Patents

Literature

311 results about "Feroxyhyte" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feroxyhyte is an oxide/hydroxide of iron, δ-Fe³⁺O(OH). Feroxyhyte crystallizes in the hexagonal system. It forms as brown rounded to concretionary masses. Feroxyhyte is opaque, magnetic, has a yellow streak, and has a relative density of 4.2.

Iron nitride powder, method of manufacturing the same, and magnetic recording medium

InactiveUS20090087688A1Excellent magnetic propertiesSuited to high-density recordingPretreated surfacesRecord information storageMischmetalIron nitride

An aspect of the present invention relates to an iron nitride powder. The iron nitride powder is comprised chiefly of Fe16N2 and comprises, on at least a portion of the powder surface, a coating layer comprising at least one element selected from the group consisting of rare earth metal elements, aluminum, and silicon, and cobalt-containing ferrite having a composition denoted by (CoxFe1−x)Fe2O4, wherein 0<x≦1. The present invention further relates to a method of manufacturing iron nitride powders and a magnetic recording medium comprising the iron nitride powder.

Owner:FUJIFILM CORP

Heavy metal ion adsorbent ferrite hollow spheres MFe2O4

InactiveCN104150540AImprove adsorption capacityWide variety of sourcesOther chemical processesFerroso-ferric oxidesSorbentPollution

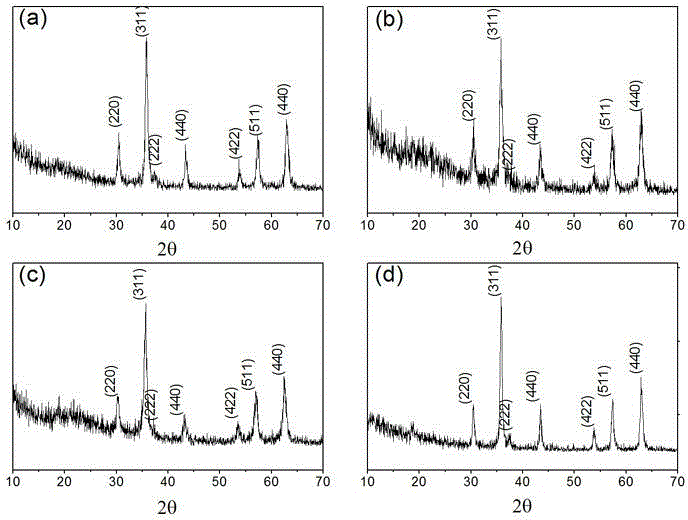

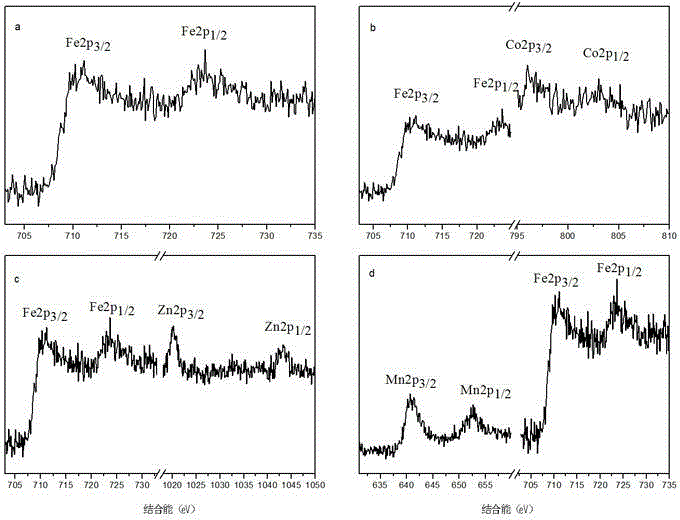

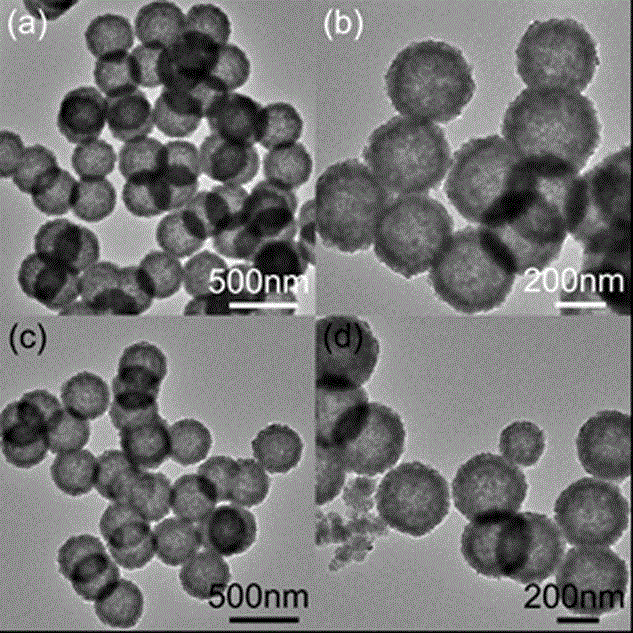

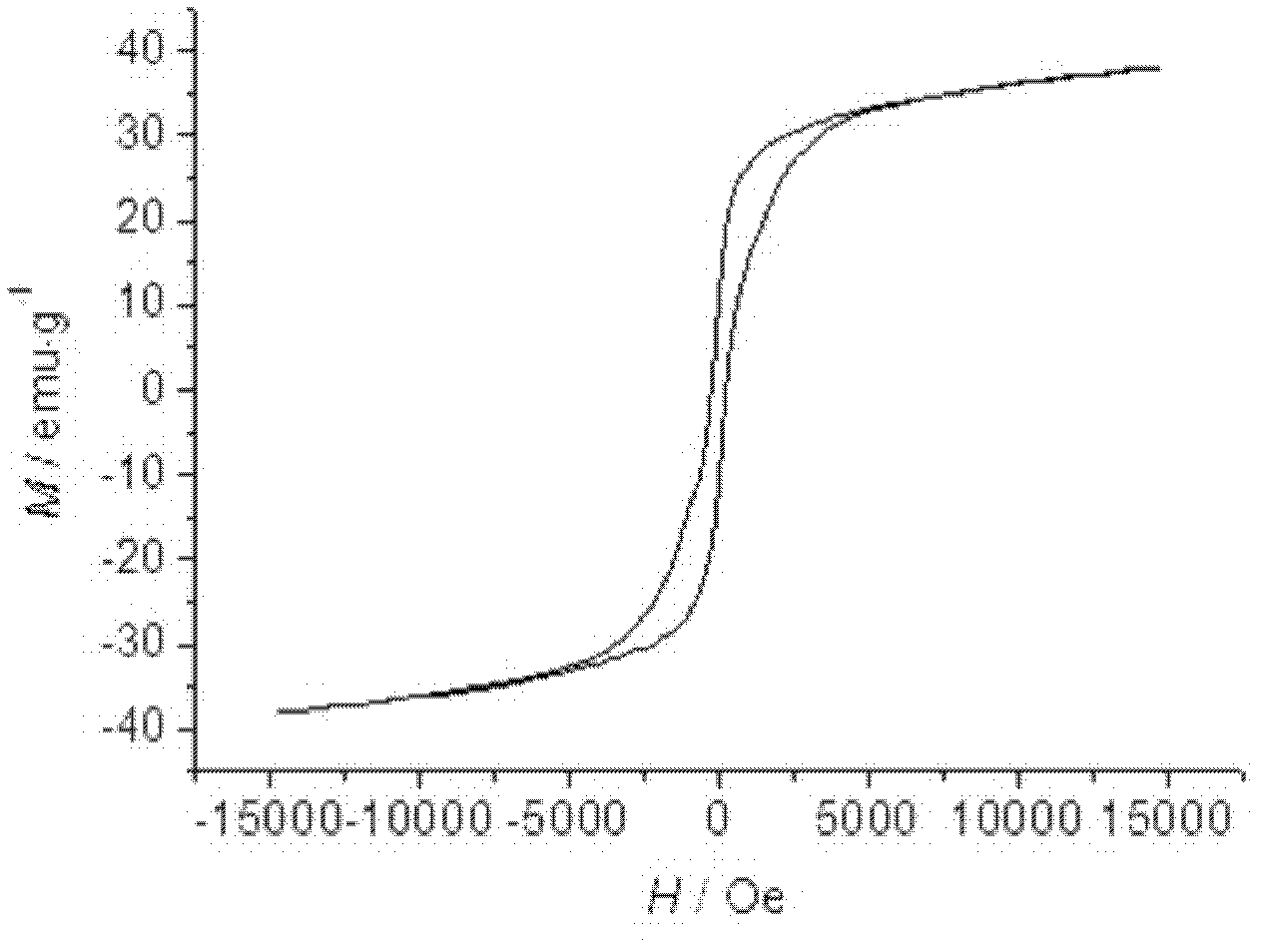

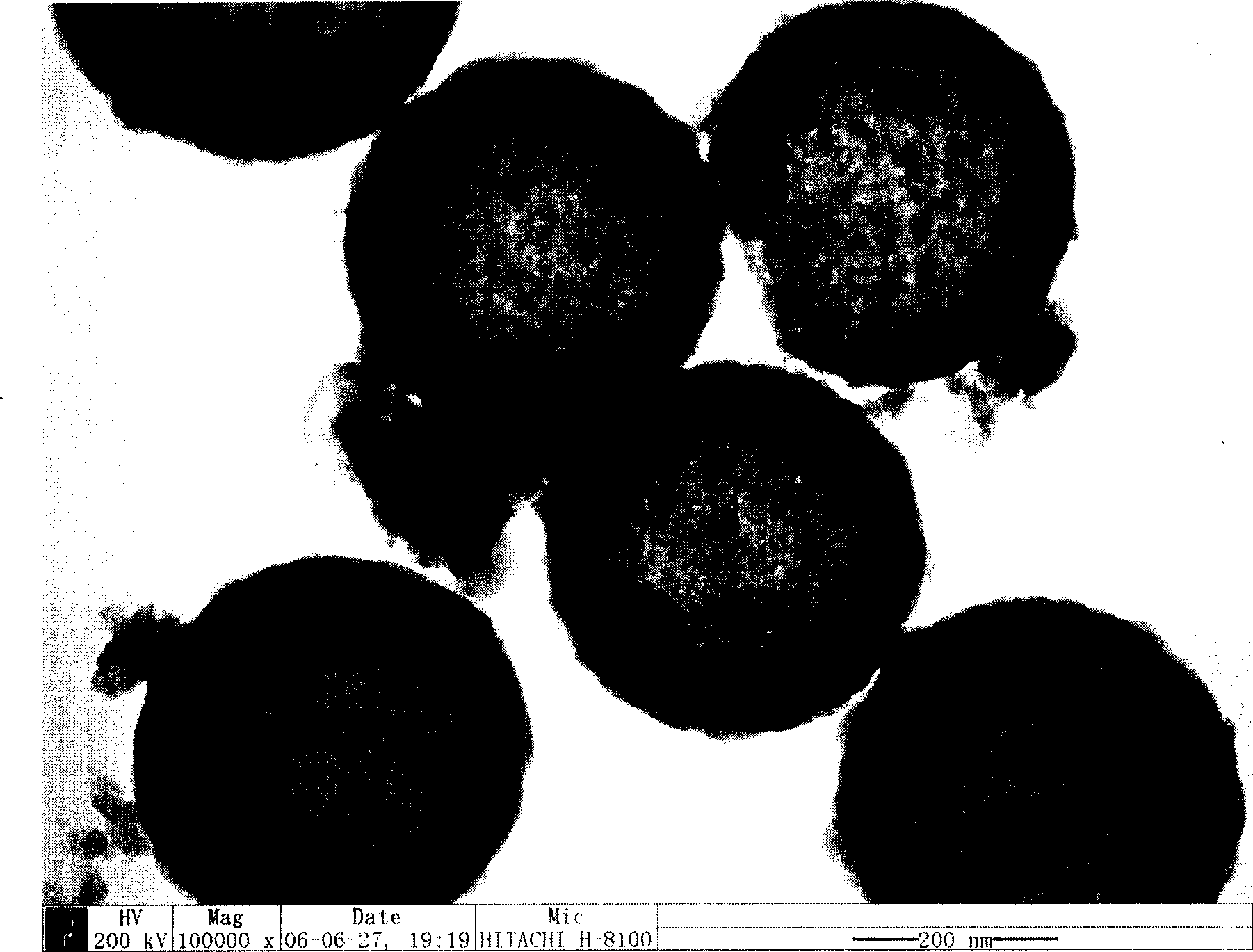

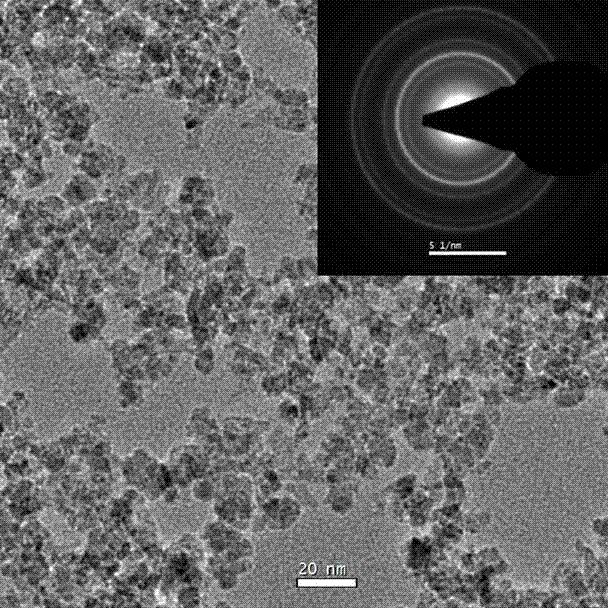

The invention belongs to the technical field of environmental protection and environmental water treatment and in particular relates to a heavy metal ion adsorbent ferrite hollow spheres MFe2O4 (M=Fe, Co, Mn or Zn) and a preparation method thereof. The preparation method of the ferrite hollow spheres MFe2O4 belongs to a hydrothermal synthesis method, and the prepared ferrite hollow spheres are 180nm-380nm in diameter and 20nm-45nm in shell layer thickness and are used for adsorbing heavy metal ions As (V) and / or Cr (VI). The preparation method provided by the invention is simple and feasible, environment-friendly, pollution-free, low in equipment requirement and high in controllable degree; the raw material source is wide and the production cost is low; compared with a compound prepared in the prior art, the prepared heavy metal ion adsorbent is relatively high in adsorption capacity, and the adsorption capacity aiming at arsenic and chromium heavy metal ions reaches up to 340mg / g and is far beyond that in the prior art, so that the heavy metal ion adsorbent has relatively good application and promotion values.

