Patents

Literature

68results about How to "No import" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linseed paste and process method thereof

An edible paste is prepared from edible linseed (35-80 wt.%), quality modifier (1-20), flavouring (15-25) and agricultural grain flour (4-20) through respective heating and grinding, proportional mixing, sieving by 80 meshes, and packing. Its advantages are rich nutrients, health-care function of reducing blood sugar and blood fat, preventing and treating prostatic cancer, and detoxicating, and no toxic by-effect.

Owner:宁夏双友精细化工研究所

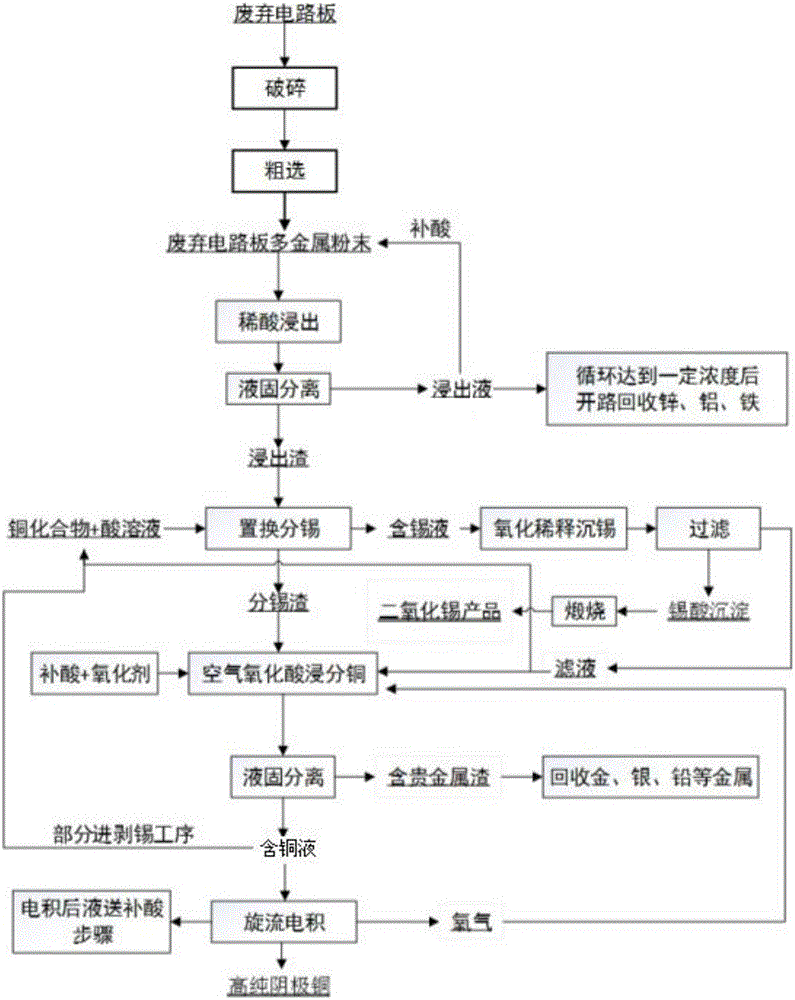

All-wet recovery process for waste circuit boards

ActiveCN105112674AReduce the burden of physical separationAchieve directional separationPhotography auxillary processesProcess efficiency improvementPregnant leach solutionOxygen

The invention discloses an all-wet recovery process for waste circuit boards. The all-wet recovery process comprises the following steps of crushing and reselecting the waste circuit boards to obtain multi-metal powder of the waste circuit boards; performing leaching on the multi-metal powder of the waste circuit boards with an acid solution with the concentration of 0.1-4 mol / L, and obtaining leach liquid and leach residues after solid-liquid separation; adding copper compounds and an acid solution with the concentration of 0.5-5 mol / L into the leach residues to replace and strip tin, and obtaining tin-bearing liquid and tin-separated residues after solid-liquid separation; adding an acid solution with the concentration of 0.2-6 mol / L into the tin-separated residues, leading oxygen and / or air into the mixture for an oxidation reaction, and obtaining copper-bearing liquid and precious metal residues after solid-liquid separation; and performing vortex electrodeposition on the copper-bearing liquid to obtain cathode copper. According to the all-wet recovery process for the waste circuit boards, the all-wet recovery process is provided for treating the waste circuit boards, so that directional separation, gathering and extraction of valuable metal in the process steps are achieved, and the problems of the dispersed moving of valuable metal elements of the waste circuit boards, the difficulty in subsequent separation and extraction and the like are solved.

Owner:CENT SOUTH UNIV

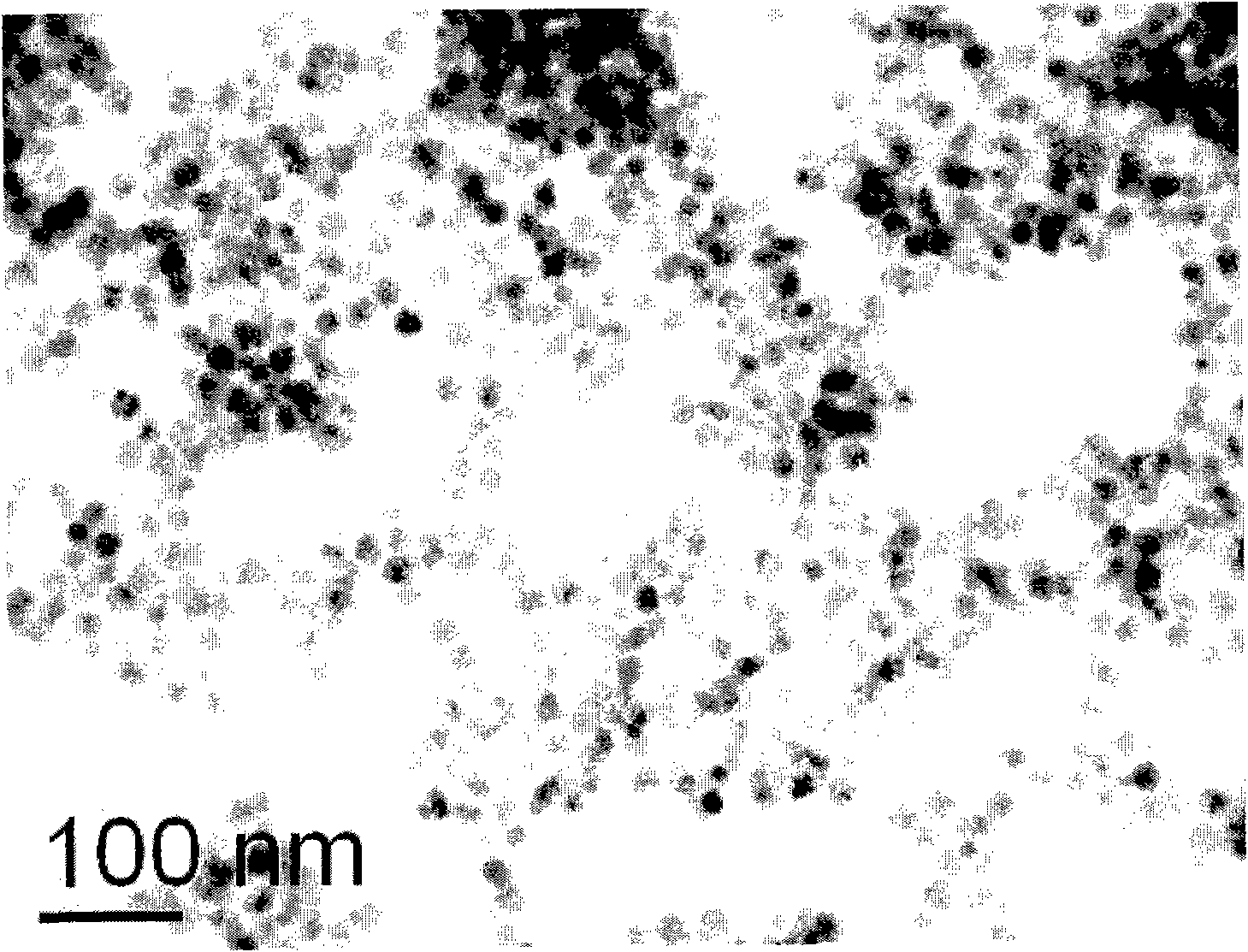

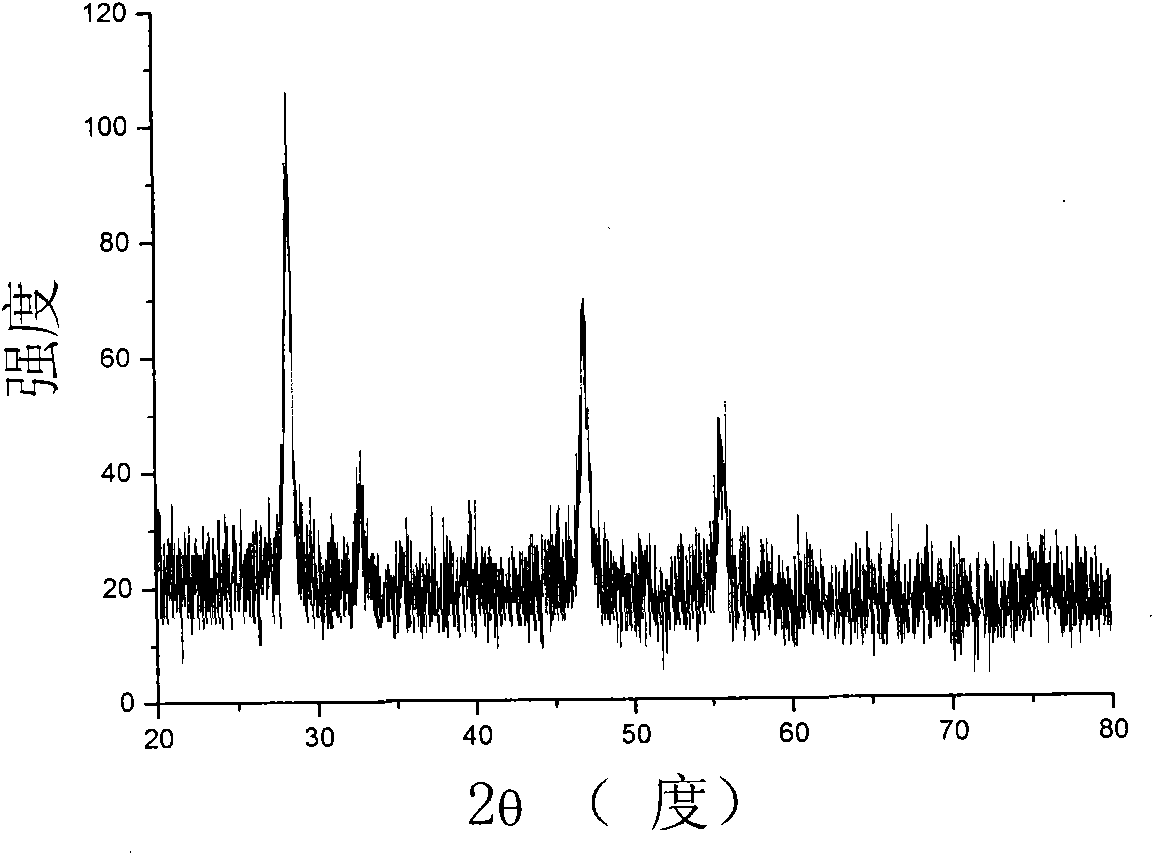

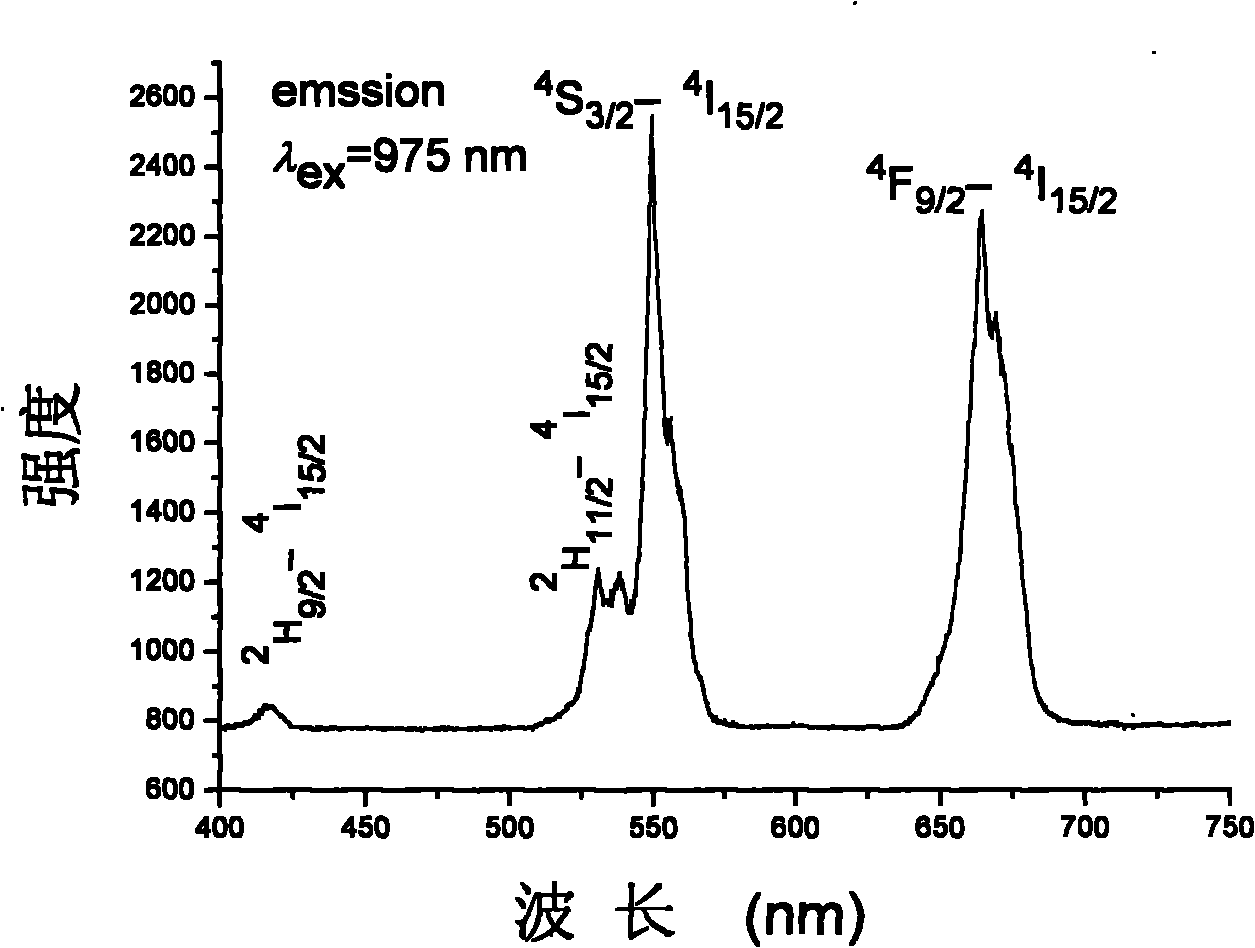

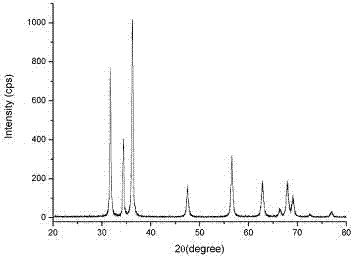

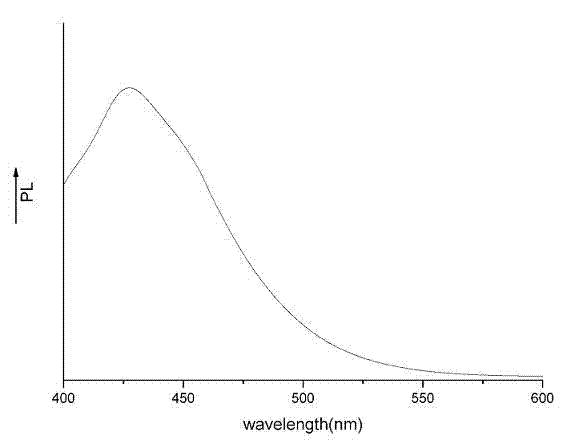

Method for synthesizing fluorescent nano particles of rare earth chlorides by microwave aqueous phase

InactiveCN101864314AHigh purityGood dispersionNanostructure manufactureLuminescent compositionsFluorescenceRare earth

The invention discloses a method for synthesizing fluorescent nano particles of rare earth chlorides by microwave aqueous phase. The method comprises the following steps: firstly, dispersing rare earth chlorides, a surface active agent, sodium chloride and ammonium fluoride in a hydrophilic solvent, then adding the obtained mixture into a microwave reactor according to certain proportion, stirring for 10-20 minutes, carrying out microwave heating, after the mixture reacts fully, centrifugally separating nano materials, using alcohol or deionized water to clean the nano materials so as to remove unreacted ions therein, then carrying out vacuum drying on the obtained nano materials, i.e. obtaining the needed water-soluble rare earth nano particles. The method has simple preparation technique, short production period, easy control of reaction conditions, no impurity introduction, low production cost and no fluoride-containing wastewater discharge, saves energy by 30%-50% compared with the prior art, and is beneficial to environmental protection and industrial production. The prepared fluorescent nano particles of rare earth chlorides have good uniformity, good dispersibility in water and small particle size, and can be used for the fields of biological fluorescent labeling, infrared detection and the like.

