Zirconium oxide composite ceramic and preparation method thereof

A composite ceramic and zirconia technology, applied in the field of zirconia composite ceramics and its preparation, can solve the problems of reducing the mechanical properties of the ceramic body and increasing the impurity content of the ceramic matrix, so as to avoid the formation of unsafe rapid discharge, improve the mechanical properties, Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

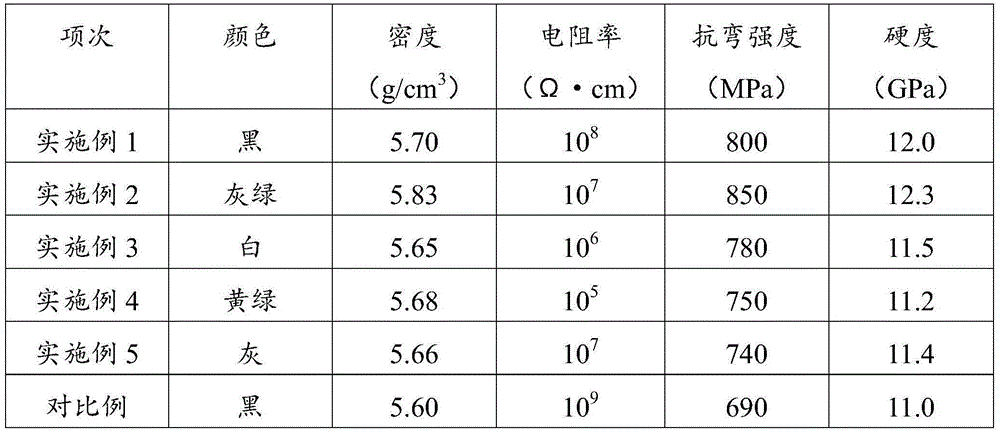

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned zirconia composite ceramics comprises the following steps:

[0035] Step S110, providing a zirconium oxychloride solution and a metal ion solution corresponding to the conductive material according to the amount of the zirconia matrix and the conductive material in the zirconia composite ceramic, and combining them to obtain a mother liquor.

[0036] Preferably, the concentration of the zirconium oxychloride solution is 80-85 g / L.

[0037] If the conductive material is a non-ferrous metal oxide or a white metal oxide, weigh the corresponding amount of metal oxide and dissolve it with nitric acid to form a metal ion solution with a concentration of 0.4mol / L-0.6mol / L.

[0038] If the conductive material is a compound with a titanium ore structure and a compound with a spinel structure, the amount of the conductive material is converted into the amount of the corresponding metal oxide, and then the corresponding metal oxide is ...

Embodiment 1

[0066] A zirconia composite ceramic comprises the following components in mass fraction:

[0067] Zirconia 76% Yttrium oxide 4% Ferric oxide 1% Nickel oxide 7% Chromium trioxide 2% Nano alumina 10%

[0068] The preparation method of the above-mentioned zirconia composite ceramics comprises the following steps:

[0069] Step 1: According to the mass ratio of zirconia in the table, the mass ratio of zirconium oxychloride is converted into the mass ratio of zirconium oxychloride according to the molar ratio, and the aqueous solution of 80g / L is prepared; then Y is weighed according to the mass ratio 2 o 3 And ferric oxide, nickel oxide, chromium oxide, and then dissolved with nitric acid, respectively dubbed 0.4mol / L nitrate solution. Finally, add the weighed solutions of each substance into the reaction kettle, and stir evenly to form a mother liquor.

[0070] Step 2: reacting and precipitating by co-precipitation method. Add deion...

Embodiment 2

[0078] An antistatic zirconia ceramic comprises the following components in mass fraction:

[0079] Zirconia 70% Yttrium oxide 5% LaSr 0.1 Cr 0.9 o 3 20% Nano Zirconia 5%

[0080] The preparation method of the above-mentioned zirconia composite ceramics comprises the following steps:

[0081] Step 1: According to the mass ratio of zirconia in the table, the mass ratio of zirconium oxychloride is converted into 82g / L aqueous solution by molar ratio; 0.1 Cr 0.9 o 3 Convert the mass ratio to the molar ratio, and then convert it to the mass ratio of the precursor oxides lanthanum oxide, strontium oxide, and chromium oxide, and then dissolve several oxides and yttrium oxide with nitric acid to prepare 0.5mol / L nitrate solution. Finally, add the weighed solutions of each substance into the reaction kettle, and stir evenly to form a mother liquor.

[0082] Step 2: reacting and precipitating by co-precipitation method. Add deionized water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com