Patents

Literature

388 results about "Spinel group" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

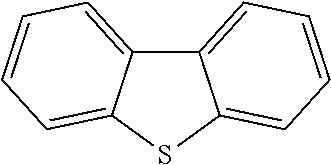

The spinels are any of a class of minerals of general formulation AB₂X₄ which crystallise in the cubic (isometric) crystal system, with the X anions (typically chalcogens, like oxygen and sulfur) arranged in a cubic close-packed lattice and the cations A and B occupying some or all of the octahedral and tetrahedral sites in the lattice. Although the charges of A and B in the prototypical spinel structure are +2 and +3, respectively (A²⁺B³⁺₂X²⁻₄), other combinations incorporating divalent, trivalent, or tetravalent cations, including magnesium, zinc, iron, manganese, aluminium, chromium, titanium, and silicon, are also possible. The anion is normally oxygen; when other chalcogenides constitute the anion sublattice the structure is referred to as a thiospinel.

Cathode intercalation compositions, production methods and rechargeable lithium batteries containing the same

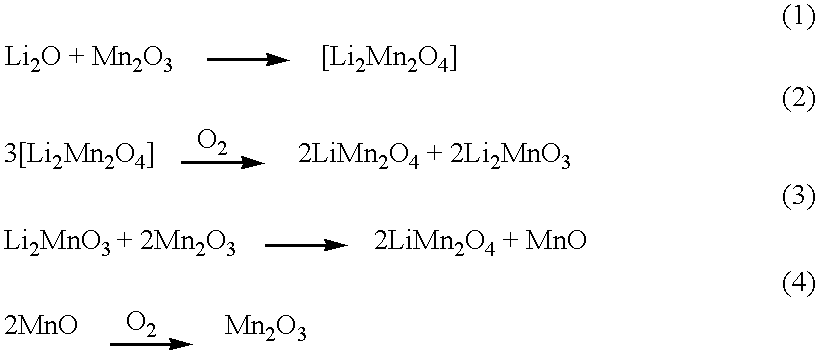

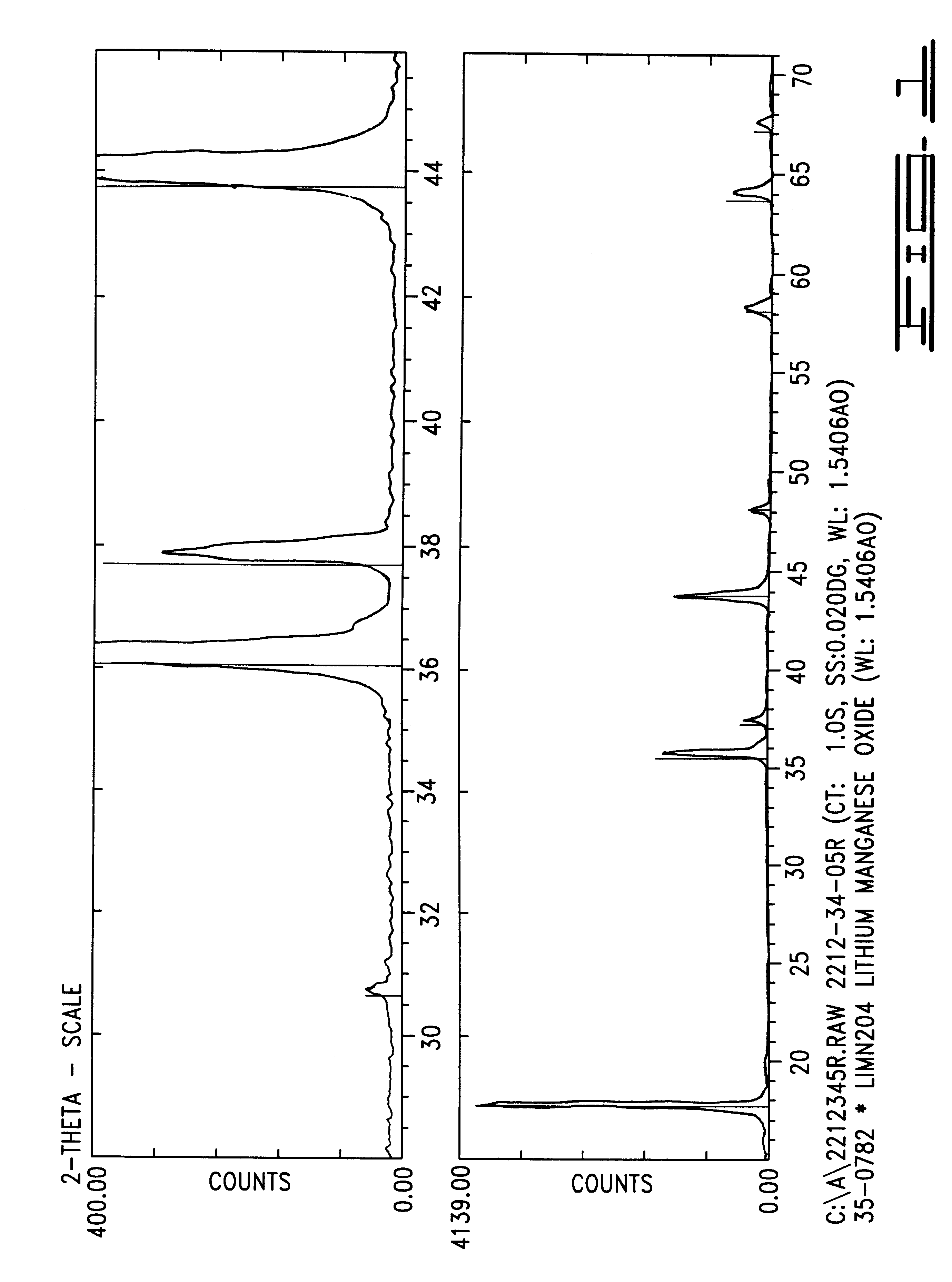

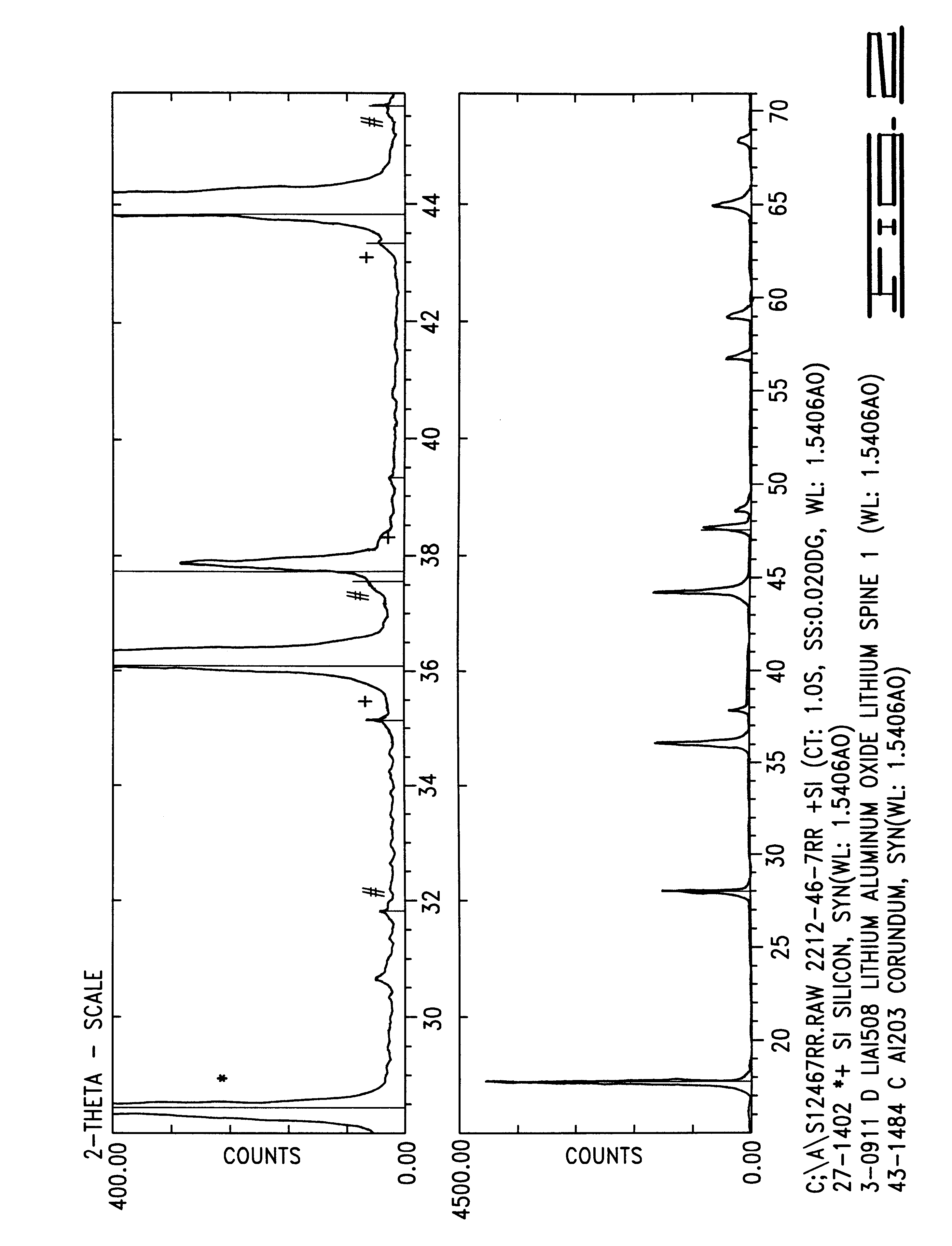

InactiveUS6248477B1Easy to adaptOxygen/ozone/oxide/hydroxideElectrode thermal treatmentMetalSpinel group

Intercalation compositions having spinel structures with crystallites of metal oxides (M2O3) dispersed throughout the structure are provided having the general formula Li1+xMyMn2-x-yO4. Methods of producing the intercalation compositions and rechargeable lithium batteries containing the compositions are also provided.

Owner:EMD ACQUISITION LLC

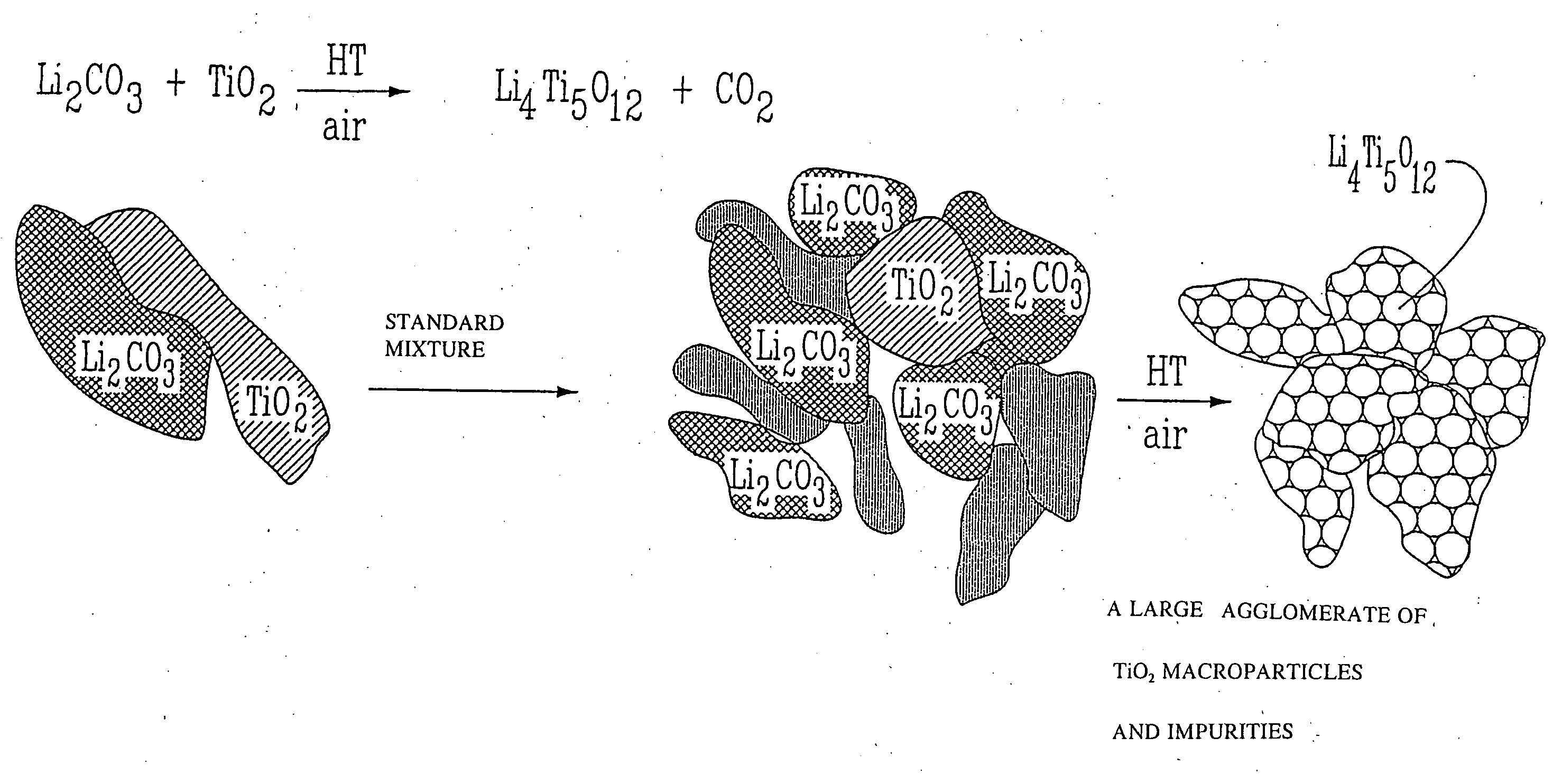

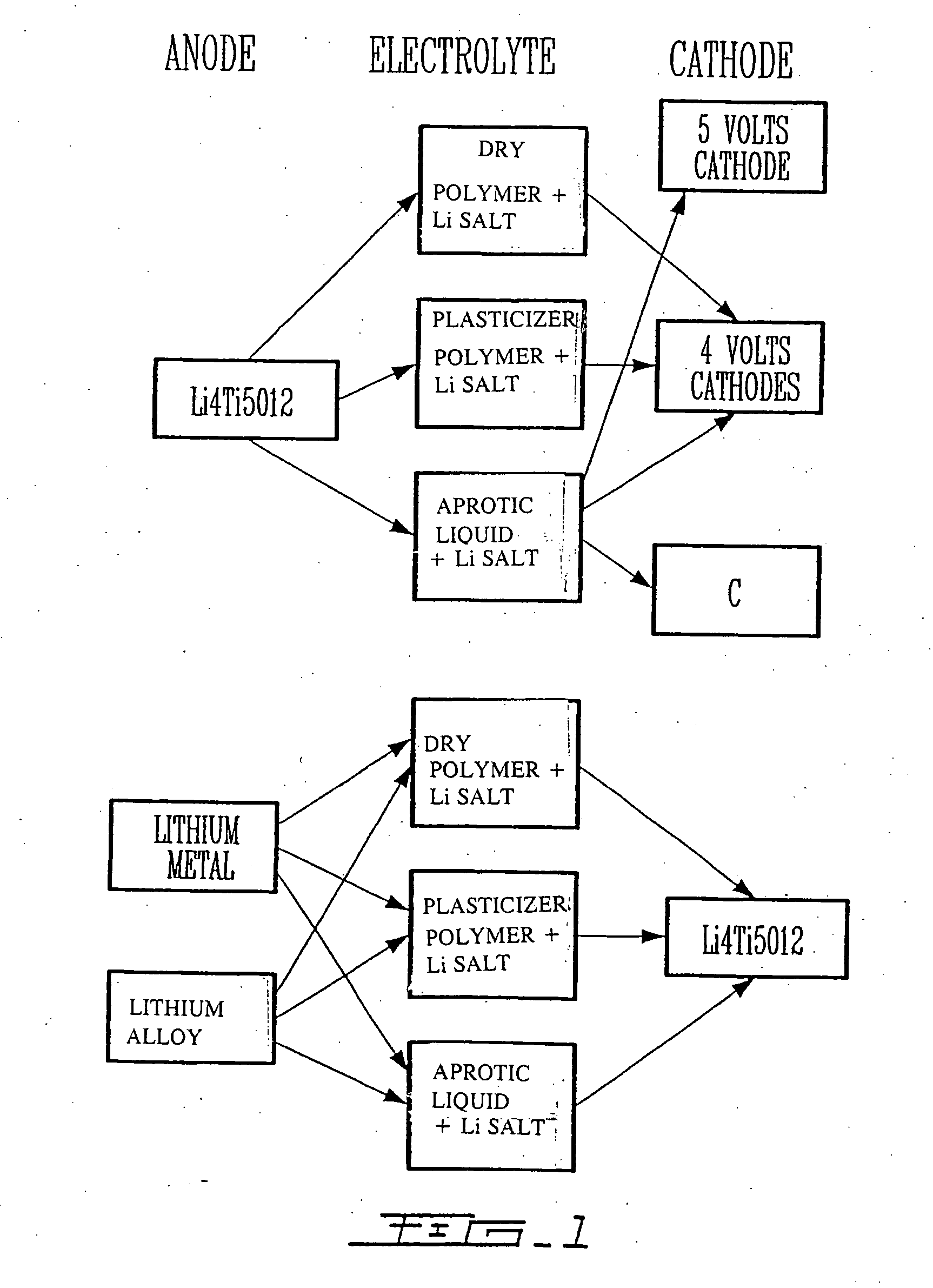

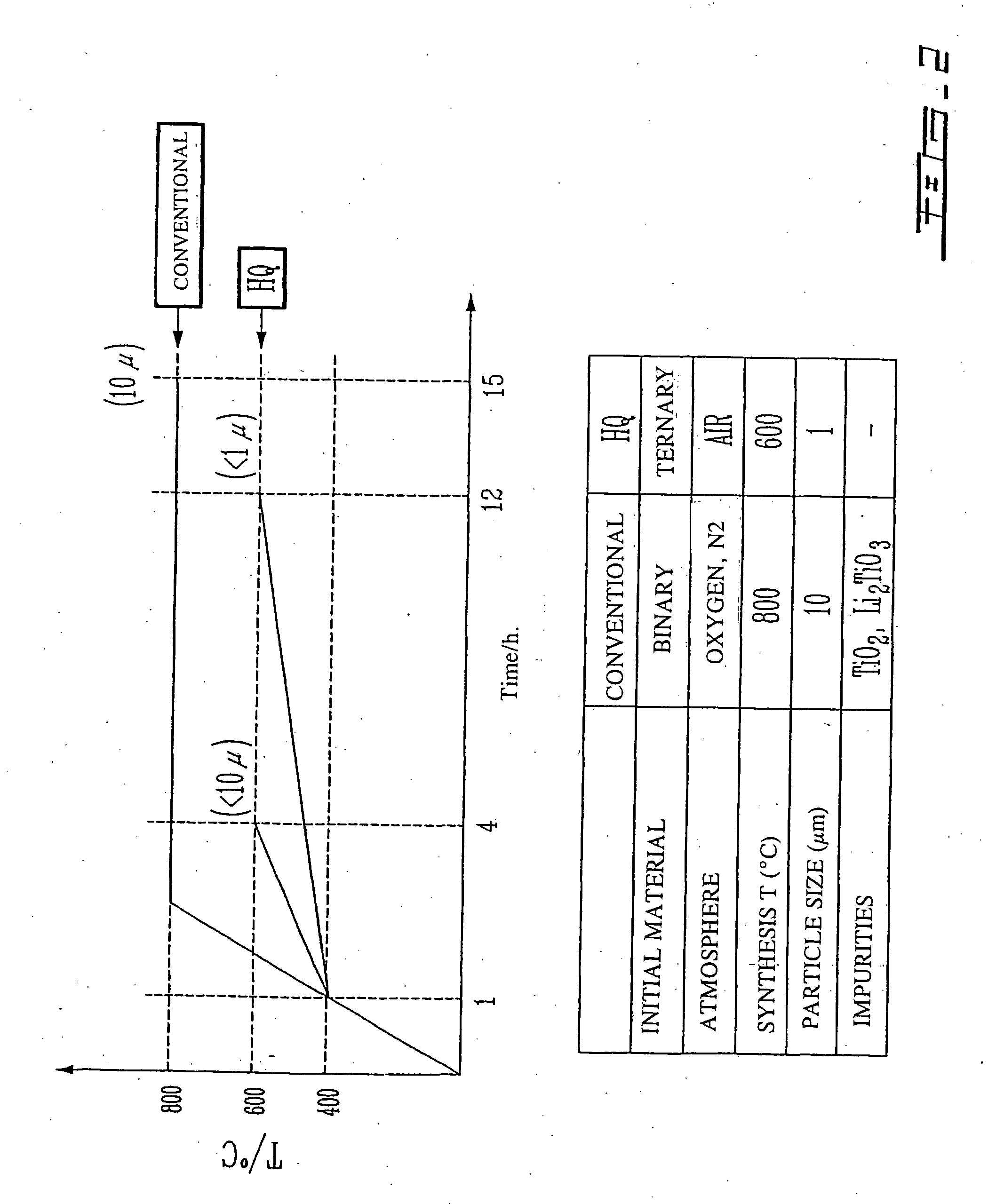

Li4Ti5O12, Li(4-alpha)Zalpha Ti5O12 or Li4ZbetaTi(5-beta)O12 particles, processes for obtaining same and use as electrochemical generators

