Manganese-zinc ferrite and preparation method thereof

A technology of ferrite and ferrite pre-fired material, which is applied in the field of manganese-zinc ferrite, can solve the problems of inconsistent deglue speed in microscopic areas, uneven temperature field and atmosphere field, and lower cut-off frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

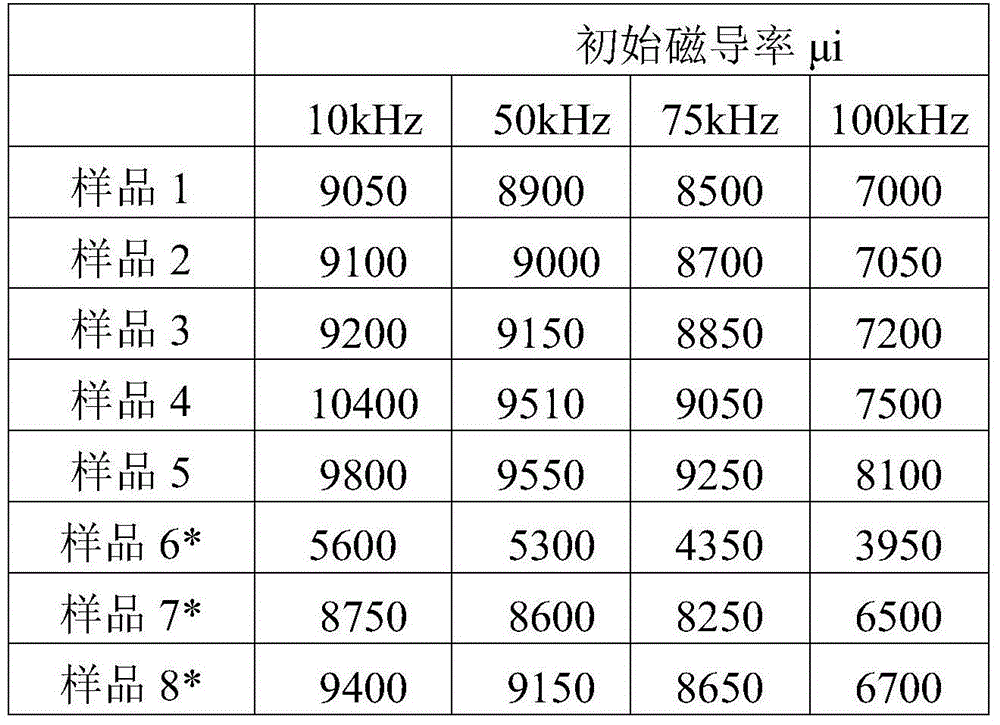

Examples

Embodiment 1

[0062] A preparation method of manganese-zinc ferrite (Ф79×Ф40×15 manganese-zinc R10k product), specifically comprising the following steps:

[0063] 1) Take 52.5mol% Fe 2 o 3 , 23.0mol% of ZnO and 24.5mol% of MnO, wet mixed for 30min, and sprayed to obtain a spray material;

[0064] 2) Pre-burn the primary spray material at 700-900°C for 2-3 hours to obtain the pre-fired material;

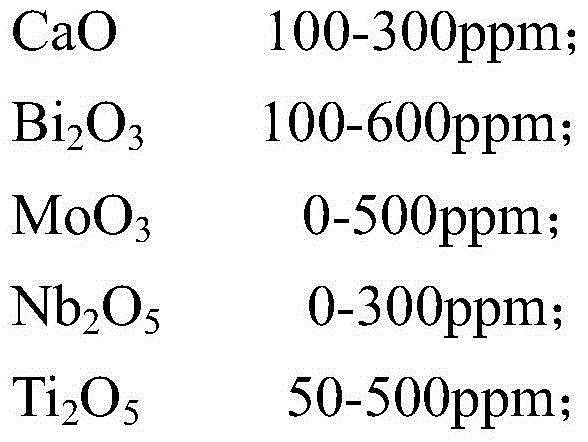

[0065] 3) According to the total weight of the ferrite pre-fired material, add auxiliary components 100ppm CaO, 300ppm Bi to the pre-fired material 2 o 3 , 200ppm MoO 3 , 200ppm Nb 2 o 5 and 100ppm Ti 2 o 5 , performing secondary wet sand grinding; controlling the particle size of the secondary wet grinding slurry to SMD=1.05-1.40 μm to obtain ferrite slurry;

