Preparation method of element doping manganese dioxide electrode material for super capacitor

A manganese dioxide electrode and supercapacitor technology, which is applied in the direction of capacitors, electrolytic capacitors, electrical components, etc., can solve the problems of high control conditions, cumbersome and complicated methods, and small specific capacitance, and achieve mature and reliable technical routes, mature processes, Avoid the effects of difficult doping control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

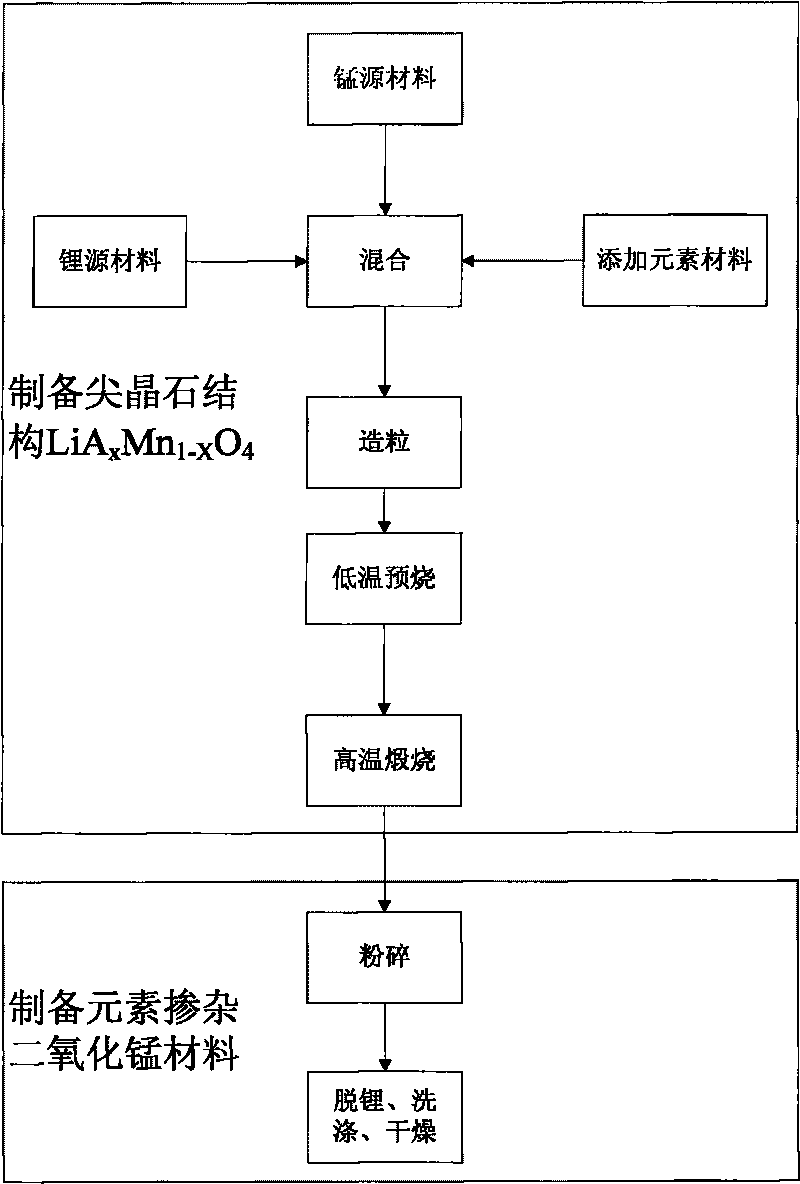

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Preparation of Ni element doped manganese dioxide electrode material

[0035] Electrolytic manganese dioxide powder with a particle size of about 20 microns and Ni(OH) 2 Stir and grind at the ratio of Ni / Mn molar ratio 0.2 and Li / Mn molar ratio 0.5 to carry out thorough mixing, and use a temperature-programmed muffle furnace to calcinate the mixture at 850-970°C for 48 hours and cool to obtain a spinel structure of LiNi x mn 2-x o 4 Powder material. The prepared spinel LiNi x mn 2-x o 4 Suspend the powder in pure water, slowly add sulfuric acid solution under stirring conditions, control the temperature not higher than 50°C, until the pH of the slurry reaches 0.5-2, continue stirring for 1 hour, centrifuge the reacted slurry, and pour off the supernatant , filtered with suction and repeatedly washed with water until the eluate is neutral, and the filtrate is vacuum-dried at a temperature not higher than 90°C to obtain nickel-doped MnO2 powder.

[0...

