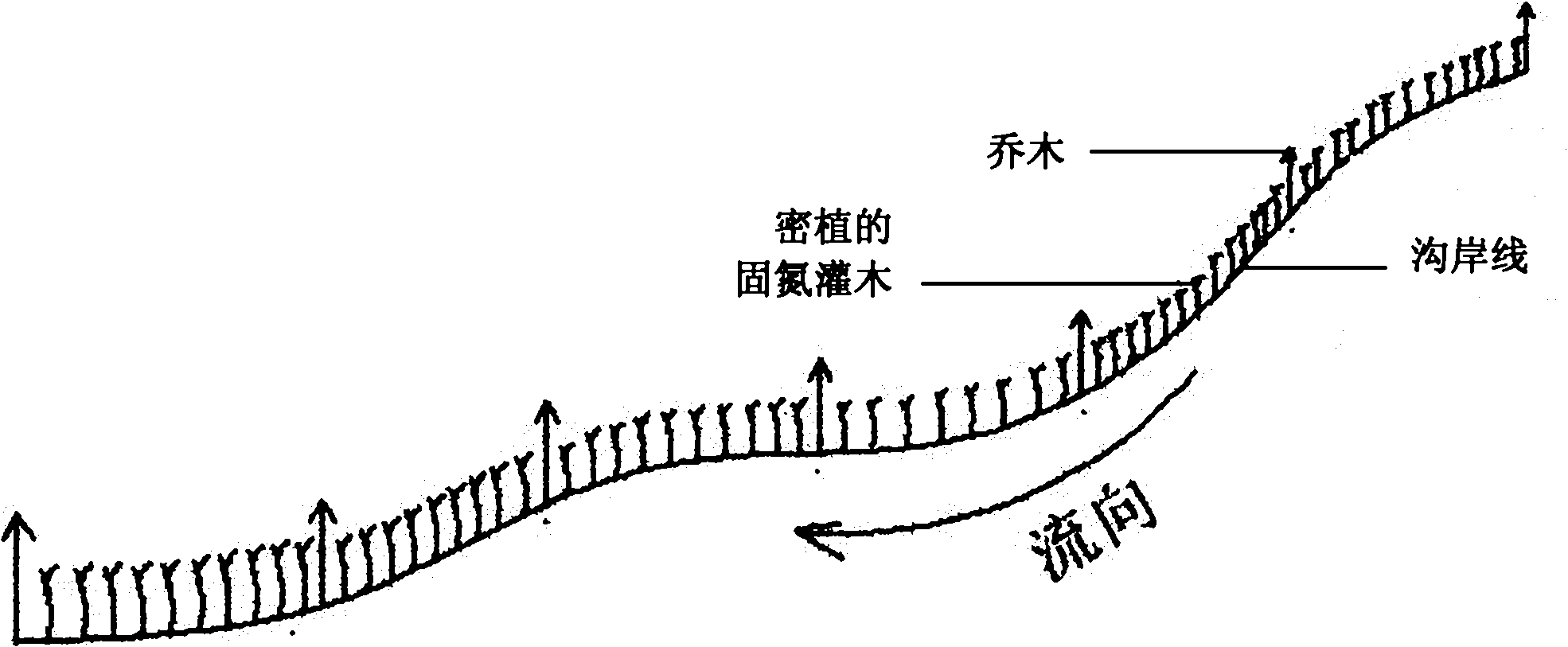

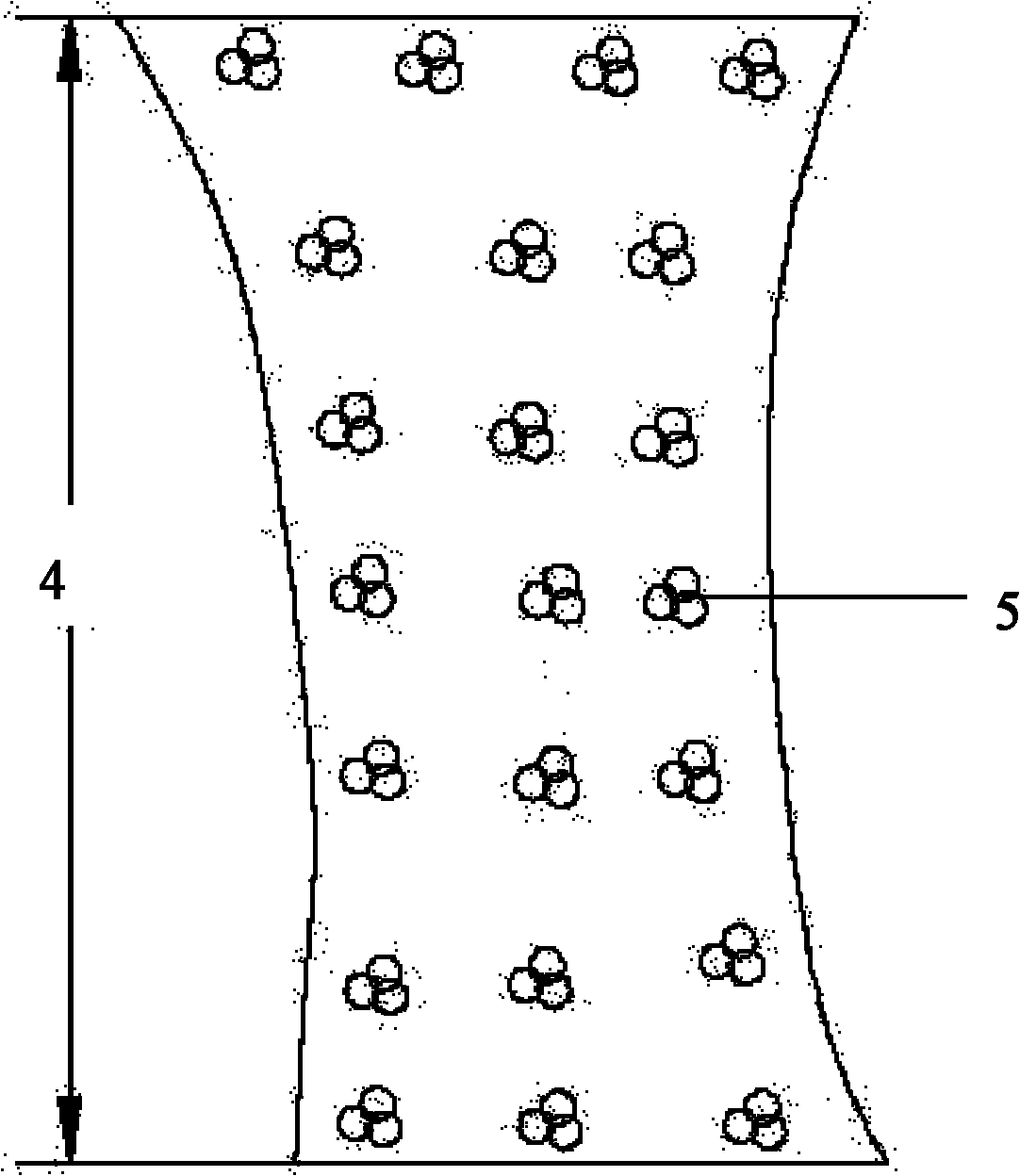

Silt retaining and consolidating method for use in debris flow gully ecological engineering and use thereof

InactiveCN102108690AImprove landscapeSimple structureMarine site engineeringProtection forestEngineering

The invention discloses a silt retaining and consolidating method for use in debris flow gully ecological engineering and use thereof. The method comprises: planting a plurality of brush woods for increasing the roughness of the gully bed in a silt transfer area between a debris flow flowing area and a silt settling area in the gully; planting bank-protecting and scouring-preventing forest at the foot of a slope of the gully along the bank of the gully for preventing flowing water from scouring the silt on the bank of the gully; and planting arbor and bush combined improved protection forest in the silt settling area to improve the impact strength of soil body. When the method is used, the use of other civil engineering measures in combination is determined according to the occurrence frequency of debris flow. Compared with the prior art, the method can effectively retain, consolidate and improve the silt in the silt transfer area, on the gully slope and in the silt settling area in the debris flow gully, consolidate and improve retained and deposited silt while reducing silt sources, improve the self-stability of the silt soil body in the silt settling area, strengthen the sand control capability of the gully and improve the landscape of the gully.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel and preparation method of low-hydrogen high-toughness seamless flux-cored wire

ActiveCN109623193AImprove impact toughnessLow melting pointWelding/cutting media/materialsSoldering mediaSilicon alloyMagnetite

The invention discloses a low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel. The seamless flux-cored wire is composed of low-carbon steel strip skin and flux core powder and used for welding of the low-temperature steel adopted in a LPG ship and a liquefied petroleum storage tank. The low-hydrogen high-toughness seamless flux-cored wire is formed by mixing, by mass percentage, 30-40% of rutile, 0.5-1% of sodium fluoride, 10-16% of manganese-silicon alloy, 1-2% of zircon sand, 5-9% of rare earth silicon iron, 10-12% of nickel powder, 3-5% of magnesium powder, 0.3-0.6% of ferroboron, 1-5% of titanium powder, 2-4% of potassium titanate, 0.5-1% of magnesia, 1-2% of magnetite and 12-14% of iron powder. The seamless flux-cored wire is high in impact toughness at thelow temperature, applicable to all-position welding, good in welding manufacturability and meanwhile good in seawater corrosion resistance and ultralow in diffusible hydrogen; and the low-hydrogen high-toughness seamless flux-cored wire is mainly applied to welding of the low-temperature steel of the LPG ship, the liquefied petroleum storage tank and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