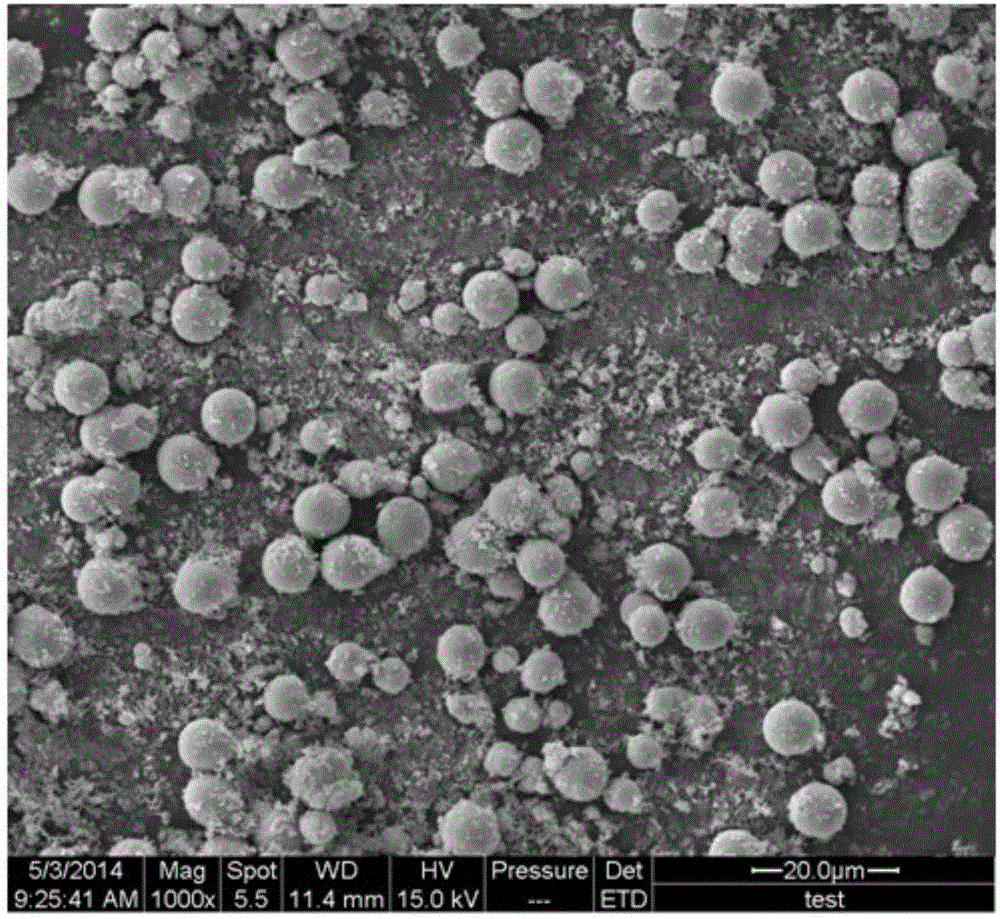

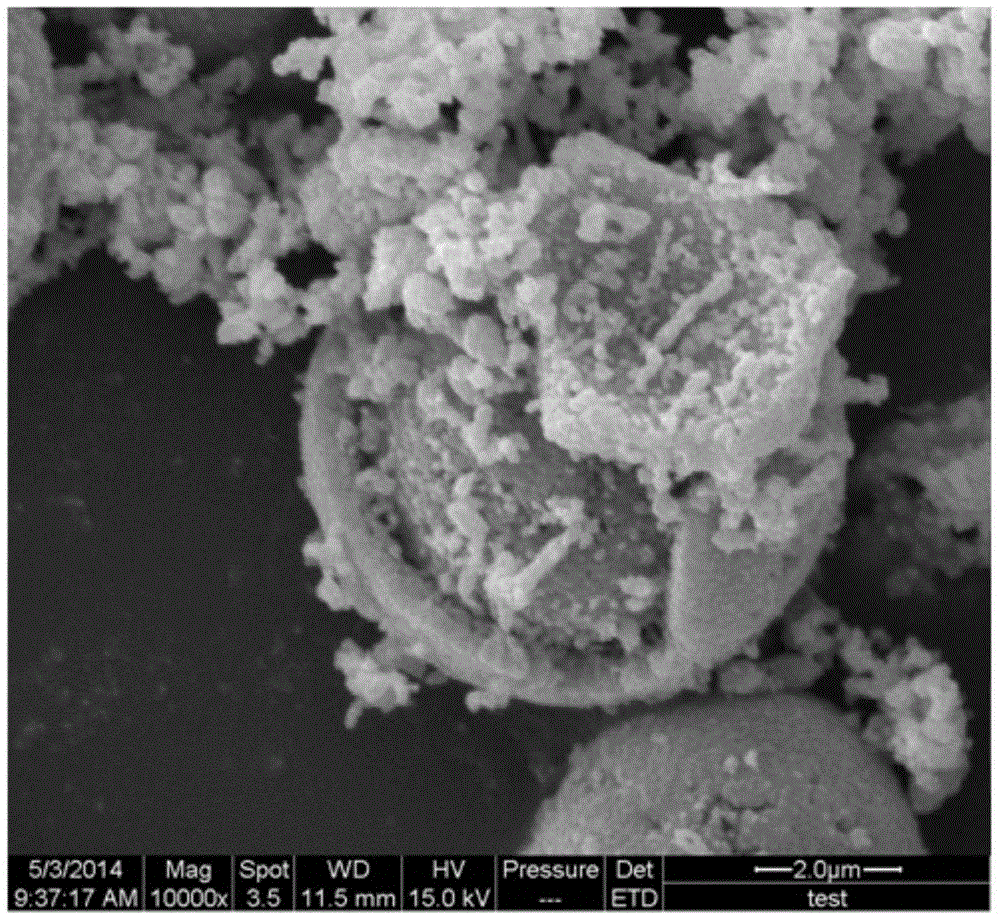

Synthesis process for new particles of Li4Ti5O12, Li(4-alpha)ZalphaTi5O12 or Li4ZbetaTi(5-beta)O12, preferably having a spinel structure, wherein beta is greater than 0 and less than or equal to 0.5 (preferably having a spinel structure), alpha representing a number greater than zero and less than or equal to 0.33, Z representing a source of at least one metal, preferably chosen from the group made up of Mg, Nb, Al, Zr, Ni, Co. These particles coated with a layer of carbon notably exhibit electrochemical properties that are particularly interesting as components of anodes and / or cathodes in electrochemical generators.

Owner:HYDRO QUEBEC CORP

Spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with core-shell structure and preparation method thereof

ActiveCN104157831APromote circulationRaise the ratioCell electrodesSecondary cellsComposite cathodeMaterial synthesis

The invention relates to a spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with a core-shell structure and a preparation method thereof, which belongs to the technical field of material synthesis. The prepared lithium ion composite cathode material takes a layered lithium-rich manganese-based Li[Lia(NixCoyMnz)]O2 as a core material, takes spinel nickel manganese acid lithium LiNi0.5Mn1.5O4 as a shell material; a coprecipitation method is employed to obtain a core-shell precursor, the core-shell precursor and the lithium source are uniformly mixed and calcined to obtain the spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with the core-shell structure. According to the invention, the layered lithium-rich manganese-based is taken as the core material, and the spinel nickel manganese acid lithium is taken as the shell material; under the prerequisite that material gram capacity is kept, material structural stability is increased, material cycle, multiplying power and safety performances are improved, function composite and complementation of the core material and the shell layer material can be realized, and the problem that high capacity and high security can not be achieved simultaneously is solved. The composite cathode material has the advantages of simple process and obviously increased performance.

Owner:南京时拓能源科技有限公司

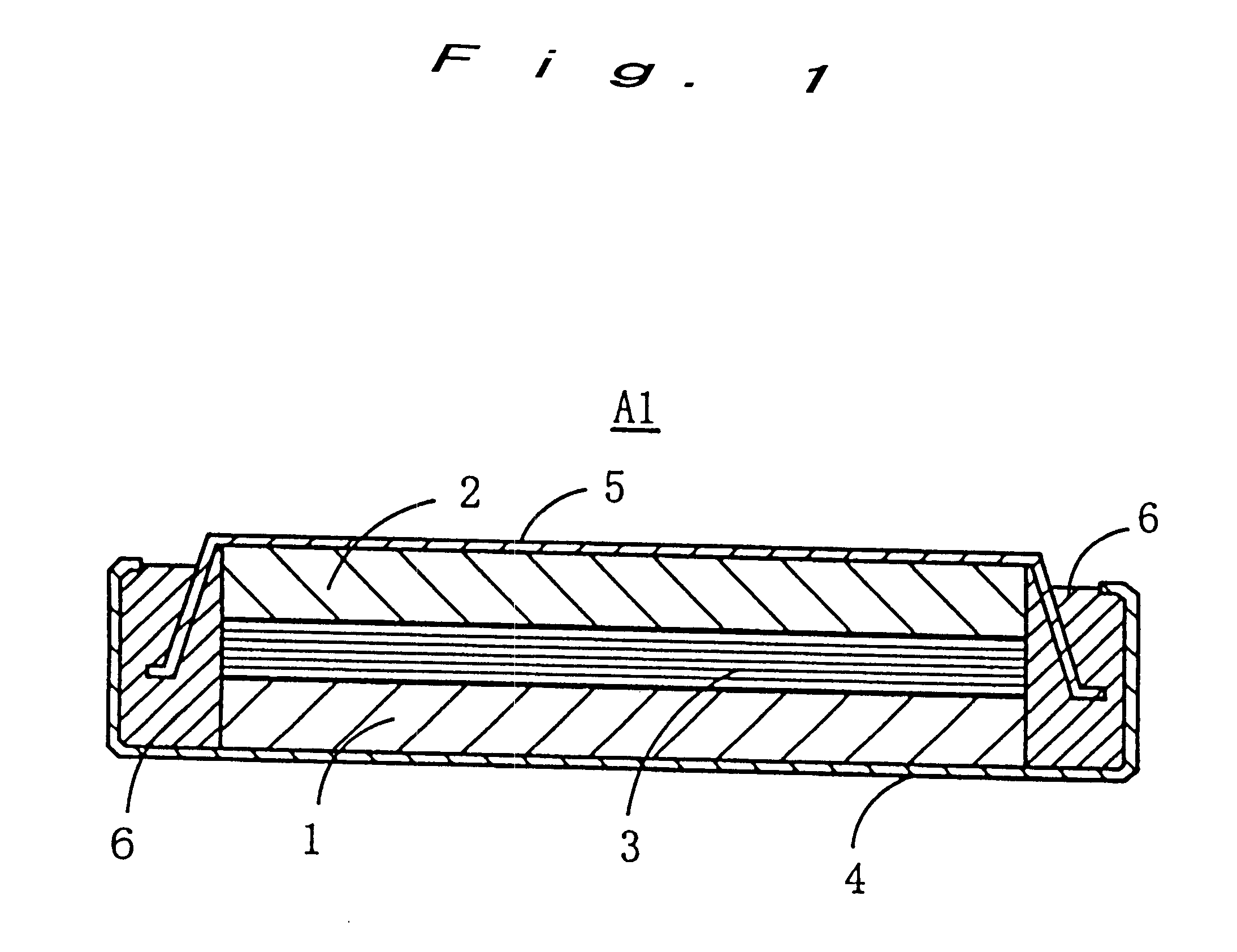

Lithium secondary battery

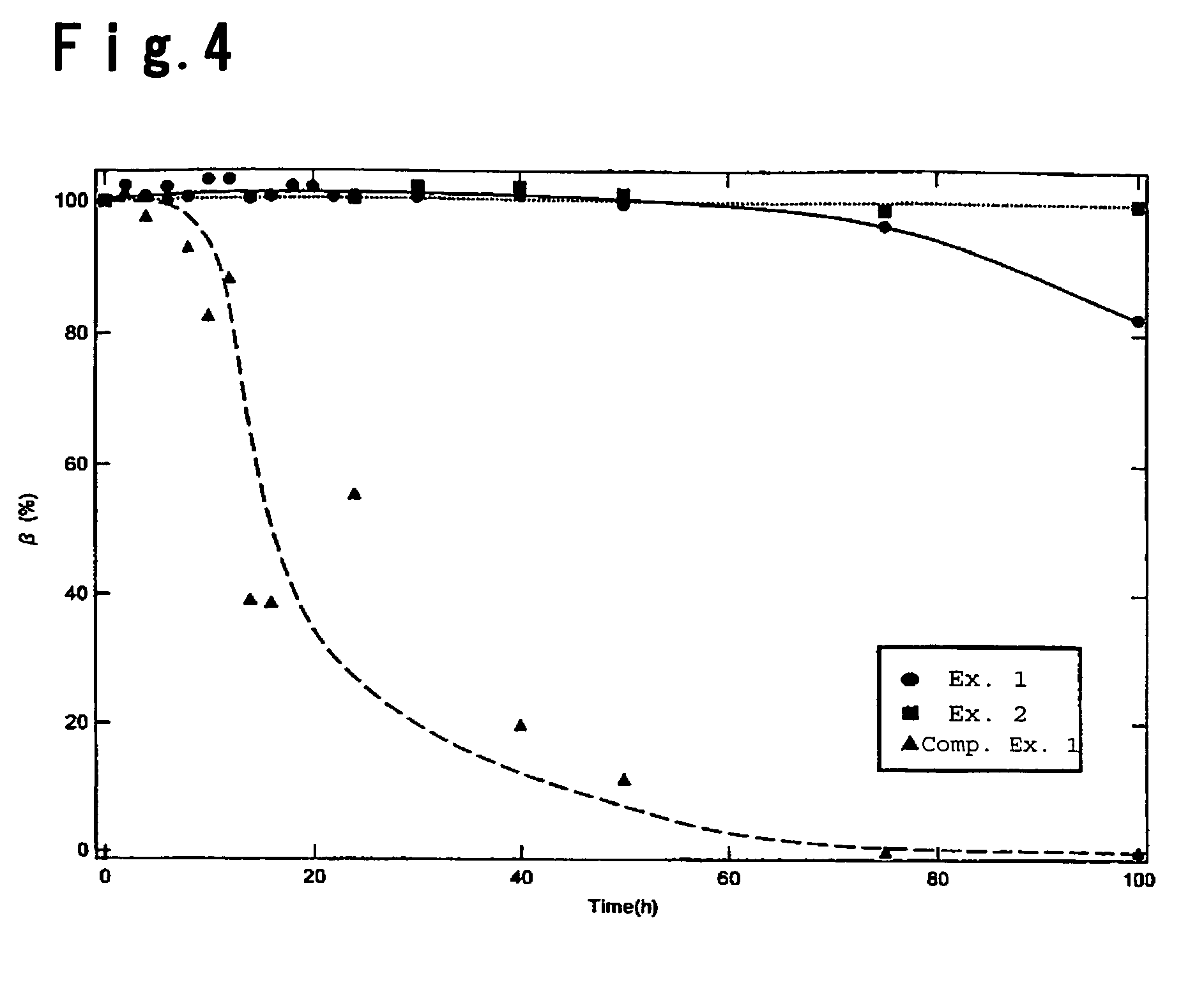

InactiveUS6337158B1Stable crystal structureRelieve pressureFuel cell auxillariesActive material electrodesCharge dischargeLithium-ion battery

A lithium secondary battery of this invention includes a positive electrode using, as an active material, a lithium-containing manganese composite oxide with a spinel structure having a composition, during charge and discharge, represented by a formula, Li.sub.x Mn.sub.2-y-z Ni.sub.y M.sub.z O.sub.4, in which M is at least one element selected from the group consisting of Fe, Co, Ti, V, Mg, Zn, Ga, Nb, Mo and Cu; 0.02.ltoreq..times..ltoreq.1.10, whereas x changes in accordance with occlusion and discharge of lithium ions during charge and discharge; 0.25.ltoreq.y.ltoreq.0.60; and 0<z.ltoreq.0.10. Thus, the invention provides a high-voltage lithium secondary battery exhibiting good charge-discharge cycle performance.

Owner:SANYO ELECTRIC CO LTD

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Preparation method of spinel-type magnetic MFe2O4/graphene composite material

InactiveCN102745675AHigh purityImprove bindingIron oxides/hydroxidesZinc oxides/hydroxidesNitrogen gasSolvent

The invention discloses a preparation method of a spinel-type magnetic MFe2O4 / graphene composite material. The preparation method utilizes a water-soluble metal M<2+> salt and a Fe<3+> salt as precursors and graphite oxide as a matrix and comprises the following steps of carrying out ultrasonic dispersion of graphite oxide in ethanol or water as a solvent to obtain a graphene oxide dispersion, adding a M<2+> salt and Fe<3+> salt-containing aqueous solution having a M<2+> / Fe<3+> mole ratio of 1: 2 into the graphene oxide dispersion, fully stirring to obtain a mixed solution, adjusting a pH value of the mixed solution to a value more than 10 by an alkali liquor, adding a reducing agent into the mixed solution, stirring at a temperature of 80 to 150 DEG C for a reaction lasting for 4 to 10 hours, after the reaction is finished, carrying out separation, washing, drying and grinding, and carrying out calcination of the grinded powder at a temperature of 300 DEG C in a nitrogen or argon atmosphere for 2 to 10 hours. Magnetic MFe2O4 nano particles of the spinel-type magnetic MFe2O4 / graphene composite material have high loading capacity, stable structures, good uniformity, good dispersibility and strong adhesion with graphene. The spinel-type magnetic MFe2O4 / graphene composite material can be widely used in the fields of magnetic targeting materials and other related function materials.

Owner:HEFEI UNIV OF TECH

Light-weight corundum-spinel castable and preparation method thereof

The invention relates to a light-weight corundum-spinel castable and a preparation method thereof. The preparation method includes following steps: (A) employing 60-75 wt% of equal-diameter micro-porous corundum spheres as an aggregate, and employing 8-12 wt% of electric-fused white corundum fine powder, 2-8 wt% of electric-fused magnesite fine powder, 2-8 wt% of magnesium aluminate spinel fine powder, 6-12 wt% of [alpha]-Al2O3 micro powder, 0.5-2.5 wt% of chromium oxide powder and 3-7 wt% of an aluminum silicone gel powder as substrate materials, wherein the aggregate and the substrate materials form a raw material in total; (B) employing organic fibers accounting for 0.02-0.08 wt% of the raw material and a polycarboxylate water reducer accounting for 0.05-0.12 wt% of the raw material as additive materials, pre-mixing the substrate material with the additive materials and adding the aggregate with uniform mixing; (C) adding water accounting for 3-5 wt% of the raw material, stirring the mixture and performing cast moulding; and (D) maintaining the temperature at 110-200 DEG C for 12-48 h, roasting the moulded product at 800-1200 DEG C for 24-72 h to obtain the light-weight corundum-spinel castable. The light-weight corundum-spinel castable is low in apparent porosity, is low in volume density, is low in heat conductivity, is strong in anti-slag-erosion capability and is long in service life.

