Preparation method of curie point controllable water-soluble nano ferrite

A nano-ferrite, water-soluble technology, applied in the intersection of materials science and biomedicine, can solve problems such as limited application fields, and achieve the effects of controllable Curie temperature, fine particles, and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

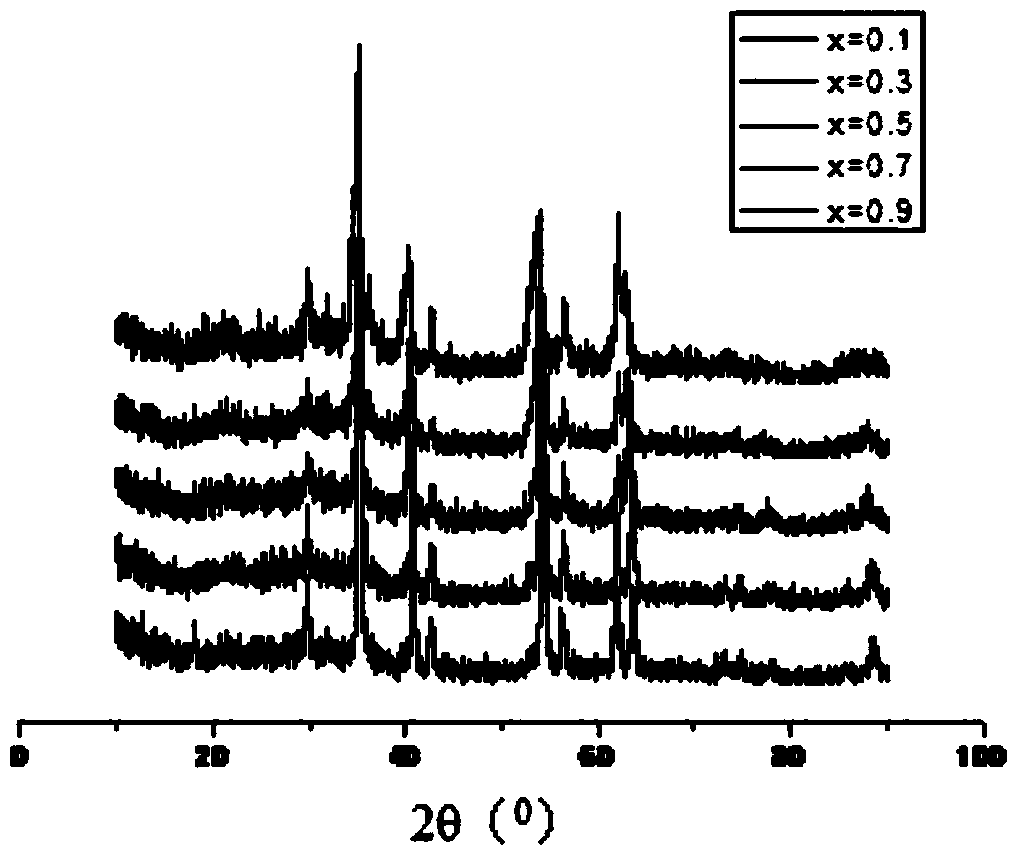

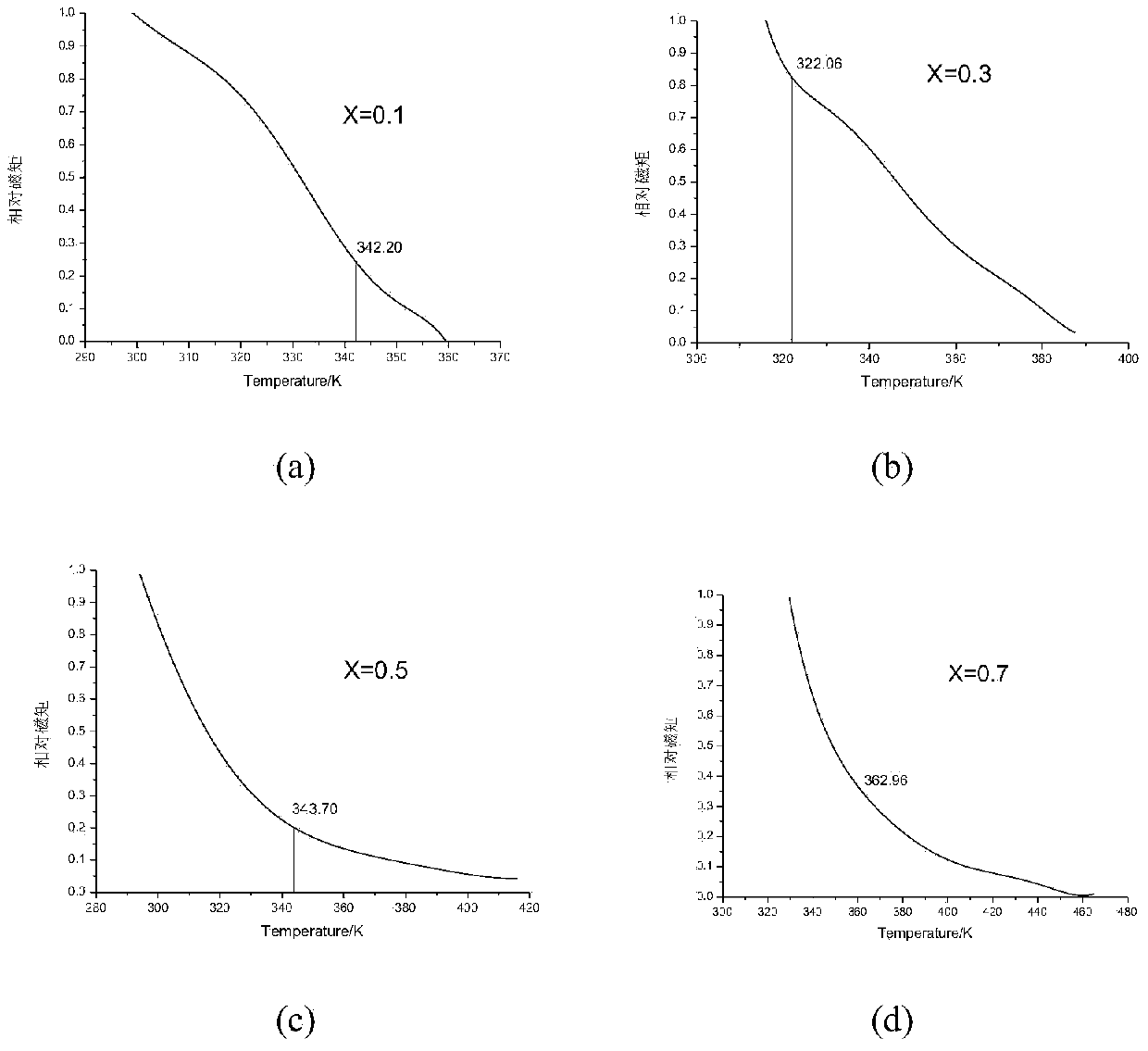

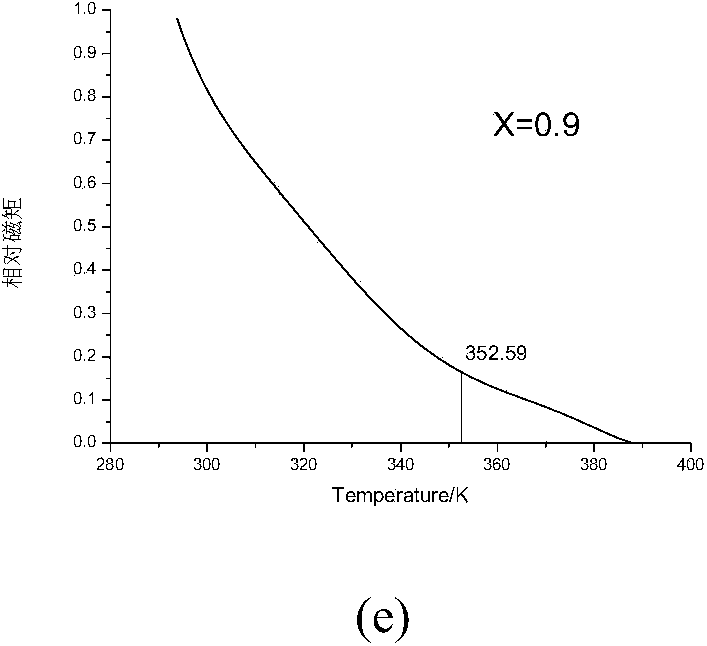

Image

Examples

Embodiment 1

[0029] (1) With 0.1295mol / L MnCl 2 4H 2 O solution, 0.01438mol / L ZnCl 2 Solution, 0.2877mol / LFeCl 3 ·6H 2 O solution, 1.1510mol / L NaOH solution as raw material, first take 150ml of sodium hydroxide solution and add it to a three-necked flask, put the three-necked flask in a 90°C water bath, and then add the MnCl prepared in proportion 2 4H 2 O, ZnCl 2 , FeCl 3 ·6H 2 Add 150ml of O mixed solution into the separatory funnel, add drop by drop under continuous stirring, and keep the temperature for 2h after the dropwise addition is completed after 1h.