Owner:WUHAN UNIV

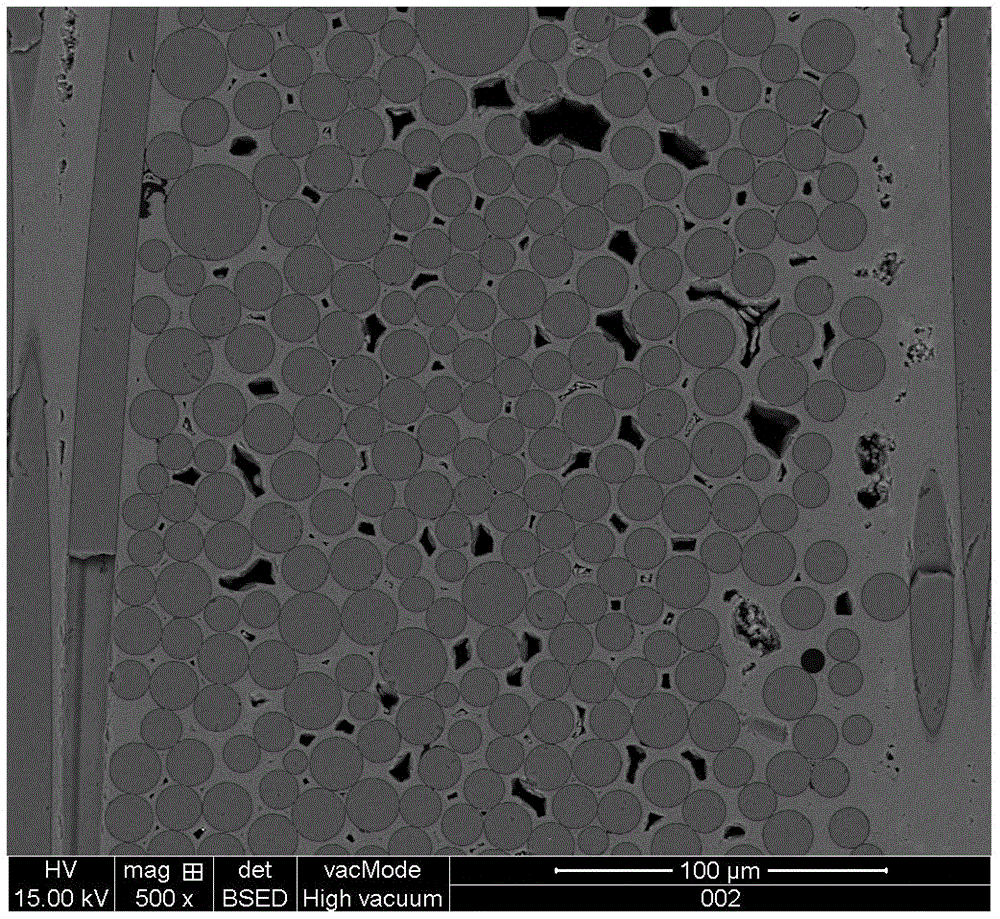

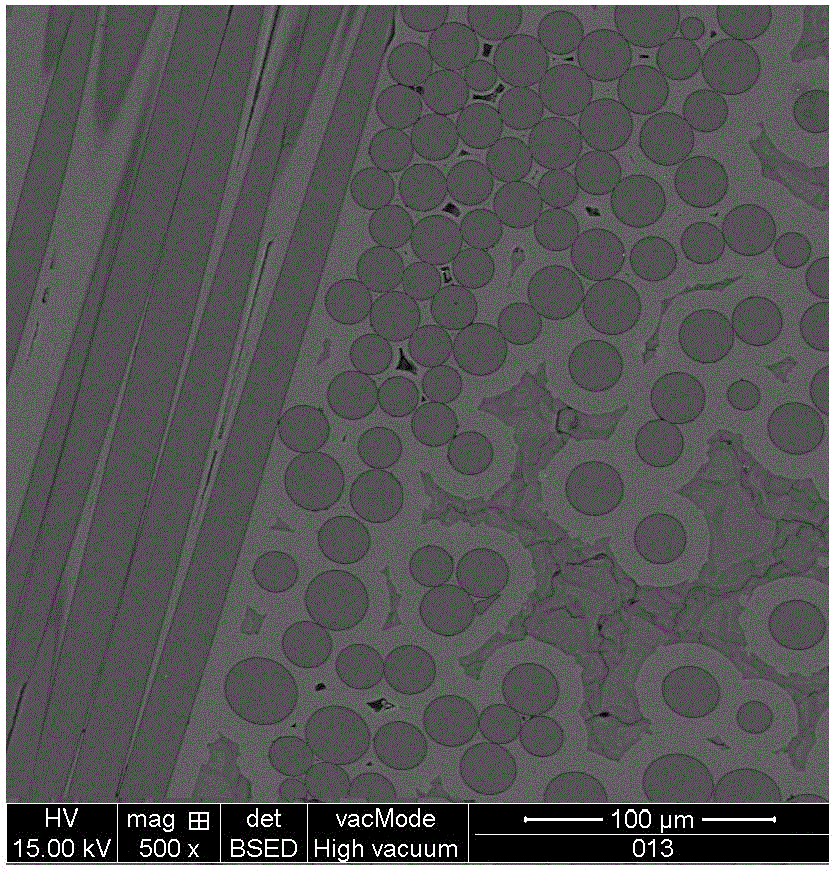

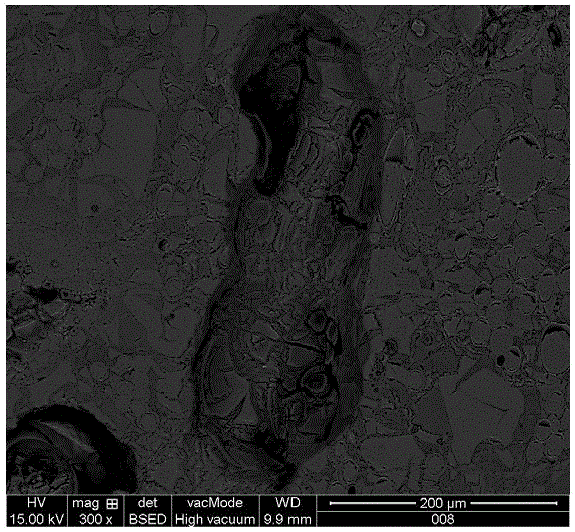

Method for enhancing density of SiC/SiC ceramic matrix composite

The invention relates to a method for enhancing density of a SiC / SiC ceramic matrix composite. The method comprises the following steps: (1) a SiC / SiC ceramic matrix composite with a certain densification degree is immersed in slurry, in which an organic precursor and SiC powder are uniformly dispersed, and impregnation is carried out in an environment of 5-10 KPa vacuum degree for 20-50 min; (2) a material which has undergone vacuum impregnation is dried and the dried material undergoes cross-linking and curing; (3) the cross-linked and cured material undergoes pyrolysis treatment; and (4) the material which has undergone pyrolysis treatment further undergoes densification process in the atmosphere of a gaseous precursor containing Si and C elements by a chemical vapor infiltration technology while infiltration temperature is 850-1100 DEG C, pressure intensity is 10-20 KPa and infiltration time is 4-30 h. The method provided by the invention has advantages of simple operation, short densification time, good repeatability and high densification efficiency and has obvious advantages in the aspect of filling material voids. The method is a method with operability and development prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

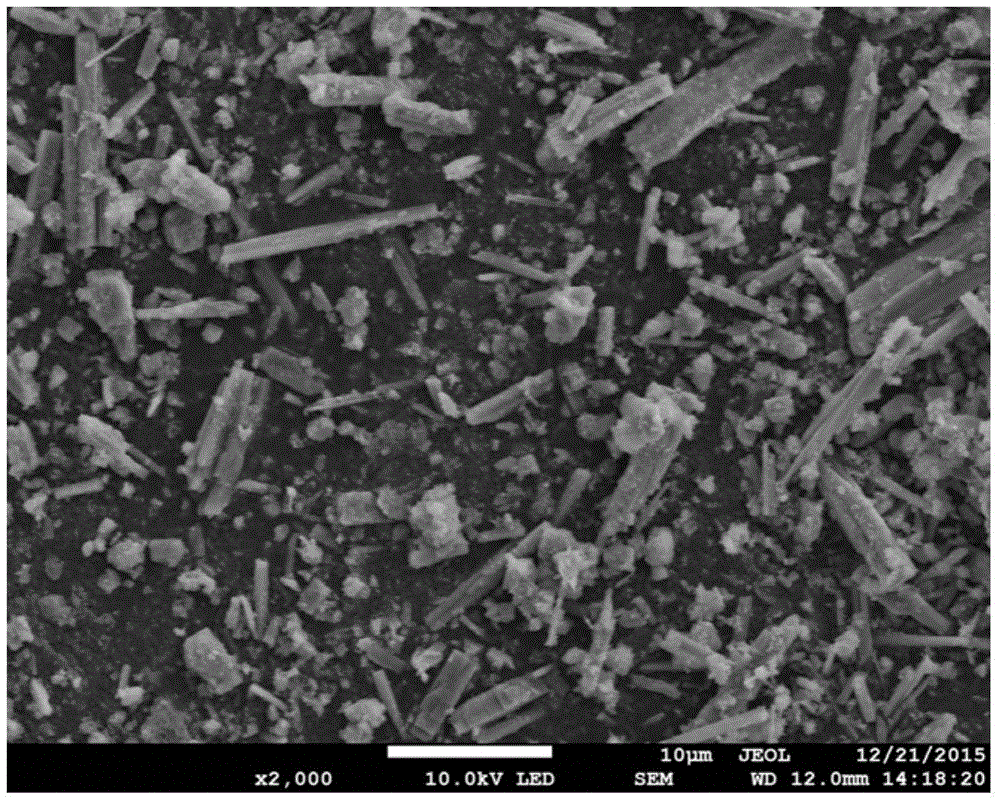

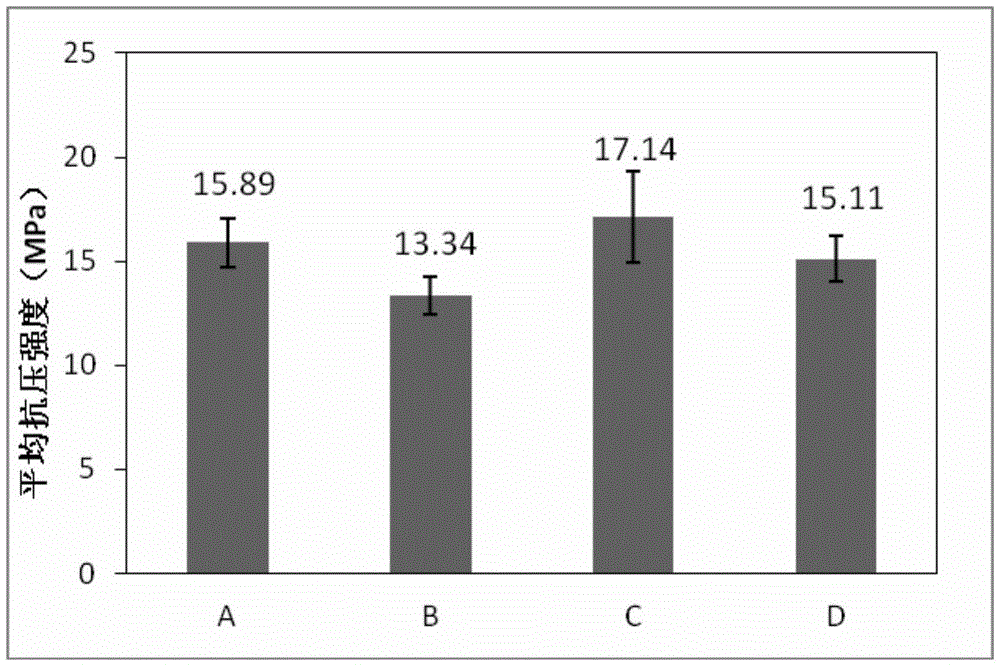

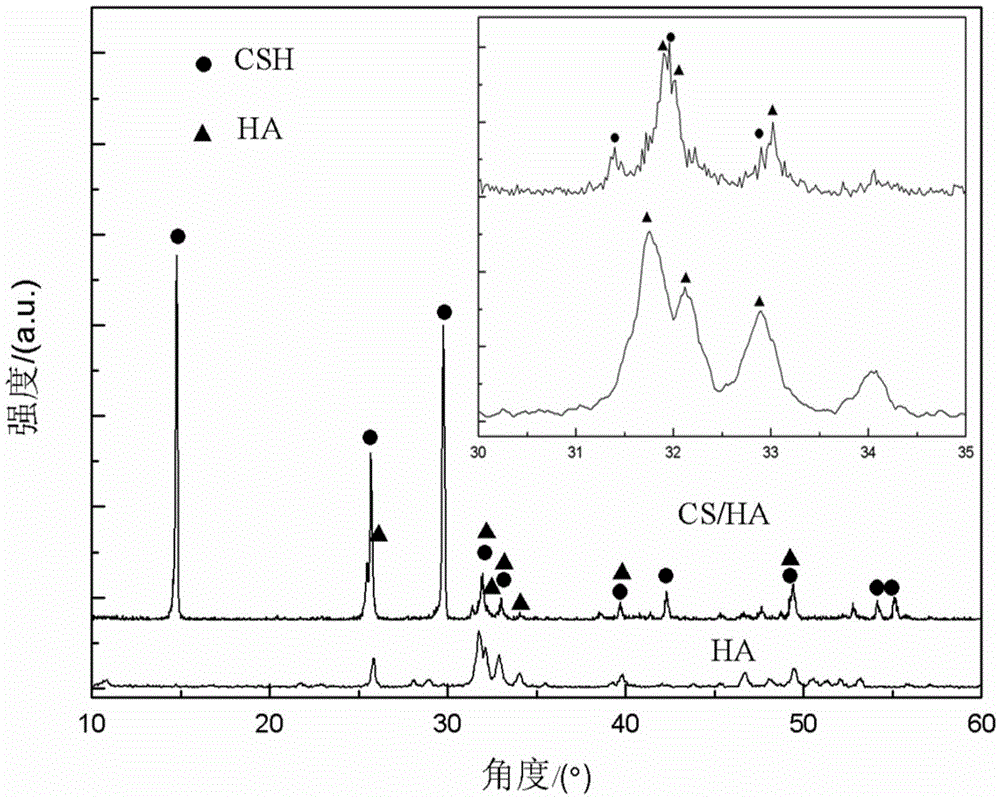

Composite bone cement and preparation method thereof

ActiveCN105536070AEasy injectionImprove mechanical propertiesTissue regenerationProsthesisMass ratioHigh pressure

The invention relates to composite bone cement for repairing bone tissues and a preparation method thereof. The bone cement is prepared from the following components in percentage by mass: 90-99.9 percent of calcium sulfate / calcium phosphate composite and 0.1-10 percent of additives. The method comprises the following steps: uniformly mixing raw materials, drying in an oven at 70 DEG C, grinding, and performing a crystal transformation reaction in a high-pressure kettle at a temperature of 120-200 DEG C and a pressure of 0.1-1MPa for 3-8 hours; after reaction, drying in an oven at 80-100 DEG C for 12 hours, and uniformly grinding to obtain bone cement powder; and weighing the bone cement powder, adding the powder into a liquid in a powder-liquid mass ratio of (1-3):1, uniformly stirring, and curing to obtain the bone cement. The prepared bone cement has the advantages of high tensile strength, good injection performance, good water scattering resistance, controllable degradation and the like, has excellent biological activity, compatibility and safety, and is used for fixing multiple bone fractures and filling bone defects.

Owner:山东明德生物医学工程有限公司

Method for preparing Ni2P catalyst

InactiveCN103263939AMild preparation conditionsNo need for high temperature and high pressure treatmentMolecular sieve catalystsPhosphidesChemistryPetrochemical

The invention provides a method for preparing a Ni2P catalyst, which belongs to the field of the petrochemical industry. The method comprises the following steps of: using metallic nickel as a precursor; separately placing a catalyst precursor (non-loading or loading nickel) and hypophosphite by the P / Ni mole ratio of 2 to 4 on two reaction beds in a closed reactor in which gas can flow; and heating to 150 to 300 DEG C to react for 1 to 3 hours at the speed of 5 to 30 DEG C / min in an inert gas atmosphere and under a closed condition, so as to prepare various non-loading or loading Ni2P catalysts. By using the preparation method provided by the invention, the catalyst can be prevented from introducing impurities, high-temperature and high-pressure treatment is not needed in the preparation process, PH3 poisonous gas is not used, the preparation methods and the advantages of the preparation methods of various efficient nickel catalysts can be transplanted to be used for preparing the Ni2P catalyst, and the preparation method is suitable for the industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