Owner:WUHAN UNIV OF SCI & TECH

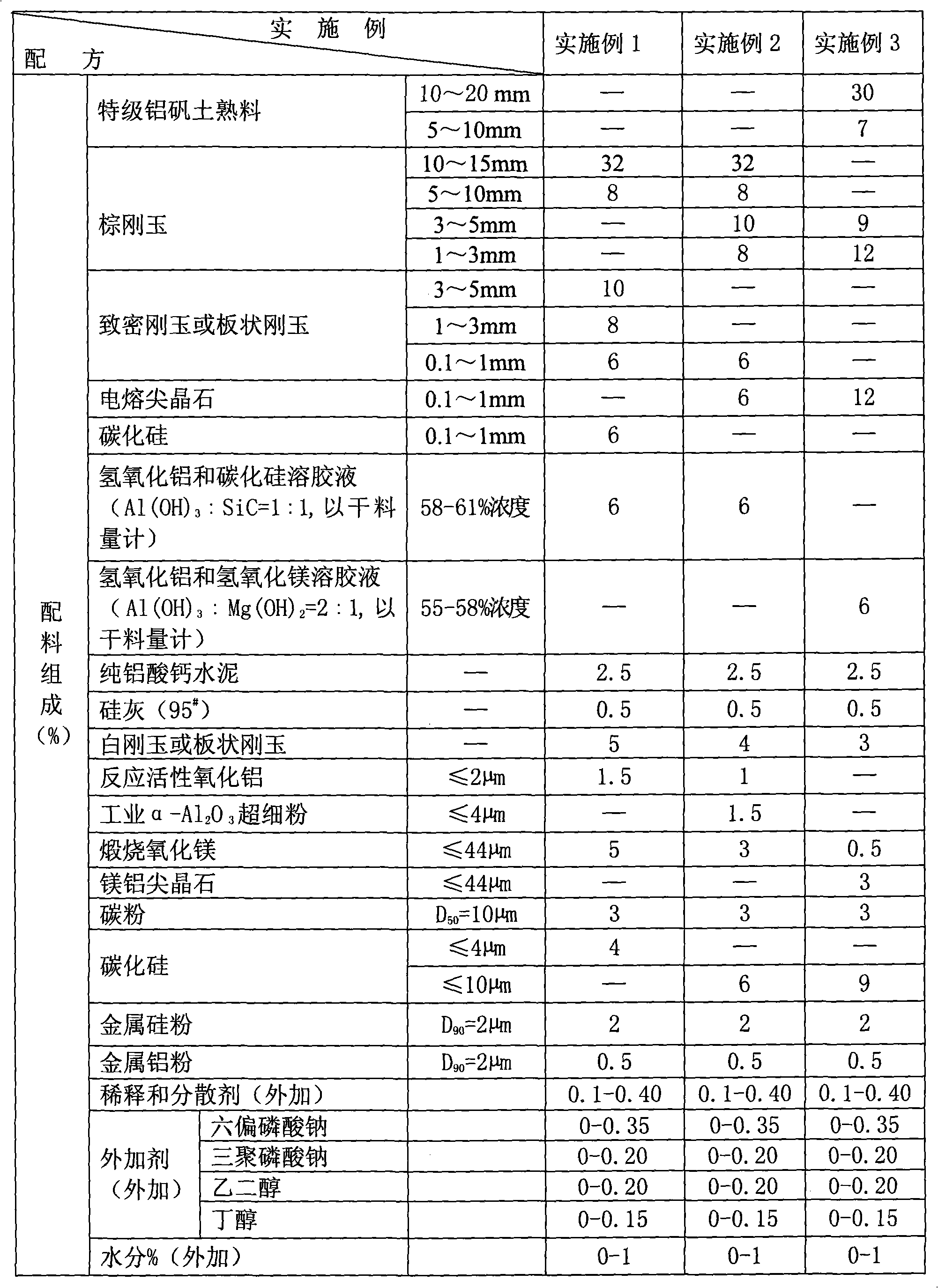

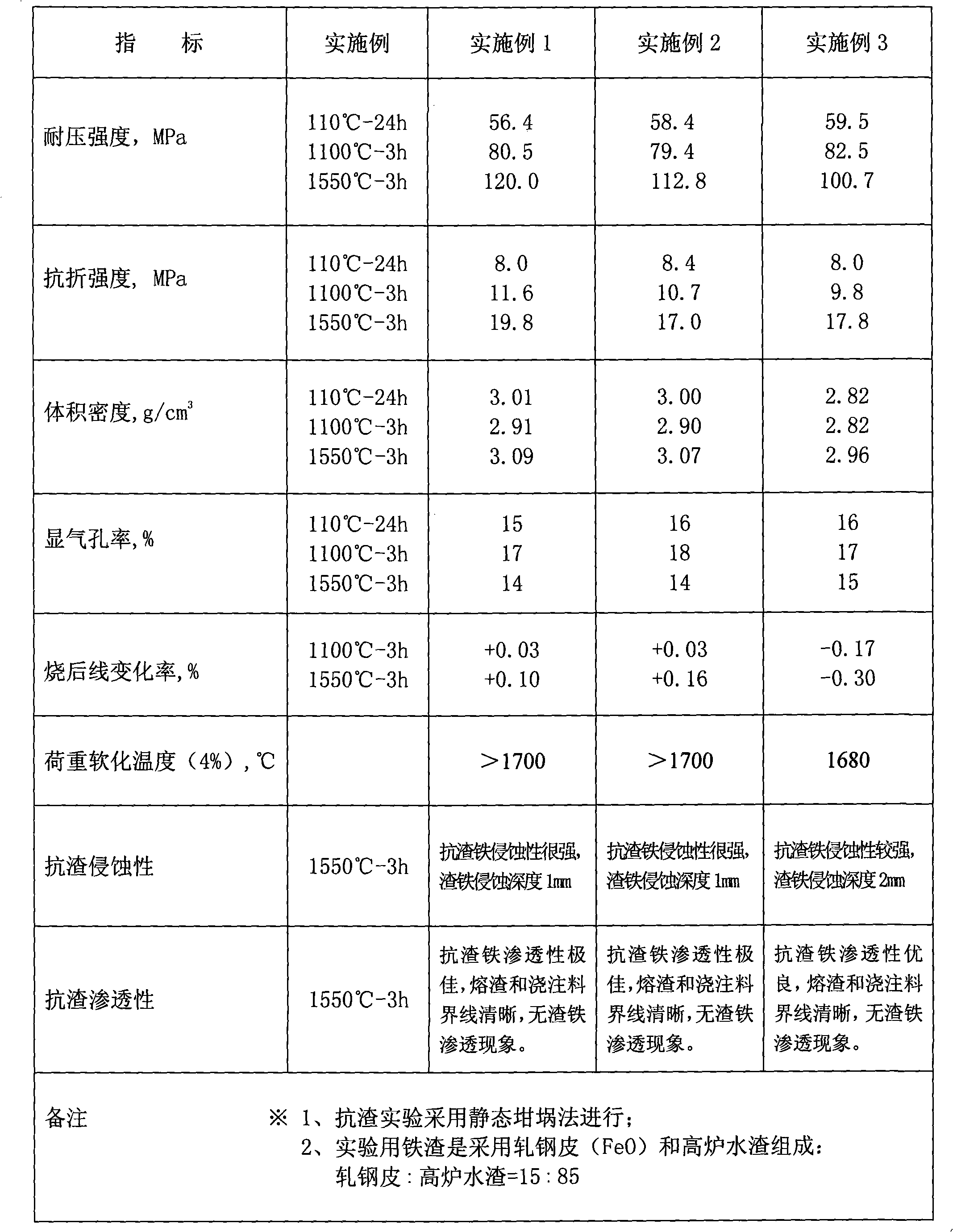

Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film and preparation method thereof

The invention relates to an Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film or nano Al2O3-MgO film, and a preparation method thereof. The preparation method of the nano carbon-containing castable material comprises: preparing carbon-containing sol suspension with Al(OH)3-SiC or Al(OH)3-Mg(OH)2 through a high-speed impact mixer, coating the carbon-containing sol suspension on the surface of carbon powder to form a compact carbon wrapping layer with complete coverage and no crack, and carrying in-situ synthesis of nano gel particles of Al2O3 and SiC or Al2O3 and MgO generated during transformation from sol to gel so as to generate a nano-sized matrix with carbon-containing nano secondary spinellite, Al2O3 and SiC as main crystalline phases, thereby completing the preparation of the Al2O3-MA-SiC-C refractory castable material made of nano material. The castable material has particularly excellent resistance against erosion and scouring of molten iron slag, and can satisfy the requirements for use in the iron tapping channel of the modern large-scale blast furnace. Moreover, the invention significantly prolongs the service life, reduces the cost and facilitates the environmental protection.

Owner:高树森

High-performance magnesium-aluminum-chromium composite spinel brick and manufacturing method thereof

The invention relates to a high-performance magnesium-aluminum-chromium composite spinel brick for RH refining furnace dip pipes and non-ferrous smelting furnaces. The high-performance magnesium-aluminum-chromium composite spinel brick is characterized by comprising the following raw materials: 14.0-20.0 parts of low-chromium fused magnesium chromium sand (6-8% of Cr2O3, at least 78% of MgO), 71.6-82.0 parts of high-purity fused magnesite, 2.0-4.4 parts of nano Cr2O3 powder, 2.0-4.0 parts of uf-Al2O3 micropowder and 2-4 parts of binder. The manufacturing method comprises the following steps: mixing, molding, drying, firing and the like. The magnesium-aluminum-chromium composite spinel brick provided by the invention has the advantages of high sintering tendency, high crystal compactness, low porosity (at most 10%), high compressive strength (at least 100 MPa), high thermal shock stability (at least 18 times by 1100 DEG C water cooling) and the like. The Cr2O3 content of the product isat most 6%, thereby reducing the Cr2O3 content in the brick, lowering the production cost and finally effectively reducing the environmental pollution of waste magnesium-chromium bricks after use.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

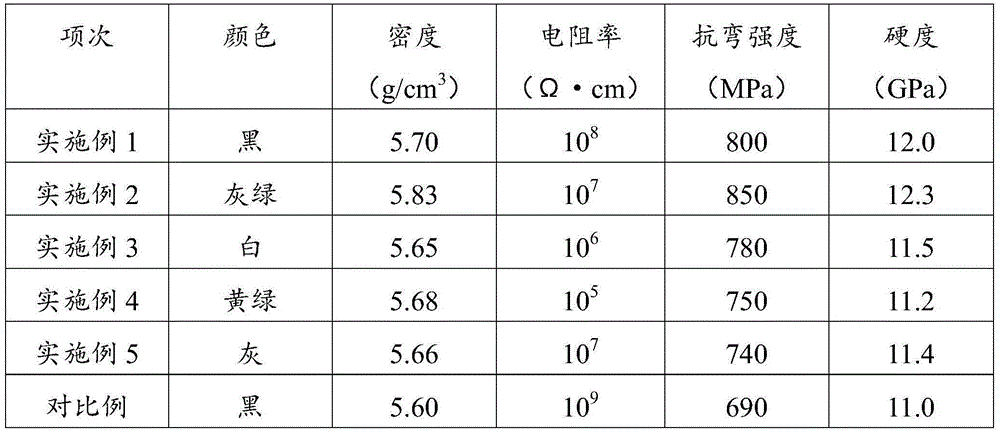

Zirconium oxide composite ceramic and preparation method thereof

InactiveCN106145938AEvenly distributedImprove mechanical propertiesComposite ceramicConductive materials

The invention relates to a zirconium oxide composite ceramic and a preparation method thereof. The zirconium oxide composite ceramic is prepared from, by mass, 65%-80% of a zirconium oxide matrix, 10%-30% of a conducting material and 2%-11% of a nanometer reinforcing material; the conducting material is selected from at least one of a non-ferrous metal oxide, a white metal oxide, a compound with a titanium structure and a compound with a spinel structure, wherein the non-ferrous metal oxide is selected from at least one of CuO, Cu2O, V2O5, NiO, MnO, MnO2, CoO, Co2O3, Co3O4, Fe2O3, FeO, Fe3O4 and Cr2O3, and the white oxide is selected from at least one of ZnO, SnO2 and TiO2; the compound with the titanium structure is selected from at least one of CaTiO3, BaTiO3, LaCrO3, LaSr(0.1)Cr(0.9)O3, SrTiO3 and LaFeO3, and the structural formula of the compound with the spinel structure is AB2O4, wherein A is selected from at least one of Mg, Fe, Zn and Mn, and B is selected from at least one of Al, Cr and Fe. The zirconium oxide composite ceramic is excellent in antistatic property and high in mechanical property.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

