Patents

Literature

82results about How to "Reinforcing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal wall putty and production process thereof

The invention belongs to the technical field of building materials, and particularly relates to an internal wall putty which comprises the following components in parts by weight: 150-300 parts of white cement, 500-900 parts of calcium carbonate powder, 10-50 parts of grey desert soil, 1-8 parts of cellulose ether, 7-30 parts of polymer latex powder, 1-10 parts of water repellent, 0.05-3 parts of starch ether and 0.5-7 parts of wood fiber. Compared with the prior art, the internal wall putty has the advantages that 107 glue water or 801 glue water is not used, thus formaldehyde is not contained, the environment is protected; and pregelatinized starch is not used, and the water repellent is added, thus the internal wall putty has the function of preventing water and moisture. In addition, with the white cement and the calcium carbonate powder as the strength basis and the grey desert soil as an auxiliary strength material, the strength of the internal wall putty is ensured; due to the synergistic effect of the cellulose ether and the starch ether, the water-retaining property and the application property of the internal wall putty are ensured; and because the polymer latex powder is added, the flexibility of the internal wall putty and the adhesion of the polymer latex powder and the wall are improved.

Owner:黄明杰

Room-temperature moisture-curable single-component flame-retardant polyurethane sealant

ActiveCN102504752AGood flame retardantNo reduction in physical propertiesNon-macromolecular adhesive additivesOther chemical processesPlasticizerRoom temperature

The invention discloses a room-temperature moisture-curable single-component flame-retardant polyurethane sealant and a preparation method thereof. The sealant is prepared from the following raw materials in parts by weight: 30-55 parts of liquid polyether type polyurethane pre-polymer base stock, 10-30 parts of flame-retardant plasticizer, 0.1-1 part of silane coupling agent, 15-30 parts of flame-retardant powder, 10-30 parts of filler, 0.01-0.05 part of catalyst and 0.2-3 parts of methyl benzenesulfonyl isocyanate, wherein the liquid polyether type polyurethane pre-polymer base stock is prepared from the following raw materials in parts by weight: 32.8-57.64 parts of common polyether glycol, 28.82-54.67 parts of flame-retardant polyether glycol, 12.51-13.53 parts of polyisocyanates, and 0.01 part of catalyst. The room-temperature moisture-curable single-component flame-retardant polyurethane sealant is excellent in physical performance, thixotropic property and flame-retardant performance, and convenient for construction.

Owner:SHANDONG NORTH MODERN CHEM IND

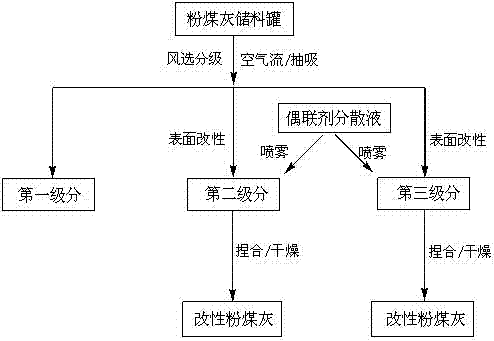

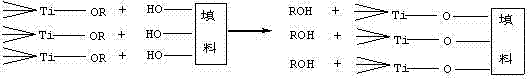

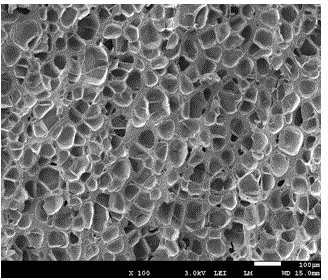

Modified fly ash, preparation method thereof, and preparation apparatus thereof

InactiveCN102732063AImprove bindingImprove the coupling effectPigment treatment with organosilicon compoundsPigment physical treatmentPolymer substrateOrganic group

The invention provides a preparation method of modified fly ash. In a sealed negative-pressure system, fly ash is adopted as a raw material. When winnowing grading processing is carried out upon the fly ash particles, the graded fine particles and ultra-fine particles are subjected to a chemical-spraying surface modification treatment; the obtained products are heated and dried, such that a target product of the modified fly ash is obtained. According to the modified fly ash provided by the invention, one or more saturated-structure or unsaturated-structure organic groups are bonded on the surfaces of the particles, and an activation index is higher than 0.9. The invention also discloses a fly ash sorting and modifying apparatus. The technical method provided by the invention is energy-saving and environment-friendly, and is advantaged in high utilization rate of fly ash. The obtained modified fly ash is advantaged in wide particle fineness selection range, small dosage of a coupling agent, uniform distribution of the coupling agent, good adaptability with polymer substrates, and the like. In rubber product filling, the modified fly ash can be used for completely replacing calcium carbonate and powdered steatile, or partially replacing carbon black. The modified fly ash is a renewable resource material with low cost and high quality.

Owner:EAST CHINA NORMAL UNIV

PET (polyethylene glycol terephthalate) fiber/polyacrylonitrile fiber composite sound absorbing cotton and preparation method of PET fiber/polyacrylonitrile fiber composite sound absorbing cotton

InactiveCN102965847AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesPolymer scienceAntioxidant

The invention discloses PET (polyethylene glycol terephthalate) fiber / polyacrylonitrile fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of polyacrylonitrile fibers, 10 to 15 parts of emulsifying agents OP-20, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SEBS (styrene ethylene butylene styrene), 15 to 20 parts of calcined clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of diisooctyl phthalate, 4 to 6 parts of tricresyl phosphate, 2 to 3 parts of polyethylene wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of dimethyl dimercapto isooctyl acetate tin, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 1035. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

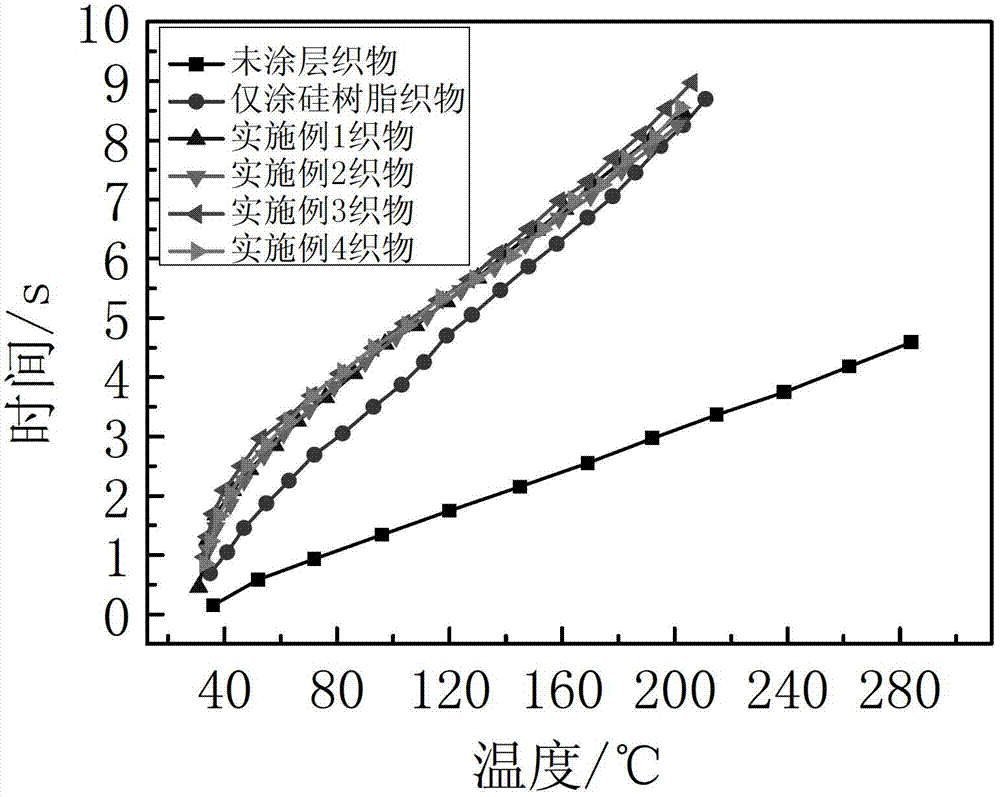

Heat-insulating and ablation-resistant glass fiber fabric and preparation method thereof

ActiveCN103205896AImprove heat resistanceImprove crack resistanceFibre treatmentResin coatingEngineering

The invention provides a heat-insulating and ablation-resistant glass fiber fabric and a preparation method thereof, belonging to the technical field of thermal protection fabrics and preparation thereof. The heat-insulating and ablation-resistant glass fiber fabric product comprises a fabric layer and coating layers on the front and back surfaces of the fabric layer, wherein the thicknesses of the coating layers on the front and back surfaces of the fabric layer are controlled at 30-80 micros; the fabric layer is made from glass fiber fabrics; the coating layers are composite organic silicon resin coating layers which are prepared by mixing an organic silicon resin solution, white carbon black, mica powder and the like in certain percentage by weight; a solute of the organic silicon resin solution is phenyl methyl silicone, a solvent of the organic silicon resin solution is dimethylbenzene, toluene or a mixture of the two, and the mass ratio of the solvent to the solute is 1:1; and a preparation method of a composite organic silicon resin coating layer solution comprises the following steps of: sequentially adding the white carbon black, the mica powder, wollastonite in powder and metallic oxide into the organic silicon resin solution, and stirring to ensure that the substances are uniformly dissolved. The heat-insulating and ablation-resistant glass fiber fabric is simple in process, easy to operate, and excellent in heat resistance, weather resistance, insulating property, reinforcement performance, scrubbing resistance and weathering resistance.

