High-temperature-resistant butyl pressure sensitive adhesive and preparation method

A high-temperature-resistant, pressure-sensitive adhesive technology, applied in adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the heat resistance, soil stress and shear resistance of asphalt modified butyl pressure-sensitive adhesives Poor cutting ability, wrinkling and sagging, affecting the anti-corrosion service life of cold-wound tapes, etc., to achieve the effects of improving cohesive strength and soil shear resistance, improving aging resistance, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

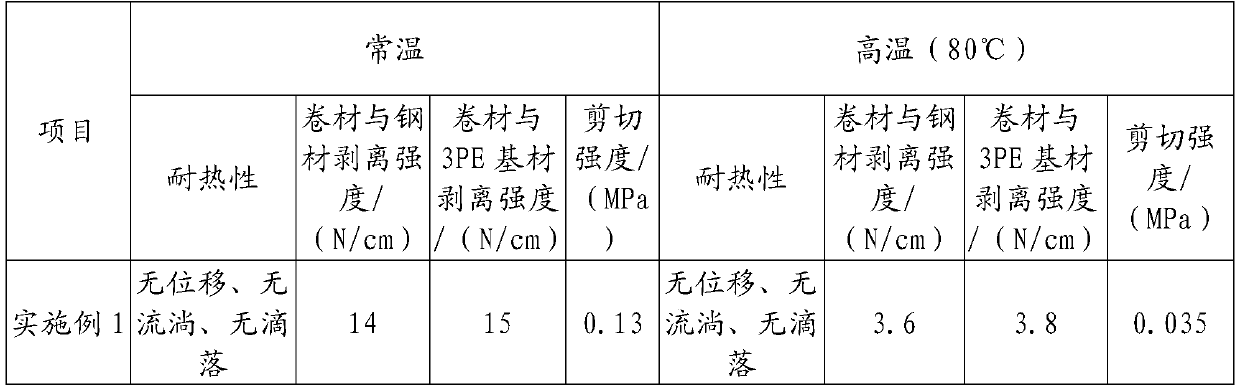

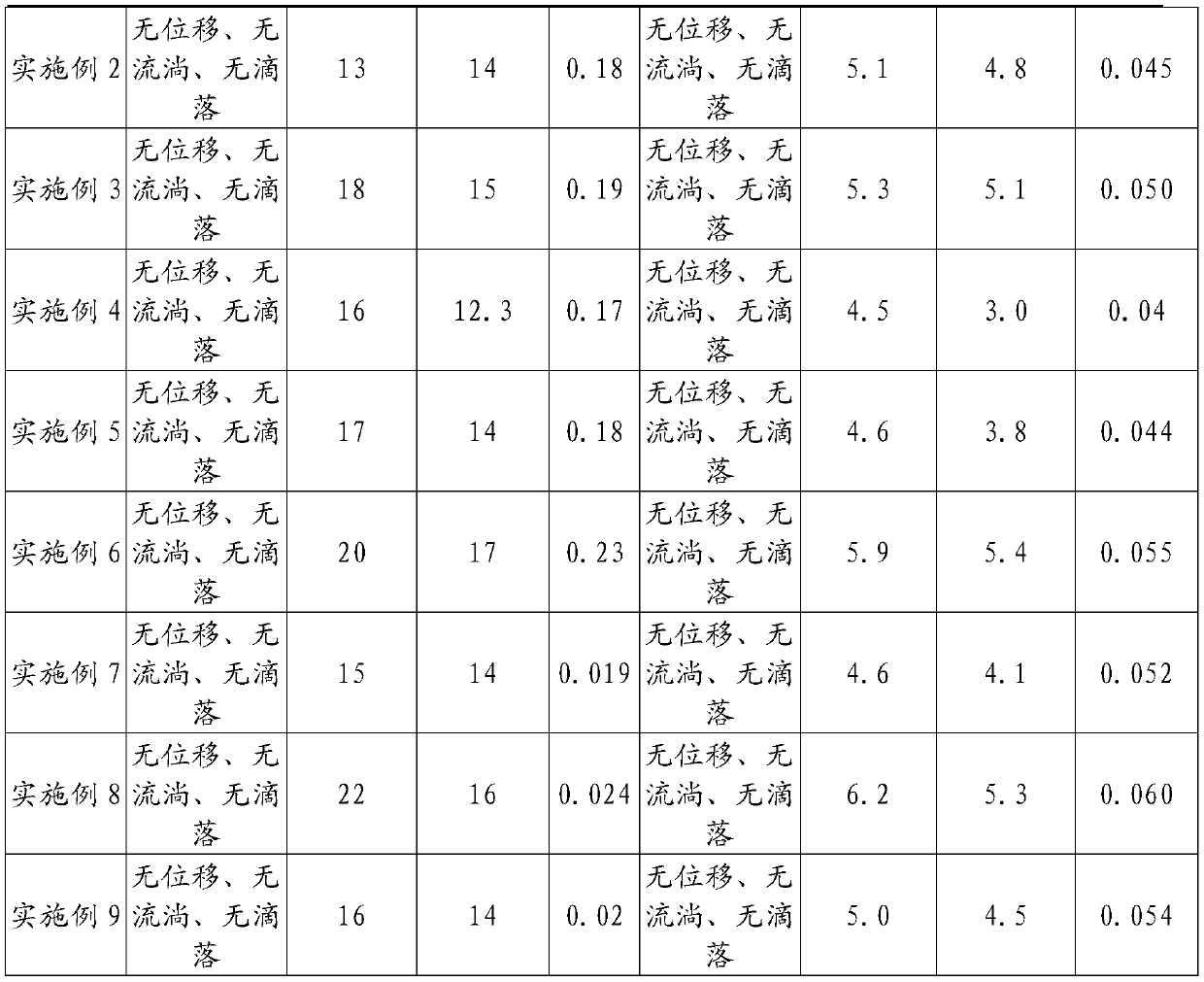

Examples

Embodiment 1

[0024] A kind of high temperature resistant butyl pressure-sensitive adhesive, its preparation process is as follows:

[0025] 1) In parts by weight, 20 parts of butyl rubber, 10 parts of polyisobutylene with a molecular weight of 70,000 to 100,000 and 39.5 parts of filler are put into a double-roll mill for mixing, and after mixing evenly, a film is produced;

[0026] 2) Add 15 parts of tackifying resin and 5 parts of SEBS into the kneader and stir, and gradually heat to 140-150°C, melt and mix the tackifying resin and SEBS to obtain mixture A;

[0027] 3) Add 10 parts of polyisobutylene with a molecular weight of 30,000 to 60,000 to the mixture A obtained in step 2), and further melt and mix it evenly at 140-150° C. to obtain mixture B;

[0028] 4) To the mixture B obtained in step 3), add the raw rubber sheet kneaded in step 1) and 0.5 parts of antioxidant in turn, stir at 140-150°C for 1 hour and discharge to obtain high temperature resistant butyl pressure sensitive glue...

Embodiment 2

[0031] A kind of high temperature resistant butyl pressure-sensitive adhesive, its preparation process is as follows:

[0032] 1) In parts by weight, 20 parts of butyl rubber, 12 parts of polyisobutylene with a molecular weight of 70,000-100,000 and 25 parts of fillers are put into a double-roll mill for mixing, and after mixing evenly, a film is produced;

[0033] 2) Add 20 parts of tackifying resin and 10 parts of SEBS into the kneader and stir, and gradually heat to 140-150°C, melt and mix the tackifying resin and SEBS to obtain mixture A;

[0034] 3) Add 12 parts of polyisobutylene with a molecular weight of 30,000 to 60,000 to the mixture A obtained in step 2), and further melt and stir at 140-150°C to obtain mixture B;

[0035] 4) To the mixture B obtained in step 3), add the raw rubber sheet kneaded in step 1) and 1 part of antioxidant in turn, stir at 140-150°C for 1 hour and discharge to obtain high temperature resistant butyl pressure sensitive glue.

[0036] Speci...

Embodiment 3

[0038] A kind of high temperature resistant butyl pressure-sensitive adhesive, its preparation process is as follows:

[0039] 1) In parts by weight, 20 parts of butyl rubber, 10 parts of polyisobutylene with a molecular weight of 70,000 to 100,000 and 20 parts of filler are put into a double-roll mill for mixing, and after mixing evenly, a film is produced;

[0040] 2) Add 20 parts of tackifying resin and 15 parts of SEBS into the kneader and stir, and gradually heat to 140-150°C, melt and mix the tackifying resin and SEBS to obtain mixture A;

[0041] 3) Add 13.5 parts of polyisobutylene with a molecular weight of 30,000 to 60,000 to the mixture A obtained in step 2), and further melt, stir and mix evenly at 140-150°C to obtain mixture B;

[0042] 4) To the mixture B obtained in step 3), add the raw rubber sheet kneaded in step 1) and 1.5 parts of antioxidant in turn, stir at 140-150°C for 1 hour and discharge to obtain high temperature resistant butyl pressure sensitive gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com