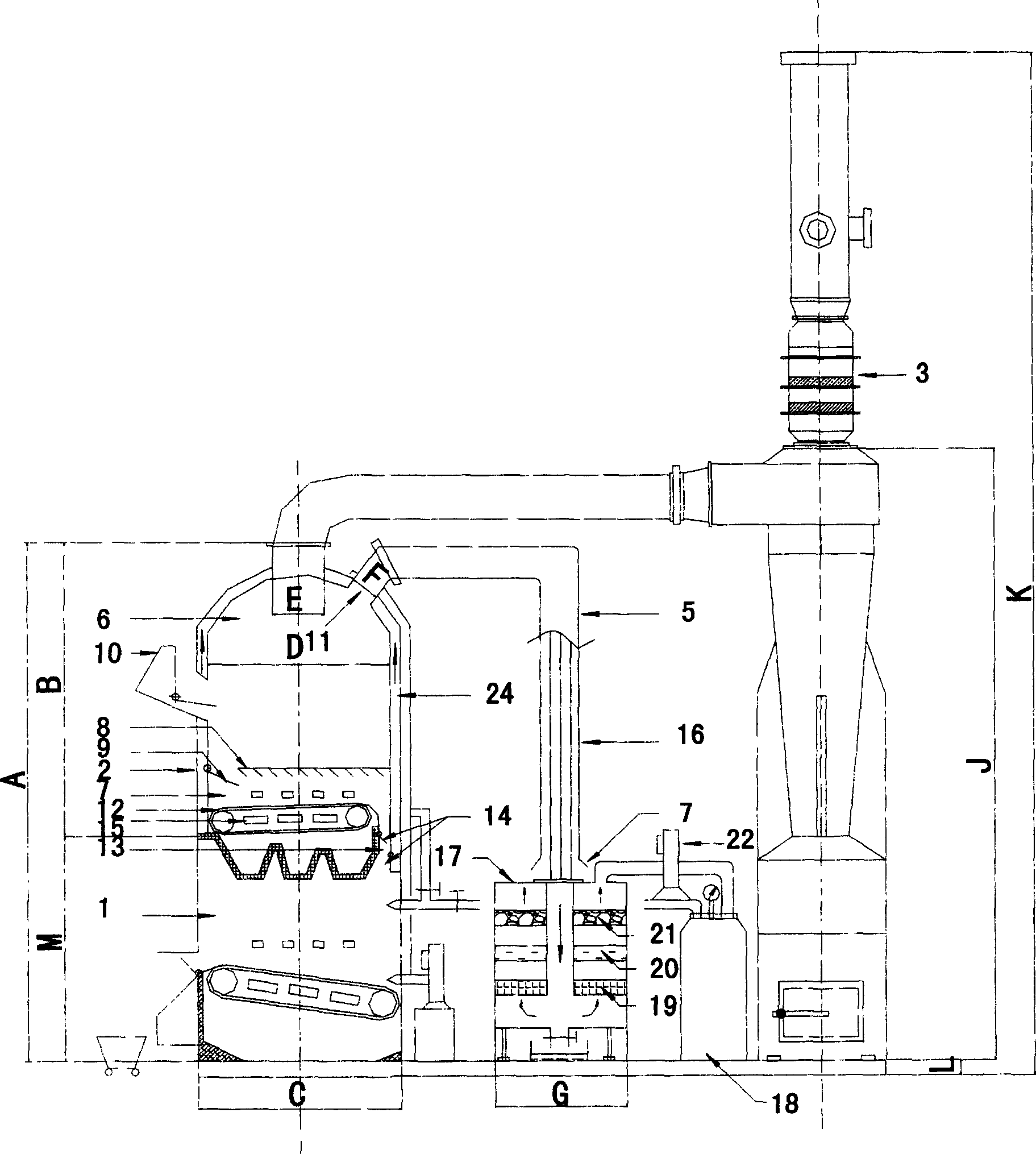

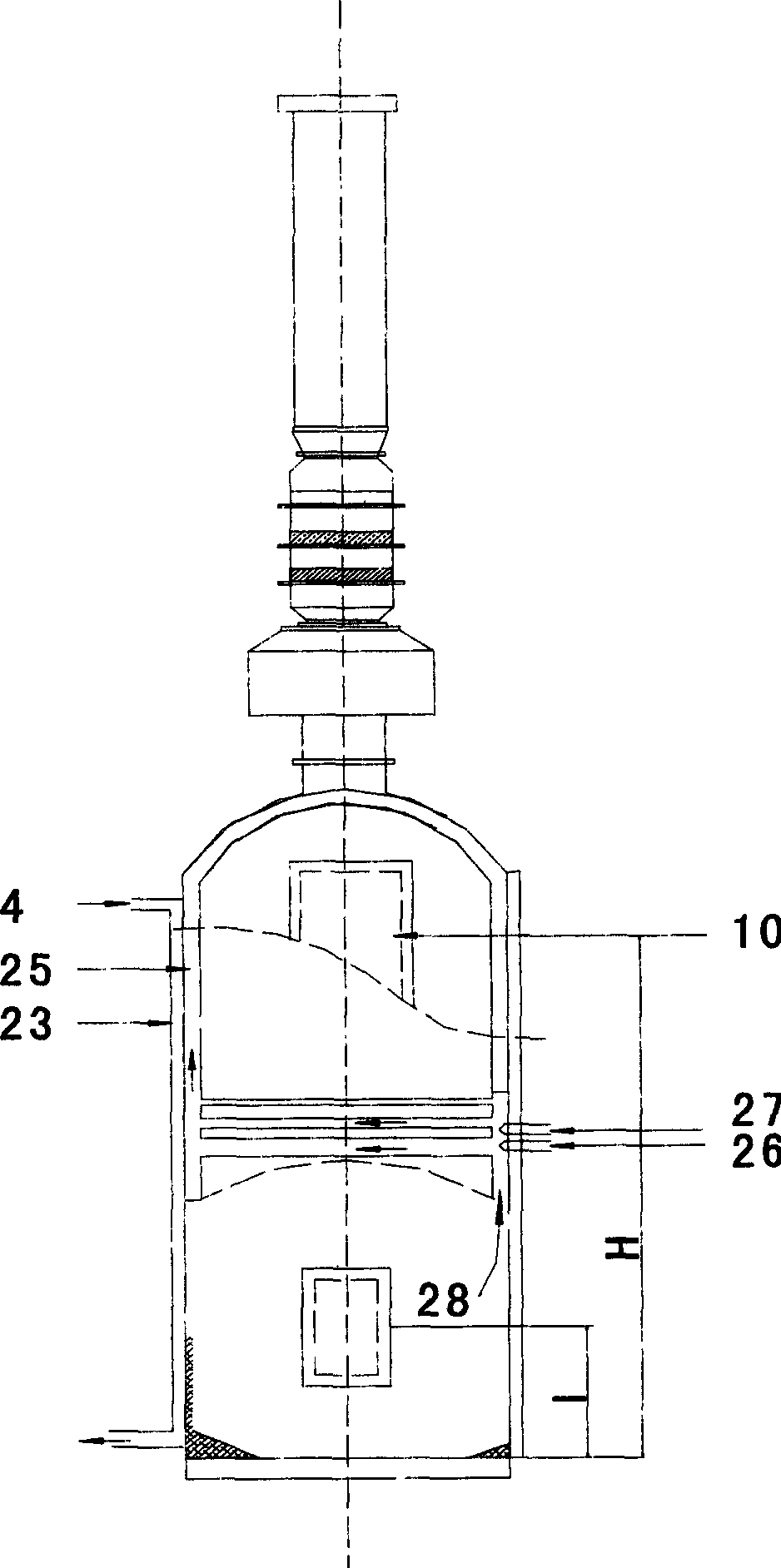

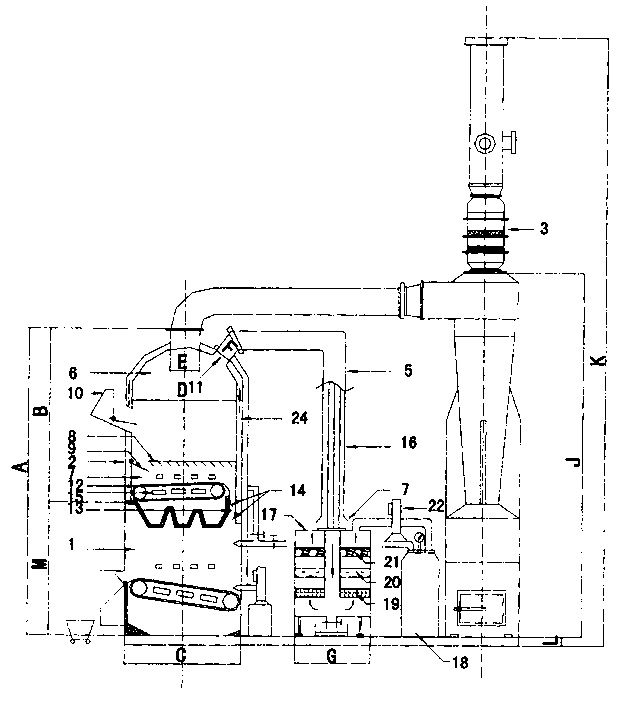

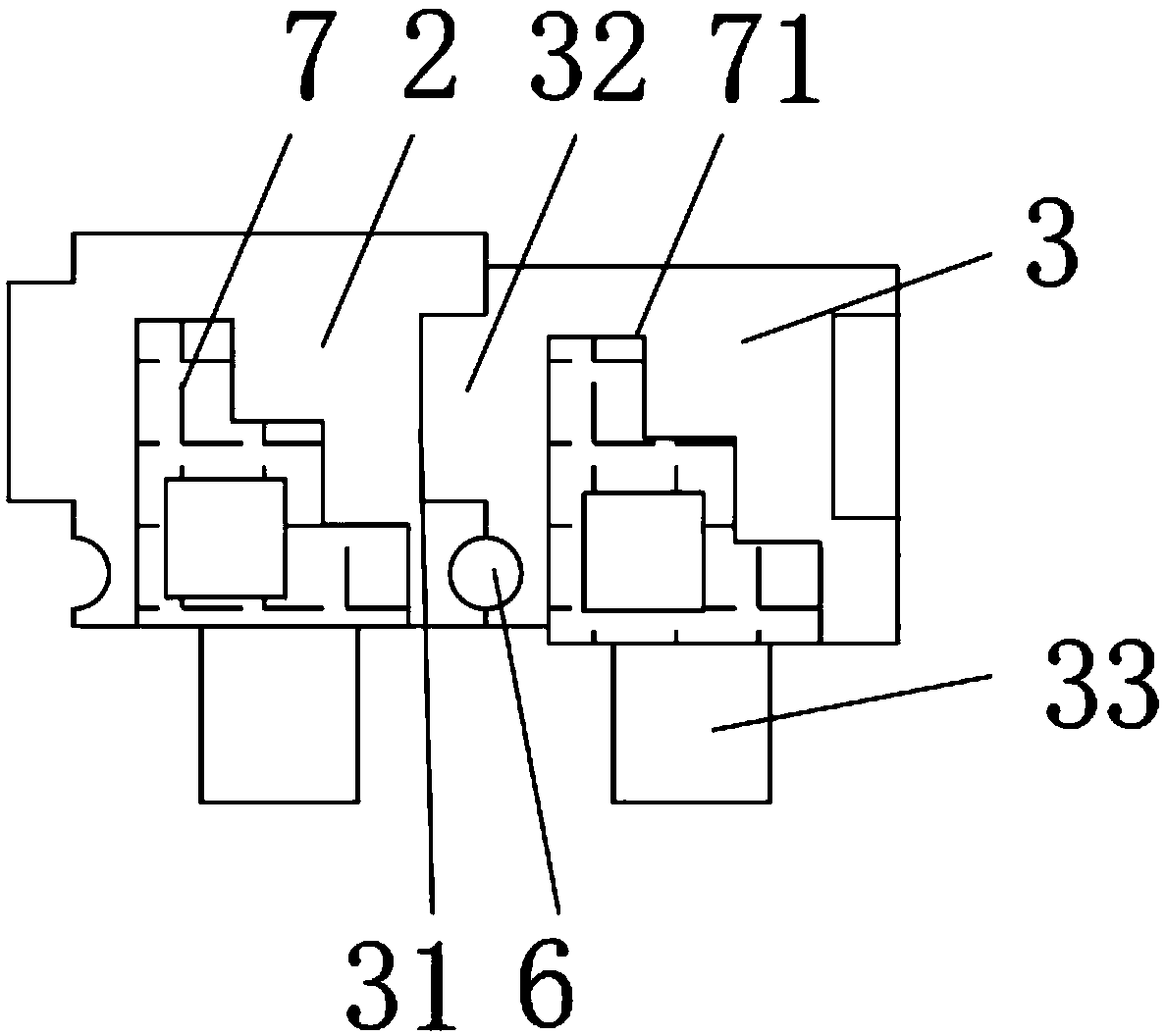

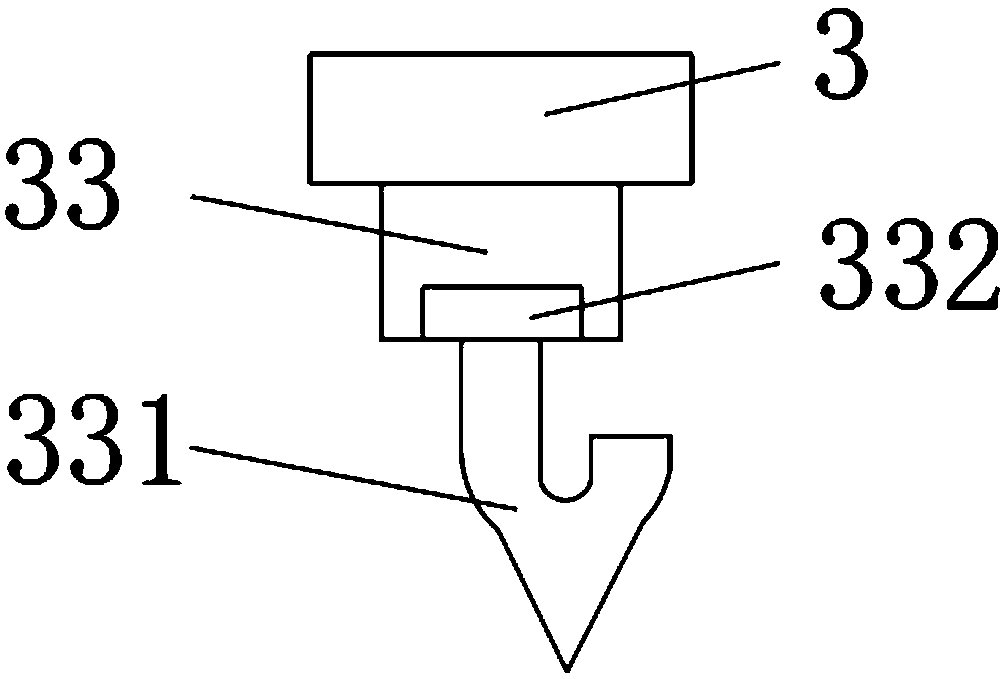

Medical refuse pyrolytic-gasification incineration apparatus

InactiveCN1470801ASource of reductionReduce generation conditionsIncinerator apparatusCombustion chamberEngineering

The incinerator, the gasifying pyrolysis stove as well as the dust removal and fume extractor are utilized in the invented equipment. The incinerator, the pyrolysis gasifying stove and the collector for cracked gas are integrated as whole body. The furnace body of the gasifying pyrolysis oven is divided into a stove chamber and a cracking chamber. The exit of the chain on the bottom of the cracking chamber is connected to the incinerator through a channel. Cracked coke can pass through two windshields in the channel, but fume and frame produced in the incinerator cannot enter into the stove. Thus, gasifying pyrolysis effect is happened in the stove without burning on. Garbage is decomposed into cracked coke, which will be burning in the incinerator, and cracked gas, which will be filteredout. The beneficial effect is that if burning these gases, dioxin will be produced. The combustible gas generated in the stove is as the fuel for the incinerator.

Owner:TIANJIN UNIV

Self-cleaning method of air conditioner heat exchanger and air conditioner

InactiveCN107655171AGuarantee job stabilityImprove job stabilityMechanical apparatusFlush cleaningEngineeringCleaning methods

The invention discloses a self-cleaning method of an air conditioner heat exchanger and an air conditioner. The air conditioner comprises the heat exchanger and heating parts. The heating parts are arranged to correspond to the heat exchanger. The self-cleaning method of the air conditioner heat exchanger comprises the following steps that a self-cleaning control command is acquired and controlled, and a self-cleaning mode is executed; the rotating speed of a fan of the air conditioner is adjusted and / or the temperature of the indoor heat exchanger is reduced so as to enable the heat exchangerto be frosted; and when frosting is completed, the heating parts are started, and the opening degree of a throttle valve of the air conditioner is adjusted so as to defrost the heat exchanger. According to the technical scheme, the work stability of the air conditioner in the defrosting process is improved, and the self-cleaning effect is greatly improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Method for preventing molten iron from splashing in KR desulfurization

The invention discloses a method for preventing molten iron from splashing in KR desulfurization. The method comprises the following steps of: controlling the generation of gas in the desulfurization process, and controlling the viscosity of molten iron, wherein the step of controlling the generation of gas in the desulfurization process comprises the steps of controlling the ignition loss of a desulfurizing agent, reducing the source of gas CO / CO2 in the desulfurizing agent, and reacting the desulfurizing agent with oxide in the slag in the presence of a desulfurizing catalyst to reduce the oxidability of slag and lower the generation of gas CO / CO2; and the step of controlling the viscosity of molten iron comprises a step of removing the molten iron slag before desulfurization. The method for preventing molten iron from splashing in KR desulfurization provided by the invention solves the problems in the existing molten iron desulfurization treatment technology that the viscosity of molten iron and the viscosity of the desulfurization slag are both increased due to Si, Ti and the like in the molten iron, the molten iron easily splashes in the KR desulfurization process and consequently economic loss is caused and the production rhythm is influenced after the conditions of the molten iron deteriorate, and therefore the splashing of molten iron is prevented in the KR desulfurization process.