Owner:赵晓明 +1

Method for improving absorption speed of water swelling rubber by employing fibre

The present invention relates to a method to improve the water-absorption speed of rubber which swells in water by means of fiber. The present invention is characterized in the following steps: 1) short fiber, solvent and rubber with the mass ratio of 5 to 40:50 to 100:10 to 100 are added into a container, which are constantly stirred until the materials are evenly dispersed; then the mixture is spilled out from the container and is dried in vacuum at the temperature of 80 DEG C to get mixture A; 2) rubber, mixture A, absorbent resin, plasticizer, stearic acid, zinc oxide, curing agent, antioxidant, reinforcing agent and accelerator are mixed together with the quality ratio of 50:50:10 to 60:0 to 15:0.5 to 3:2 to 6:0.5 to 5:0 to 3:30 to 60:0.5 to 3 ratio to generate mixture B; 3) mixture B is placed evenly on the twin-roll open mill to get rubber which swells in water within the temperate range between 25 DEG C to 150 DEG C. The method can enhance the water-absorption speed of the rubber which swells in water, and can maintain the mechanical properties of the rubber.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

PET (Polyethyleneglycol Terephthalate) fiber/glass fiber composite sound absorbing cotton and preparation method thereof

InactiveCN102965842AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesFiberPhosphoric Acid Esters

The invention discloses PET (Polyethyleneglycol Terephthalate) fiber / glass fiber composite sound absorbing cotton, which is prepared from the following raw materials in parts by weight: 70-80 parts of PET fiber, 40-50 parts of quartz glass, 15-20 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 20-30 parts of peregal O-10, 80-100 parts of PP (Polypropylene), 30-40 parts of LDPE (Low-Density Polyethylene), 15-20 parts of calcium carbonate whiskers, 10-15 parts of modified diatomite, 2-3 parts of stearic acid, 5-8 parts of trioctyl trimellitate, 4-6 parts of ammonium polyphosphate, 2-3 parts of oxidized polyethlene wax, 1-2 parts of di(dioctyloxy pyrophosphate)ethylene titanium ester, 2-3 parts of zinc stearate, 1-2 parts of dimethyldimercaptoisooctylacetate tin, 0.5-1.5 parts of anti-aging agent RD, and 1-2 parts of antioxidant 1010. The sound absorbing cotton prepared in the invention has the advantages of high appearance flatness, uniform thickness, soft handfeel, high product viscosity, high tensile property, high sound absorbing performance, good flame retarding effect and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

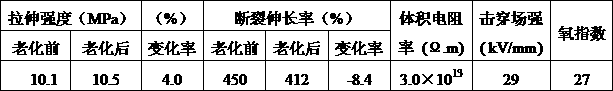

Halogen-free flame-retardant POE (Polyolefin Elastomer) compound material and preparation method thereof

The invention discloses a halogen-free flame-retardant POE (Polyolefin Elastomer) compound material and a preparation method thereof. The halogen-free flame-retardant POE compound material is prepared from the following components in parts by weight: 100 parts of POE resin, 70-140 parts of halogen-free compound retardant, 5-30 parts of modifier, 3-10 parts of lubricating dispersing agent and 0.1-0.6 parts of anti-oxidant. The preparation method comprises the following steps of: putting the POE resin, the halogen-free retardant, the modifying agent, the lubricating dispersing agent and the anti-oxidant into a high-speed mixing machine for mixing till the materials are heated to 65-75 DEG C through frication heat generated by mixing, discharging and cooling; and feeding a cooled mixed material into a double-screw extruder for melting and extruding, cooling an extruded bar stock with a water groove, and drawing into a granulating machine for granulating to obtain the halogen-free frame-retardant POE compound material. The elongation rate of the halogen-free flame-retardant POE compound material is over 600 percent, the oxygen index is over 30 percent, the liquidity of a melt is high, and the heat ageing resistance is high.

Owner:JIANGSU UNIV OF TECH

High-strength heat-resistant modified silicon rubber power cable sheath material

InactiveCN104292836AHigh strengthImprove heat resistanceRubber insulatorsInsulated cablesPolymer scienceBenzoyl peroxide

The invention discloses a high-strength heat-resistant modified silicon rubber power cable sheath material which is prepared from the following raw materials in parts by weight: silicone rubber, fluorine rubber, nano calcium carbonate, modified silica, potassium titanate whiskers, aluminum hydroxide, ferric oxide, tin oxide, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, methyltris(methylethylketoximino)silane, benzoyl peroxide, hydroxyl silicone oil, an amino silane coupling agent, dibutyltin dilaurate, magnesium oxide, a hydroxy stearic acid, an accelerant, an antiager, and a plasticizer. The high-strength heat-resistant modified silicon rubber power cable sheath material disclosed by the invention is high in strength and good in heat resistance, and a cable sheath prepared by using the high-strength heat-resistant modified silicon rubber power cable sheath material is good in comprehensive performance and long in service life.