Owner:HENAN UNIVERSITY

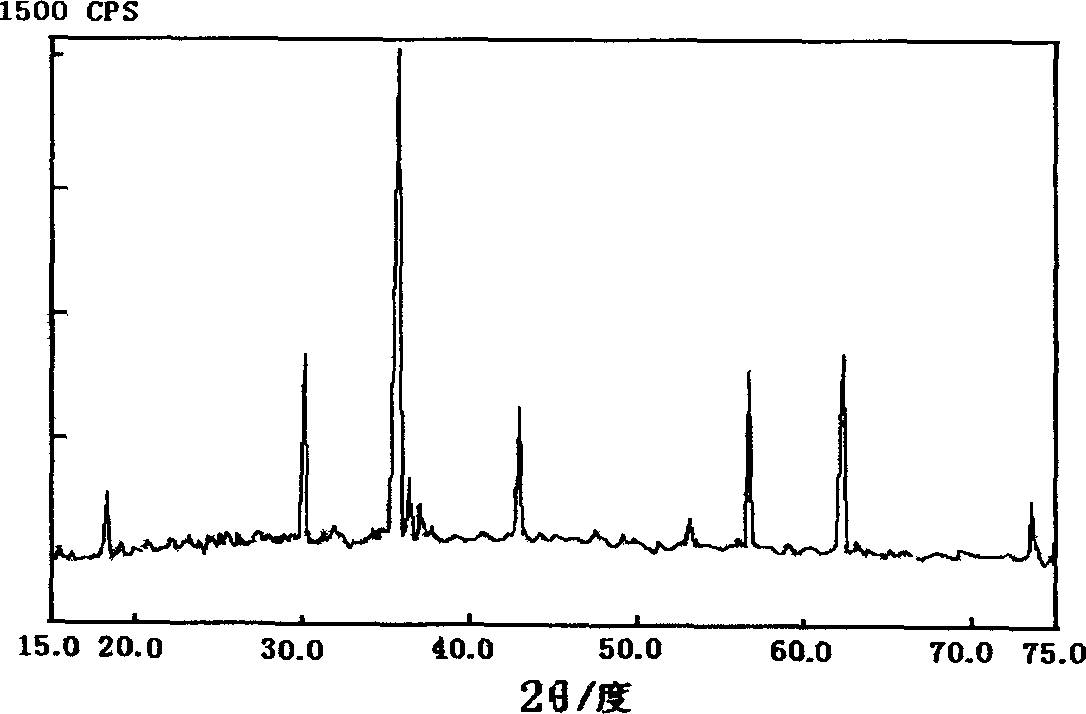

Hexagonal crystal system Y-type ferrite electromagnetic material and preparation method thereof

InactiveCN102674823AFacilitated DiffusionFully contactedInorganic material magnetismCrystal systemHexagonal crystal system

The invention provides a hexagonal crystal system Y-type ferrite electromagnetic material and a preparation method thereof. The material is a Ba2Co2-xZnxFeyO22 (x is more than or equal to 0 and less than or equal to 2, and y is more than or equal to 10 and less than or equal to 14) ferrite material with hexagonal flaky morphology, and is obtained by uniformly mixing reactants and a reaction medium and calcining, wherein the reactants at least comprise a barium source, an iron source and a cobalt source; the reaction medium is one kind of chlorate or a mixture of two kinds of chlorate; the molar ratio of various elements in the reactants is that the ratio of Ba to Fe is 2:(10-14), and the ratio of Ba to Co is 2:(0-2); and the ratio of the mass of the reaction medium to the total mass of the reactants is (1-4):1. The invention has the advantages that the morphology of ferrite powder particles can be well controlled; inorganic molten salt is taken as the reaction medium, and the reactants are quickly dispersed and fully contacted in the molten salt by utilizing the dissolution of the reactants in the molten salt so as to reduce reaction temperature and improve reaction rate; the molten salt runs through generated barium ferrite particles in the reaction process, so the mutual agglomeration among the particles can be stopped; and the process is simple, the product is high in purity, the resultant temperature is low, the mechanical ball milling is not required, the doping is avoided, and the particle size distribution is narrow.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

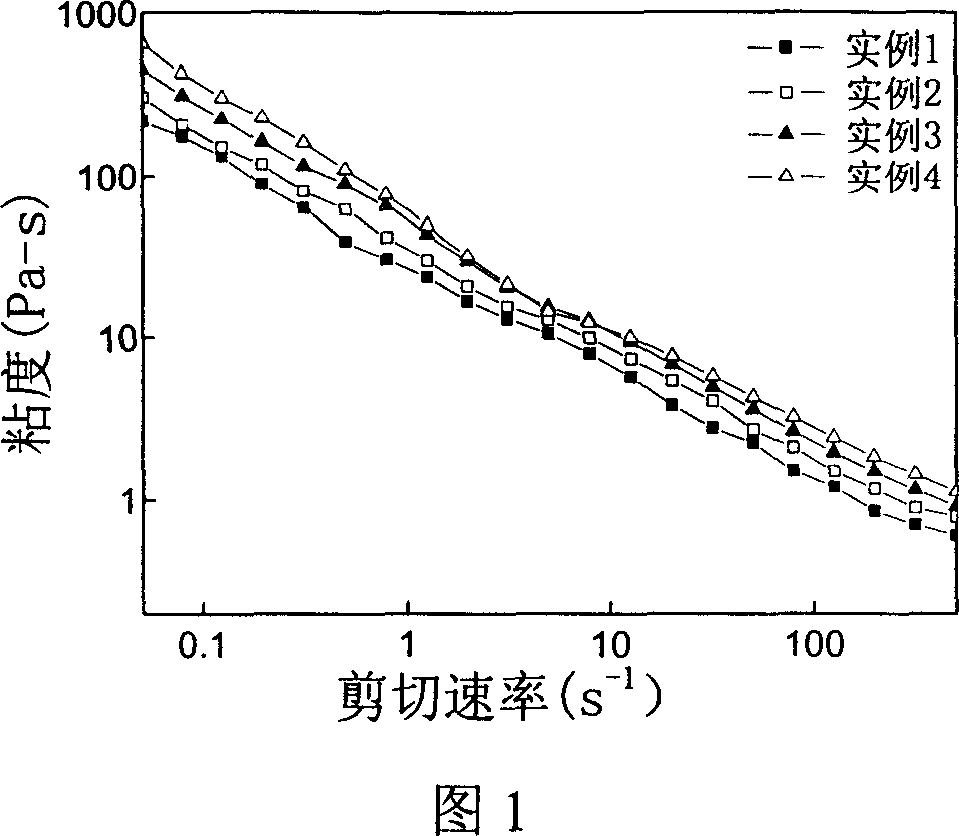

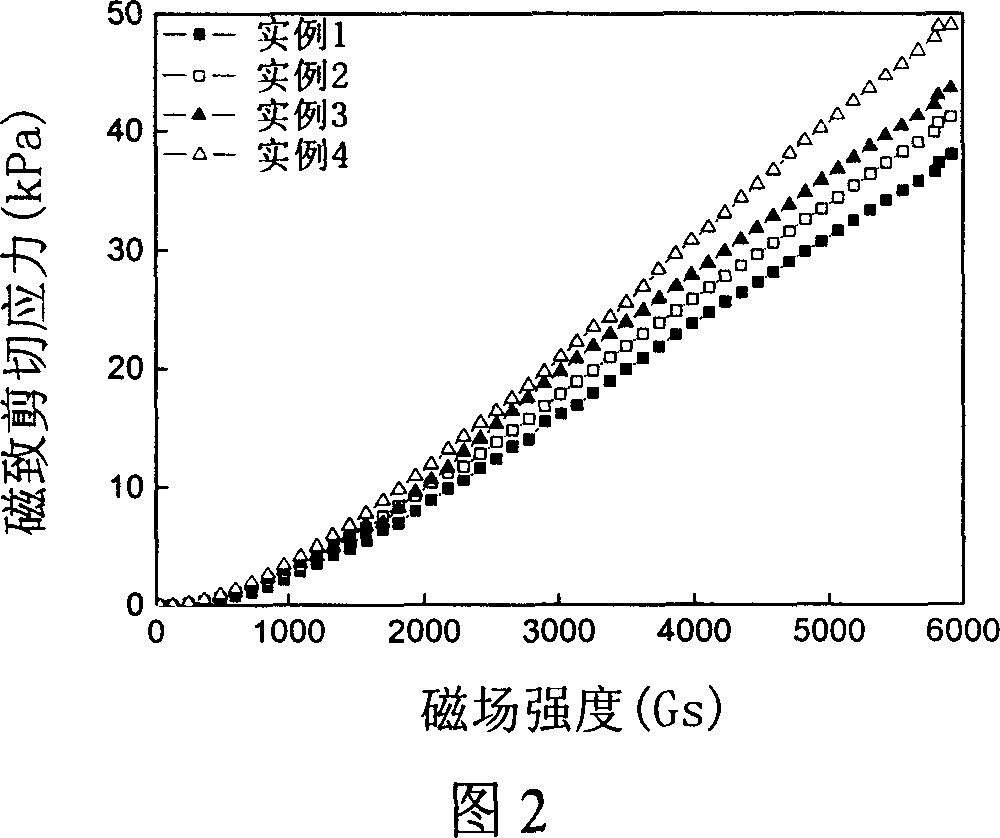

Stable water based magnetic rheologic liquid, and preparation method

InactiveCN1959871APrevent agglomeration and sedimentationImprove anti-sedimentation stabilityMagnetic liquidsInductances/transformers/magnets manufactureAntioxidantChelation

The magnetic rheologic liquid is composed of following components according to portions of mass: magnetic particles 60-90 portions, water based compound assorted carrier liquid 10-40 portions, additive 1-10 portions. The said magnetic particles include ferrocarbonyl powder, reduced iron powder, iron cobalt alloy particles, or ferrite particles with mean grain size 1-10 micro. The water based compound assorted carrier liquid includes following materials according to mass percent: water 70%-90%, and chelation type surfactant 10%-30%. The surfactant includes following components according to percents of total mass of magnetic rheologic liquid: 0.05-2% thixotropic agent, 0.1%-1% antioxidant, 1%-3% antiwear additive, 0.1%-1% pH value regulator, and 0.1%-1% surfactant. Features are: better magnetic rheologic effect, and better standing stability. The magnetic rheologic liquid is applicable to polishing process, civil engineering, and damper for cars.