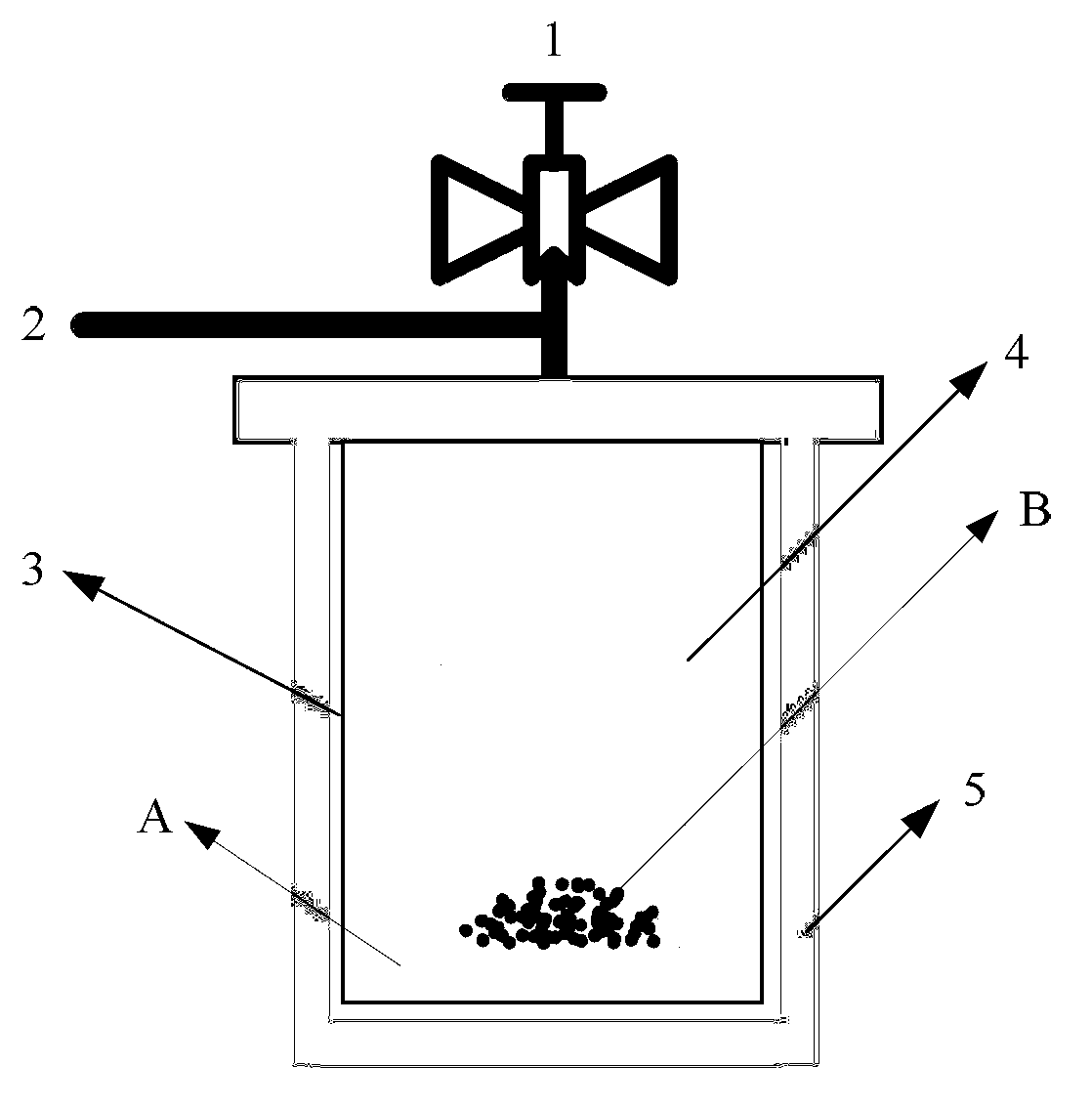

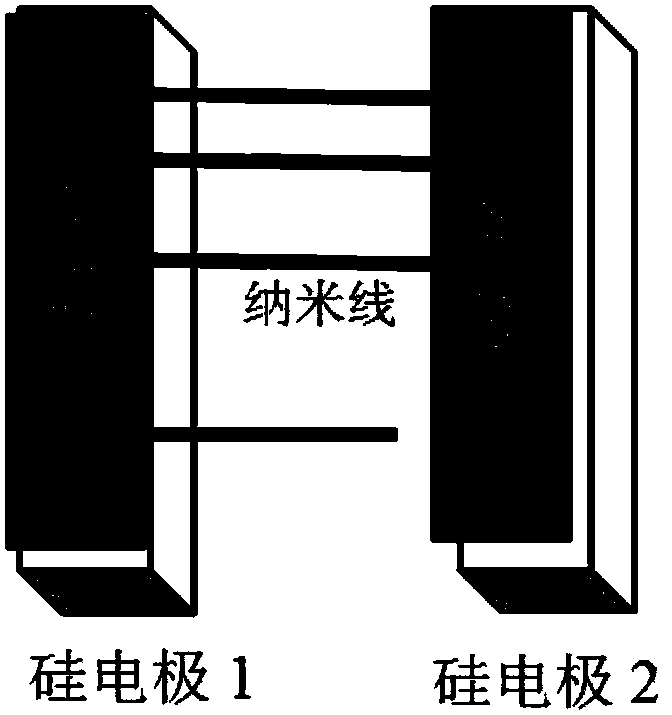

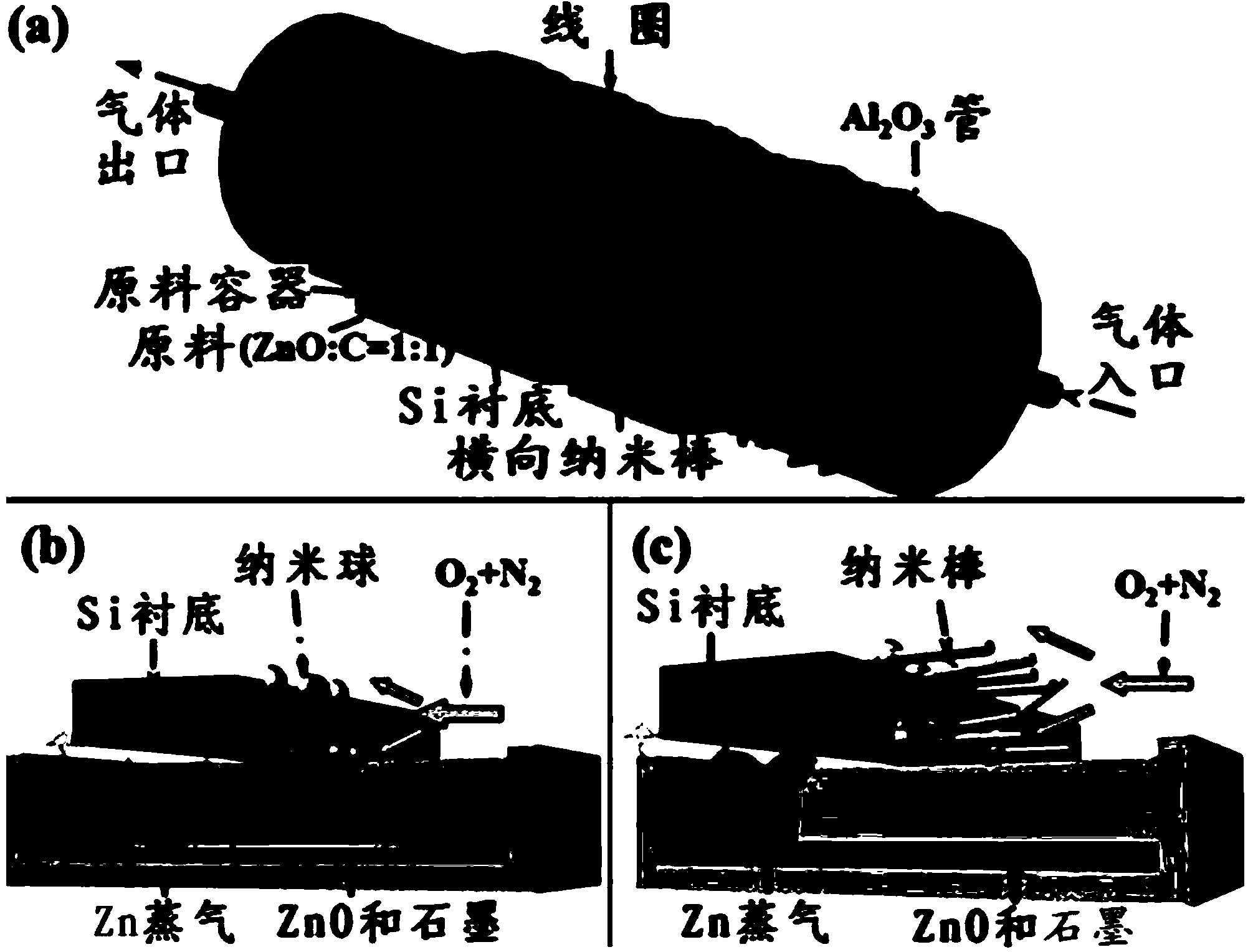

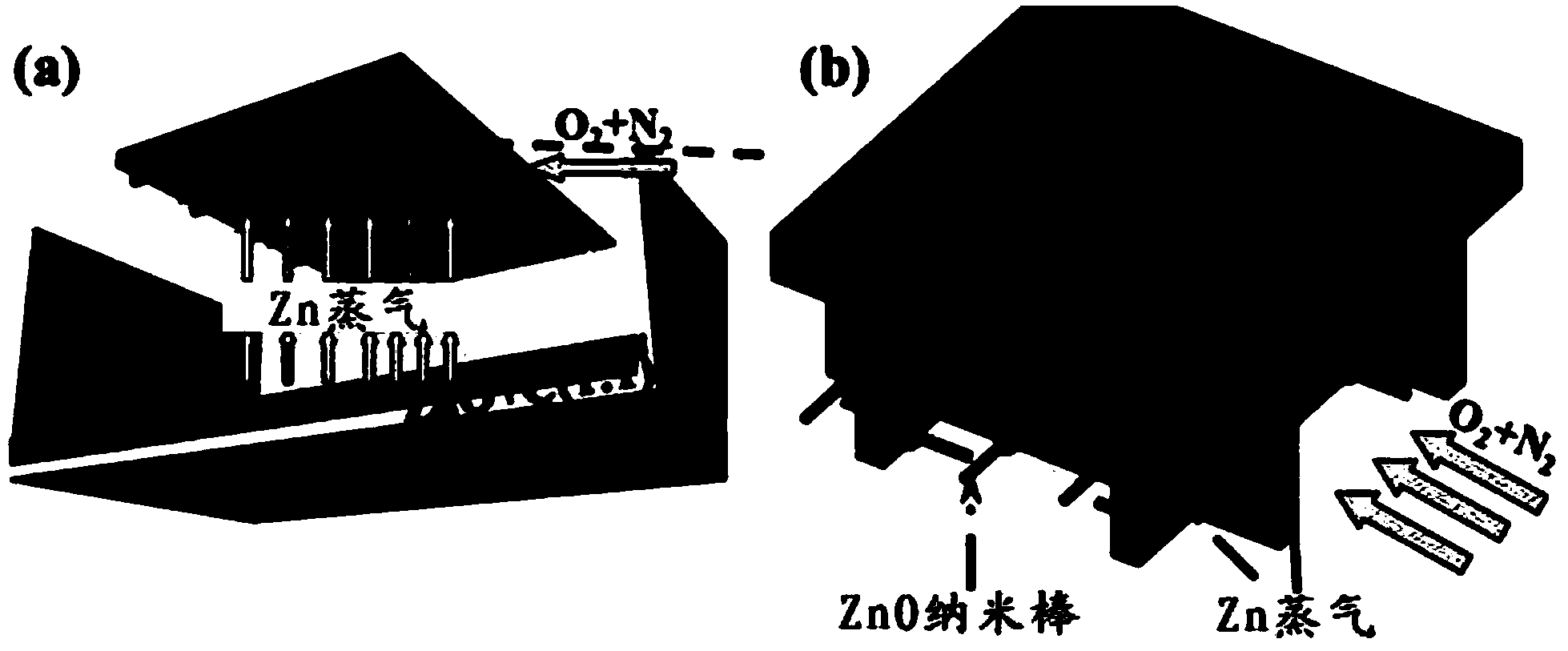

Method for positioning transversely-growing zinc oxide nanowires on silicon electrode

ActiveCN103966662AAvoiding the Problems of Growing ZnO NanowiresNo importPolycrystalline material growthSemiconductor/solid-state device manufacturingMetal catalystSilicon electrode

The invention discloses a method for positioning transversely-growing zinc oxide nanowires on a silicon electrode through chemical vapor deposition. The method comprises the steps as follows: preparation of zinc vapor, delivery of the zinc vapor and synthesis and deposition of zinc oxide. In the step of delivery of the zinc vapor, the included angle formed by the speed direction and a silicon electrode growth surface is in a range of 85-95 degrees when the zinc vapor is contacted with the silicon electrode growth surface. Particularly, the included angle formed by the speed direction and the gravity direction of the zinc vapor is in a range of 0-5 degrees. According to the method, the included angle formed by the speed direction and the silicon electrode growth surface is in the range of 85-95 degrees when the zinc vapor is contacted with the silicon electrode, the zinc vapor firstly reacts with oxygen on edges to be crystalized to produce zinc oxide nanometer points, and the nanometer points grow preferentially and finally form the transversely-growing zinc oxide nanowires. According to the method, a metal catalyst is not required to be evaporated on the surface in advance, and the method has the advantages that processes are simplified and impurities are avoided; and the transversely-growing zinc oxide nanowires can also be independently prepared on the silicon electrode with the method.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

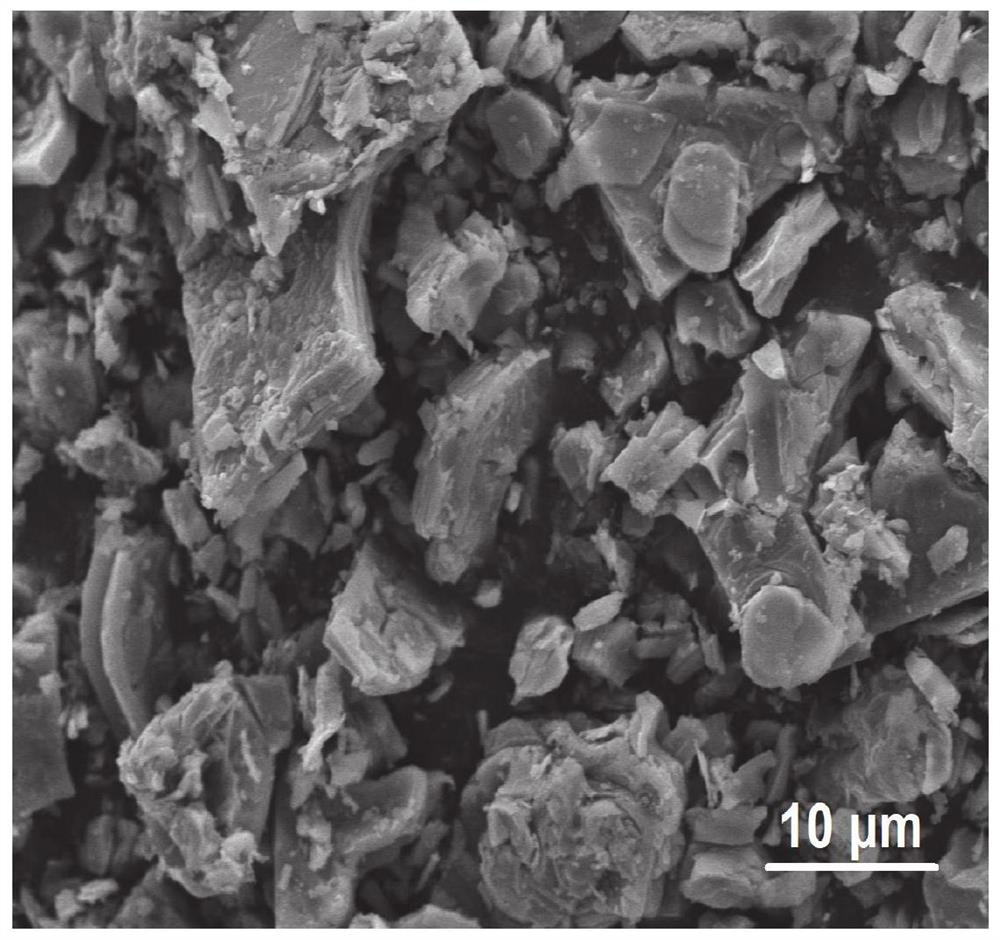

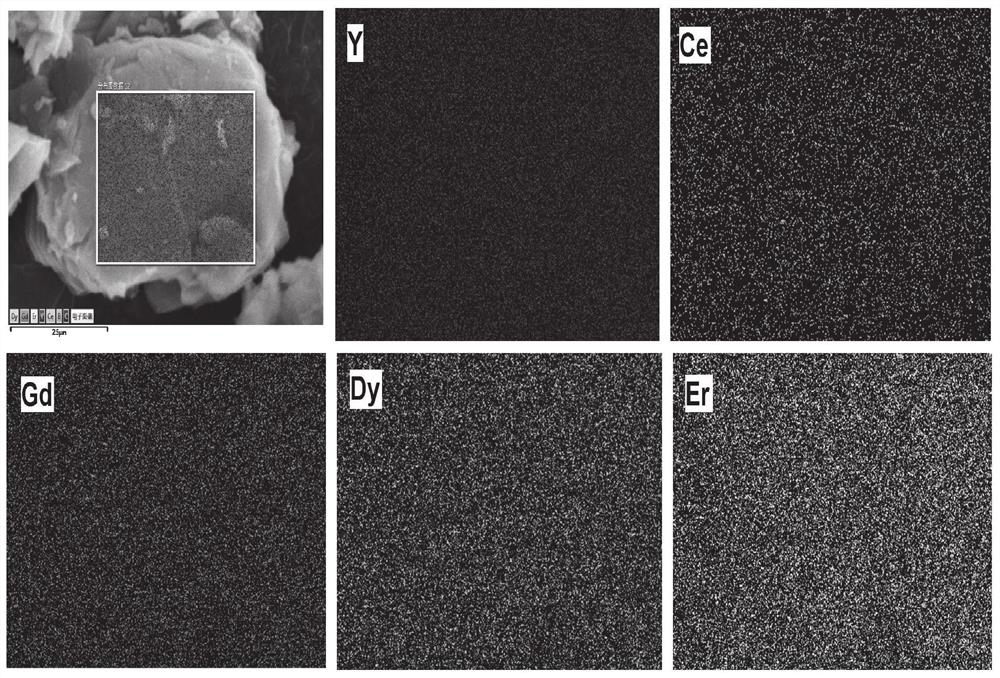

Layered high-entropy double-boron carbide ceramic powder and preparation method thereof

InactiveCN112830785ASimple preparation processThe reaction process is simpleBatch productionCarbon source

The invention relates to the technical field of high-entropy ceramic materials, in particular to layered high-entropy double-boron carbide ceramic powder and a preparation method thereof. The chemical formula of layered high-entropy double-boron carbide in the layered high-entropy double-boron carbide ceramic powder is REB2C2, wherein RE is at least three different elements selected from Y, Ce, Gd, Dy and Er, and the molar ratio of each of the elements is 1. The preparation method comprises the following steps: ball-milling and mixing at least three metal oxides, a boron source and a carbon source, compacting the uniformly mixed powder to obtain a densified green body, sintering the green body at high temperature to obtain a layered high-entropy double-boron carbide block material, and finally, carrying out crushing and grinding to obtain the layered high-entropy double-boron carbide powder. The single-phase high-entropy double-boron carbide ceramic powder with uniform components can be synthesized by taking the metal oxides as raw materials and adopting a carbon / boron thermal reduction method; and the method is simple in preparation process, easy to control the reaction process, free of impurity introduction, low in product preparation cost and suitable for batch production.

Owner:SHANDONG UNIV

Preparation method of insoluble egg protein aggregate particles and application thereof

ActiveCN105660983AImprove suspension stabilityImprove wettabilityProtein composition from eggsAnimal proteins working-upEgg proteinColloid

The invention discloses a preparation method of insoluble egg protein aggregate particles as well as an application thereof and belongs to the technical field of food. According to the invention, the egg protein aggregate particles are prepared by a combined heat treatment-mechanical shearing technology. This kind of particles have very good suspension stability in water, and have approximately spherical shapes whose granule particle sizes are 0.03-3 microns. Moreover, this kind of particles have very good wetting properties that the particles can be rapidly re-watered after drying, and the re-watered colloid has viscosity and smoothness similar to those of the fat as well as sensory properties of the colloid. The egg protein aggregate particles disclosed by the invention are used as emulsifiers, thickeners, brighteners, turbid agents and stabilizers in the food systems, including beverages, coffees, salad sauces, ice creams and the like, so as to maintain sensory properties of the systems while reducing fat contents and improving added nutritional values.

Owner:JIANGNAN UNIV

Liquid-phase preparation method of cuprous sulfide film

The invention relates to a liquid-phase preparation method of a cuprous sulfide film. The method comprises the following steps: dissolving a copper source into an alcoholic solution containing a complexing agent and a small molecule sulfur reagent; adding a certain of viscosity modifier, so as to form a clear, transparent and stable precursor solution; depositing the precursor solution into a precursor film on a substrate by a non-vacuum film deposition technology, and heating and baking; annealing the precursor film at 300-650 DEG C under atmosphere of sulfur group elements for 20-200 minutes, so as to form the cuprous sulfide film. Copper oxide, cuprous oxide, copper hydroxide and / or copper acetylacetonate are taken as copper sources, anionic impurities are not introduced to the film, and the complexing agent, the viscosity modifier and the like are added, so that the precursor solution is clear, transparent and stable. Thus, the preparation process can be operated in air, and the formed film is even in distribution and excellent in quality.