Owner:ANHUI CONSTANT CRYSTAL CABLE GROUP

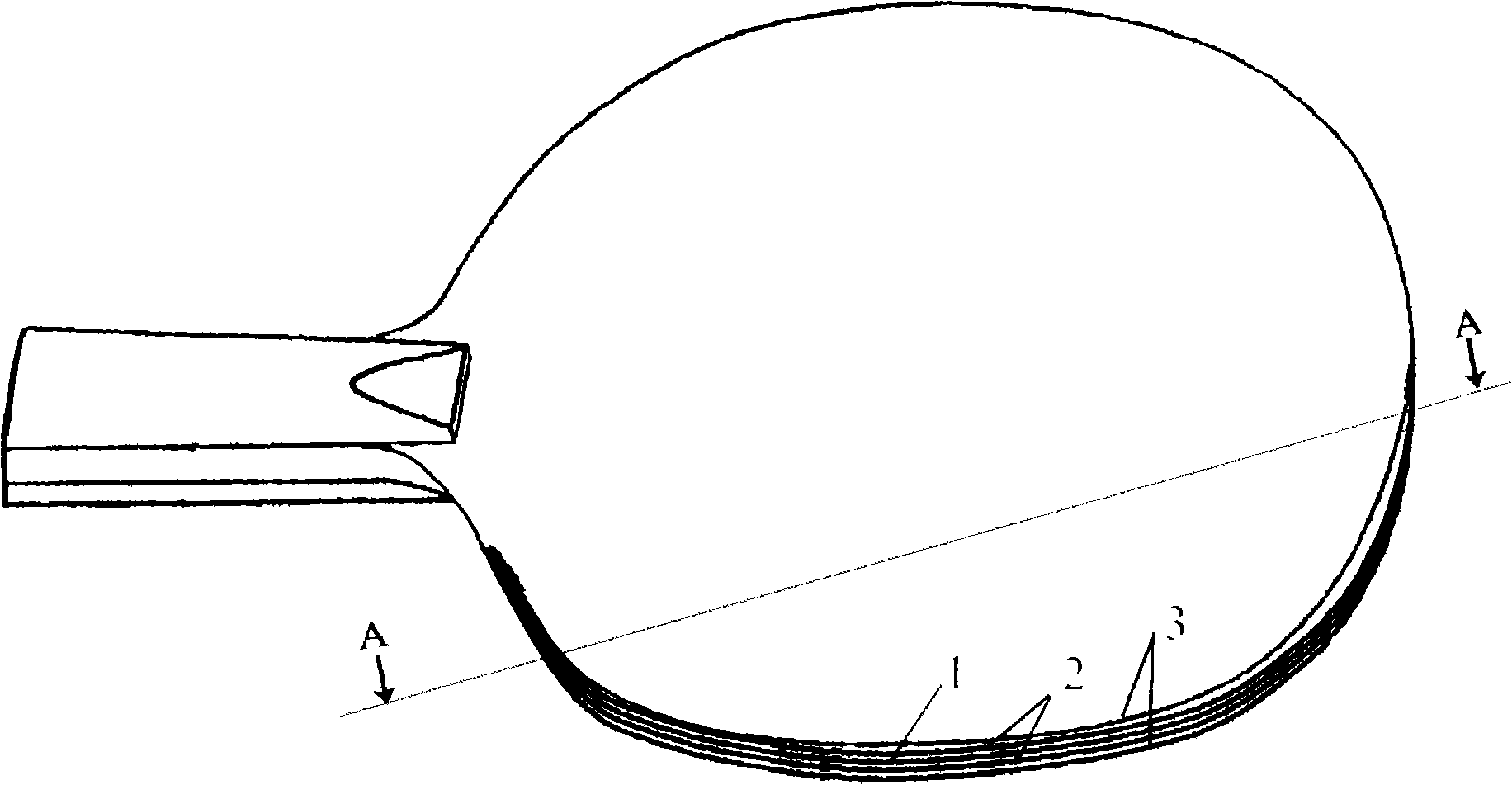

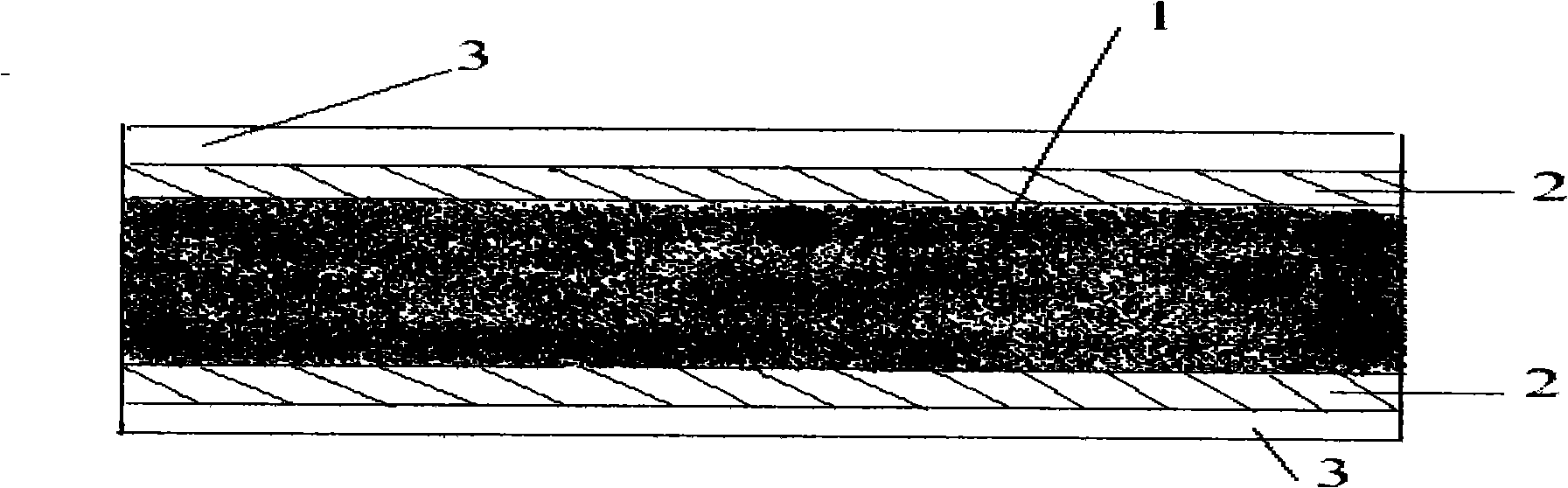

Inorganic composite plate and preparation and use thereof

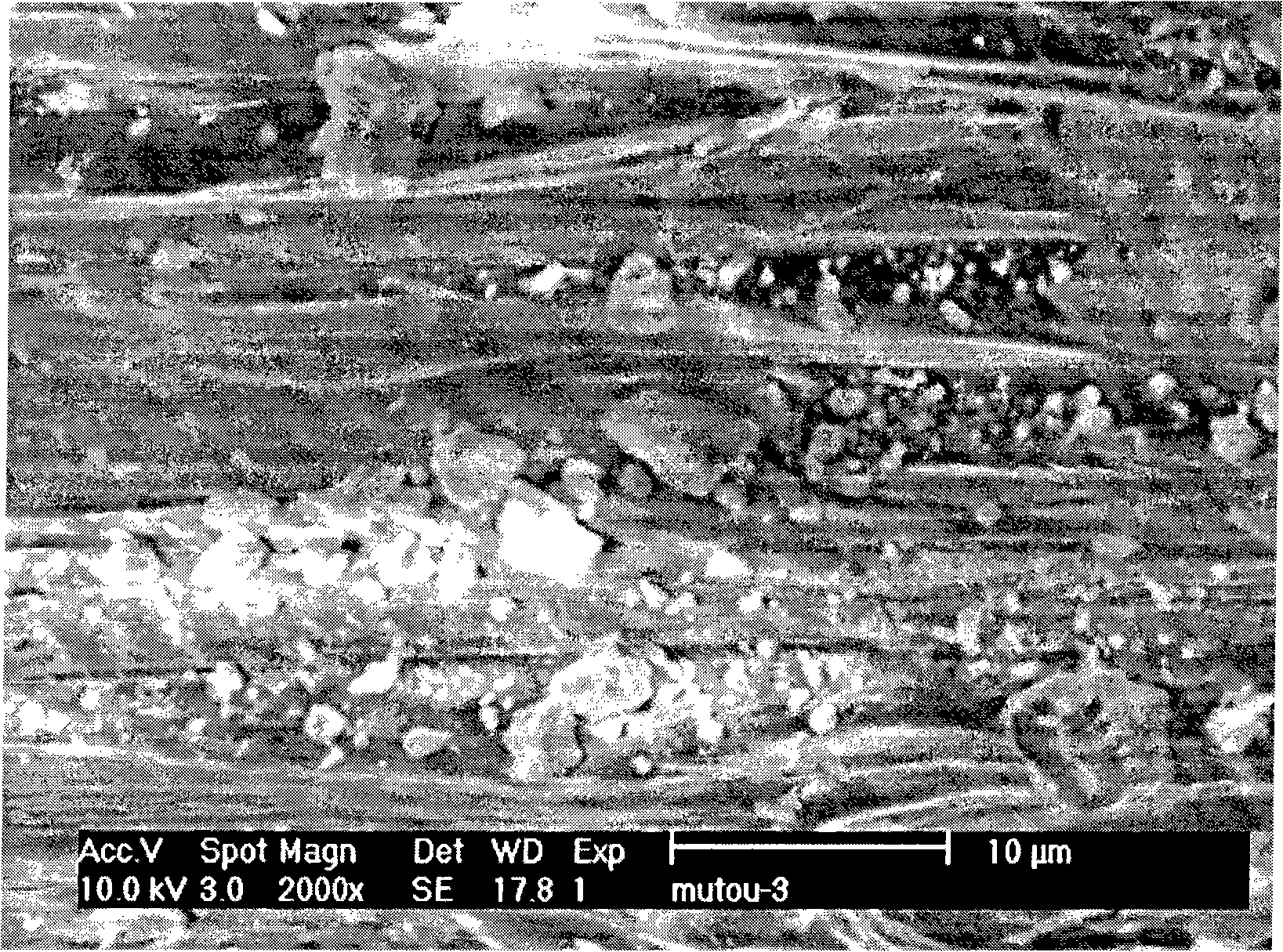

InactiveCN101279458AIncrease elasticityImprove mechanical propertiesWood treatment detailsRacket sportsRoom temperatureComposite plate

The invention provides a method for preparing inorganic composite plates. The invention includes the steps that: the plates are put into alkaline cooking liquor with the temperature ranging from 100 to 130 DEG C and taken out after being steamed and cooked for 1.5 to 3 hours; the processed plates are put into clear water for an immersion lasting for 24 to 48 hours at room temperature and dried in vacuum to reach the water content ranging from 10 percent to 15 percent so as to obtain the delignification plates; the delignification plates are then put into silicasol solution with a quality percentage concentration ranging from 10 percent to 20 percent for an immersion lasting for 20 to 26 hours and takes out to rest for 20 to 26 hours; the process is repeated for 3 to 5 times and finally the delignification plates are dried in vacuum at the temperature ranging from 60 to 110 DEG C till the water content of plates reaches 10 to 15 percent. The inorganic composite plates prepared according to the preparation method can be used for making bottom plates of table tennis bats which have the advantages of adjustable service performance, stable ball control, good rebound force, etc.

Owner:SOUTH CHINA UNIV OF TECH

PET (polyethylene glycol terephthalate) fiber/ceramic fiber composite sound absorbing cotton and preparation method of PET fiber/ceramic fiber composite sound absorbing cotton

InactiveCN102965840AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / ceramic fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of ceramic fibers, 10 to 15 parts of emulsifying agents OP-4, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SBR (styrene butadiene rubber), 15 to 20 parts of nanometer bauxite, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of glycerol triglycerin acid ester, 4 to 6 parts of triphenyl phosphate, 2 to 3 parts of microcrystalline wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of zinc stearate, 1 to 2 parts of lead sulfate tribasic, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 168. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