Embodiment 2

[0037] Preparation of Example 2Ti element doped manganese dioxide electrode material

[0038] As described in Example 1, with 1250 orders below the anatase type TiO powder is prepared to obtain titanium-doped manganese oxide electrode material;

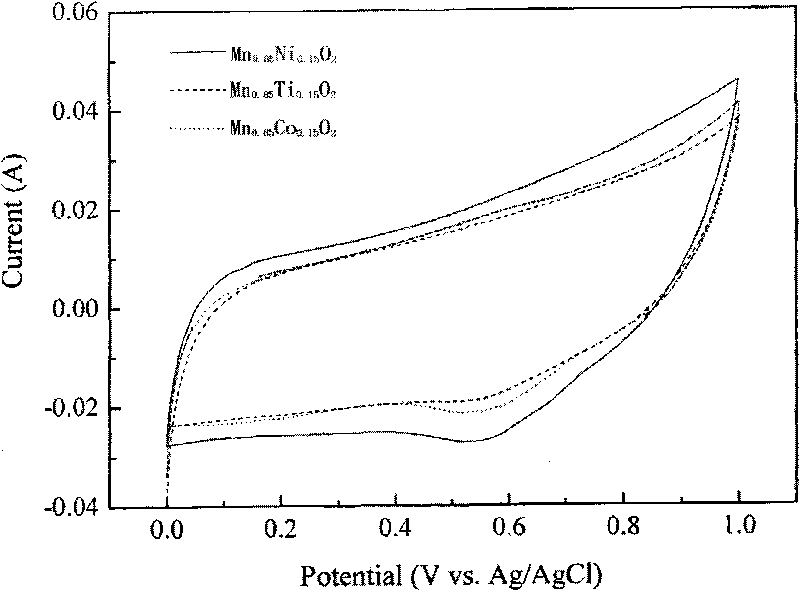

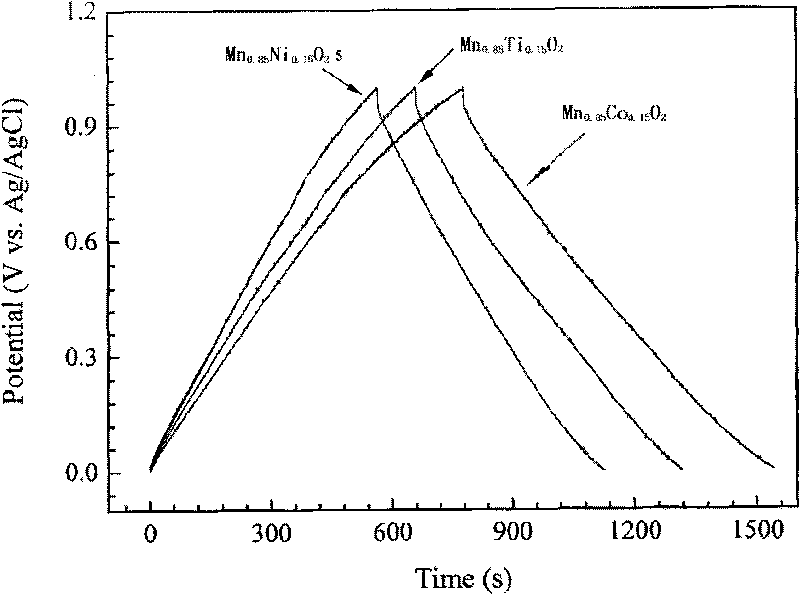

[0039] The prepared Ti-doped manganese dioxide electrode material was used as the positive electrode, the graphite electrode was used as the negative electrode, the Ag / AgCl electrode was used as the reference electrode, and 1MNa2SO4 was used as the electrolyte to form a three-electrode test system to test the electrochemical performance of the material. Cyclic voltammetry scanning speed 10mv / s, scanning interval 0.0-1.0V; constant current charge and discharge current 200mA / g, voltage interval 0-1.0v. The Ti-doped manganese dioxide electrode has a specific capacitance of 163f / g after 500 cycles.

Embodiment 3

[0040] The preparation of embodiment 3Co element doping manganese dioxide electrode material

[0041] As described in Example 1, cobalt-doped manganese oxide electrode material is prepared with Co2O3 powder below 1250 orders;

[0042] The prepared Co-doped manganese dioxide electrode material was used as the positive electrode, the graphite electrode was used as the negative electrode, the Ag / AgCl electrode was used as the reference electrode, and 1MNa2SO4 was used as the electrolyte to form a three-electrode test system to test the electrochemical performance of the material. Cyclic voltammetry scanning speed 10mv / s, scanning interval 0.0-1.0V; constant current charge and discharge current 200mA / g, voltage interval 0-1.0v. Co-doped manganese dioxide electrode has a specific capacitance of 178f / g after 500 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com