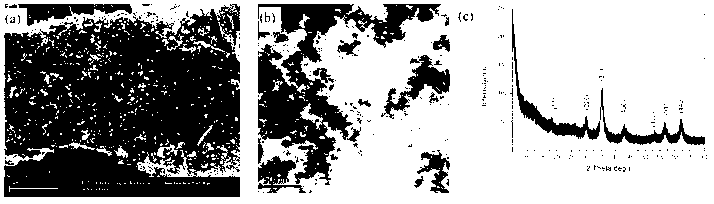

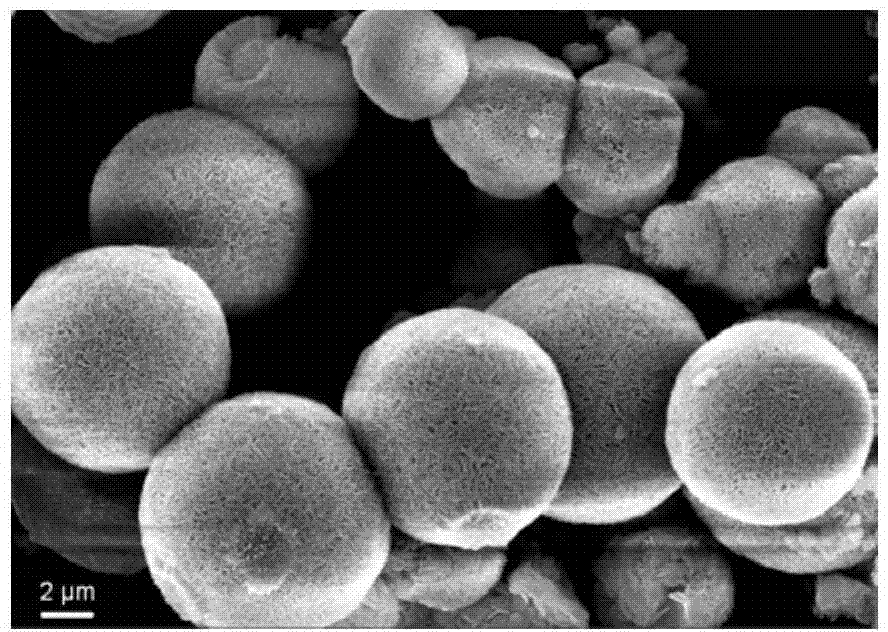

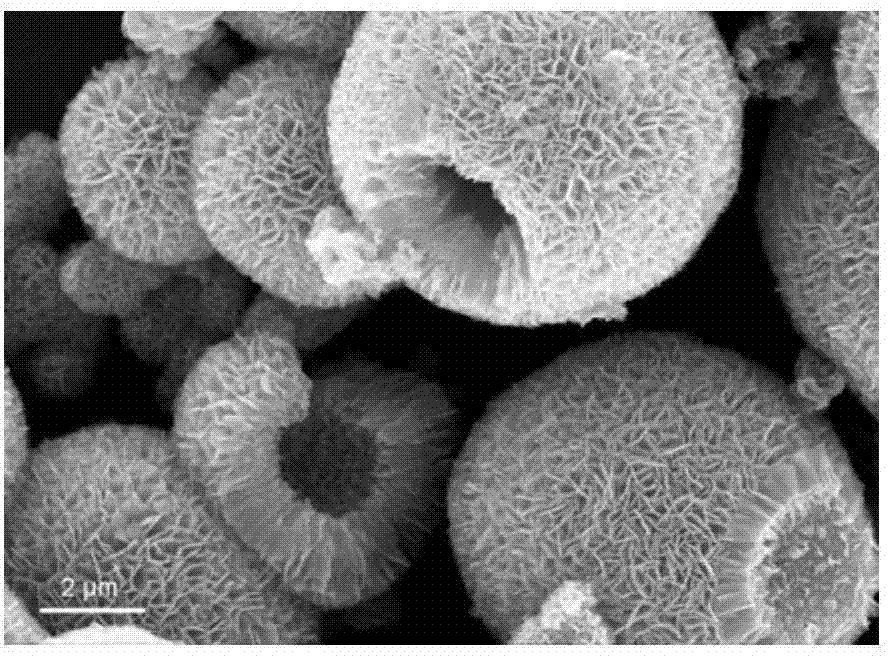

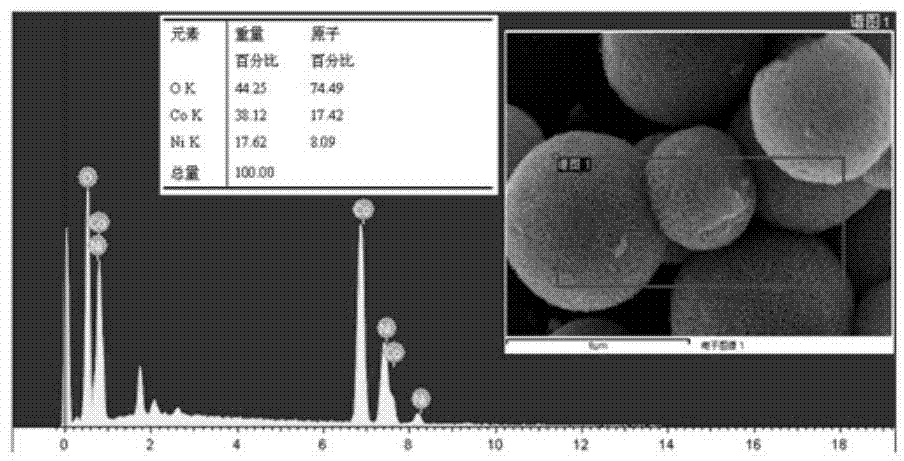

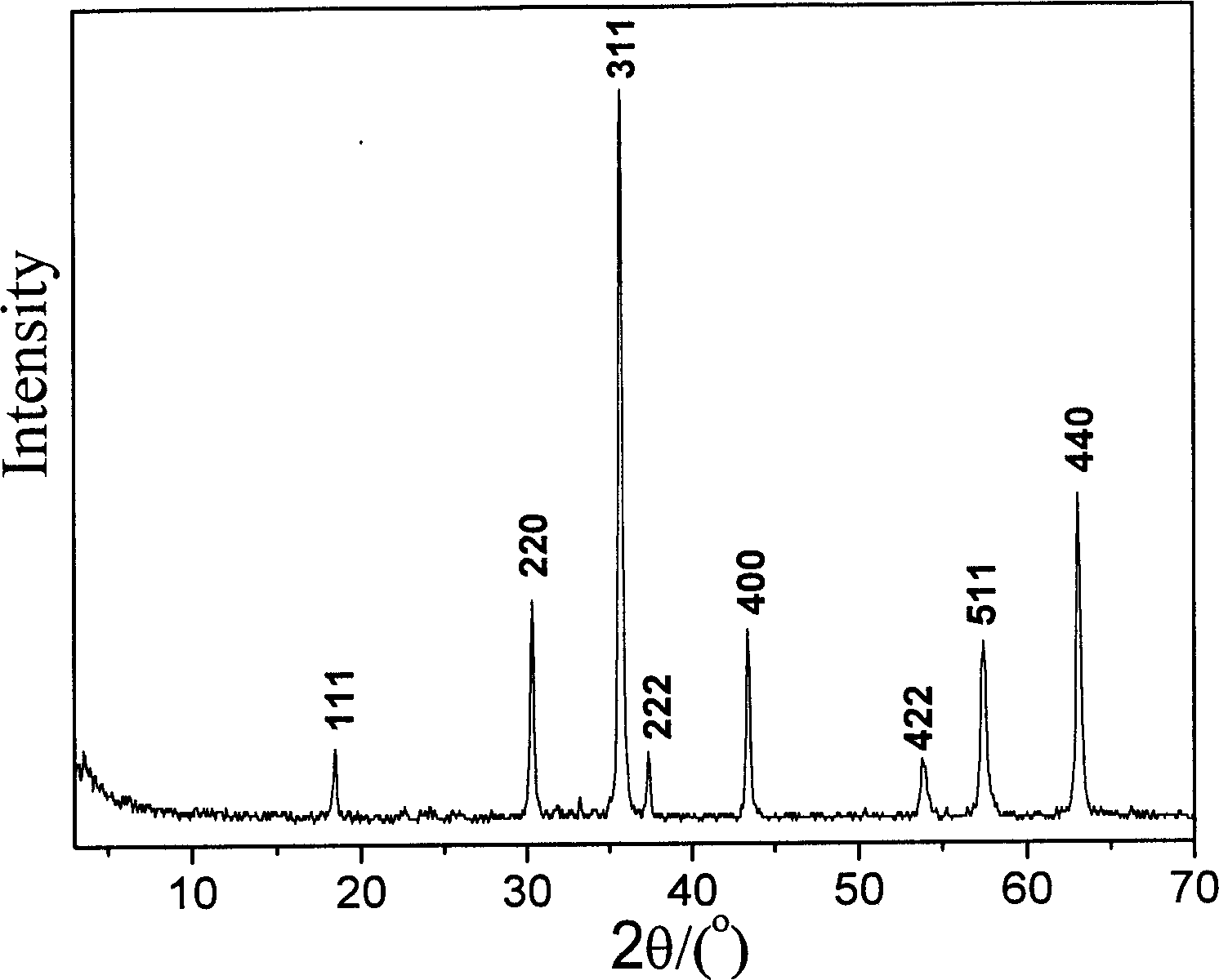

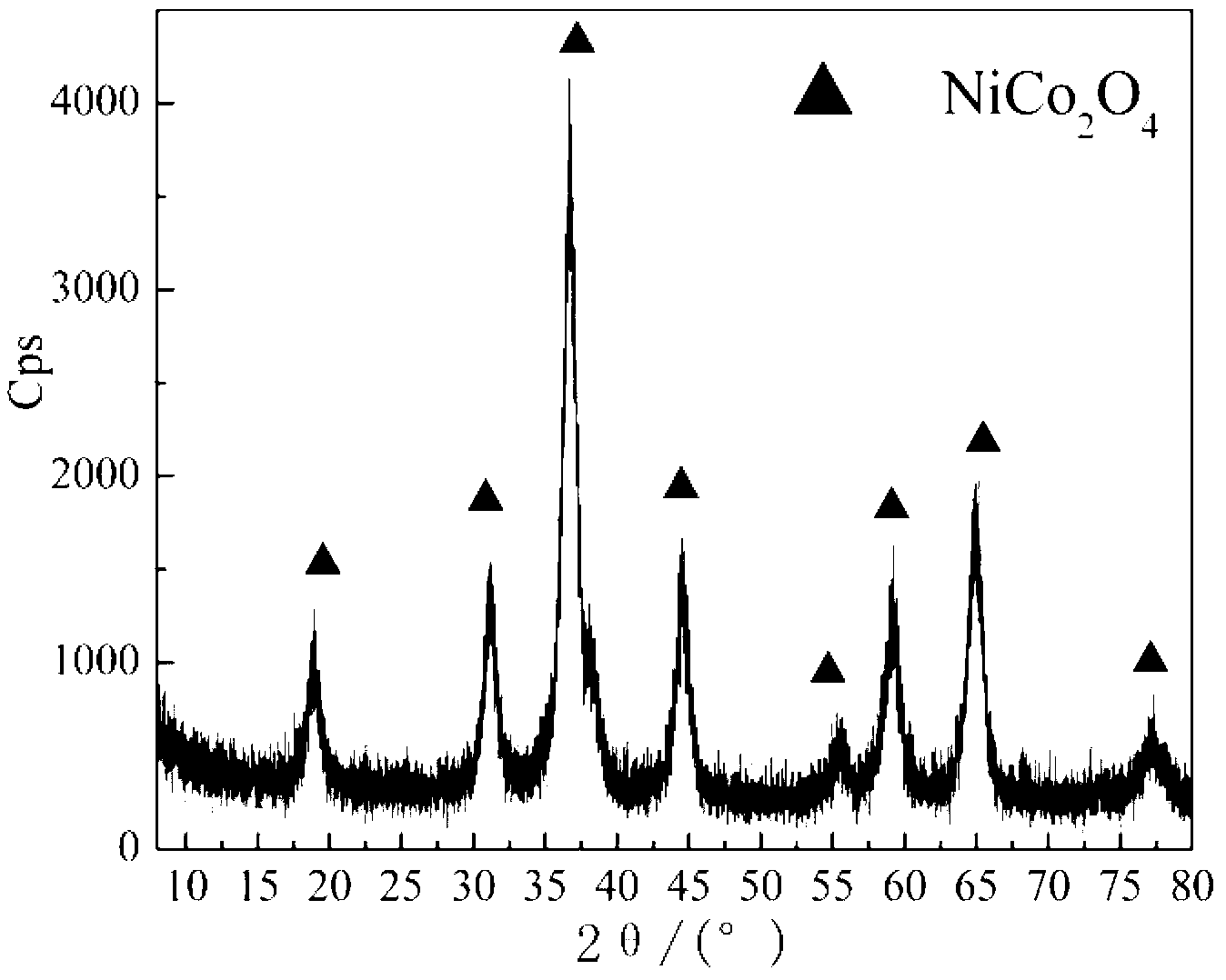

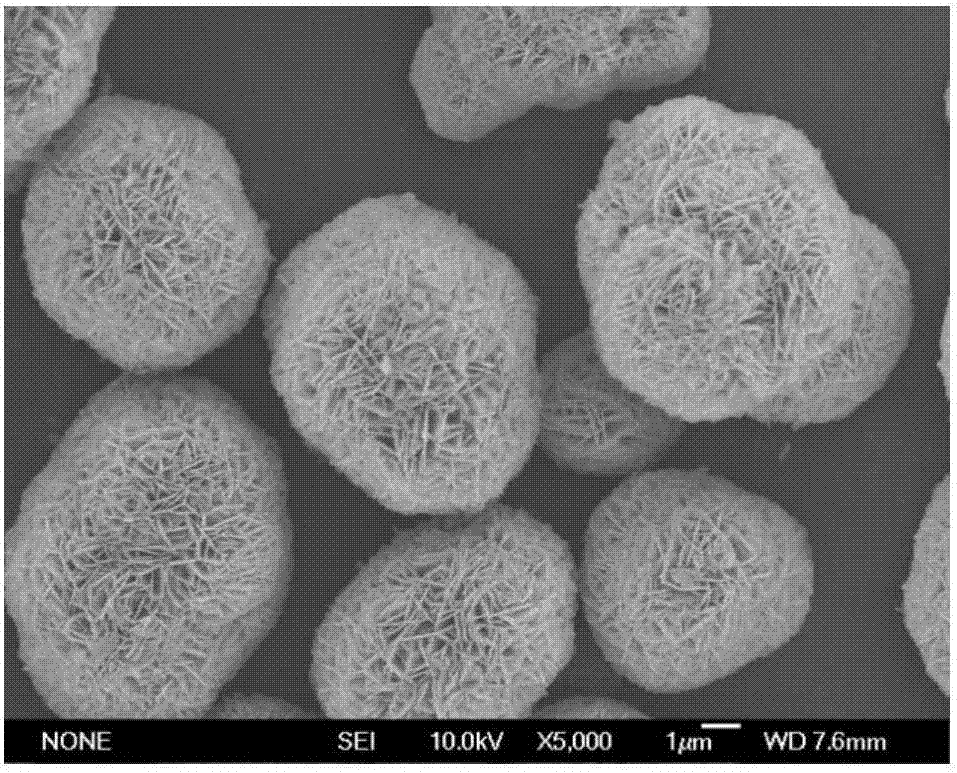

Preparation method of three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres

InactiveCN104773764AEasy to operateGood experimental reproducibilityMaterial nanotechnologyNickel compoundsAir atmosphereNano catalyst

The invention relates to a preparation method of three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres, and relates to the technical field of multi-level structured nano-grade catalyst materials. First, nickel nitrate hexahydrate and cobalt nitrate hexahydrate are adopted as a nickel source and a cobalt source, a deionized water-isopropanol mixed phase with a proper proportion is adopted as a solvent, methanol is adopted as a reactant, and no additional base precipitating agent is adopted; a three-dimensional flower-shaped nano-sheet microsphere precursor is prepared in a Ni<2+>-Co<2+>-NH3-NH4<+>-SG<n->-H2O-IPA-CH3OH system (SG<n-> is CO3<2-> or HCOO<->); the temperature is increased to 300-400 DEG C in an air atmosphere with a speed of 1 DEG C / min, and the precursor is calcined for 2-3h, such that the three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres are obtained. According to the invention, co-precipitation of the formulated cobalt and nickel in the raw materials is realized. The prepared three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres are spinel cubic phases with high purity, and are formed by ultrathin nano-sheet self-assembly. The microspheres comprise rich mesopores, and have a large specific surface area. The method has the advantages of simple operation, appropriate conditions and easy control.

Owner:BEIJING UNIV OF CHEM TECH

Spinel type composite metal oxide electrode material and preparing process thereof

InactiveCN1719642AHigh specific capacitanceGood electrochemical cycle performanceElectrode manufacturing processesFinal product manufactureSolid phasesMetal oxide electrode

This invention provides a spinel compound metal oxide electrode material and its preparation method, in which, the composition of the electrode material is Mfe204, M is one element or composition of any two elements in Co, Ni Cu and Fe of +2 valence transition metal elements. Taking compound metal oxide M-Fe2+-Fe3+|-LDHs as the precursor and M is one element or composition of any two elements in Co, Ni, Cu, Fe elements, the electrode material is got by baking them under a certain temperature, compared with carbon materials, said electrode material has higher mass ratio capacity and volume ratio capacity.

Owner:BEIJING UNIV OF CHEM TECH

Cobalt-based catalyst for fischer-tropsch synthesis

Owner:INST FR DU PETROLE +1

Glass-ceramic materials having a predominant spinel-group crystal phase

Disclosed are glass-ceramics having predominantly Spinel-group crystal phases and methods of making the glass-ceramics. Disclosed are glass-ceramics harder than 10 GPa (Vickers) and methods of making the glass-ceramic. Disclosed are articles of manufacture made of the glass-ceramics. Disclosed is the use of the glass-ceramics in armor and related applications.

Owner:D&D SALOMON INVESTMENT

Catalytic compositions useful in removal of sulfur compounds from gaseous hydrocarbons, processes for making these and uses thereof

A catalytic composition is disclosed, which exhibits an X-ray amorphous oxide, with a spinel formula and highly dispersed crystals of ZnO, CuO, and optionally CeO2. The composition is useful in oxidative processes for removing sulfur from gaseous hydrocarbons.

Owner:SAUDI ARABIAN OIL CO +1

Catalyst for decomposing nitrous oxide, process for producing the same and method for decomposing nitrous oxide

The invention relates to a catalyst for decomposing nitrous oxide, which is [1] a catalyst comprising a support having supported thereon aluminum, magnesium and rhodium, [2] a catalyst comprising an alumina support having supported thereon magnesium and rhodium, [3] a catalyst comprising a support having supported thereon rhodium, the support comprising a spinel crystalline composite oxide formed by magnesium and at least a part of aluminum, [4] a catalyst comprising a support having supported thereon aluminum, rhodium and at least one metal selected from zinc, iron, manganese and nickel, [5] a catalyst comprising an alumina support having supported thereon rhodium and at least one metal selected from zinc, iron, manganese and nickel, or [6] a catalyst comprising a support having supported thereon rhodium, the support comprising a spinel crystalline composite oxide formed by at least a part of aluminum and the at least one metal selected from zinc, iron, manganese and nickel. The catalyst is not easily deteriorated in the activity due to moisture, favored with low-temperature decomposition activity and capable of reducing the amount of NOx generated to the allowable concentration or less. The invention also relates to a process for producing the catalyst and to a method for decomposing nitrous oxide.

Owner:SHOWA DENKO KK

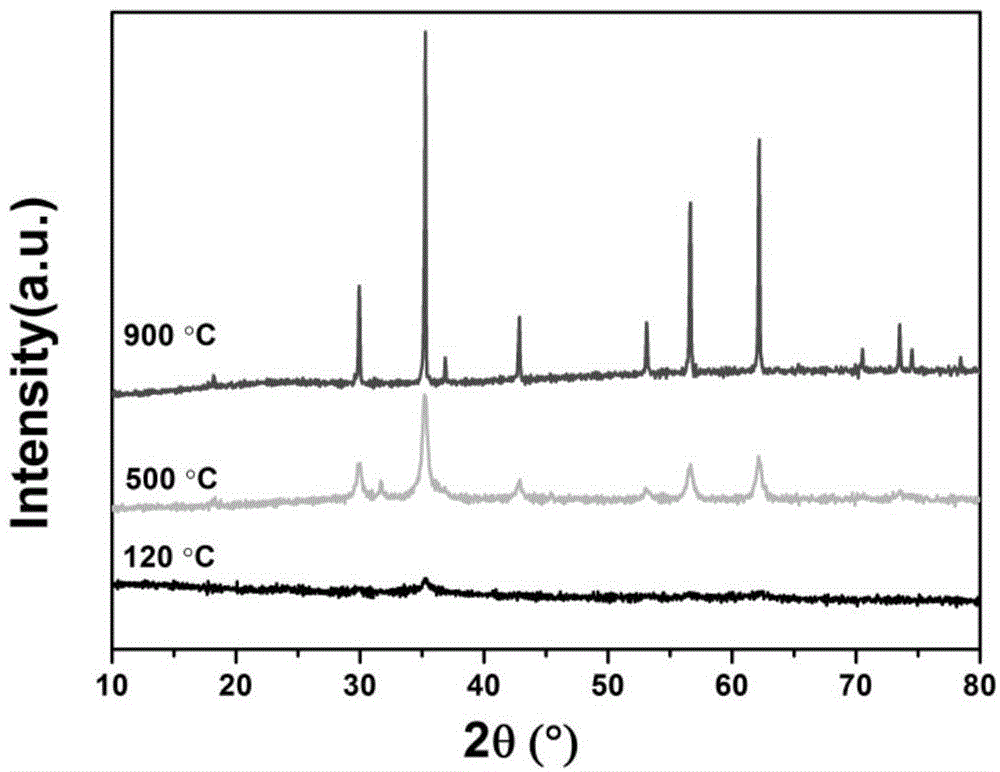

Ferrite/metal oxide material and preparation method and application thereof

InactiveCN106140173AHigh activityImprove stabilityWater/sewage treatment by irradiationWater contaminantsFenton reactionAir atmosphere

The invention provides a ferrite / metal oxide material and a preparation method and application thereof. The ferrite / metal oxide material is a composite material of ferrite or ferrite-metal oxide, wherein the ferrite is of a spinel structure, a formula is MFe2O4, the metal oxide is one or more of Fe2O3 and metal M oxides, and M is one or more of Zn, Co, Mn, Cu and Ni. The preparation method comprises the steps that an iron precursor and a metal M precursor are dissolved in an organic solvent, and heating and stirring are performed; an aqueous hydrogen peroxide solution is added, stirring continues to obtain sol, and drying is performed under the condition of 120-150 DEG C; under a nitrogen or air atmosphere, calcination is performed at the temperature of 200-900 DEG C for 4-6 hours to obtain the ferrite / metal oxide material. The obtained product is small in particle size and controllable in composition, the preparation method is simple in process, and the ferrite / metal oxide material has a very good effect when serving as a catalyst to activate PMS and degrade organic pollutants in light-like fenton reaction and has an industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

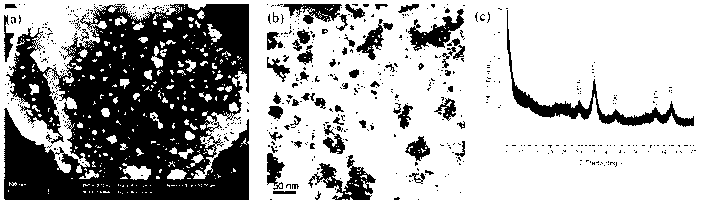

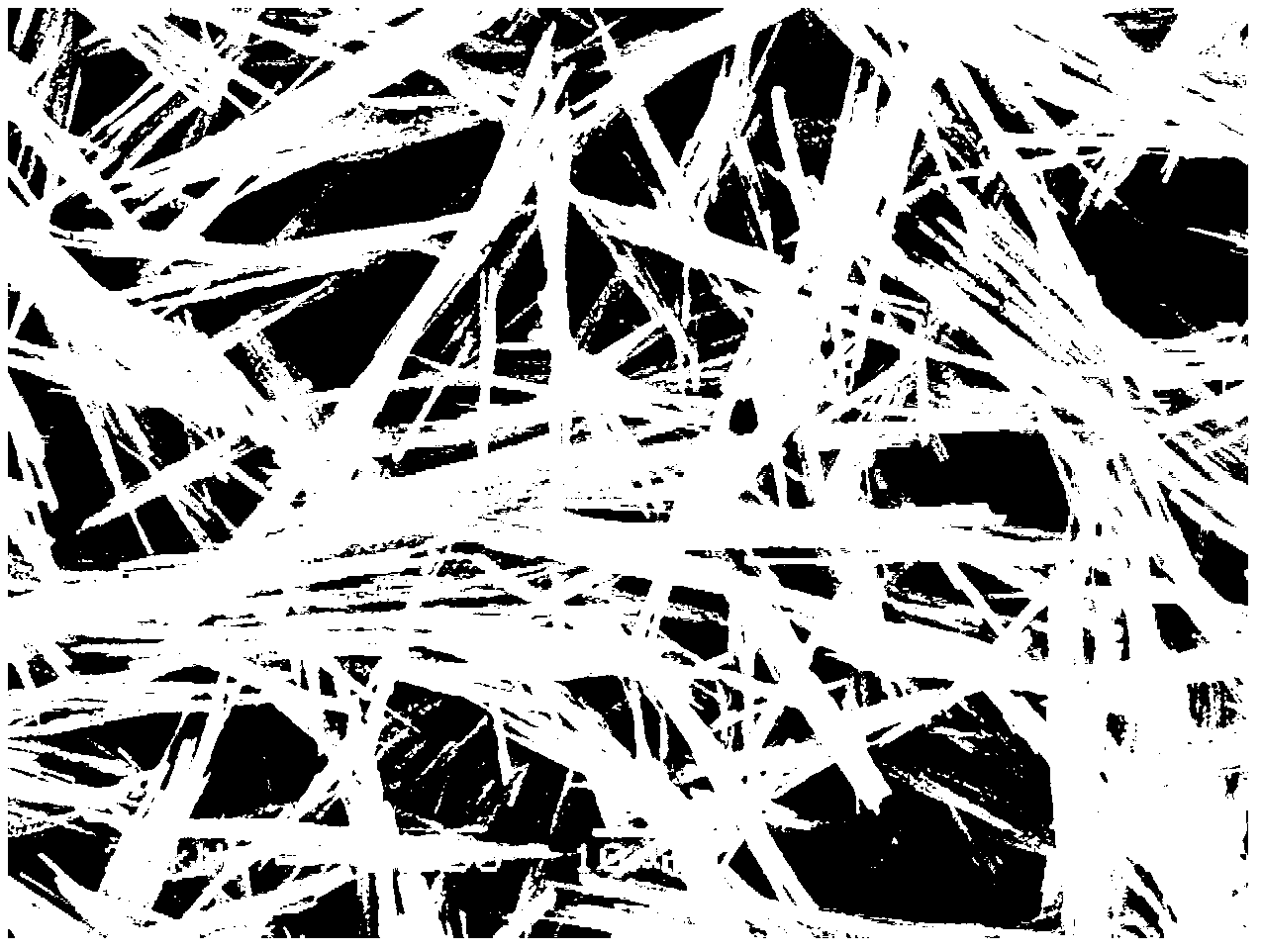

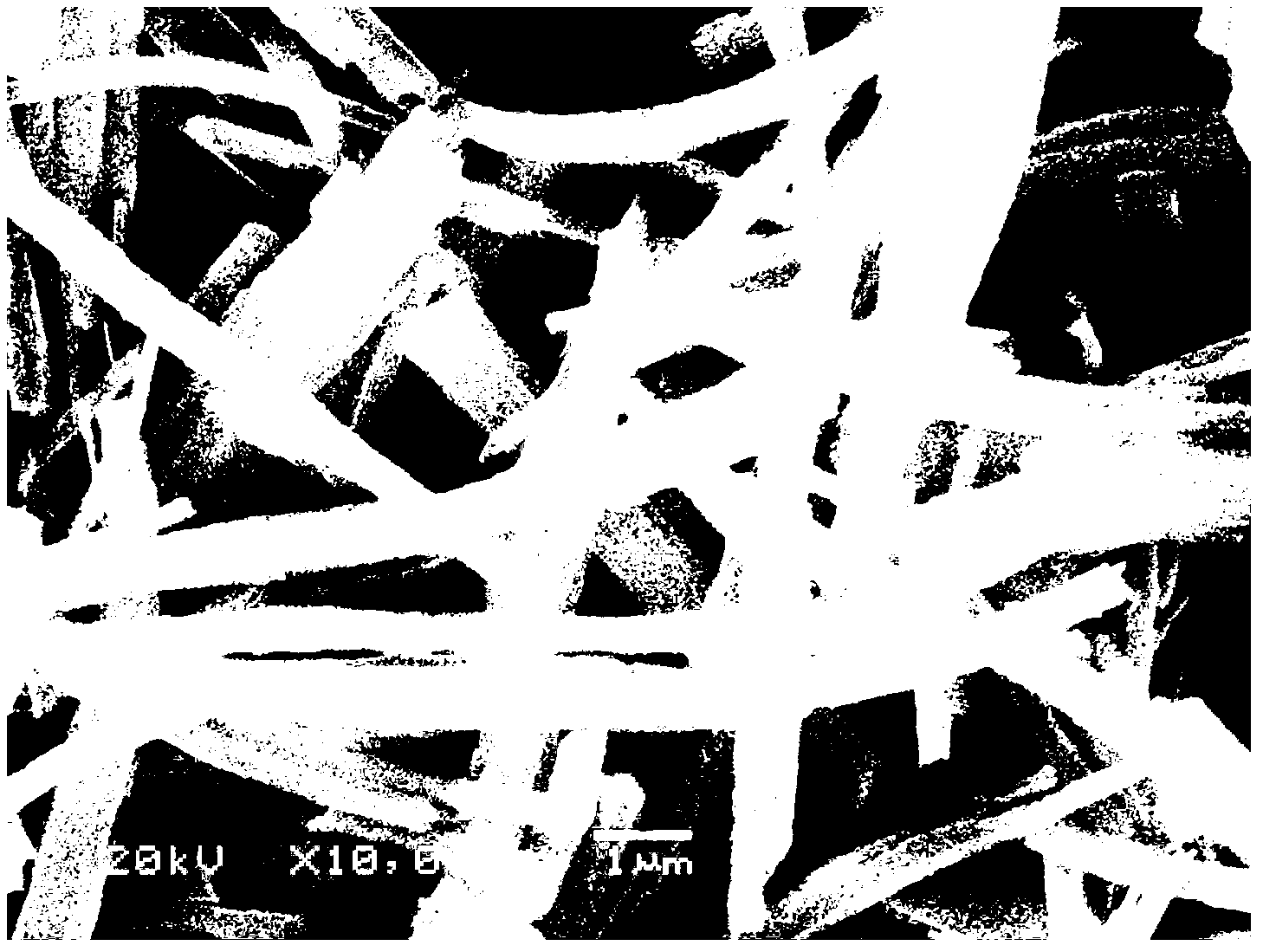

Preparation method of mesoporous nickel cobaltate fiber and application thereof

ActiveCN103318978AEasy to operateGood experimental reproducibilityCell electrodesNickel compoundsFiberAir atmosphere

