Patents

Literature

30results about How to "Long anti-aging time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-aging glutinous rice composition and preparation method thereof

The invention relates to an anti-aging glutinous rice composition and a preparation method thereof, which belong to the field of food processing. The anti-aging glutinous rice composition comprises the following raw material components in portion by weight: 7 portions of white granulated sugar, 5 portions of glutinous rice flour, 0.3 portion of albumen powder, 0.03 portion of sucrose ester fatty acid, 7 portions of malt syrup, 6 portions of water, and 1.2 portions of pueraria lobata powder. The anti-aging glutinous rice composition and the preparation method have the advantages of reasonable design, good aging resistance, stable quality, low manufacturing cost, and advanced process flow.

Owner:杭州源淇食品科技有限公司

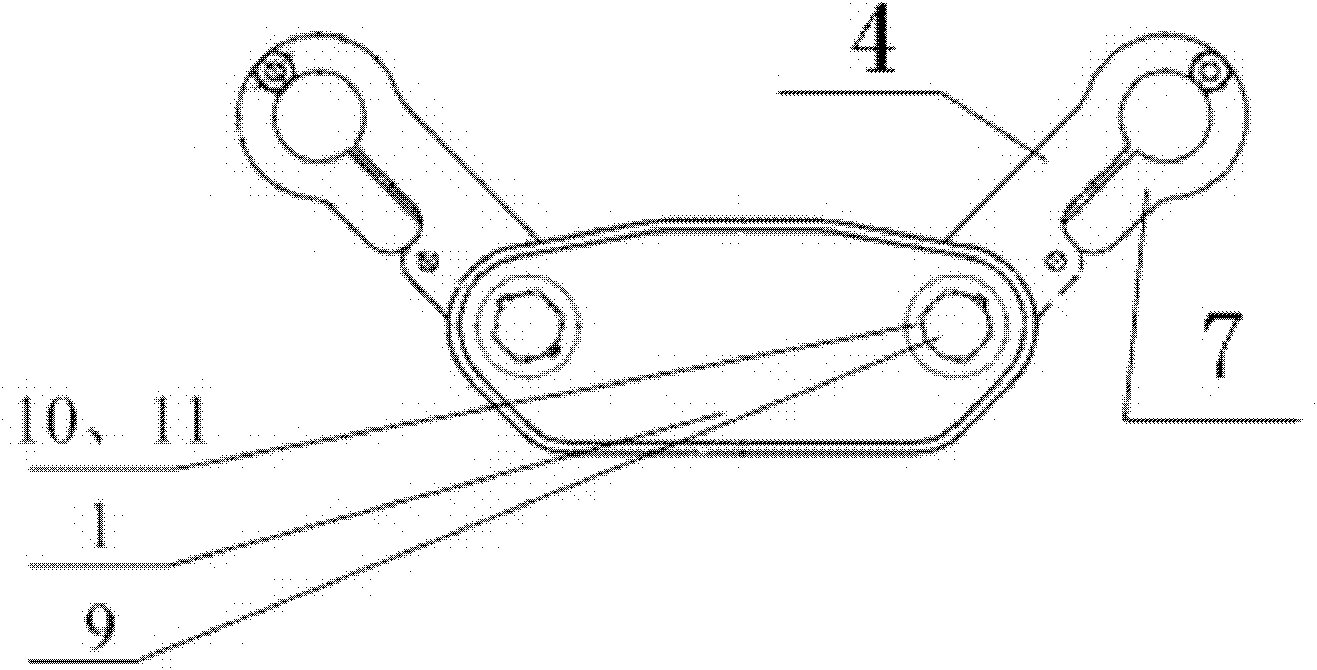

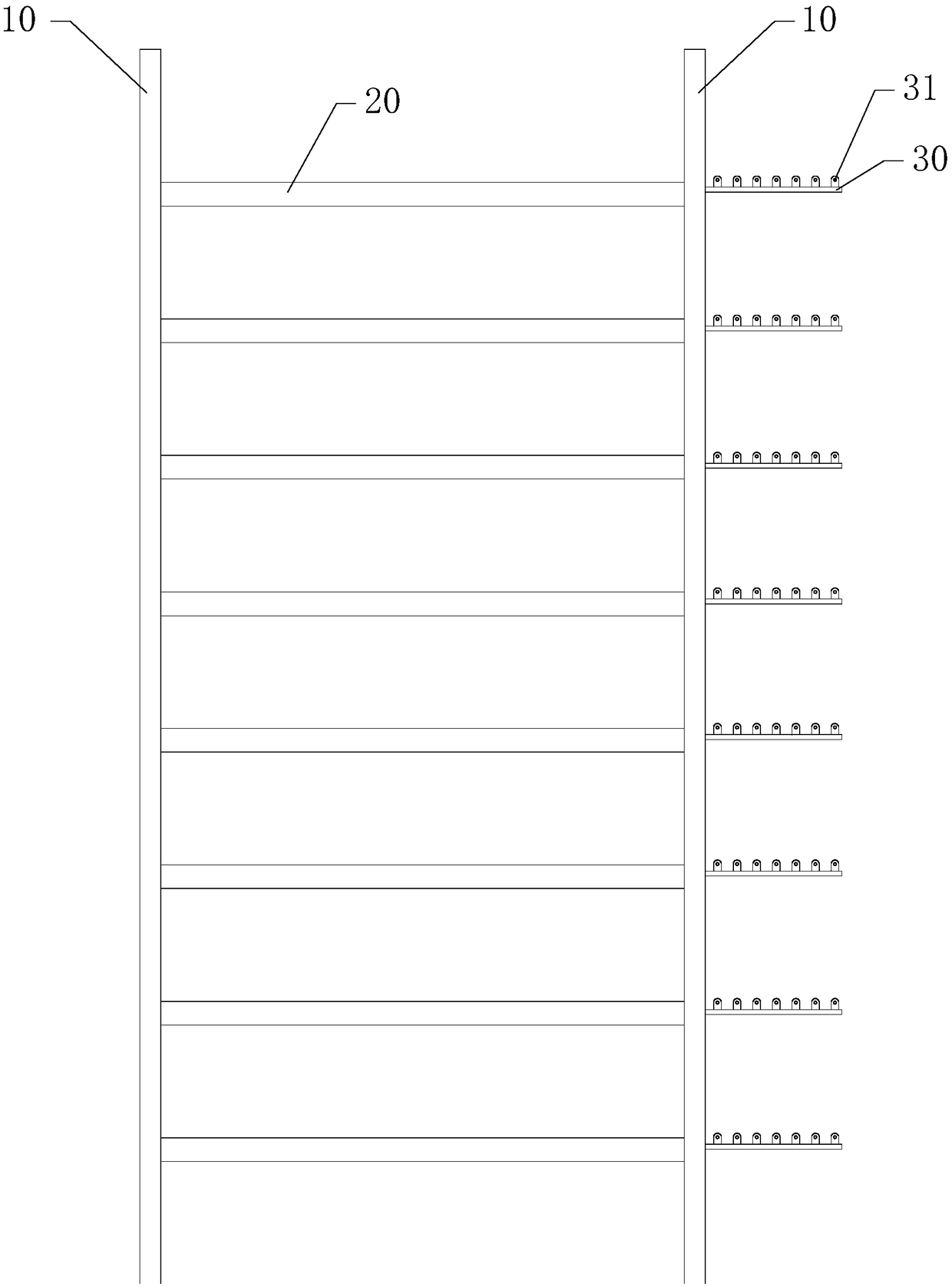

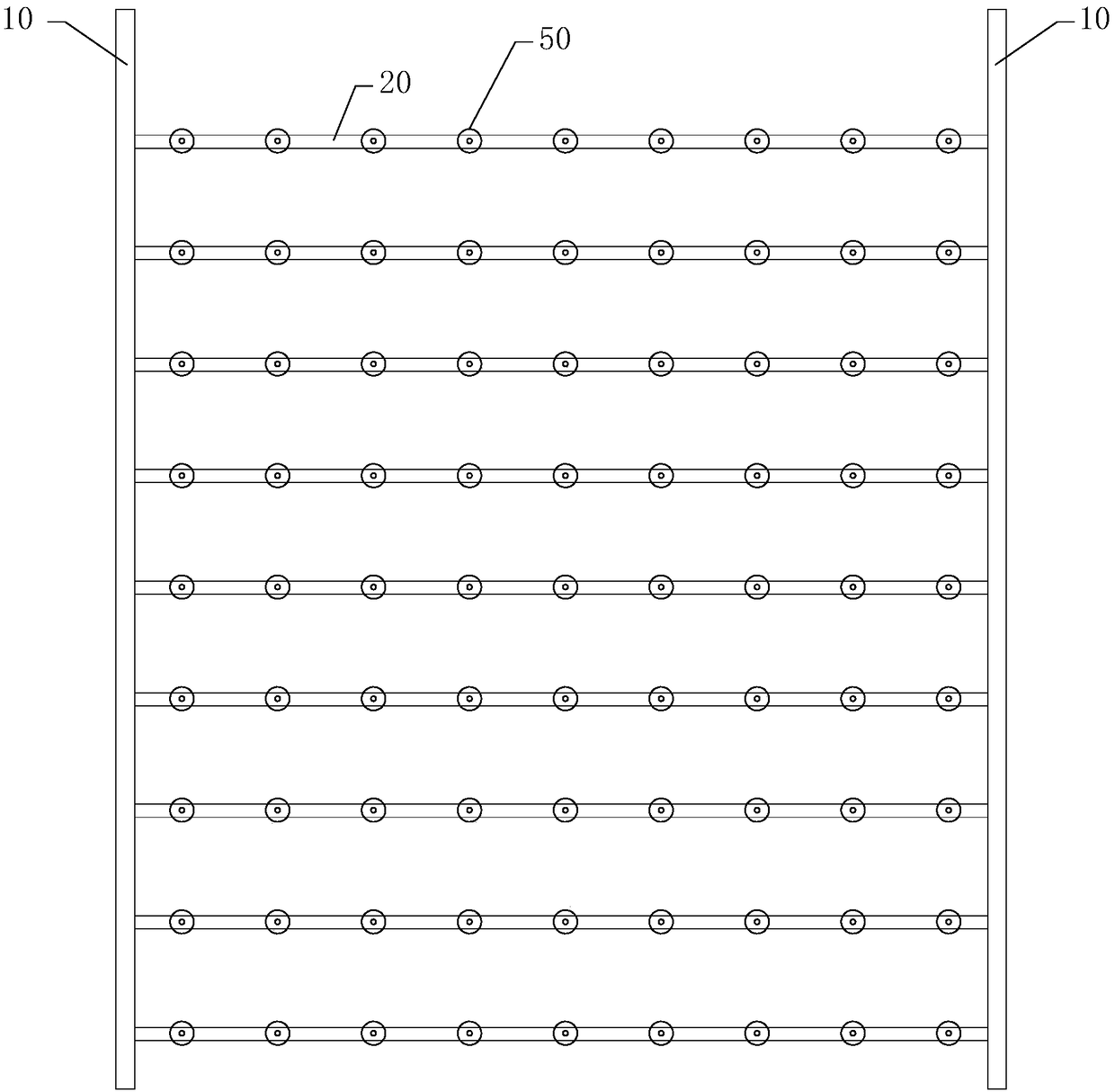

Composite material light energy-saving conductor spacer

InactiveCN102545123ANo power lossGood value for moneyMaintaining distance between parallel conductorsHysteresisLight energy

The invention discloses a composite material combination type light energy-saving conductor spacer, which is formed in the way that a frame (1), a cross shaft sleeve (3), a wire clip body (4) and a cover plate (7) are all made of fiber composite materials on the basis of a common conductor spacer. The conductor spacer adopts the fiber composite materials and a specially optimized structure, does not generate hysteresis lag or eddy-current loss, does not generate corona, is free of corona noise and electromagnetic energy loss, and is obvious in energy saving effects. The conductor spacer is high