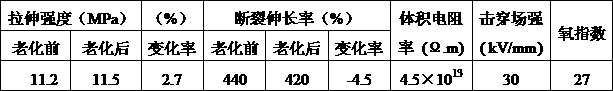

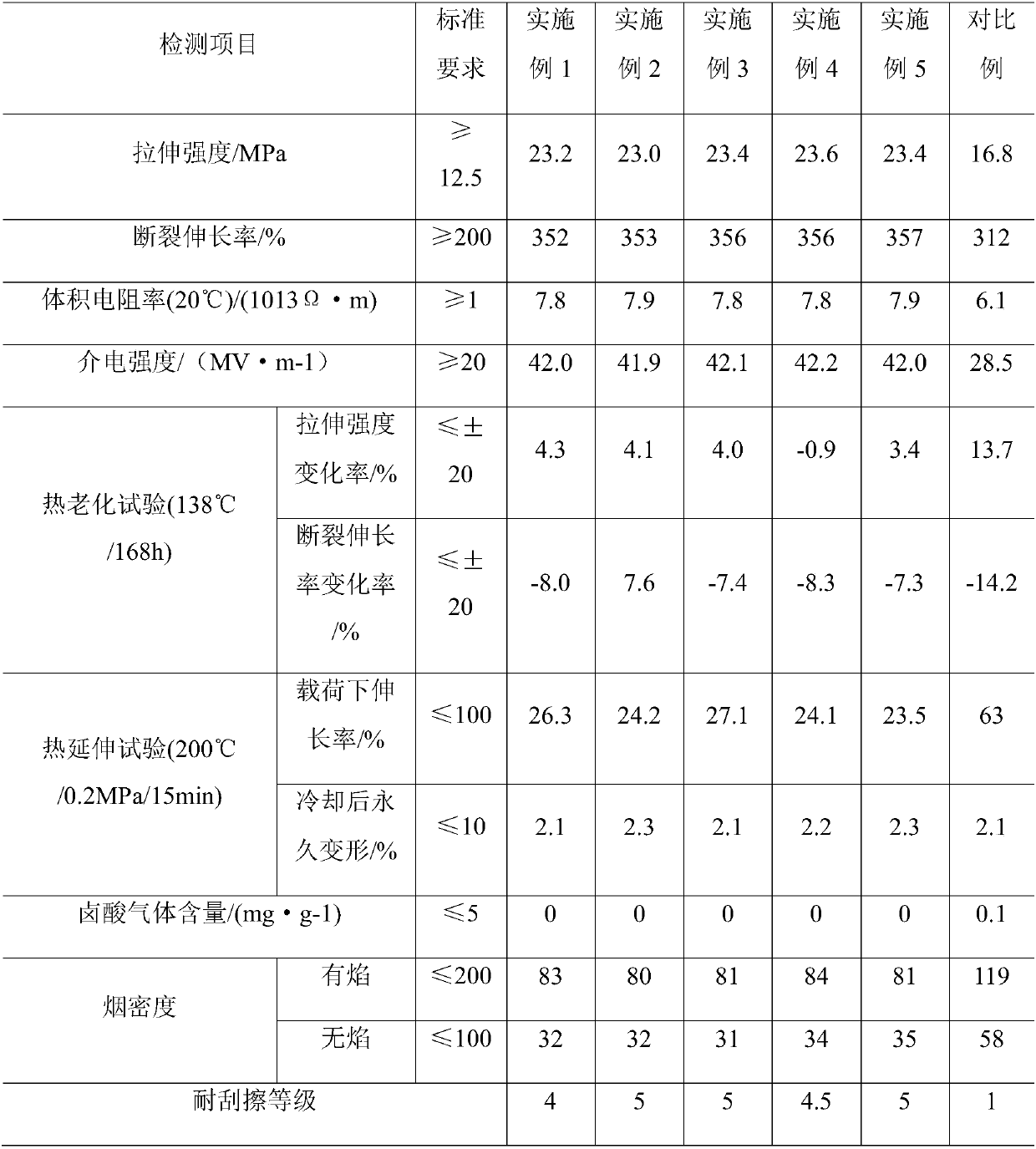

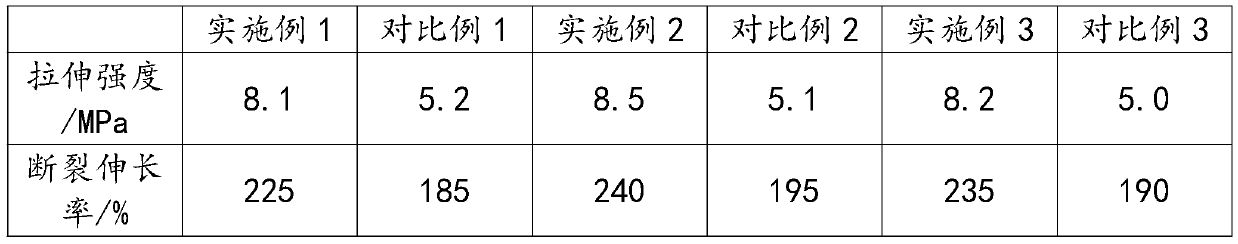

High-strength high-elongation flame retardant rubber insulated cable material and preparation process thereof

ActiveCN103232630AOvercome the difficulty of swinging glueImprove electrical performancePlastic/resin/waxes insulatorsInsulated cablesElastomerParaffin wax

The invention discloses a high-strength high-elongation flame retardant rubber insulated cable material and a preparation process thereof. The high-strength high-elongation flame retardant rubber insulated cable material comprises the following components in parts by weight: 8-14 parts of chlorinated polyethylene (CPE), 15-21 parts of ethylene-octylene copolymer elastomer (POE), 3-6 parts of fumed silica, 15-19 parts of aluminium hydroxide, 13-18 parts of calcined clay, 5-8 parts of 800# paraffin base rubber oil, 0.5-1 part of active magnesium oxide, 4-7 parts of superfine talcum powder, 1-2 parts of zinc oxide, 0.3-0.6 part of environmental stabilizer, 1-2 parts of microcrystalline wax, 0.5-1 part of titanium dioxide, 0.5-0.8 part of 4,4' bis(alpha, alpha dimethyl benzyl) diphenylamine, 1-2 parts of dicumyl peroxide and 1-1.5 parts of triallyl cyanurate. By adopting the high-strength high-elongation flame retardant rubber insulated cable material, uniform addition of inorganic powder is facilitated, a process range is wide, higher elongation at break is still maintained when a continuous vulcanizing temperature is 190-210 DEG C, a fire retardant and a high reinforced filler are added without reducing electrical property, and tensile strength and oxygen index are greatly increased; and cost is greatly reduced.

Owner:JIANGSU HENGTONG POWER CABLE

PET (polyethylene glycol terephthalate) fiber/aluminum silicate fiber composite sound absorbing cotton and preparation method of PET fiber/aluminum silicate fiber composite sound absorbing cotton

InactiveCN102965845AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / aluminum silicate fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of aluminum silicate fibers, 10 to 15 parts of emulsifying agents OP-10, 5 to 10 parts of peregal O-35, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of CPE (chlorinated polyethylene), 15 to 20 parts of nanometer celestite powder, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl maleate, 4 to 6 parts of zinc borate, 2 to 3 parts of ethylene bis stearamide, 1 to 2 parts of isopropyl dioleic(dioctylphosphate) titanate, 2 to 3 parts of calcium stearate, 1 to 2 parts of bi-sulfydryl isooctyl acetate di-n-octyl tin, 0.5 to 1.5 parts of anti-aging agents NBC and 1 to 2 parts of antioxidants DSTP. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