The invention brings forward a preparation method of mesoporous nickel cobaltate fiber. According to the preparation method, an organic solvent is added during the preparation process of a precursor; a mixed phase of a water phase and an organic phase is used as a solvent, soluble nickel salt and cobalt salt are used as raw materials, and oxalate is used as a precipitating agent; in a system of Ni<2+>-Co<2+>-NH3-NH4<+>-SG<n->-C2O4<2->-H20-C2H5OH, a fibrous precursor is prepared; and the fibrous precursor is subjected to thermal decomposition in the air atmosphere at 250-400 DEG C so as to obtain the mesoporous NiCo2O4 fiber. According to the invention, coprecipitation based on the Ni-Co ratio set in the raw materials is effectively realized. The prepared NiCo2O4 powder is a cubic phase, has high purity and large specific surface area, is fibrous and porous, and is applicable to be used as a catalyst or an alkaline solution oxygen-evolution / hydrogen-evolution electrode material or direct alcohol fuel cell anode catalyst. The method provided by the invention is simple to operate and easy to control, has advantages of mild condition and low cost, and is suitable for commercialized production.

Owner:CENT SOUTH UNIV

Composite spinel-zirconium refractory material for smelting colored heavy metal

The invention discloses a composite spinel-zirconium refractory material for smelting colored heavy metal. The technical scheme is as follows: the material comprises 30-45 parts of 5mm-0mm emery, 10-30 parts of 5mm-0mm magnesia chromite clinker,15-25 parts of 3mm-1mm magnalium spinel clinker, 7-20 parts of 3mm-0mm magnesite clinker, 1-5 parts of chrome green less than or equal to 0.045mm and 2-8 parts of zirconium dioxide less than or equal to 0.045mm by weight part and a bonding agent is aluminium dihydrogen phosphate liquid the adding amount of which is 3-15% of the total weight of the emery, the magnesia chromite clinker, the magnalium spinel clinker, the magnesite clinker, the chrome green and the zirconium dioxide. A hydraulic press is adopted for molding and the composite spinel-zirconium refractory material is sintered by a hyperthermia tunnel kiln. The content of Cr2O3 of the composite spinel-zirconium refractory material is less than 10%, so that the composite spinel-zirconium refractory material not only is environment-friendly, but also has better slag erosion resistance, high-temperature melt washing resistance, metal melt permeation resistance and thermal shock stability performance.