[0030] (2) Seal the reacted precipitate with plastic wrap and age it at room temperature for 5 hours; filter and wash the aged precipitate until the solution is neutral, then put it in a vacuum drying oven and dry it under vacuum at 80°C After 24 hours, the obtained ferrite powder was ground and sieved for later use.

[0031] (3) Take 1g of the ferrite obtained above, add it to 750ml of 20% ethanol solution, and disperse i...

Embodiment 2

[0037] (1) With 0.09981mol / L MnCl 2 4H 2 O solution, 0.04277mol / L ZnCl 2 Solution, 0.2852mol / LFeCl 3 ·6H 2 O solution, 1.1407mol / L NaOH solution as raw material, first take 150ml of sodium hydroxide solution and add it to a three-necked flask, put the three-necked flask in a 90°C water bath, and then add the MnCl prepared in proportion 2 4H 2 O, ZnCl 2 , FeCl 3 ·6H 2 Add 150ml of O mixed solution into the separatory funnel, add drop by drop under continuous stirring, and keep the temperature for 2h after the dropwise addition is completed after 1h.

[0038] (2) Seal the precipitate after reaction with plastic wrap, and age at room temperature for 5 hours. The aged precipitate was filtered and washed until the solution was neutral, then put into a vacuum drying oven, dried in vacuum at 80° C. for 24 hours, and the obtained ferrite powder was ground and sieved for later use.

[0039] (3) Take 1g of the ferrite obtained above, add it to 750ml of 20% ethanol solution, and...

Embodiment 3

[0045] (1) With 0.07066mol / LMnCl 2 4H 2 O solution, 0.07066mol / LZnCl 2 Solution, 0.2822mol / LFeCl 3 ·6H 2 O solution, 1.1306mol / L NaOH solution as raw material, first take 150ml of sodium hydroxide solution and add it to the three-necked flask, put the three-necked flask in a 90°C water bath, and then add the MnCl prepared in proportion 2 4H 2 O, ZnCl 2 , FeCl 3 ·6H 2 Add 150ml of O mixed solution into the separatory funnel, add drop by drop under continuous stirring, and keep the temperature for 2h after the dropwise addition is completed after 1h.

[0046] (2) Seal the reacted precipitate with plastic wrap and age it at room temperature for 5 hours; filter and wash the aged precipitate until the solution is neutral, then put it in a vacuum drying oven and dry it under vacuum at 80°C After 24 hours, the obtained ferrite powder was ground and sieved for later use.

[0047] (3) Take 1g of the ferrite obtained above, add it to 750ml of 20% ethanol solution, and disperse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com