Method for preparing red nano fluoresent powder of rare earth

A nano-fluorescent powder and red technology, which is applied in the field of preparation of rare earth nano-phosphor powder, can solve the problems of high industrial production cost, easily destroyed crystal lattice, low purity of phosphor powder, etc., achieve shortened reaction time, low industrial production cost, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

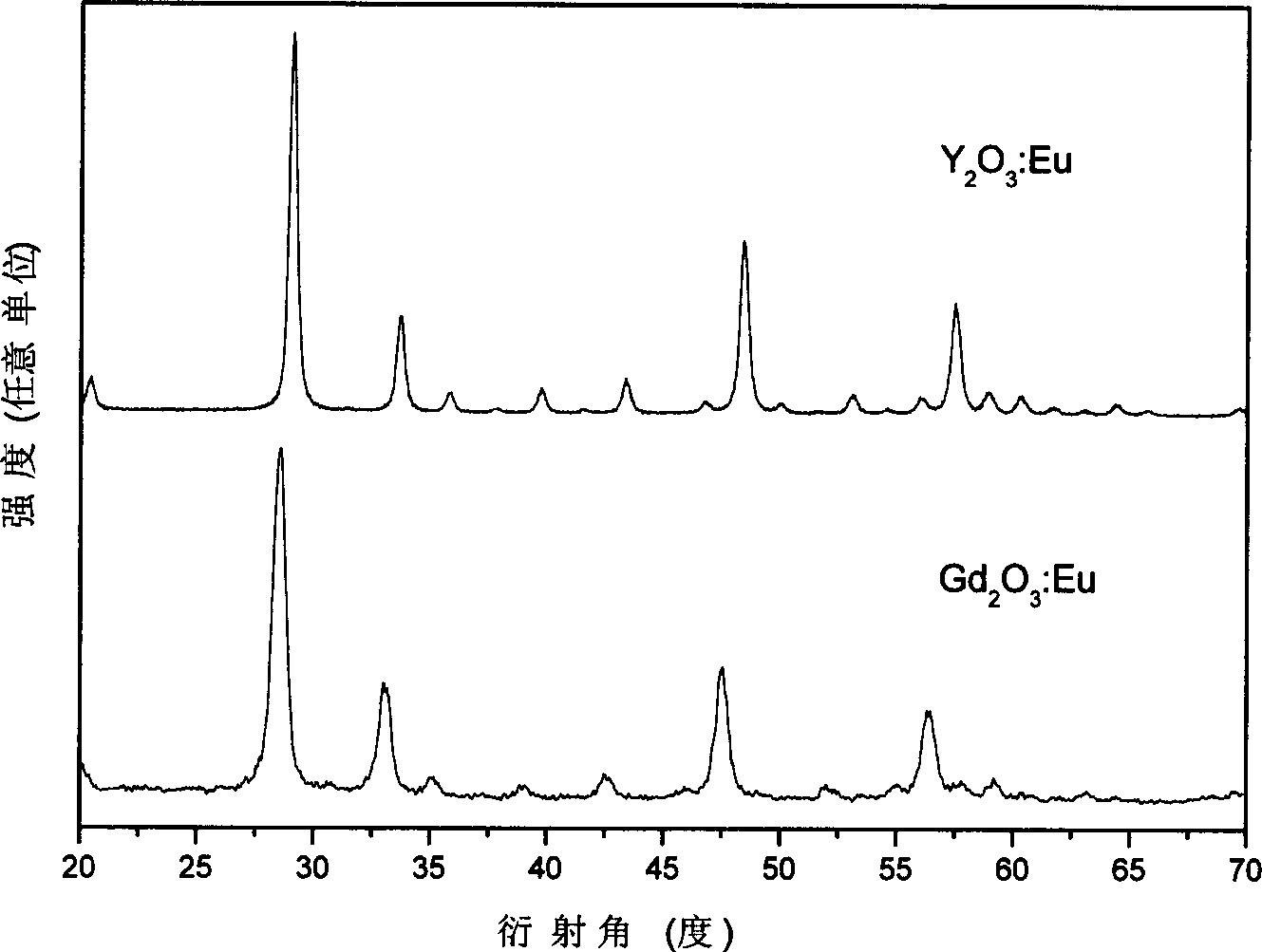

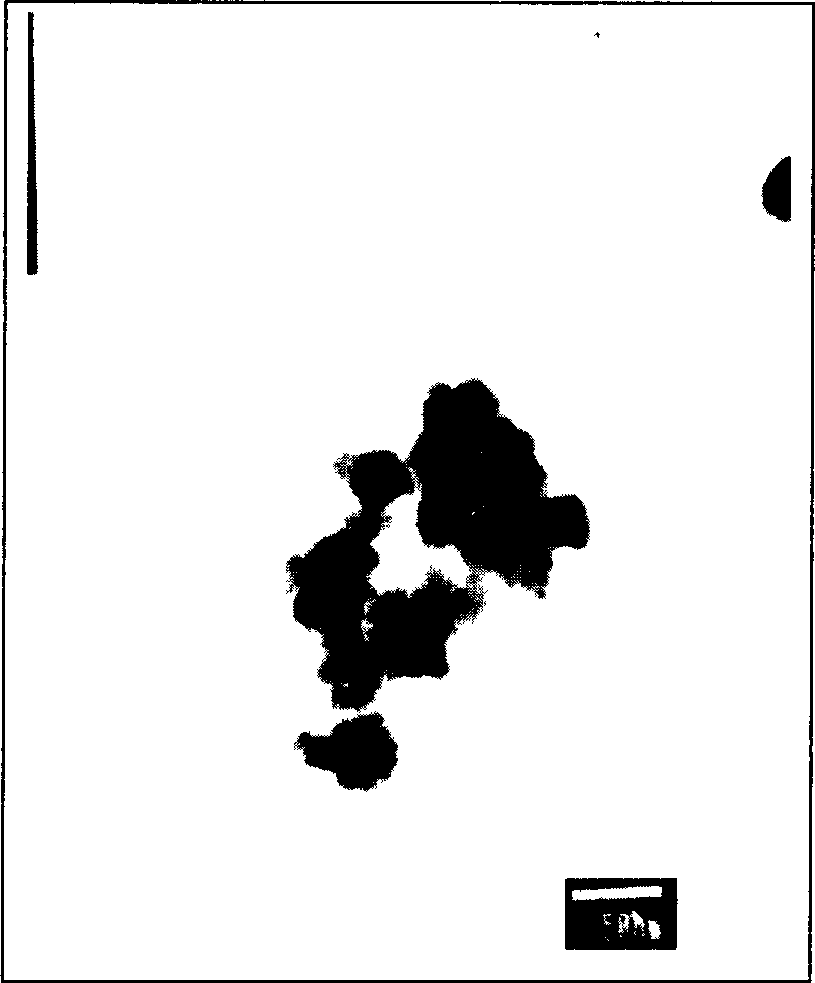

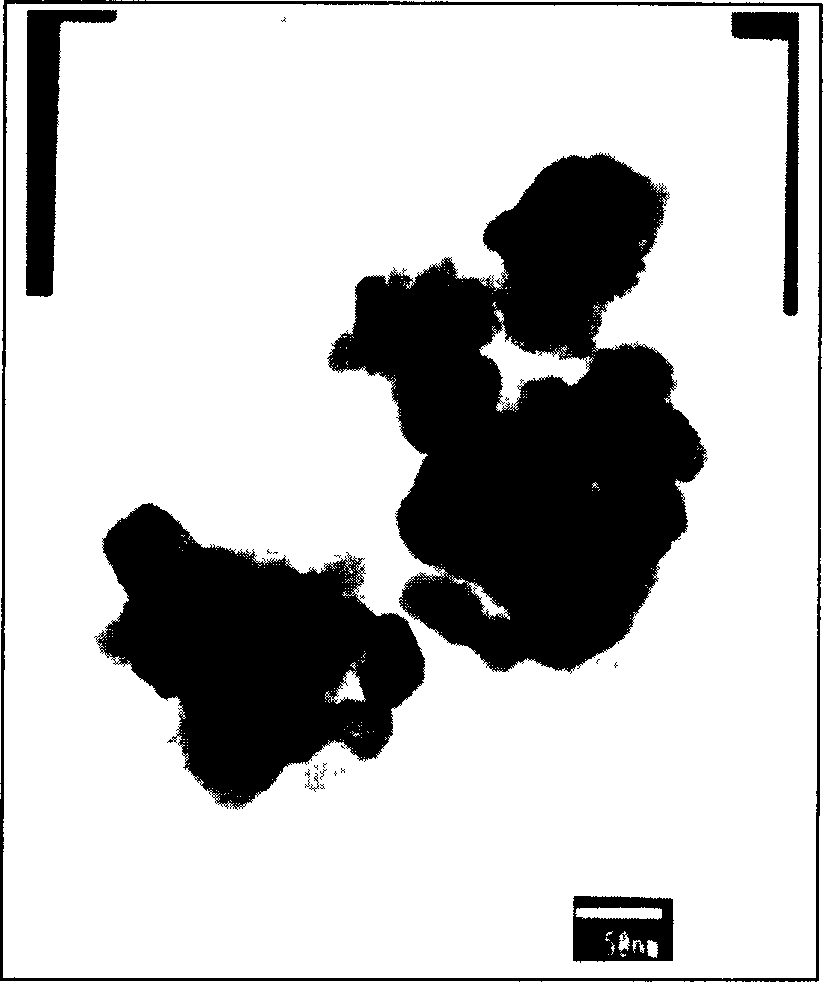

[0006] Specific embodiment one: present embodiment carries out the preparation of rare earth red nano-fluorescent powder according to the following steps: (one) Eu 2 o 3 and Ln 2 o 3 Add the sucrose solution prepared by deionized water after being dissolved in concentrated nitric acid, so that the molar ratio of metal ions and sucrose in the solution is 1:1-30, and then adjust the pH value of the solution to 1-3 to obtain a transparent solution; (2) transparent solution Water bath under the condition of 50-90 ℃ and continuously stirred for 1-5 hours, so that the transparent solution loses water to form an opaque viscous colloid; (3) The opaque viscous colloid is evaporated by microwave heating until a fluffy brown-black xerogel is obtained (4) Calcining the xerogel at 600-1000° C. for 0.5-5 hours to obtain rare earth red nano-fluorescent powder.

specific Embodiment approach 2

[0007] Specific embodiment two: the difference between this embodiment and specific embodiment one is: step (1) will Eu 2 o 3 and Ln 2 o 3 Soluble in concentrated nitric acid, the molar ratio of Eu and Ln in the solution is 1-30:100. Other steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0008] Specific embodiment three: the difference between this embodiment and specific embodiment one is: step (1) will Eu 2 o 3 and Ln 2 o 3 Soluble in concentrated nitric acid, the molar ratio of Eu and Ln in the solution is 5-25:100. Other steps are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com