Owner:SHOUGANG CORPORATION

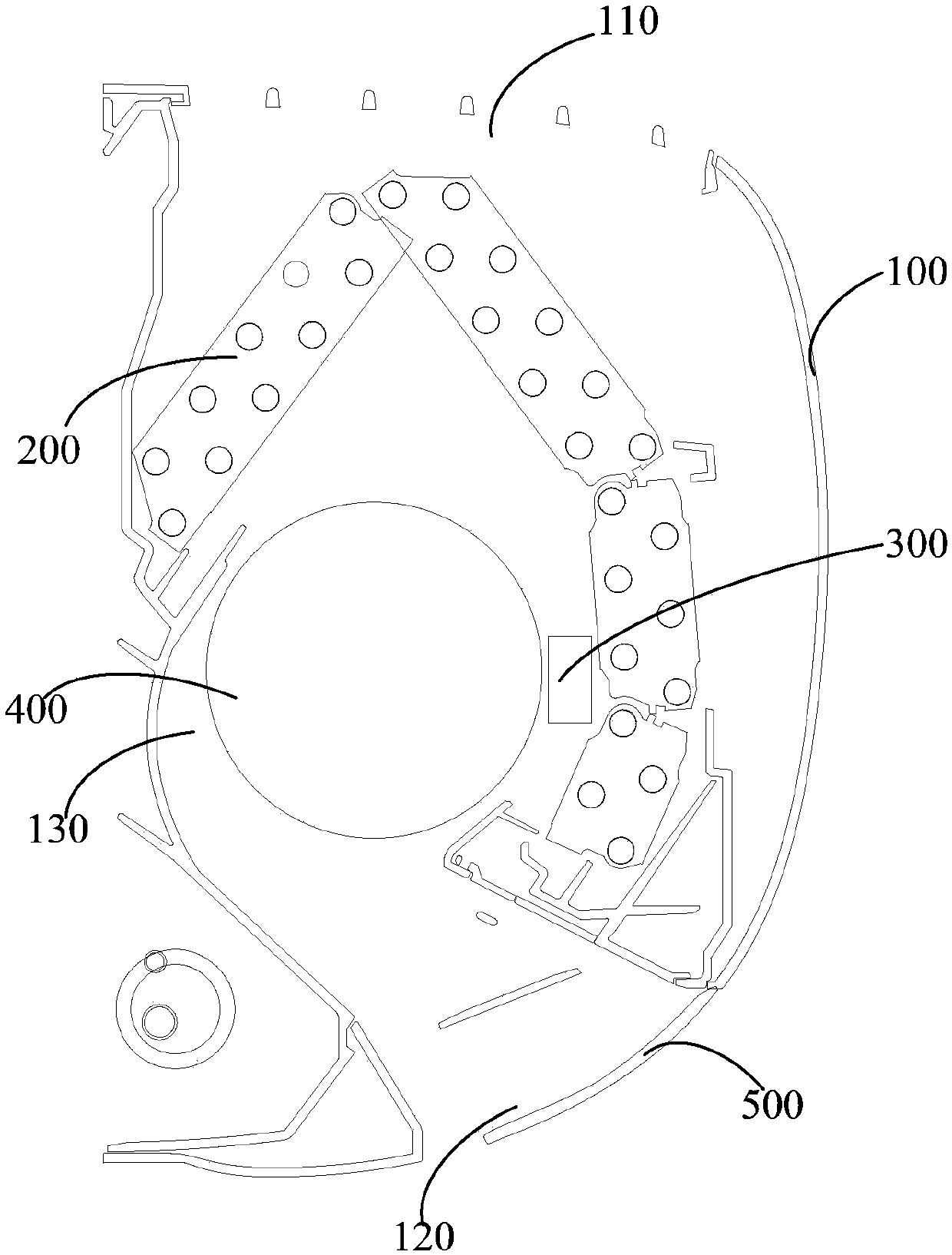

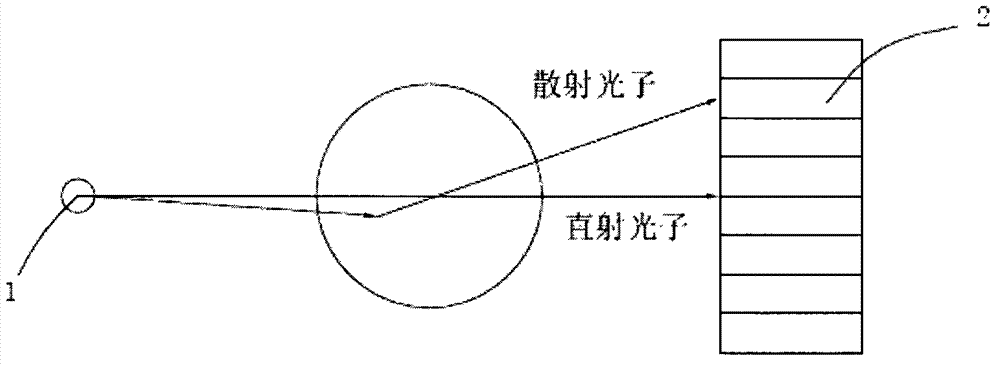

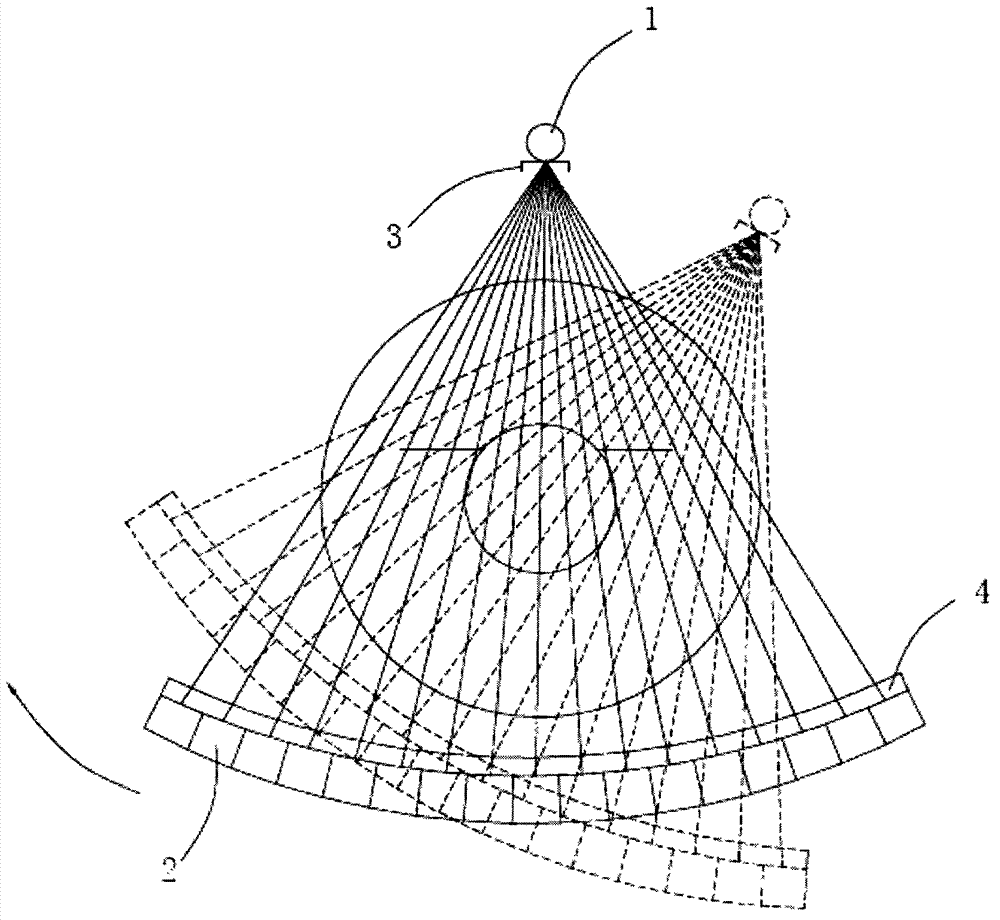

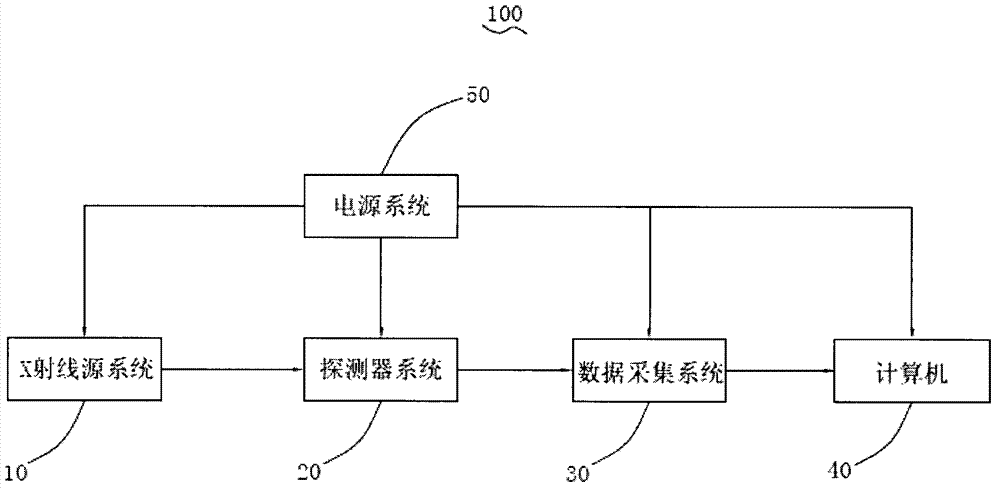

Static CT (computed tomography) scanner and scattering X-photon correction method thereof

ActiveCN102764137ASource of reductionImprove signal-to-noise ratioComputerised tomographsTomographyPhysicsCorrection method

A static CT (computed tomography) scanner comprises an X-ray source system, a detector system, a data acquisition system, a power system and a computer. The X-ray source system comprises an annular X-ray source and a front annular collimator arranged at an exit of the annular X-ray source. The annular X-ray source comprises a plurality of X-ray source modules, a plurality of collimator slits limiting emitting scope of X rays are distributed on the front annular collimator. The detector system comprises two annular detectors with the slits in between which are arranged on the inner side of the front annular collimator. Each annular detector comprises a plurality of detector modules capable of distinguishing energies for X photons. The front annular collimator can completely cover detection area of the detector modules. The detector system further comprises two rear annular collimators arranged on the inner side of the annular detectors and two annular monitoring detectors. The data acquisition system is connected with the detector system and the monitoring detectors. The computer processes data acquired by the data acquisition system and then reconstructs images.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH

Fertilizer suitable for rice and preparation method and application of fertilizer

InactiveCN110746228AAids in synthesisGood for longevityCalcareous fertilisersBio-organic fraction processingPlant growthBacteriocides

The invention relates to a fertilizer suitable for rice and a preparation method and application of the fertilizer. The fertilizer comprises a leaf surface spraying agent and a soil conditioner, wherein the leaf surface spraying agent comprises 200-230 parts of silicon dioxide, 60-80 parts of potassium nitrate, 8-15 parts of calcium nitrate, 2-3 parts of selenium, 2 or less parts of added elements, 1-2 parts of a plant growth regulator, 0.1 or less part of a bacteriostat and 1,000 parts of water; and the soil conditioner comprises 60-100 parts of potassium-rich rock, 30-50 parts of quick lime,150-300 parts of a sugar alcohol solution, 3-4 parts of urine, 4-5 parts of diammonium phosphate, 0.5-1.5 parts of microelements, 30-50 parts of livestock feces, 20-40 parts of crop straw, 10-30 parts of humic acid, 0.5-1.5 parts of biological bacteria and 0.1 or less part of a bactericide. According to the fertilizer, cadmium is effectively reduced through both the leaf surface spraying agent and the soil conditioner.

Owner:ANALYSIS & TESTING CENT CHINESE ACADEMY OF TROPICAL AGRI SCI

Full-nutrition dietary fiber solid beverage and preparation method thereof

InactiveCN108651806ARich collocationWith balanceVitamin food ingredientsFood ingredient functionsReady to eatAdditive ingredient

The invention discloses a full-nutrition dietary fiber solid beverage and a preparation method thereof, and relates to the technical field of health food. The full-nutrition dietary fiber solid beverage is prepared by: using Chenopodium quinoa Willd powder, collagen peptides, chia seed powder, beta-glucan, white kidney bean powder and oats as main components, and compounding the main components with various dietary fibers including barley and other grains, fruits, vegetables, etc., traditional Chinese medicinal materials with homology of medicine and food including cassia seeds, barbary wolfberry fruits, etc. and nutrient components including vegetable proteins, skimmed milk powder, compound minerals, compound vitamins, etc. Therefore, the full-nutrition dietary fiber solid beverage is balanced and reasonable in nutrient component composition, good in satiety feeling, good in effect, quick to tale effect, ready-to-eat once preparing, good for absorption of the human body, beneficial tohelp people shape the body and capable of meeting people's demands for a perfect figure very well.

Owner:吕军龙

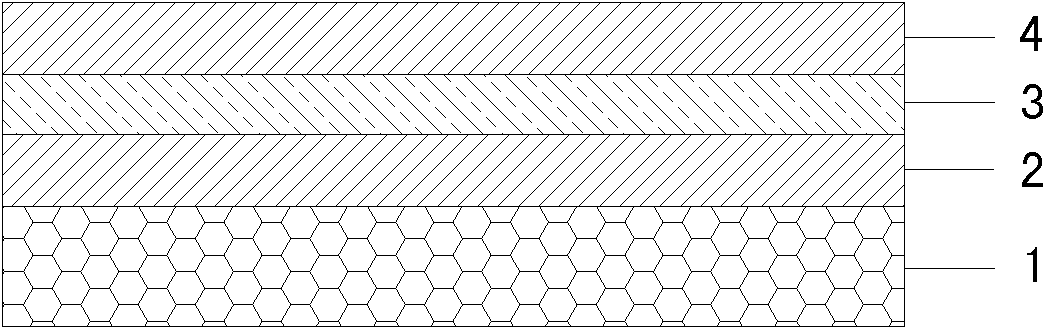

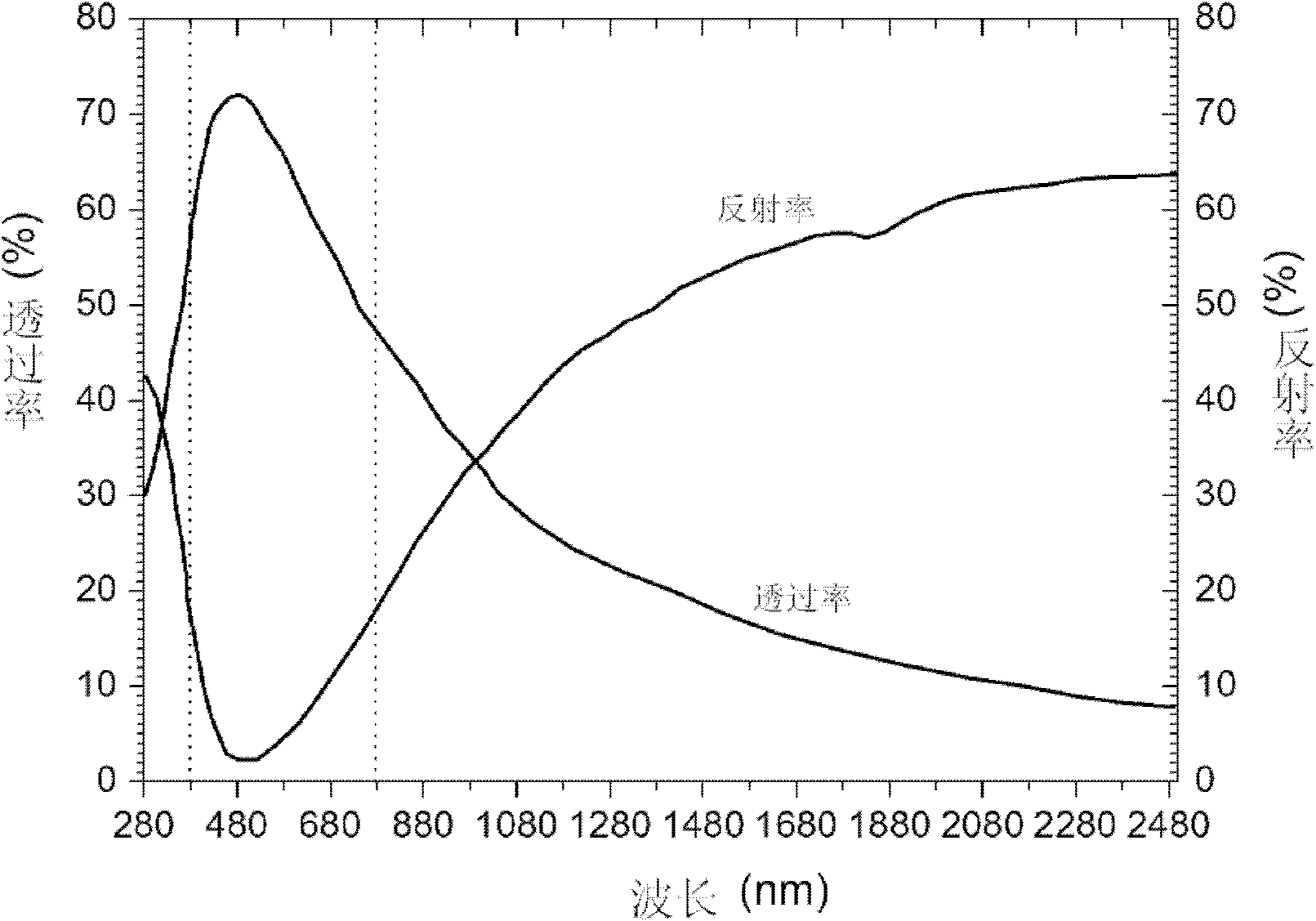

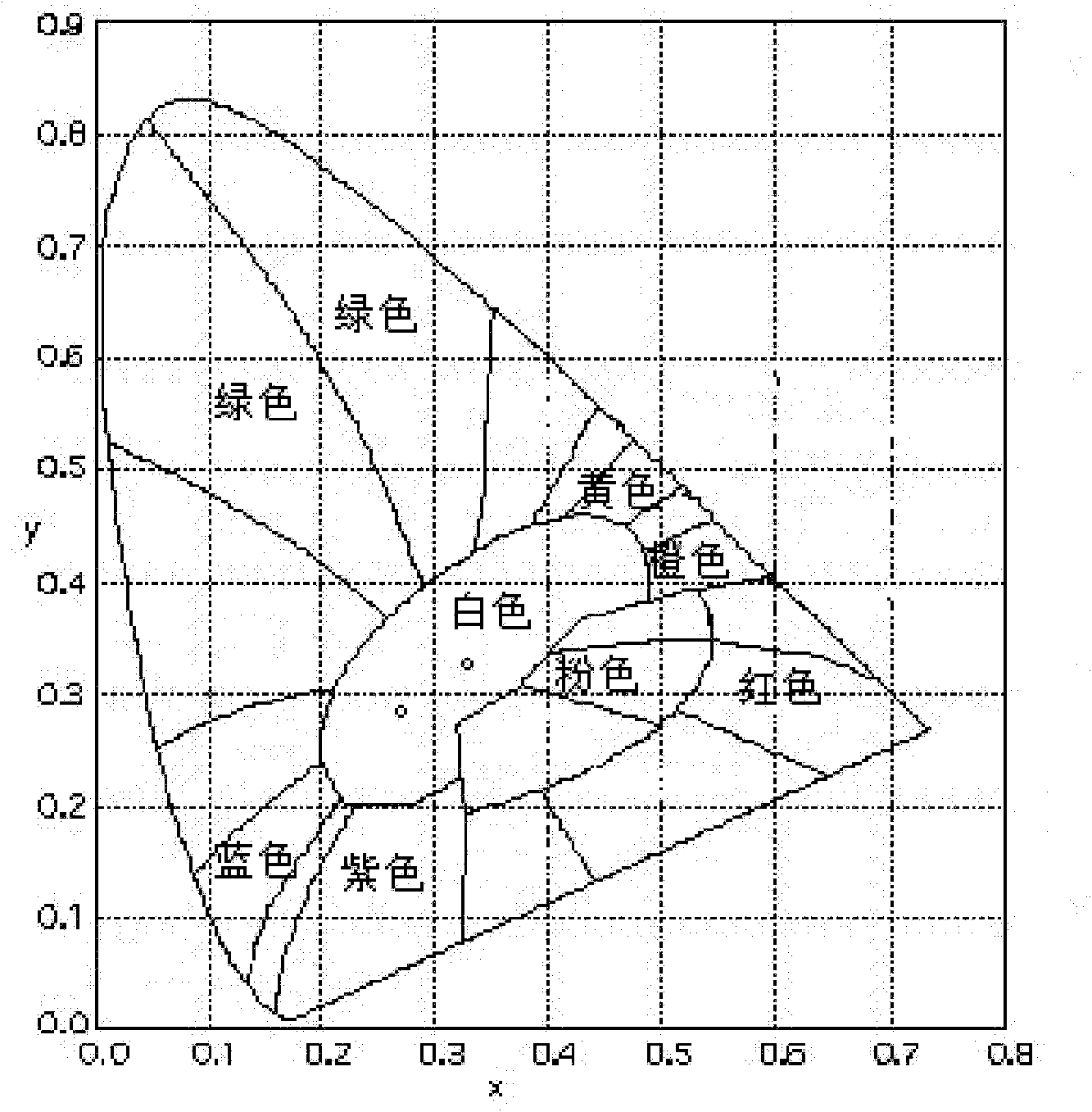

Nanometer ceramic solar film

InactiveCN102837460AGood spectral selectivityImprove transmittanceSynthetic resin layered productsVacuum evaporation coatingInfraredThermal insulation

The present invention relates to a nanometer ceramic solar film. According to the nanometer ceramic solar film, a firs layer titanium dioxide film, a second layer titanium nitride film and a third titanium dioxide film are sequentially plated on a surface of a substrate PET through magnetron sputtering, wherein a thickness of the substrate PET is 23-50 mum, a thickness of the first layer titanium dioxide film is 26-38 nm, a thickness of the second layer titanium nitride film is 20-26 nm, and a thickness of the third layer titanium dioxide film is 26-38 nm. The nanometer ceramic solar film of the present invention has the following characteristics that: good spectral selective permeability, high transmittance in a visible light region, and high reflectivity in an infrared region are provided, wherein infrared rays are blocked so as to reduce heat source, such that thermal insulation is achieved while transmittance on visible light is not affected; and titanium dioxide and titanium nitride have high chemical stability at a room temperature, are not easily oxidized, and do not react with oxygen, water, steam, hydrochloric acid, sulfuric acid and the like under normal circumstances, such that performances are stable, fading and discoloration can not be generated, and a service life is long.