Owner:辽宁青花耐火材料股份有限公司

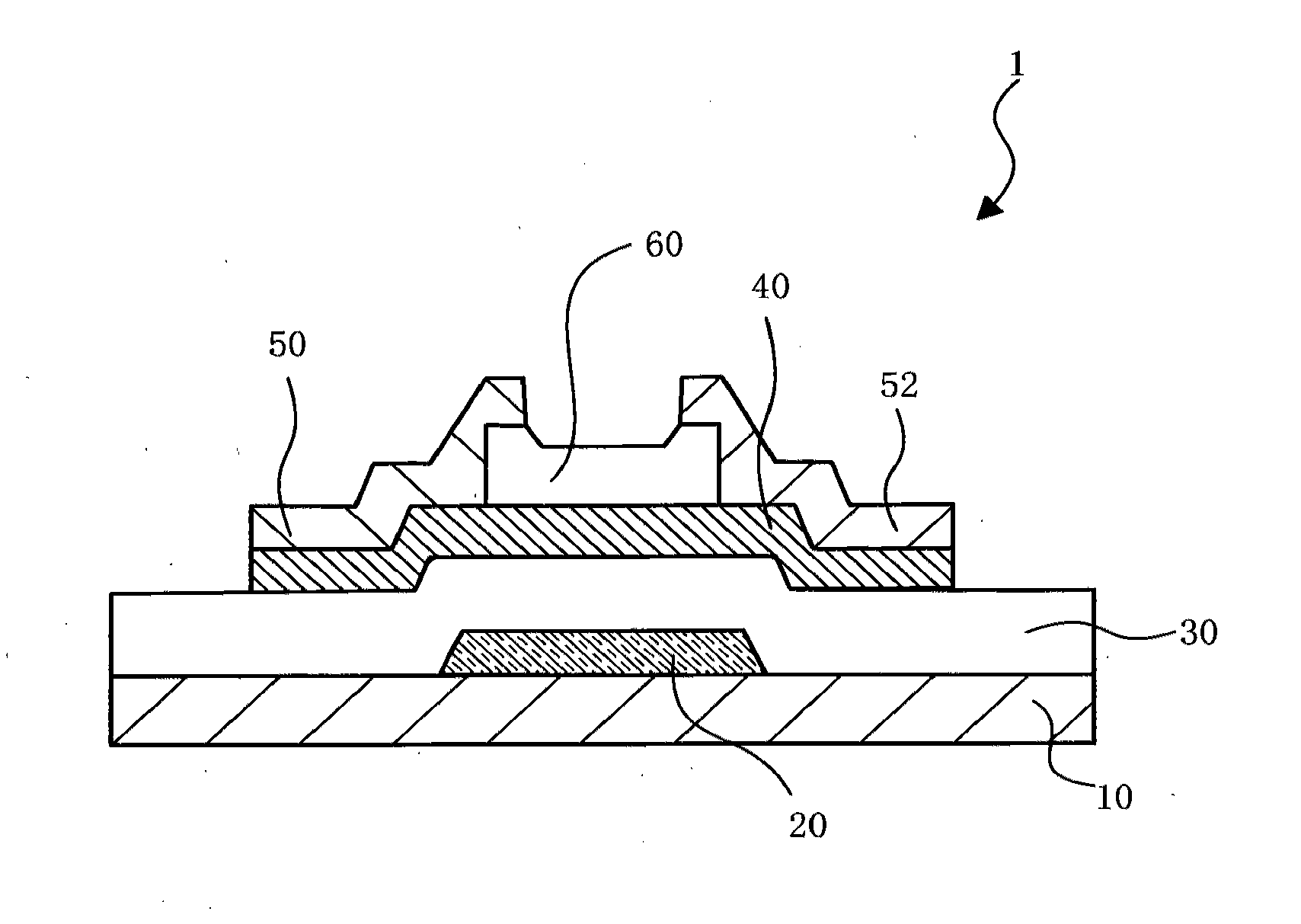

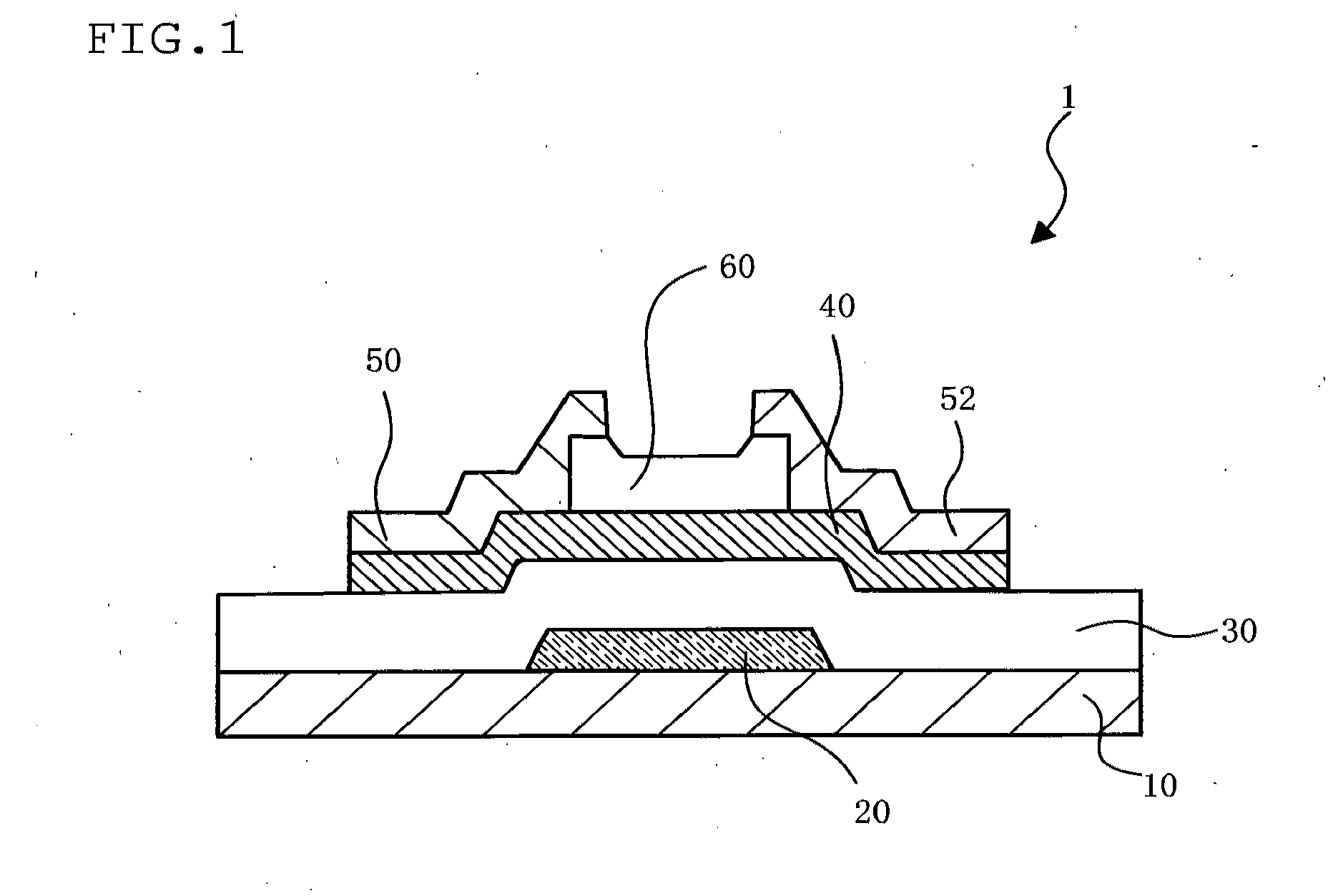

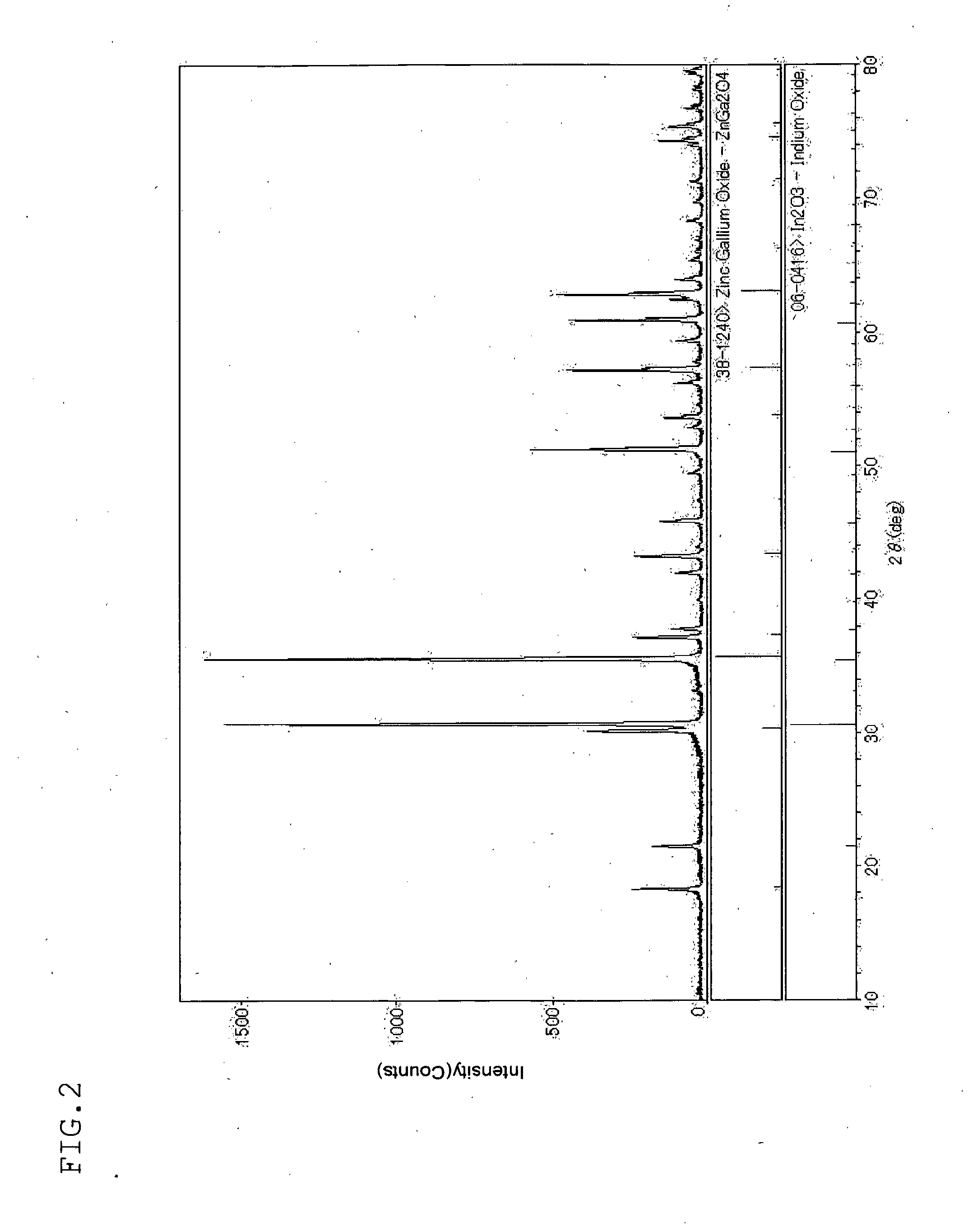

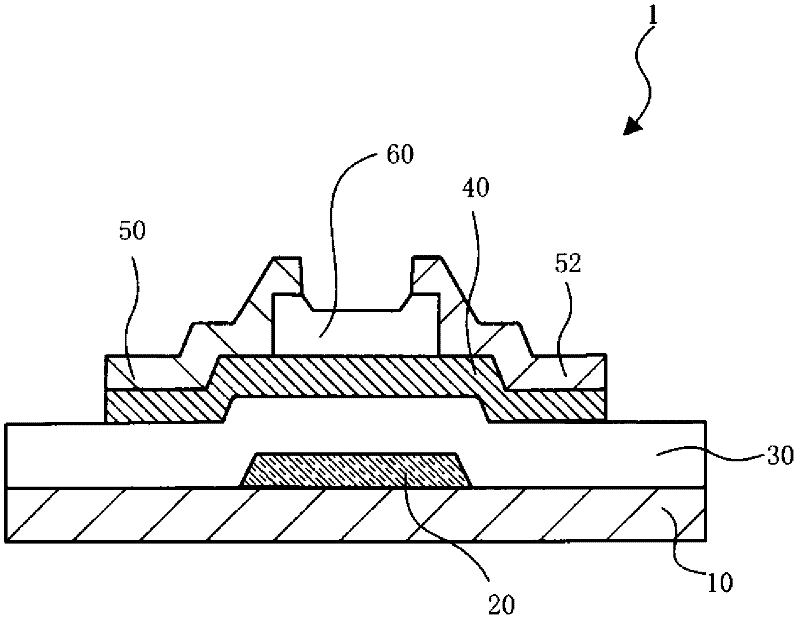

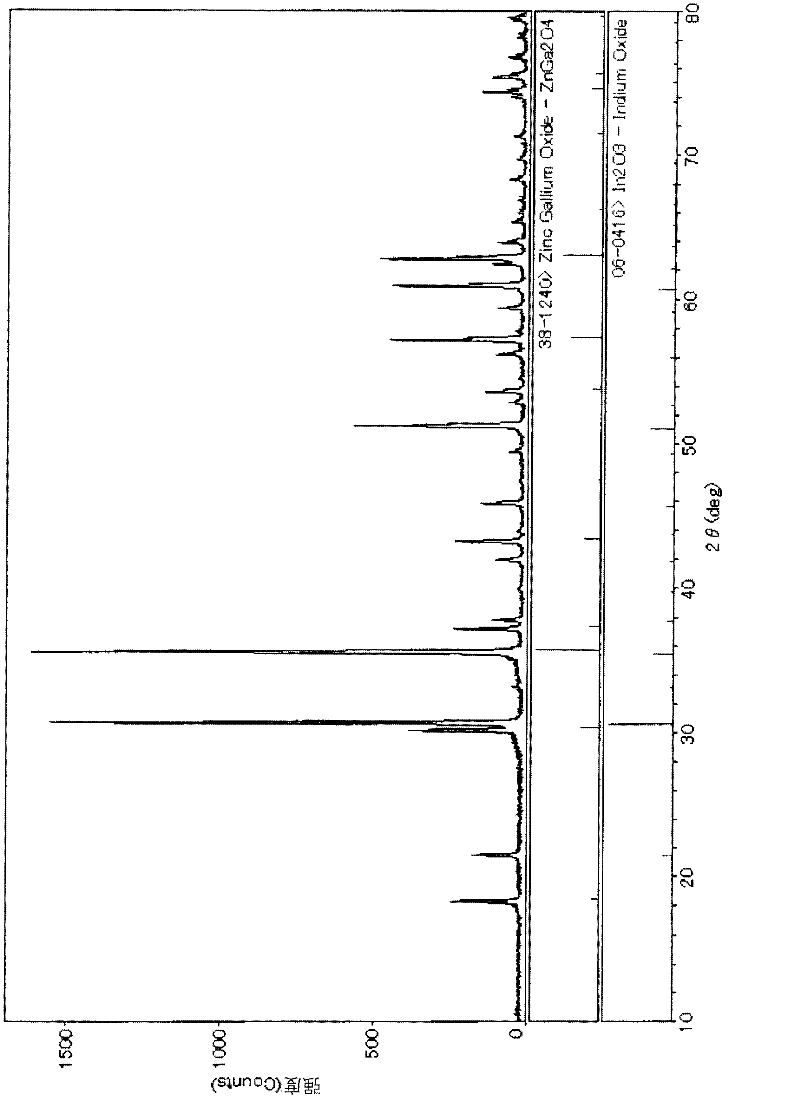

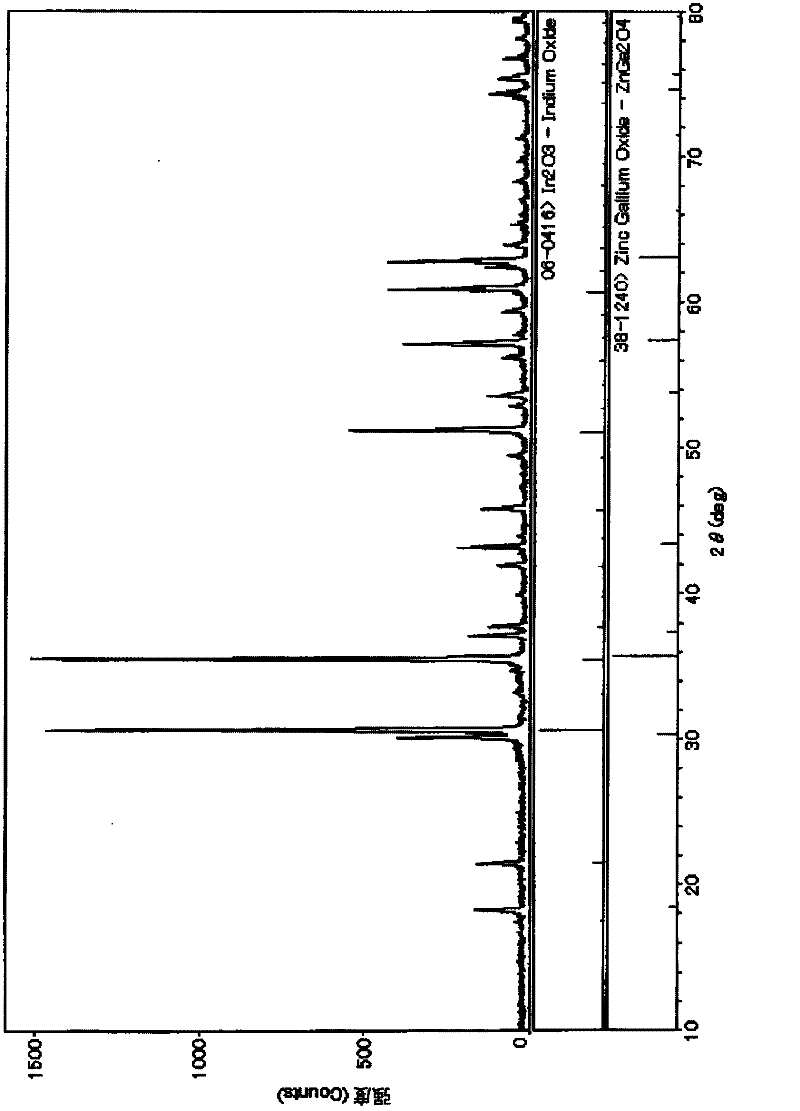

SINTERED In-Ga-Zn-O-TYPE OXIDE

InactiveUS20120184066A1Improve developmentLow resistivityCellsVacuum evaporation coatingIndiumOxygen

An oxide sintered body including In (indium element), Ga (gallium element) and Zn (zinc element), having a total content of In, Ga and Zn relative to total elements except for an oxygen element of 95 at % or more, and including a compound having a bixbyite structure represented by In2O3 and a compound having a spinel structure represented by ZnGa2O4.

Owner:IDEMITSU KOSAN CO LTD

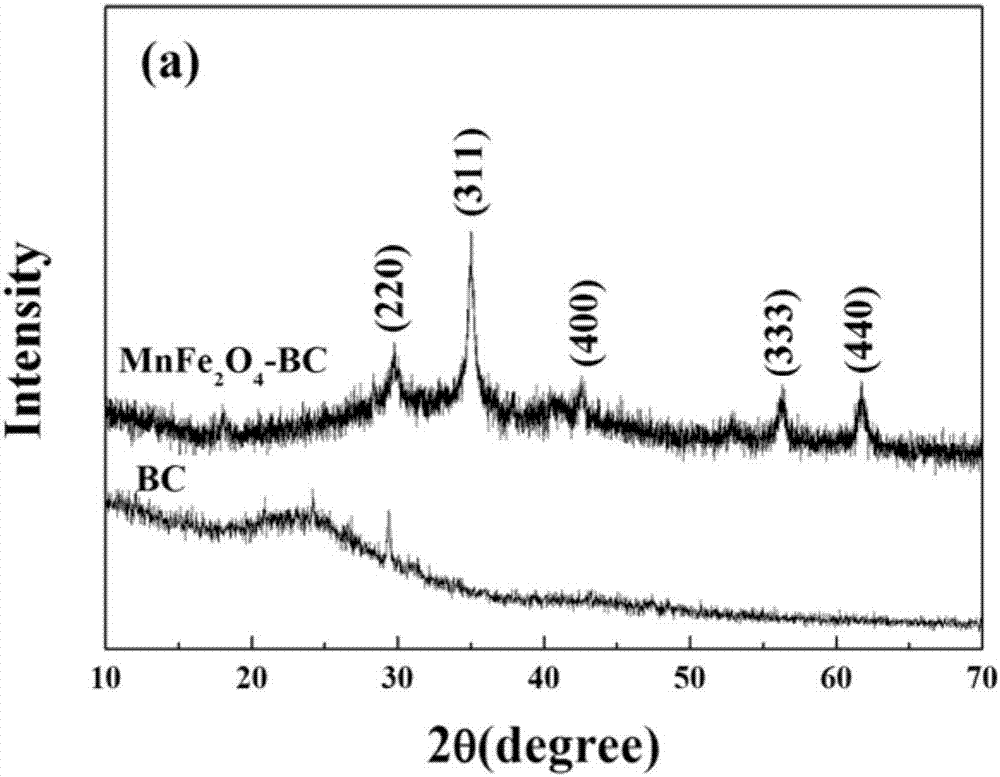

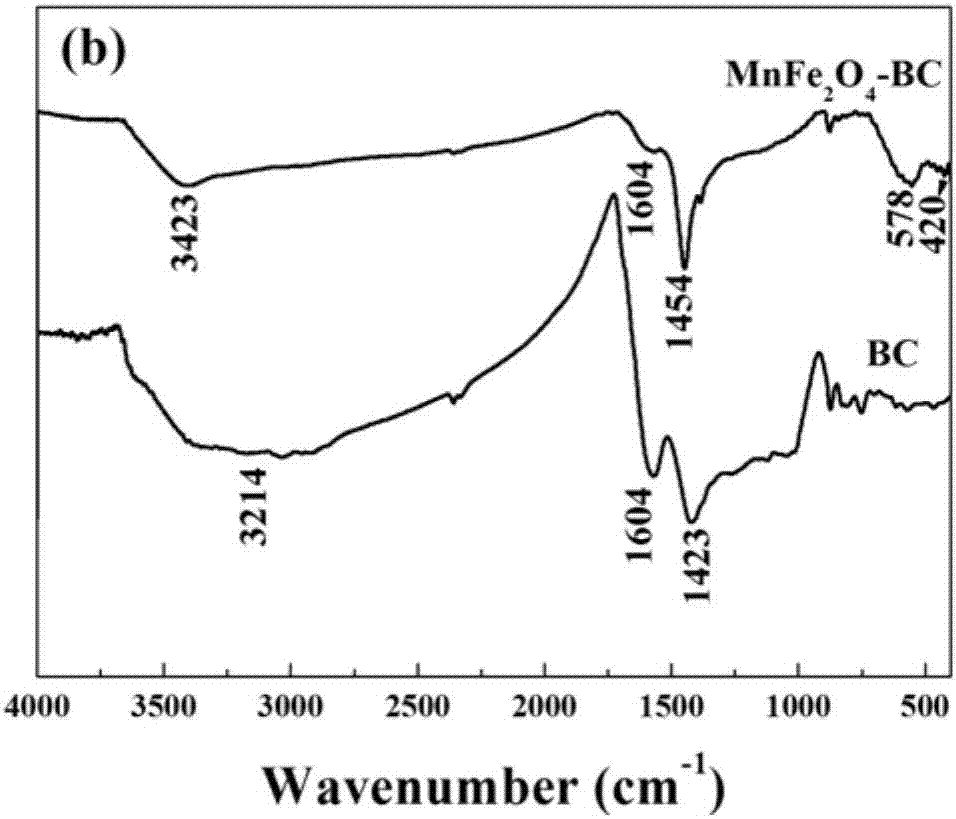

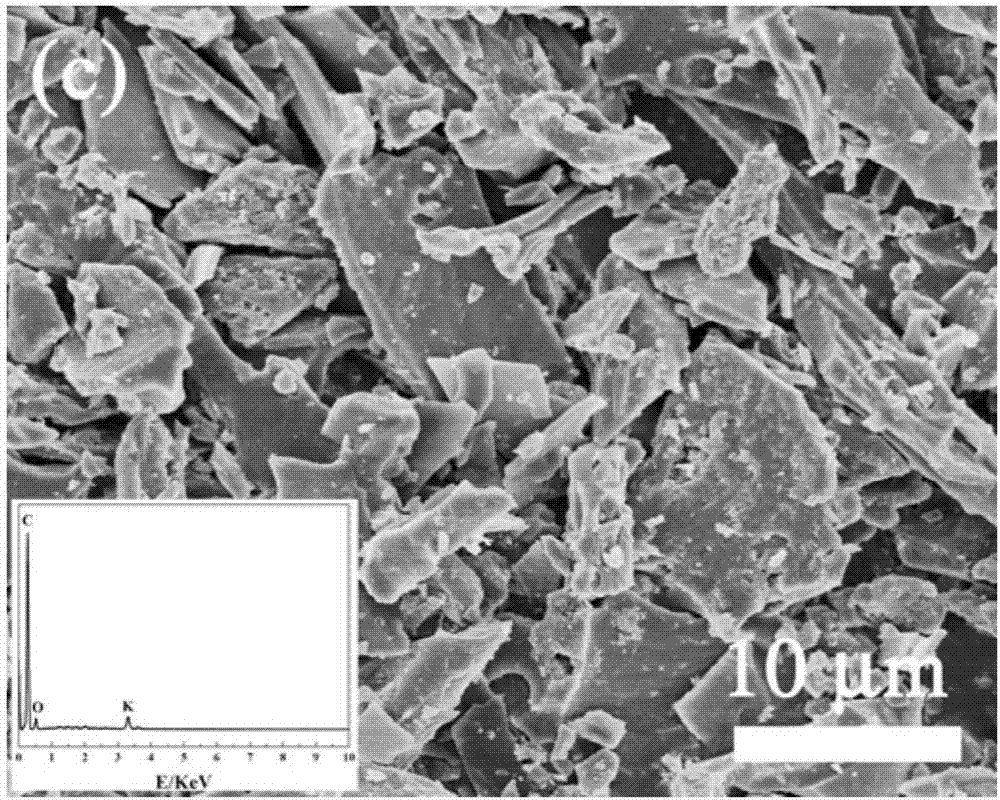

Biochar, iron and manganese spinel composite material for adsorbing heavy metal antimony and cadmium

ActiveCN107413296AIncrease the areaLarge porosityOther chemical processesWater contaminantsPorosityCadmium Cation

The invention belongs to the technical field of adsorption materials, and discloses a biochar, iron and manganese spinel composite material for adsorbing heavy metal antimony and cadmium. Solution B is dripped into suspension A at the constant speed, the solution B and the suspension A are stirred for 2.5-3.5 hours and are centrifuged, washed and dried to obtain the biochar, iron and manganese spinel composite material. The solution B is potassium permanganate solution with the concentration of 0.1 mol / L, and the suspension A comprises water, ferrous sulfate heptahydrate and from tea leaf and branch biochar according to a weight ratio of 100:(8.0-8.5):(0.8-1.2). The biochar, iron and manganese spinel composite material has the advantages that the biochar, iron and manganese spinel composite material has a large specific surface area and is large in porosity and favorable for adsorbing the heavy metal; adsorption environments are mild, and the heavy metal can be efficiently adsorbed in neutral and slightly weakly acidic environments; excellent adsorbing and removing effects can be realized by the biochar, iron and manganese spinel composite material for single heavy metal environments, and excellent heavy metal adsorbing and removing effects also can be realized by the biochar, iron and manganese spinel composite material for heavy metal antimony and cadmium co-existence environments.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorus and low-carbon alumina-magnesia unburned brick for a stainless steel ladle and a manufacturing method of the brick. The non-phosphorus and low-carbon alumina-magnesia unburned brick comprises the following components by mass percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 10-15% of bauxite less than or equal to 1mm in particle size, 10-15% of 3-1mm fused magnesite, 5-10% of fused magnesite less than or equal to 1mm in particle size, 10-15% of emery powder, 15-20% of spinel powder, 2-5% of aluminum oxide micropowder less than or equal to 25 micrometers, 0.1-2% of silicon carbide additive, 0.1-2% of wetting agent and a phenolic resin binding agent. Compared with the prior art, the brick and the method have the prominent advantages that a burning technology in the conventional method is omitted, energy sources are saved, the brick is free from phosphorus; aluminum and magnesium perform spinel reaction at the high temperature; and the brick is subjected to machine molding in the absence of the phosphorus, has higher density, avoids pollution of molten stainless steel, and has a longer service life.

Owner:长兴南冶冶金材料有限公司

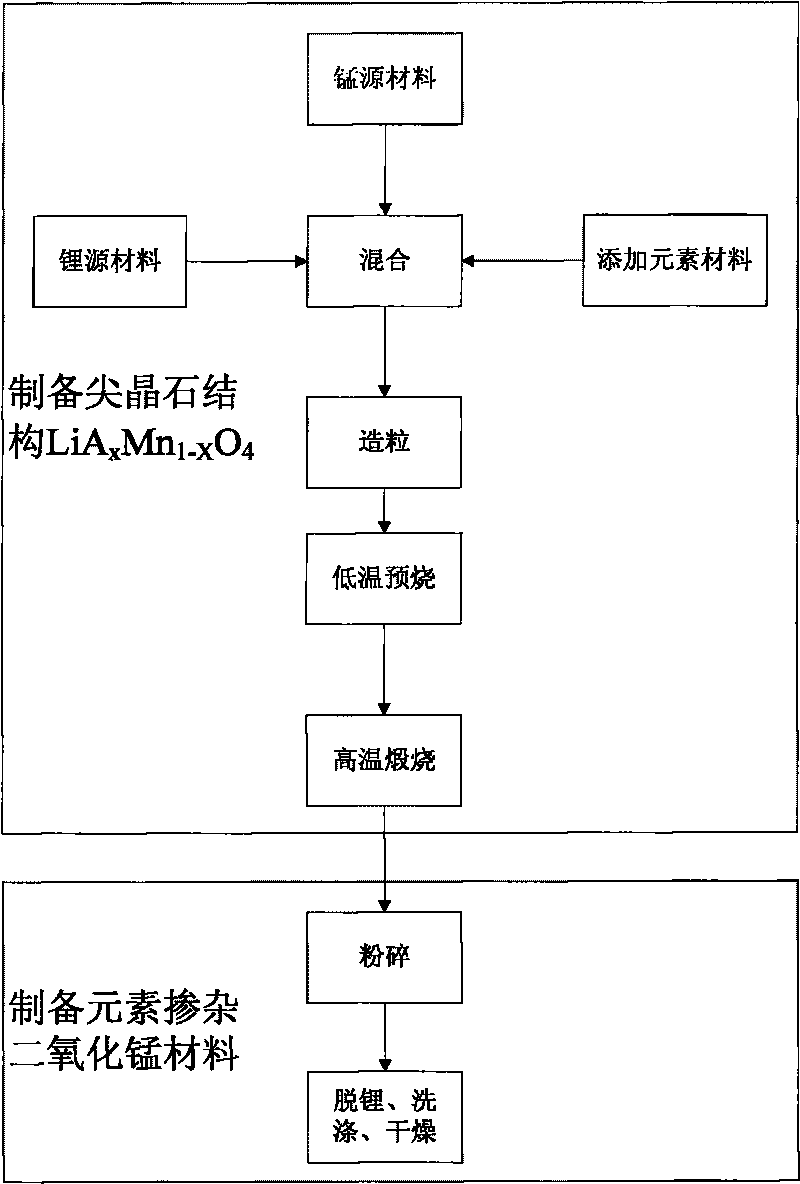

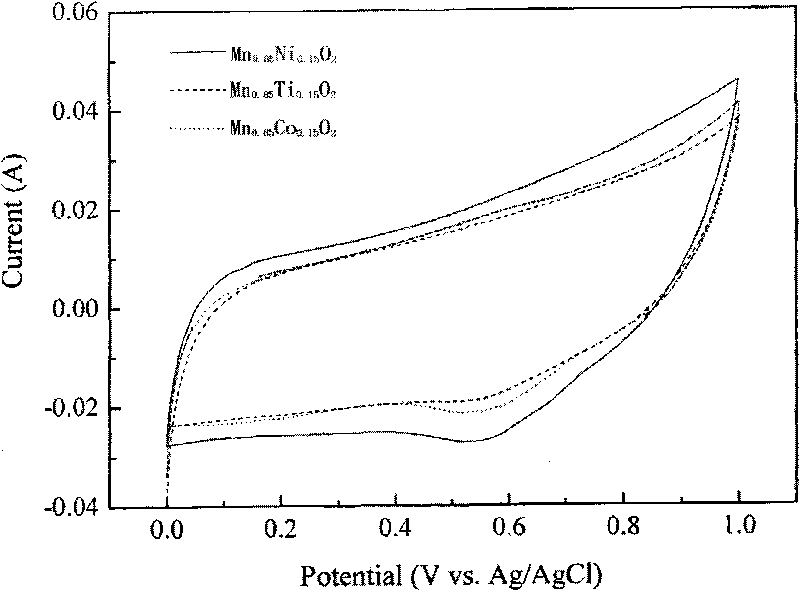

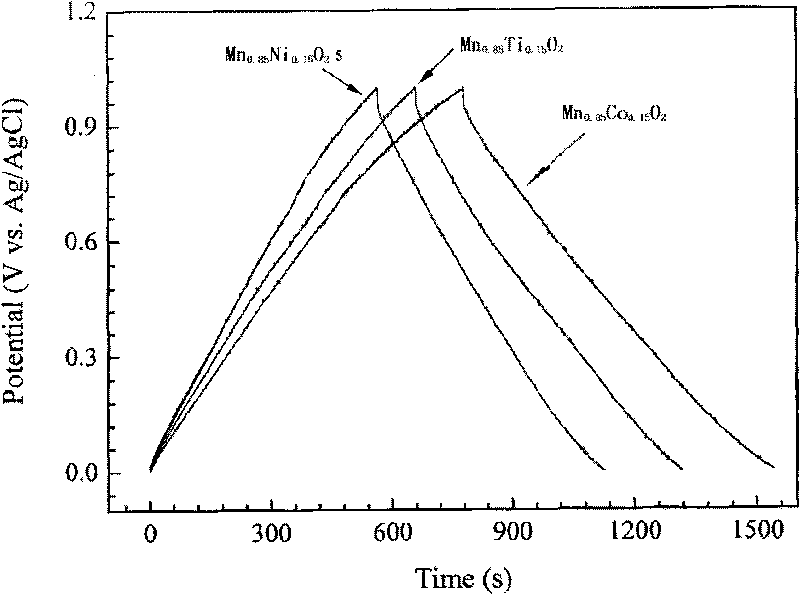

Preparation method of element doping manganese dioxide electrode material for super capacitor

ActiveCN101702375AMature technologyUniform substitution dopingElectrolytic capacitorsLithiumSupercapacitor

The invention discloses a preparation method of an element doping manganese dioxide electrode material for a super capacitor, which is characterized by comprising the following steps: (1) synthesizing a LiAxMn2-xO4 powder material with a spinel structure by utilizing a suitable method, wherein A is selected from metallic addictive elements Ti, Ni, Sn, Co, Zn and Al, and x is within the range of 0.01-0.25%; and (2) utilizing lithium ion removal agent to remove lithium ions from the LiAxMn2-xO4 powder material obtained from step (1) under the condition of not destructing the spinel structure of a precursor, thereby obtaining the element-replacement MnO2-doping electrode material for the super capacitor. For the element doping manganese dioxide electrode material prepared by the invention, the Mn part in a lattice can be evenly replaced by doped elements, and the method has high industrial maturity and is a way with great potential for preparing the manganese dioxide electrode material for the super capacitor.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS

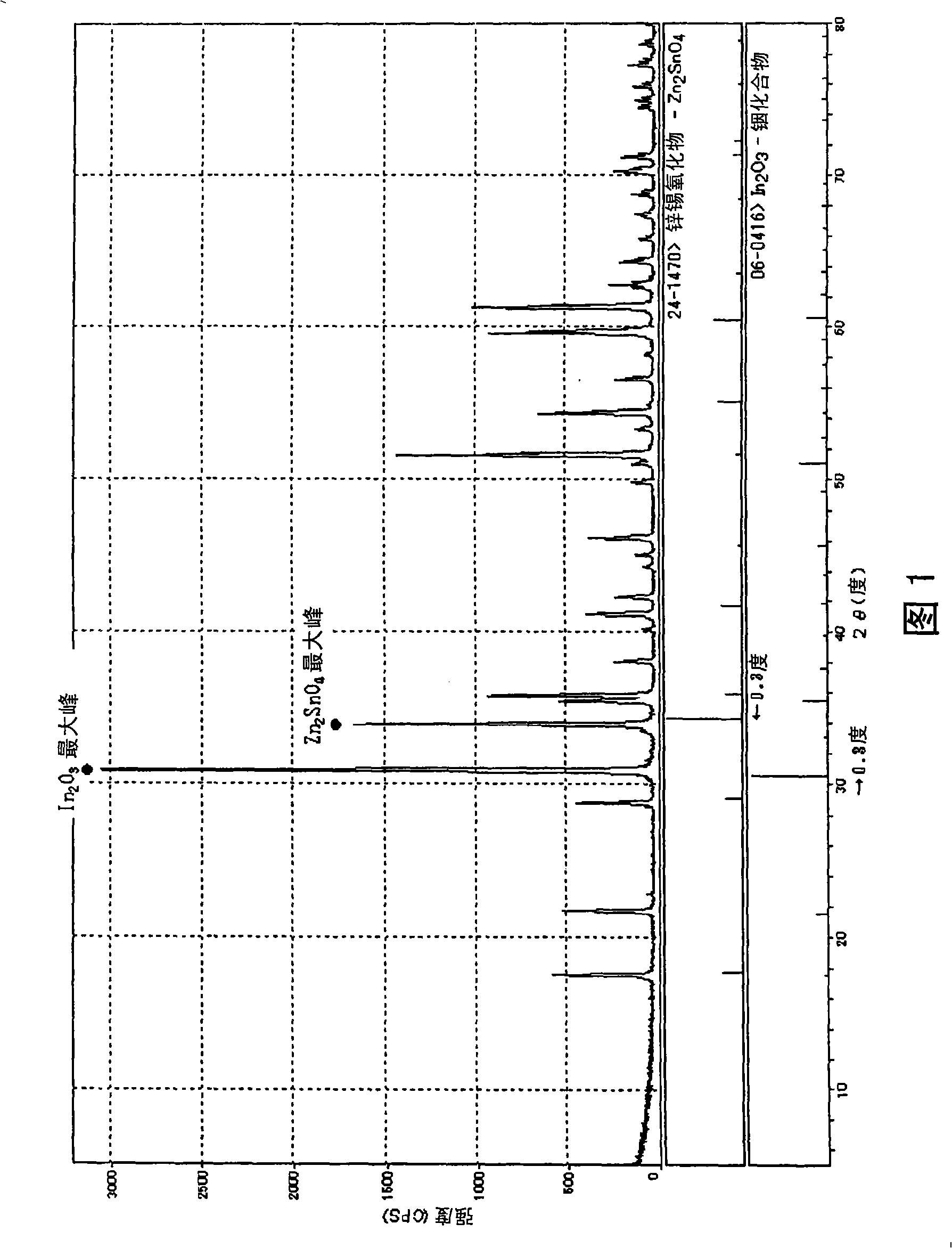

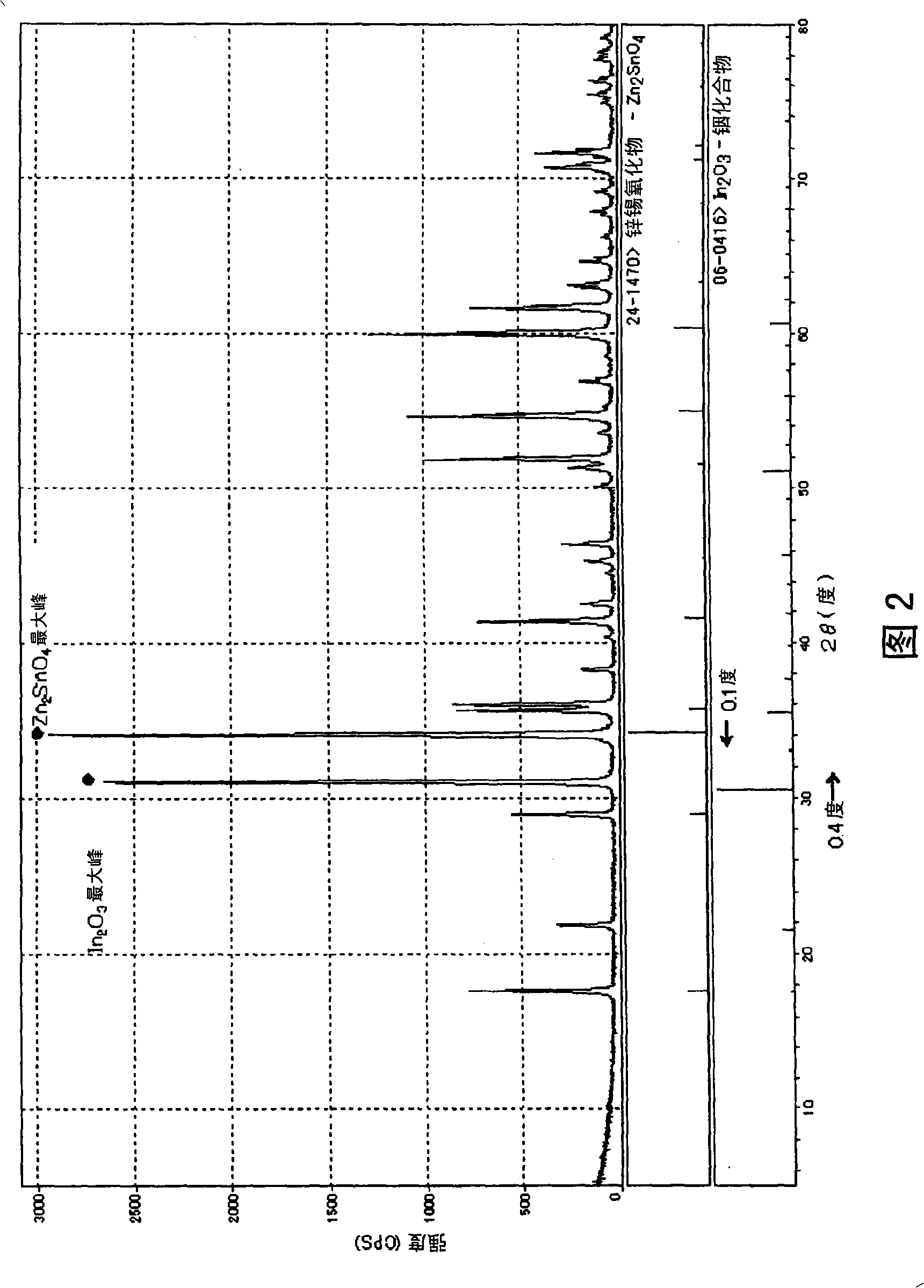

Sputtering target, transparent conductive film and transparent electrode

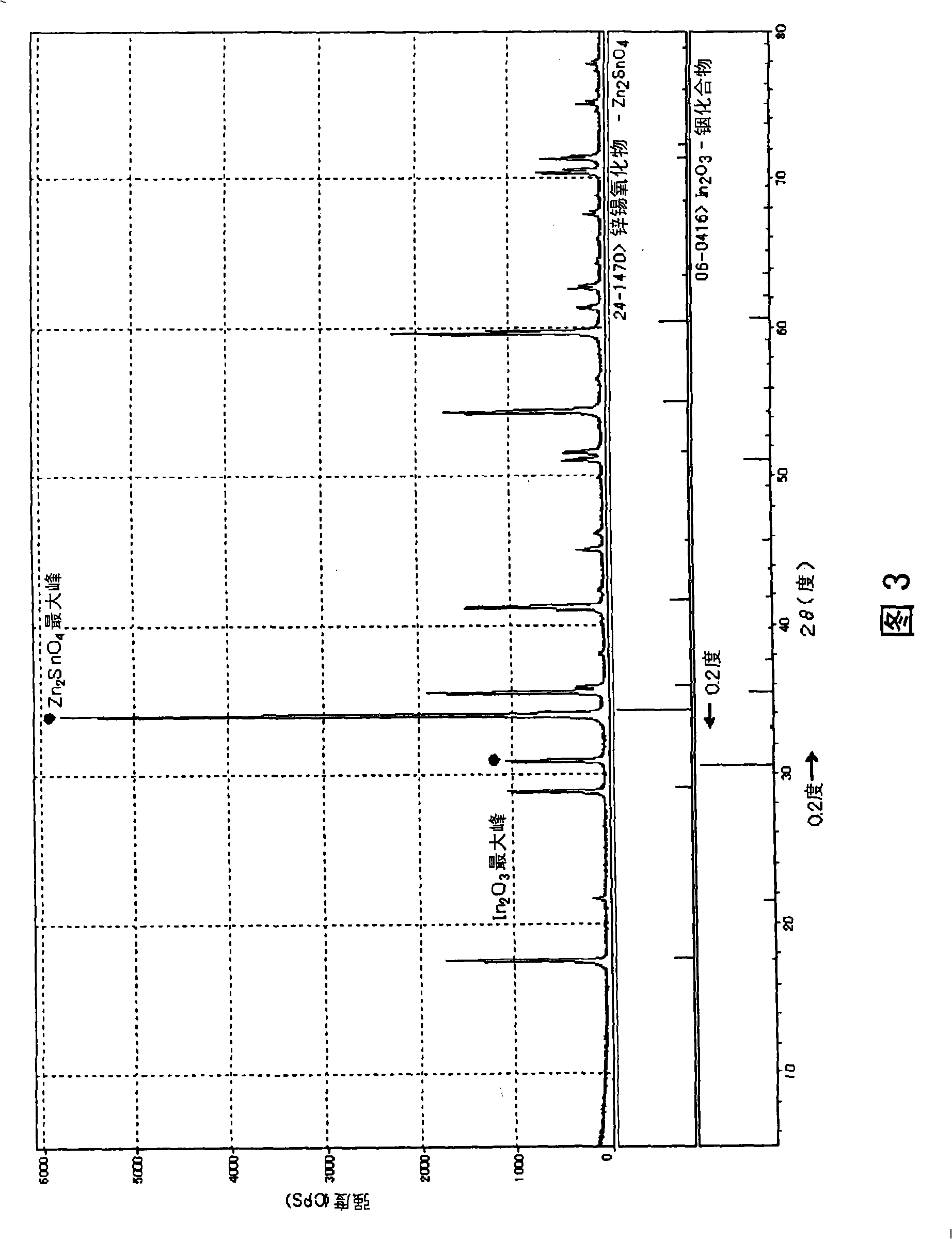

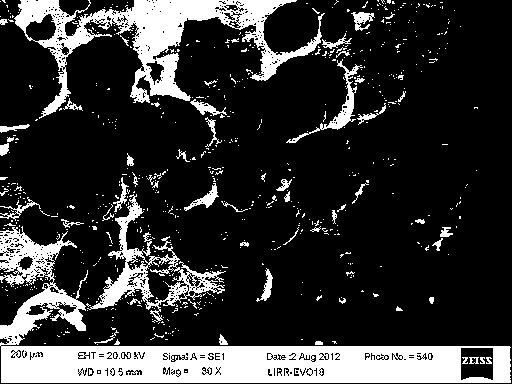

Disclosed is a sputtering target which is characterized by being a sintered body of an oxide which contains at least indium, tin and zinc and includes a spinel structure compound expressed as Zn2SnO4 and a bixbite structure compound expressed as In2O3. Also disclosed is a sputtering target which is characterized in that it contains indium, tin, zinc and oxygen and only a peak ascribed to a bixbite structure compound is practically observed by x-ray diffraction (XRD).

Owner:IDEMITSU KOSAN CO LTD

Magnesium aluminate spinel light refractory castable and production method thereof

The invention relates to a magnesium aluminate spinel light refractory castable and a production method thereof. According to the magnesium aluminate spinel light refractory castable and the production method thereof, the purpose of improving the porosity of the refractory castable is achieved by using magnesium aluminate spinel light aggregate and introducing air bubbles during the production of the castable. According to the magnesium aluminate spinel light refractory castable and the production method thereof, a foaming method and castable are combined, not only is the characteristic of large raw critical particle size in the castable ensured but also the porosity of the castable is improved. According to the magnesium aluminate spinel light refractory castable and the production method thereof, 50-65 wt% of light magnesium aluminate spinel particles which serve as the aggregate and 10-15 wt% of sintered magnesium aluminate spinel fine powder, 10-15 wt% of aluminum oxide micro powder and one of 15-20 wt% of pure calcium aluminate cement or hydrated alumina which serve as the matrix are mixed; and a water reducing agent, a foaming agent and a foam stabilizer are added. The magnesium aluminate spinel light refractory castable produced according to the method provided by the invention has high porosity, low thermal conductivity and good thermal shock resistance, and the serviceability temperature reaches 1700 DEG C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

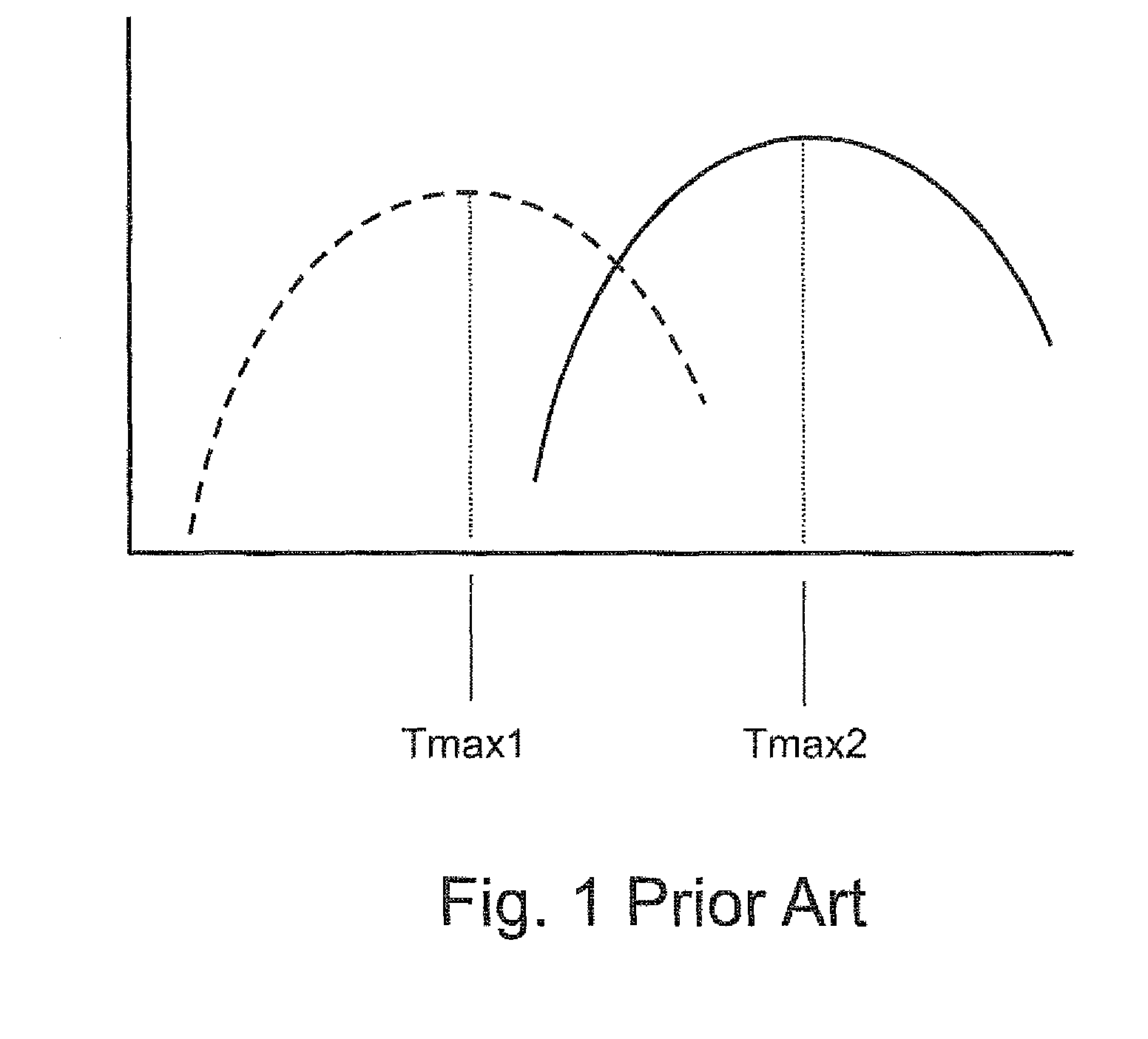

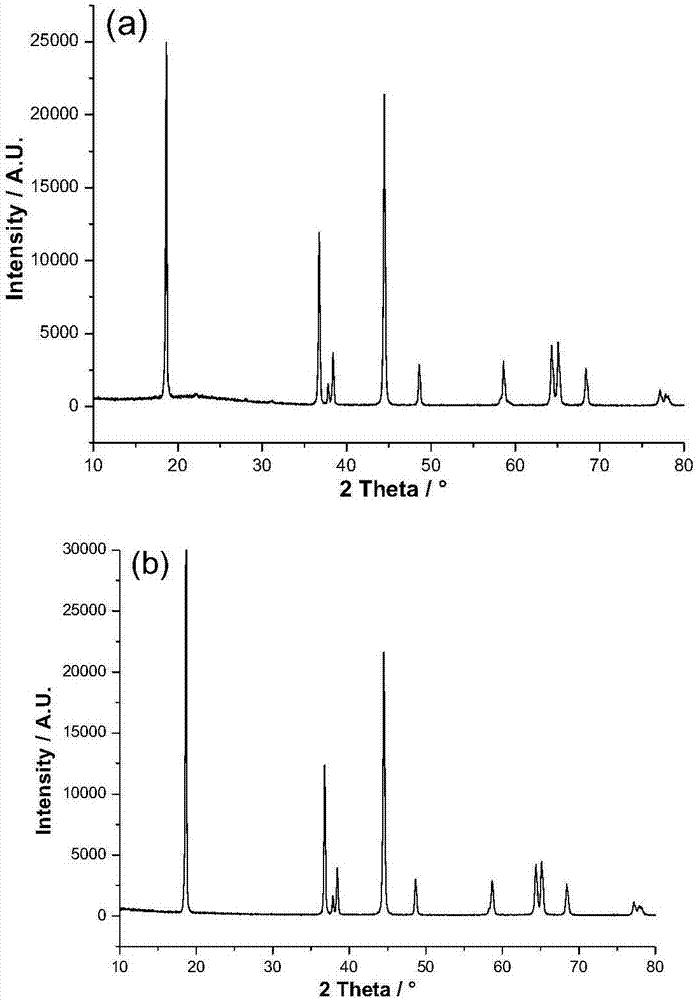

MnZn ferrite material with high saturation magnetic flux density and low power consumption

ActiveCN101552073AReduce manufacturing costReduce power consumptionInorganic material magnetismVolumetric Mass DensityMaterials science

The utility model provides a MnZn ferrite material with high saturation magnetic flux density and low power consumption, which improves the saturation magnetic flux density (Bs) and keeps the power consumption at a low level simultaneously. The material is a spinel polycrystalline structure and comprises the main compositions (calculated by the content of oxide) of 53.5-54.8mol% of Fe2O3, 38.5-44.5mol% of MnO, and 1.5-7.5mol% of ZnO; furthermore, the material also comprises SiO2 and CaO that are taken as a first auxiliary composition, comprises Nb2O5, Ta2O5, V2O5, ZrO2 and HfO2, wherein one or two combinations are taken as a second auxiliary composition, also comprises TiO2 and SnO2, wherein one or two combinations are taken as a third auxiliary composition, and also comprises CoO which is taken as a fourth auxiliary composition.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

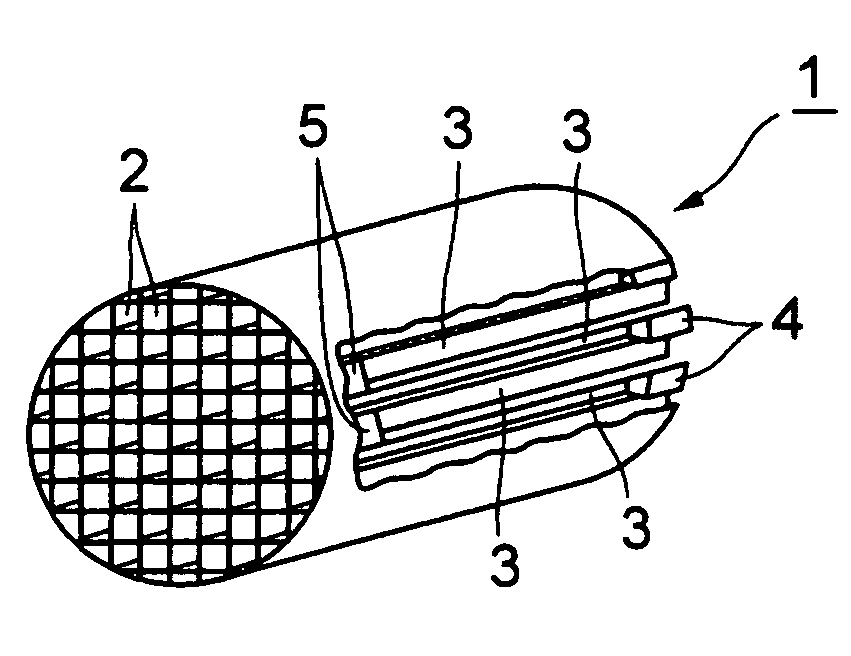

Honeycomb filter for clarifying exhaust gas and method for manufacture thereof

InactiveUS7550025B2Improve thermal shock resistanceSmall coefficient of thermal expansionCombination devicesAuxillary pretreatmentSolid particleThermal shock

Provided is a honeycomb filter which includes an aluminum titanate sintered product obtained by a process involving firing at a temperature of 1,250-1,700° C. a raw material mixture composed of: 100 wt. % of a first mixture having TiO2 and Al2O3 in a molar ratio of 40-60 / 60-40; and 1-10 wt. % of a second mixture composed of: an alkali feldspar according to the formula NayK1-yAlSi3O8, wherein 0≦y≦1; and a component selected from an oxide having a spinel structure composed of Mg and / or MgO, MgO and a precursor compound composed of Mg that is converted to MgO by firing, wherein the honeycomb filter exhibits excellent properties with respect to mechanical strength, thermal decomposition resistance, thermal shock resistance and thermal stability at high and fluctuating temperatures. Also provided is a method and an apparatus for cleaning an exhaust gas by removing solid particles predominantly containing carbon from the exhaust gas with the honeycomb filter. Also provided is a process for producing the honeycomb filter.