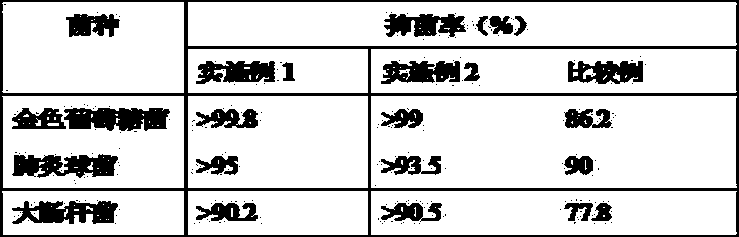

Antibacterial rubber condom and preparation method thereof

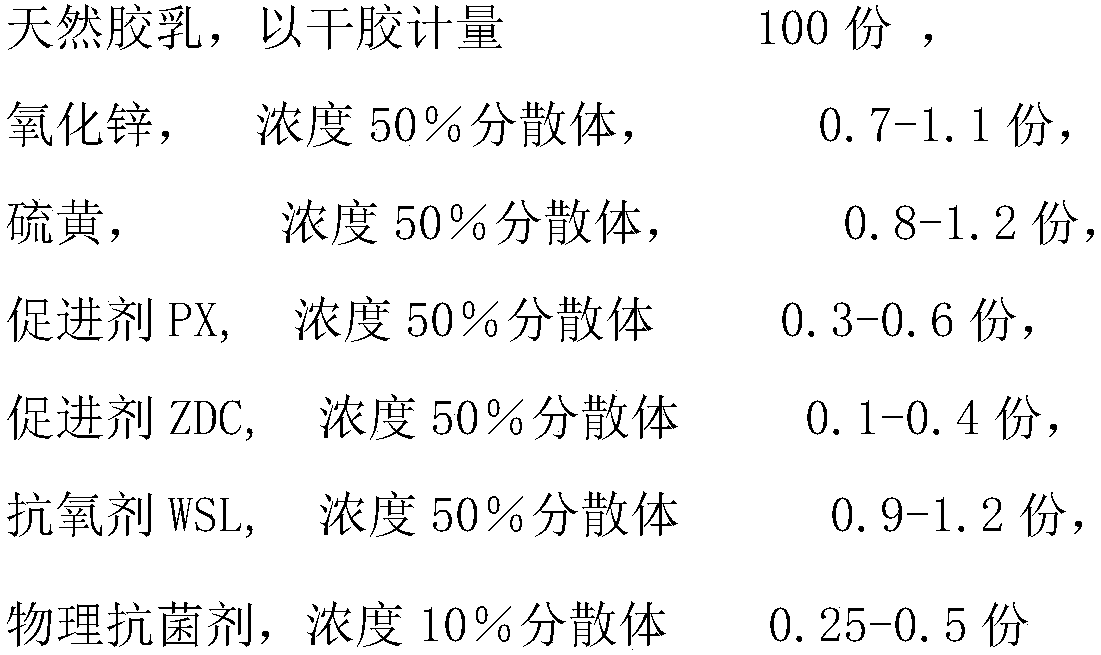

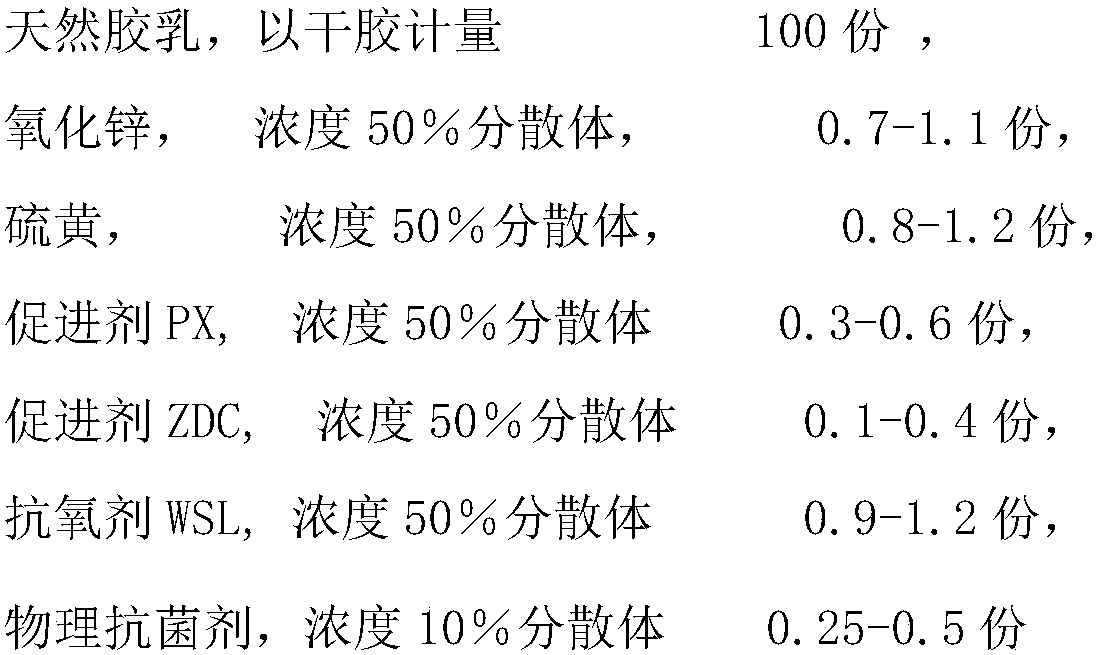

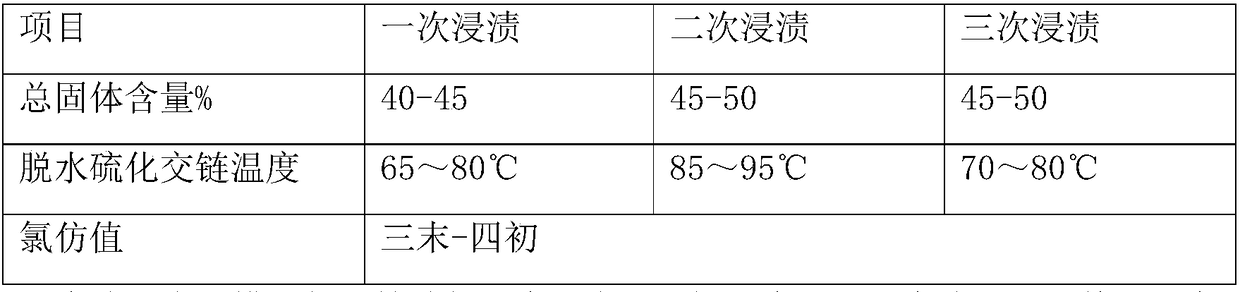

The invention relates to an antibacterial rubber condom and a preparation method thereof. The antibacterial rubber condom is prepared by using natural latex as a base material, and is prepared from the following raw materials in parts by mass: 100 parts of the natural latex (weighed based on dry latex), 0.7-1.1 parts of zinc oxide with 50% dispersion, 0.8-1.2 parts of sulfur with 50% dispersion, 0.3-0.6 part of an accelerant PX with 50% dispersion, 0.1-0.4 part of an accelerant ZDC with 50% dispersion, 0.9-1.2 parts of an antioxidant WSL with 50% dispersion, and 0.25-0.5 parts of a physical antibacterial agent with 10% dispersion. The antibacterial rubber condom is prepared by the steps of preparing emulsion, dipping, drying and vulcanizing, carrying out electric inspection, and the like.The antibacterial rubber condom has very good antibacterial effect and sterilizing effect.

Owner:SUZHOU COLOR WAY ENTERPRISE DEV

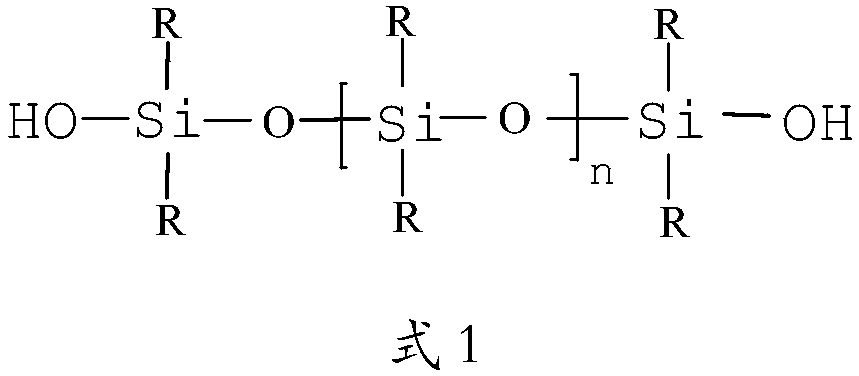

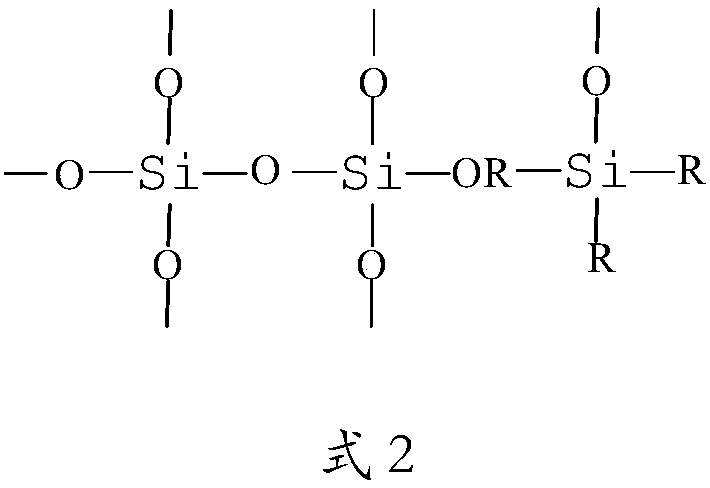

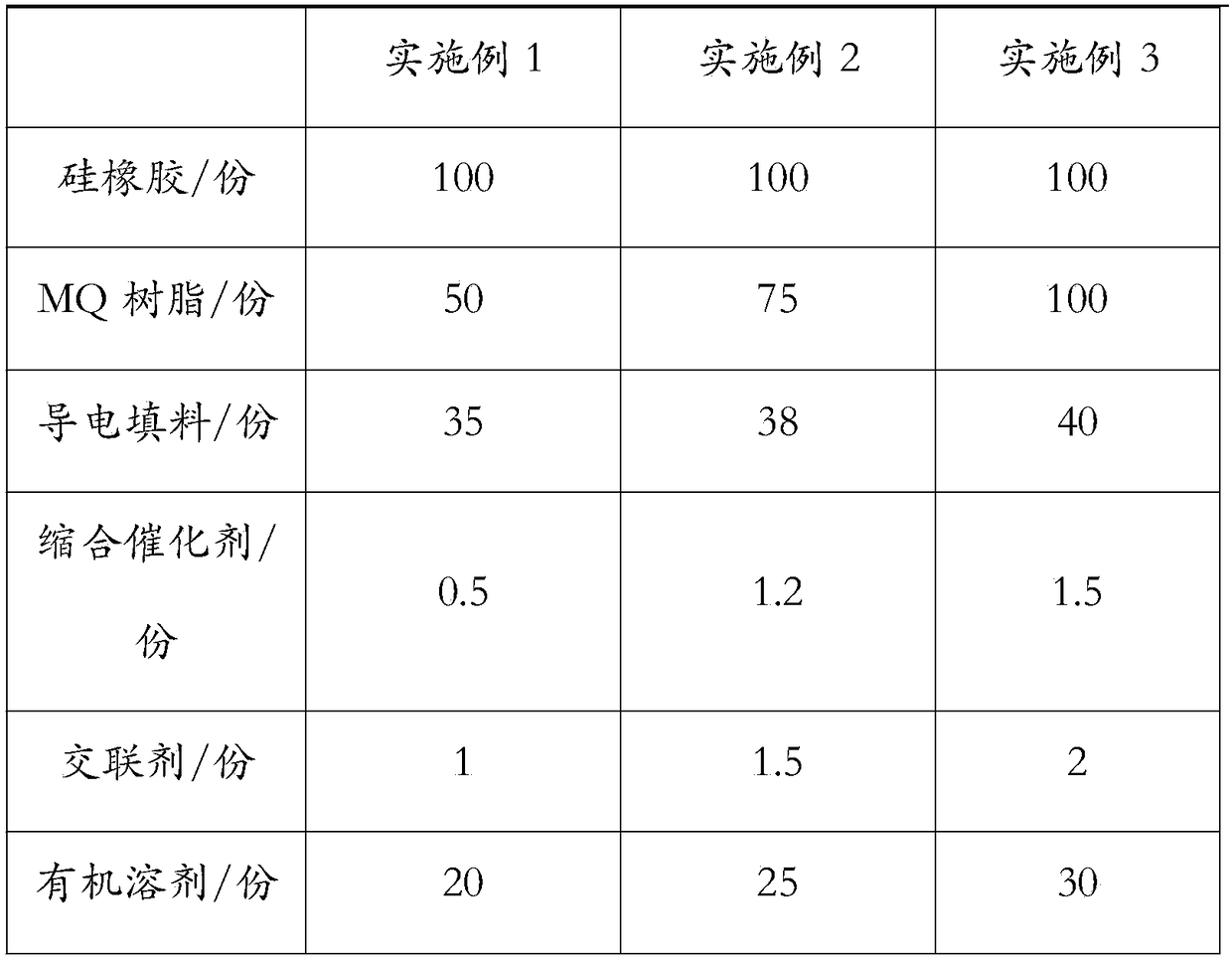

High and low temperature-resistant conductive organosilane pressure-sensitive adhesive and preparation method and application thereof

ActiveCN108865053AWide temperature rangeIncrease stickinessNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesOrganic solventUltimate tensile strength

The invention discloses a high and low temperature-resistant conductive organosilane pressure-sensitive adhesive and a preparation method and application thereof. The high and low temperature-resistant conductive organosilane pressure-sensitive adhesive is prepared from the following components in parts by weight: 100 parts of silicon rubber, 50 to 100 parts of silicon resin, 35 to 40 parts of conductive filler, 0.15 to 1.5 parts of condensation catalyst, 1 to 2 parts of crosslinking agent, and 20 to 30 parts of organic solvent. The high and low temperature-resistant conductive organosilane pressure-sensitive adhesive has the advantages that the temperature-resistant range is wider; the stable high stripping strength and viscosity-maintaining property can be maintained under the high temperature environment of 240 DEGC or above and the low temperature environment of -40 DEG C or below, the good conductivity can be maintained, and the higher viscosity and conductive property can be still maintained in the temperature change process; the high and low temperature-resistant conductive organosilane pressure-sensitive adhesive can be applied to the occasions requiring circuit connecting,such as installation of electronics and electric appliances, so as to reach the function of using adhering to replace welding.

Owner:SHENZHEN NIKTO TAPE NEW MATERIAL CO LTD

Silicone sponge health care material and preparation method and application thereof

InactiveCN104194342ABalance electrolytePromote blood circulationRubber layered productsBacteriostatic agentFamily medicine

The invention discloses a silicone sponge health care material and a preparation method and application thereof. The silicone sponge health care material comprises the following ingredients in percentage by mass: 60-70 percent of silicone main materials, 1-7 percent of a foaming agent, 5-15 percent of a deodorant bacteriostatic agent, 15-25 percent of anion powder, 5-18 percent of far infrared ray powder, 0.1-1.5 percent of a vulcanizing agent and 0.05-1.0 percent of a vulcanizing accelerator. The preparation method comprises the following steps of preparation of a mixture and mould pressing or injection molding. The silicone sponge health care material has the advantages of weight loss, water absorption, ventilation, bacteriostasis, deodorization and the like, and products made of the silicone sponge health care material are comfortable in wearing and wide in range of application.