[0066] 4) Add 0.5wt% PVA binder calculated by ferrite powder weight, 0.5wt% dispersant 1-methylpentanol and 0.2wt% defoamer siloxane to the ferrite slurry Spray granulation; the granulated powder is molded into a blank, and the de...

Embodiment 2

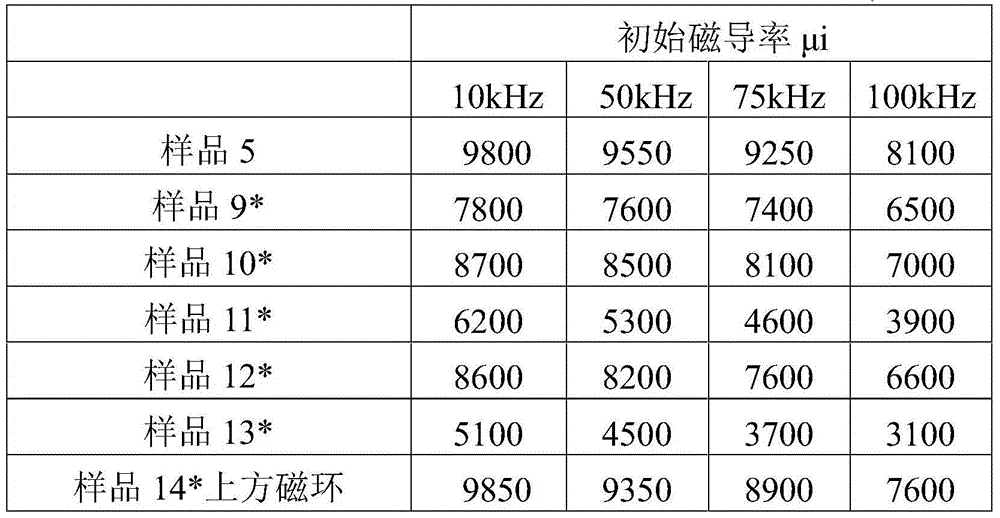

[0078] The green sample ring was pressed and formed according to the provisions of sample 5 in the above-mentioned embodiment 1, and filled according to the charging method in Table 3. After the filling is completed, sintering is carried out, and the specific operation of sintering is the same as in Example 1.

[0079] Table 3 shows the charging methods of different samples

[0080]

Number of stacks

Lower gasket

top cover

Gasket material permeability

Whether to burn

Sample 5

single

Have

Have

≥5000

Surrounded by fire

Sample 9*

single

Have

Have

≥5000

Not surrounded by fire

Sample 10*

single

Have

Have

<3000

Surrounded by fire

Sample 11*

single

none

Have

≥5000

Surrounded by fire

Sample 12*

single

Have

none

≥5000

Surrounded by fire

Sample 13*

single

none

none

≥5000

Surrounded ...

Embodiment 3

[0088] The green sample ring is pressed and formed according to the provisions of sample 5 in the above-mentioned embodiment 1, and the filling method is carried out according to the method of sample 5 in the embodiment 2. The specific operation of the heating and cooling curve of sintering is carried out according to Table 5, and the control of oxygen partial pressure in each temperature range is carried out according to Example 1.

[0089] Table 5 Sintering heating and cooling curve specific operation

[0090]

[0091]

[0092] *) indicates that it is outside the scope of the present invention; 19* is compared with the temperature rise rate before 950°C of 5; 20* is compared with the temperature rise rate after 950°C of 16; 21* is compared with the constant temperature of 15; 22* is compared with the constant temperature of 15 5 compared with the cooling rate after constant temperature;

[0093] Table 6 shows the test results of the initial permeability μi of samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com