Owner:SOUTHWESTERN INST OF PHYSICS

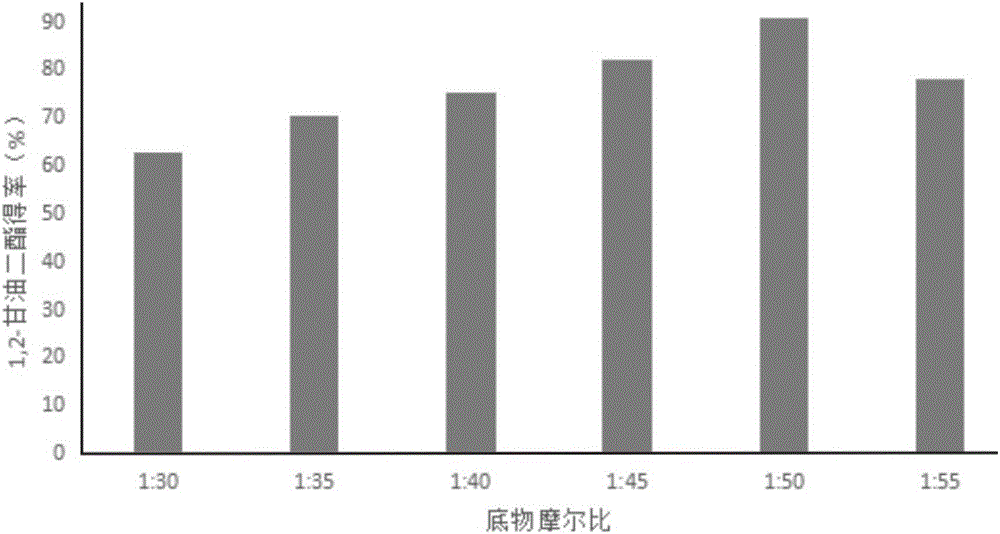

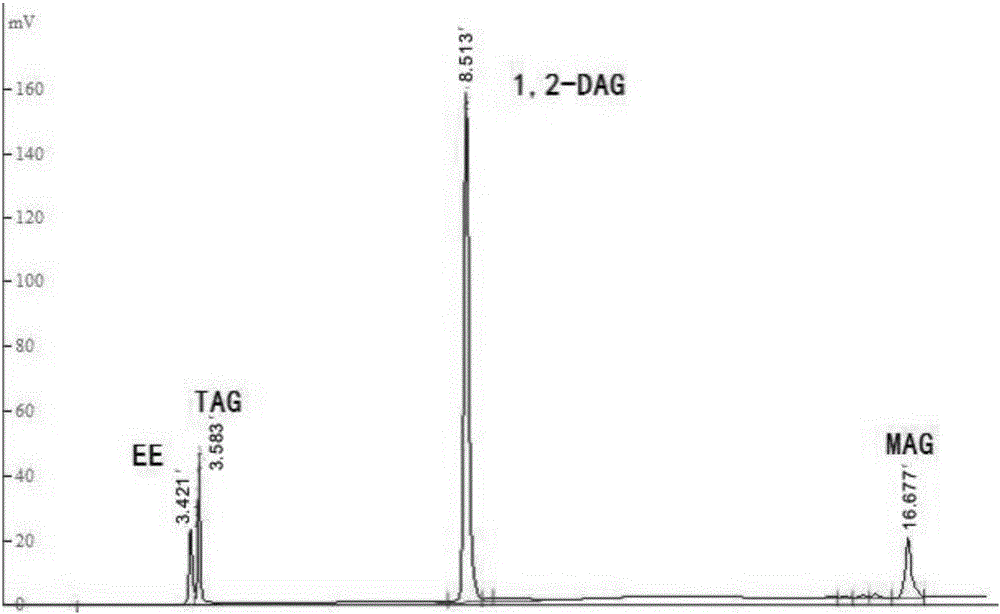

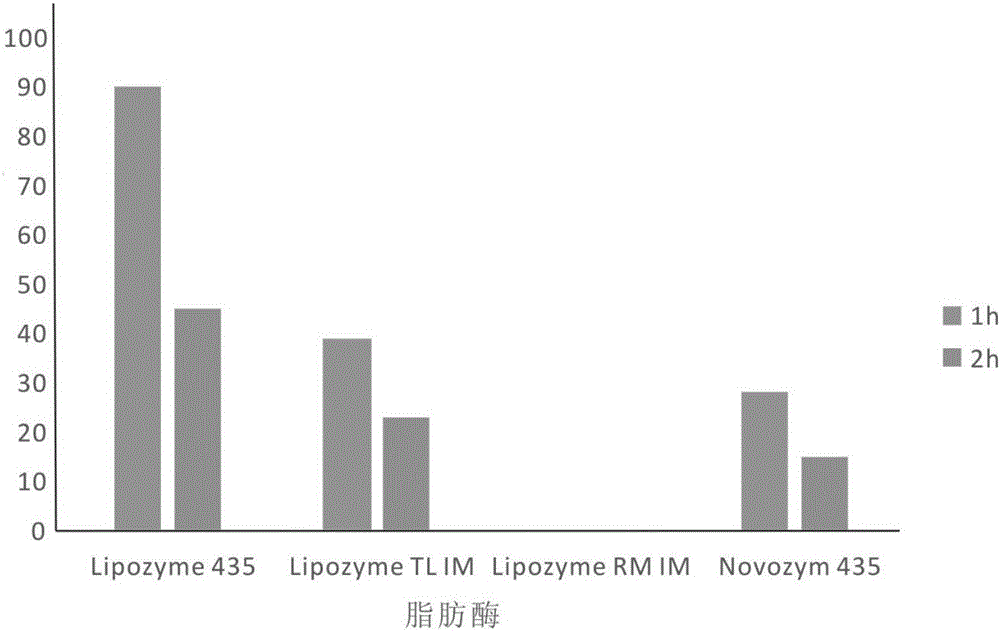

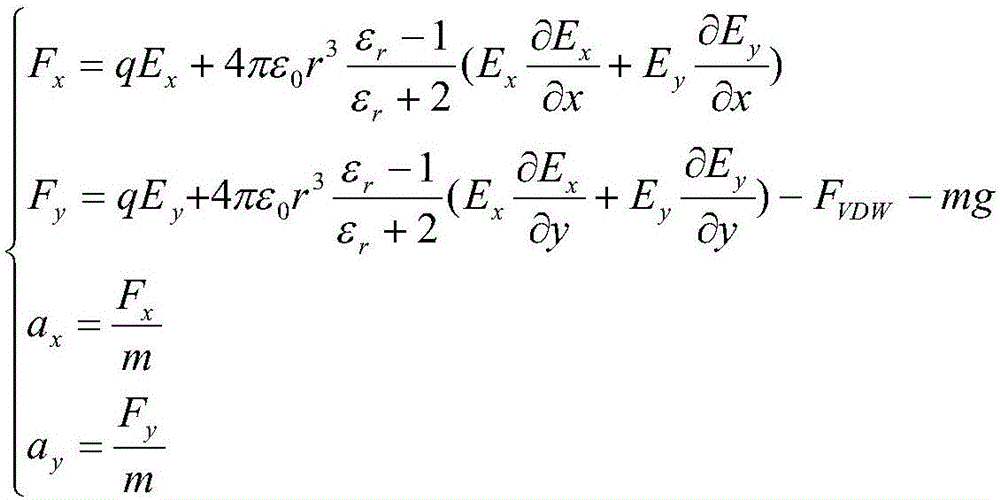

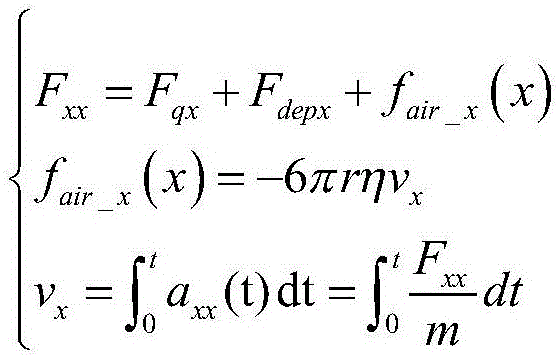

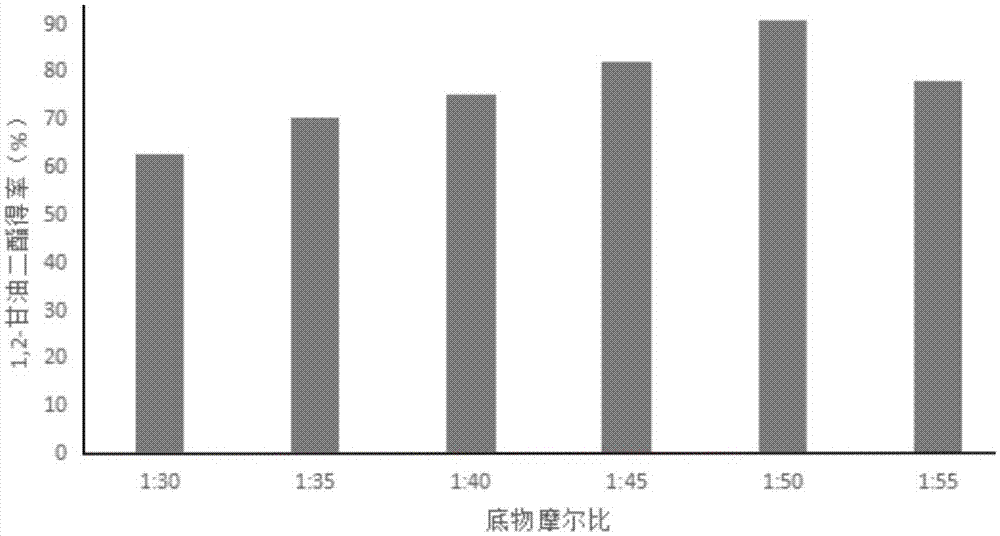

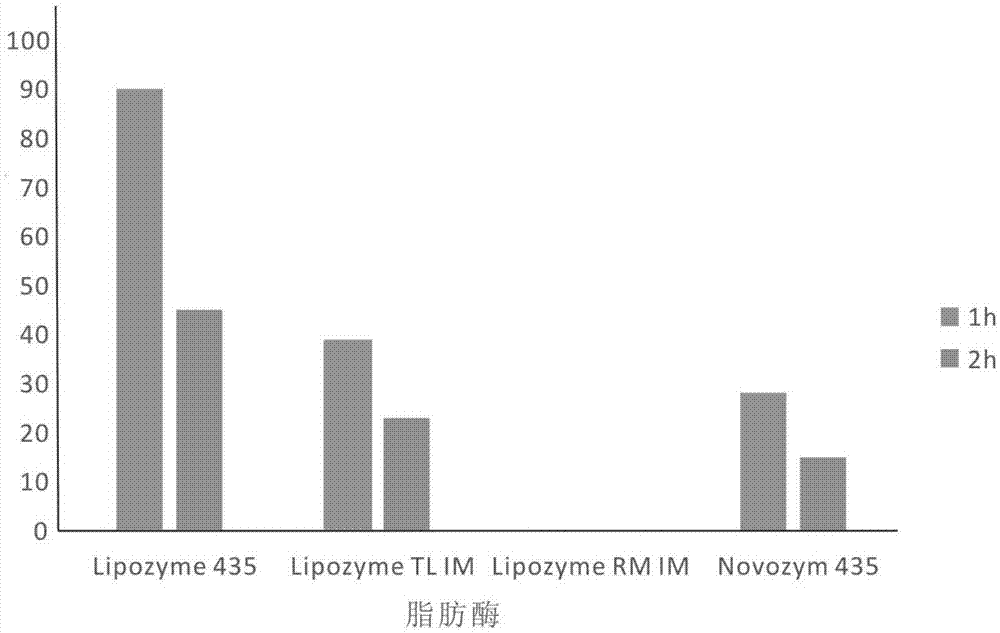

Method for enzymatic synthesis of 1,2-diacylglycerol and method for purifying obtained 1,2-diacylglycerol

ActiveCN106399405ASource of reductionWide variety of sourcesOrganic compound preparationFatty acids production/refiningEnzymatic synthesisVegetable oil

The invention discloses a method for enzymatic synthesis of 1,2-diacylglycerol and a method for purifying obtained 1,2-diacylglycerol. The enzymatic synthesis method comprises the steps that vegetable oil and an organic solvent are mixed based on a molar ratio of 1 to 10-100; after stirring and emulsification, immobilized lipase with the mass accounting for 2 to 20% of the total mass of a substrate is added; after reaction for 0.5 to 6 hours at a temperature of 20 to 70 DEG C, centrifugal removing of lipase is carried out to obtain a product containing 1,2-diacylglycerol. The purification method comprises the step that two-step-crystallization-process-based purification is carried out on the product and two kinds of organic solvents. The purity of the purified 1,2-diacylglycerol can reach up to 100%. According to the method for synthetizing 1,2-diacylglycerol and the method for purifying the obtained 1,2-diacylglycerol provided by the invention, the reaction rate can increase obviously and the yield is high; the product is easy to purify and the purity is high. The methods conforming to a green chemistry concept have advantages of being high in efficiency, being fast in speed, and being convenient for industrial production.