in mechanical strength, stable in grip power, waving resistant and small in maintenance cost. By means of special optimized structure design, the conductor spacer effectively prevents abrasion caused of connection of different materials of connection joints, improves abrasion resistance, prolongs service life, is light in weight and convenient to construct and install, saves electric energy and is remarkable in economical and social benefits.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

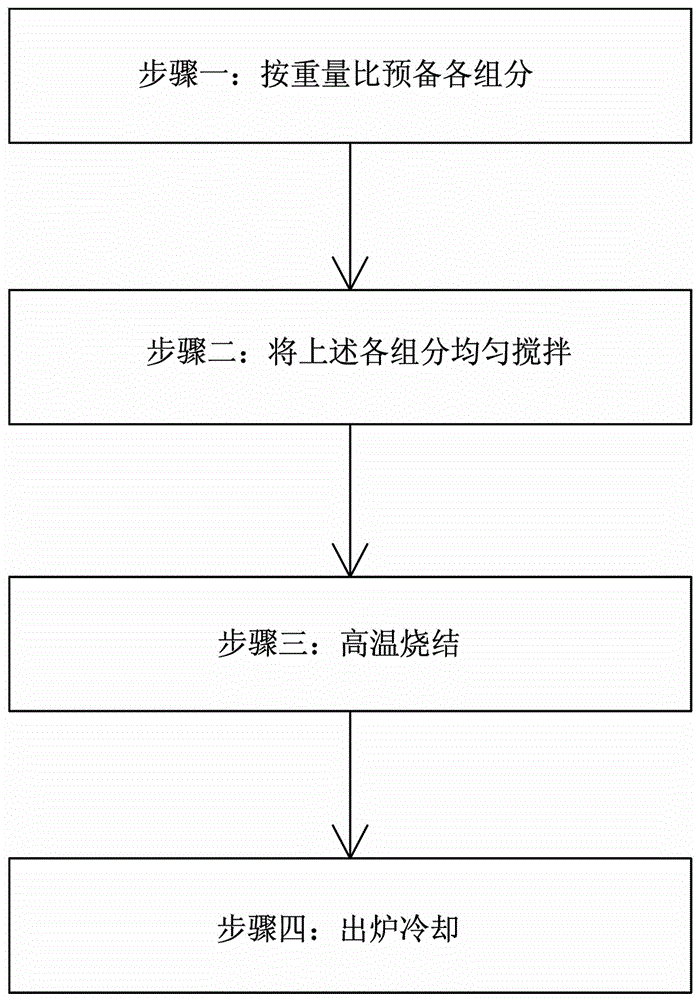

Sintered colored sand and preparation method

The invention discloses sintered colored sand and a preparation method thereof. The sintered colored sand contains sand grains, a color inorganic coating is wrapped on the external of the sand grain; the color inorganic coating contains adhesive, coloring agent and fluxing agent, wherein the sand grain and the color inorganic coating contain the following components in part by weight: 900-1100 parts of sand grain, 20-50 parts of adhesive, 5-35 parts of coloring agent and 1-10 parts of fluxing agent. The sintered colored sand disclosed by the invention has the advantages of being low in production cost, small in energy consumption, firm in colored sand coloring, good in weather resistance and long in anti-ageing time; through the adoption of the preparation method of the sintered colored sand disclosed by the invention, the sintering temperature can be obviously lowered, and the method has the advantages of being simple and easy in color control, and simple in process.

Owner:赖伟阳

Water absorption resin for well repair and leaking stoppage and synthesis method thereof

ActiveCN102181008AGood effect in sealing formation seepageThe synthesis method is simpleDrilling compositionSynthesis methodsNitrogen