Owner:何相华

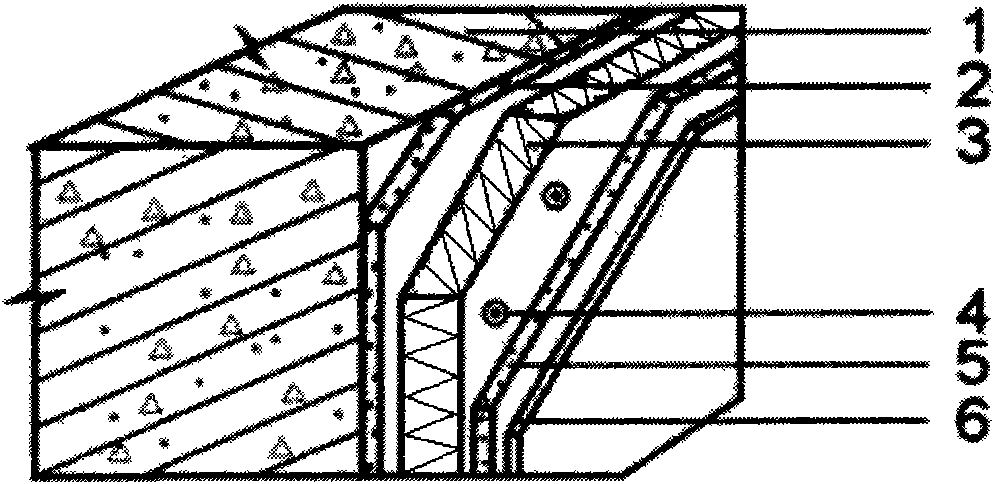

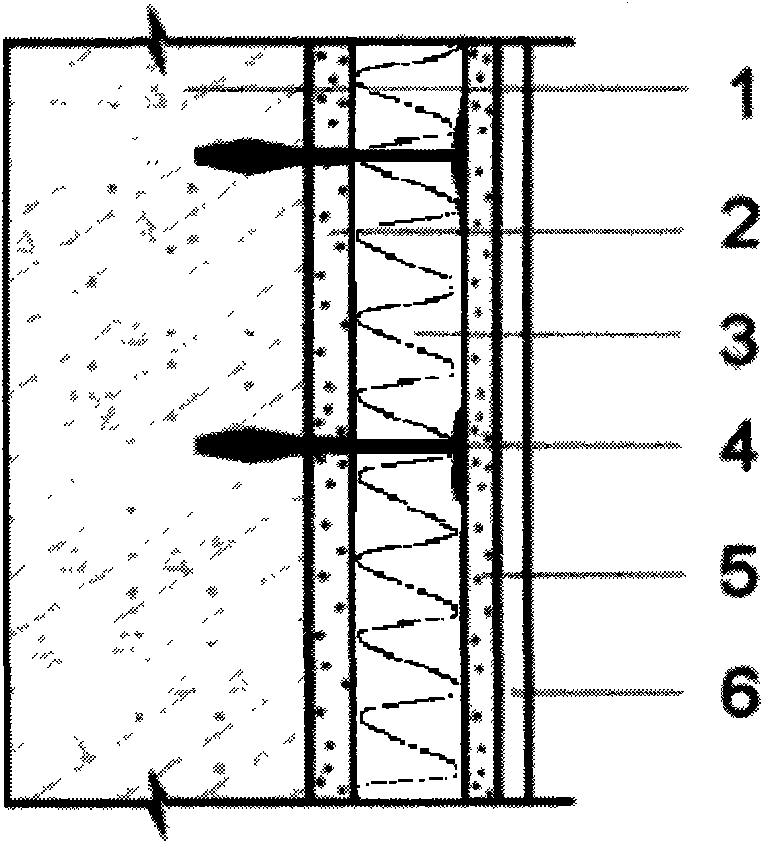

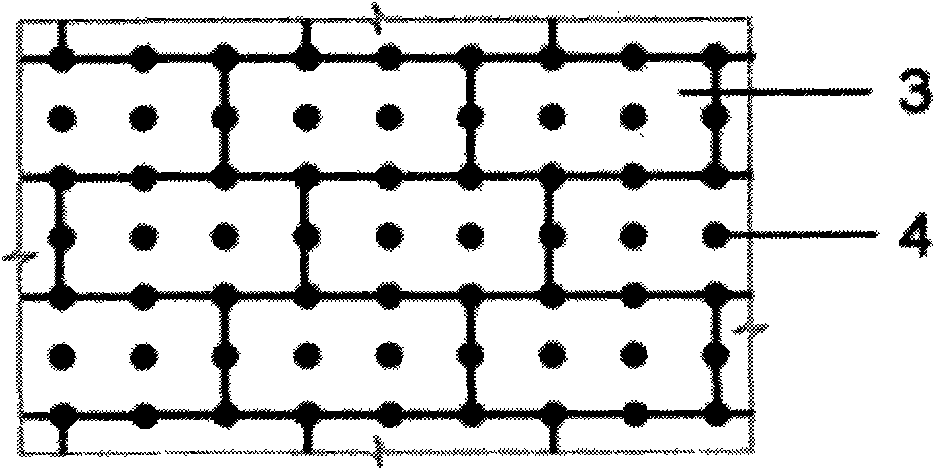

Outer heat insulating wall body for mechanically anchoring grid reinforcing rib mineral wool plate and construction process thereof

InactiveCN102002989AHigh tensile strengthImprove flexural strengthWallsClimate change adaptationEngineeringSurface preparation

The invention relates to an outer heat insulating wall body for anchoring a grid reinforcing rib mineral wool plate by adopting a mechanical fixing device and a construction process thereof, which is characterized in that the wall body of a basic layer is leveled to be used as a combined layer; the grid reinforcing rib mineral wool plate for heat insulation is bonded on the wall before a leveling layer is dried so as to take the action of auxiliary connection and stabilization and to guarantee the flatness of the mineral wool plate; drill holes are carried out on the surface of the plate, and the grid reinforcing rib mineral wool heat insulating plate is directly fixed on the wall body of the basic layer by adopting a plastic expansion anchor so that all load of the outer heat insulating system is fully loaded by a fixed anchor bolt and is transferred to the wall body of the basic layer structure; and the organic combination of the anchor bolt and the reinforcing rib mineral wool plate can simultaneously take the action of the auxiliary stabilization on the load of the leveling layer of the wall body of the basic layer. Thus, the outer heat insulating wall body and the construction process thereof are especially suitable for the outer heat insulating and energy saving modification project of the outer wall of a building and can preferably solve the technical difficulties of poor loading force and difficult surface treatment of the old basic layer of the outer wall.

Owner:SHANGHAI ONE GOLD ENERGY SAVING TECH

Environment-friendly cable insulation layer, and preparation method thereof

InactiveCN107722439AHas flame retardant propertiesImprove scratch resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolyolefin

The invention discloses an environment-friendly cable insulation layer, and belongs to the field of wire cable. The environment-friendly cable insulation layer comprises an internal insulation layer and an external insulation layer; a double layer co-extrusion insulation layer is composed of the internal insulation layer and the external insulation layer; the internal insulation layer is preparedfrom an irradiation crosslinked polyethylene insulation material; the external insulation layer is prepared from a low-smoke halogen-free flame-resistant irradiation crosslinked polyolefin insulationlayer; the external insulation layer comprises, by weight, 43 to 65 parts of an ethylene-vinyl acetate copolymer, 40 to 60 parts of linear low density polyethylene, 35 to 47 parts of ethylene propylene diene monomer, 54 to 75 parts of a scratch-resistant agent, 25 to 30 parts of a sensitizing agent, 48 to 60 parts of a silicon nitrogen flame retardant, 25 to 35 parts of a composite anti-aging agent, 12 to 20 parts of a reinforcing filler, and 25 to 35 parts of a composite compatilizer. The environment-friendly cable insulation layer, is friendly to the environment, and is capable of improvingthe scratch resistance of cables greatly.

Owner:南京创贝高速传动机械有限公司

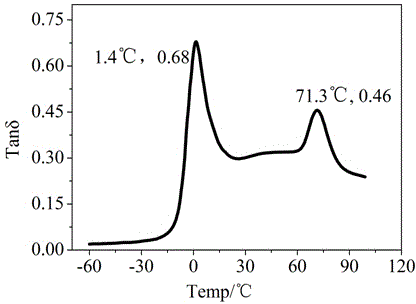

Preparation method of wide-temperature-range and high-damping rubber and plastic blended foam material

InactiveCN103951921AHalogen Free Flame RetardancyWide damping temperature rangePolymer scienceVulcanization

The invention discloses a preparation method of a wide-temperature-range and high-damping rubber and plastic blended foam material. The preparation method comprises the following steps of carrying out first-stage mixing by using an internal mixer, adding polylactic acid firstly, then, adding ethylene-polyvinyl acetate rubber and white carbon black, and mixing; carrying out second-stage mixing by using a two-roll mixing mill, sequentially adding zinc oxide, stearic acid, a foaming agent and a vulcanizing agent BIPB into a first-stage rubber compound at normal temperature, thinning and batching off to prepare a rubber compound a; standing the rubber compound a for 8-16h, then, molding, vulcanizing and foaming by using a plate vulcanizing machine to prepare a wide-temperature-range and high-damping blended material with uniform foam holes. The preparation method has the beneficial effects of effectively widening the damping temperature range and increasing damping factors; and in addition, the material prepared by using the preparation method disclosed by the invention is uniform in foam holes, smooth in surface, attractive in appearance and excellent in mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH

Efficient halogen-free flame retardant butadiene styrene rubber composition and preparation method thereof

InactiveCN107118412AHigh synergistic flame retardant performanceFlame retardantPolymer sciencePliability

The invention discloses an efficient halogen-free flame retardant butadiene styrene rubber composition and a preparation method thereof. The efficient halogen-free flame retardant butadiene styrene rubber composition is prepared from the following raw materials in parts by weight: 100 parts of butadiene styrene rubber, 20 to 40 parts of hydroxymethylated lignin, 40 to 80 parts of transition metal silicate, 40 to 60 parts of magnesium hydrate, 20 to 40 parts of carbon black, 5 to 8 parts of activating agent, 2 to 4 parts of anti-aging agent, 0.6 to 1.2 parts of promoter, and 1 to 3 parts of vulcanizing agent. By adopting the efficient halogen-free flame retardant butadiene styrene rubber composition disclosed by the invention, on the premise of ensuring the mechanical performance such as flexibility, tensile strength and tearing strength of a product, the limit oxygen index is increased remarkably, and less smoke and nontoxicity are realized during burning.