Owner:山东中科泰阳光电科技有限公司

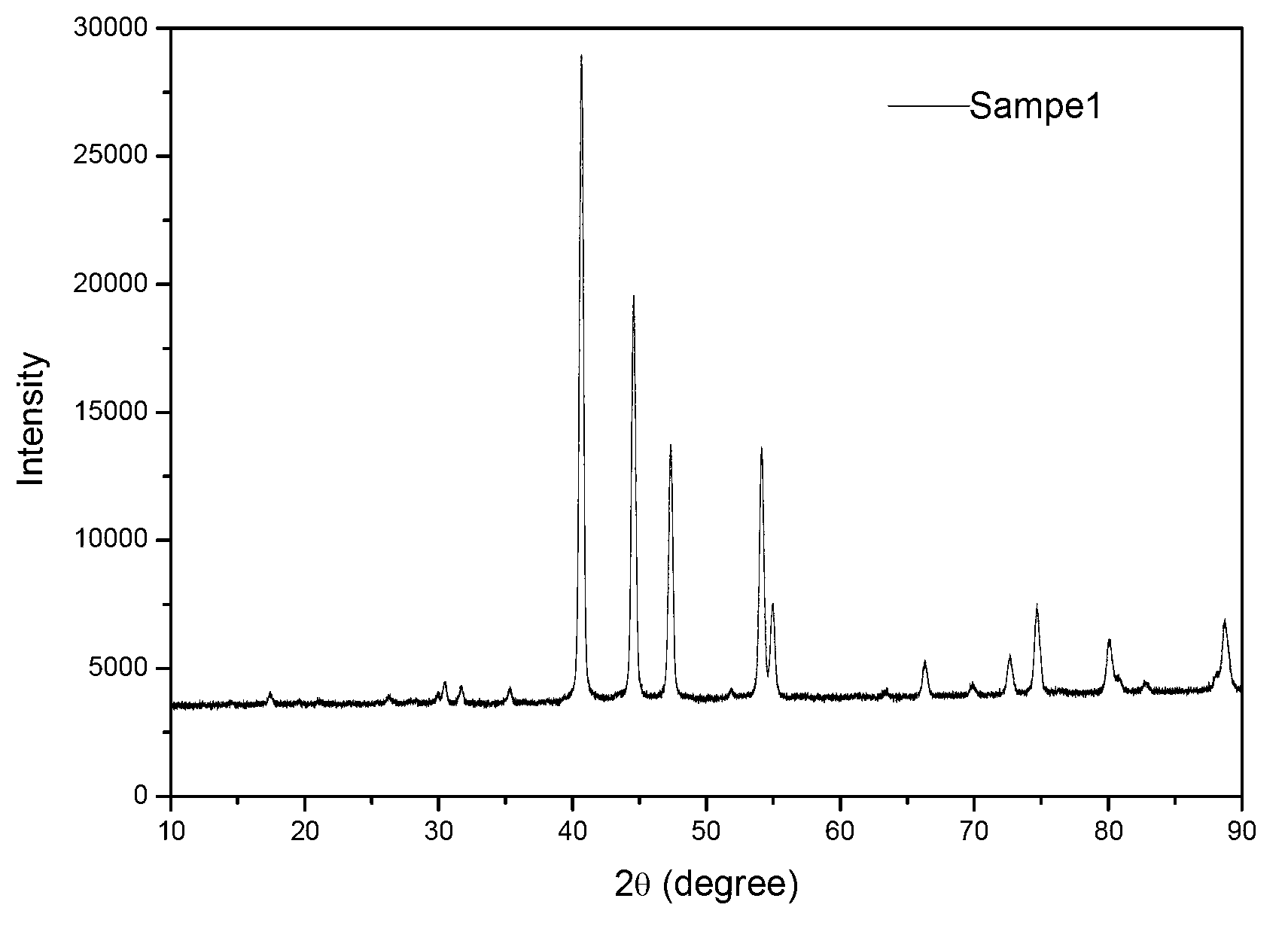

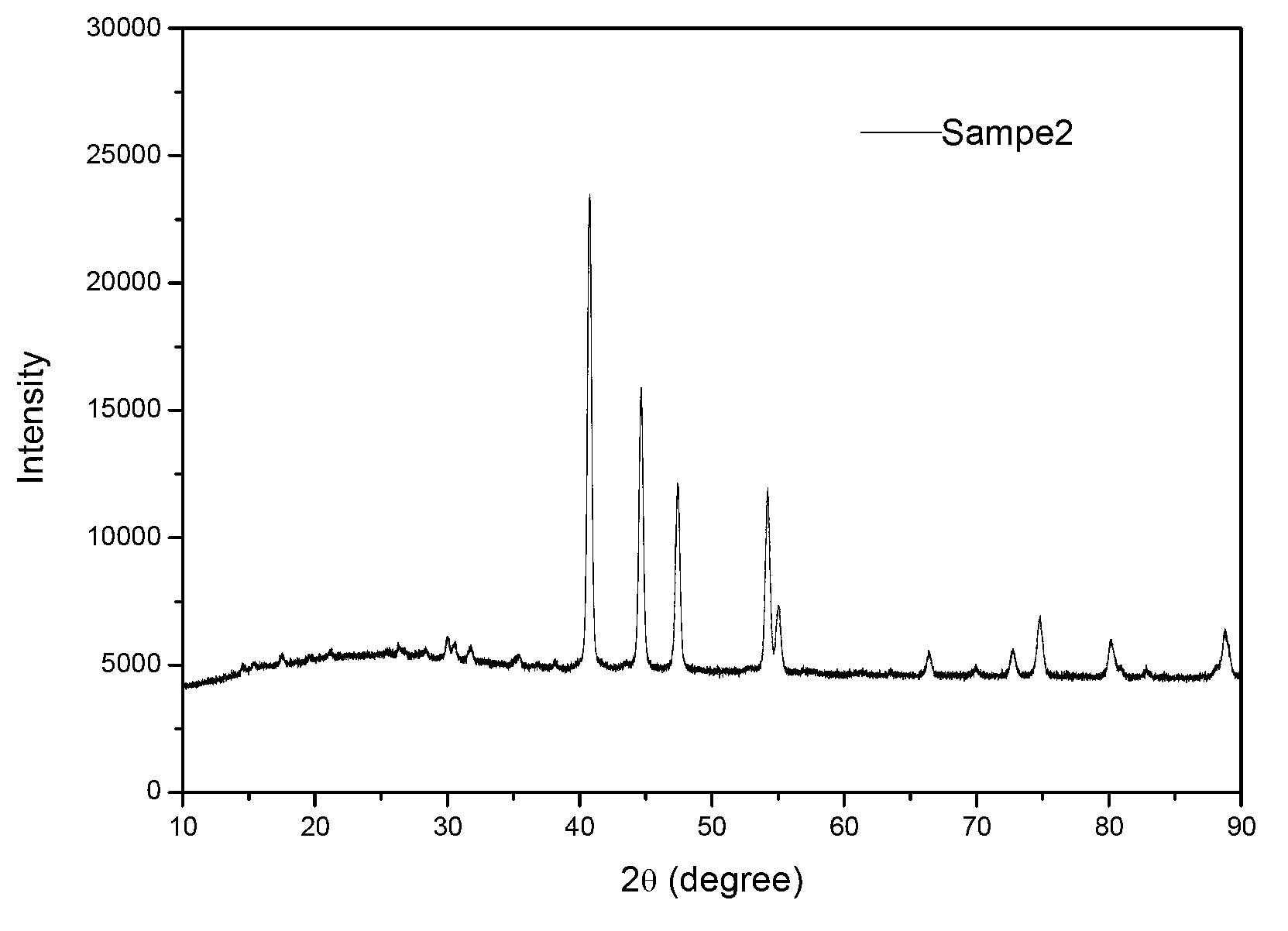

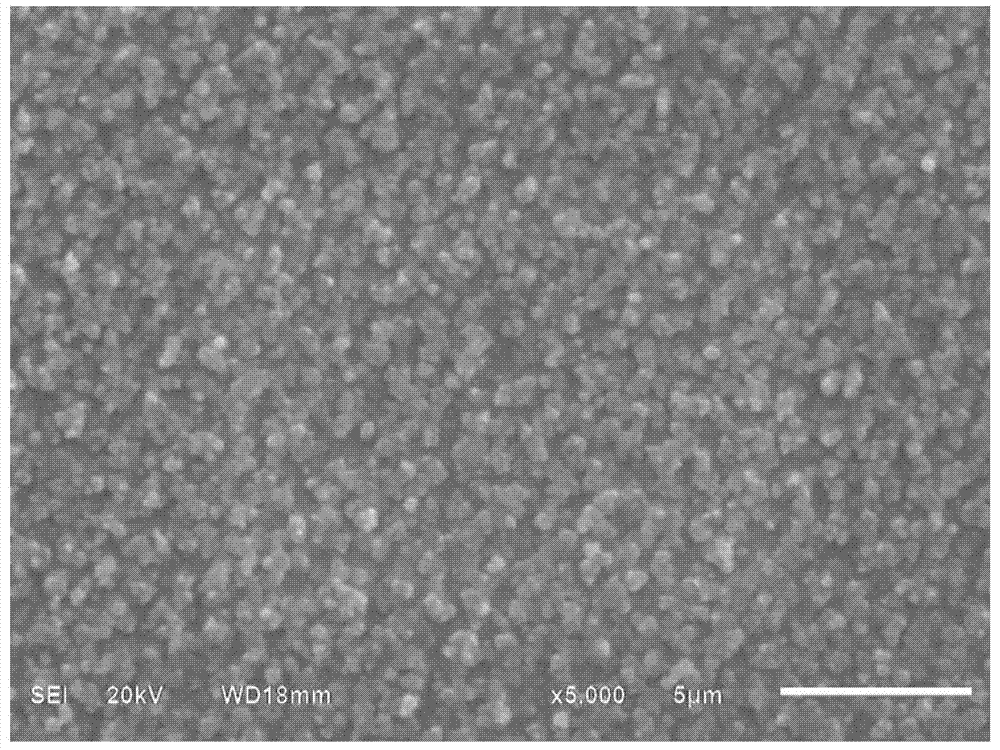

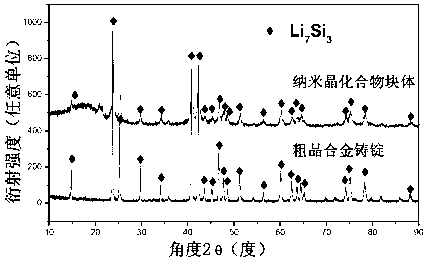

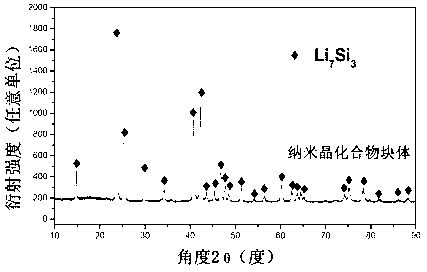

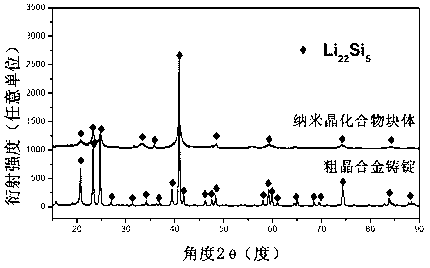

Preparation method of nanocrystal lithium-rich single-phase Li-Si compound block material

The invention discloses a preparation method of a nanocrystal lithium-rich single-phase Li-Si compound block material, belonging to the technical field of nanometer functional materials. The preparation method comprises the steps of: firstly weighing certain quantity of Li and Si according to target components and preparing a LixSi alloy ingot by utilizing a discharge plasma sintering technology; crushing the alloy ingot into powder and then ball-milling to obtain alloy powder in an amorphous structure; and finally sintering-molding the amorphous powder rapidly by utilizing the discharge plasma sintering technology to obtain a single-phase LixSi nanocrystal block material. The preparation method of the nanocrystal lithium-rich single-phase Li-Si compound block material, disclosed by the invention, has the advantages of pure phase, fine crystal particles, high density, simple and practicable process route and short synthetic cycle.

Owner:BEIJING UNIV OF TECH

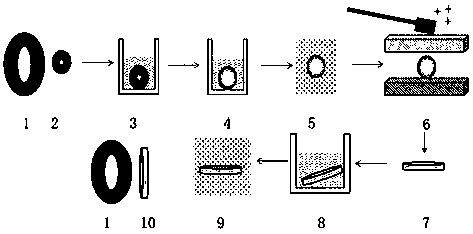

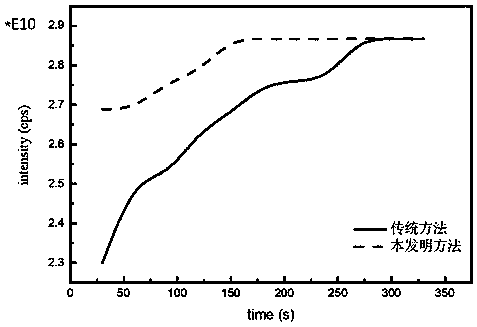

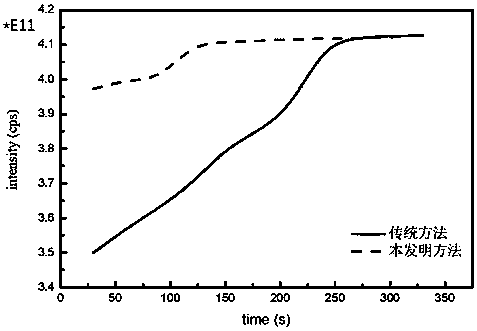

Pre-test treatment method of high-purity indium sample for glow discharge mass spectrometric detection

ActiveCN110542604ACreate pollutionNo importPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumTest sample

The invention discloses a pre-test treatment method of a high-purity indium sample for glow discharge mass spectrometric detection. According to the method, firstly, the to-be-tested high-purity indium sample is subjected to ultrasonic corrosion, then the corroded sample is subjected to ultrasonic cleaning and blow-drying sequentially, and the blow-dried sample is placed between two non-metallic hard plates; an external force is applied to the upper non-metallic hard plate, so that a plane is generated at the bottom of the sample after the sample is extruded; the external force continues to beapplied to the upper hard plate till the plane at the bottom of the sample is gradually enlarged to a size required by a glow discharge mass spectrometric test, and then application of the external force is stopped; and the flaky sample between the two non-metallic hard plate is taken out, cleaned and blow-dried, and then a to-be-tested sample sheet meeting the test demand is obtained. Compared with a traditional pre-test treatment method, the method is simple, easy to implement, free of impurity introduction and pollution to the sample and low in cost; and through the method, the time of theglow discharge mass spectrometric detection is shortened, the detection speed is increased, and the practical value is high.

Owner:KUNMING UNIV OF SCI & TECH

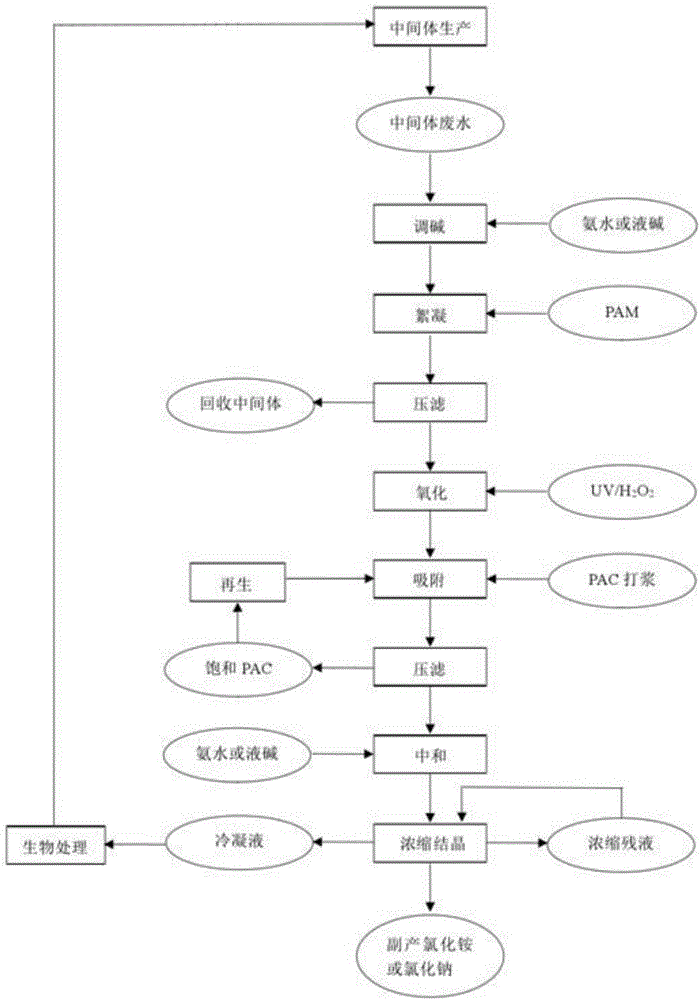

Recycling treatment method for anilines intermediate production wastewater

InactiveCN106167332AAchieve recyclingSimple processTreatment using aerobic processesWater/sewage treatment by irradiationFlocculationHydrogen

The invention provides a recycling treatment method for anilines intermediate production wastewater. The method includes the following steps of (1) flocculation: separately collecting and regulating the pH (potential of hydrogen) value of wastewater, adding flocculant for flocculation, and filtering to obtain precipitate I and treating fluid I; (2) oxidation: regulating the pH value of the treating fluid I, adding oxidizing agent, and performing adequate oxidation to obtain treating fluid II; (3) adsorption bleaching: regulating the pH value of the treating fluid II, adding adsorbent, and performing full adsorption prior to separation to obtain treating fluid III; (4) neutralization, concentration and crystallization: regulating pH value of the treating fluid III, entering a concentration device for concentration and crystallization, performing separation to obtain sodium chloride or ammonium chloride solid, returning mother fluid to the concentration device for continuous concentration and crystallization, and collecting condensate, namely treating fluid IV; (5) biological treatment: subjecting the treating fluid IV to treatment in a biological aerated filter to obtain treating fluid V, so as to finish treatment.