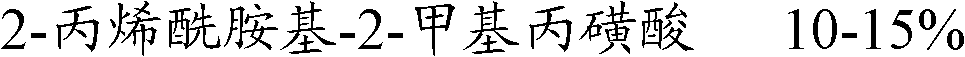

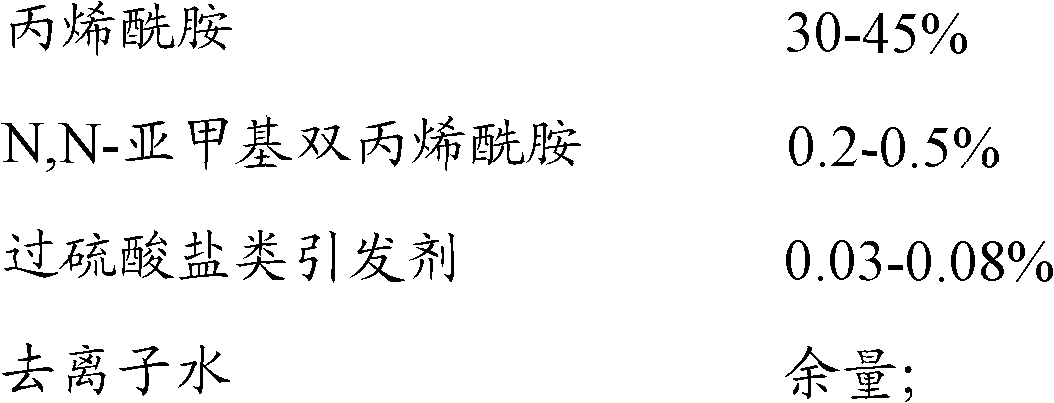

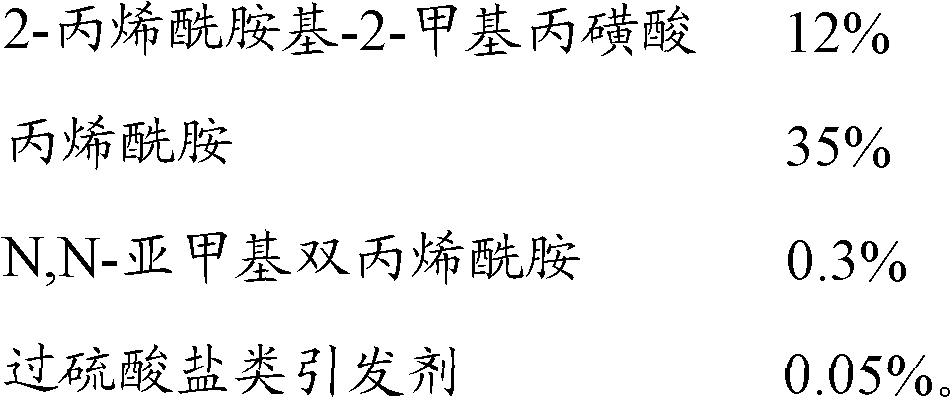

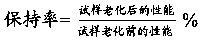

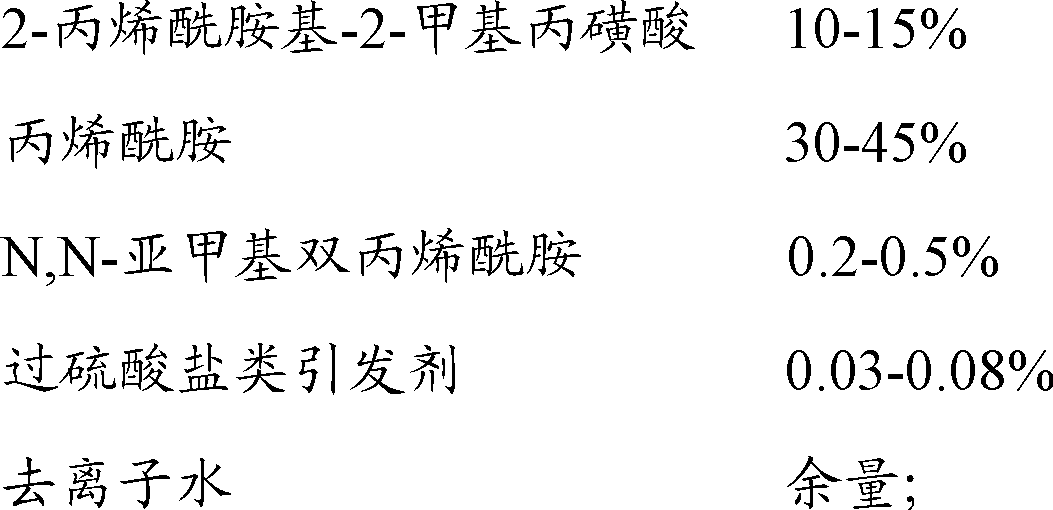

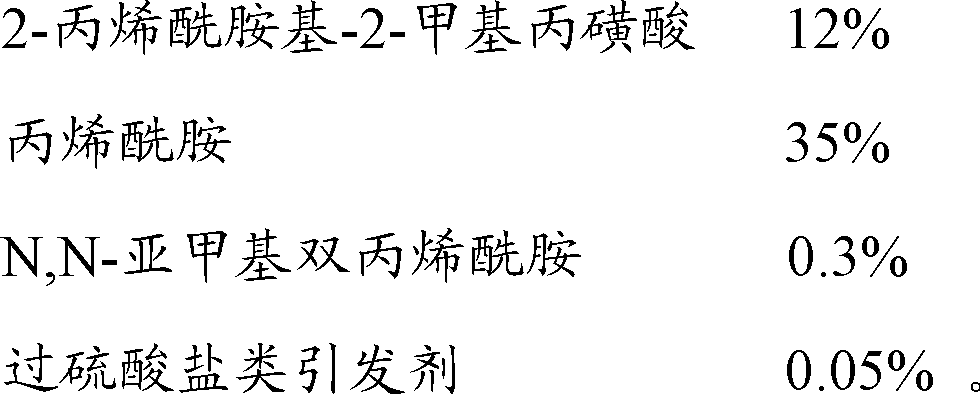

The invention relates to water absorption resin for well repair and leaking stoppage. The water absorption resin is prepared by the following synthesis steps of: a, mixing 10 to 15 percent of 2-acrylamide-2-methylpropanesulfonic acid, 30 to 45 percent of acrylamide, 0.2 to 0.5 percent of N,N-methylenebisacrylamide and deionized water in a weight ratio with stirring to form a mixture, wherein the stirring time is 5 to 10 minutes and the stirring temperature is 30 to 50 DEG C; b, putting the prepared mixture into a polymerization reaction kettle, stirring the mixture, introducing nitrogen for 30 minutes to displace air in the polymerization reaction kettle, simultaneously heating the polymerization reaction kettle to the temperature of between 40 and 50 DEG C, then adding 0.03 to 0.08 weight percent of persulfate initiator into the mixture, performing polymerization reaction on the mixture to generate the water absorption resin, and preserving heat for at least 6 hours after the polymerization reaction starts; and c, drying the prepared water absorption resin at the temperature of not more than 120 DEG C for 24 hours till complete drying, and crushing the dried water absorption resin into granules with a diameter of 0.5 to 40 millimeters to obtain the water absorption resin for well repair and leaking stoppage.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Antiaging rubber

InactiveCN107254074AImprove anti-aging propertiesLong anti-aging timeMicrocrystalline waxPolymer science

The invention belongs to the technical field of rubber, and specifically discloses an anti-aging rubber, which is prepared from the following components in parts by weight: 70-90 parts of natural rubber SVR3L, 10-30 parts of butadiene rubber 9000, 5-8 parts of zinc oxide, 1-2 parts of stearic acid, 5-8 parts of ordinary paraffin, 3-5 parts of microcrystalline wax, 3-5 parts of coumarone resin, 2-3 parts of coupling agent, 2-5 parts of dispersing aid, softener 5-10 parts, anti-aging agent mixture 5-7 parts, accelerator mixture 1.3-1.8 parts, carbon black mixture 70-85 parts, sulfur 1.8-2.5 parts, anti-scorch agent 0.2-0.4 parts. The anti-aging agent mixture is anti-aging agent RD, anti-aging agent 4010NA, and the accelerator mixture is accelerator CZ, accelerator DM, and accelerator TMTD. The anti-aging rubber of the invention has good anti-oxidation and anti-aging capabilities, and good mechanical strength and fatigue resistance.

Owner:ZHEJIANG HONGLEE AUTO PARTS

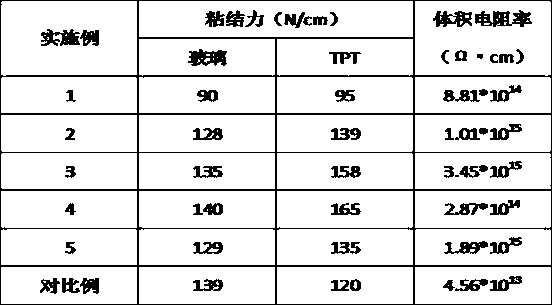

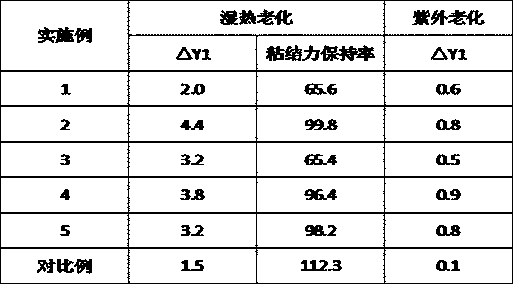

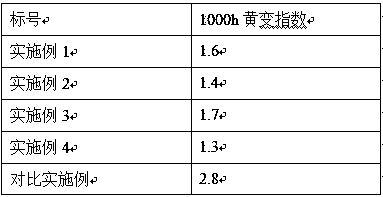

Preparation method of polyolefin packaging film for solar cell module

InactiveCN109206653AExtends free radical lifeLow monomer residueFinal product manufacturePhotovoltaic energy generationPolyolefinElectrical battery

The invention belongs to the technical field of solar packaging materials, in particular to a preparation method of a polyolefin packaging film for a solar cell module. the preparation method comprises the following steps: (1) adding raw materials into a stirring device, uniformly mixing, then adding into a single-screw extruder to carry out reaction extrusion, controlling the extrusion temperature of the screw extruder to be 80-100 DEG c and the screw rotating speed of 20-30 rpm, then extruding, casting and cooling to form a film; and (2) carrying out radiation treatment on the surface of oneside of the prepared packaging film in the step (1), and finally cutting and winding to obtain the polyolefin packaging film for the solar cell module; an anti-oxidant, an ultraviolet light absorbentand a light stabilizer are added to prevent the composition from being subjected to yellowing caused by transition thermal oxidative degradation in the blending extrusion process, so that yellowing and aging of the packaging film can be effectively prevented at the beginning of production of the packaging film, the aging and yellowing resistance of the packaging film after being subjected to solar radiation in the using process can be also improved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Composition for delaying aging of big cake and big cake preparation method

InactiveCN109090429ALong anti-aging timeSoft tasteFood preservationFood ingredient functionsVegetable oilCarrageenan

The invention discloses composition for delaying aging of a big cake and a big cake preparation method. The composition comprises components as follows: beta-glucan, trehalose and carrageenan. The preparation of the big cake comprises steps as follows: glutinous rice and polished round-grained rice are taken as raw materials and treated, the treated raw materials are smashed, moistened and subjected to mixed blending with sugar, vegetable oil and composition for delaying aging of the big cake, and after a mixture is subjected to die pressing, moistening, slicing and packaging, a finished product is obtained. According to the scheme, the preparation method capable of delaying aging of the big cake is convenient, practical and economical, additional equipment is not required, and an originalproduction technological process is not changed; compared with an unprocessed big cake under the same condition, the big cake produced by addition of beta-glucan has the advantage that the anti-agingtime is prolonged obviously; added beta-glucan is a biological response modifier, and healthy quality of the big cake is improved.

Owner:镇江市智农食品有限公司 +1

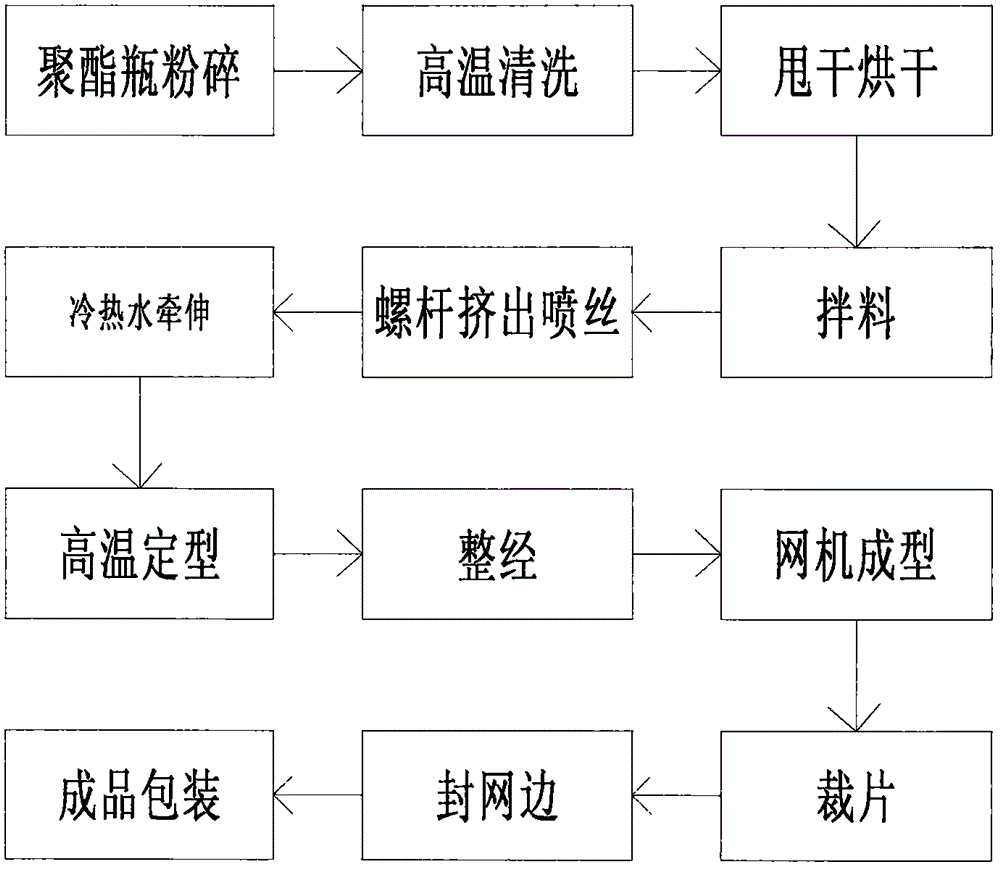

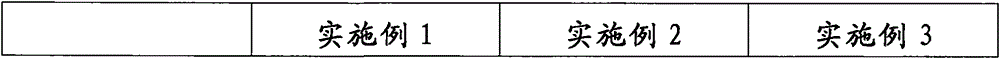

Polyester flame-retardant dense screen production process

InactiveCN106192058AIncreased flame retardant permanenceLong anti-aging timeFlame-proof filament manufactureWarping machinesPolyesterSizing