Owner:OHCERA CO LTD

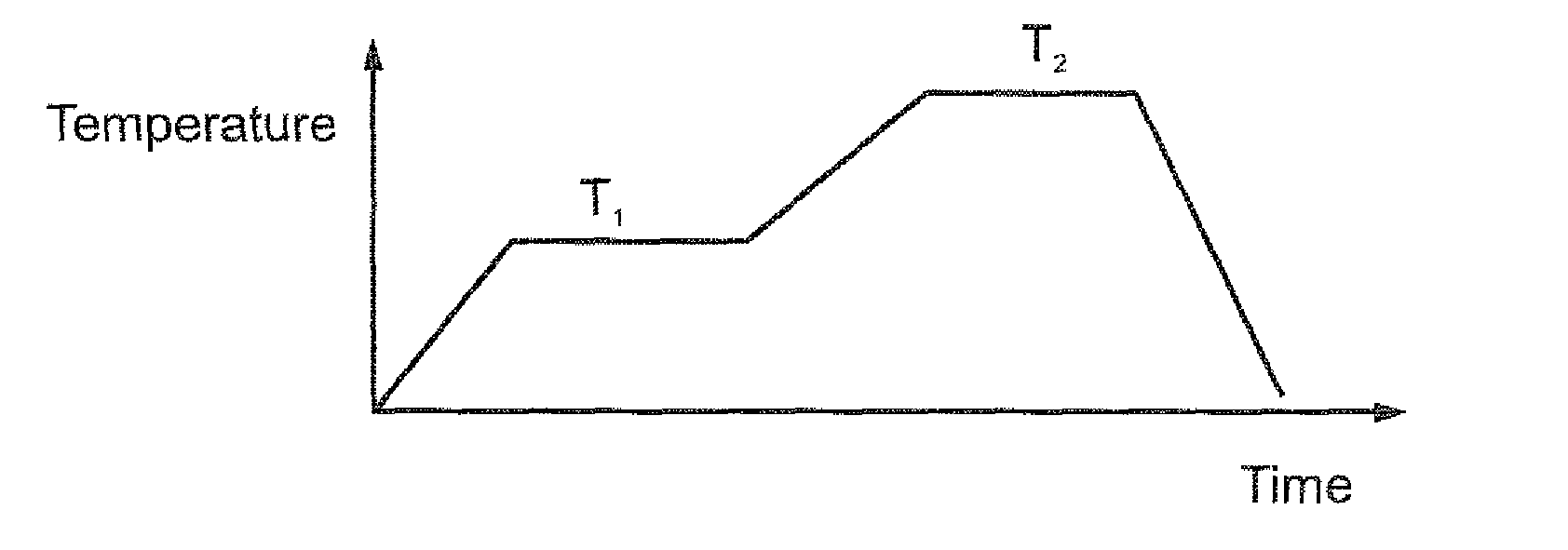

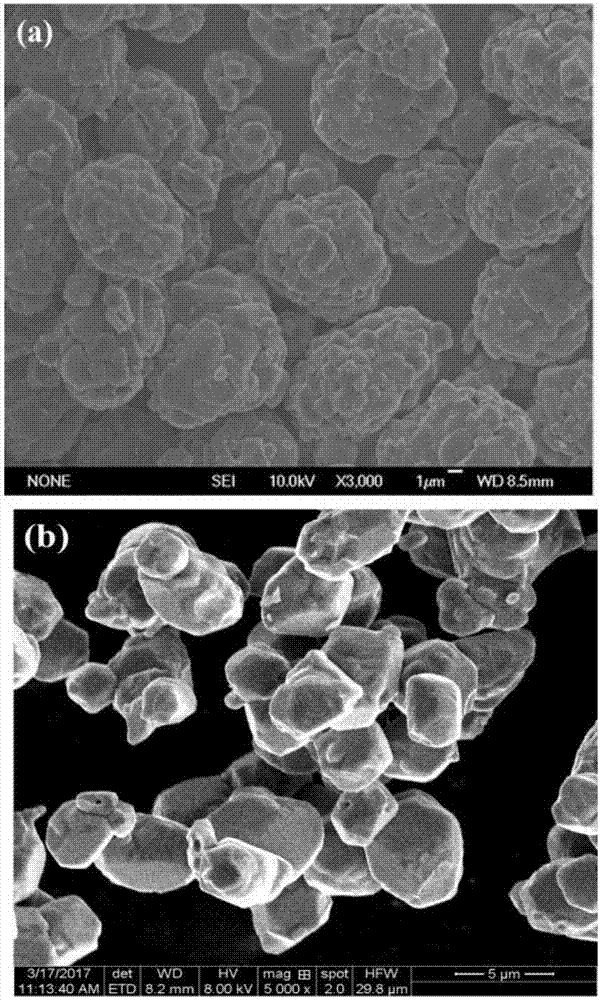

Improved preparation method of large single crystal layered positive electrode material for lithium ion battery

ActiveCN107311242AHigh tap densityIncrease compaction densitySecondary cellsPositive electrodesSodium-ion batterySingle crystal

The invention discloses an improved preparation method of a large single crystal layered positive electrode material for a lithium ion battery. The method comprises the following steps of firstly mixing Co-Mn precursors with a lithium source, wherein the mol ratio of the lithium element to the transition metal element is between 0 and 1; high-temperature calcination is performed; at the moment, a spinel phase is formed due to insufficiency of the lithium element; the spinel phase is favorable for the fusion and the growth of the primary crystal grains; micrometer stage large-dimension composite phase primary crystal grains or pure phase primary crystal grains are obtained; then, a lithium source and a nickel source at the chemical metering ratio are supplemented into the prepared primary crystal grains, so that the mol ratio of the nickel element to the cobalt element to the manganese element Ni / Co / Mn is (1-x-y) / x / y; the mol ratio of the lithium element to the transition metal element Li / Ni-Co-Mn is (1+z) / (1-z) to (1+z) / (1-z)+0.05; in the high-temperature calcination, the solid phase reaction is initiated by the diffusion of lithium ions and nickel ions; the large single crystal layered positive material for the lithium ion battery is obtained.

Owner:UNIV OF JINAN

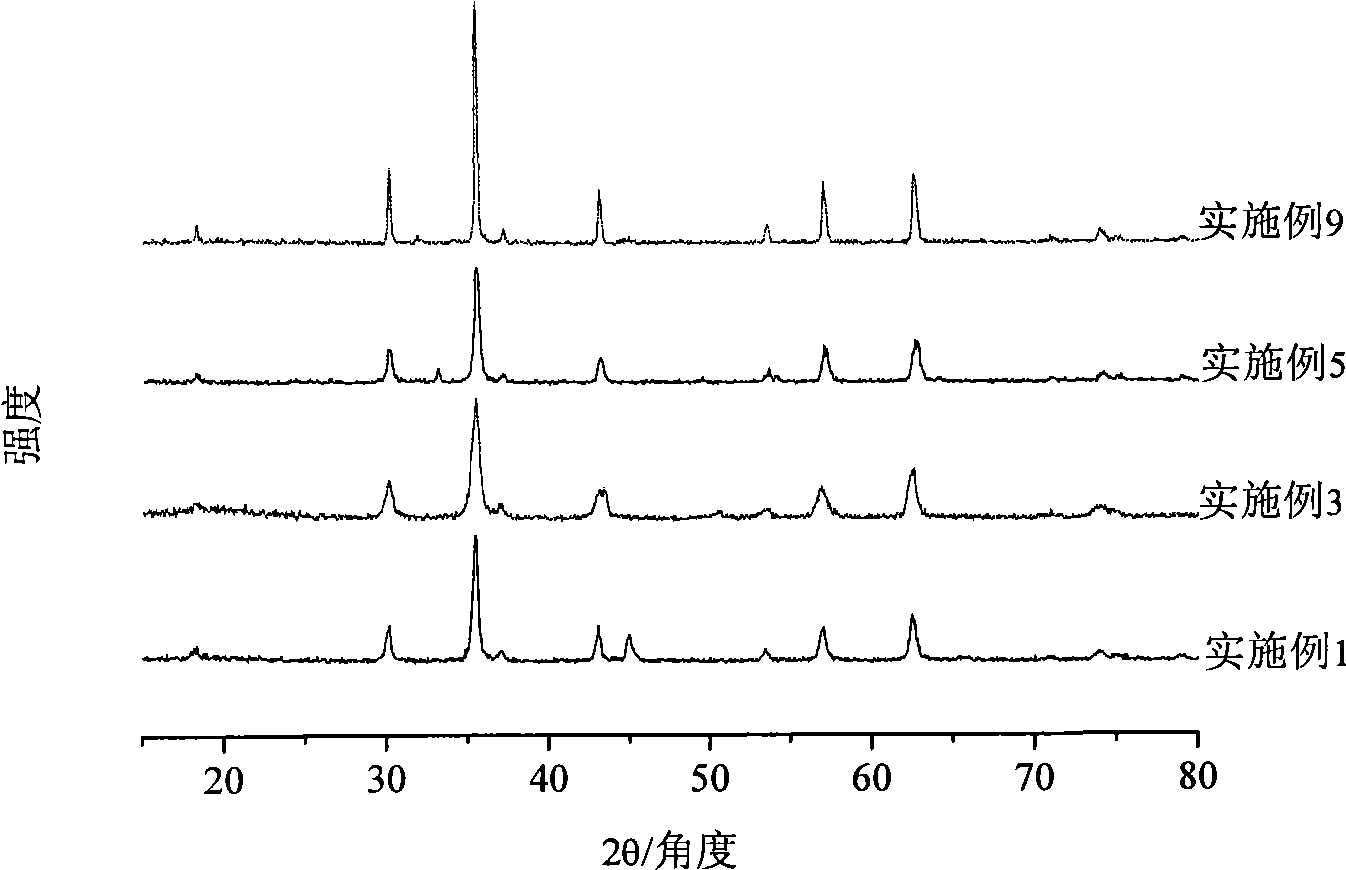

Sintered in-ga-zn-o-type oxide

InactiveCN102482156ALow resistivityHigh densityTransistorVacuum evaporation coatingPhysical chemistryGallium

A sintered oxide containing In (element indium), Ga (element gallium) and Zn (element zinc), having a total content of In, Ga and Zn of 95 at.% or more relative to the total amount of elements contained in the sintered oxide excluding element oxygen, and comprising a compound that is represented by the formula: In2O3 and has a bixbyite structure and a compound that is represented by the formula: ZnGa2O4 and has a spinel structure.

Owner:IDEMITSU KOSAN CO LTD

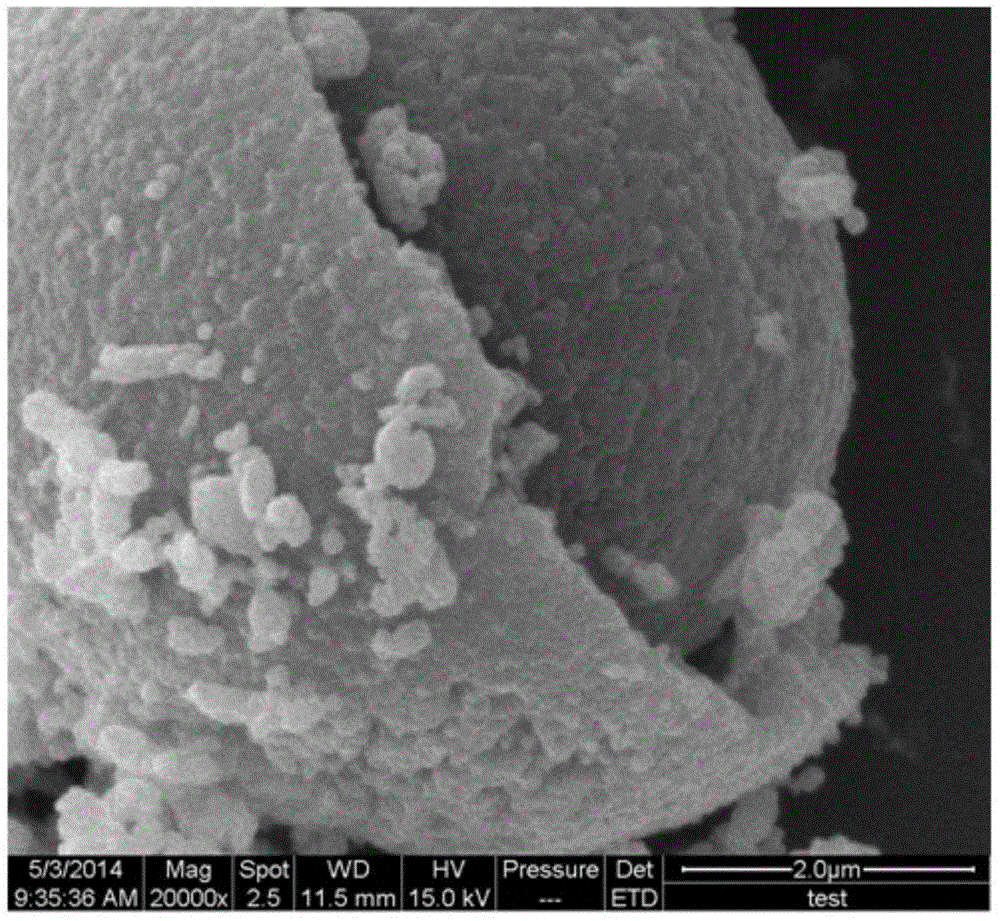

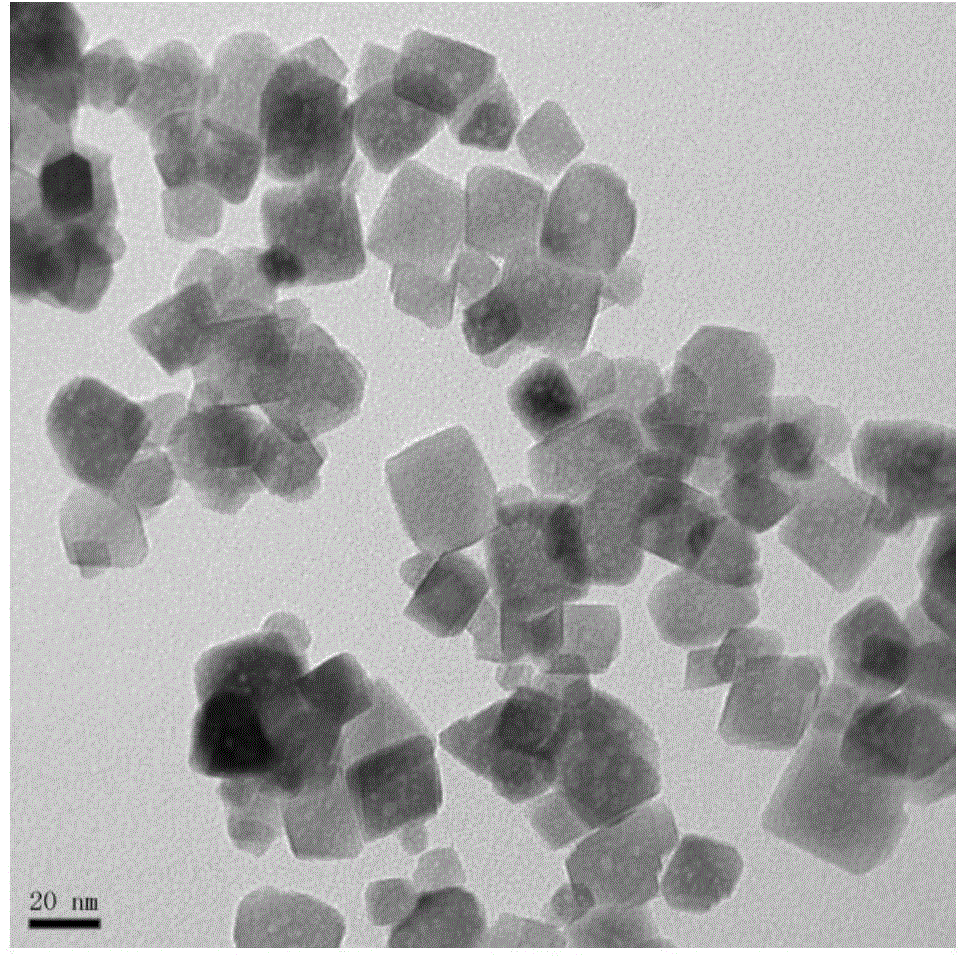

Magnetic spinel structure ferrite nano particle and preparation thereof

InactiveCN101486492AOvercoming productivityOvercoming the use of large amounts of organic solventsIron compoundsCobalt compoundsOctahedronSpinel

The invention discloses magnetic spinel-structure ferrite nano-particles and a preparation method thereof, which pertains to the field of magnetic nano-materials and aims at solving the problem that in the prior art, the defects of high production cost, low yield, environmental pollution, complicated operations, inadaptability to the commercial production and the like exist. The molecular formula of the magnetic spinel-structure ferrite nano-particles is CoxCuyZnzFe3-x-y-zO4, wherein, x ranges from 0 to 1, y ranges from 0 to 1 and z ranges from 0 to 1; and the magnetic spinel-structure ferrite nano-particles have the diameter of 20nm to 400nm and take the shapes of a ball, a regular tetrahedron, a regular hexahedron, a regular octahedron or a stick. The preparation method comprises the steps that: a soluble salt solution plated with transition metal ions is mixed with an alkali metal-hydroxide solution according to the volume ratio of 16:1-8 so as to carry out hydrothermal treatment, with the hydrothermal temperature of 120 DEG C to 180 DEG C and the hydrothermal time of 2 hours to 6 hours. The preparation method has the advantages of low cost, simple processes, strong applicability, adaptability to the industrialized production, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com