Owner:JIANGNAN UNIV

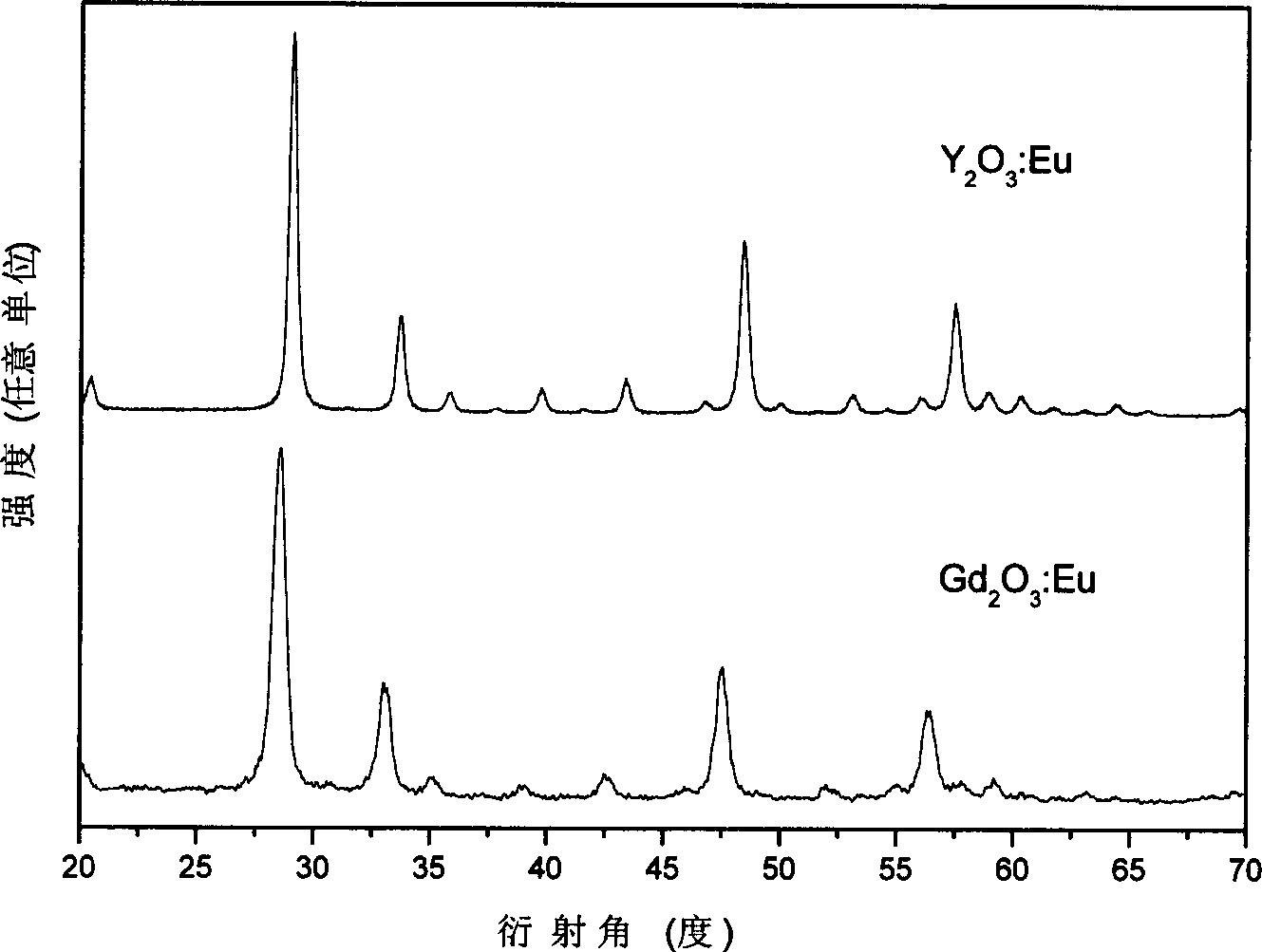

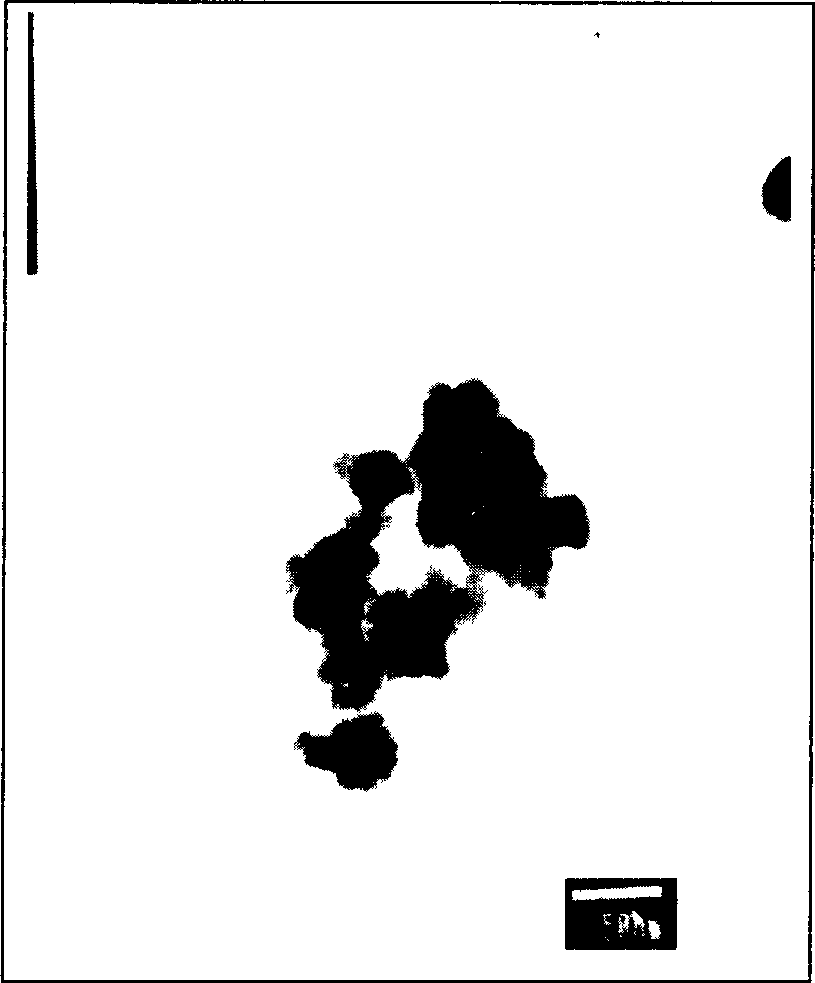

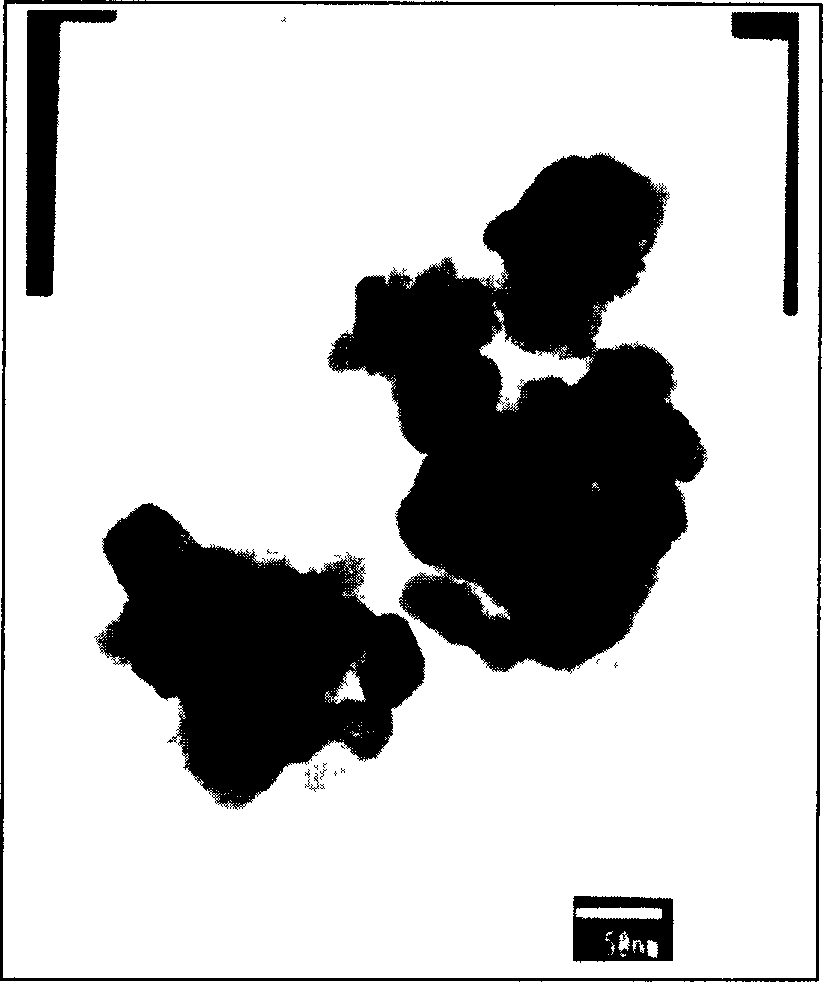

Method for preparing red nano fluoresent powder of rare earth

The preparation method for red nano rare-earth fluorescent powder with 10-30nm grain size overcomes the problems of complex process, low product purity and high cost in prior art, and comprises: (1) dissolving the Eu2O3 and Ln2O3 into strong HNO3 solution, adjusting pH value; (2) water bathing and continual stirring; (3) heating with microwave; (4) calcining the dried gel. This invention brings no impurity, reduces about 30% energy, and convenient to be controlled.

Owner:HARBIN INST OF TECH

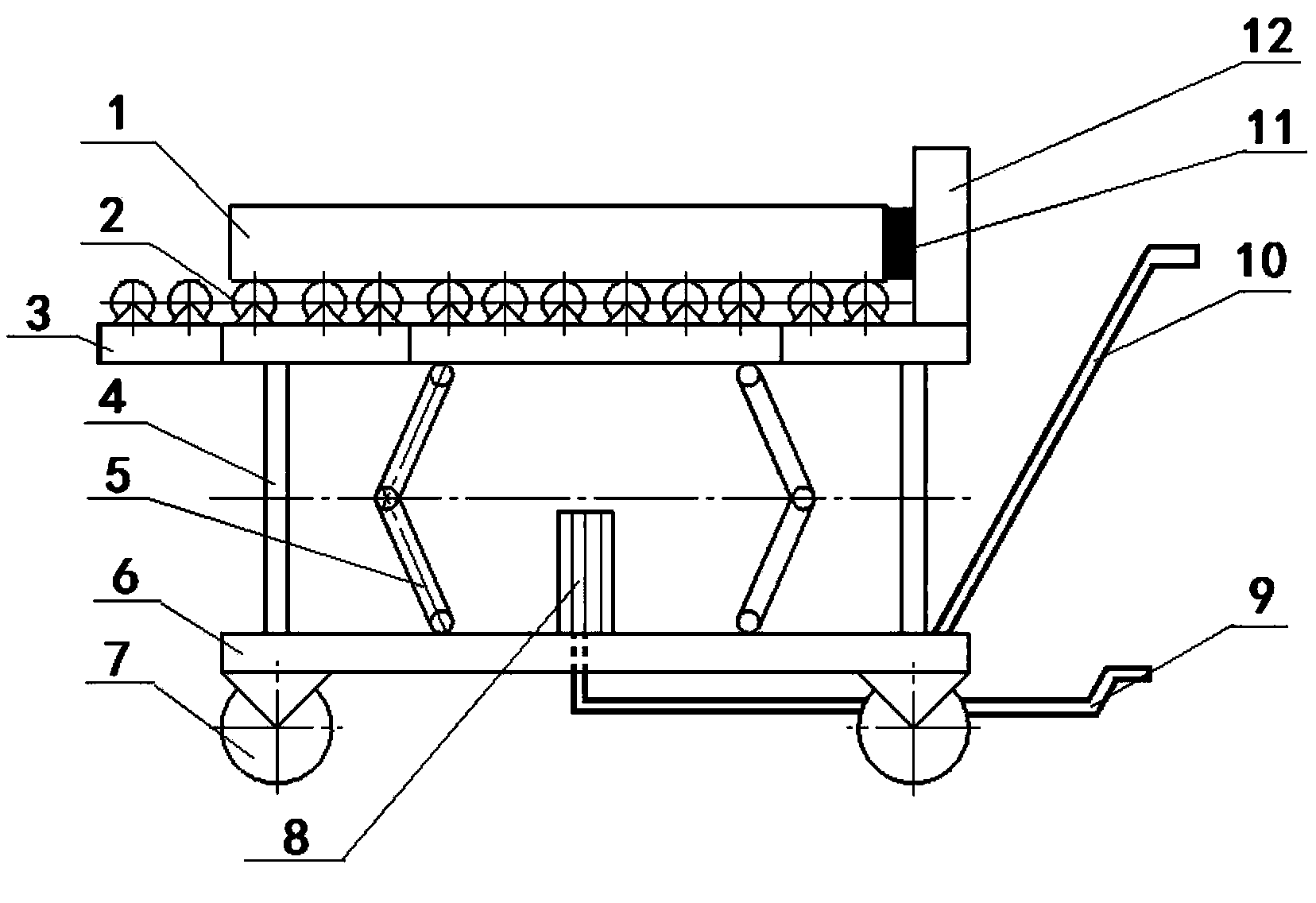

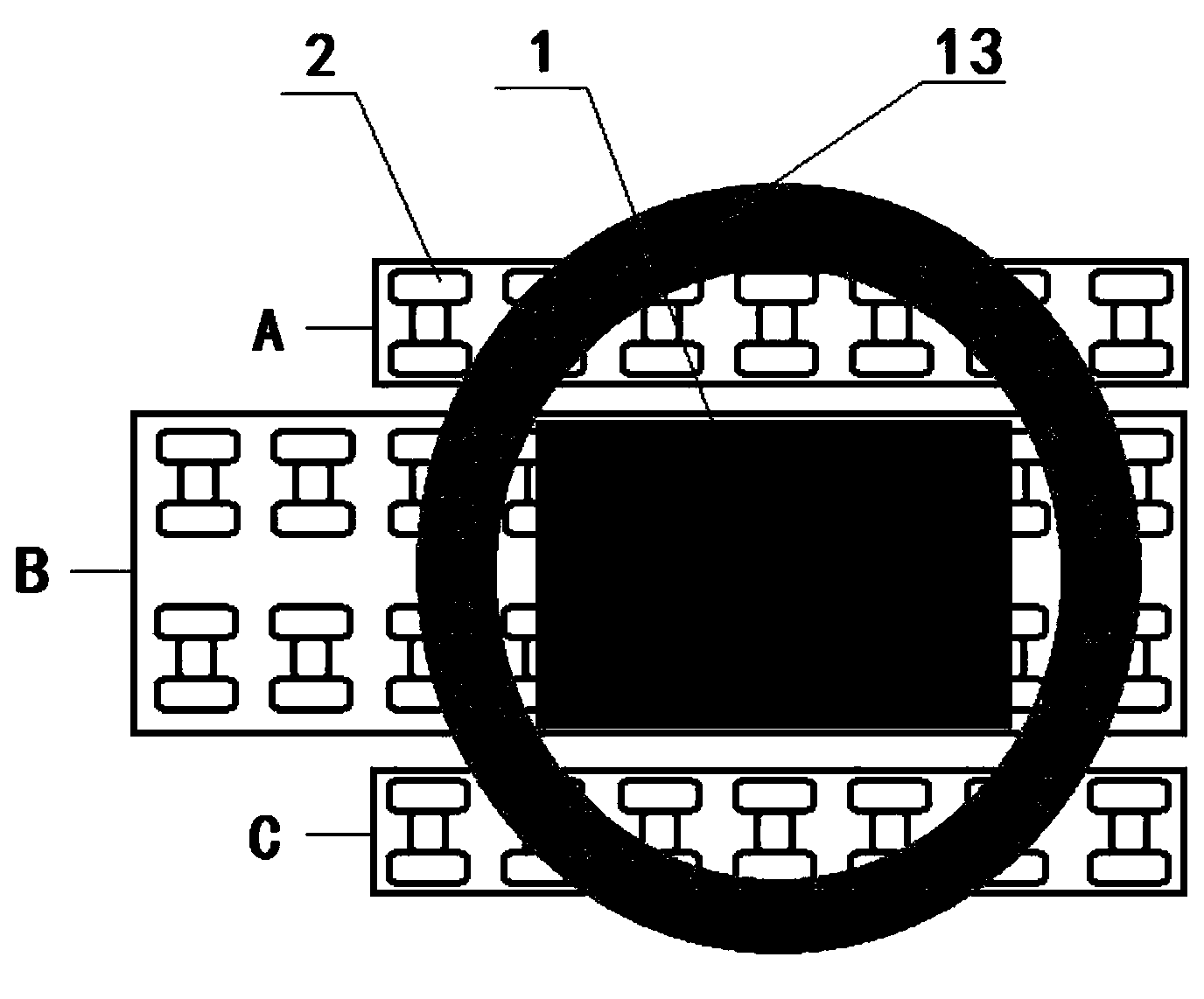

Large-scale ring polishing machine workpiece carrying transportation vehicle

InactiveCN103448766AReduce labor intensityReduce sources of impuritiesHand carts with multiple axesEngineeringGasket

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Low-harm fracturing fluid and preparation method thereof

The invention relates to a low-harm fracturing fluid and a preparation method thereof. In the prior art, the fracturing fluid can produce much residue, and therefore bringing residue harm and other adverse effects on the fracturing effect. In the technical scheme provided by the invention, the components of the low-harm fracturing fluid and the content of each component are as follows: 0.15 to 0.2 percent of natural vegetable gum thickening agent, 0.3 to 0.5 percent of viscoelastic surfactant, 0.4 to 0.8 percent of cross-linking agent and the balance of water; the viscoelastic surfactant is unsaturated fatty acid salt which has viscoelasticity under the alkaline condition; and the cross-linking agent is conventional boron cross-linking agent. The invention has the following characteristics: (1) since the usage of natural vegetable gum is reduced, residue is reduced; (2) the amount of the residue of the guar gum can be reduced to 13 percent of the usage of the guar gum, so that the harm of the fracturing fluid on crude oil reservoirs can be decreased; and (3) compared with the cost of the clean fracturing fluid, the cost of the low-harm fracturing fluid is lower.