The invention discloses a polyester flame-retardant dense screen production process. The process comprises the steps of polyester bottle smashing, high-temperature cleaning, spin-drying, blending, screw extrusion spinning, cold drawing, high-temperature sizing, beam warping, screening machine molding, piece-cutting and mesh edge sealing, and finished product packaging. The process has the beneficial effects of simple structure and high practicability.

Owner:孙中志

Anti-aging anti-fogdrop greenhouse film and preparation method thereof

InactiveCN104311947ALong anti-aging timeHigh anti-fog effective timeLow-density polyethyleneLinear low-density polyethylene

The invention discloses an anti-aging anti-fogdrop greenhouse film and a preparation method thereof. The anti-aging anti-fogdrop greenhouse film is prepared from the following components in parts by mass: 60-80 parts of polyethylene, 0.1-0.9 part of triphenyl phosphite, 0.15-0.2 part of dilauryl thiodipropionate, 0.05-0.18 part of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, 3-6 parts of sodium alkyl benzene sulfonate, 1-4 parts of polyvinylpyrrolidone, 1-3 parts of dioctyl sulfodibutyrate and 0.1-0.5 part of antioxidant. The polyethylene is prepared by mixing LDPE (low-density polyethylene) and LLDPE (linear low-density polyethylene) according to a mass ratio of (6-8):1. The antioxidant is antioxidant 1010 or antioxidant DLPP. The greenhouse film has long anti-aging time, and does not need to be replaced within three years; the anti-fogdrop effective time of the greenhouse film is up to 900 hours; and thus, the greenhouse film has wide application prospects.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

Environment-friendly corrosion-resistant PVC (Polyvinyl Chloride) section bar for closed door and window and preparation method thereof

The invention discloses an environment-friendly corrosion-resistant PVC (Polyvinyl Chloride) section bar for a closed door and window. The section bar comprises a PVC substrate and a heat-resistant modifier, wherein the content of the PVC substrate is 95.5-96.5 percent; the content of the heat-resistant modifier is 3.5-4.5 percent; 2-5 parts of rare earth composite stabilizer is added into the heat-resistant modifier; the rare earth composite stabilizer comprises the following components in parts by mass: 40-61 parts of mixed rare earth chloride, 18-26 parts of zinc sulfate, 16-20 parts of calcium chloride, 20-28 parts of barium chloride, 20-25 parts of sodium hydroxide, 5-10 parts of stearic acid and 10-12 parts of colorant. The invention also designs a preparation method of the environment-friendly corrosion-resistant PVC section bar for the closed door and window. The weather fastness of the PVC material can be enhanced, the anti-aging time is prolonged, and the energy consumption is reduced while the production efficiency is improved.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

Production method for cement utility pole coated with weather-resistant artificial tree bark

The invention provides a production method for a cement utility pole coated with weather-resistant artificial tree bark. The production method comprises the following steps: S1, producing a cement utility pole; S2, preparing weather-resistant artificial tree bark slurry; S3, applying the weather-resistant artificial tree bark slurry to produce the cement utility pole coated with the weather-resistant artificial tree bark. The cement utility pole coated with a weather-resistant artificial tree bark layer is attractive in appearance and is in harmony with the surroundings, visual enjoyment can be brought to a tourist attraction environment, and beauty elements can be added to a tourist attraction. The weather-resistant artificial tree bark slurry is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, heavy calcium carbonate powder, fumed silica, pigment printing paste, glass fibers, a curing agent, an antioxidant, an ultraviolet light absorber, dibutyl phthalate and a mixed solvent. Construction is simple and fast, and the applied bark is natural in texture and good in weather resistance and used for beautifying the cement utility pole and brings visual enjoyment.

Owner:广西凯威铁塔有限公司

Starch-polyamide anti-aging and anti-fogging greenhouse film and preparation method thereof

InactiveCN106279786ALong anti-aging timeHigh anti-fog effective timeClimate change adaptationGreenhouse cultivationPolyamidePlant saponin

The invention discloses starch-polyamide anti-aging and anti-fogging greenhouse film and a preparation method thereof. The starch-polyamide anti-aging and anti-fogging greenhouse film is prepared from, by weight, 50-60 parts of polyamide, 8-15 parts of calcium carbonate, 1-4 parts of nano-titanium dioxide, 10-20 parts of triphenyl phosphate, 7-9 parts of sodium alkyl benzene sulfonate, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of chitosan, 60-65 parts of corn starch, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-di-tert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of polyvinyl pyrrolidone and 4-6 parts of plant saponin. According to the greenhouse film prepared from the materials, the anti-aging time is long, the film does not need to be replaced in three years after being arranged on a greenhouse in a covering mode, the effective anti-fogging time of the greenhouse film reaches up to 900 h, and a wide application prospect is achieved.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

Impact-resistant plastic electric power fitting composite material and making method thereof

The invention discloses an impact-resistant plastic electric power fitting composite material. The composite material is made from, by weight, 100 parts of waste nylon 66 plastic, 2.1-2.4 parts of o-cresol formaldehyde epoxy resin, 20-21 parts of glass fibers, 1.1-1.4 parts of nanometer magnesium oxide, 18-20 parts of carbon black, 6-8 parts of a silane coupling agent KH550, 3-5 parts of chlorinated paraffin, 6-8 parts of a polyurethane emulsion and 4-6 parts of wheat straw fiber micro-powder. Nylon is modified with the epoxy resin to form a matrix, modified glass fibers are adopted as a reinforcement material, the nanometer magnesium oxide grafted and modified with the polyurethane emulsion is added to a material, and other effective components are adopted to prepare the composite material, so the composite material has the advantages of solving of hysteresis loss and eddy current loss, no electric energy loss, high impact resistance, high mechanical strength and long ageing resistance.

Owner:马鞍山市华能电力线路器材有限责任公司

Manufacturing method for simulation cement telegraph pole

The invention provides a manufacturing method for a simulation cement telegraph pole. The method includes the following steps that S1, a cement telegraph pole is manufactured; S2, simulation tree bark slurry is prepared; and S3, the simulation tree bark slurry is smeared, and the simulation tree bark cement telegraph pole is manufactured. The outer surface of the cement telegraph pole is coated with a layer of simulation tree bark, the appearance is elegant, the telegraph pole and the surroundings are coordinated, visual enjoyment of the environment of a tourism area can be brought, and beautiful elements can be added to the tourism area as well. The simulation tree bark slurry is made of the following raw materials including epoxy resin, polyaniline, carboxyl polysiloxane, calcium magnesium powder, fumed silica, pigment printing paste, glass fibers, aliphatic polyamine, iron trioxide, dibutyl phthalate and a mixed solvent. By the adoption of the method, construction is easy, convenient and quick, the smeared bark is natural in texture and good in weather resistance and is used for beautifying the cement telegraph pole, and visual enjoyment can be brought for people.

Owner:广西凯威铁塔有限公司

Technical process for spraying and coating electrostatic powder on surface of metal workpiece

The invention relates to a technical process for spraying and coating electrostatic powder on the surface of a metal workpiece. The technical process comprises the steps of workpiece surface pre-treatment including derusting, water washing, deoiling, water washing and phosphorization; cleaned part drying: natural sunlight drying or baking in a baking oven after complete water draining; powder spraying technical processes including selection, element hanging, powder spraying and baking. The technical process for spraying and coating electrostatic powder on the surface of the metal workpiece has the advantages that high plastic film adhesive force of the surface of the workpiece can be ensured, the fluidity is good, the color is pure, the anti-aging time is long, the repair rate is low, and the technical process is particularly suitable for surface treatment on outdoor workpieces.

Owner:SHANDONG GOLDKING ELECTRICAL APPLIANCES

Weather-proof simulation tree bark and preparation method thereof

The invention discloses a weather-proof simulation tree bark and a preparation method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, a curing agent, an antioxidant, an ultraviolet absorber, dibutyl phthalate and a mixed solvent. The preparation method comprises the following steps: adding the epoxy resin into a reaction kettle; adding the mixed solvent and dissolving; adding the polyaniline and epoxy resin into the reaction kettle and mixing; stirring at a high speed; controlling the pH value of the reaction to 1 and the reaction temperature to 20-25 DEG C; after 1 hour of reaction, adding the carboxyl polysiloxane, and further reacting for 2-5 hours at room temperature-50 DEG C; adding the dibutyl phthalate, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, curing agent, antioxidant and ultraviolet absorber, mixing and stirring uniformly and pouring into a pre-placed bark mould; and performing micro-pressure standing to obtain a finished product of the weather-proof simulation tree bark which has good weather-proof property.