Owner:ZHEJIANG DIBANG CHEM

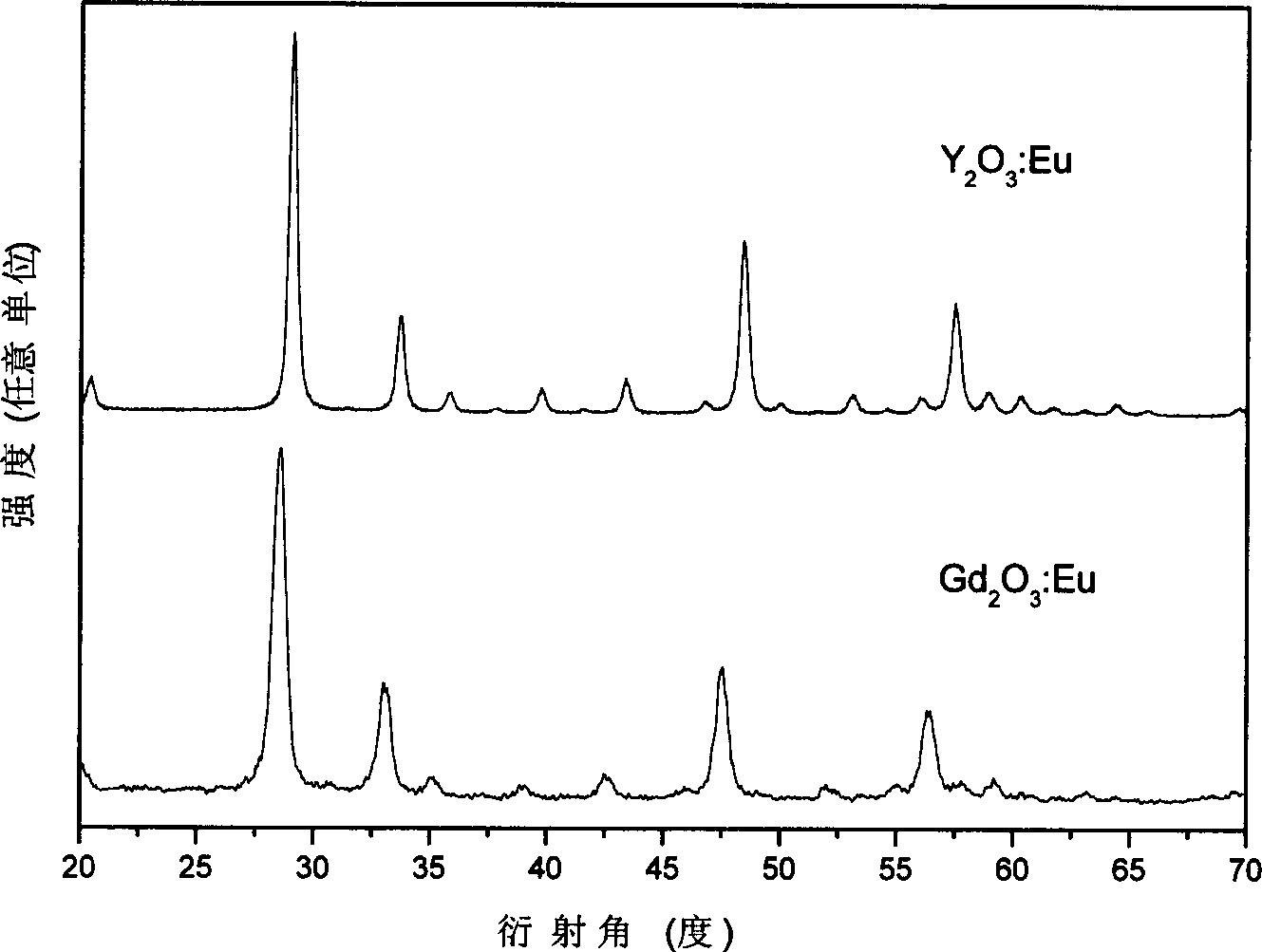

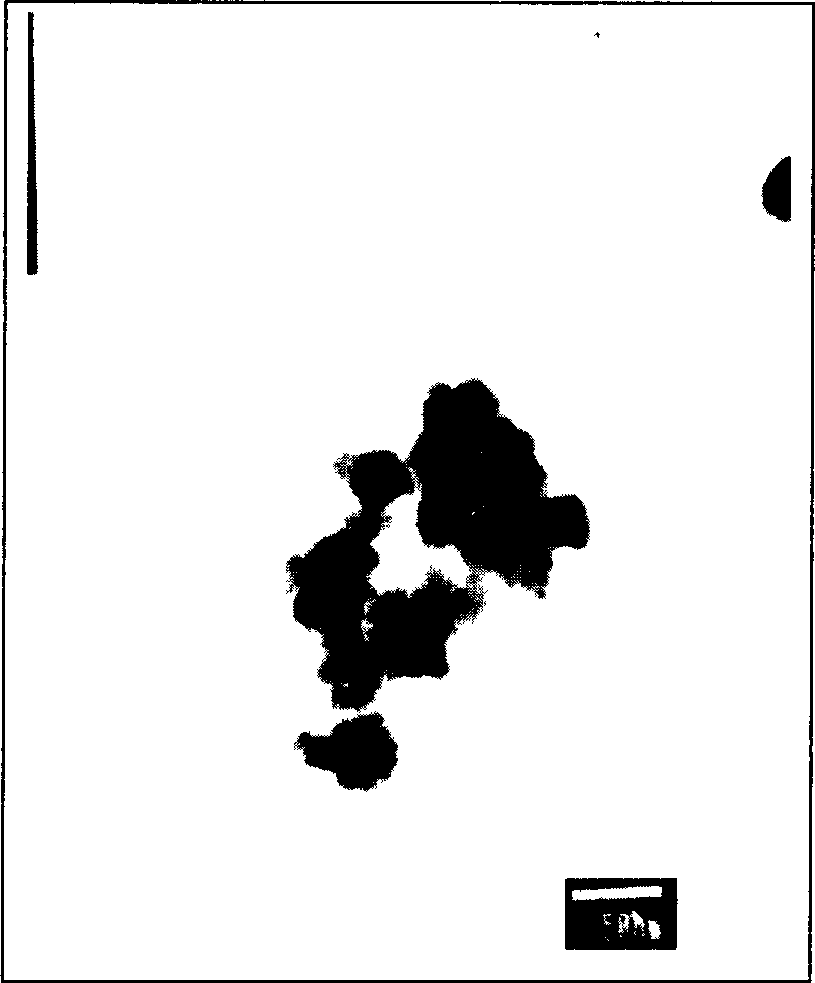

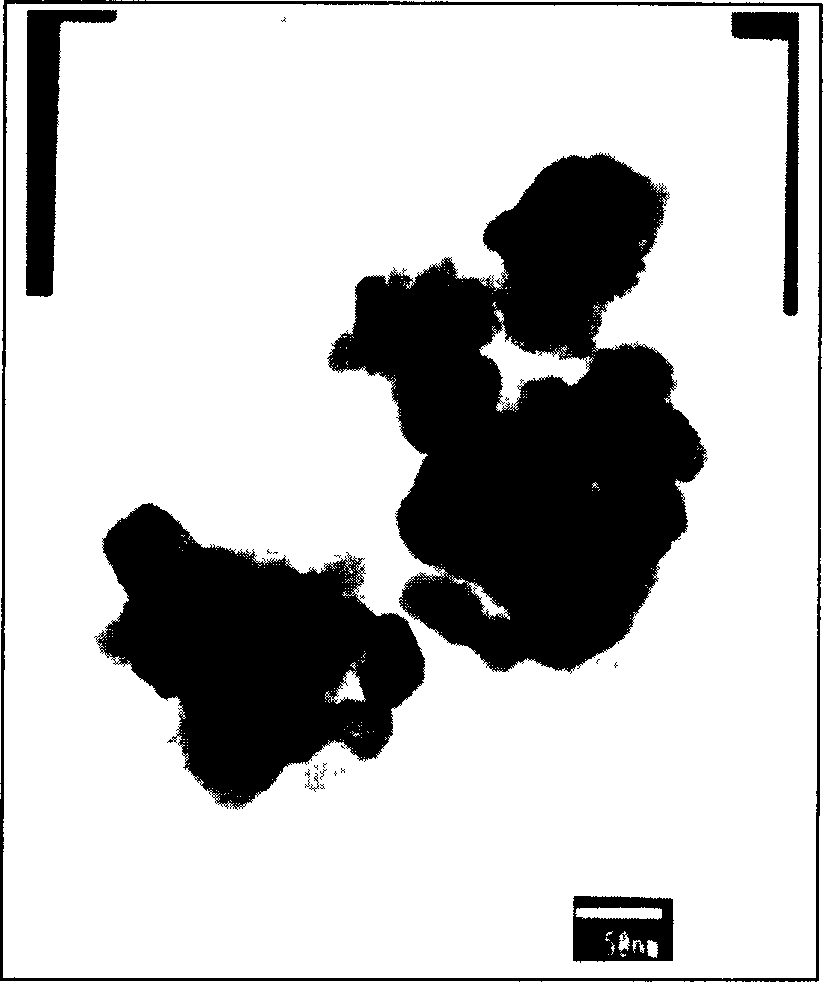

Method for preparing red nano fluoresent powder of rare earth

The preparation method for red nano rare-earth fluorescent powder with 10-30nm grain size overcomes the problems of complex process, low product purity and high cost in prior art, and comprises: (1) dissolving the Eu2O3 and Ln2O3 into strong HNO3 solution, adjusting pH value; (2) water bathing and continual stirring; (3) heating with microwave; (4) calcining the dried gel. This invention brings no impurity, reduces about 30% energy, and convenient to be controlled.

Owner:HARBIN INST OF TECH

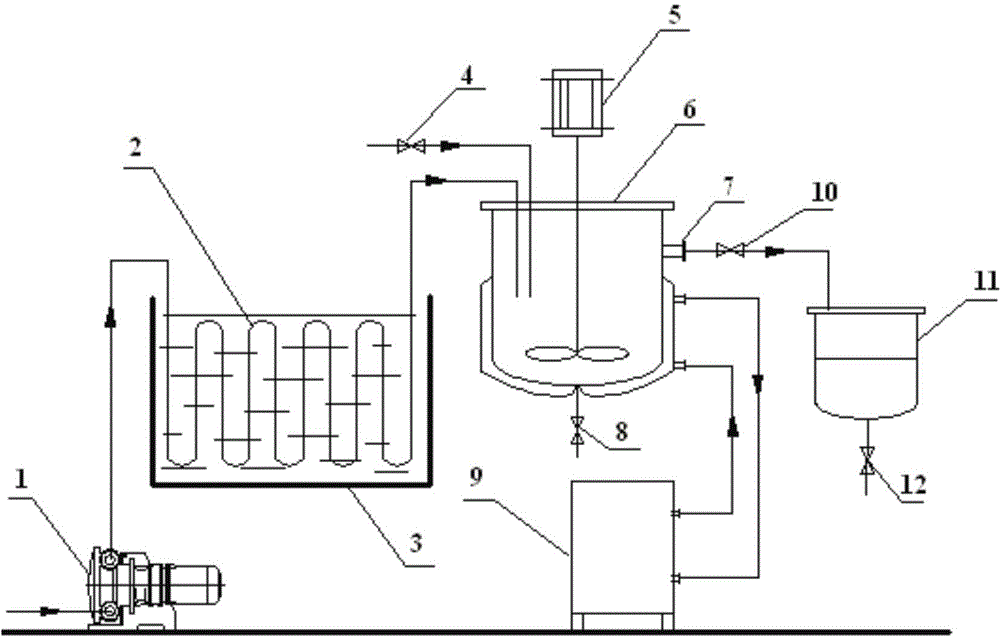

Continuous crystallization process for preparing nitroguanidine through nitric acid method

InactiveCN104860849AEmission reductionNo importOrganic chemistryOrganic compound preparationNitroguanidineFiltration

The invention relates to a continuous crystallization process for preparing nitroguanidine through a nitric acid method. The process is applied to continuous crystallization for preparing single-compound explosive nitroguanidine and belongs to the technical field of preparation processes of explosives and powder. According to the process disclosed by the invention, the nitroguanidine is dissolved in a nitric acid solution, the synthetic process is optimized by virtue of a micro-tube reactor, the requirement of the reaction system on the nitric acid concentration is reduced, and the product yield is improved. A continuous crystallizer and a filter are arranged behind the micro-tube reactor, the continuous crystallization and filtration process is established, the manual operation is reduced, and the production efficiency of the product is improved; and moreover, with the adoption of ultrasonic oscillating and washing, the washing frequency is reduced, and wastewater emission is reduced. The process disclosed by the invention has the advantages of simplicity, high continuity, high product yield, small wastewater emission amount and the like and is particularly suitable for continuous crystallization for preparing single-compound explosive nitroguanidine.

Owner:XIAN MODERN CHEM RES INST

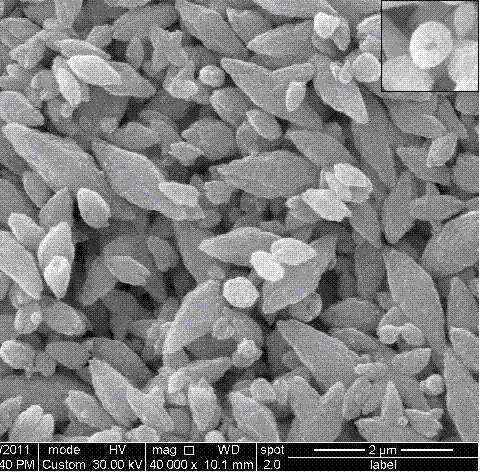

Method for preparing hollow spindle-shaped micro-structured zinc oxide

InactiveCN102249285AGood dispersionUniform shapeZinc oxides/hydroxidesNanotechnologyZinc ionPhysical chemistry

The invention relates to a method for preparing hollow spindle-shaped micro-structured zinc oxide, and belongs to a method for preparing a semiconductor micro material. The method comprises the following steps of: dissolving soluble zinc salt in deionized water, and stirring to obtain uniform and transparent solution, wherein the total concentration of zinc ions is 0.01 to 0.50mol / L; adding sodium borohydride into the solution in a ratio, stirring, and preheating; and transferring the solution to a hydrothermal reaction kettle for reaction, naturally cooling to room temperature after the reaction is finished, and collecting, washing, and drying a product. The micro-structured zinc oxide has high dispersibility and crystallinity, a uniform shape and obvious cavities; and the reaction system is simple, and convenient to wash, the reaction is mild, cost is low, yield reaches 99.2 percent, and wide application prospects are achieved.

Owner:YUNNAN UNIV

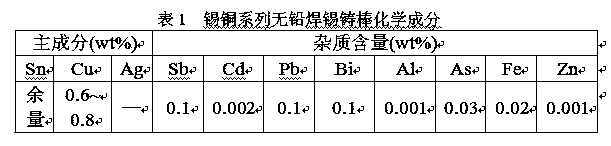

Technological method for reducing defect of extrusion rod

ActiveCN103394826AAvoid segregationReduce product defectsWelding/cutting media/materialsSoldering mediaTitanium alloyMetal

The invention discloses a technological method for reducing a defect of an extrusion rod. According to the technological method, an unleaded alloy electro-magnetic induction melting furnace serves as a melting furnace, and metal melting liquid is pumped into a heat preservation furnace made of the same titanium alloy for continuous casting after refinement, so that oxidation of the metal melting liquid and lead-in of oxidation impurities on the surface of the metal melting liquid are avoided; casting ingot components can be prevented from generating segregation effectively by a process that continuous casting is conducted by a condenser; the mass of a sawed casting ingot is greater than 35KG; the defect of a product due to a joint between the ingots in the traditional casting extrusion process is reduced effectively; and a casting ingot oxidation film, the segregation of the product and breakage of a follow-up wire drawing technology are avoided by utilizing the unleaded titanium alloy electro-magnetic induction tin melting furnace and the titanium alloy liner heat preservation furnace and adopting a horizontal continuous casting method, so that the production quality of a drawing wire is improved, the production cost is saved, and the technological method can be used for industrial production.