Owner:SOUTH CHINA UNIV OF TECH

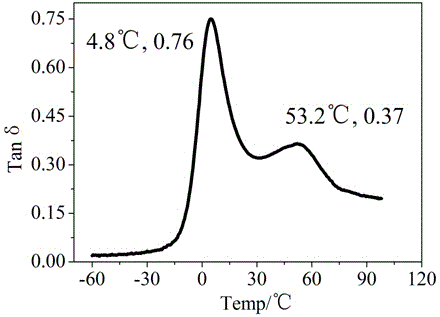

Heat conducting adhesive and preparation method and application thereof

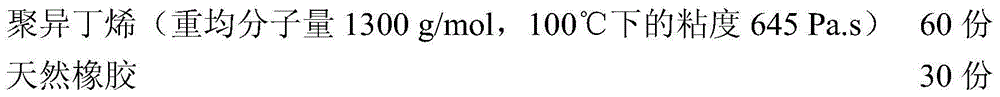

ActiveCN104817985AAchieve a tight bondImprove performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a macromolecular heat conducting composite material, in particular to a heat conducting adhesive and a preparation method and application thereof. The heat conducting adhesive is made of, by weight, 60-100 parts of softener, 20-60 parts of rubber flexibilizer, 50-150 parts of heat conducting filler, 2-10 parts of tackifier, 0.2-5 parts of antioxidant and 0.2-5 parts of antiager. The preparation method includes the steps: rolling the rubber flexibilizer, sequentially adding the softener, the heat conducting adhesive, the tackifier, the antioxidant and the antiager, and mixing for 1-2h at the temperature of 80-150 DEG C to obtain the heat conducting adhesive. The heat conducting adhesive has the advantages of freeness of curing, convenience in processing, excellent adhesion performance, high heat conductivity and the like. Close adhesion of devices can be realized only by application of a proper pressure at the normal temperature, and the heat conducting adhesive is cheap and environment friendly.

Owner:国科广化(南雄)新材料研究院有限公司 +1

PET (polyethylene glycol terephthalate) fiber/polyimide fiber composite sound absorbing cotton and preparation method of PET fiber/polyimide fiber composite sound absorbing cotton

InactiveCN102965846AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / polyimide fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of polyimide fibers, 10 to 15 parts of emulsifying agents OP-15, 5 to 10 parts of peregal O-10, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SBS (styrene butadiene styrene block polymer), 15 to 20 parts of nanometer dolomite powder, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dibutyl phthalate, 4 to 6 parts of triethyl phosphate, 2 to 3 parts of ethylene bis oleamide, 1 to 2 parts of tetraisopropyl di(dioctylphosphate) titanate, 2 to 3 parts of calcium stearate, 1 to 2 parts of lead sulfate tribasic, 0.5 to 1.5 parts of anti-aging agents MB and 1 to 2 parts of antioxidants 1010. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

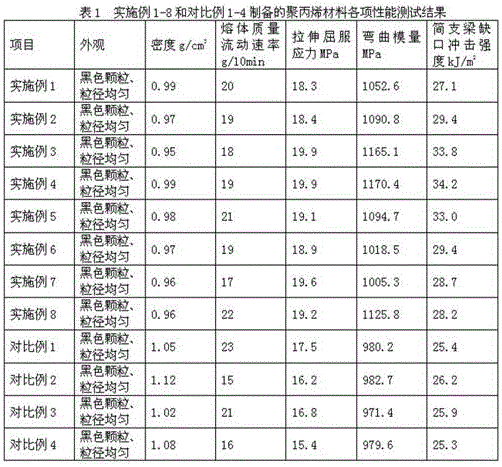

Polypropylene material for car bumper and preparation method of polypropylene material

The invention discloses a polypropylene material for a car bumper and a preparation method of the polypropylene material. The polypropylene material for the car bumper is prepared from, by weight, 50-80 parts of isotatic polypropylene, 20-30 parts of a thermoplastic elastomer, 10-30 parts of modified inorganic filler, 0.1-0.5 part of an antioxidant, 0.2-0.6 part of a coupling agent, 0.1-0.3 part of an ultraviolet light absorbent and 2-9 parts of a lubricating agent. According to the polypropylene material for the car bumper and the preparation method of the polypropylene material, wollastonite powder and glass fibers are activated and modified by the aluminic acid ester coupling agent and then coordinate with the lubricating agent in the raw materials to form a winding structure, so that the interface compatibility of a wollastonite powder and glass fiber pre-polypropylene material is greatly enhanced; accordingly, polypropylene particles cannot break away from a base material in the impact process, and the impact resistance of the polypropylene material is improved from the source.

Owner:HUANGHE S & T COLLEGE

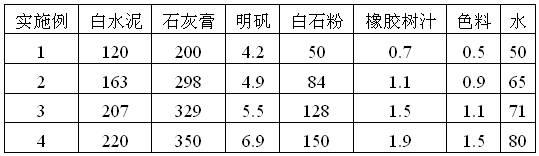

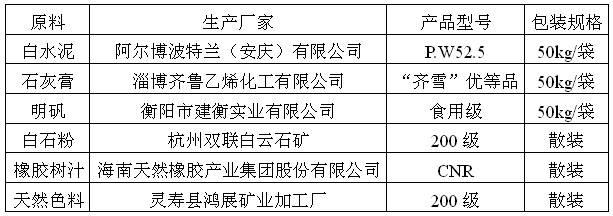

Natural building exterior wall coating

A natural building exterior wall coating is mixed by raw materials including, by weight, from 120 to 220 parts of white cement, from 200 to 350 parts of lime putty, from 4.2 to 6.9 parts of alum, from 50 to 150 parts of white stone powder, from 0.7 to 1.9 parts of rubber sap, from 0.5 to 1.5 parts of pigment and from 50 to 80 parts of water. Particular preparation method include crushing the white stone powder and the alum; then mixing the white cement with the lime putty, feeding mixture of the cement and the lime putty into a blender, sequentially feeding the crushed white stone powder and the crushed alum into the blender, uniformly stirring the materials in the blender, then adding the rubber sap into the blender and uniformly mixing the materials in the blender; and discharging dry solid after stirring, adding the water and the pigment into the solid and preparing the natural building exterior wall coating finished product. The natural building exterior wall coating has excellent technical performances and is low in cost, the consumed raw materials are natural, non-toxic and harmless, resources can be saved, environments are protected, and the natural building exterior wall coating can be widely applied to exterior coating projects of various buildings.

Owner:无锡市康顺节能材料科技有限公司

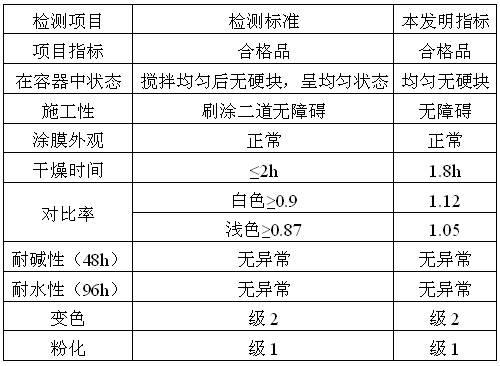

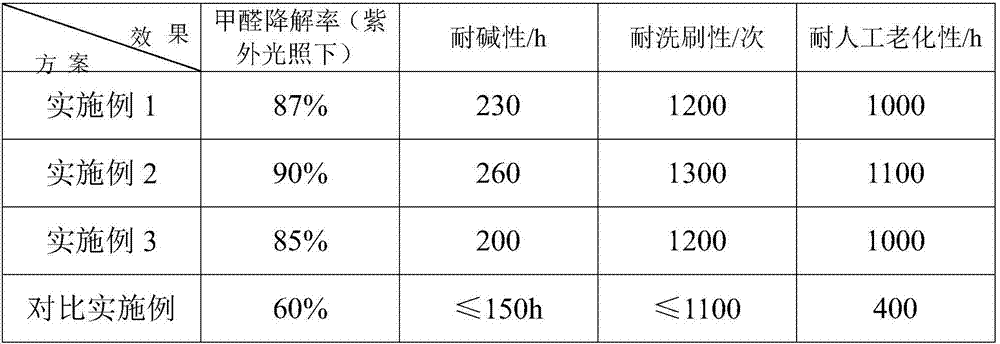

Synthetic method of high-performance mesoporous nano TiO2 as well as application thereof in latex paint

InactiveCN108002436AReduce concentrationInhibit bindingMaterial nanotechnologyAntifouling/underwater paintsAcetic acidAlcohol