Owner:广西凯威铁塔有限公司

Preparation method of anti-aging glutinous rice composition

The invention relates to an anti-aging glutinous rice composition and a preparation method thereof, which belong to the field of food processing. The anti-aging glutinous rice composition comprises the following raw material components in portion by weight: 7 portions of white granulated sugar, 5 portions of glutinous rice flour, 0.3 portion of albumen powder, 0.03 portion of sucrose ester fatty acid, 7 portions of malt syrup, 6 portions of water, and 1.2 portions of pueraria lobata powder. The anti-aging glutinous rice composition and the preparation method have the advantages of reasonable design, good aging resistance, stable quality, low manufacturing cost, and advanced process flow.

Owner:杭州源淇食品科技有限公司

Water absorption resin for well repair and leaking stoppage and synthesis method thereof

ActiveCN102181008BGood effect in sealing formation seepageThe synthesis method is simpleDrilling compositionSynthesis methodsNitrogen

The invention relates to water absorption resin for well repair and leaking stoppage. The water absorption resin is prepared by the following synthesis steps of: a, mixing 10 to 15 percent of 2-acrylamide-2-methylpropanesulfonic acid, 30 to 45 percent of acrylamide, 0.2 to 0.5 percent of N,N-methylenebisacrylamide and deionized water in a weight ratio with stirring to form a mixture, wherein the stirring time is 5 to 10 minutes and the stirring temperature is 30 to 50 DEG C; b, putting the prepared mixture into a polymerization reaction kettle, stirring the mixture, introducing nitrogen for 30 minutes to displace air in the polymerization reaction kettle, simultaneously heating the polymerization reaction kettle to the temperature of between 40 and 50 DEG C, then adding 0.03 to 0.08 weight percent of persulfate initiator into the mixture, performing polymerization reaction on the mixture to generate the water absorption resin, and preserving heat for at least 6 hours after the polymerization reaction starts; and c, drying the prepared water absorption resin at the temperature of not more than 120 DEG C for 24 hours till complete drying, and crushing the dried water absorption resin into granules with a diameter of 0.5 to 40 millimeters to obtain the water absorption resin for well repair and leaking stoppage.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Oil felt base cloth and production method thereof

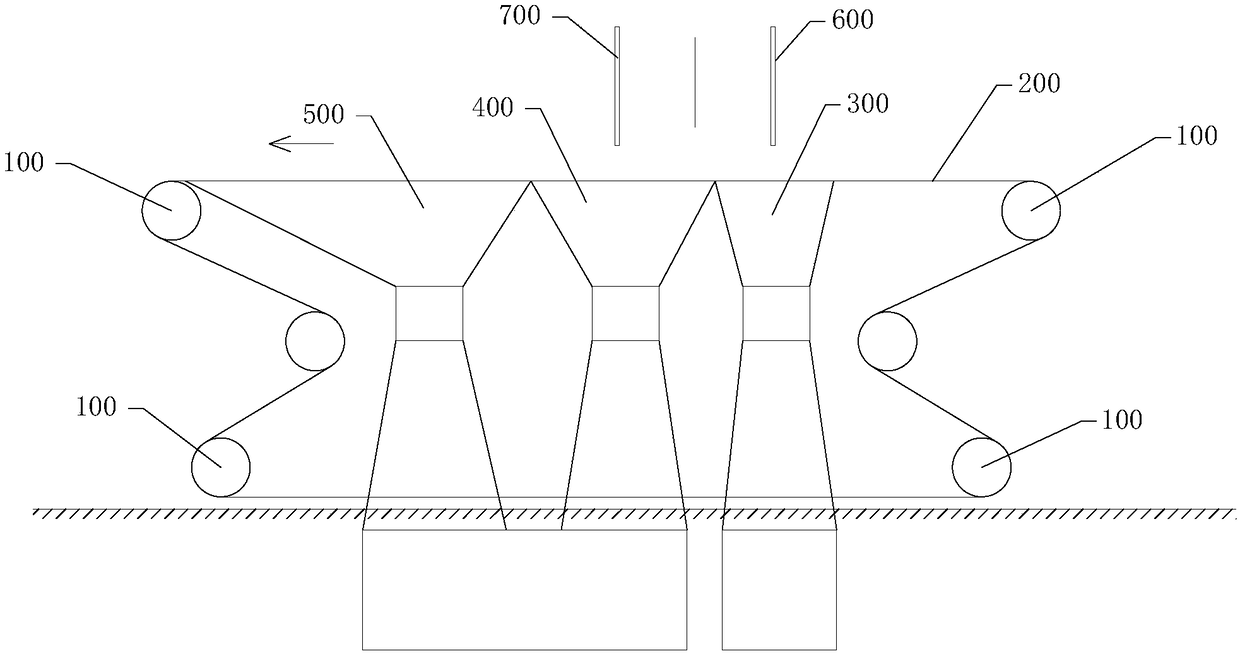

InactiveCN109505066ARealize localizationIncrease production speedNon-woven fabricsPolyesterGlass fiber

The invention belongs to the technical field of production of spunbonded nonwoven fabrics and provides oil felt base cloth. The oil felt base cloth comprises a fiber web layer I and a fiber web layerII which are sequentially arranged from top to bottom, wherein a plurality of reinforcing ribs are arranged between the fiber web layer I and the fiber web layer II and are uniformly distributed in the transverse direction of fiber webs, and the fiber web layer I, the reinforcing ribs and the fiber web layer II are reinforced through needling and gum dipping. The invention also provides a production method of the oil felt base cloth. The production method comprises the following steps that polyester chips are all processed into the fiber web layer I and the fiber web layer II, fiber glass filaments are added between the fiber web layer I and the fiber web layer II to obtain middle cloth, pre-needling, main needling, gum dipping and drying are conducted on the middle cloth to obtain an oilfelt base cloth finished product. By adopting the above technical scheme, the problem is solved that in the prior art, a nonwoven fabric is high in heat shrinkage rate and is prone to deformation.

Owner:ANGUO QIANJIN NONWOVEN CO LTD

Novel anti-aging big cake production method

The invention discloses a novel anti-aging big cake production method which comprises the following steps: (1) after using water to cleaning up sticky rice, placing the sticky rice into a treating agent composite I and soaking the sticky rice for 3.5 hours; (2) using a treating agent composite II to neutralize the sticky rice treated by the treating agent composite I to neutral; conducting dehydration, airing, frying and smash on the sticky rice treated by the step (2); (4) mixing three kinds of liquid components including anti-hardening syrup, sesame oil and vegetable oil uniformly, mechanically mixing the sticky rice powder produced by the step (3) with a certain amount of sesame uniformly, adding the compound to a grinding tool, the compound is molded in a mechanically-pressing grinding mode, standing for 10 min, demoulding, the big cake comprises, by mass, 57% of the sticky rice powder, 34% of the anti-hardening syrup, 1% of the sesame oil, 5% of the vegetable oil and 3% of the sesame; (5) placing finished products prepared by the step (4) in an aseptic condition, and packing the finished products after standing for one day.

Owner:阜宁县益林镇吉祥糕点厂

Manufacturing method of simulated cement utility pole

The invention provides a manufacturing method for a simulation cement telegraph pole. The method includes the following steps that S1, a cement telegraph pole is manufactured; S2, simulation tree bark slurry is prepared; and S3, the simulation tree bark slurry is smeared, and the simulation tree bark cement telegraph pole is manufactured. The outer surface of the cement telegraph pole is coated with a layer of simulation tree bark, the appearance is elegant, the telegraph pole and the surroundings are coordinated, visual enjoyment of the environment of a tourism area can be brought, and beautiful elements can be added to the tourism area as well. The simulation tree bark slurry is made of the following raw materials including epoxy resin, polyaniline, carboxyl polysiloxane, calcium magnesium powder, fumed silica, pigment printing paste, glass fibers, aliphatic polyamine, iron trioxide, dibutyl phthalate and a mixed solvent. By the adoption of the method, construction is easy, convenient and quick, the smeared bark is natural in texture and good in weather resistance and is used for beautifying the cement telegraph pole, and visual enjoyment can be brought for people.

