Submicron hollow cobalt ferrite wave-absorbing material and preparation method thereof

A hollow cobalt iron, sub-micron technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, cobalt compounds, etc. Small size effect, improved impedance matching, no effect of impurity introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

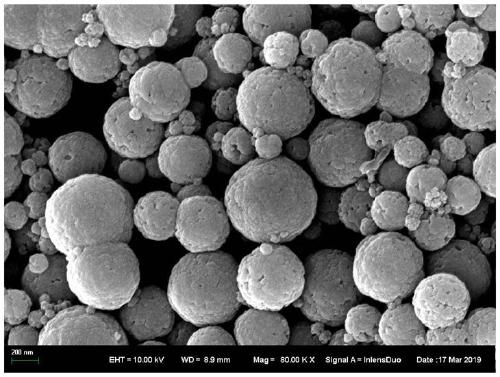

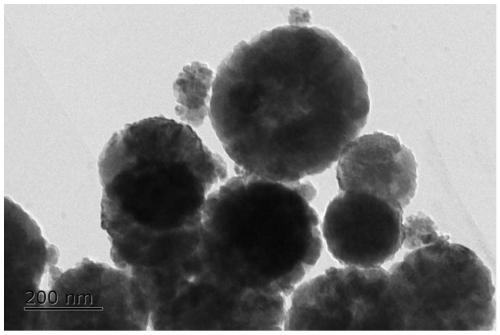

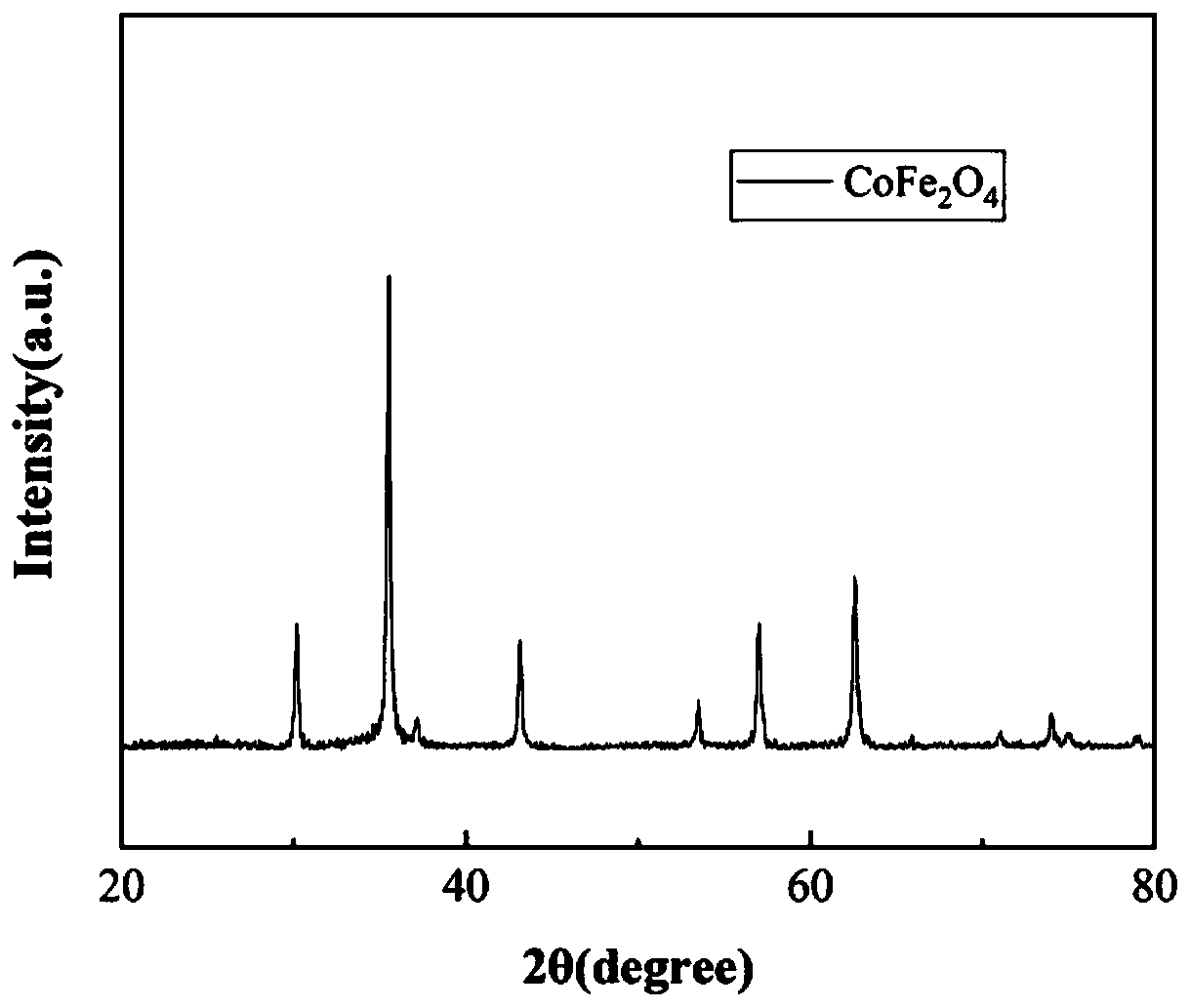

[0029] Weigh 13.52g of ferric chloride hexahydrate, 5.56g of cobalt chloride hexahydrate, 36g of urea, and 20ml of polyethylene glycol, respectively add to 400ml of ethylene glycol solvent, stir evenly for 30min, weigh 20g of polyvinylpyrrolidone and add to In the above solution, stir evenly to form a suspension. After mixing evenly, add it into a polytetrafluoroethylene-lined autoclave, and keep it in a blast drying oven at 200°C for 8 hours. After cooling to room temperature, it was washed with deionized water and absolute ethanol several times by centrifugation. Then, put it into a vacuum drying oven at 60° C. for 24 hours under vacuum. figure 1 It is a scanning electron microscope photo of cobalt ferrite absorbing material, the crystal grain is spherical, the size is between 100-500nm, it is a submicron structure, and there is no obvious agglomeration phenomenon. figure 2 It is a transmission electron microscope photo of cobalt ferrite absorbing material. It can be seen...

Embodiment 2

[0031] Weigh 13.52g of ferric chloride hexahydrate, 5.56g of cobalt chloride hexahydrate, 36g of urea, and 20ml of polyethylene glycol, respectively add to 400ml of ethylene glycol solvent, stir evenly for 30min, weigh 40g of polyvinylpyrrolidone and add to In the above solution, stir evenly