A kind of mechanochemical method prepares the method for cobalt ferrite nanoparticle

A technology of cobalt ferrite and nanoparticles, which is applied in the field of spinel-type magnetic cobalt ferrite nanoparticles and its preparation, can solve the problems of high cost, complicated production process, and low yield, and achieve low cost, The effect of less energy consumption and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

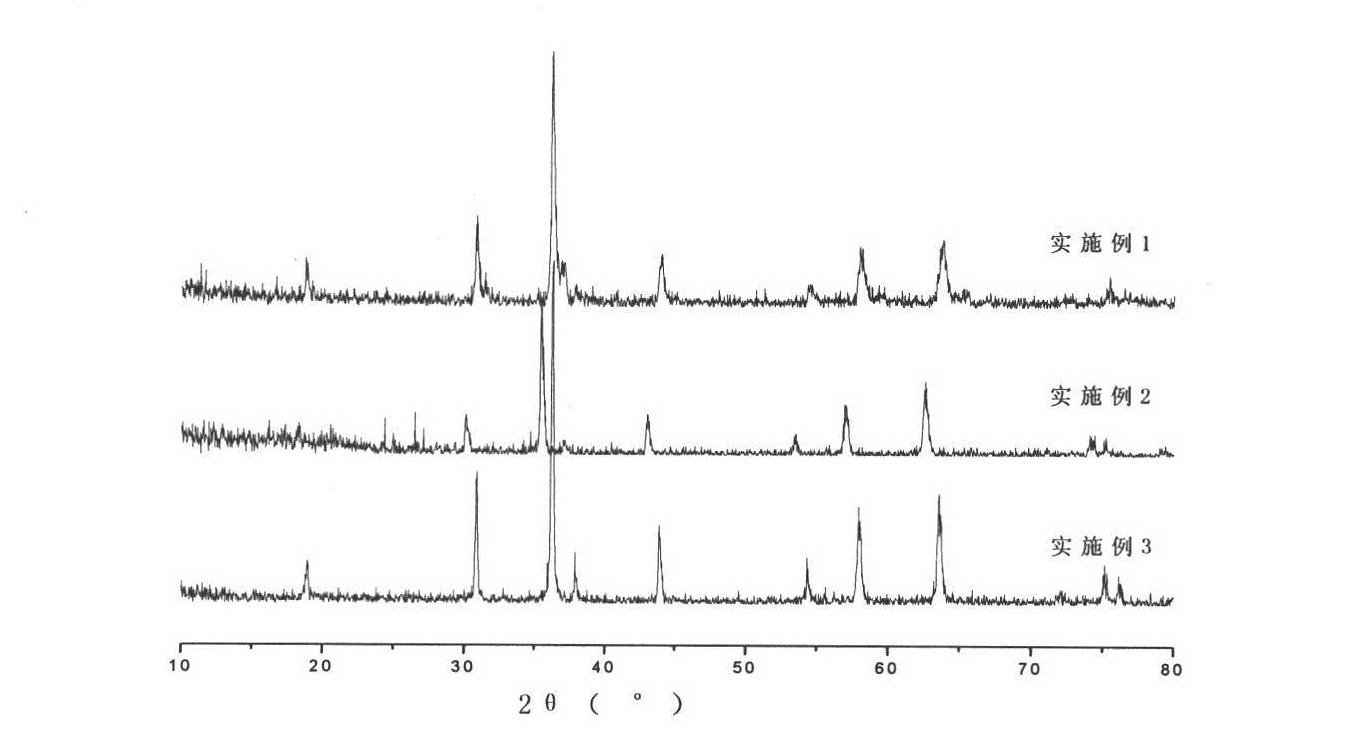

Embodiment 1

[0020] (1) take by weighing cobalt chloride 11.904g, ferric nitrate 10.213g and citric acid 21.206g by the molar ratio of iron and cobalt as 1: 2;

[0021] (2) Pour in an appropriate amount of absolute ethanol, and then add zirconium balls of a certain quality, so that the mass ratio of the ball material is 2:1;

[0022] (3) Set the rotation speed of the planetary mill to 200r / min, grind in the planetary mill for 5 hours, the material undergoes a chemical reaction through mechanical force in the planetary mill, then take out the slurry and dry it at 100°C to obtain a xerogel;