Owner:广西凯威铁塔有限公司

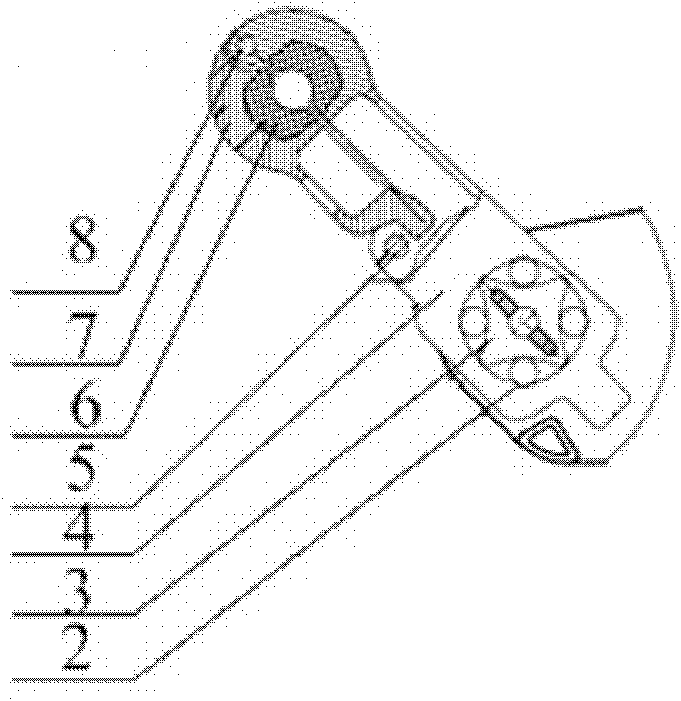

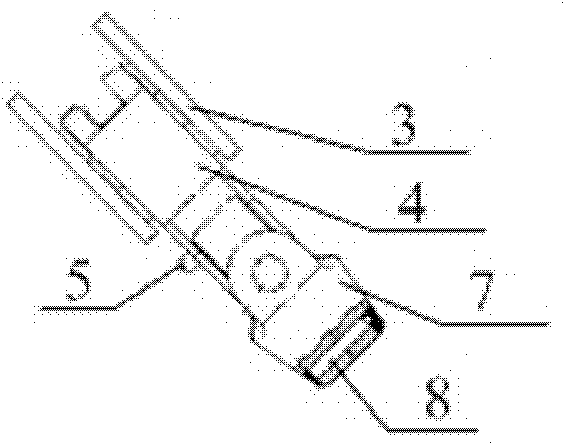

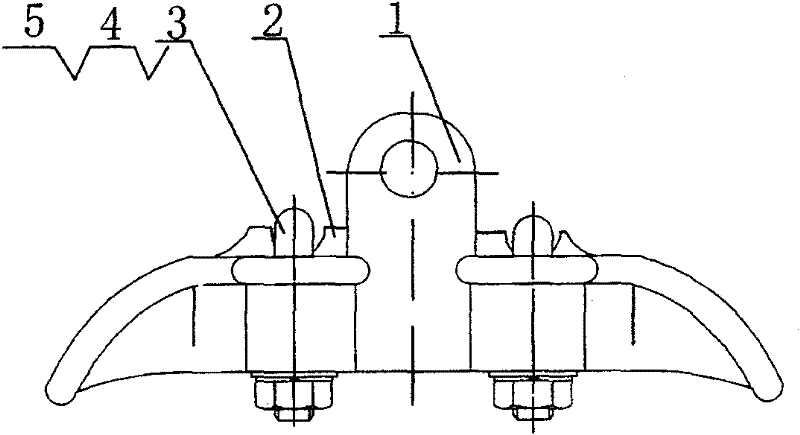

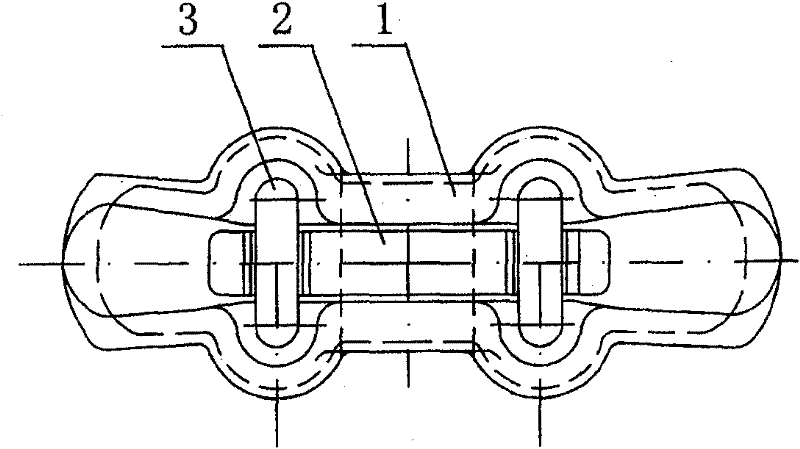

A polymer alloy suspension clamp

ActiveCN101447656BHigh mechanical strengthNo power lossSuspension arrangements for electric cablesHysteresisPolymer alloy

A polymer alloy suspension clamp, classified in overhead installation of wires or cables, H02G7 / 05, 7 / 06, Suspension devices for cables or wires, or devices for suspending cables or wires along separate support wires, involving transmission The technical field of a power fitting in a substation line. It is characterized in that: a semicircular groove is axially arranged in the middle of the main body of the wire clip (1), a wire is threaded in the groove, and the groove is connected to a whole pressing plate (2) in close contact with the wire. The U-bolt (3) passes through the screw hole in the main body of the wire clamp (1), and locks the wire through the washer (4) and the nut (5). The invention better solves the hysteresis loss and eddy current loss, has no power loss, has high mechanical strength, long anti-aging time, high temperature resistance and wear resistance, and reduces maintenance costs.

Owner:JIANGSU YIDING POWER TECH

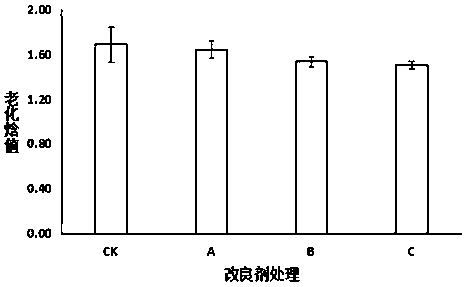

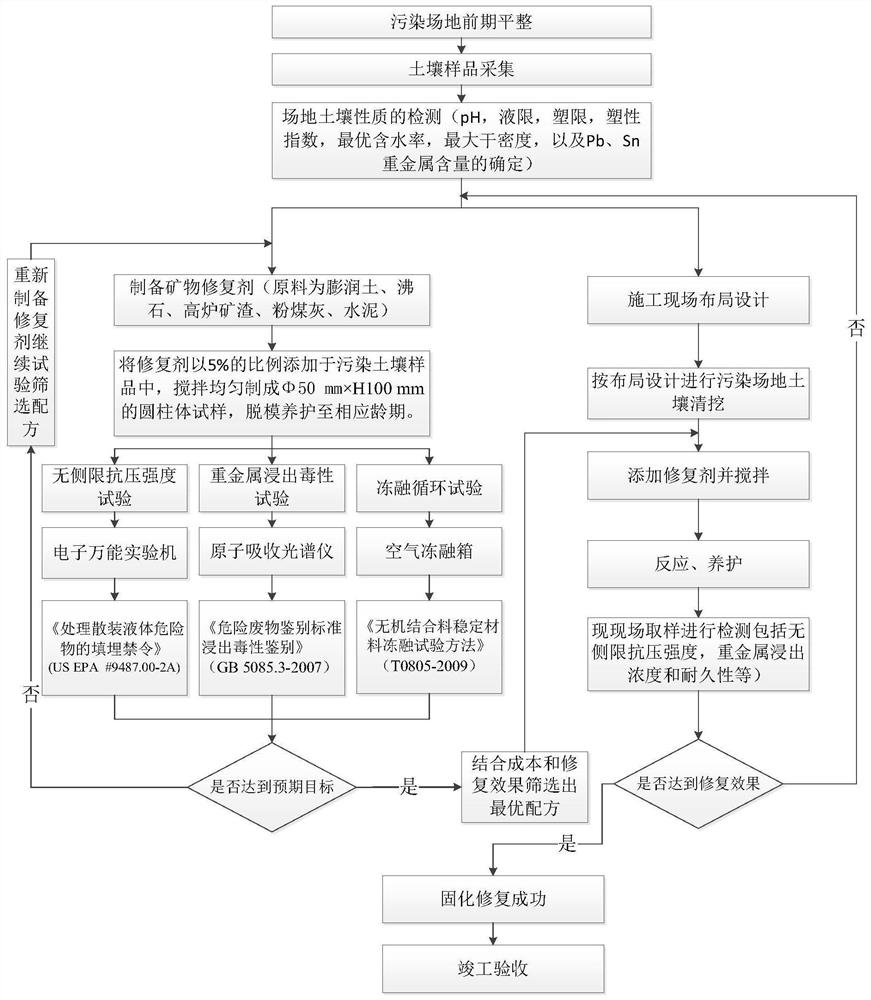

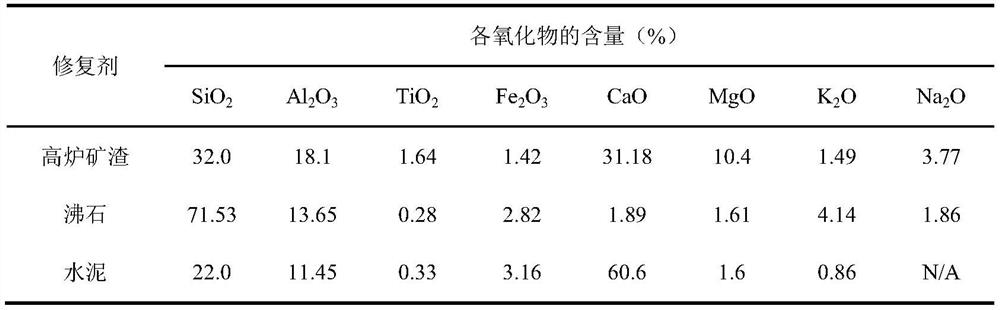

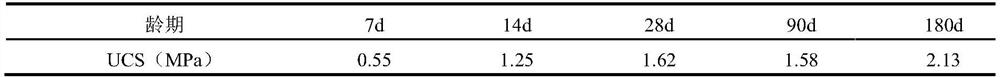

A kind of combined repairing agent formula, method and application of soil heavy metal tin and lead

ActiveCN111218287BRealize secondary developmentRealize comprehensive utilizationContaminated soil reclamationOrganic fertilisersSlagSoil heavy metals

The invention discloses a formula, methods and an application of a combined remediation agent for heavy metals tin and lead in soil. Zeolite, blast furnace slag, biochar formed by firing agriculturalwastes and cement are adopted as raw materials. The remediation agent concretely comprises, by mass, 2-4 parts of cement, 2-4 parts of blast furnace slag, 0.5-2.5 parts of zeolite, 0-1 part of biocharand 2-6.7 parts of cement; the remediation agent accounts for 1-5% of the weight of the contaminated soil, and the water content in a mixed system of the contaminated soil and the remediation agent is 10-30%; and the combined remediation agent is directly prepared by mixing the zeolite, blast furnace slag, biochar and cement, the heavy metal contaminated soil and the remediation agent are evenlymixed through a stirrer, and then a solidified sample is obtained through molding, demolding and curing in sequence. The remediation agent and the remediation method for the heavy metal composite contaminated soil are efficient and environmentally friendly, are suitable for high-concentration composite contaminated heavy metal contaminated soil, and particularly have a good solidification remediation effect on Sn and Pb, and the remediation agent has certain strength and frost resistance.