Owner:四川朗峰电子材料有限公司

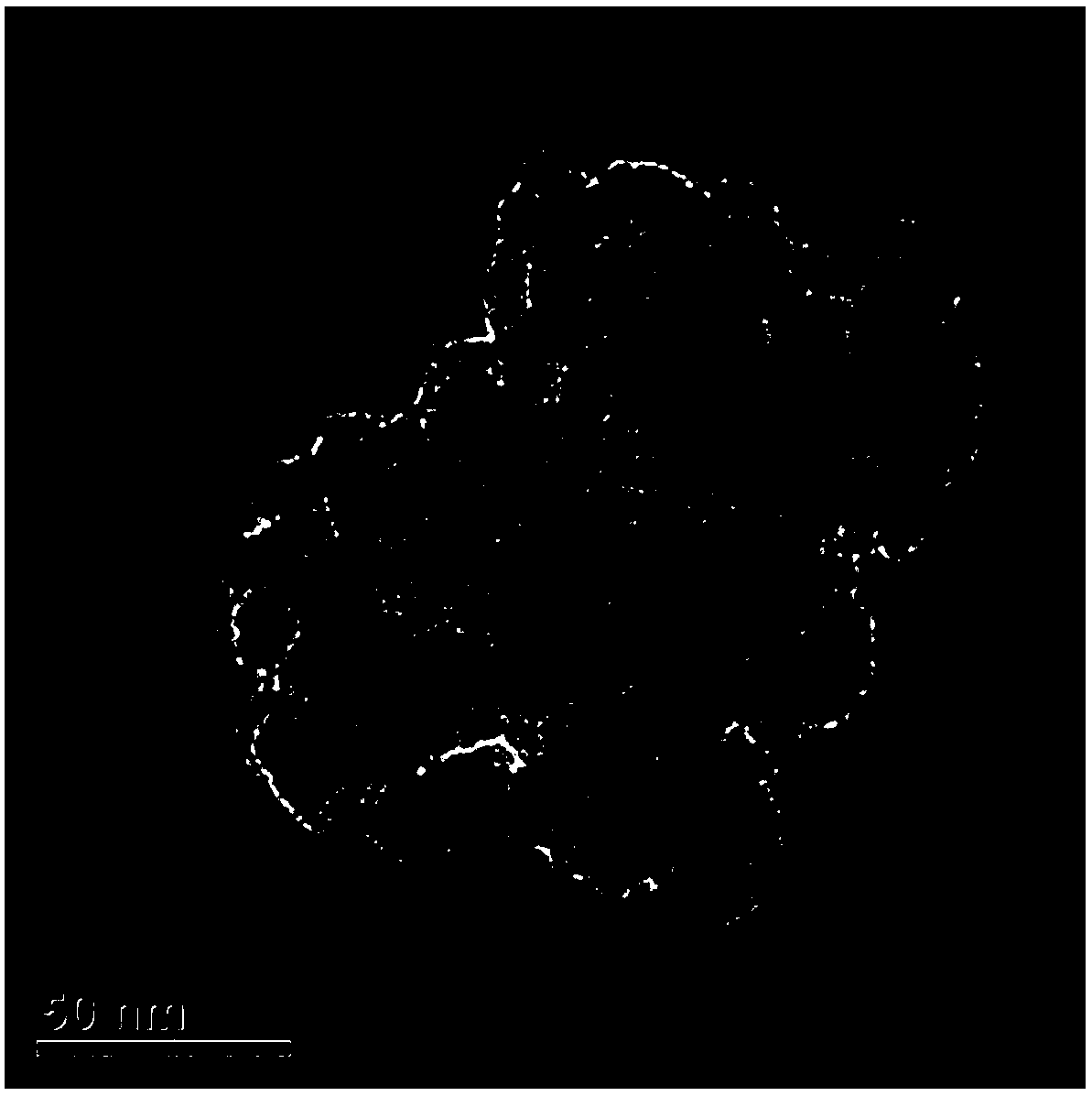

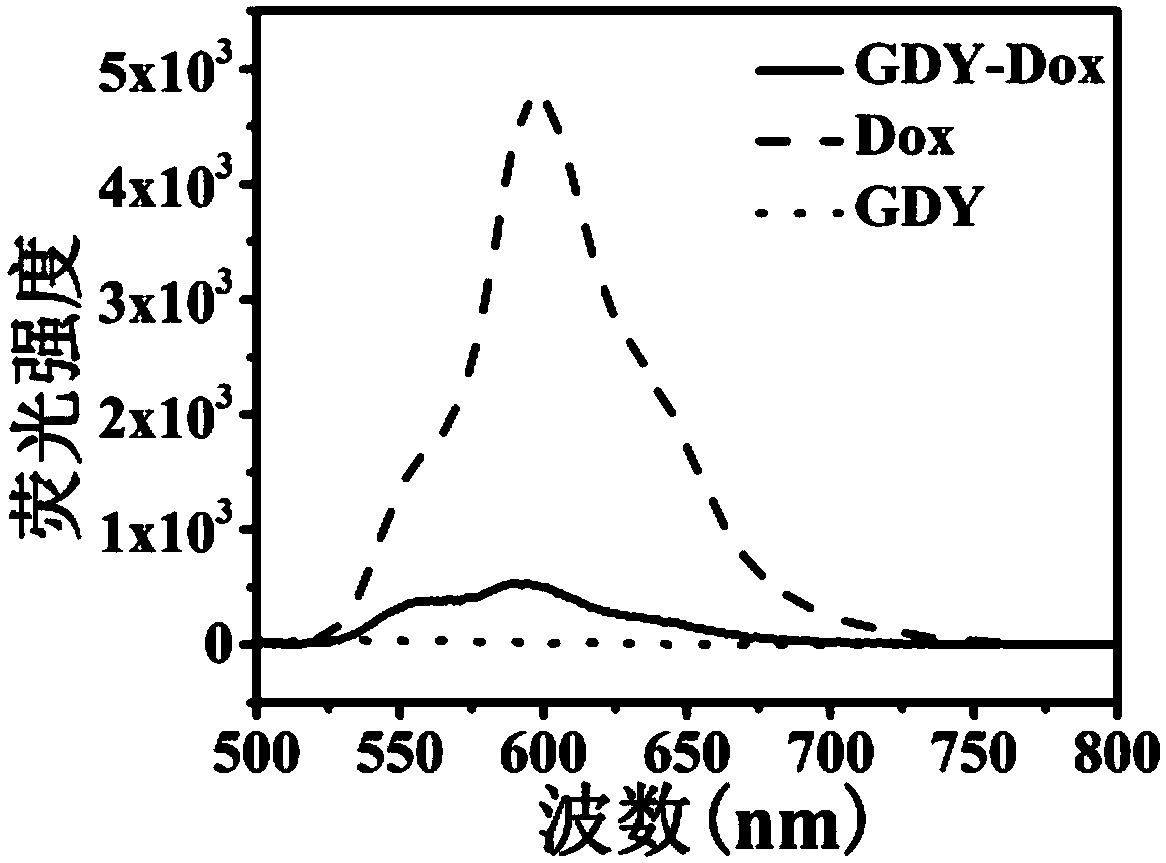

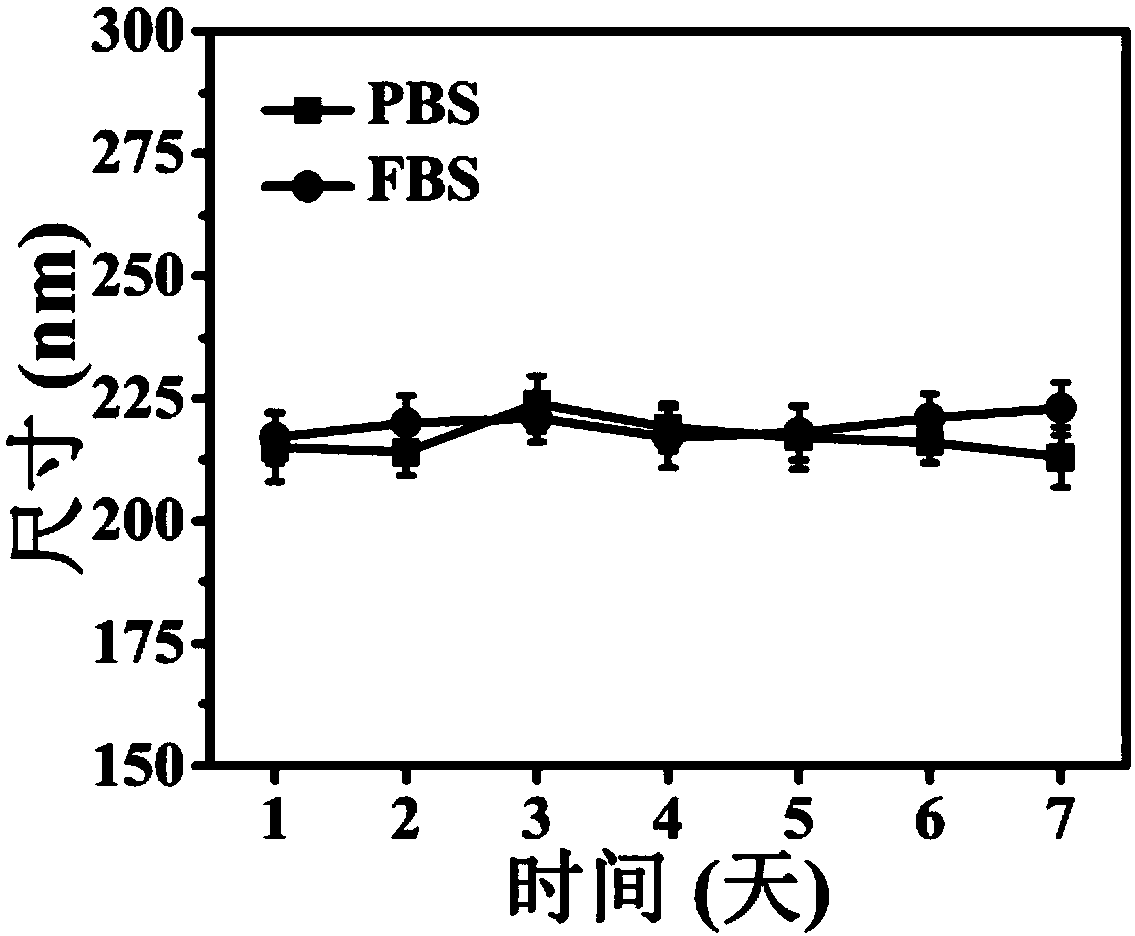

Graphdiyne nanosheet based multifunctional medicine carrying system as well as preparation method and application thereof

ActiveCN108295257AIncrease loading capacityGood photothermal effectOrganic active ingredientsDrug photocleavageMedicineDual response

The invention provides a graphdiyne nanosheet based multifunctional medicine carrying system as well as a preparation method and application thereof. For the graphdiyne nanosheet based multifunctionalmedicine carrying system, the graphdiyne nanosheet based multifunctional medicine carrying system is a medicine carrying system formed by loading medicine molecules on a graphdiyne nanosheet throughthe Pi-Pi conjugation and electrostatic mutual effect. The graphdiyne nanosheet based multifunctional medicine carrying system can be well dispersed in a water solution, and has good solid tumor high-permeability and retention (EPR) effect; the targeting goal is realized; the characteristics of laser and pH dual response release are realized. The preparation method of the graphdiyne nanosheet based multifunctional medicine carrying system is simple and is easy to implement; the reaction conditions are mild; the medicine carrying rate is high; the introduction of hazardous reagents is avoided;good biocompatibility and safety are realized; wide application prospects are realized in the field of biological medicine.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for improving colors of polyether polyol

The invention discloses a method for improving colors of polyether polyol. The method is implemented by the aid of two-step processes and includes adding decolorizing agents H2O2 into high-pressure reaction kettles after first phases, in other words, reaction between initiators and ethylene oxide in the high-pressure reaction kettles, are completely carried out in polyether polyol preparation procedures, heating the decolorizing agents, vacuumizing the high-pressure reaction kettles for 30 minutes and removing the decolorizing agents; adding compound decolorizing agents into the reaction kettles after the polyether polyol is completely prepared, heating the compound decolorizing agents and filtering and removing the compound decolorizing agents to obtain the color-improved polyether polyol. The method has the advantages that the polyether polyol obtained by the aid of the method is high in yield, the production cost can be reduced, the procedures are easy to implement, the decolorizing agents are easy to remove, impurities can be prevented from being led into the polyether polyol, and the like.

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

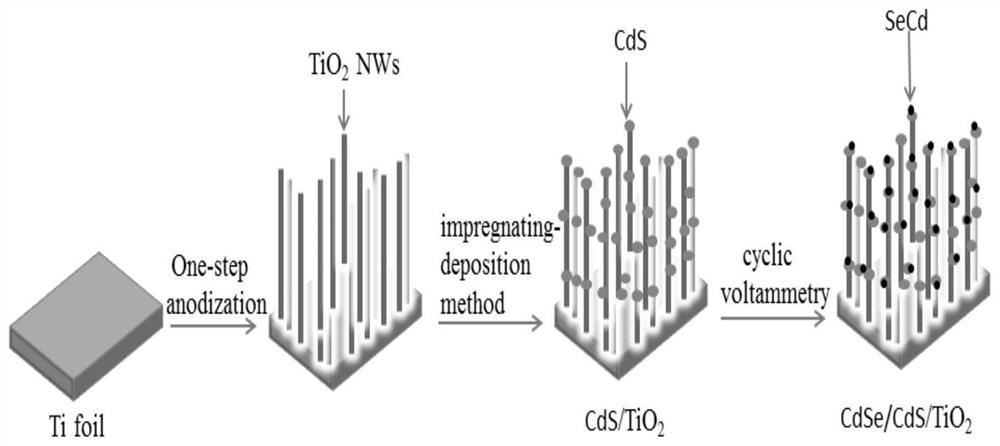

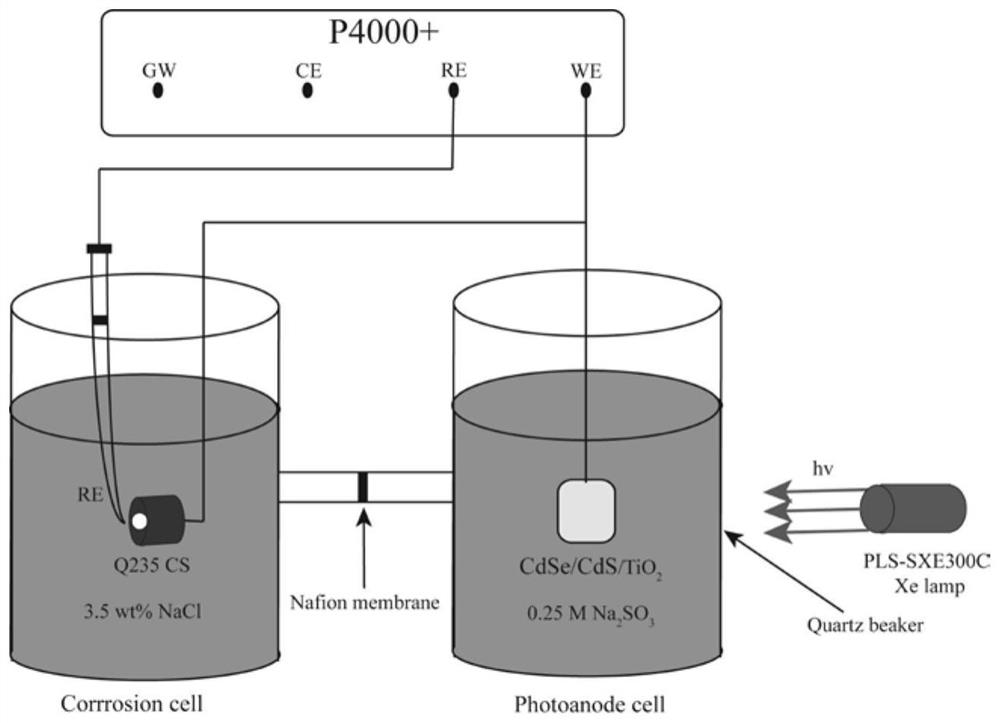

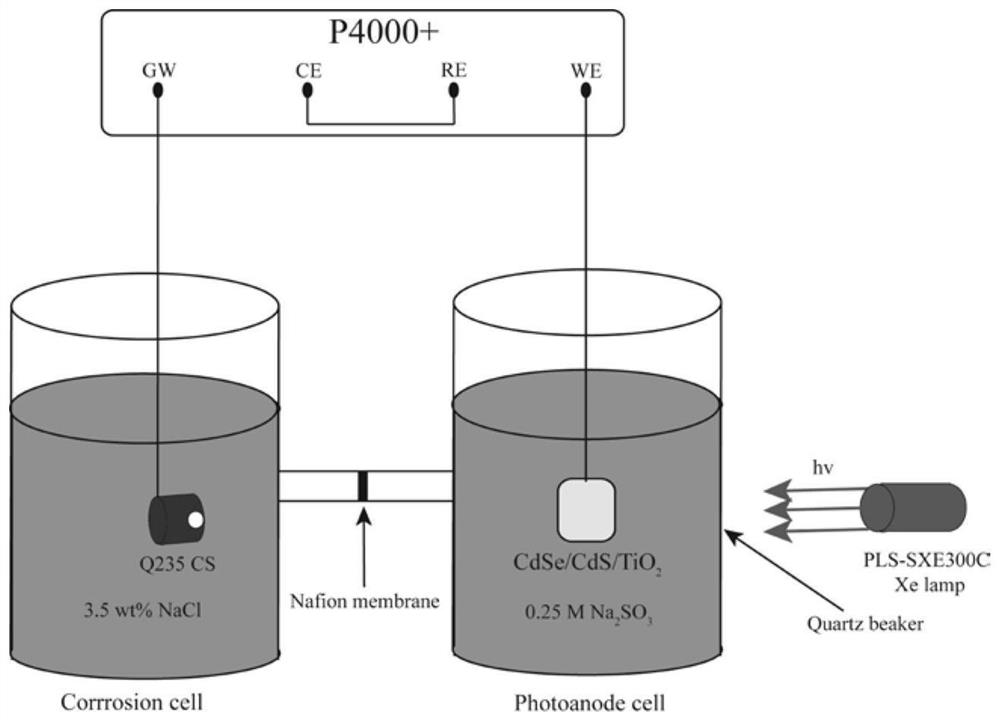

Photo-anode composite membrane material and application thereof

ActiveCN112779542ABroaden the response rangeIncrease profitMaterial nanotechnologyElectrolytic inorganic material coatingElectrode potentialNanowire

The invention relates to a photo-anode material, in particular to a photo-anode nano composite membrane material (CdSe / CdS / TiO2 composite membrane photo-anode) prepared by adopting an impregnation-deposition method and a cyclic voltammetry and application. CdSe and CdS nano particles are compounded on the surface of a TiO2 nanowire by adopting the impregnation-deposition method and the cyclic voltammetry to prepare the CdSe / CdS / TiO2 nano composite membrane photo-anode material. When the composite membrane is used as a photo-anode material for cathodic protection, compared with a pure TiO2 material, the photo-anode nano composite membrane material has the advantages that the visible light utilization rate of TiO2 and the separation rate of photo-induced electron-hole pairs are remarkably improved, the electrode potential of Q235 carbon steel is reduced, the corrosion rate is reduced, and the photo-induced cathodic protection performance of TiO2 on Q235 carbon steel is effectively improved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