The invention discloses a synthetic method of high-performance mesoporous nano TiO2 as well as application thereof in latex paint, which belongs to the technical field of nano TiO2. The synthetic method comprises the following steps: adding deionized water and glacial acetic acid into absolute ethyl alcohol to prepare a mixed solution; successively dropwise adding tetrabutyl titanate TBOT solution, polyethyleneglycol 400 and cetyl trimethyl ammonium bromide CTAB into the mixed solution in a stirring process, forming a sol system, placing the sol system into a hydrothermal reaction kettle to perform the hydrothermal reaction, obtaining precursor precipitates, successively centrifugally washing, drying and roasting the precursor precipitates, and obtaining the mesoporous nano TiO2 having anordered mesoporous passage. The prepared mesoporous nano TiO2 has high reinforcing performance and high catalytic activity. When the mesoporous nano TiO2 is applied to latex paint, the stability of alatex paint film is improved, a high effect for killing bacteria in indoor air can be realized, the latex paint has a lasting efficacy for resisting bacteria and killing the bacteria, and the indoor hygienic condition is effectively improved.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Antiaging rubber

InactiveCN107254074AImprove anti-aging propertiesLong anti-aging timeMicrocrystalline waxPolymer science

The invention belongs to the technical field of rubber, and specifically discloses an anti-aging rubber, which is prepared from the following components in parts by weight: 70-90 parts of natural rubber SVR3L, 10-30 parts of butadiene rubber 9000, 5-8 parts of zinc oxide, 1-2 parts of stearic acid, 5-8 parts of ordinary paraffin, 3-5 parts of microcrystalline wax, 3-5 parts of coumarone resin, 2-3 parts of coupling agent, 2-5 parts of dispersing aid, softener 5-10 parts, anti-aging agent mixture 5-7 parts, accelerator mixture 1.3-1.8 parts, carbon black mixture 70-85 parts, sulfur 1.8-2.5 parts, anti-scorch agent 0.2-0.4 parts. The anti-aging agent mixture is anti-aging agent RD, anti-aging agent 4010NA, and the accelerator mixture is accelerator CZ, accelerator DM, and accelerator TMTD. The anti-aging rubber of the invention has good anti-oxidation and anti-aging capabilities, and good mechanical strength and fatigue resistance.

Owner:ZHEJIANG HONGLEE AUTO PARTS

Nano hybrid filler reinforced rubber material and preparation process thereof

The invention discloses a nano hybrid filler reinforced rubber material prepared from the following raw materials in parts by weight: 40-50 parts of natural rubber, 20-30 parts of auxiliary material rubber, 5-7 parts of a hybrid filler, 10-12 parts of white carbon black, 2-3 parts of cerium dioxide, 2-3 parts of asbestos fibers, 35-45 parts of tetrahydrofuran, 11-15 parts of oil, 1-2 parts of stearic acid, 4-6 parts of nano zinc oxide, 0.7-0.8 part of an accelerant, 3-5 parts of sulfur and 0.6-1 part of an anti-aging agent. The invention also discloses a preparation process of the rubber material. The natural rubber and the auxiliary material rubber are used as rubber matrixes, the auxiliary material rubber comprises ethylene propylene diene monomer rubber, nitrile rubber, fluororubber andbutadiene rubber, the auxiliary material rubber plays a complementary role in the natural rubber, and the rubber matrix with excellent performance is obtained; through compounding of the hybrid filler, the white carbon black, the cerium dioxide and the asbestos fibers, the rubber is reinforced, and the mechanical property and the wear resistance of the rubber material are improved, so that the service life of the rubber material is prolonged.

Owner:杭州睿琦化工科技有限公司

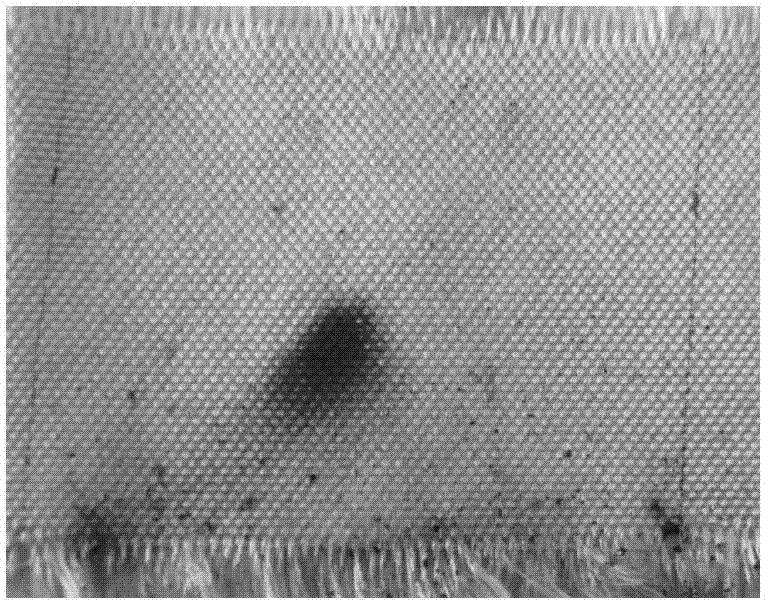

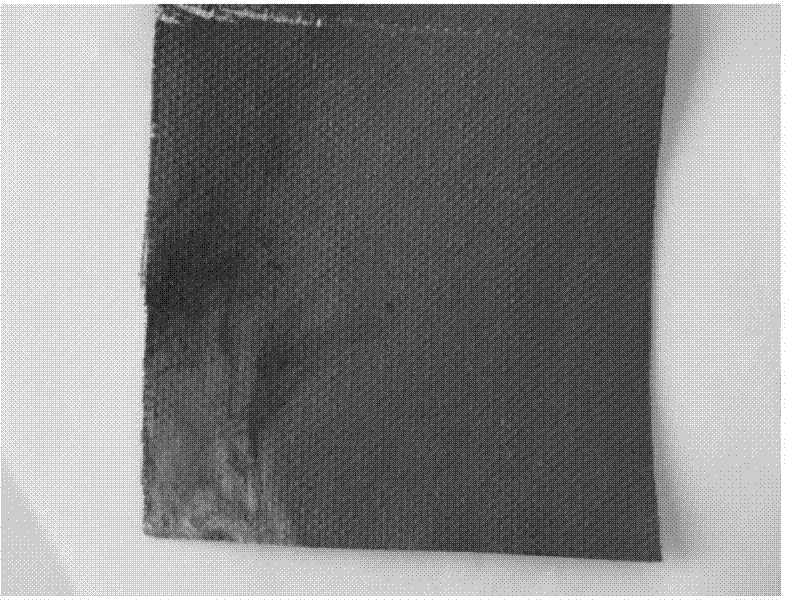

Anti-bacterial composite paint for fabrics and preparation method of anti-bacterial composite paint

The invention relates to an anti-bacterial composite paint for fabrics and a preparation method of the anti-bacterial composite paint. The anti-bacterial composite paint is prepared from base material paint and surface paint, wherein the base material paint is prepared from the following raw materials in parts by weight: 60-70 parts of unsaturated polyester resin, 4-5 parts of silver-coated copper powder, 3-8 parts of 1,4-butanediol, 10-13 parts of triethylamine, 1-3 parts of nano-zinc oxide, and 0.2-0.5 part of jade powder; and the surface paint is prepared from the following raw materials in parts by weight: 10-15 parts of polyvinyl alcohol, 10-15 parts of tea tree oil, 8-9 parts of zinc sulfide, 1-5 parts of butadiene-styrene, 0.1-1.3 parts of adipic acid lipid polyester plasticizer, 1-4 parts of magniferous aluminum oxide, and 0.2-0.6 part of gaseous silicon dioxide. The paint for fabrics has good anti-bacterial property and is harmless to human body.

Owner:宿迁和泰户外用品有限公司

High-temperature-resistant butyl pressure sensitive adhesive and preparation method

ActiveCN110358476AGood heat resistanceStrong adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesChemistryCorrosion

The application provides a high-temperature-resistant butyl pressure sensitive adhesive and a preparation method, wherein the high-temperature-resistant butyl pressure sensitive adhesive comprises thefollowing raw materials by weight: 20-30% of butyl rubber, 5-15% of SEBS, 10-15% of polyisobutylene with a molecular weight of 70000-100000, 10-15% of polyisobutylene with a molecular weight of 30000-60000, 15-25% of a tackifying resin, 20-40% of a filler, and 0.5-1.5% of an antioxidant. According to the present invention, the high-temperature-resistant butyl pressure sensitive adhesive does notcontain asphalt components, has good heat resistance, and has excellent adhesion under normal temperature and high temperature conditions; by using SEBS with high hard section glass transition temperature and high mechanical property, the shear strength of the butyl pressure sensitive adhesive at a high temperature is improved while the aging resistance and the corrosion resistance of the butyl pressure sensitive adhesive are improved; and the used inorganic filler has reinforcing effect so as to improve the cohesive strength and the soil shear resistance of the butyl pressure sensitive adhesive.

Owner:廊坊市中油嘉昱防腐技术有限公司

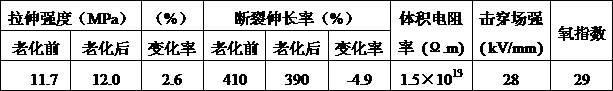

Method for reinforcing silicone rubber by applying liquid crystal polymer microfibrillation

The invention belongs to the field of silicone rubber reinforcement and in particular relates to a method for reinforcing silicone rubber by applying liquid crystal polymer microfibrillation. Ingredients of a composite material comprise high temperature vulcanized silicone rubber, white carbon black and liquid crystal polymers. A preparation method comprises the following steps: firstly preparingmaterials according to the ingredients, uniformly mixing on a mixer by adopting a melting and heat mixing method, and then vulcanizing, so that the silicone rubber-based composite material is obtained. the method provided by the invention has the advantages that the liquid crystal polymers can be fibrillated into a fibrous structure in a processing process, anchoring effect is achieved, mechanicalproperties of the silicone rubber-based composite material are improved, and the development requirement that the future silicone rubber-based composite material gives consideration to flame retardance, heat resistance, low density and high strength at the same time.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com