to form a suspension. After mixing evenly, add it into a polytetrafluoroethylene-lined autoclave, and keep it in a blast drying oven at 200°C for 8 hours. After cooling to room temperature, it was washed with deionized water and absolute ethanol several times by centrifugation. Then, put it into a vacuum drying oven at 60° C. for 24 hours under vacuum. Figure 5 It is a scanning electron microscope photo of cobalt ferrite absorbing material, the crystal grain is spherical, the size is between 100-300nm, it is a submicron structure, and there is no obvious agglomeration phenomenon. Figure 6 It is a transmission electron microscope photo of the hollow cobalt ferrite absorbing material. It...

Embodiment 3

[0033] Weigh 13.52g of ferric chloride hexahydrate, 5.56g of cobalt chloride hexahydrate, 36g of urea, and 20ml of polyethylene glycol, respectively add to 400ml of ethylene glycol solvent, stir evenly for 30min, weigh 60g of polyvinylpyrrolidone and add to In the above solution, stir evenly to form a suspension. After mixing evenly, add it into a polytetrafluoroethylene-lined autoclave, and keep it in a blast drying oven at 200°C for 8 hours. After cooling to room temperature, it was washed with deionized water and absolute ethanol several times by centrifugation. Then, put it into a vacuum drying oven at 60° C. for 24 hours under vacuum. Figure 9 It is a photograph of the morphology of cobalt ferrite absorbing material, the crystal grain is spherical, the size is between 50-150nm, and it is a mixed structure of nanometer and submicron. Figure 10 It is a transmission electron microscope photo of cobalt ferrite absorbing material. It can be seen from the figure that most o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com