Owner:北京中海沃邦能源投资有限公司

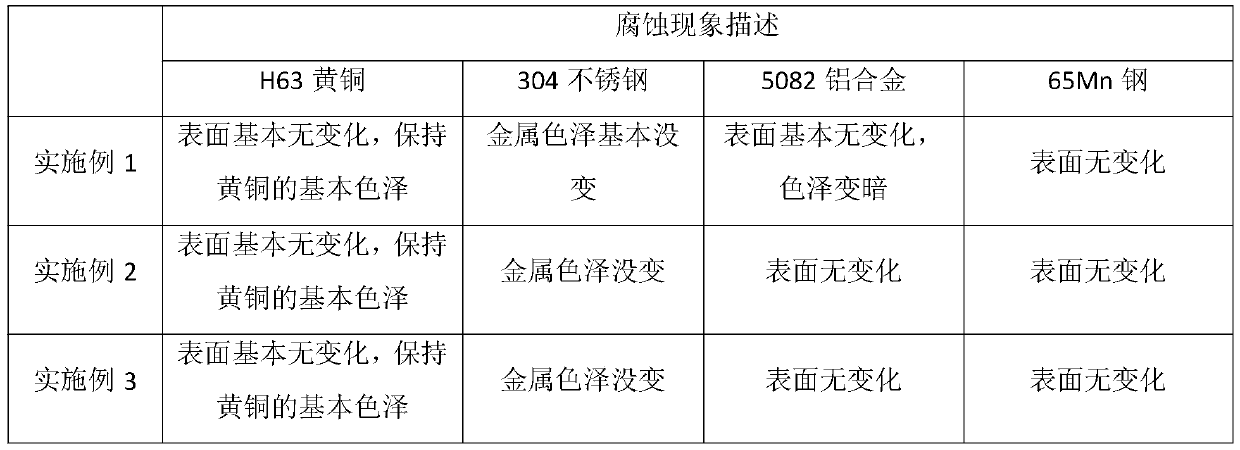

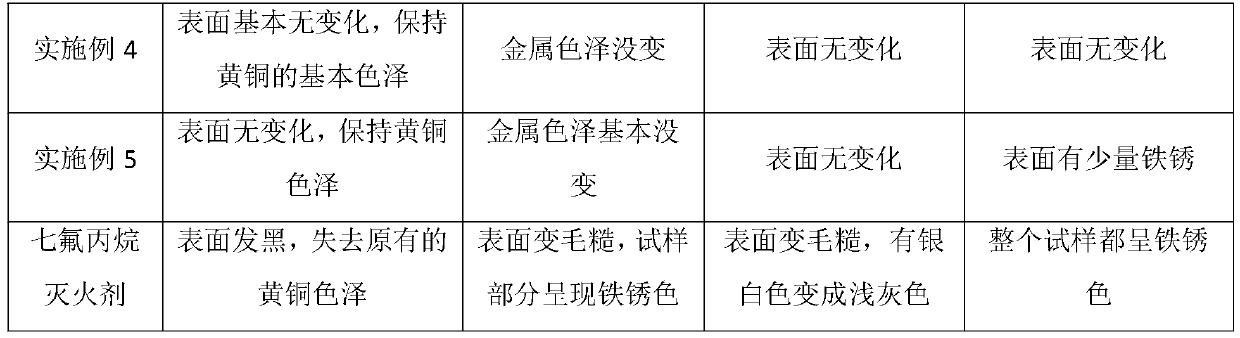

Efficient composite fire extinguishing agent and preparation method thereof

The invention discloses an efficient composite fire extinguishing agent and a preparation method thereof, and relates to the technical field of firefighting. The fire extinguishing agent comprises, byweight, 28-36 parts of heptafluoropropane, 40-48 parts of 1,1,2,2,3,3,4-heptafluorocyclopentane, 4-8 parts of liquid nitrogen, 6-12 parts of ammonium bicarbonate, 1-5 parts of calcium carbonate, 1-3parts of potassium sulfate, 2-6 parts of talcum powder and 1-5 parts of diatomite. The fire extinguishing agent has the advantages of combination of the fire extinguishing advantages of several physical and chemical fire extinguishing agents, improved fire extinguishing efficiency, low corrosivity, long atmospheric survival time and low greenhouse effect potential value.

Owner:JIUJIANG CSSC CHEM TECH

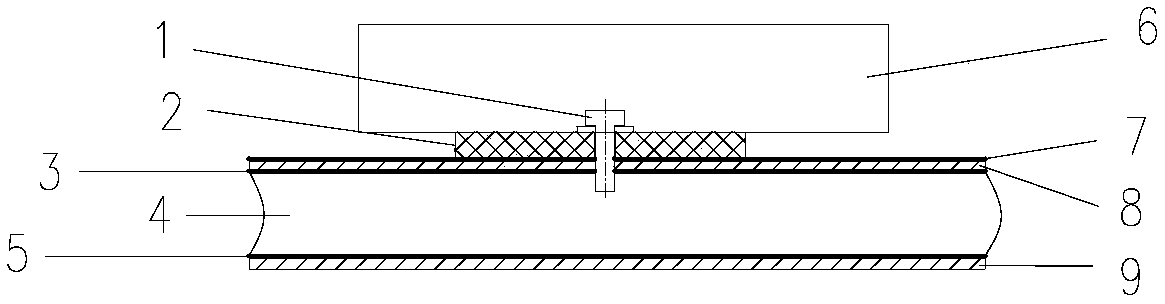

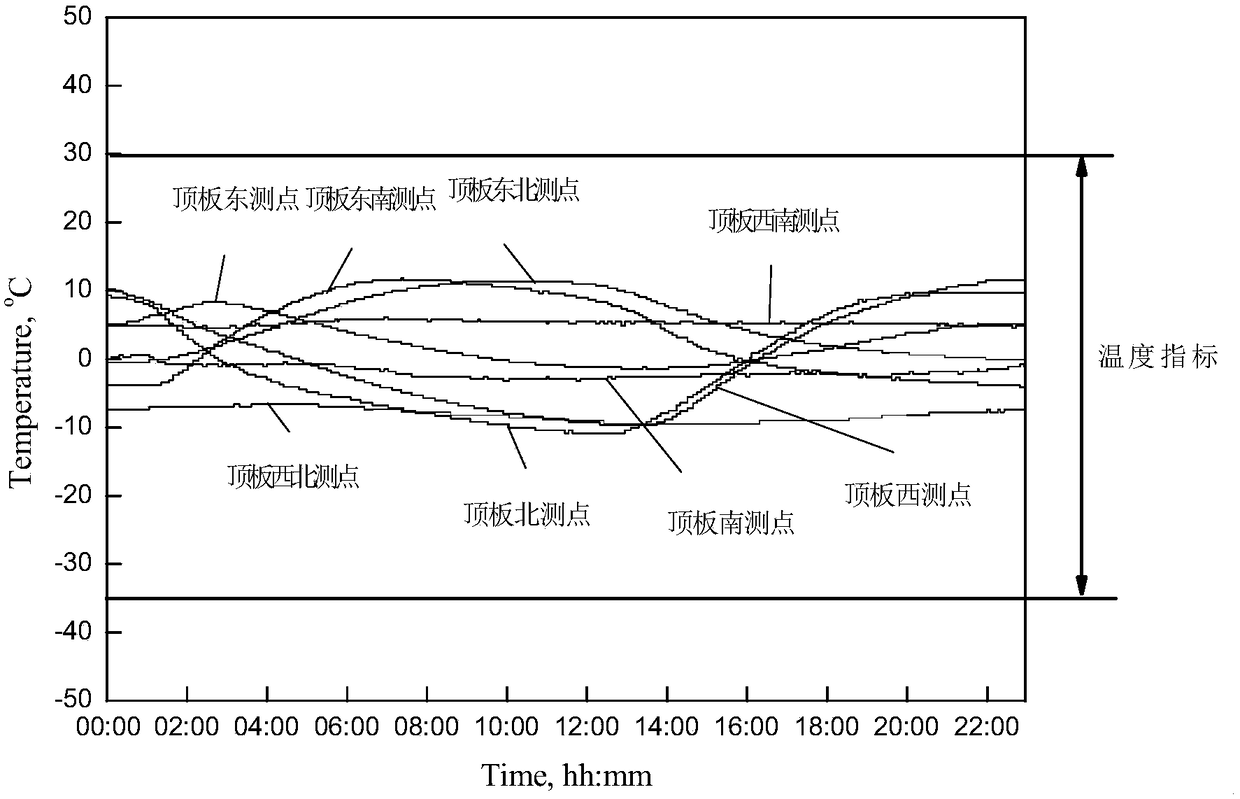

Satellite roof refined thermal design device

InactiveCN108528760AReduce the impactReduce temperature gradients and fluctuationsCosmonautic partsArtificial satellitesThermal insulationSatellite

The invention discloses a satellite roof refined thermal design device which comprises a satellite roof, a multilayer structure, a thermal insulation gasket and screws, wherein the multilayer structure comprises a satellite interior multilayer thermal insulation assembly and a satellite exterior multilayer thermal insulation assembly; the satellite interior multilayer thermal insulation assembly is coated on the lower side of the satellite roof and arranged towards the satellite interior side; the satellite exterior multilayer thermal insulation assembly is coated on the upper side of the satellite roof and arranged towards the satellite exterior side; a load is connected onto the satellite roof by virtue of screws; the thermal insulation gasket is positioned between the load and the satellite roof. According to the satellite roof refined thermal design device disclosed by the invention, the influences of space environment and internal external heat flux on the roof can be greatly reduced, the temperature gradient and fluctuation of the roof can be reduced, and different temperature requirements of the roof on a transition section and during an in-orbit period can be met; due to athermal insulation design of the roof and the load, heat leakage of the load can be effectively reduced, and the temperature gradient and fluctuation of the roof can be reduced; the thermal design method is reasonable and feasible, full in material source, high in reliability, simple in process operation, easy to realize and low in cost.

Owner:SHANGHAI SATELLITE ENG INST

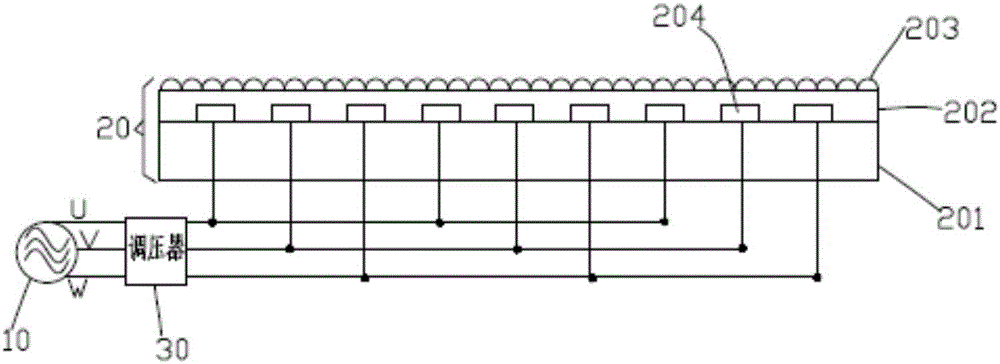

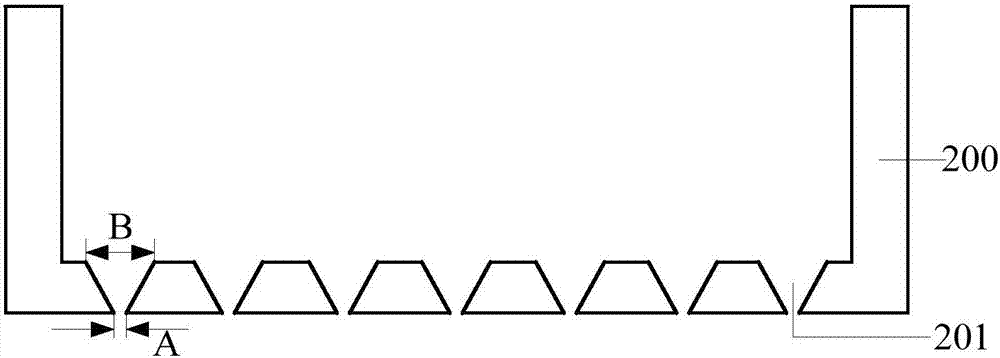

Three-phase traveling wave electric curtain dust removing system and construction method thereof

InactiveCN106540929AImprove dust removal efficiencyGood effectPhotovoltaicsPhotovoltaic energy generationEngineeringThree-phase

The invention discloses a three-phase traveling wave electric curtain dust removing system. The system comprises a three-phase alternating-current power supply and an electric curtain plate; the electric curtain plate consists of an insulation substrate, and multiple sets of electrodes uniformly distributed on the surface of the substrate; the electrodes are cuboids, and are in parallel; the widths of the electrodes are equal to gaps between two adjacent electrodes; every three adjacent electrodes form one set as a moving period; and three electrodes in the moving period are connected with a U-phase line, a V-phase line and a W-phase line of the three-phase alternating-current power supply correspondingly. Through reasonable design of the electrode structures, micro dust continuously moves in an electric field formed among the electrodes to be removed, so that the dust removing effect is effectively improved.

Owner:苏州中环建科环境科技有限公司

Method for synthesizing 1,2-diglyceride with an enzymic method

ActiveCN105441494ASource of reductionWide variety of sourcesFermentationOrganic solventVegetable oil

The invention discloses a method for synthesizing 1,2-diglyceride with an enzymic method. The method comprises the steps of mixing vegetable oil with an organic solvent according to the mole ratio of 1:10 to 100, stirring, emulsifying, then adding immobilized lipase of which the mass is 2 to 20% of the total mass of substrates, reacting for 0.5 to 6 h at the temperature of 20 to 70 DEG C, and centrifuging to remove the lipase, so as to obtain a product which contains the 1,2-diglyceride. The synthetic method provided by the invention has the advantages of high yield, high efficiency, rapidity and convenience in industrial production and conforms to green chemistry, the reaction rate can be obviously increased, and the product is easy to purify.

Owner:JIANGNAN UNIV

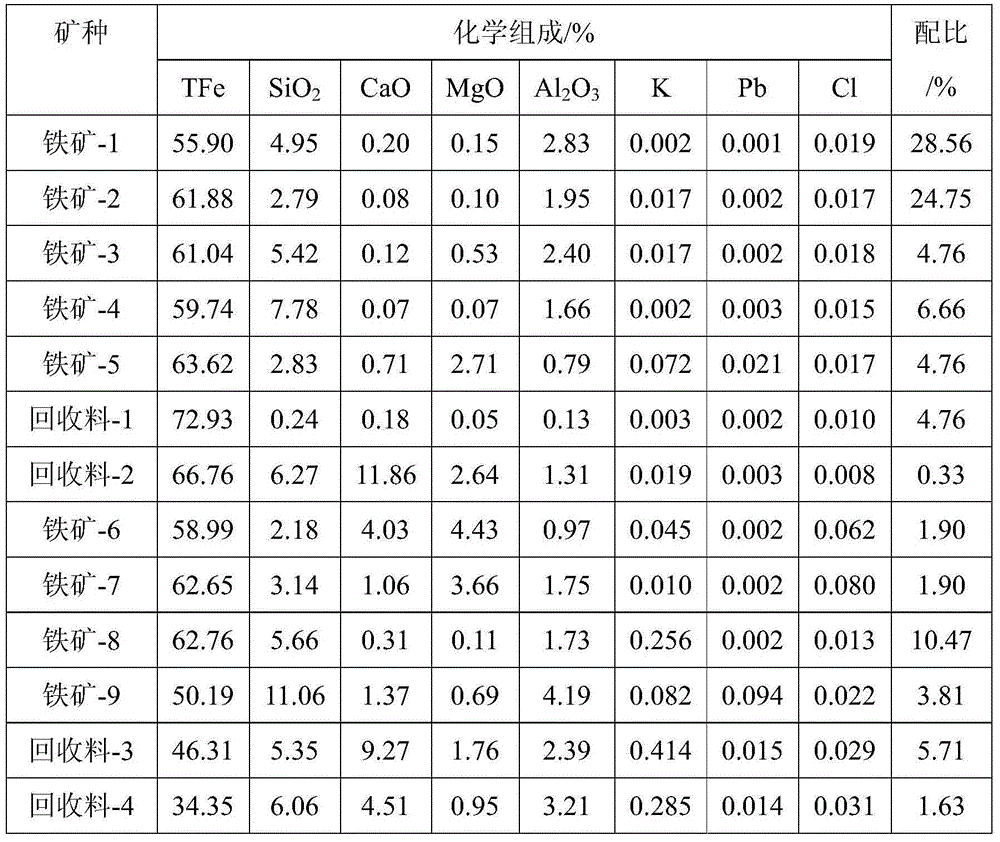

Method for reducing emission of PM2.5 in iron ore sintering flue gas

The invention discloses a method for reducing the emission of PM2.5 in iron ore sintering flue gas. According to the method, ferriferous raw materials are divided into high-alkaline-metal ferriferous raw materials, high-lead ferriferous raw materials, high-chlorine ferriferous raw materials and low-harmful-impurity ferriferous raw materials according to the contents of harmful elements such as K (Na), Pb and Cl; the high-alkaline-metal ferriferous raw materials and / or high-lead ferriferous raw materials and raw materials including quicklime are mixed and subjected to primary granulation; granules obtained by primary granulation, the high-chlorine ferriferous raw materials and / or the low-harmful-impurity ferriferous raw materials and raw materials including a silicon-containing solid absorbent are mixed and subjected to secondary granulation; granules obtained by secondary granulation are sintered; and during the sintering process, the granules obtained by secondary granulation can inhibit K (Na) and Pb from being converted into PM2.5 and enhance the PM2.5 adsorption of liquid-phase substances and the solid absorbent, thereby realizing effective control over the emission of PM2.5.