Owner:WUHAN UNIV OF TECH +1

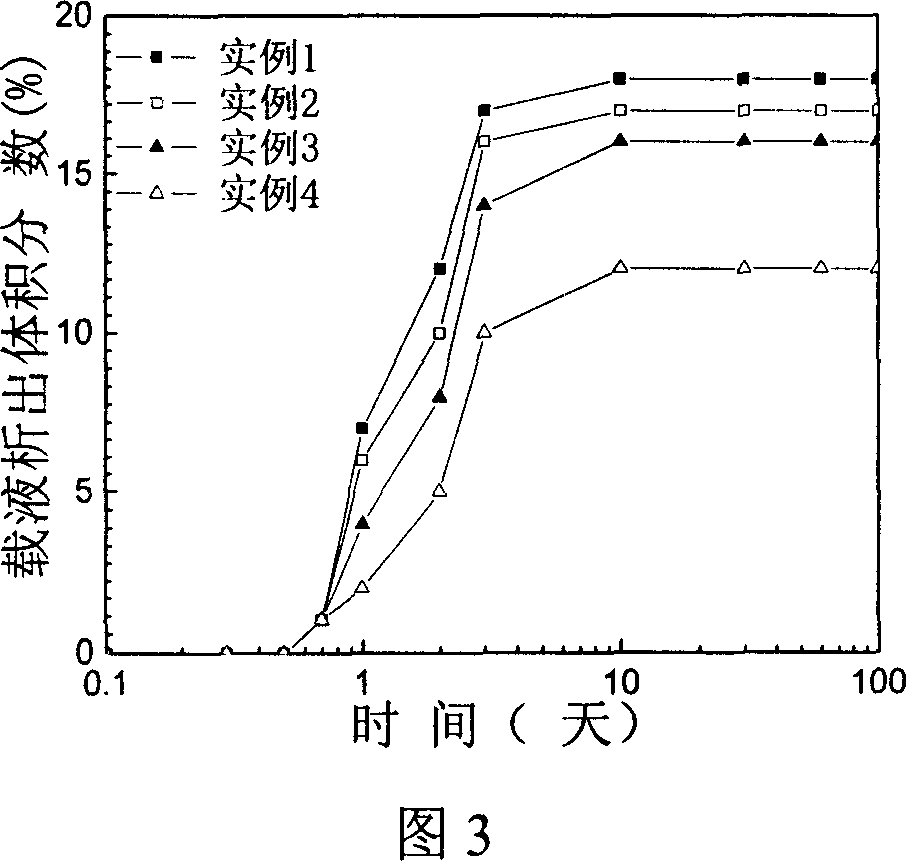

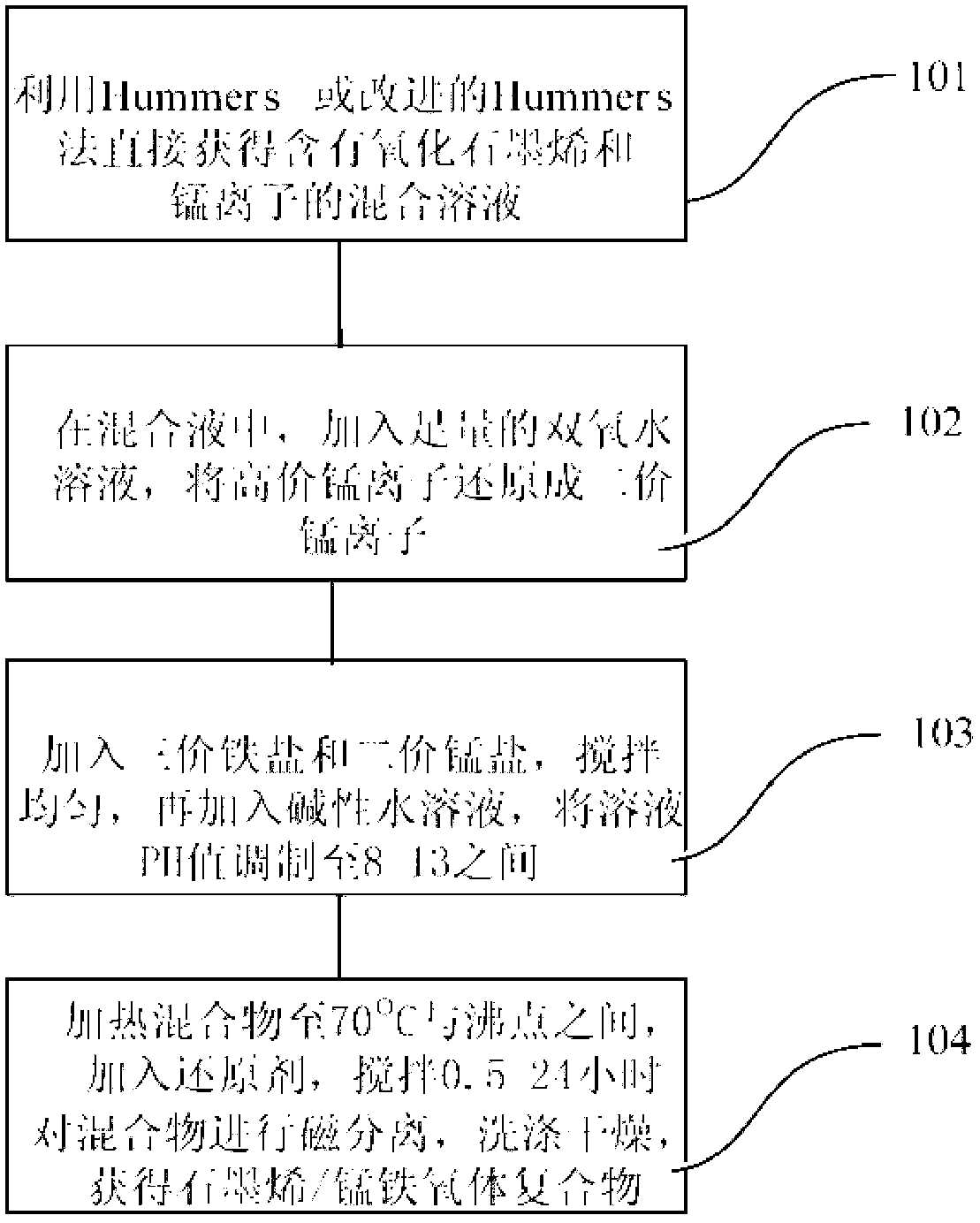

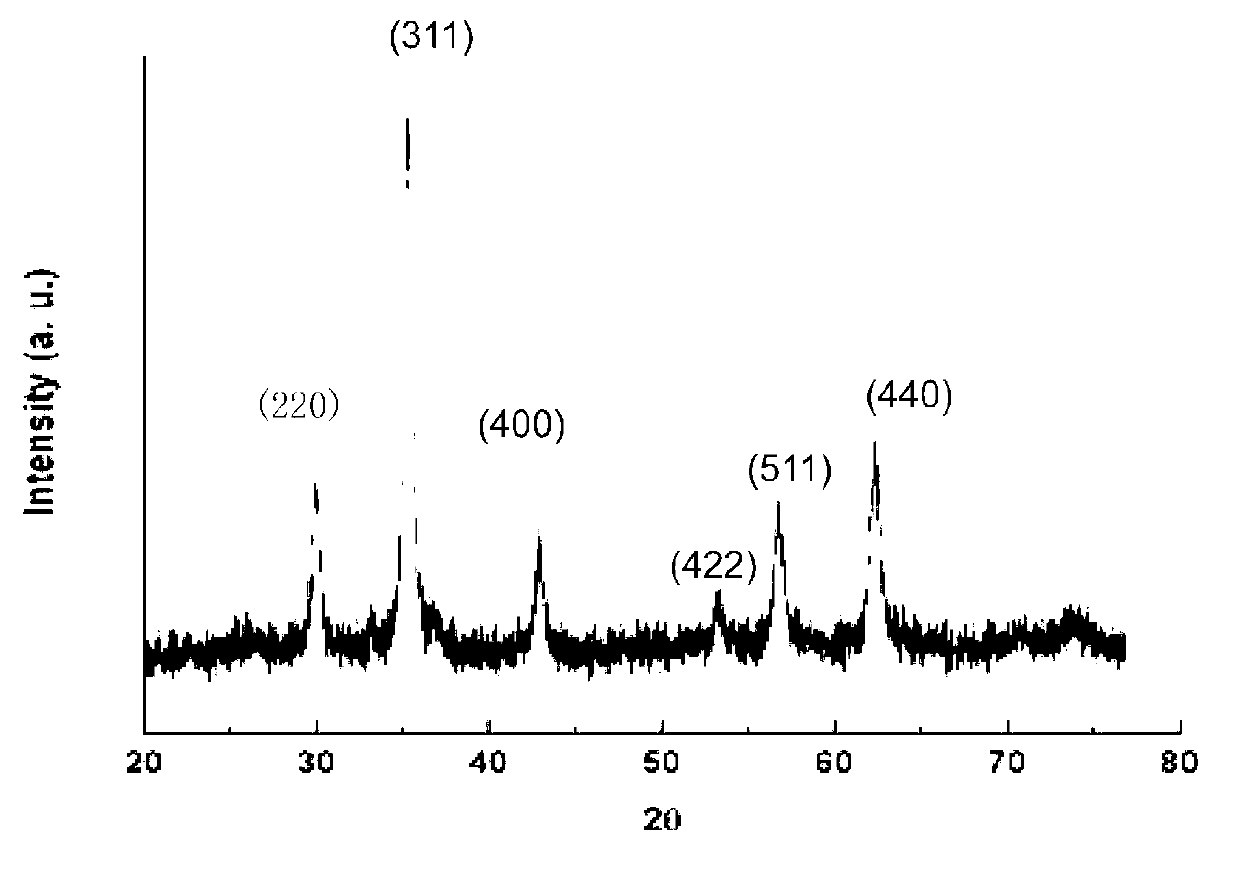

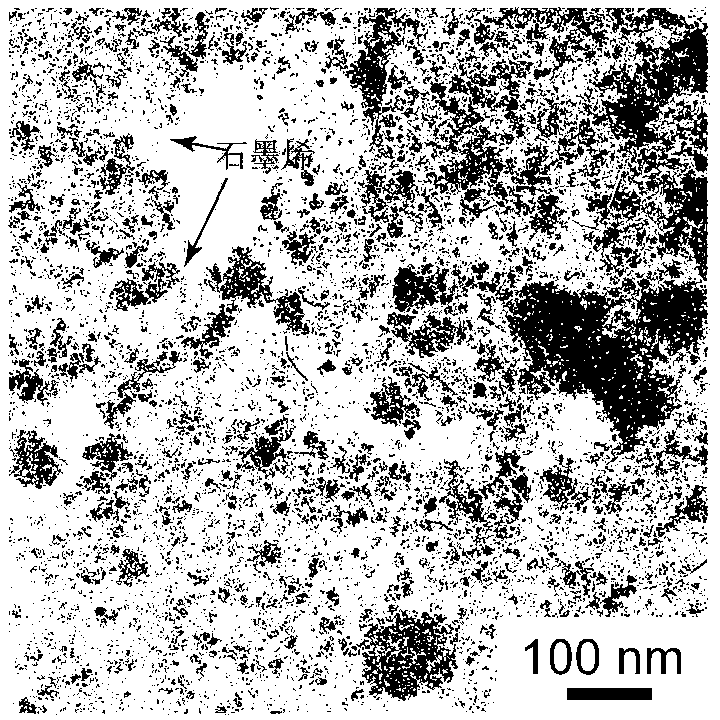

Preparation method of manganese ferrite nanoparticle-graphene compound

InactiveCN103341346AAvoid separabilityAvoid operabilityOther chemical processesMagnetic/electric field screeningEnvironmental resistanceCvd graphene

The invention provides a preparation method of a manganese ferrite nanoparticle (MnFe2O4)-graphene compound. The preparation method comprises the following steps of: obtaining a mixed solution of manganese ions and oxidized graphene in the process of preparing the oxidized graphene by using a potassium permanganate graphite oxidizing method; adding enough H2O2 in the mixed solution, and reducing the manganese element into divalent manganese ions; adding tervalent ferric salt and divalent manganese salt, uniformly stirring the mixture, then, adding an alkaline solution in the mixed solution, adjusting the pH value of the solution to 8-13, then, heating the mixed solution to 70-99 DEG C, adding a reducing agent, and stirring for 0.5-24h to obtain a suspension liquid; and magnetically separating the suspension liquid and drying to obtain the manganese ferrite nanoparticle-graphene compound. According to the preparation method of the manganese ferrite nanoparticle-graphene compound, potassium permanganate used when the oxidized graphene is prepared can be sufficiently utilized so that the potassium permanganate can be converted into a nanomaterial containing manganese ferrites; and the preparation method has the characteristics of simplicity, environment friendliness, low cost and the like.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

Method of treating alkaline sludge containing heavy metal as resources

InactiveCN101618929AStrong process versatilityEasy to controlSludge treatmentCalcium/strontium/barium sulfatesSludgeSlag

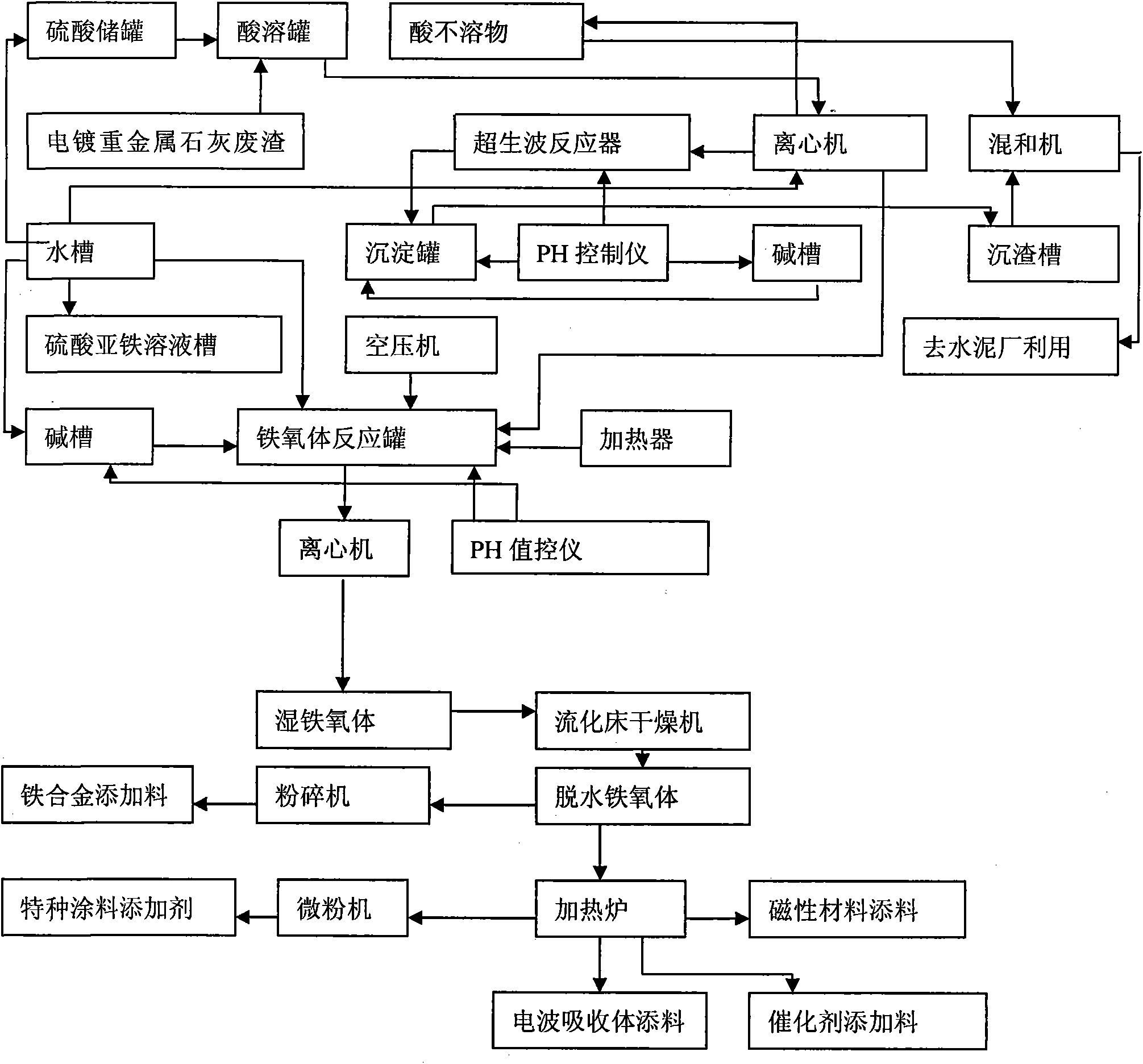

The invention relates to the technical field of environmental protection and discloses a method for treating alkaline sludge containing heavy metal as resources; the method comprises the following steps: first, using sulfuric acid liquor to leach valuable metals in the alkaline sludge containing heavy metal, solid-liquid separating acid leached slag and acid leached liquor containing SiO2; treating the acid leached liquor by using ultrasonic waves, adding alkaline and controlling pH value of the solution to precipitate and separate CaSO4, carrying out solid-liquid separation to obtain the liquid part and the solid part containing SiO2 and CaSO4; first using ferrous sulphate to treat the liquid part and then adding alkaline to adjust pH value of the liquid part, injecting compressed air to oxidize the liquid part to form ferrite and prepare the ferrite into additives with multiple usages. The solid part is used as additives for producing cement. The method of the invention not only features good commonality but also treats various alkaline sludge containing heavy metal; in addition, the method features easily controlled process conditions, simple equipment, easy realization of large-scale production, reduction of treatment cost, thus being a technology featuring reduction and decontamination for treating heavy-metal-containing alkaline sludge waste residue as a usable resource.

Owner:刘文治 +2

Hollow structured magnetic microsphere coated with mono-dispersed silicon dioxide and its preparation method

InactiveCN1911495ASimple manufacturing methodUniform number of coresInorganic material magnetismMicroballoon preparationMicrosphereParamagnetic nanoparticles

The present invention is monodisperse silica coated hollow magnetic microsphere and its preparation process and belongs to the field of nanometer magnetic material technology. Superparamagnetic nanometer ferrite particle is first prepared in coprecipitatin method and monodisperse polymer microsphere with surface functional radical is synthesized in emulsion polymerization; the superparamagnetic nanometer ferrite particle and the monodisperse polymer microsphere is then compounded by means of coordination effect, and the compound is coated with silica; and the composition particle is finally calcined at 500-700 deg.c for 5-12 hr to produce the silica coated hollow magnetic microsphere. The present invention has simple preparation process and controllability of the granularity and cavity size of the magnetic microsphere, and the magnetic microsphere has high chemical and colloid stability and may be used in biological detection and other fields.

Owner:JILIN UNIV

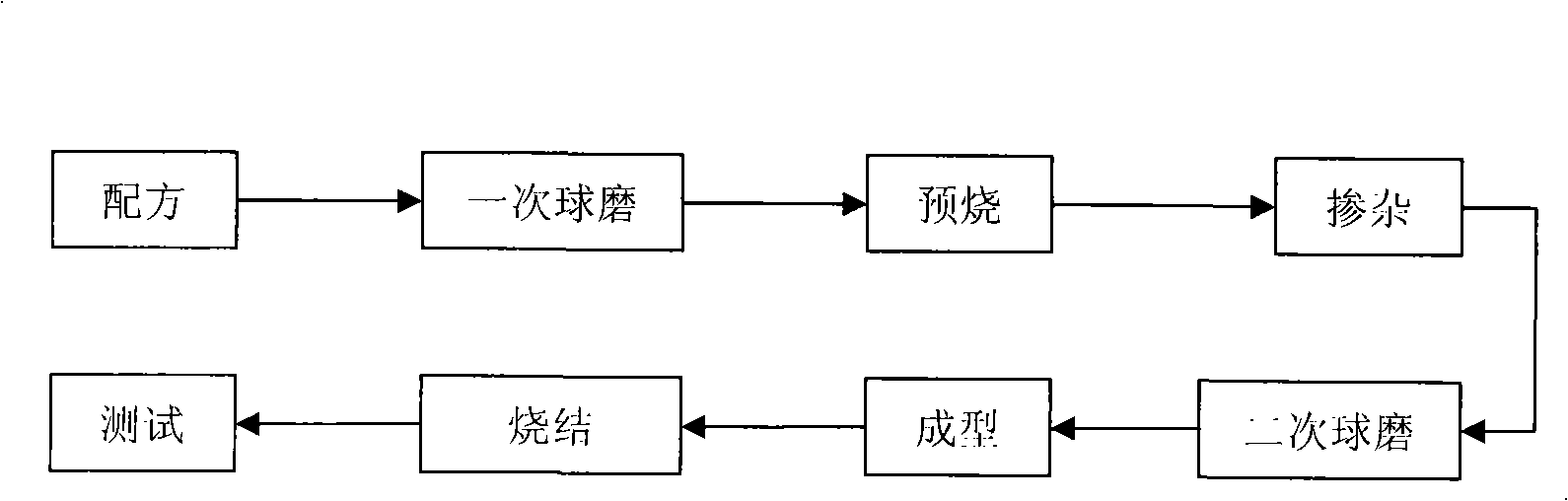

NiZn series ferrite material and preparing method thereof

InactiveCN101256865AImprove current carrying capacityImprove reliabilityInorganic material magnetismManufacturing technologyMiniaturization

The present invention relates to ferrite material of NiZn and method for manufacturing, and belongs to manufacturing technology field of ferrite material. The main constituent is calculated by oxide with molar percentage: 48.5-52.5mol% Fe2O3,25-33mol%ZnO,0.5-8.0mol%CuO, allowance being NiO; doping agent is calculated by oxide with molar percentage 0.001-0.15wt%CaO, 0.01-0.12wt% MoO3, 0.01-0.08wt%Bi2O3, 0.01-0.20wt%Nb2O5, 0.01-0.20wt% SnO2, 0.01-0.16wt%V2O5. The beneficial effect of the present invention is, first, improving power density, implementing miniaturization; second, improving reliability of electric system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