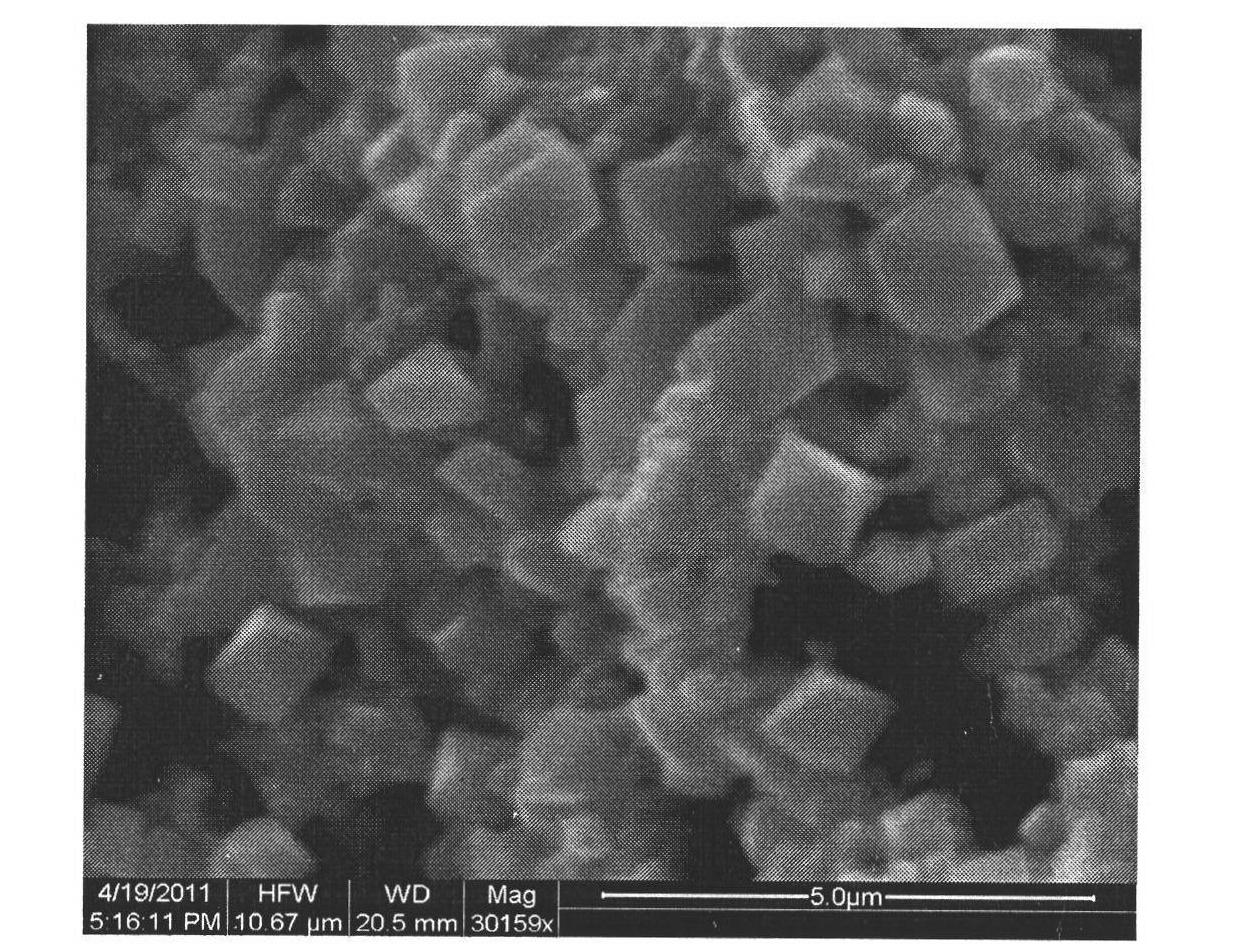

[0023] (4) Put the dry gel into a high-temperature furnace and calcinate it at 500°C for 4 hours to obtain spinel-type magnetic nanoparticles Co 2 Fe0 4 ,Such as figure 2 As shown, the product is in the shape of regular octahedron, and the grain size is about 47.6nm. Figure 5 It is the hysteresis loop of this product, and the saturation magnetization is 26.9emu / g.

Embodiment 2

[0025] (1) take by weighing cobalt chloride 5.965g, ferric nitrate 20.188g and citric acid 21.320g by weighing 2: 1 by the molar ratio of iron and cobalt;

[0026] (2) Pour in an appropriate amount of absolute ethanol, and then add zirconium balls of a certain quality, so that the mass ratio of the ball material is 2:1;

[0027] (3) Set the rotation speed of the planetary mill to 400r / min, grind in the planetary mill for 8h, the material undergoes a chemical reaction through mechanical force in the planetary mill, then take out the slurry and dry it at 100°C to obtain a xerogel;

