High Tc, wide temperature ultrahigh Bs MnZn ferrite material and preparation method

A ferrite material, ultra-high technology, applied in the field of ferrite material preparation, can solve the problem of high loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the present invention comprises the following steps:

[0045] 1. Formula

[0046] Using 58.0-62.0mol% Fe 2 o 3 , 10.0-15.0mol% ZnO, 4.0-6.0mol% NiO, the balance is MnO;

[0047] 2. One ball milling

[0048] Mix the above powders evenly in the ball mill for 1-3 hours;

[0049] 3. Pre-burning

[0050] Dry the ball abrasive obtained in step 2, press it into a round cake at 60-100MPa, and pre-fire it in a furnace at 800-1000°C for 1-3 hours;

[0051] 4. Doping

[0052] Add the following dopant by weight ratio to the powder obtained in step 3: 0.001-0.30wt%MoO 3 , 0.01-0.40wt%Bi 2 o 3 , 0.001-0.05wt%SnO 2 , 0.001-0.05wt%Nb 2 o 5 , 0.001-0.20wt%Ta 2 o 5 ;

[0053] 5. Secondary ball milling

[0054] Mix superhard ball milling media with different diameters in the ball mill according to a certain ratio, mix the powder obtained in step 4 according to a certain ball ratio, and mill in the ball mill for 4-8 hours;

[0055] 6. Forming

[...

Embodiment 1-4

[0066] Embodiment 1-4: A kind of high Curie temperature T c , wide temperature and high saturation magnetic induction BB s and lower loss P L The MnZn ferrite material of characteristic and preparation method thereof, comprises the following steps:

[0067] 1. Formula

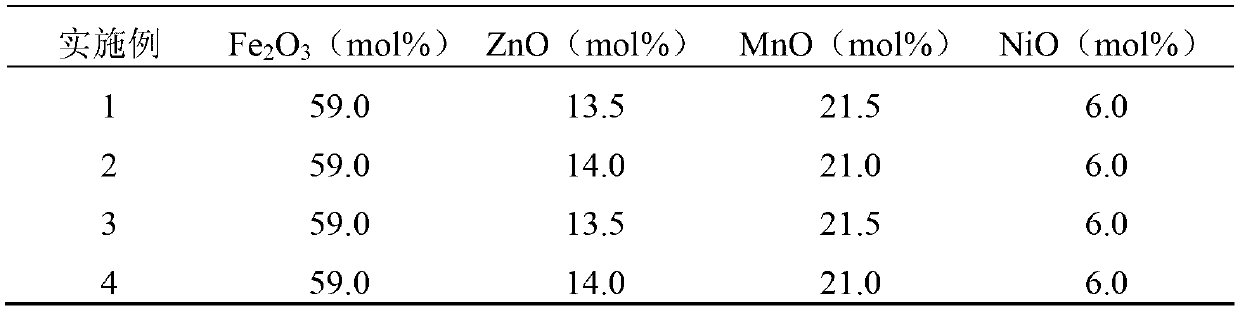

[0068] Embodiment 1-4 major ingredient formula sees the following table:

[0069]

[0070] 2. One ball milling

[0071] Mix the above powders evenly in a ball mill for 2 hours;

[0072] 3. Pre-burning

[0073] Dry the ball mill material obtained in step 2, press it into a round cake at 60MPa, and pre-fire it in a furnace at 850°C for 2 hours;

[0074] 4. Doping

[0075] Add the powder obtained in step 3 into the dopant shown in the following table by weight:

[0076]

[0077] 5. Secondary ball milling

[0078] Mix superhard ball milling media with different diameters in the ball mill according to a certain ratio, mix the powder obtained in step 4 according to a certain ball ratio, and mill in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com