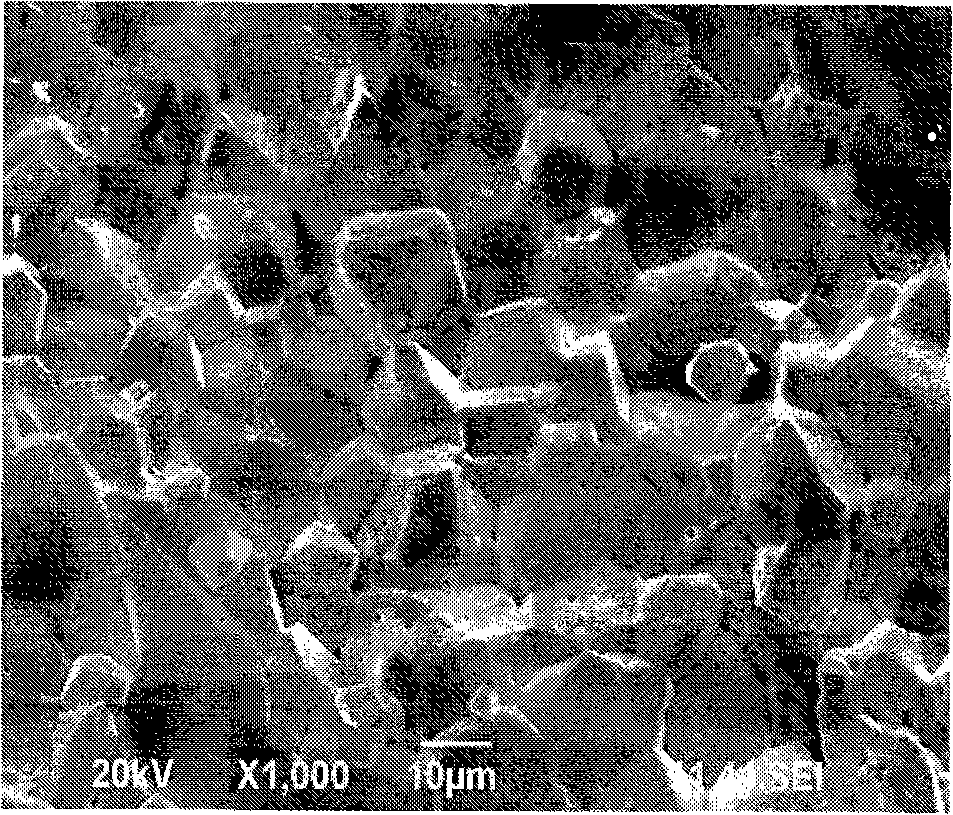

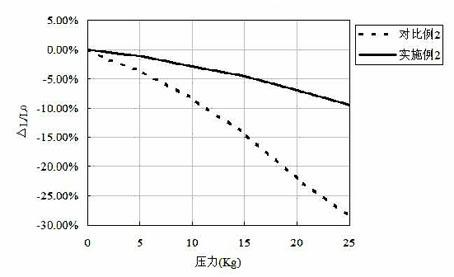

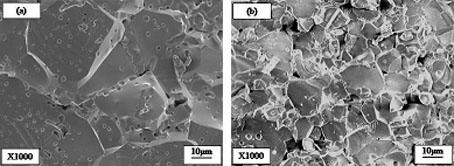

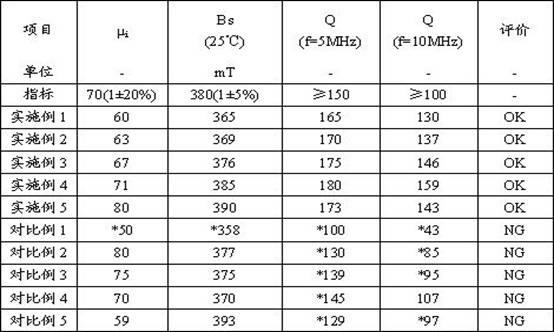

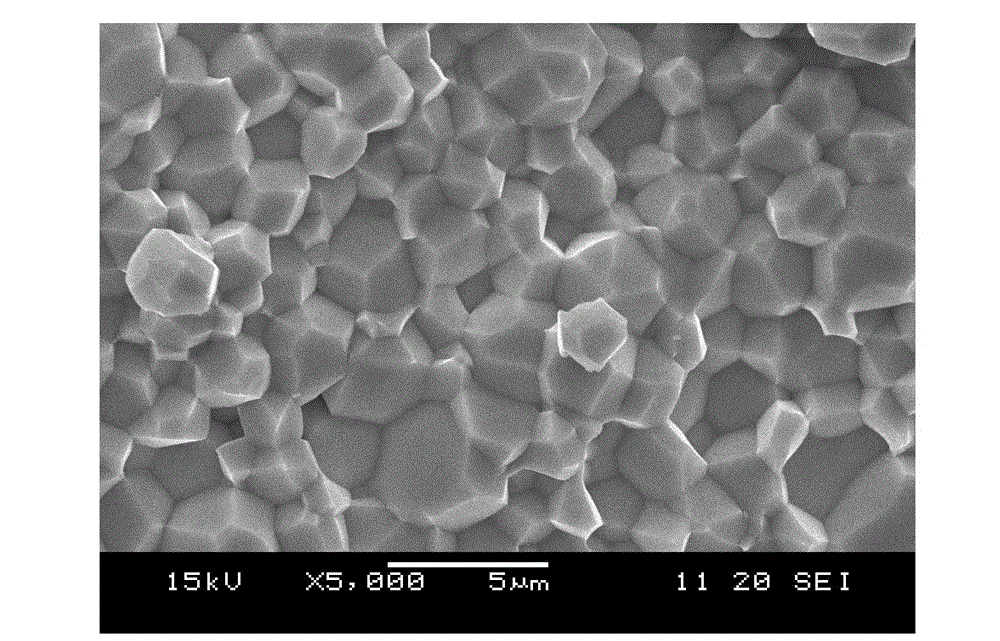

Stress-resistant nickel zinc ferrite with initial permeability of 120, and preparation method of stress-resistant nickel zinc ferrite

The invention relates to a stress-resistant nickel zinc ferrite which has the initial permeability of 120 and is applicable to a power inductor and a preparation method of the stress-resistant nickel zinc ferrite. The stress-resistant nickel zinc ferrite comprises the main components based on respective reference substance: 46.5-50mol% of ferric oxide (Fe2O3), 20-25mol% of nickel oxide (NiO), 20-25mol% of zinc oxide (ZnO) and 9-12mol% of copper oxide (CuO); and the nickel zinc ferrite comprises the accessory ingredient by respective reference substance: 0.1-0.3wt% of calcium carbonate (CaCO3), 0.035-0.10wt% of cobalt oxide (Co2O3), 0.05-0.45wt% of bismuth oxide (Bi2O3), 0.1-1.0wt% of talcum powder and 0.1-1.0wt% of mica powder. The stress-resistant nickel zinc ferrite is prepared by an oxide method and is sintered under a certain condition. After sintering, the product has the crystallized grain size of 20-30mu m, has obvious crystal boundary, and has the characteristic of less inductance change under the stress action, thus meeting the requirement of the power inductor needed to be packaged by resin on the stress resistance of the ferrite material.

Owner:TDG HLDG CO LTD

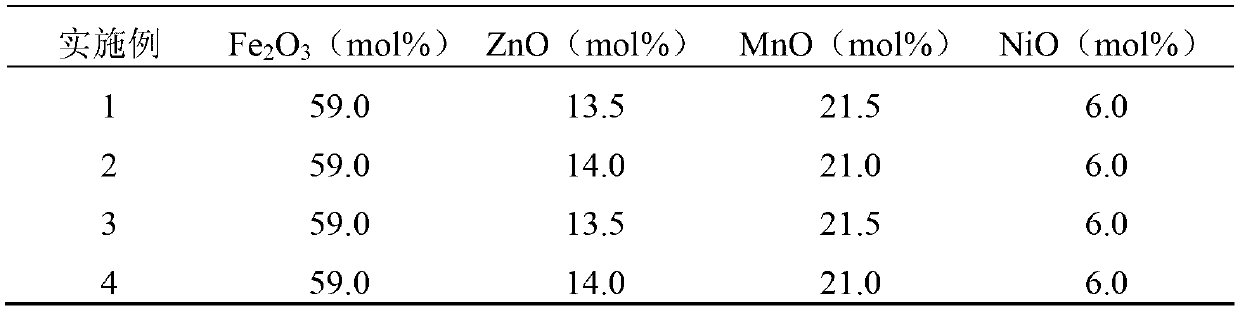

High Tc, wide temperature ultrahigh Bs MnZn ferrite material and preparation method

Belonging to the technical field of ferrite material preparation, the invention relates to a high Tc, wide temperature ultrahigh Bs MnZn ferrite material and a preparation method. The ferrite material provided in the invention is composed of main materials and doping agents. The ferrite material is characterized in that, the main materials include: 58.0-62.0mol% of Fe2O3, 10.0-15.0mol% of ZnO, 4.0-6.0mol% of NiO, and the balance MnO; and by weight percentage, with the pre-sintered main materials as reference and in terms of oxides, the doping agents include: 0.001-0.30wt% of MoO3, 0.01-0.40wt% of Bi2O3, 0.001-0.05wt% of SnO2, 0.001-0.05wt% of Nb2O5, and 0.001-0.20wt% of Ta2O5. The MnZn ferrite material provided in the invention has the characteristics of high Curie temperature (with Tc greater than or equal to 320DEG C), high wide temperature BBs (at 25DEG C, with BBs being greater than or equal to 600mT; at 100DEG C, with BBs being greater than or equal to 490mT), and low loss (100DEG C, 100kHz200mT, with PL being smaller than or equal to 800kW / m<3>), etc.