Owner:CENT SOUTH UNIV

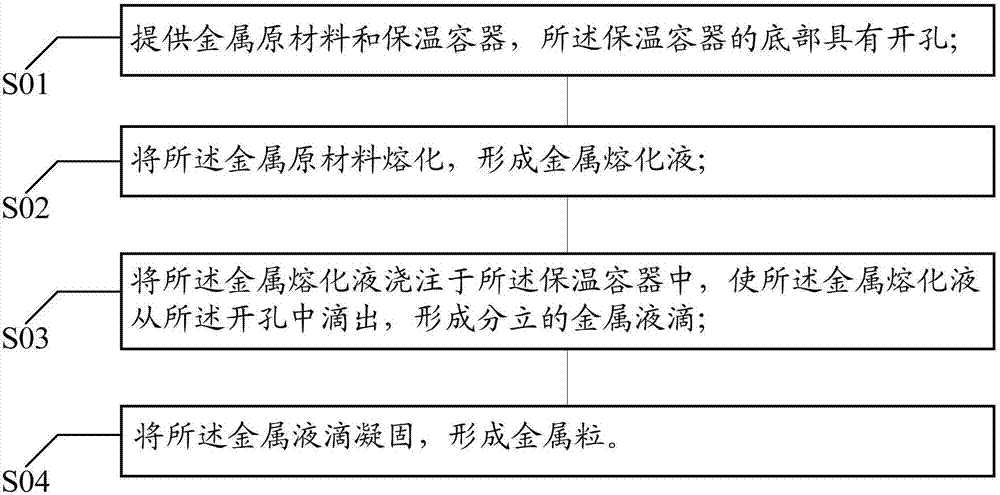

Metal particle forming method and metal particle preparing device

The invention provides a metal particle forming method and a metal particle preparing device. The metal particle forming method comprises the steps that a metal raw material and a heat preservation container are provided, and the bottom of the heat preservation container is provided with holes; the metal raw material is melted, and metal molten liquid is formed; the metal molten liquid is poured into the heat preservation container and dripped out of the holes, and independent metal liquid drops are formed; and the metal liquid drops are solidified, and metal particles are formed. According to the metal particle forming method, the purity of the metal particles can be guaranteed, and the technology efficiency is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

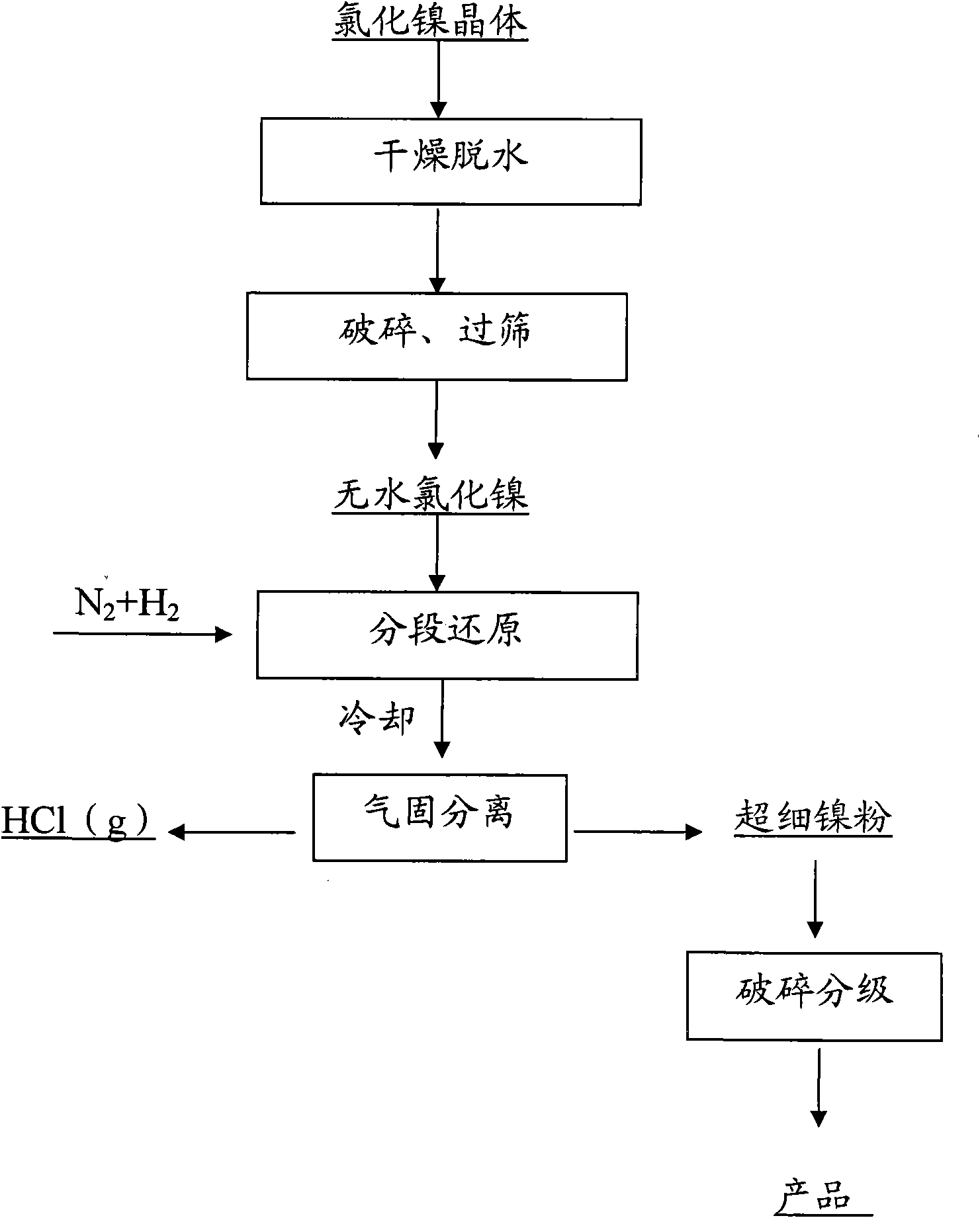

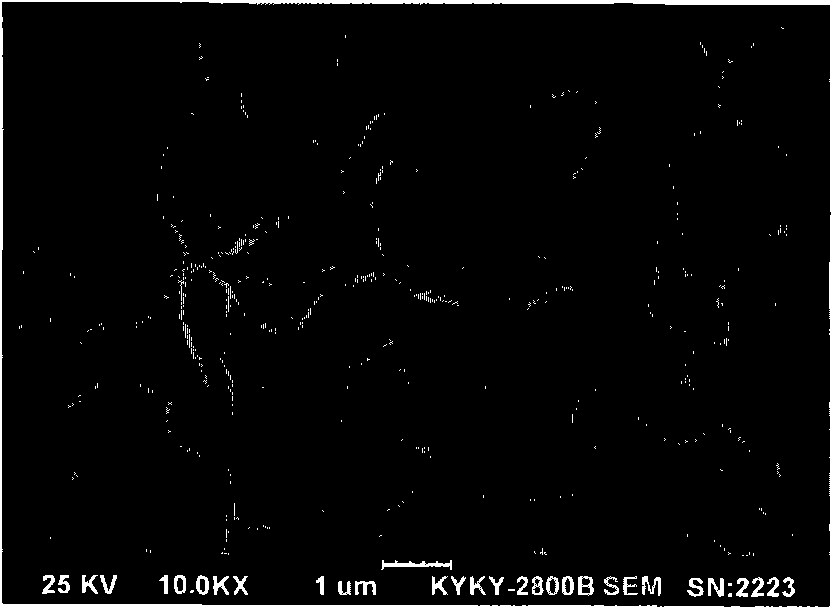

Method for preparing superfine nickel powder by direct reduction

The invention relates to a process for preparing metal powder and provides a method for superfine nickel powder by direct reduction. The method comprises the following steps: drying and dehydrating nickel chloride crystals serving as a nickel source to obtain absolute nickel chloride; and performing a reduction reaction by using hydrogen at 230 to 700 DEG C in a protective gas to obtain the superfine nickel powder. In the preparation method, the absolute nickel chloride crystals are reduced directly to form the nickel powder. As the synthesis of a precursor (such as the nickel carbonate or nickel oxalate in the conventional wet-method process) is not required in the solid-phase direct reduction method, working procedures are saved and process cost is reduced greatly; and meanwhile, almostno waste water is discharged, so the method is favorable for environment protection. In addition, the absolute nickel chloride crystals are used as a nickel raw material to undergo a reaction in a hydrogen reducing atmosphere, so the source of carbon is reduced, the carbon content of the final product is reduced, and the low-carbon and environment-protection requirements are met.

Owner:JINGMEN GEM NEW MATERIAL +1

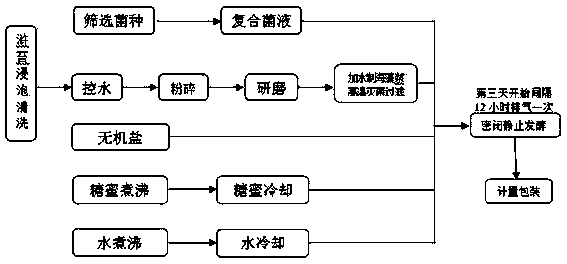

Seaweed biological deodorant and preparation method thereof

ActiveCN103656712APromote proliferationStrong bactericidal abilityDeodrantsBacterial agentProteolysis

The invention discloses a seaweed biological deodorant and a preparation method thereof. The seaweed biological deodorant comprises the following components in parts by weight: 10-20 parts of a composite bacterial agent, 20-40 parts of seaweed pulp, 3-8 parts of inorganic salt, 5-15 parts of molasses, and 40-60 parts of water. The seaweed biological deodorant, provided by the invention, is prepared through the steps of screening and culturing a group of multi-functional microbial flora and fermenting for two times through different fermentation bases, and is the fermented microorganism and metabolite thereof as well as fermentation base material, and can deodorize for purifying air, and can kill pathogenic microorganisms, so that the amount of ammonia gas generated through proteolysis is reduced, and further, environment pollution is reduced.

Owner:日照贝斯特环保生物科技有限公司

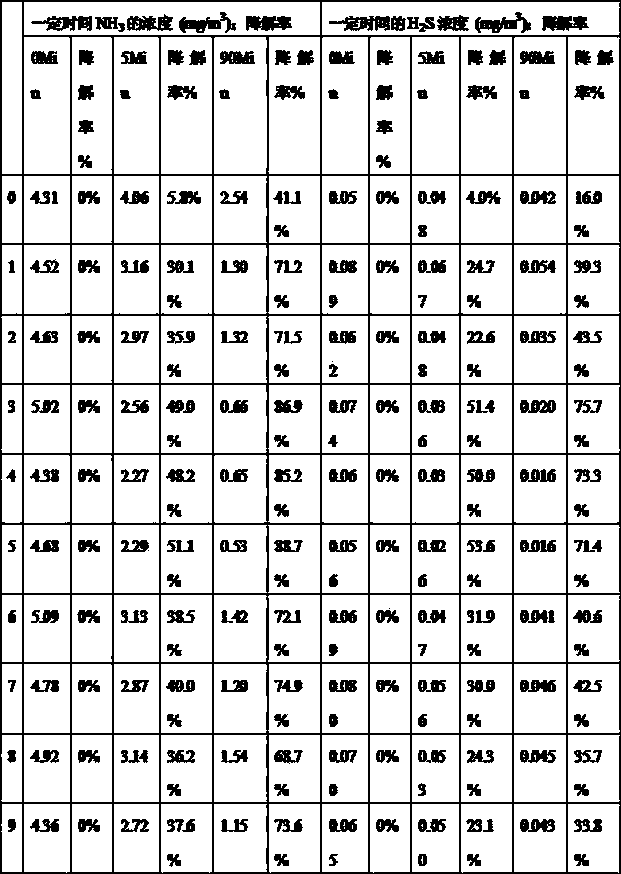

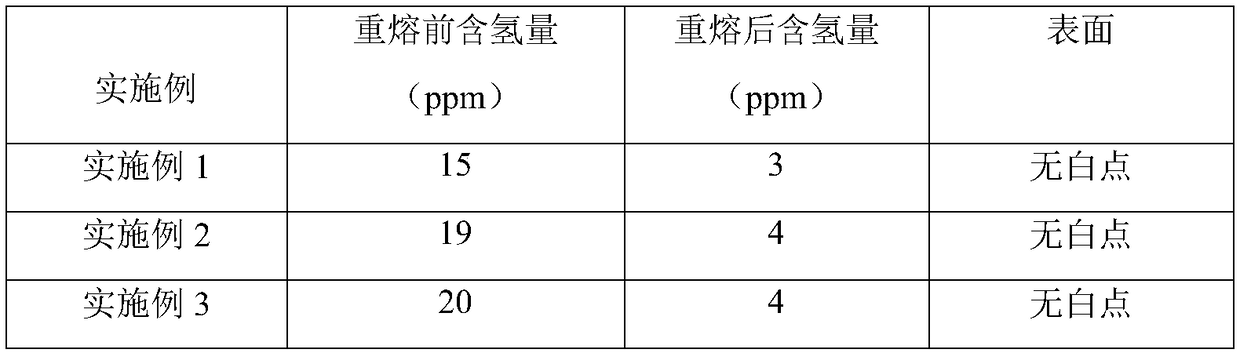

Electroslag remelting slag system and electroslag remelting 40CrNiMoA low-hydrogen control method

The invention discloses an electroslag remelting slag system and an electroslag remelting 40CrNiMoA low-hydrogen control method. The slag system adopted in electroslag remelting comprises components including, by weight percent, 20%-30% of Al2O3, 5%-8% of SiO2, 3%-5% of MgO and the balance CaF2. The alkalinity of the electroslag remelting slag system is 0.7-0.9. Slag materials, electrodes and argon are subjected to drying treatment, and the source of hydrogen in the electroslag process is greatly reduced. Aluminum powder needs to be evenly added in the electroslag remelting process, and the aluminum powder adding speed is 1.5-3 g / min. According to the low-hydrogen control method, the hydrogen reduction effect is extremely good, operation is simple, and energy consumption and cost are low.The hydrogen content of the prepared remelting 40CrNiMoA alloy is low to 3 ppm, and the surface is free of white spots. The method is easy to control and low in cost. The properties such as strength,tenacity, abrasion resistance and corrosion resistance are shown excellently.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