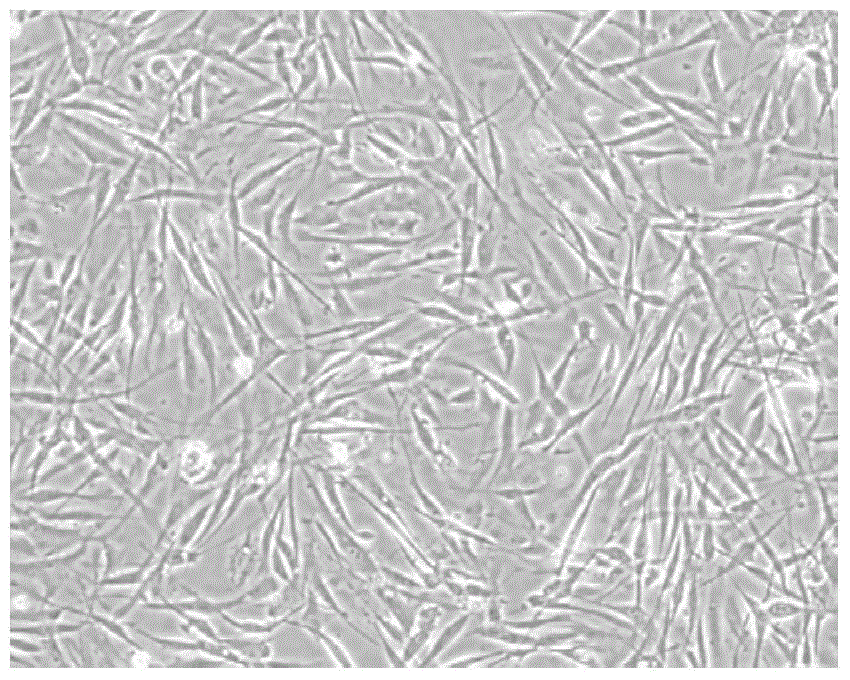

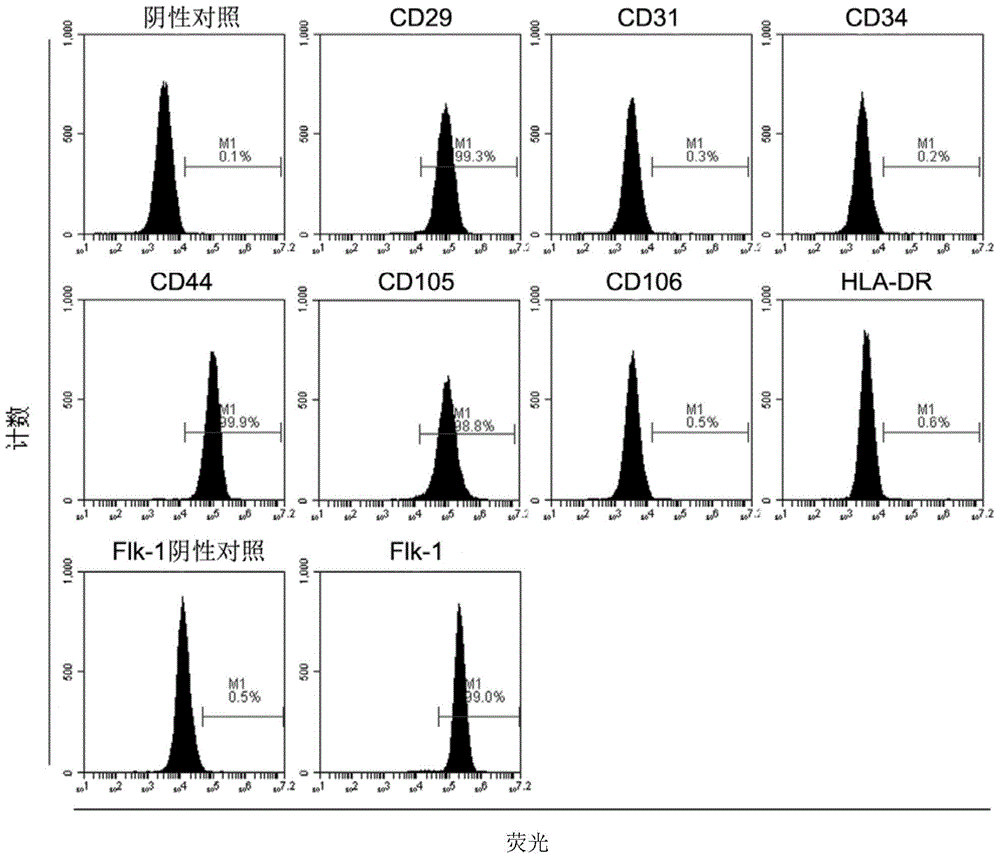

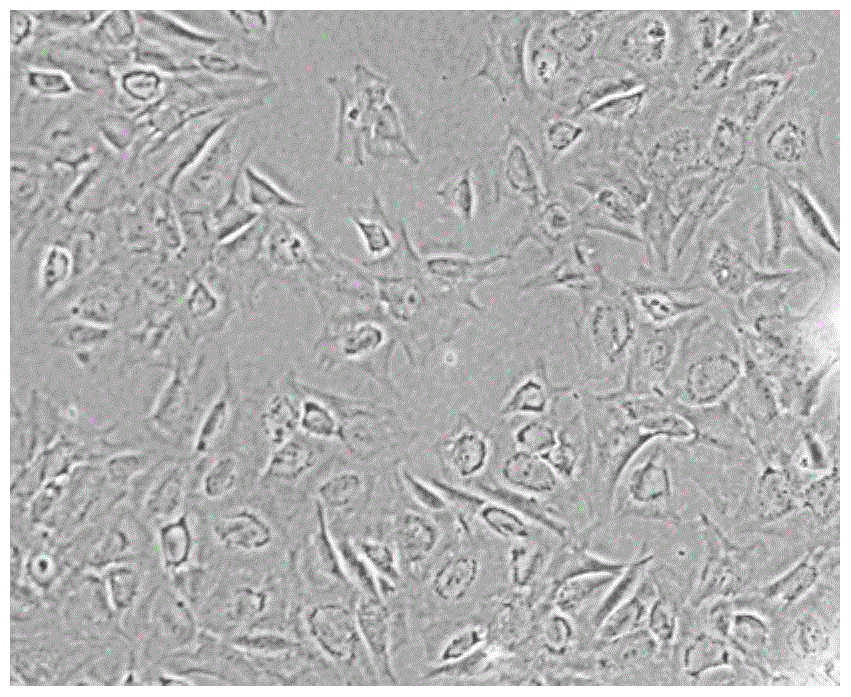

Preparation method of kidney sertoli cells and special mediums thereof

ActiveCN105087467AEasy to operateImprove efficiencyArtificial cell constructsVertebrate cellsTretinoinBiology

The invention relates to a preparation method of kidney sertoli cells and special mediums thereof, in particular provides a method of inducing mesenchymal stem cells into the kidney sertoli cells, and the method comprises the following steps: (1) inoculating the mesenchymal stem cells into a medium I; and (2) transferring the mesenchymal stem cells done in step (1) into a medium II so as to obtain the kidney sertoli cells, wherein the medium I is composed of a zooblast basic medium and solutes, and the solutes comprise 1.9 percent to 2.1 percent of fetal calf serum, 9.75ng / mL to 10.25ng / mL of activin A and 0.95*10 to 5mol / L to 1.05*10 to 5mol / L of tretinoin; and the medium II is composed of a zooblast basic medium and solutes, and the solutes comprise 1.9 percent to 2.1 percent of fetal calf serum, 9.75ng / mL to 10.25ng / mL of activin A, 0.95*10 to 7mol / L to 1.05*10 to 7mol / L of tretinoin and 19ng / ml to 21ng / ml of BMP7. An induction culture method of the invention is suitable for the mesenchymal stem cells of various sources, and is free of virus introduction, easy in operation and high in efficiency.

Owner:THE INST OF BASIC MEDICAL SCI OF CHINESE ACAD OF MEDICAL SCI

Preparation method of lithium tetrafluoroborate

InactiveCN104692405AIncrease profitEfficient removalTretrafluoboric acidLithium compoundFluoboric acid

The invention discloses a preparation method of lithium tetrafluoroborate. The preparation method comprises the following steps: 1) adding boric acid into hydrofluoric acid and reacting to obtain a fluoboric acid solution; 2) adding a lithium compound into the fluoboric acid solution and reacting to obtain a lithium tetrafluoroborate solution; 3) concentrating the lithium tetrafluoroborate solution, cooling, crystallizing and filtering to obtain lithium tetrafluoroborate crystals; 4) drying the lithium tetrafluoroborate crystals to obtain a lithium tetrafluoroborate crude product; and 5) putting the lithium tetrafluoroborate crude product into a reactor, introducing fluorine gas or fluorine-nitrogen mixed gas and reacting to obtain lithium tetrafluoroborate. According to the preparation method of lithium tetrafluoroborate disclosed by the invention, the deficiencies of the existing preparation method are made up, the process is simple to operate, no organic solvent is introduced, and the obtained lithium tetrafluoroborate product is high in purity and low in water content; and the whole preparation process is strong in operability and high in utilization rate of raw materials, has no emission of three wastes, and is suitable for large-scale industrial production.

Owner:DO FLUORIDE CHEM CO LTD

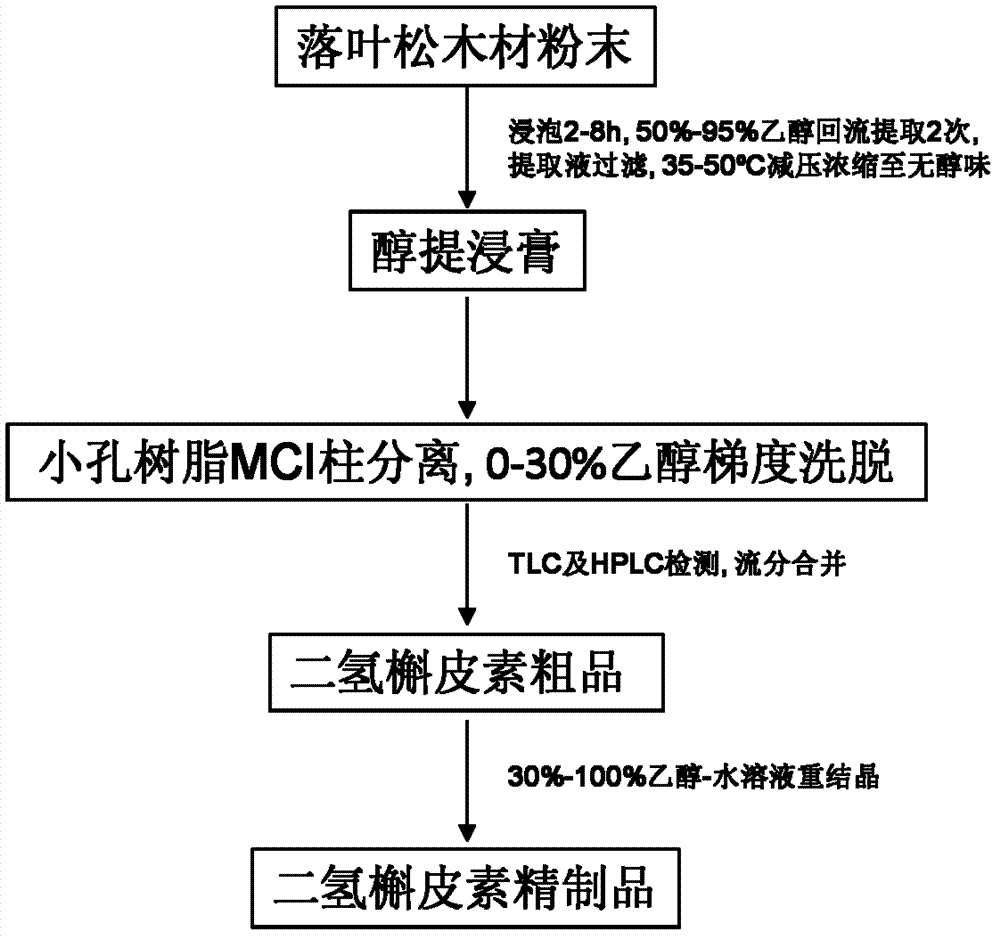

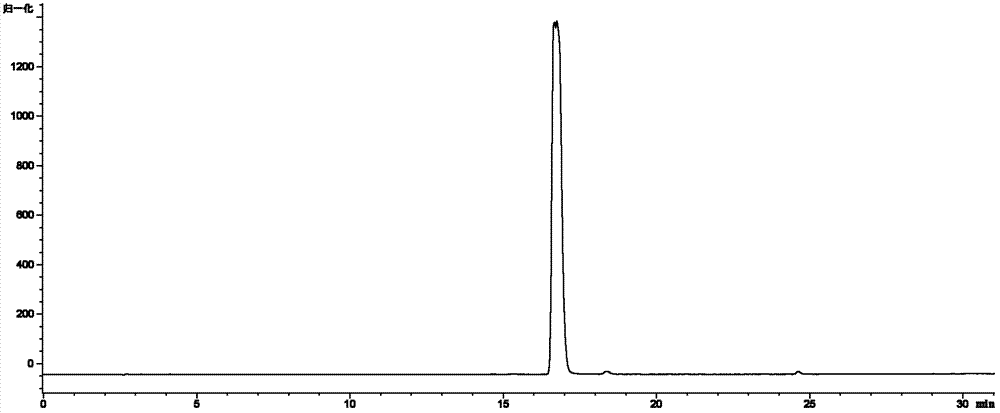

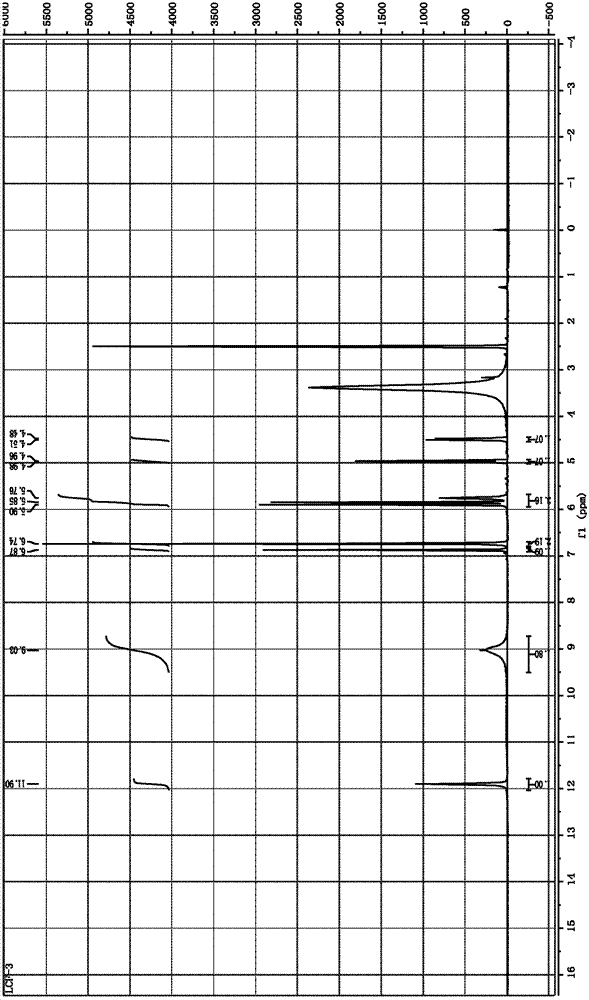

Method for refining dihydroquercetin from larch

The invention discloses a method for refining dihydroquercetin from larch by using micro-porous resin. The method comprises the following steps: (1) after crushing the raw material larch wood, adding ethanol water solution to extract, collecting extracting solution and concentrating to obtain extract; (2) performing liquid phase adsorption separation on the extract by using micro-porous resin MCI, performing gradient elution by taking the ethanol water solution with volume fraction of 0-30 percent as an eluant, collecting and combining elution components with volume fraction of 20-25 percent, concentrating and drying to obtain a dihydroquercetin rough product; and (3) recrystallizing the dihydroquercetin rough product to obtain refined dihydroquercetin. According to the method, environment-friendly solvents such as water and ethanol are adopted, are pollution-free and can be recycled; the used adsorbent micro-porous resin introduces less impurities and can be reused for times; the obtained product has purity of greater than 99 percent and has no toxic ingredient residues, and the pharmaceutical-grade raw material can be directly obtained. The method has the advantages of simple route, economy, environmental friendliness and high yield and is suitable for industrial production.

Owner:PEKING UNIV +1

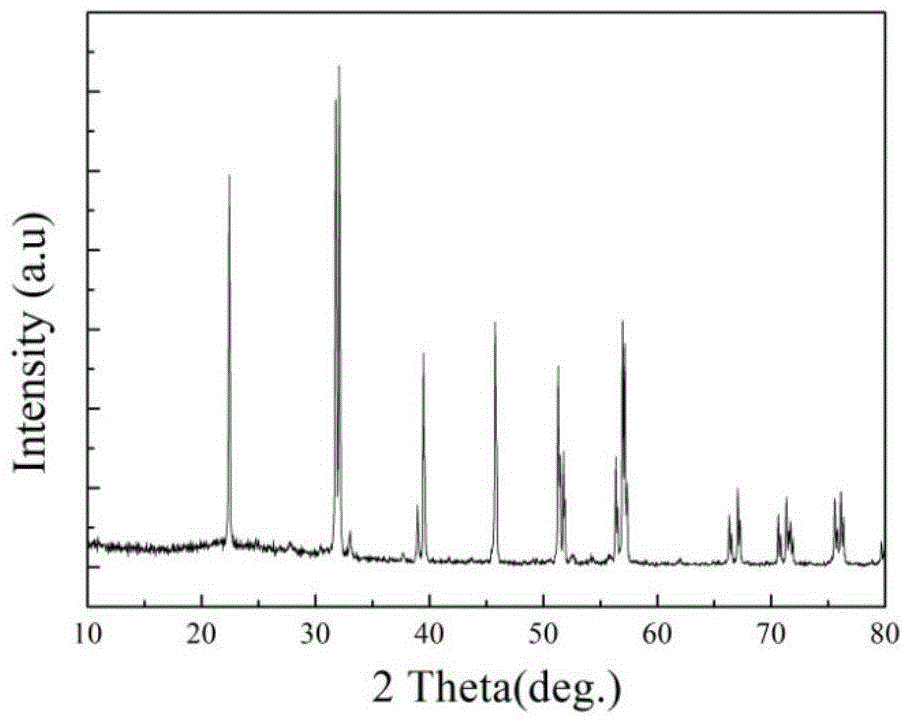

Preparation method of high-purity copper oxide powder material

InactiveCN103553114AReduce or eliminate the use ofNo pollutionCopper oxides/halidesCopper wireCopper oxide

The invention discloses a method for preparing a high-purity copper oxide powder material, belonging to the field of high-performance functional materials. The raw material for preparing the high-purity copper oxide powdery material is red copper wires or red copper rods. The preparation method comprises the steps of cutting recovered waste red copper wires or red copper rods into small pieces, heating the small pieces in a rotary furnace embedded with a pure copper lining plate or high-temperature-resisting stainless copper lining plate, putting red copper balls into the rotary furnace to serve as grinding balls at the same time, starting to inflate oxygen into the rotary furnace when the rotary furnace is heated to a certain temperature to ensure that copper is in full contact with the oxygen under a high-temperature condition to generate an oxidation reaction, and fully crushing copper oxide generated through the reaction under the action of the grinding balls at the same time, thereby obtaining the high-purity copper oxide powder material. The method disclosed by the invention is simple in production process and low in production cost, and the oxidation of copper and the crushing of copper oxide are performed at the same time, so that the process flow is effectively shortened. Impurities are not introduced during processing and preparation, so that the obtained copper oxide powder material is high in purity which can reach more than 99%.