Owner:马鞍山新康达磁业有限公司

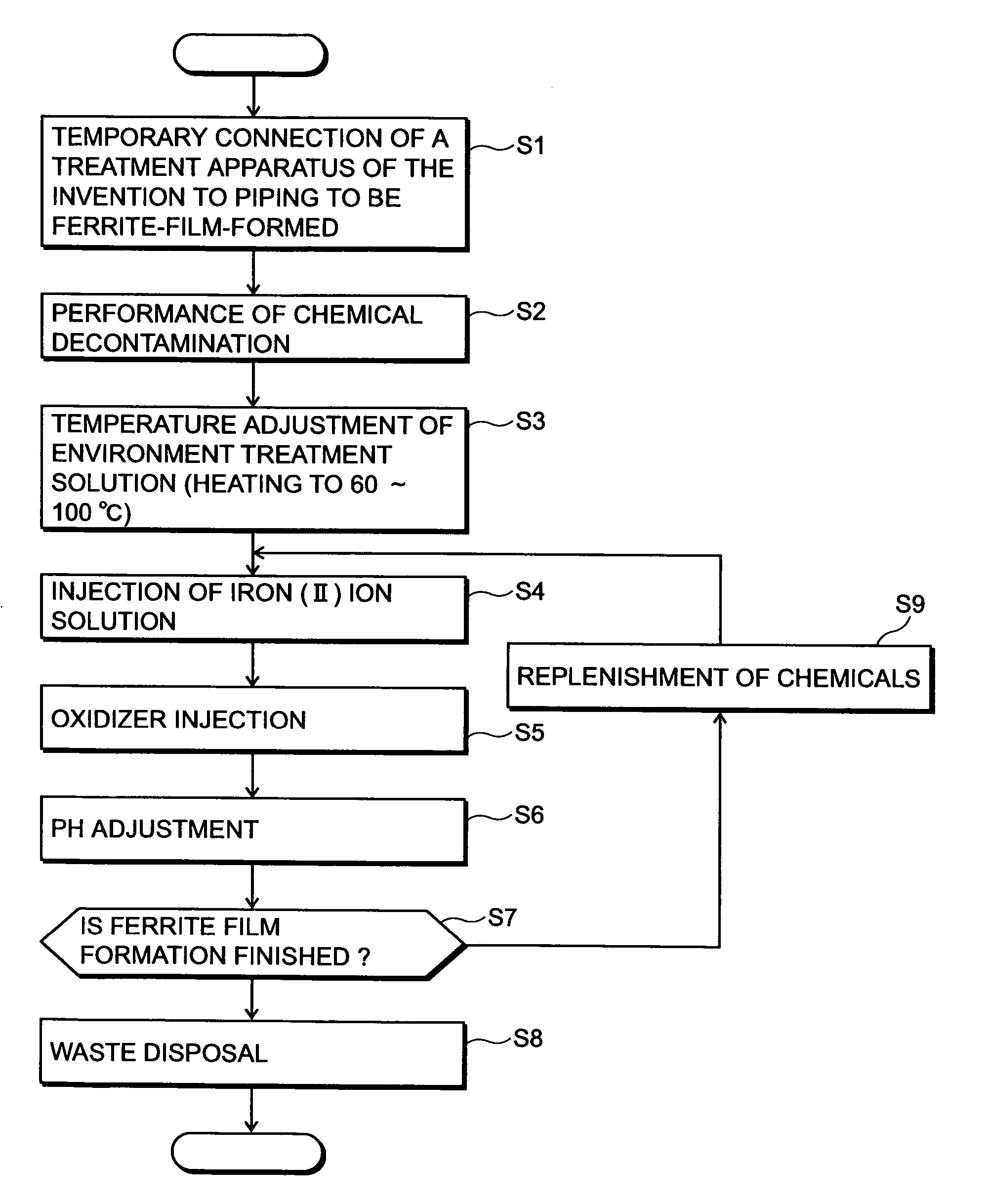

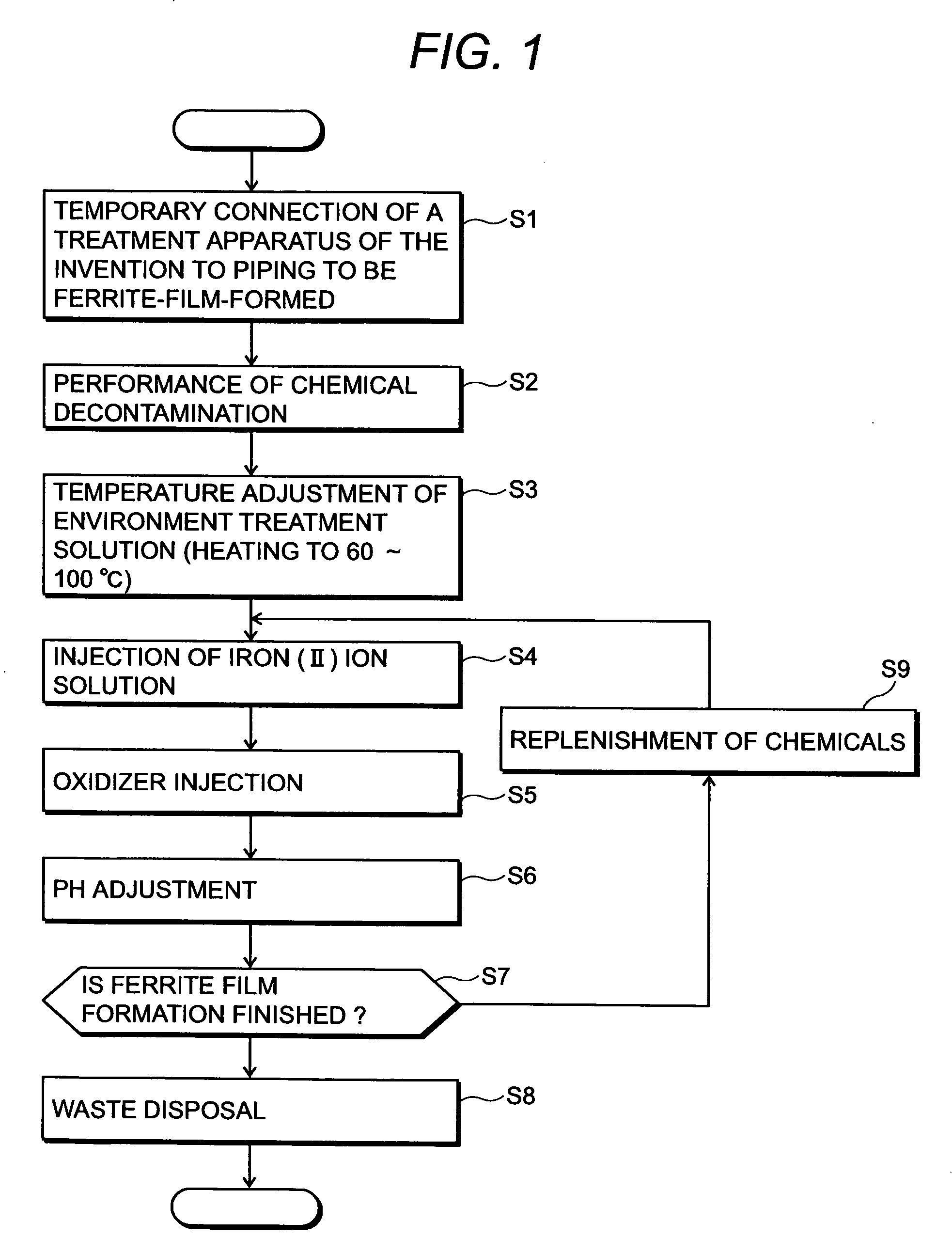

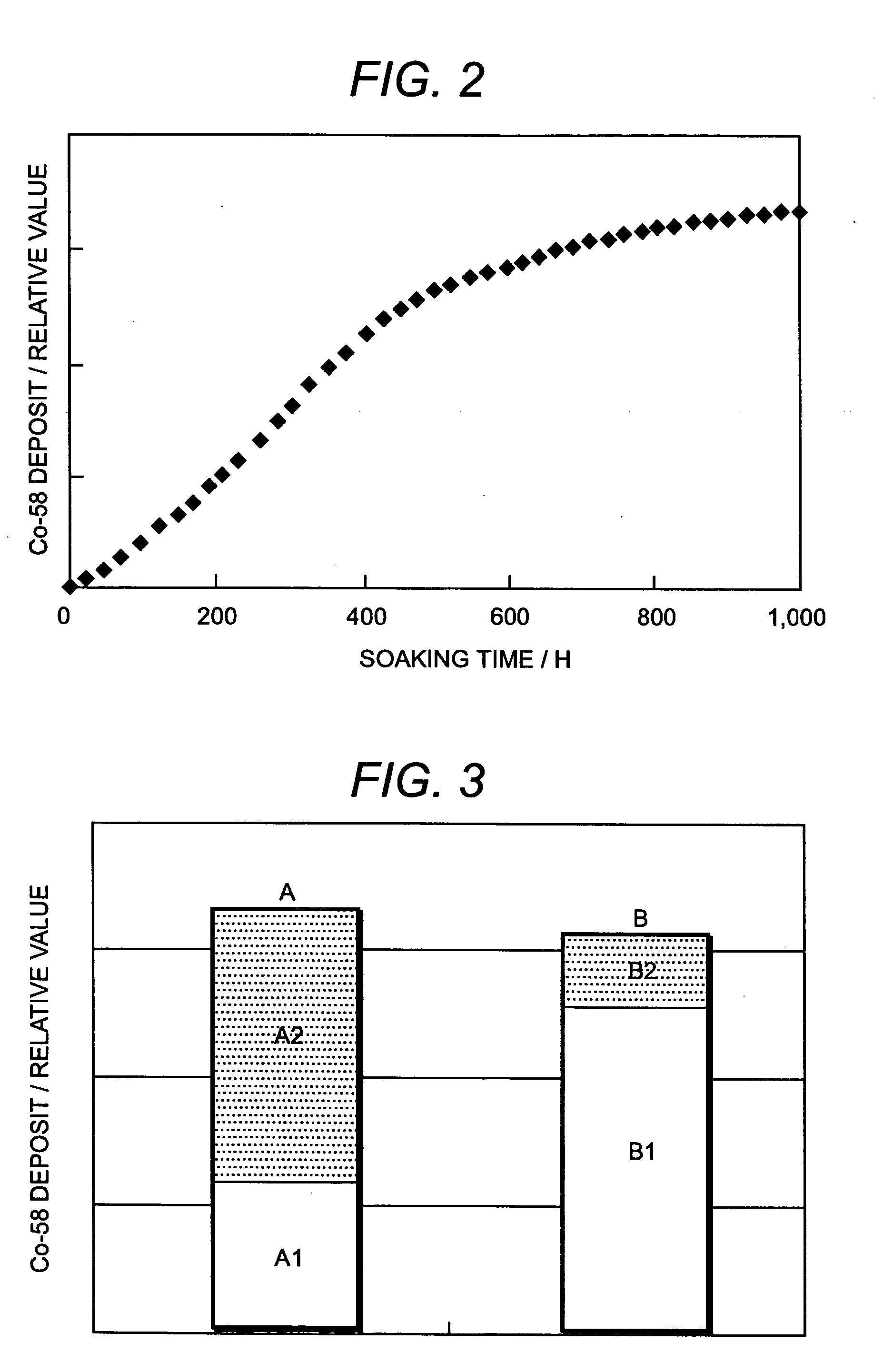

Suppression method of radionuclide deposition on reactor component of nuclear power plant and ferrite film formation apparatus

InactiveUS20060067455A1Avoid depositionNuclear energy generationNuclear monitoringNuclear plantCompound (substance)

A method of suppressing deposition of radionuclides on components of a nuclear power plant comprises forming a ferrite film by contacting a first chemical including iron (II) ions, a second chemical for oxidizing the iron (II) ions to iron (III) ions, and a third chemical for adjusting the pH of a processing solution containing a mixture of the first and second chemicals to be 5.5 to 9.0 with the metal member surface in a time period from a finishing stage in decontamination step of removing contaminants formed on the surface of metal member composing the nuclear power plant, and suppressing deposition of radionuclides on the metal member by the ferrite film.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

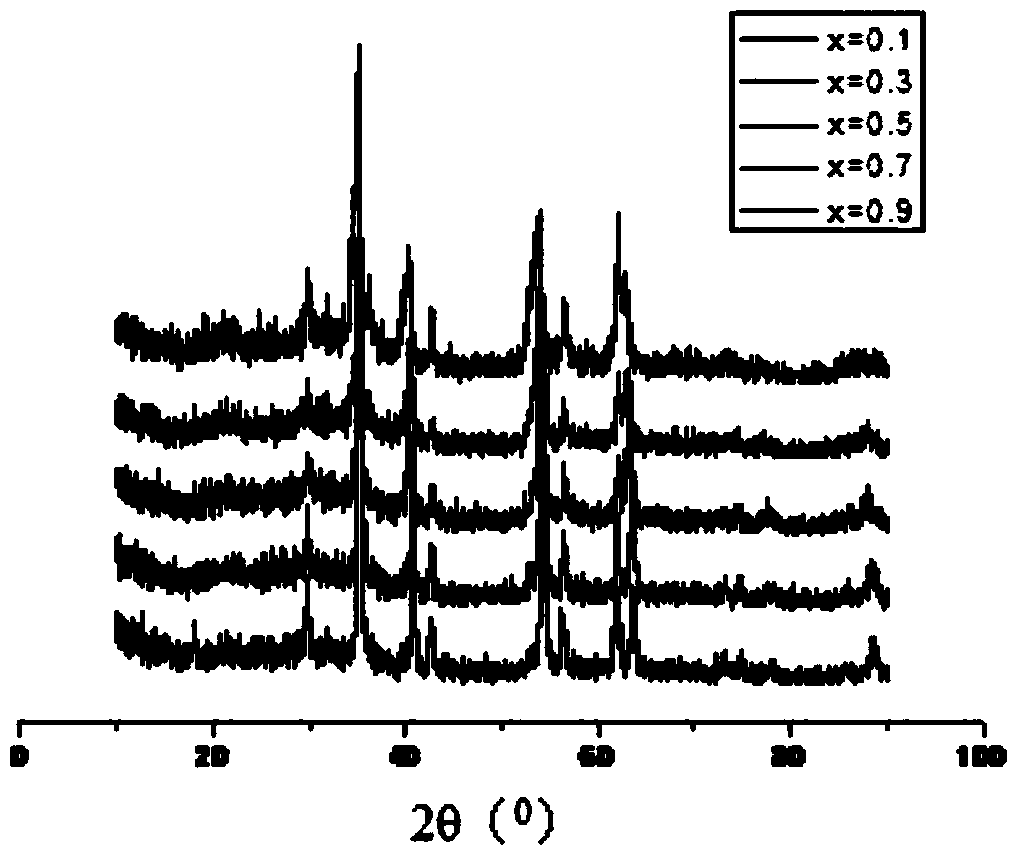

Titanium-doped barium ferrite ceramic material and preparation method thereof

The invention discloses a titanium-doped barium ferrite ceramic material and a preparation method thereof. Densification sintering of the ceramic material is achieved through titanium doping, and electron hopping and a nonuniform conduction structure are formed through the replacement of iron ions to titanium ions. The ceramic has high residual magnetization, and great dielectric constant can be produced by utilizing the nonuniform conduction structure. The preparation method of the titanium-doped barium ferrite ceramic comprises the following steps of: preparing a ceramic precursor through a citrate sol-gel method, and then molding and sintering at high temperature to obtain the titanium-doped barium ferrite ceramic, wherein the molar ratio of titanium to barium is controlled between 0.4 and 0.8; and the molar ratio of iron to barium is between 11.6 and 11.2. According to the titanium-doped barium ferrite ceramic material and preparation method thereof, the process is simple, the cost is low, and meanwhile extremely high dielectric constant, high saturation magnetization and residual magnetization can be obtained. The residual magnetization acts as an important multifunctional material and can be used for developing preparation of relative electronic components.

Owner:ZHEJIANG UNIV

Method for preparing high-performance wave-absorbing composite powder

The invention belongs to the technical field of microwave absorbing material, and more particularly relates to a preparation method of high-performance wave-absorbing composite powder, comprising thesteps of: respectively adding distilled water into soluble metal nitrate, ferric nitrate and citric acid for dissolving, and then mixing the water solutions to prepare a precursor; dripping ammonia water solution to adjust the pH value of the mixed solution to be neutral; putting the solution into water bath with the temperature of 70-90 DEG C to be stirred, adding inorganic porous medium and modifying agent in the stirring process, stirring until the liquid is sticky colloid; drying the prepared colloidal sol for 7.5-8.5h at the temperature of 115-125 DEG C, and obtaining dried gel; putting the gel into a muffle furnace for calcining, heating up to 850 DEG C, preserving the temperature for 1-2h, naturally and slowly cooling, and obtaining ferrite composite powder; and finally, mixing thecomposite power and carbonyl iron powder, and then obtaining the needed product. The stoichiometric proportion among the nitrate, the ferric nitrate and the citric acid is 1: 12: 19 or 1: 2: 4, the ratio between the theoretical value of the ferrite and the mass of the modifying agent is 1: 0.1-1:0.05, the ratio between the theoretical value of the ferrite and the mass of the porous medium is 1: 0.2-1: 5, and the mass ratio between ferrite-porous medium composite power and the carbonyl iron powder is 1: 0.2-1: 5. Compared with the traditional product, the wave-absorbing powder improves the wave-absorbing performance, and has good covering effect and a certain function of heat insulation. Therefore, the method can be used for preparing building wave-absorbing paint.

Owner:TONGJI UNIV

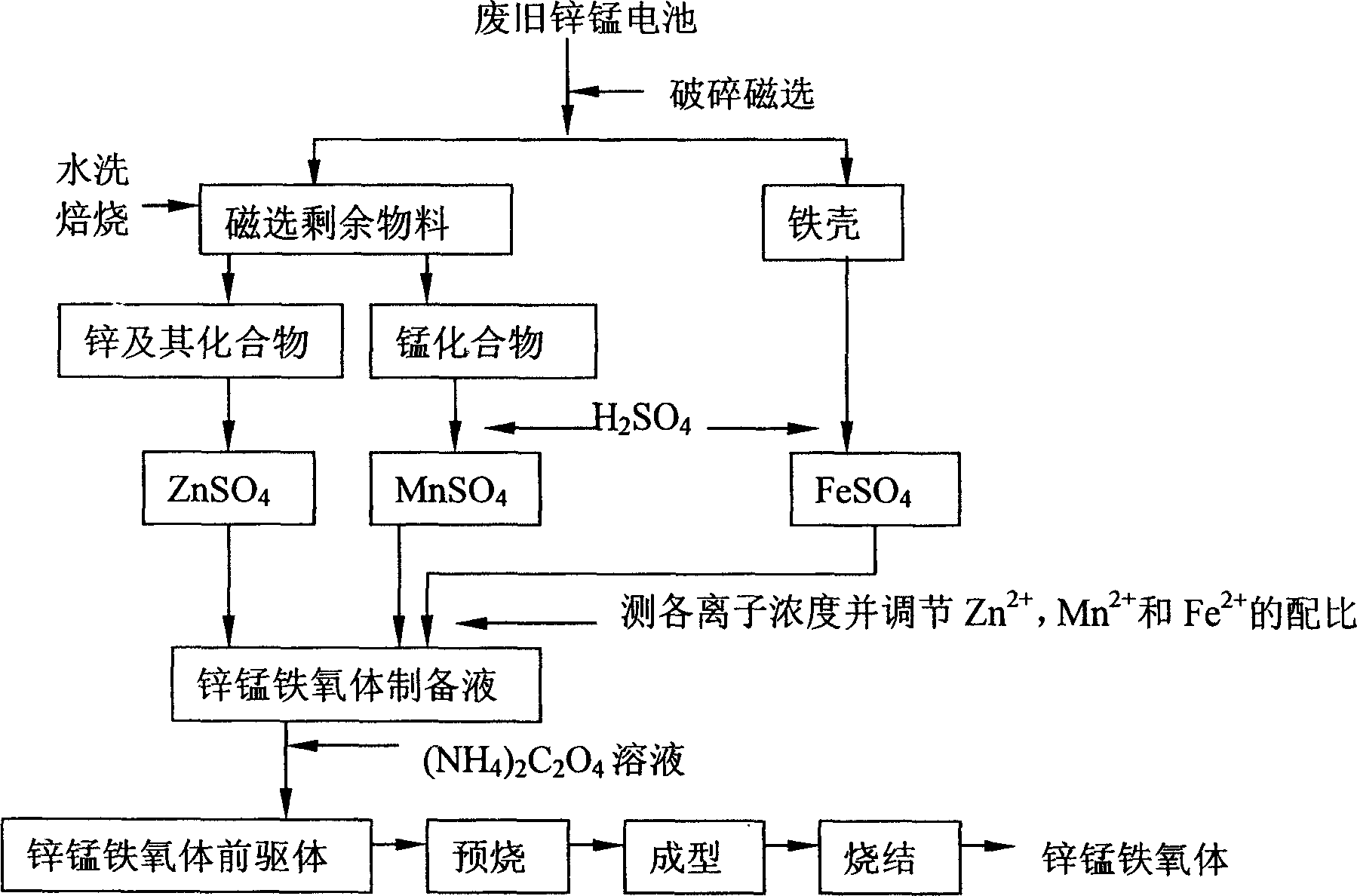

Method of prepn of ferrite from waste zinc-magnesium battery

InactiveCN1601661AAvoid pollutionRealize recyclingSolid waste disposalReclaiming serviceable partsManganesePhysical chemistry

The method includes following steps: (1) crashing zinc-manganese cells, solving coarsely separated iron-zinc-manganese so as to obtain solution of reaction predecessor: ferrous sulfate, zinc sulfate and manganese sulfate; (2) preparing predecessor of ferrite by reaction between mixed predecessors according to proportion and ammonium oxalate; (3) baking predecessor of ferrite in high temperature so as to obtain product of ferrite. The method carries out innoxiousness treatment and changes matter in cells to resources. Features are simple, economical and practical.

Owner:SOUTH CHINA NORMAL UNIVERSITY

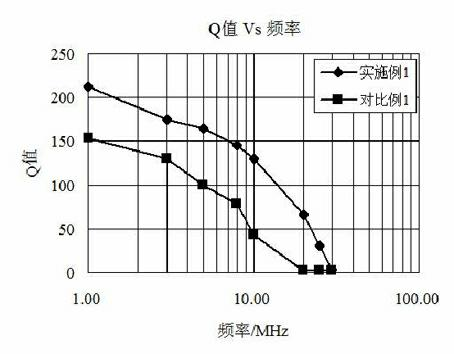

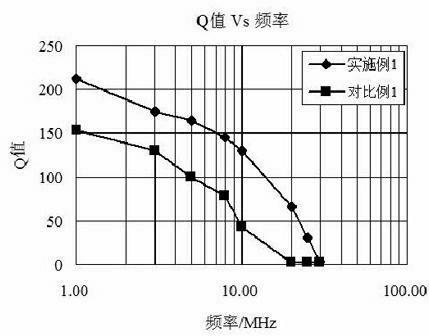

High-Q value nickel and zinc ferrite with initial permeability of 70 and preparation method thereof

The invention relates to high-Q value nickel and zinc ferrite with the initial permeability of 70 and a preparation method thereof, which are suitable for a power inductor. The nickel and zinc ferrite comprises the following main ingredients calculated by the oxide: 47.0-49.0mol% of Fe2O3, 25.1-28.5mol% of NiO, 16.3-20.5mol% of ZnO, 4.3-7.5mol% of CuO, and also comprises the following auxiliary components: 0.1-0.2wt% of CaCO3, 0.8-1.3wt% of SiO2, 2-7wt% of LiFe5O8, 0.3-0.6wt% of Co2O3 and 0.8-1.3wt% of Bi2O3. The high-Q value nickel and zinc ferrite is prepared with an oxide method and is sintered under certain condition. The sintered product has the characteristics of high Q value within the high-frequency range of 5-10MHz, and is suitable for the requirement of high frequency and low loss of the ferrite material by the power inductor.