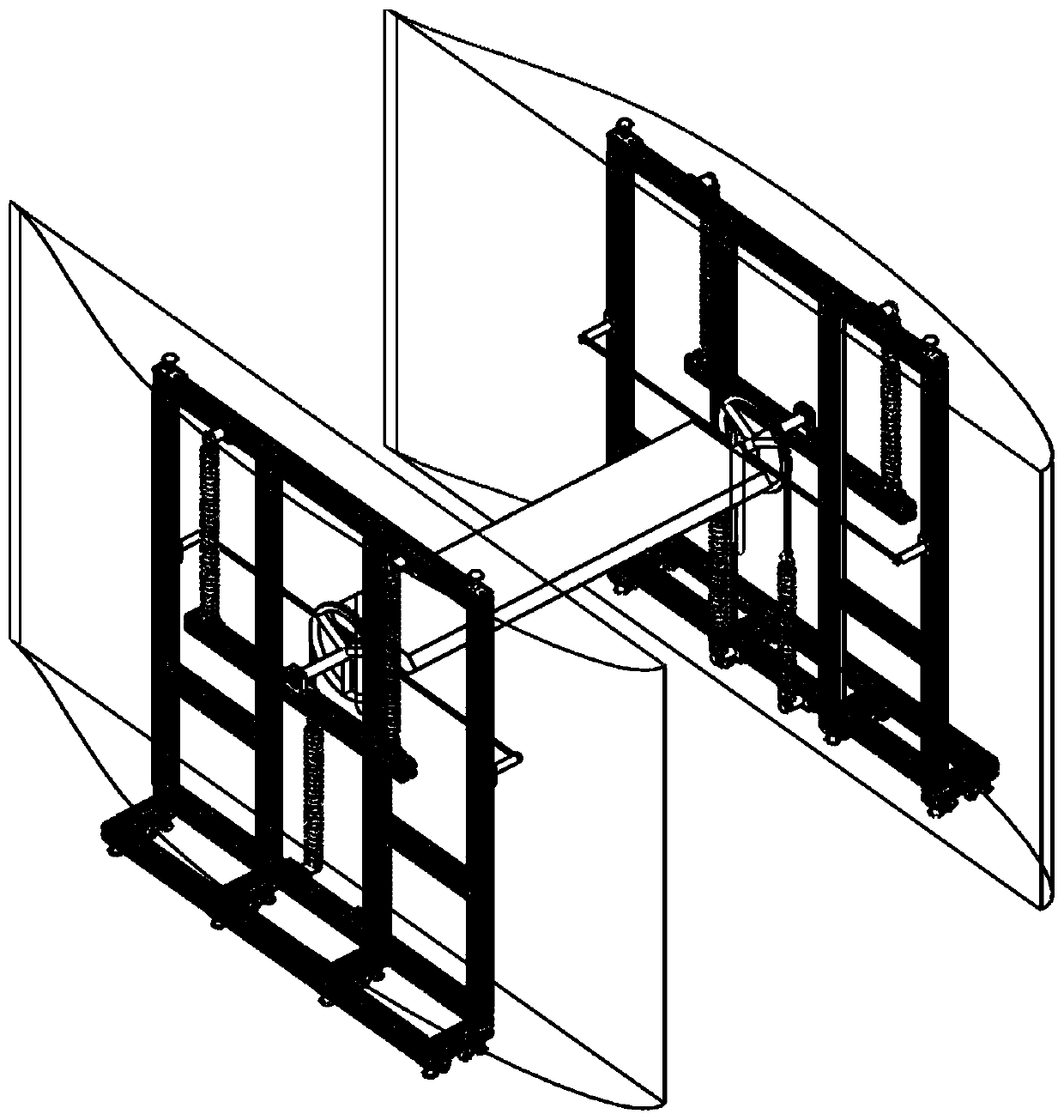

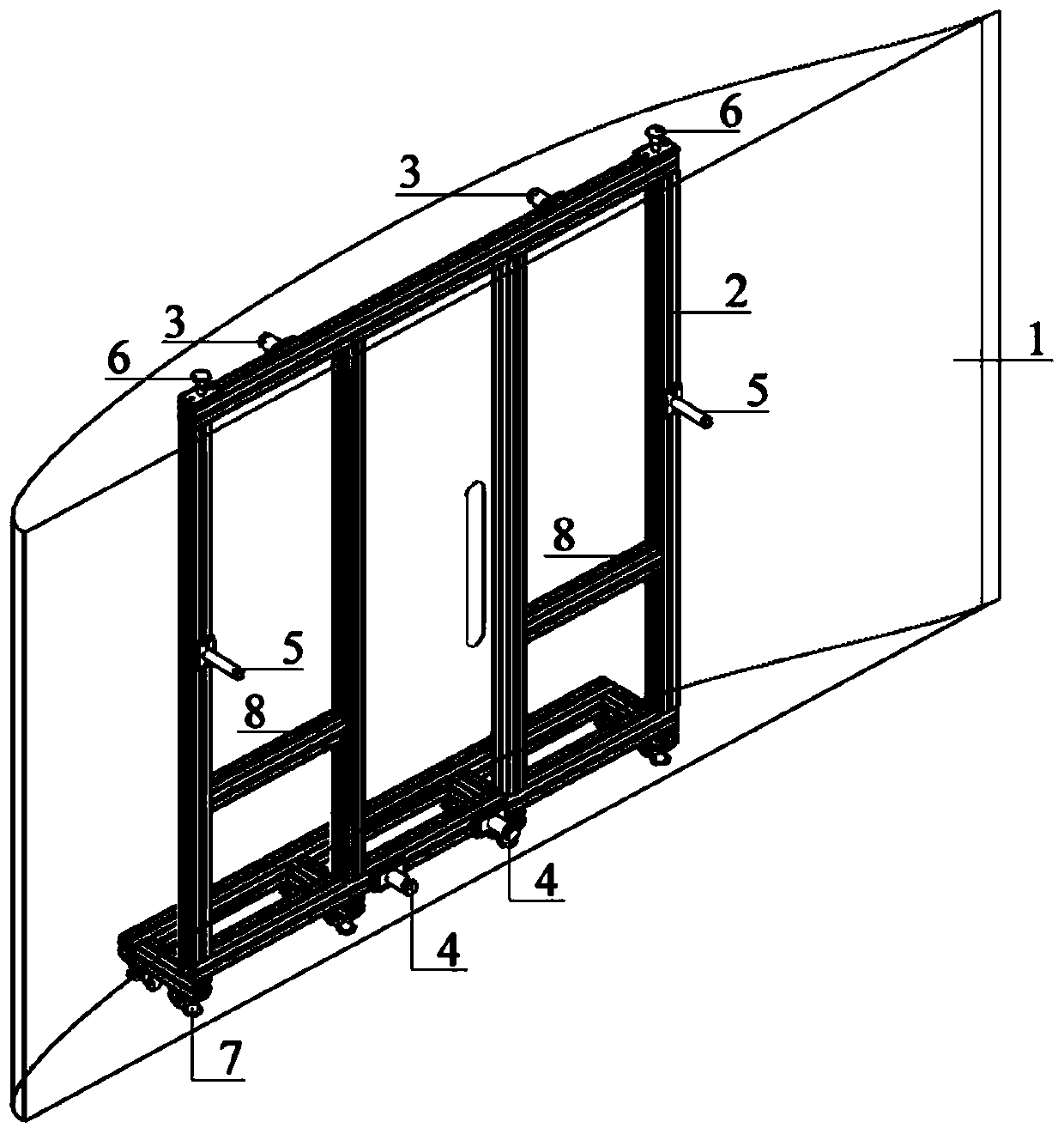

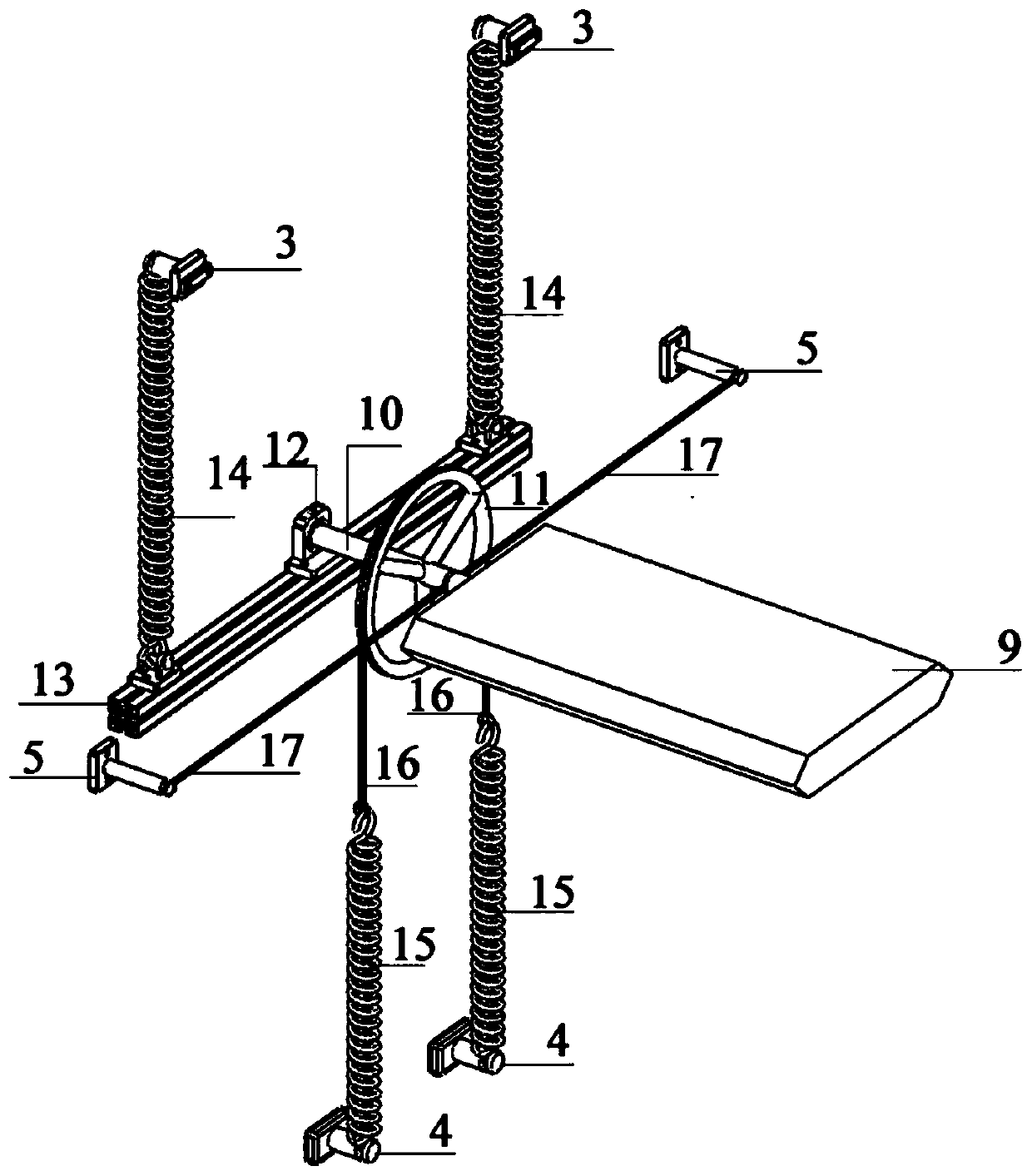

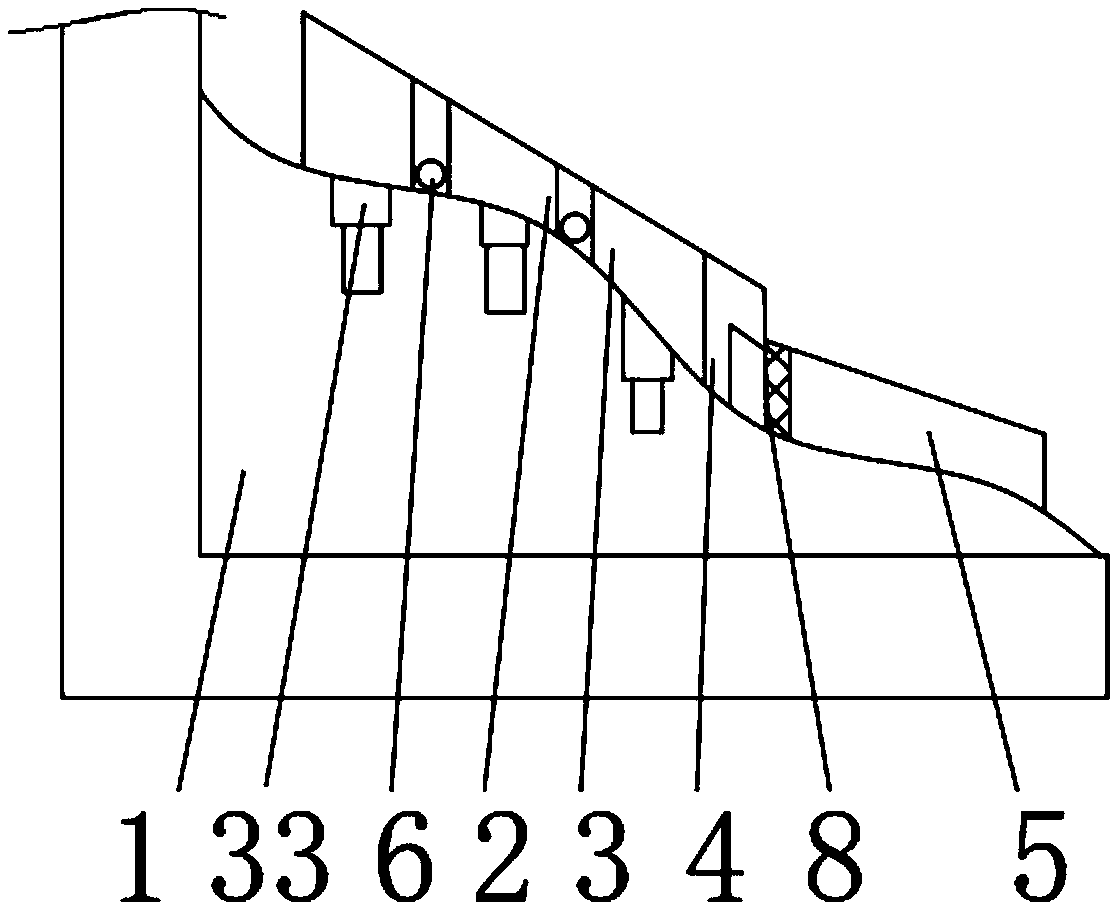

Vertical-torsion coupled large-amplitude free vibration wind tunnel experiment system

ActiveCN111562080ANo bending and torsion resistanceReduce stiffnessAerodynamic testingVibration testingBraced frameClassical mechanics

The invention relates to a vertical-torsion coupled large-amplitude free vibration wind tunnel experiment system. The system comprises two symmetrically-installed supporting frames, the tops of the supporting frames are provided with at least two upper spring fixing arms, and the upper spring fixing arms are connected to the upper ends of upper springs; lower spring fixing arms are arranged at thebottoms of the supporting frames; the lower spring fixing arms are connected to the lower ends of lower springs; the lower ends of the two upper springs are connected through a rigid suspension arm;a bearing seat is mounted on the rigid suspension arm; two ends of a rigid test model are respectively fixedly connected to one end of a rigid shaft; the other end of the rigid shaft is fixedly arranged in the bearing seat; a hub is fixedly connected to the rigid shaft, a torsion center line of the rigid test model is collinear with the axis of the rigid shaft and the center line of the hub, the periphery of the hub is sleeved with and fixedly connected to the middle of a first flexible connecting piece, and two ends of the first flexible connecting piece extend downwards and are connected tothe upper ends of the lower springs respectively. The system is independently provided with a torsional rigidity system, so that the flexibility of the test device is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Deodorizing and purifying concentrated solution, and preparation method and application thereof

ActiveCN111249173ACatch quicklyPromote decompositionAntibacterial agentsCosmetic preparationsBiotechnologyArginine

The invention provides a deodorizing and purifying concentrated solution, and a preparation method and an application thereof. The deodorizing and purifying concentrated solution comprises lysine, arginine, glycine, taurine, trehalose, an antibacterial saccharide compound, glycerol monoalkyl ester, a bactericide, a solubilizer and water. The deodorizing and purifying concentrated solution providedby the invention has the following advantages: through mutual cooperation of all components, the synergistic effect is achieved; peculiar smell molecules in the environment can be rapidly captured; organic matter generating odor can be decomposed or neutralized; the source of generated odor gas is reduced; the generated odor gas can be eliminated in time; various common bacteria or fungi can be restrained; the action time is short; the inhibition effect is strong; meanwhile, the deodorizing and purifying concentrated solution can be directly sprayed or diluted and then sprayed onto the body or hair of a pet, and is safe, reliable and low in irritation.

Owner:XIAOPEI NETWORK TECH (SHANGHAI) CO LTD

Manufacturing method of ultra-thin rhenium foil

ActiveCN113058999AEasy to roll and thinProvides rolling efficiencyMetal rolling arrangementsVacuum furnaceMachine press

The invention relates to a manufacturing method of ultra-thin rhenium foil. The manufacturing method comprises the following steps that rhenium powder with the particle size ranging from -100 meshes to -300 meshes and the purity being 4 N or above is placed in a press machine, and a pure rhenium pressed blank with the thickness being 10 mm is prepared under the pressure ranging from 100 Mpa to 200 Mpa; the pure rhenium pressed blank is placed in a vacuum furnace or a high-temperature furnace to be subjected to high-temperature sintering, and a pure rhenium plate blank uniform in crystallization is prepared; the pure rhenium plate blank is continuously rolled by adopting a multi-roll mill and annealing linkage, and continuous rolling and annealing are carried out until a rhenium sheet is obtained; and the rhenium sheet is subjected to a combined rolling process in which chemical etching thinning and multi-roll mill finish rolling are carried out in parallel, and finally the ultra-thin rhenium foil with the target product thickness being 9-11 microns is obtained. The method has the advantages of high efficiency, good surface quality, low equipment investment and the like.

Owner:中铼新材料有限公司

Debris flow prevention and treatment device and method

InactiveCN109371862AImprove stabilityRealize the flow away situationBarrages/weirsProtective constructionWater flowLandslide

The invention discloses a debris flow prevention and treatment device and method. A debris flow ditch is included, the outer surface of the upper end of the debris flow ditch is provided with first intercepting dams and second intercepting dams, the first intercepting dams are located on one sides of the second intercepting dams, a water flowing groove is formed between the two first interceptingdams in a longitudinal connection manner, and a first baffle is arranged between the two first intercepting dams in a transverse connection manner. The method comprises the following steps that firstly, related situations of the debris flow ditch are investigated and analyzed; secondly, the field area of the debris flow ditch is subjected to the statistics, and the development tendency of the debris flow ditch is predicted; thirdly, the intercepting and dredging project is set; and fourthly, the scour prevention forest is arranged. Mainly for the debris flow prevention and treatment device andmethod, components in the debris flow can be effectively subjected to flow dividing, the flow swashing speed of the debris flow can be reduced, large-solid landslide can be effectively hindered, thedownward flow activity of gravels and liquid is not hindered, the situation that the solid is left and liquid flows away is achieved, in addition, the strength of soil is improved, and the loose solidobject source is reduced.

Owner:浙江杭博生态环境建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com