Three-dimensional weaving forming method for composite material

一种复合材料、三维织造的技术,应用在非织造布、纺织品和造纸、织机等方向,能够解决致密度低、尺寸小、浸渍后空隙多等问题,达到加强致密度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

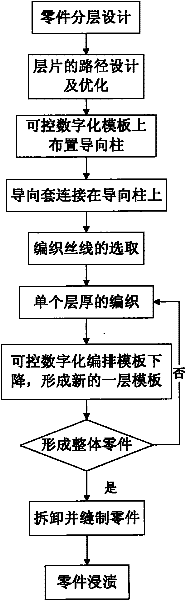

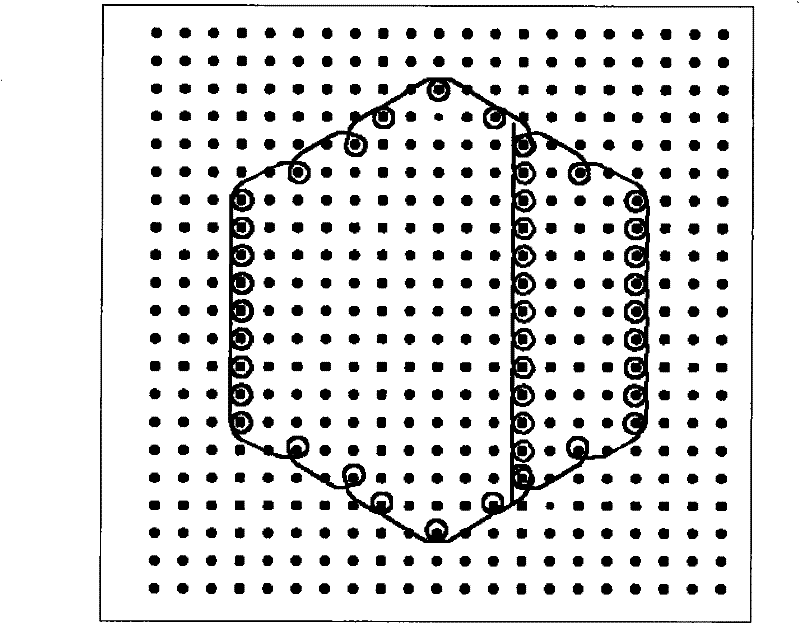

[0031] In order to clearly express the step characteristics of a three-dimensional weaving forming method for composite materials of the present invention, a weaving method of a simple hexagonal prism whose cross section is a regular hexagon is listed below.

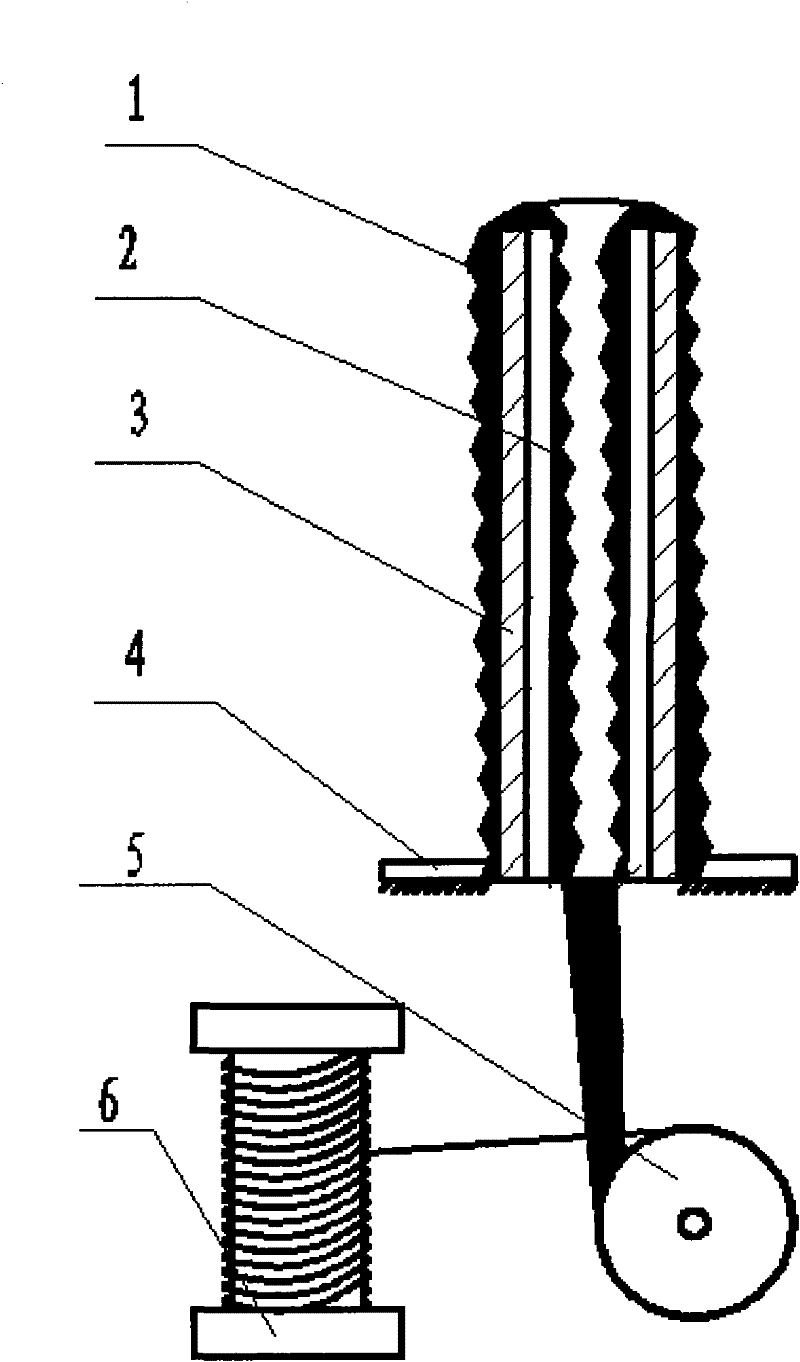

[0032] According to the characteristics of the parts, the weaving guide posts are densely arranged on the formwork at a distance of 3mm to form a controllable digital layout formwork of 60×60mm; according to the performance requirements of the parts, several hollow guide sleeves with smooth exterior and threaded interior are woven; The guide sleeve passes through the hollow guide column in the Z direction and is fixed on the controllable digital template, wherein the smooth wall 2 of the guide sleeve is close to the inner wall of the hollow guide column, and the outer wall 1 of the guide sleeve with threads is wrapped around the outer wall of the hollow guide column. The guide sleeve that is enclosed within the bottom end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com