Owner:TDG HLDG CO LTD

Zirconium-doped barium ferrite wave-absorbing material and preparation method thereof

ActiveCN104030667AApplication frequency band wideningMatching Thickness ReductionOther chemical processesBarium nitrateElectromagnetic shielding

The invention discloses a zirconium-doped barium ferrite wave-absorbing material having a chemical formula of BaFe12-xZrxO19, wherein x is 0.3-0.5, zirconium-doped barium ferrite is a polycrystalline powder, and Fe<3+> and Fe<2+> exist in the barium ferrite simultaneously. A preparation method comprises the preparation steps: mixing barium nitrate, iron nitrate and zirconium nitrate, adding deionized water, and dissolving into a nitrate solution; placing EDTA in deionized water, and dissolving into an EDTA solution; adding the nitrate solution into the EDTA solution, heating, drying, and thus obtaining a dry gel; and sintering the dry gel to obtain a zirconium-doped barium ferrite powder, then grinding, and thus obtaining the zirconium-doped barium ferrite wave-absorbing material. The wave-absorbing material has the characteristics of thin matching thickness and wide wave-absorbing frequency band, can be used for a wave-absorbing coating layer, and can have wide applications in the electromagnetic shielding and stealth fields.

Owner:ZHEJIANG UNIV

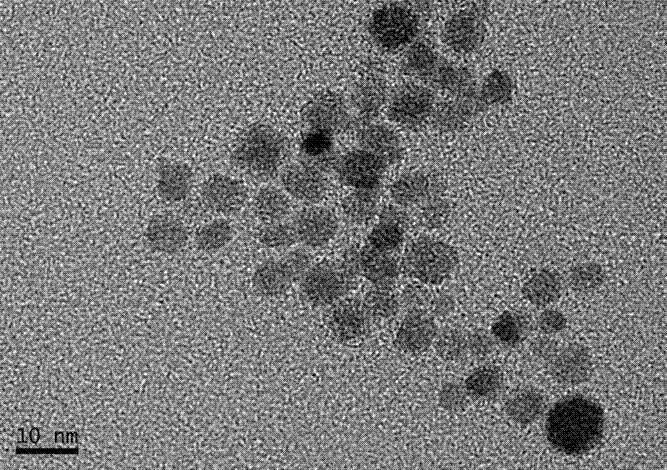

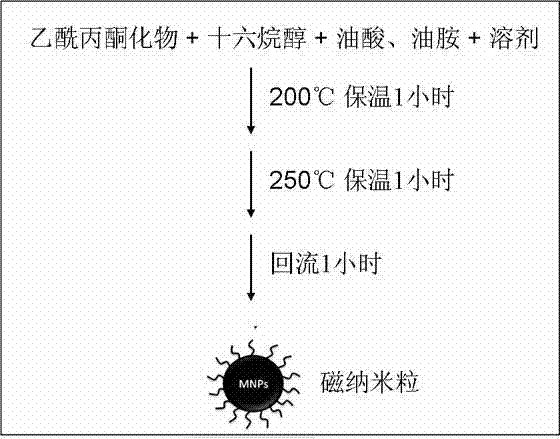

Mn element and Zn element-doped super-paramagnetic ferrite nanoparticles and preparation method thereof

ActiveCN102786299AControlling Saturation MagnetizationRegular shapeMaterial nanotechnologyHexadecaneActive agent

The invention discloses Mn element and Zn element-doped super-paramagnetic ferrite nanoparticles and a preparation method thereof. Manganese element is added or manganese element and zinc element are simultaneously added into a face-centered cubic crystal structure of ferriferrous oxide nanoparticles by using a method of decomposing metal precursor compound at a high temperature; the magnetic performance of the prepared super-paramagnetic nanoparticles is improved by changing the doping amount and the distribution of the metal element; and primarily, the saturation magnetization is improved. The preparation method specifically comprises the following steps of: mixing acetylacetones of Fe and Mn as well as Zn with 1,2-hexadecanol; performing high-temperature decomposition in high-boiling-point solvent by taking oleic acid and oleylamine as surfactants; or performing high-temperature decomposition on composite oleate of Fe, Mn and Zn by taking the oleic acid as the surfactant; heating and preserving heat in stages in argon or nitrogen protective atmosphere to guarantee growth of nanoparticle nuclear; and cooling to room temperature after reaction is finished and settling and centrifuging to finally obtain the super-paramagnetic ferrite nanoparticles which are uniformly dispersed in normal hexane solution.

Owner:SICHUAN UNIV

Slurry for coating non-carbon metal-based anodes for metal production cells

InactiveUS6361681B1Reduce consumptionImprove responseMachining electrodesPretreated surfacesParticulatesOxygen ions

A method of coating an electronically conductive and heat resistant substrate of an anode of a cell for the electrowinning of metals, in particular a cell for the electrowinning of aluminium, to protect and make the surface of the anode active for the oxidation of the oxygen ions present in the electrolyte. The method comprises applying onto the substrate a slurry comprising at least one oxide or oxide precursor as a non-dispersed but suspended particulate in a colloidal and / or inorganic polymeric carrier. The applied-slurry is then solidified and made adherent to the substrate upon heat treatment to form an adherent, protective, predominantly oxide-containing coating. The colloidal and / or inorganic polymeric carrier may comprise at least one of alumina, ceria, lithia, magnesia, silica, thoria, yttria, zirconia, tin oxide and zinc oxide. The oxide of the coating may be a chromite or a ferrite, such as a ferrite selected from cobalt, copper, manganese, nickel and zinc.

Owner:MOLTECH INVENT

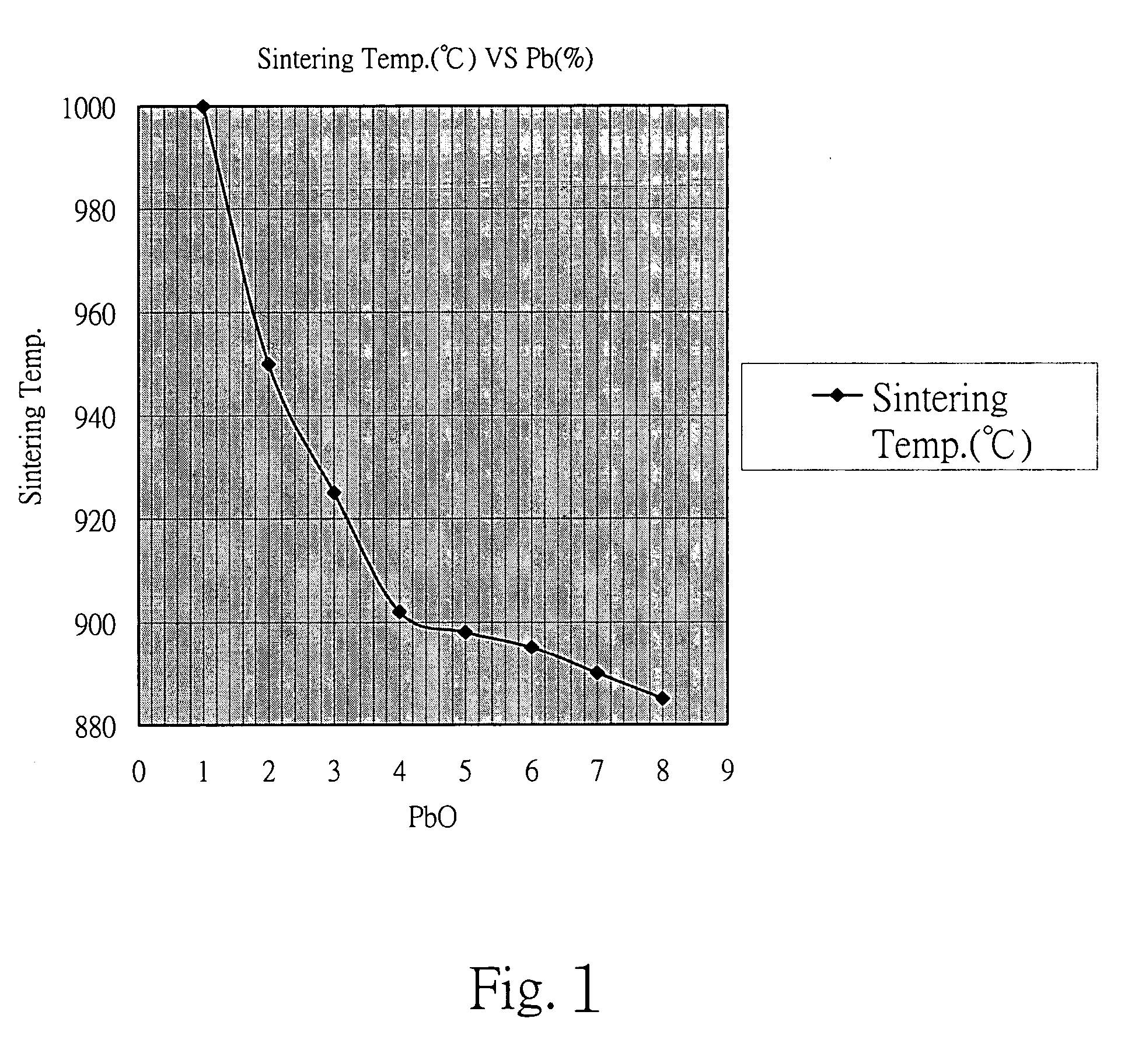

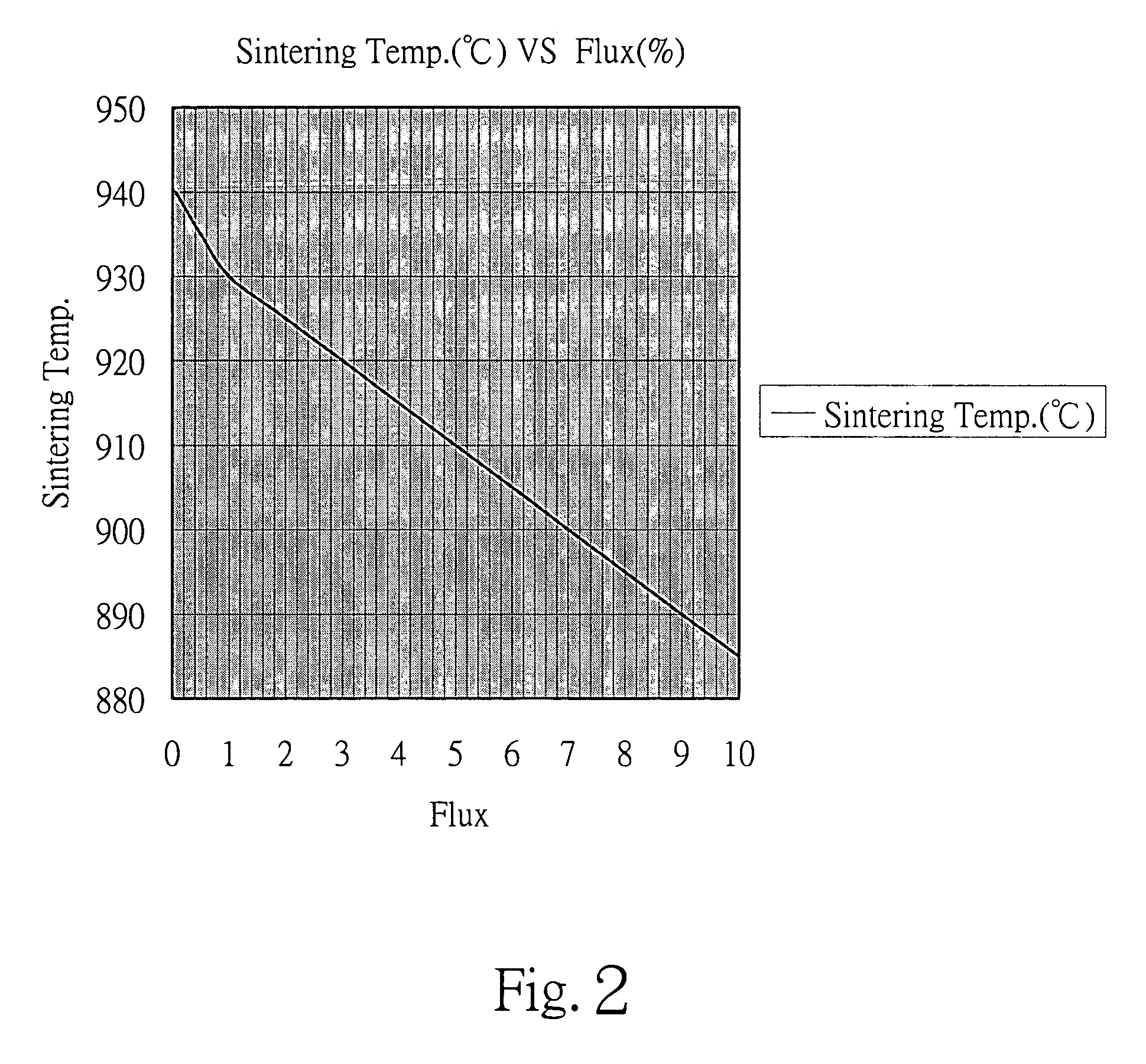

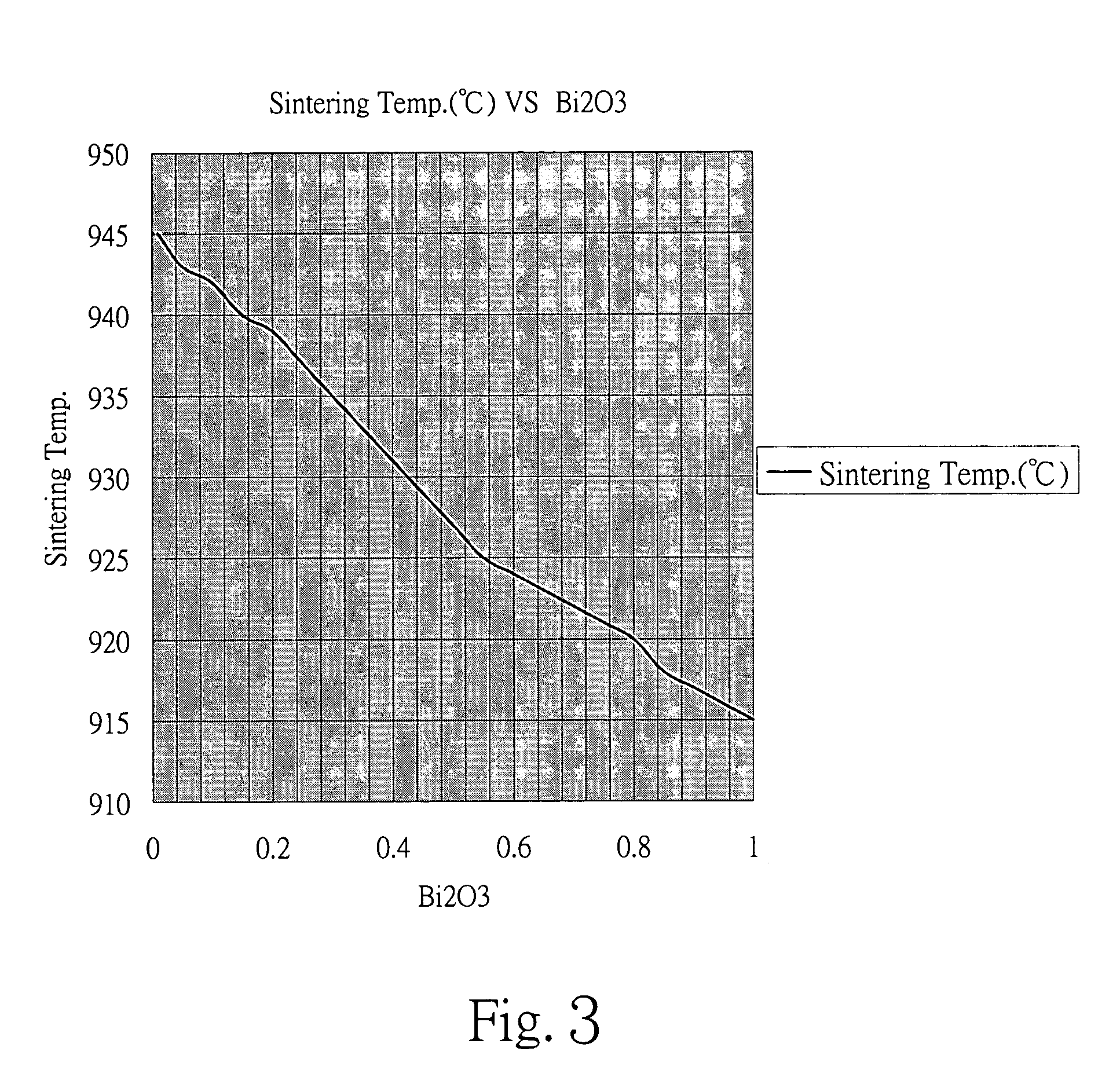

Flux compositions for sintering Ni-Zn ferrite material

InactiveUS20050034633A1Lower sintering temperatureMaintain effective electric propertyOther chemical processesInorganic material magnetismPotassiumCopper oxide

Flux compositions for sintering Ni—Zn ferrite material are disclosed in the present invention, each flux composition basically and selectively has zinc oxide (ZnO), silicon dioxide (SiO2), boric oxide (B2O3), bismuth trioxide (Bi2O3), aluminum oxide (Al2O3), potassium trioxide (K2O3), barium oxide (BaO), sodium oxide (Na2O), calcium oxide (CaO), and magnesium oxide (MgO). Each flux composition is added into a mixture of Ni—Zn ferrite material composed of ferric oxide (Fe2O3), nickel oxide (NiO), zinc oxide (ZnO), cupric oxide (CuO) and cobalt oxide (CoO) and ranges from 0.05 to 10 weight percent based on the total weight of the Ni—Zn ferrite material. The flux compositions of the present invention decrease sintering temperature when the ferrite material is sintered and contain no lead (Pb) element so as to reduce toxic pollutants.