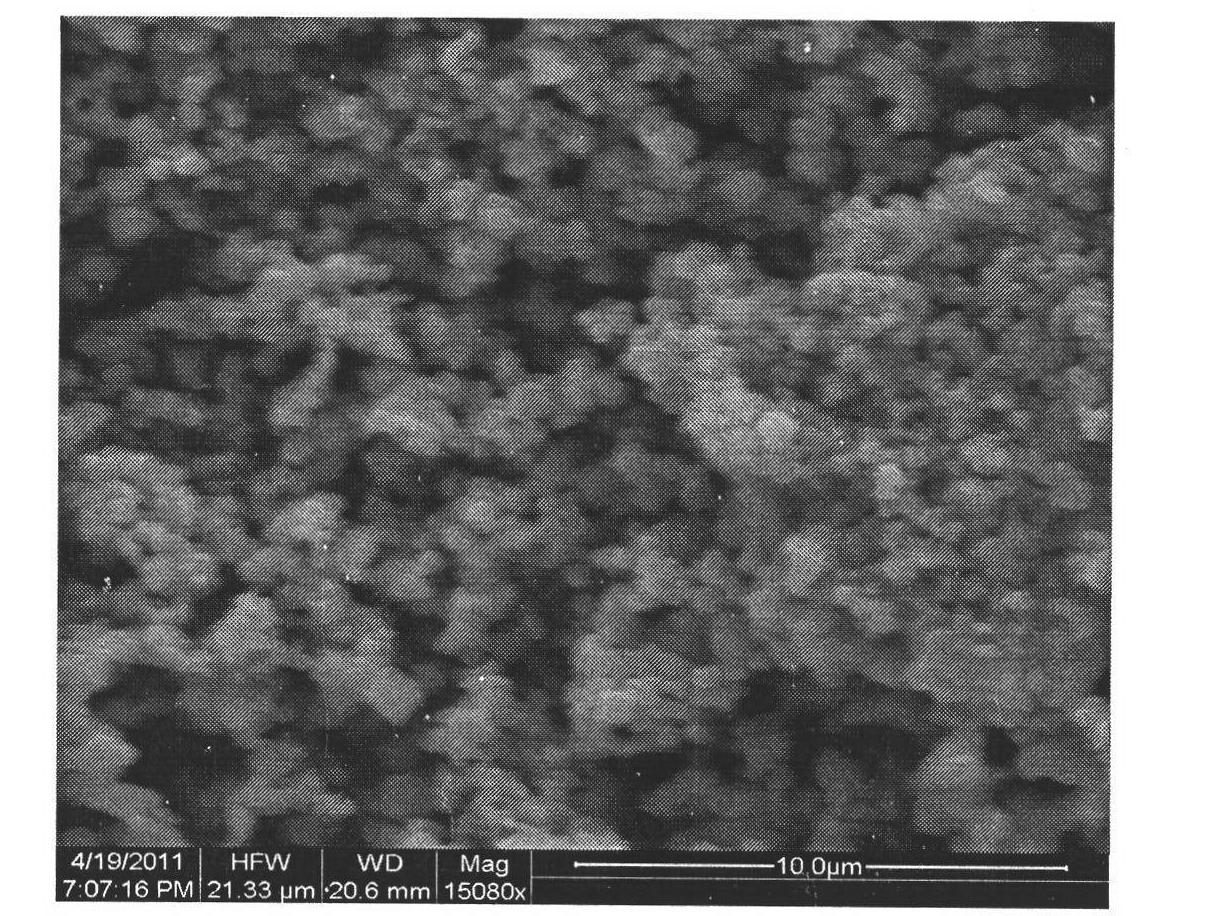

[0028] (4) Put the dry gel into a high-temperature furnace and calcinate it at 500°C for 4 hours to obtain spinel-type magnetic nanoparticles CoFe 2 o 4 ,Such as image 3 As shown, the product is spherical, and the grain size is about 57nm. Figure 6 It is the hysteresis loop of this product, and the saturation magnetization is 51.3emu / g.

Embodiment 3

[0030] (1) take by weighing cobalt chloride 11.904g, ferric nitrate 20.185g and citric acid 21.324g by the molar ratio of iron and cobalt is 1: 1;

[0031] (2) Pour in an appropriate amount of absolute ethanol, and then add zirconium balls of a certain quality, so that the mass ratio of the ball material is 2:1;

[0032] (3) Set the rotation speed of the planetary mill to 600r / min, grind in the planetary mill for 10 hours, the material undergoes a chemical reaction through mechanical force in the planetary mill, then take out the slurry and dry it at 100°C to obtain a xerogel;

[0033] (4) Put the dry gel into a high-temperature furnace and calcinate it at 500°C for 4 hours to obtain spinel-type magnetic nanoparticles Co 1.5 Fe 1.5 o 4 ,Such as Figure 4 As shown, the product is in the shape of a regular tetrahedron, and the grain size is about 84.5nm. Figure 7 It is the hysteresis loop of the product, and the saturation magnetization is 57.8emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com