Owner:HUNAN UNIV

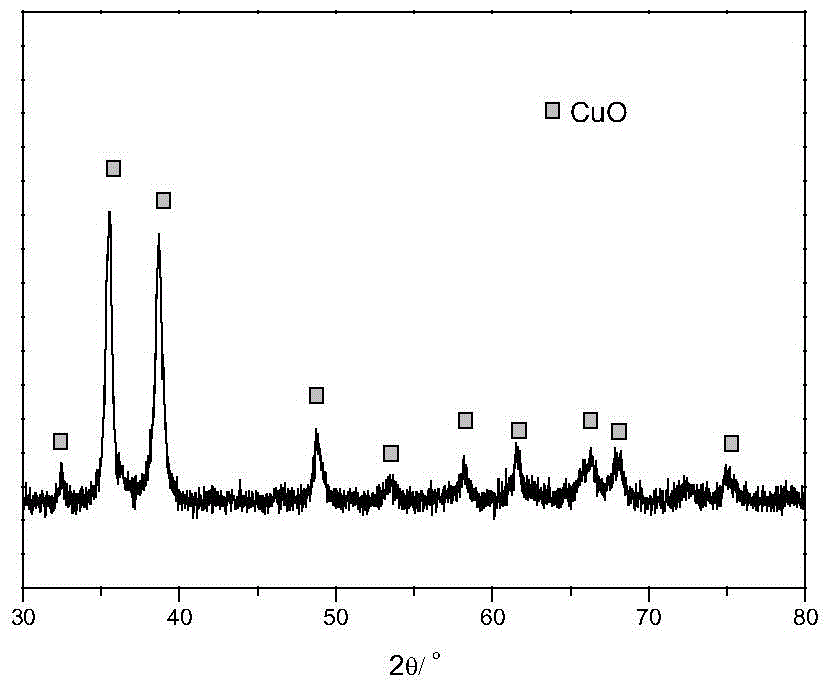

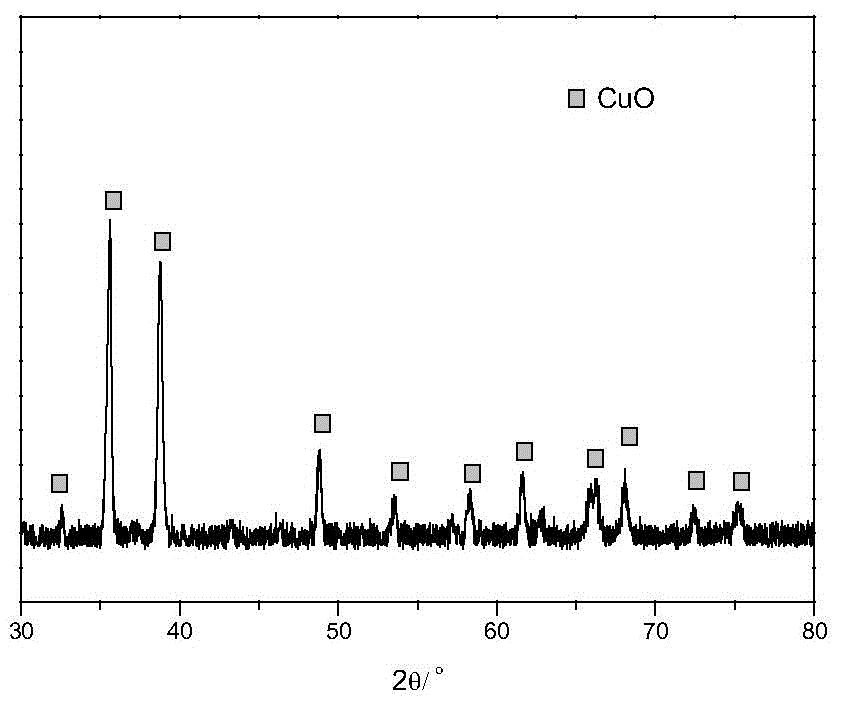

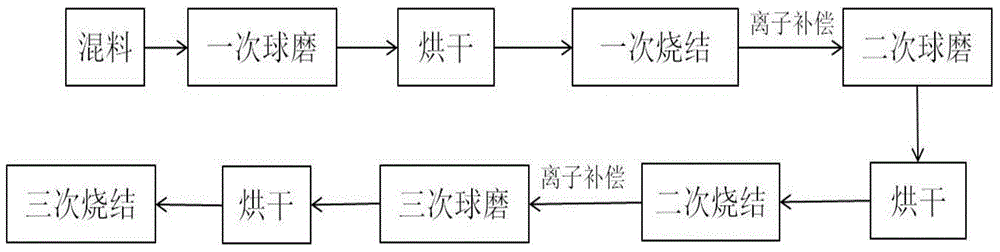

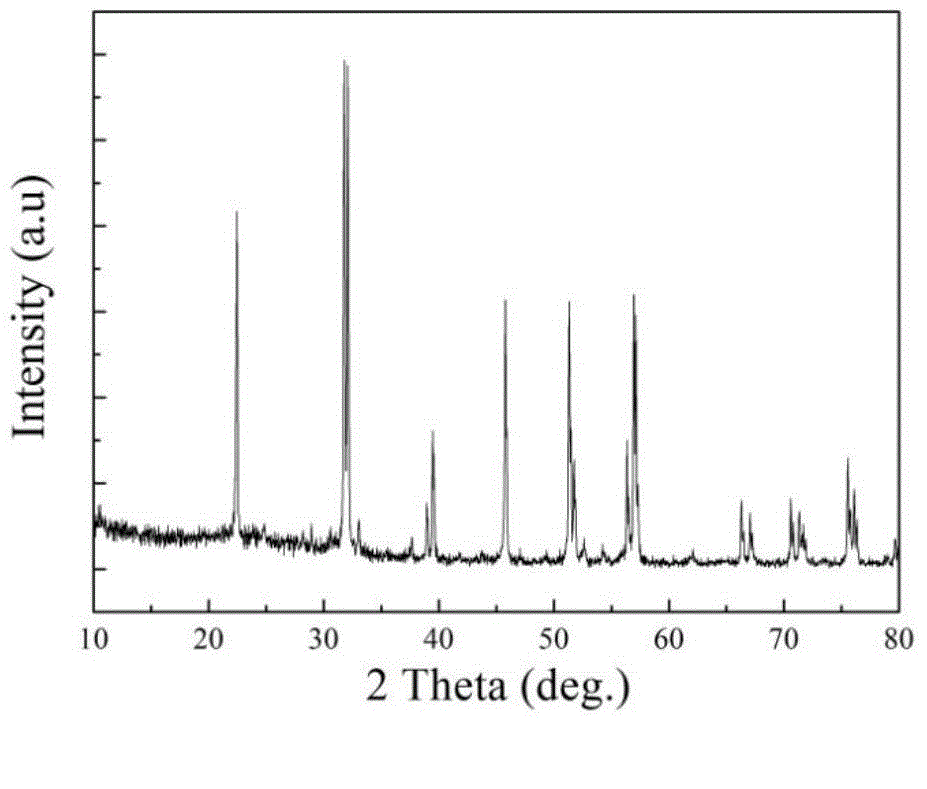

Preparation method of single pure-phase bismuth ferrite material based on ionic compensation

InactiveCN104961162ASolve technical problems of composition segregationReduce the ratioIron compoundsRoom temperatureIron oxide

The invention provides a preparation method of a single pure-phase bismuth ferrite material based on ionic compensation, which belongs to the field of ceramic material preparation. Firstly, a bismuth ferrite ceramic reaction mixture is prepared and then is dried for presintering for the first time; then 0.3 to 0.7wt percent of bismuth oxide is added through secondary ball milling for ionic compensation, and drying is performed for presintering for the second time; 0.2 to 0.4wt percent of bismuth oxide is added through third ball milling for ionic compensation, drying is performed for presintering for 0.5 to 1.5 h at 810 to 835 DEG C, and natural cooling is performed to room temperature along with a furnace, so as to obtain the single pure-phase bismuth ferrite material. According to the preparation method, the bismuth oxide and ferric oxide are used as raw materials, and three-step sintering and twice ionic compensation are adopted to prepare the single pure-phase bismuth ferrite material, so as to solve the technical problem of composition segregation caused by volatile bismuth oxide in the preparation process of bismuth ferrite and prepare the single pure-phase bismuth ferrite material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

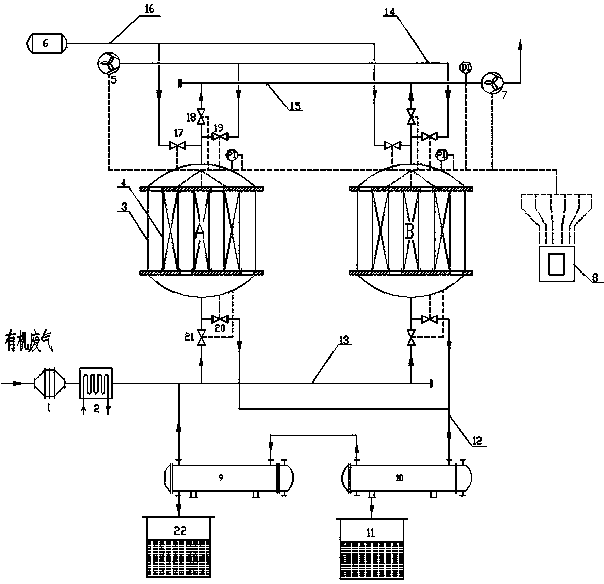

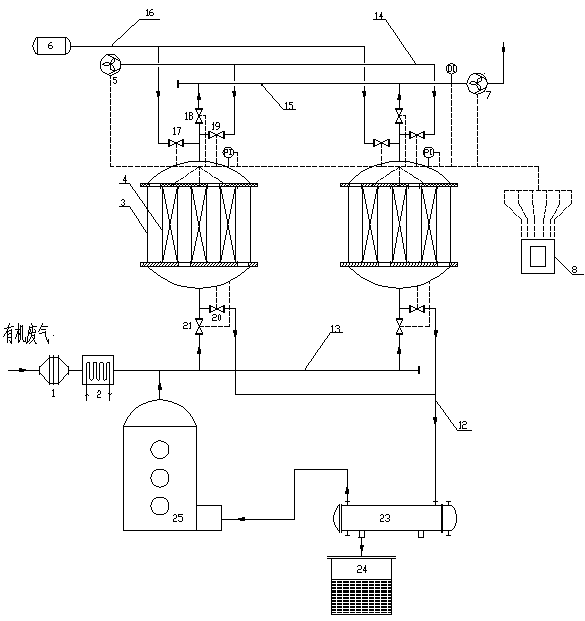

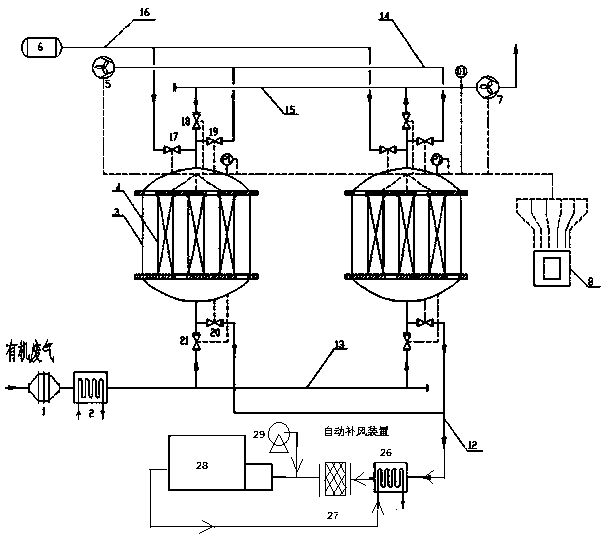

Electrified heating regenerated active carbon adsorption purification system and electrified heating regenerated active carbon adsorption purification method

InactiveCN110975515AReduce heat damageNo importGas treatmentDispersed particle separationFiberActivated carbon

The invention discloses an electrified heating regenerated active carbon adsorption purification system and an electrified heating regenerated active carbon adsorption purification method. The systemcomprises a filter, a cooler and at least more than two active carbon adsorbers, wherein an adsorption purification unit is arranged in the active carbon adsorber, and comprises an active carbon fiberbed layer, electrodes, a temperature sensor and an enclosure structure, the active carbon fiber bed layer is formed by overlapping active carbon fiber fabrics, a temperature sensor is arranged in thebed layer, the electrodes are arranged on any two opposite end surfaces of the bed layer, and the electrode adopts a mode that an electric-conducting band and an active carbon fiber fabric are overlapped layer by layer or the electric-conducting band and plural layers of active carbon fiber fabrics are overlapped. According to the invention, the electric-conducting bands are uniformly arranged inthe end surface area of the bed layer to ensure the uniform distribution of the bed layer current in the electric heating process, so that the uniform temperature rise of the active carbon bed layeris realized, organic matter desorption is thorough, regeneration is complete, and the electric heating filtering core can keep good adsorption performance for a long time.

Owner:张蕾 +1

Quality identification method for lead powder of lead-acid storage battery raw material

The invention discloses a quality identification method for lead powder of a lead-acid storage battery raw material, which is characterized by comprising the following steps of: dissolving the lead powder by using a sulfuric acid solution, taking out a residue lead cluster, and immediately absorbing water; under the closed high-temperature condition, melting the residues, and obtaining a pure metal block; detecting the bismuth content of the metal block. The detection method adopts atomic emission spectrometry or analyzes the bismuth content according to the national standard. The determination method provided by the invention is simple, easy to operate, capable of simultaneously analyzing and determining a plurality of samples, few in types of required chemical reagents and accurate and reliable in analysis result.

Owner:李彤

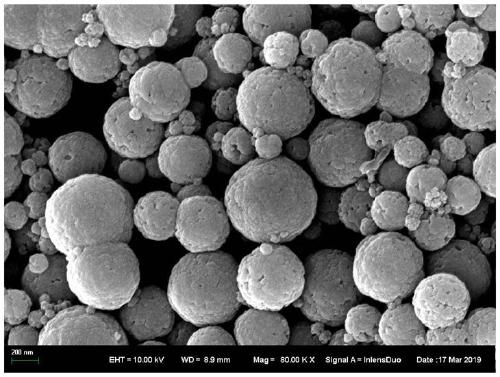

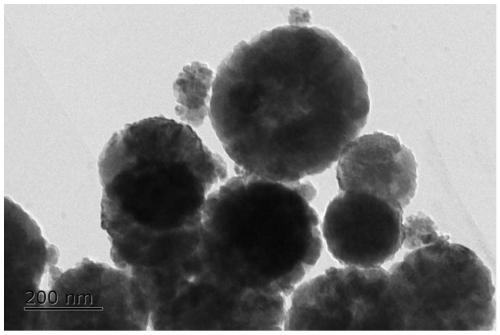

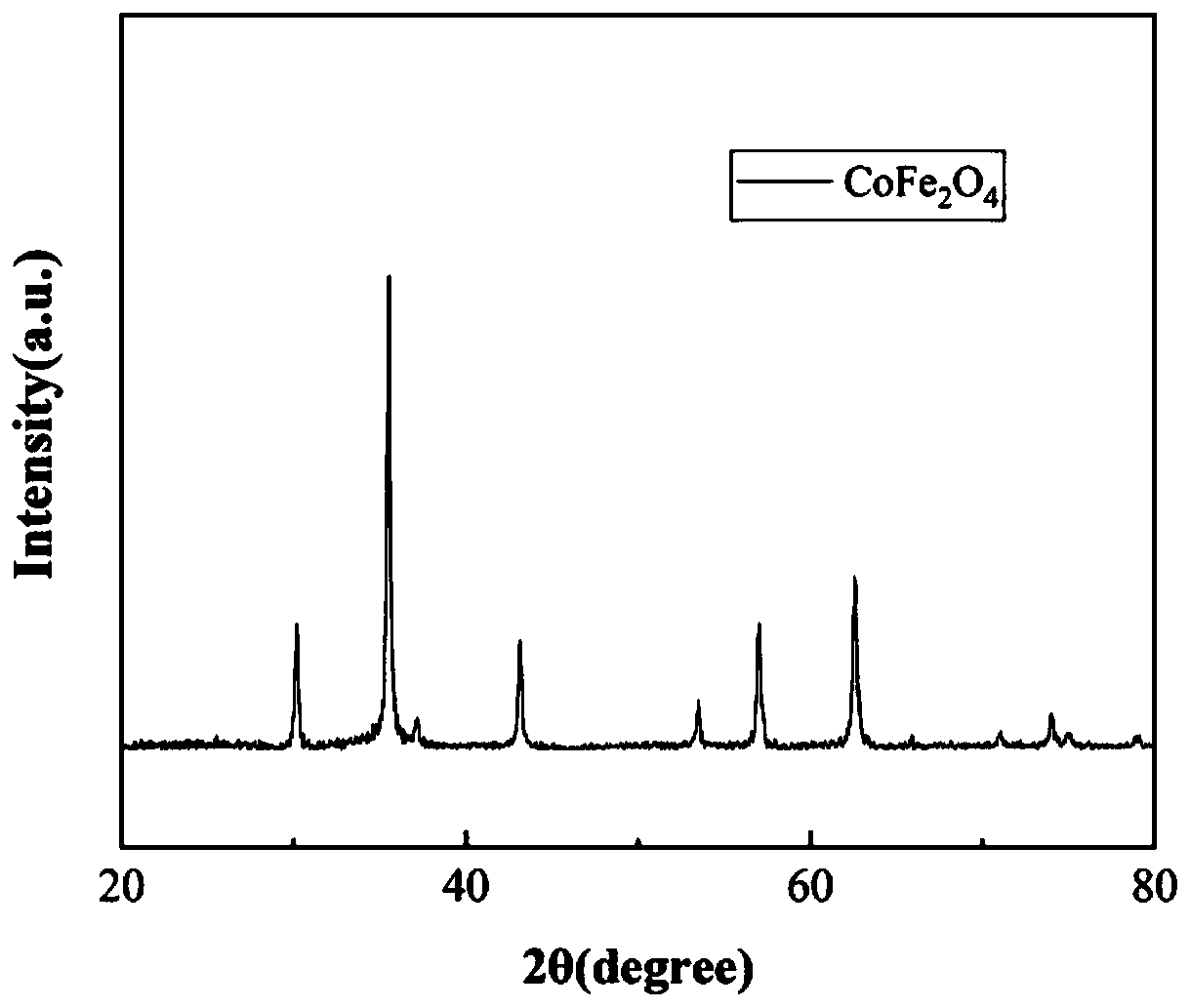

Submicron hollow cobalt ferrite wave-absorbing material and preparation method thereof

PendingCN111533177ANo importWith energy savingMaterial nanotechnologyCobalt compoundsPhysical chemistryIron chloride

The invention provides a submicron hollow cobalt ferrite electromagnetic wave-absorbing material and a preparation method thereof. The submicron hollow cobalt ferrite electromagnetic wave-absorbing material is prepared by taking ferric chloride hexahydrate and cobalt chloride hexahydrate as main raw materials. Cobalt ferrite is generated through a hydrothermal method. The submicron hollow cobalt ferrite wave-absorbing material prepared by the hydrothermal method has the advantages of energy conservation, consumption reduction, simple operation process and the like. The product is submicron powder, the small-size effect and the interface effect are increased, the product is of a hollow structure, impedance matching is improved, the electric loss capacity is improved, and the electromagneticwave absorption capacity of the material is improved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Method for preparing Zaorenanshen oral liquid

InactiveCN108607017AKeep active ingredientsContinuous alcohol-free productionNervous disorderDispersion deliveryAlcohol freeCLARITY

The invention discloses a method for preparing a Zaorenanshen oral liquid. The method adopts a form of combining a plurality of separation modes, improves the clarity on the basis of realizing the maximum reservation of effective components in a Zaorenanshen liquid in the manners of cold sink and centrifugation of extracted concentrate, and external pressure ultrafiltration after the addition of oral liquid ingredients, and the like, realizes continuous alcohol-free production of the Zaorenanshen liquid, avoids the introduction of impurities, and has the advantages of simple operation, low cost and the like, and the Zaorenanshen liquid prepared by the method reserves effective components, and has good clarity, high uniformity and good treatment effect without introducing any impurities.

Owner:LIAONING XIANCAOTANG PHARMA

Method for deeply removing copper from nickle electrolysis anode solution by using ion exchange resin

ActiveCN106283108AAvoid generatingNo importElectrolysis componentsPhotography auxillary processesElectrolysisIon exchange

The invention discloses a method for deeply removing copper from a nickle electrolysis anode solution by using ion exchange resin. The method comprises the following steps: chelating ion exchange resin is used for carrying out multi-stage counter current absorption on the nickle electrolysis anode solution, the concentration of Cu in the nickel solution is reduced to be 40 mg / L or below, filtering is performed, a low-concentration acid solution is used for washing resin, Ni physically carried or chemically absorbed is removed, and then an acid solution is used for desorbing so as to obtain a copper solution with the Cu / Ni ratio of larger than 20; dynamic adsorption is performed on the nickel solution with the Cu content lower than 40 mg / L, the flow rate and the temperature of the solution are controlled, and therefore, the nickel solution with the Cu content lower than 3 mg / L is obtained. According to the method provided by the invention, the ratio of Cu / Ni loaded in the resin is high and reaches 30 or above, production of copper slag can be avoided, and no-slag copper removal can be achieved. The method provided by the invention has the advantages of high copper removing degree, simple process, zero impurity introduction, low cost, and zero waste gas and waste residue discharge, and has significant economic benefits and an environmental value.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com