Owner:CHILISIN ELECTRONICS

Preparation method of graphene oxide/barium ferrite wave-absorbing material

InactiveCN104449561AHeating evenlyAvoid high temperature calcination processOther chemical processesBarium nitratePhysical chemistry

The invention relates to a novel material for absorbing electromagnetic waves, and in particular relates to a preparation method of a graphene oxide / barium ferrite wave-absorbing material. The preparation method comprises the following steps: forming a sol from analytically pure barium nitrate Ba(NO3)2 and ferric nitrate Fe(NO3)3 with a graphene oxide water solution by taking citric acid and ethylene glycol as a compound complexing agent; continuously heating and stirring the sol to form a gel; and igniting the gel by virtue of microwave-assisted auto-combustion to further prepare the graphene oxide / barium ferrite wave-absorbing material. The preparation method disclosed by the invention is simple and controllable in process, uniform in temperature distribution of the entire system through microwave field heating, and meanwhile, the preparation method can be used for greatly shortening reaction time and greatly improving the wave-absorbing performance of a barium ferrite material with the doping of the graphene oxide.

Owner:SHANGHAI YUEDA NEW MATERIAL TECH

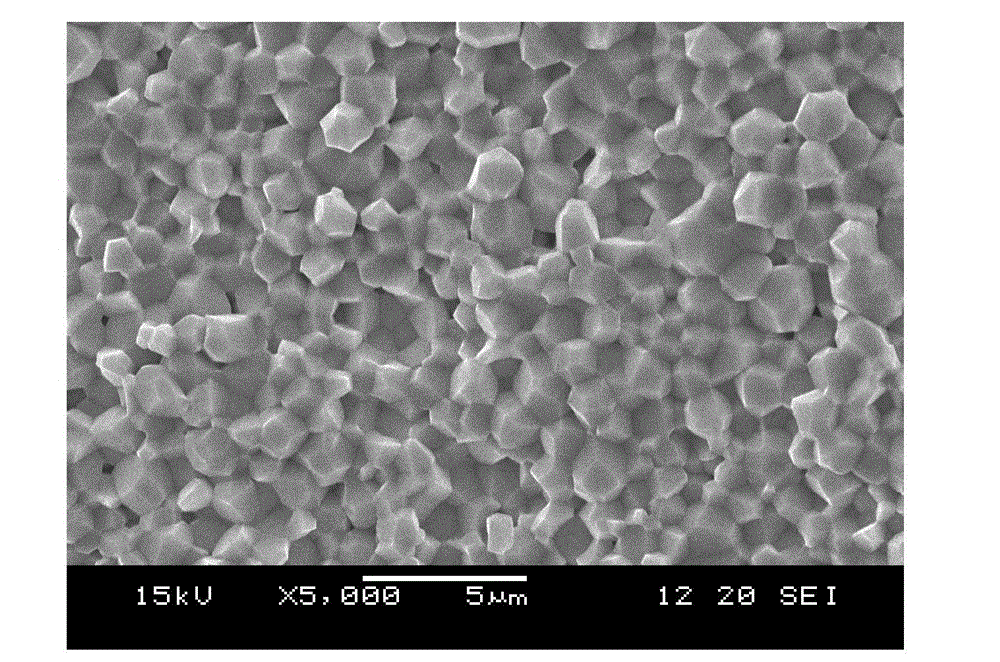

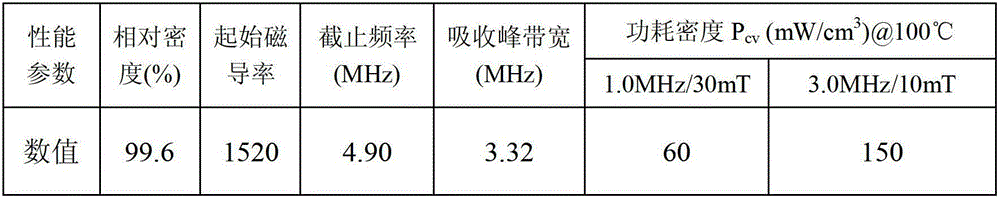

Ultralow-high-frequency-loss-power MnZn ferrite and preparation method thereof

InactiveCN102976739AExquisite control of sizeFinely tuned dispersionChemical compositionAverage size

The invention relates to an ultralow-high-frequency-loss-power MnZn ferrite and a preparation method thereof. The ultralow-high-frequency-loss-power MnZn ferrite is composed of a spinel-structure main crystal phase and a doping component in the grain boundary and crystal, wherein the chemical composition of the spinel-structure main crystal phase is [MnxZnyFe<2>]Fe2<3>O4. The microstructure is characterized in that the relative density of the sintered body is 99.2-99.6%, the average size of the crystal grains is 2.0 mu m@30mT / 1MHz / 100 DEG C and 145<=P[cv]<=160mW / cm<3>@10mT / 3MHz / 100 DEG C.

Owner:NANJING UNIV OF TECH

Manganese-zinc ferrite and preparation method thereof

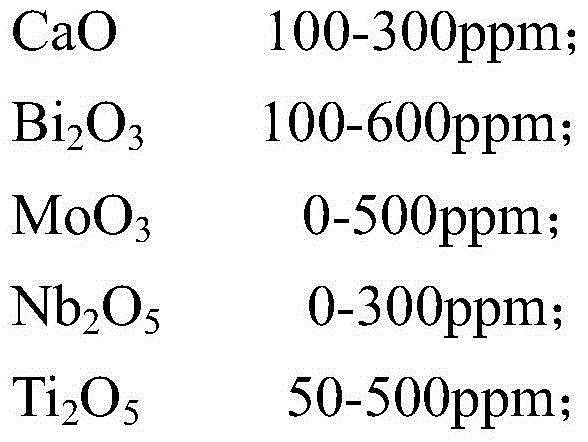

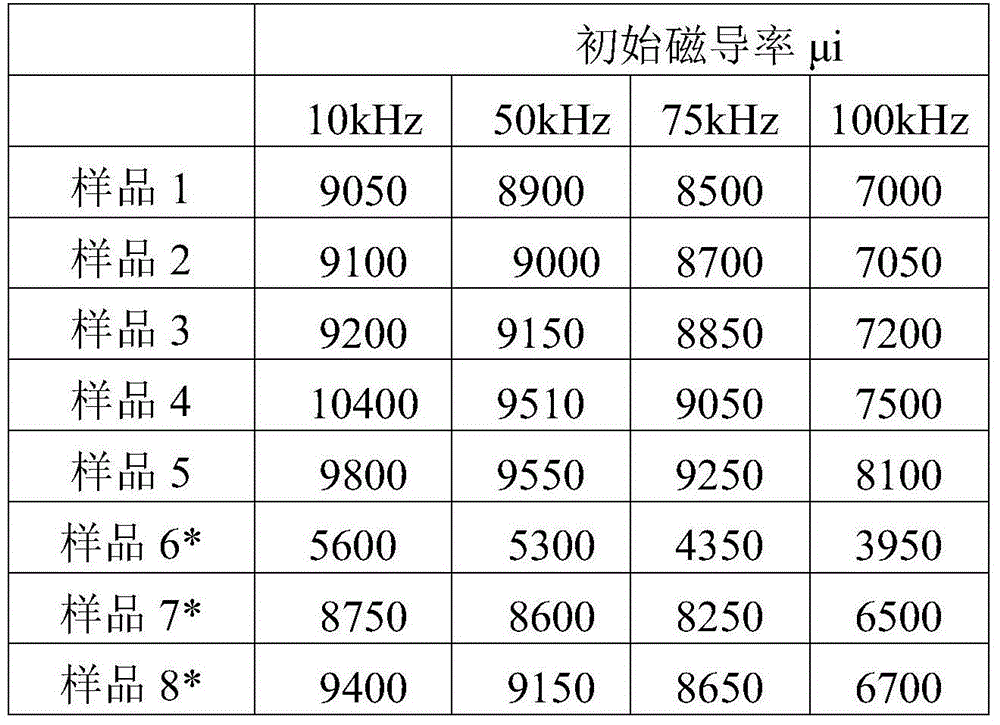

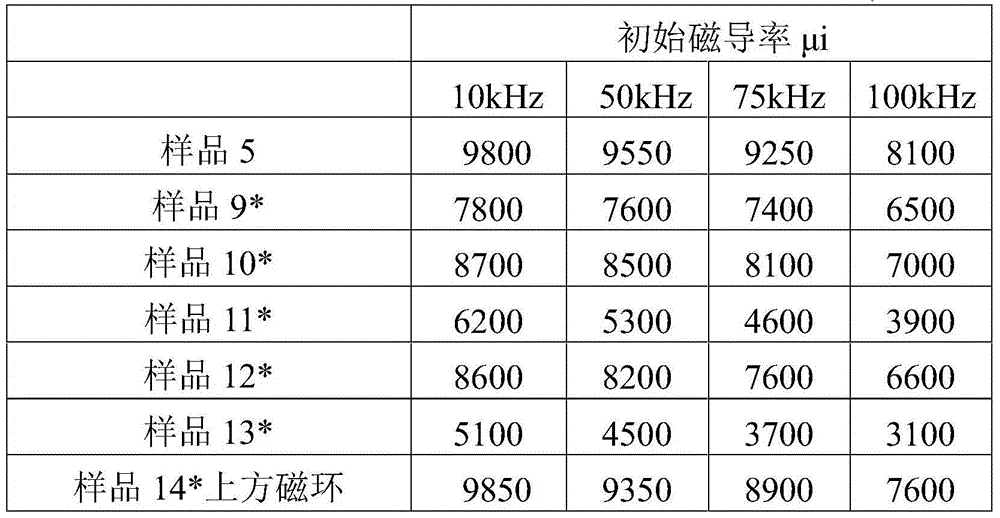

The invention discloses a manganese-zinc ferrite of which the outer diameter is more than or equal to phi79mm and a preparation method thereof, and belongs to the technical field of manganese-zinc ferrite. The manganese-zinc ferrite disclosed by the invention comprises a ferrite pre-sintering material, an auxiliary component, a bonding agent, a dispersant and a defoamer, wherein the ferrite pre-sintering material consists of the following substances in molar percentage content: 52.0-53.0mol% of Fe2O3, 23.0-25.5mol% of ZnO and 21.5-25.0mol% of MnO; and the auxiliary component comprises CaO, Bi2O3, MoO3, Nb2O5 and Ti2O5. The preparation method disclosed by the invention can be used for preparing a manganese-zinc ferrite big magnetic ring of which the outer diameter is more than or equal to phi79mm; the obtained manganese-zinc ferrite big magnetic ring does not have cracking and marco-crystalline phenomena; and under the condition that the temperature is 25 DEG C and B is less than or equal to 0.25mT, the measured 10kHz initial magnetic permeability reaches 9000-11000, and the 100kHz magnetic permeability reaches 7000.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

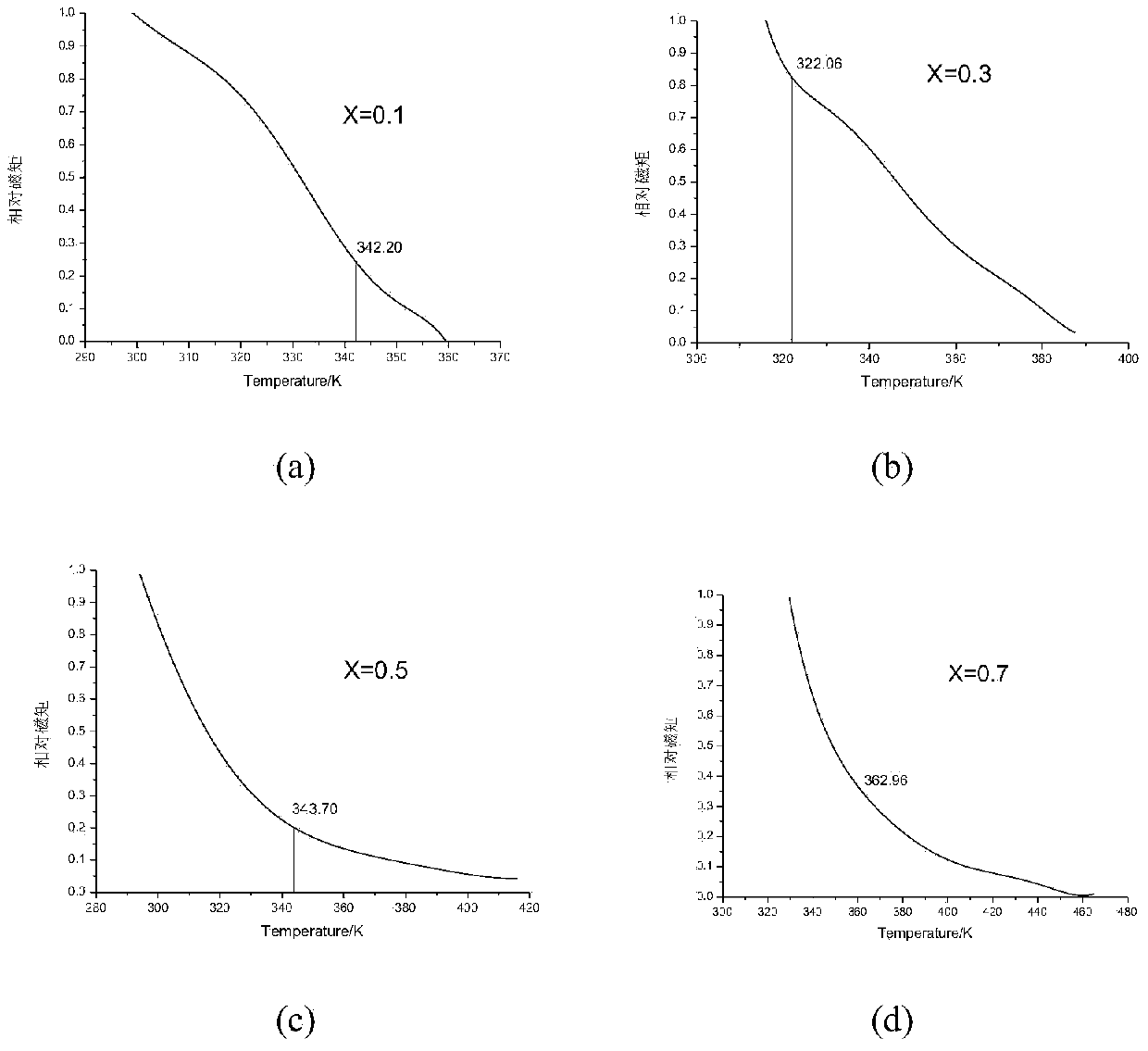

Preparation method of curie point controllable water-soluble nano ferrite

InactiveCN103467080AFirmly connectedGood water solubilityMaterial nanotechnologyAntiendomysial antibodiesSilicic acid

The invention relates to a preparation method of a curie point controllable water-soluble nano ferrite, which comprises the steps of allowing an MnCl2.4H2O solution, a ZnCl2 solution, an FeCl3.6H2O solution and a sodium hydroxide solution to perform precipitation reaction, ultrasonically dispersing a precipitate in an alcohol solution, allowing the precipitate to react with ethyl orthosilicate, and then with 3-amino propyltriethoxysilane after reaction, obtaining a precipitate, dispersing in a PBS (Phosphate Buffer Solution) and obtaining a final product. With the adoption of the technology, the superparamagnetic ferrite which is fine in particle, has controllable curie temperature and good water solubility, can be dissolved in PBS and is bonded with an amino group is prepared, and a foundation can be laid for the ferrite to be inoculated with a tumor antibody and a cell marker to have a target positioning effect.