Owner:红河创新技术研究院有限责任公司 +1

A kind of anti-aging artificial tree bark and preparation method thereof

InactiveCN106010116BDryLow shrinkageAnti-corrosive paintsEpoxy resin coatingsEpoxyReaction temperature

The invention discloses an anti-aging simulation tree bark and a preparation method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, a curing agent, dibutyl phthalate, an anti-ultraviolet agent and a mixed solvent. The preparation method comprises the following steps: adding the epoxy resin into a reaction kettle; adding the mixed solvent and dissolving; adding the polyaniline and epoxy resin into the reaction kettle and mixing; stirring at a high speed; controlling the pH value of the reaction to 1 and the reaction temperature to 20-25 DEG C; after 1 hour of reaction, adding the carboxyl polysiloxane, and further reacting for 2-5 hours at room temperature-50 DEG C; adding the dibutyl phthalate, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, curing agent and anti-ultraviolet agent, mixing and stirring uniformly and pouring into a pre-placed bark mould; and performing micro-pressure standing to obtain a finished product of the anti-aging simulation tree bark. The simulation tree bark disclosed by the invention is soft and safe and has good anti-aging property.

Owner:广西凯威铁塔有限公司

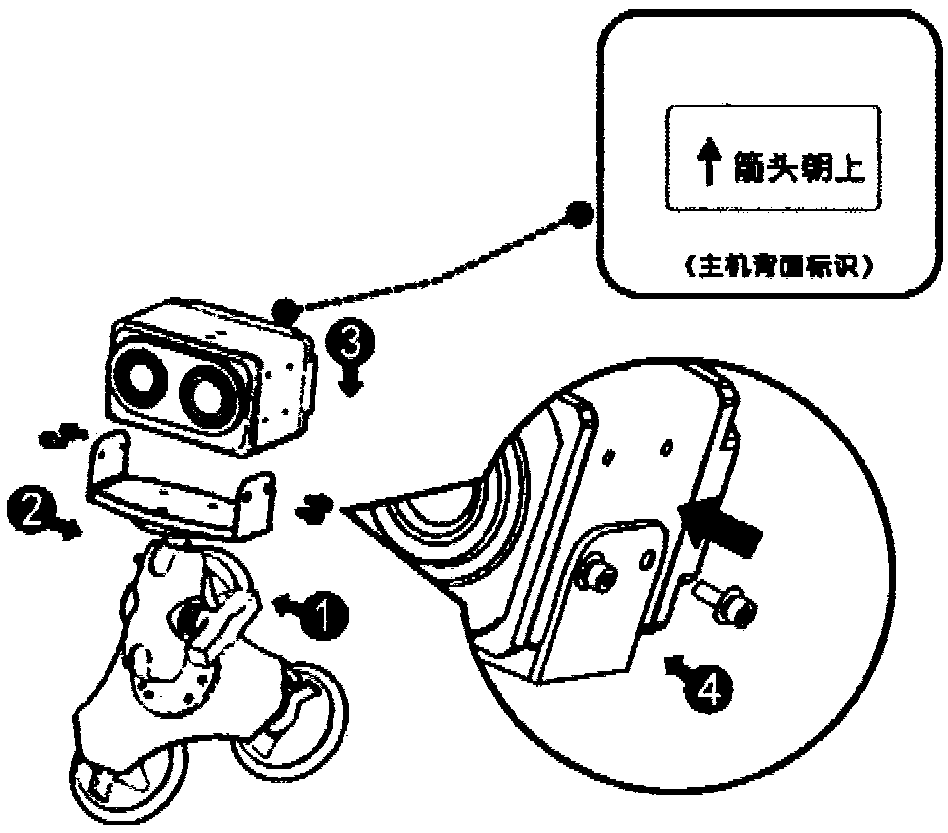

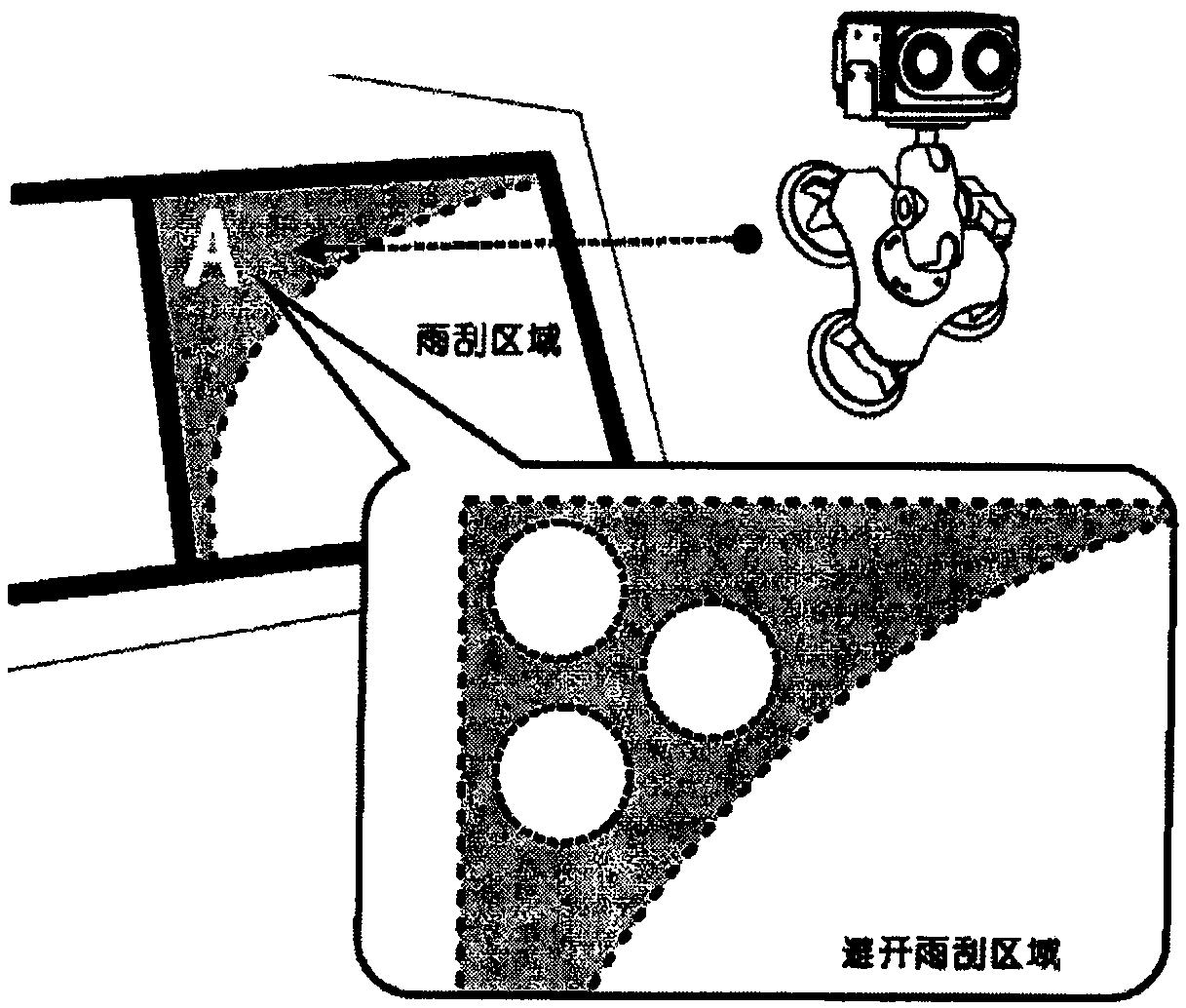

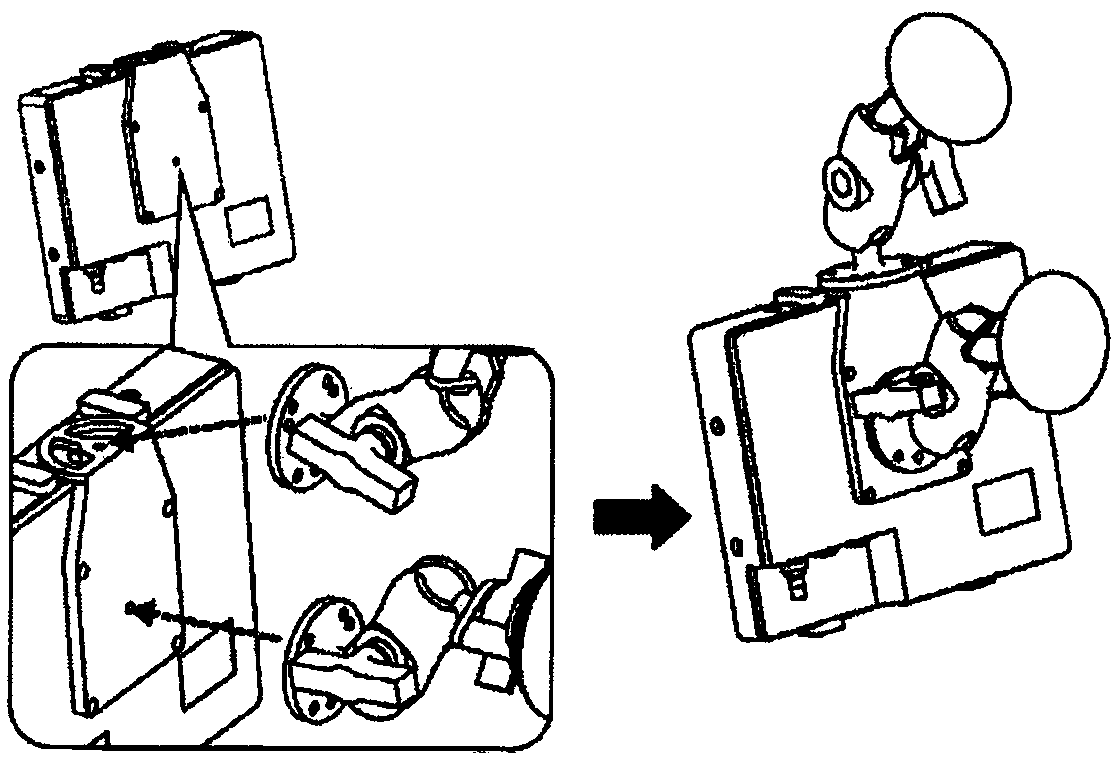

Mounting method of military vehicle-mounted auxiliary night-vision device system

InactiveCN109398250AQuick and stable installationEasy to useVehicle componentsInterior spaceEngineering

