Liquid-phase preparation method of cuprous sulfide film

A technology of cuprous sulfide and thin film, which is applied in the direction of copper sulfide, etc., can solve the problems of chemical method film introducing impurities, not suitable for large-scale production, poor experiment repeatability, etc., and achieve the effect of low cost, simple equipment and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a liquid-phase preparation method of a cuprous sulfide thin film. First, an organic precursor solution containing copper and sulfur is synthesized, a precursor thin film is deposited by a non-vacuum liquid-phase film-making technology, and finally annealed to form a cuprous sulfide thin film. The method is simple and convenient to operate, does not introduce anion impurities, uses simple equipment, has low cost, good process repeatability, and is suitable for large-scale production. Specifically, as an example, the method of the present invention may include the following steps.

[0026] First, the copper source is dissolved in an alcohol solution containing a complexing agent and a sulfur-containing small molecule reagent, and if necessary, a certain viscosity regulator is added to form a clear, transparent and stable precursor solution.

[0027] Wherein, the copper source may be one or a mixture of two or more of copper oxide, cuprous oxide, cop...

Embodiment 1

[0042] First, 1 mmol of cuprous oxide was dissolved in 10 mL of a mixed solution of thioacetic acid, ethanolamine, propylene glycol, and isopropanol, wherein the ratio of thioacetic acid, ethanolamine, propylene glycol, and isopropanol was 2:0.5:1:6.5. Stir at room temperature to obtain a clear and transparent precursor solution;

[0043] Secondly, the precursor film was deposited by spin coating and dried on a 300°C heating plate;

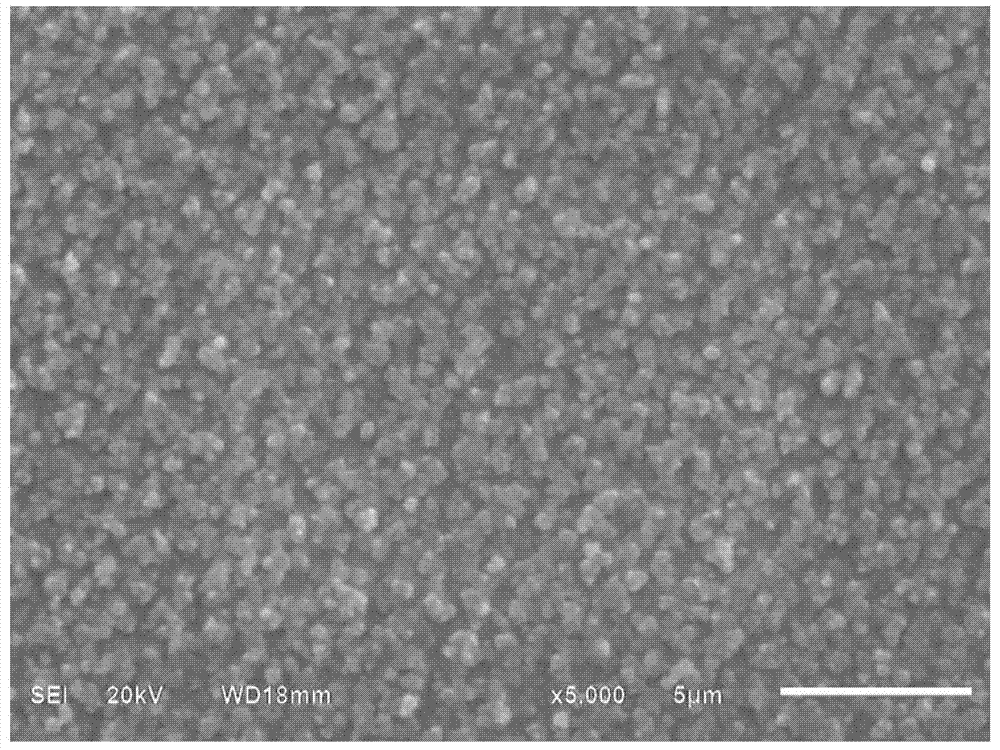

[0044] Finally, anneal the precursor film at 500° C. for 30 minutes in a sulfur atmosphere to obtain a cuprous sulfide film. figure 1 A scanning electron microscope (SEM) photo of the cuprous sulfide film is shown, and it can be seen from the figure that the cuprous sulfide film is uniformly distributed and of excellent quality.

Embodiment 2

[0046] First, 2 mmol of copper oxide was dissolved in 10 mL of a mixed solution of thioacetic acid, diethanolamine, and ethanol, wherein the ratio of thioacetic acid, diethanolamine, and ethanol was 2:1:7. Stir at room temperature to obtain a clear and transparent precursor solution;

[0047] Second, the precursor film was deposited by spin coating and dried on a 350°C heating plate;

[0048]Finally, anneal the precursor film at 500° C. for 30 minutes in a sulfur atmosphere to obtain a cuprous sulfide film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com