Owner:SHANDONG UNIV

Ferrite-nickle composite powder for electro-magnetism suction wave and preparation method

InactiveCN101329921AWith broadband and high-efficiency electromagnetic absorption performanceScreening apparatusMass ratioNickel compounds

The invention relates to a ferrite-nickel compound powder used for electromagnetic wave-absorption and a preparation method thereof. Metallic nickel powder is taken as a matrix; a chemical method is adopted to prepare a product required by cladding ferrites on the surface of the nickel powder; the mass ratio of the ferrites to the nickel compound powder is between 1 to 5 and 1 to 0.01; the grain diameter of the nickel powder is 0.5 to 5 microns; the ferrites are ferrites of spinel type or ferrites of magneto plumbite type. Any method of the citrate sol-gel method, the self-propagating method or the coprecipitation method is adopted to prepare the product required. A compound powder material prepared by the invention has electromagnetic wave-absorption performance with broad band and high efficiency and can be prepared into wave-absorption coatings that are widely applied to various civilian and military wave-absorption fields.

Owner:TONGJI UNIV

Wide-temperature MnZn power ferrite material and preparation method thereof

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

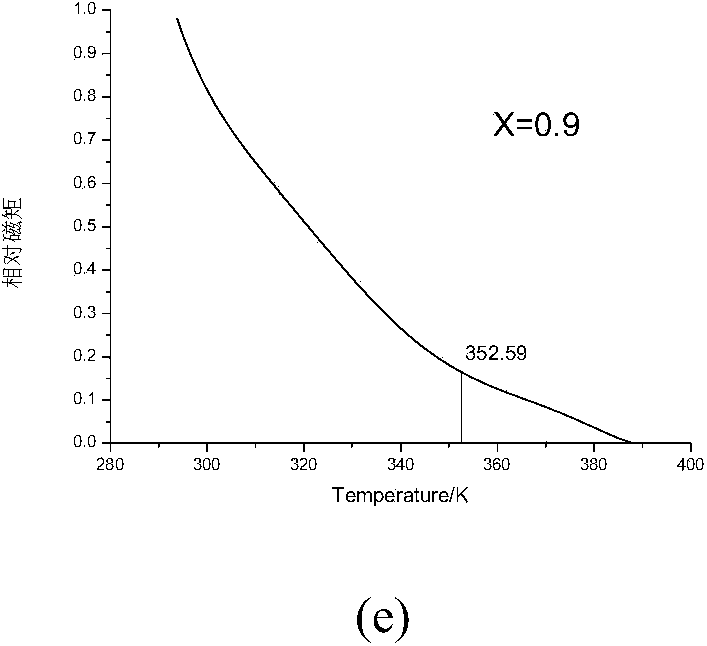

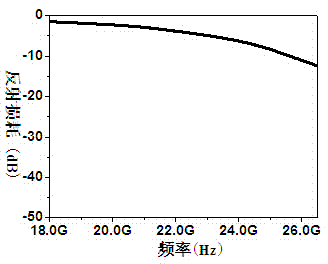

Zirconium and titanium-co-doped barium ferrite wave-absorbing powder material and preparation method therefor

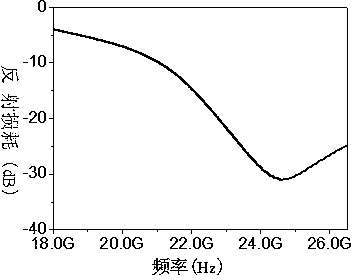

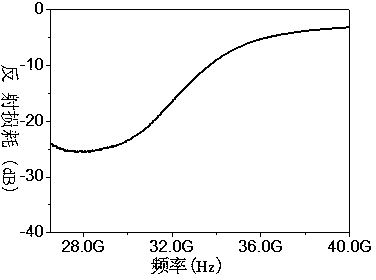

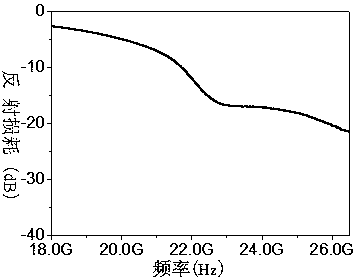

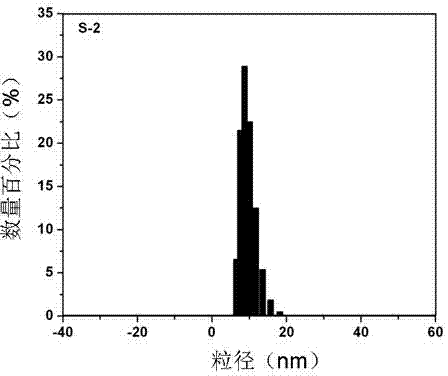

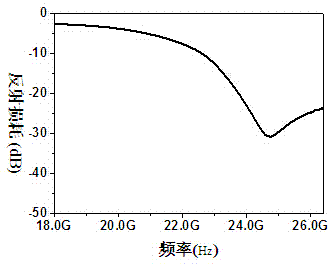

ActiveCN104844182AReduce the heterosexual fieldAbsorbing frequency modulation range widenedReflection lossElectromagnetic shielding

The invention discloses a zirconium and titanium-co-doped barium ferrite wave-absorbing powder material. The chemical formula is BaFe(12-x)ZrxTixO19, wherein x is equal to 0.2-0.4. The zirconium and titanium-co-doped barium ferrite is single-phase polycrystalline powder, and Fe<3+> and Fe<2+> exist in the barium ferrite at the same time. A preparation method comprises the following step of preparing the zirconium and titanium-co-doped barium ferrite wave-absorbing powder material by virtue of a self-propagating combustion method which is combined with ball-milling and a sequential secondary vacuum high-temperature thermal treatment process. The wave-absorbing material disclosed by the invention has the characteristics of being strong in absorption loss, wide in wave absorbing bandwidth, thin in match thickness and wide in modulated wave-absorbing frequency range. The effective wave absorbing bandwidth is controlled in a frequency range of 18-40GHz, double absorption peaks appear, the maximum absorbing bandwidth can reach 16GHz, the optimum match thickness is just about 1mm, and the optimum reflection loss RL value at the special frequency can reach about -48dB. The barium ferrite wave-absorbing powder material is simple in preparation process, can be used for a wave-absorbing coating, and can be widely applied to the fields of electromagnetic shielding and stealth.

Owner:ZHEJIANG UNIV

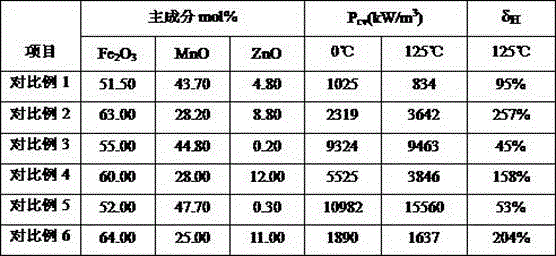

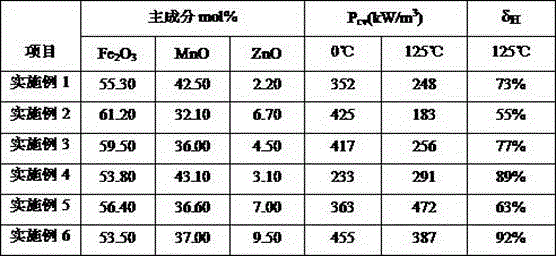

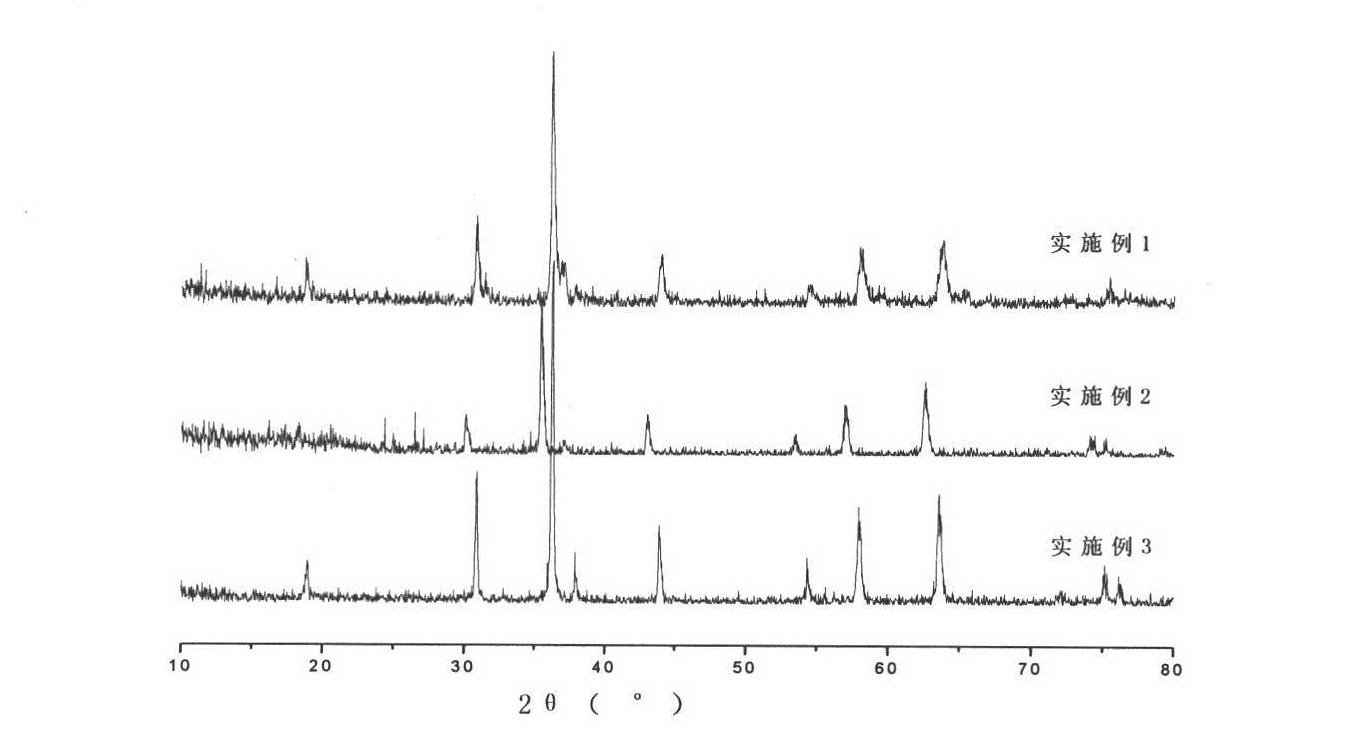

High-frequency manganese-zinc ferrite material

The invention relates to a high-frequency manganese-zinc ferrite material. The main component of the material is composed of 53-62 mol% of Fe2O3, 0.5-10.0 mol% of ZnO and the balance of MnO. The accessory components I are composed of CaCO3, Nb2O5, SiO2, V2O5 and Li2CO3, and account for 0.02-0.15 wt% of the main component; the accessory components II are composed of ZrO2, Co2O3, TiO2 and SnO2, and account for 0.10-0.75 wt% of the main component; and the combination of the accessory components comprises at least one accessory component II. The high-frequency manganese-zinc ferrite material has low power loss and high working frequency range within the temperature range of 0-125 DEG C: the loss is 500kW / m<3> or below under the conditions of f<=5MHz and B<=30mT. The high-frequency manganese-zinc ferrite material has the advantages of small power loss change rate and stable performance, is used for manufacturing various inductors and transformers, and is applicable to the field of high frequency.

Owner:TDG HLDG CO LTD

A kind of mechanochemical method prepares the method for cobalt ferrite nanoparticle

The invention relates to a method for mechanochemically preparing spinel magnetic cobalt ferrite nanoparticles. The steps of the method are: weighing an appropriate amount of cobalt salt, iron salt and citric acid according to a certain molar ratio, adding an appropriate amount of absolute ethanol to mix evenly, adding zirconium balls, and the mass ratio of the ball material is 2:1; The material is put into a high-energy planetary grinding tank, and ground at 200-600r / min. The material is ground under the action of mechanical force for 5-10 hours to obtain a wet gel. The wet gel is dried at 100°C and placed in a high-temperature furnace. Calcining at 500° C. for 4 hours, the spinel-type magnetic cobalt ferrite nanoparticles can be obtained. The chemical formula of this ferrite is CoxFeyO4, where x+y=3, the average grain size is 40-100 nm, the shape is spherical, regular tetrahedral or regular octahedral, and the saturation magnetization is 25-60 emu / g. The invention has the advantages of simple process, less energy consumption, easy control of production links, and easy realization of industrialized production; it solves the problems of high cost, high energy consumption, complicated process and the like in the prior art.

Owner:YANCHENG INST OF TECH

Method for preparing nano cobalt ferrite

The invention discloses a method for preparing nano-powder of nano cobalt ferrite (CoFe2O4) with a spinel structure at a low temperature. The preparation method comprises the steps of weighing ferric trichloride and cobaltous chloride in proportion, and mixing to prepare water solution A; evenly mixing the prepared NaOH or HOK aqueous alkali, and then dropwise adding N2H4.H2O to obtain solution B; rapidly stirring the water solution A obtained in the step 1 at 20-40 DEG C, and slowly dropwise adding the mixed solution B prepared in the step 2 into the water solution A to react, so as to obtain cobalt ferrite (CoFe2O4) powder sediment with a black spinel structure.

Owner:LANZHOU UNIVERSITY

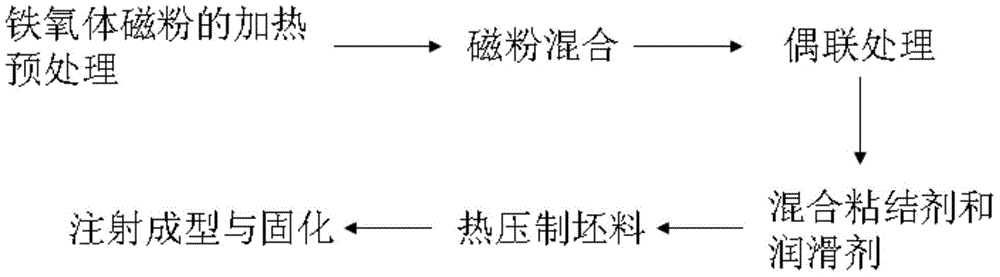

Manufacturing method for thermoplastic compound macromolecule bonded magnet

ActiveCN104599834AImprove liquidityInorganic material magnetismInductances/transformers/magnets manufactureThermoplasticEpoxy

The invention provides a manufacturing method for a thermoplastic compound macromolecule bonded magnet. The manufacturing method comprises the following steps: taking and uniformly mixing neodymium iron boron rare earth magnetic powder and ferrite magnetic powder; adding the mixed magnetic powder into an acetone solution dissolving a silane coupling agent and performing a coupling treatment; taking an epoxy resin binder, dissolving in acetone and forming a solid gum, and volatilizing the acetone; soaking the magnetic powder after the coupling treatment into a fixing glue solution, fully mixing for more than 12 hours and drying, thereby forming a mixture; adding a zinc stearate lubricating agent into the mixture , heating to 90-110 DEG C, keeping constant temperature, pressing and treating for a preset time duration under the pressure more than 1000MPa, thereby acquiring a blank; heating the blank to be at 180 DEG C under inert atmosphere, injecting and forming, and adding solidifying agent for solidifying. According to the manufacturing method provided by the invention, the liquidity of mixture slurry mixed by the bonding agent and the magnetic powder is promoted, the temperature range for causing the slurry to have the liquidity is widened, and the method is fit for the production of articles of various complex shapes.

Owner:HEYE HEALTH TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com