The invention discloses a mounting method of a military vehicle-mounted auxiliary night-vision device system. The mounting method of the military vehicle-mounted auxiliary night-vision device system comprises the steps of fixedly assembling a host and a host sucker component by using an equipped screw wrench; after assembling is finished, mounting the host sucker component to an appropriate position of a vehicle front windshield, tightening a locking handle, and confirming that reliable adsorption has been realized; determining the mounting position of a display screen and the number of suckercomponents according to a vehicle interior space situation; and then fixing the display screen in an appropriate position in a cab; enabling one end of a night-vision device data cable to penetrate out from an opened vehicle door to be connected to the host and then to be connected to a power supply cable; after cable connection is finished, confirming that part mounting and connection are accurate first and then starting a host power supply; by observing images, carrying out final adjustment on mounting; and after all adjustments are finished, pushing a power supply key for 2 seconds, switching off an equipment power supply to close and arrange the cable. According to the mounting method of the military vehicle-mounted auxiliary night-vision device system, the military vehicle-mounted auxiliary night-vision device system is mounted, the mounting is rapid and firm, and the use effect is perfect.

Owner:JIANGSU TAIZHOU CITY HUARUN TEXTILES CO LTD

Imitative landscape iron tower

The invention provides an imitative landscape iron tower. The imitative landscape iron tower comprises a trunk, an imitative tree bark, imitative tree branches and a support, wherein the trunk is vertically and fixedly arranged on ground, the imitative tree bark coats the outside of the trunk; the imitative tree branches are fixedly arranged on the trunk, extend dendritically and are dispersedly distributed; the support is arranged at the top of the trunk, communication equipment is arranged on the support; an iron tower is simply treated, designed into a modelling of an imitative tree, beautiful in appearance and coordinated with a surrounding environment; and a beautiful element is added for a tourist area. The imitative tree bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, heavy calcium carbonate powder, gas phase white carbon black, coating pigment paste, glass fibers, aliphatic polyamine, ferric oxide, dibutyl phthalate and a mixed solvent, and the produced imitative tree bark is natural in texture, strong in weather resistance, simple and rapid in construction, long in anti-aging time and used for beautifying the iron tower and brings visual enjoyment to people.

Owner:广西凯威铁塔有限公司

Corrosion-resistant network camera

The invention discloses a corrosion-resistant network camera which comprises a lens and a shell for mounting the lens, wherein the shell comprises the following components in parts by weight: 20-40 parts of PVC resin, 25-38 parts of phenolic resin, 10-13 parts of acrylic resin, 9-15 parts of chlorinated polyethylene, 5-7 parts of glycol octyl phenyl ether, 3-5 parts of light calcium carbonate, 8-15 parts of filler, 4-7 parts of an epoxy crosslinking agent, 2-8 parts of a plasticizer, 1-3 parts of a silane coupling agent, 5-8 parts of a lubricant and 1-3 parts of rare earth elements. The network camera is long in service life and the cost is lowered.

Owner:苏州威斯道智能科技有限公司

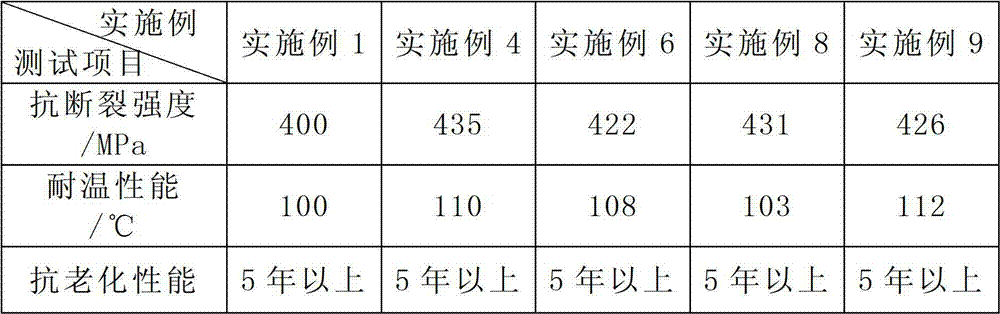

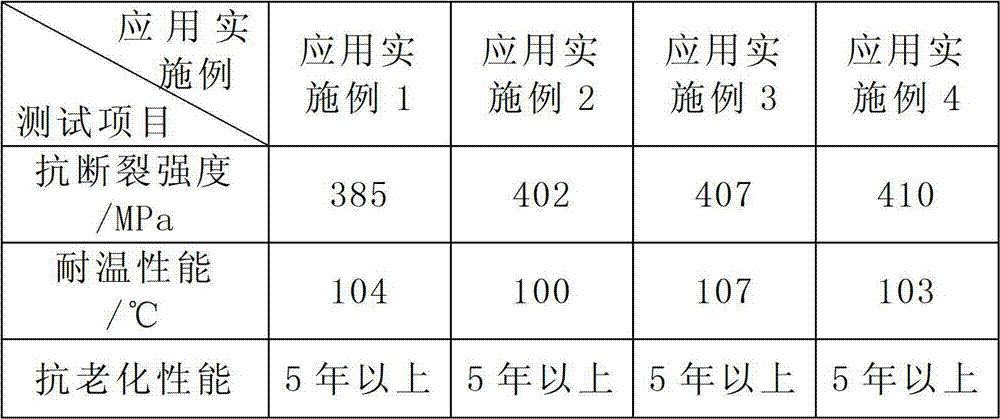

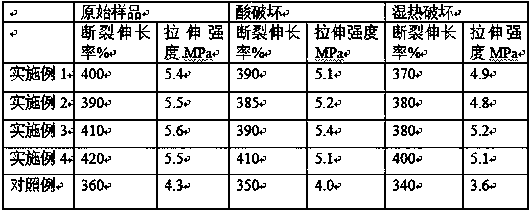

Polyethylene composite material used for bionic vine

The invention relates to a polyethylene composite material used for bionic vine, belongs to the technical field of materials and aims at solving the technical problems that in the prior art, the polyethylene composite material is bad in fracture-resistant strength, low in aging-resistant capacity, high in possibility of breaking and bad in flow performance. The polyethylene composite material disclosed by the invention is prepared mainly from the following raw materials by weight percent: 85%-95% of high pressure polyethylene, 1.0%-5.0% of low pressure polyethylene, 0.5%-1.5% of polyisobutene, 3.0%-10% of flexibilizer, 0.1%-0.6% of antioxidant, 0.1%-0.6% of anti-ultraviolet agent and one or two of 1.0%-5.0% of titanium pigment and 1.0%-5.0% of toner. The polyethylene composite material disclosed by the invention has the advantages of good flow performance, good flexibility, strong aging-resistant performance and good aesthetic property; and the aging-resistant time of the polyethylene composite material at least achieves more than five years, and the breaking-resistant strength of the polyethylene composite material achieves more than 400MPa.

Owner:ZHEJIANG MINZO NEW MATERIALS CO., LTD

Weather-resistant simulated tree bark and method for making the same

The invention discloses a weather-proof simulation tree bark and a preparation method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, a curing agent, an antioxidant, an ultraviolet absorber, dibutyl phthalate and a mixed solvent. The preparation method comprises the following steps: adding the epoxy resin into a reaction kettle; adding the mixed solvent and dissolving; adding the polyaniline and epoxy resin into the reaction kettle and mixing; stirring at a high speed; controlling the pH value of the reaction to 1 and the reaction temperature to 20-25 DEG C; after 1 hour of reaction, adding the carboxyl polysiloxane, and further reacting for 2-5 hours at room temperature-50 DEG C; adding the dibutyl phthalate, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, curing agent, antioxidant and ultraviolet absorber, mixing and stirring uniformly and pouring into a pre-placed bark mould; and performing micro-pressure standing to obtain a finished product of the weather-proof simulation tree bark which has good weather-proof property.

Owner:广西凯威铁塔有限公司

A simulated landscape iron tower

The invention provides an imitative landscape iron tower. The imitative landscape iron tower comprises a trunk, an imitative tree bark, imitative tree branches and a support, wherein the trunk is vertically and fixedly arranged on ground, the imitative tree bark coats the outside of the trunk; the imitative tree branches are fixedly arranged on the trunk, extend dendritically and are dispersedly distributed; the support is arranged at the top of the trunk, communication equipment is arranged on the support; an iron tower is simply treated, designed into a modelling of an imitative tree, beautiful in appearance and coordinated with a surrounding environment; and a beautiful element is added for a tourist area. The imitative tree bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, heavy calcium carbonate powder, gas phase white carbon black, coating pigment paste, glass fibers, aliphatic polyamine, ferric oxide, dibutyl phthalate and a mixed solvent, and the produced imitative tree bark is natural in texture, strong in weather resistance, simple and rapid in construction, long in anti-aging time and used for beautifying the iron tower and brings visual enjoyment to people.

Owner:广西凯威铁塔有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com