Water absorption resin for well repair and leaking stoppage and synthesis method thereof

A water-absorbent resin and well workover technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature and salt resistance, chemical stability and anti-aging properties, and achieve good water absorption and swelling effect. Prevent leakage, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

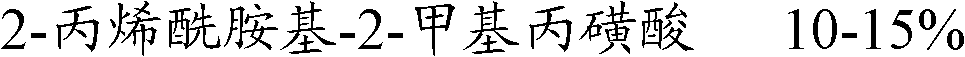

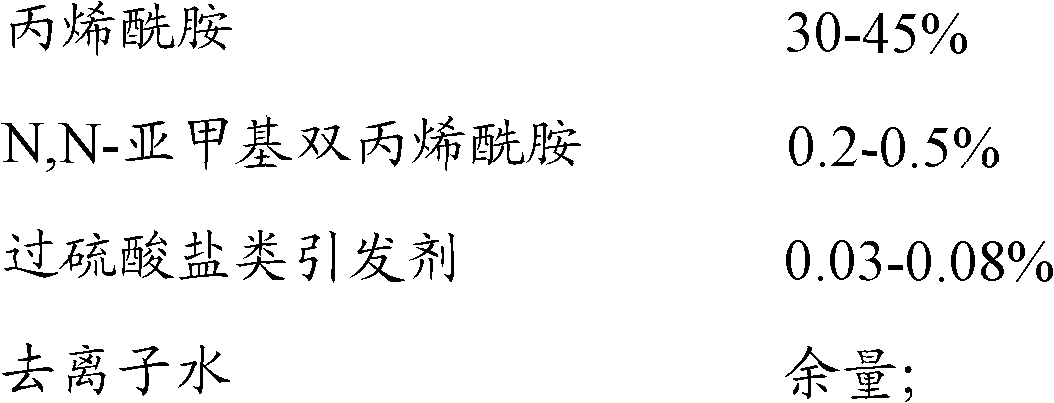

[0036] (1) Selection of raw materials. The water-absorbing resin used for workover and plugging in this embodiment selects the following raw materials:

[0037] 2-acrylamido-2-methylpropanesulfonic acid: 30g, the source of raw material is imported from Japan, the purity is 99%, and the use form is white crystalline powder;

[0038] Acrylamide: 80g, the raw material is produced by Beijing Chemical Reagent Company, the purity is 98%, and the use form is white crystal;

[0039] N, N-methylenebisacrylamide: 1g, the raw material is produced by Beijing Chemical Reagent Company, the purity is 98%, and the use form is white crystalline powder;

[0040] Sodium persulfate: 0.1g, the raw material is produced by Tianjin Jinhui Taiya Chemical Reagent Co., Ltd., the purity is 99%, and the use form is white crystal;

[0041] Deionized water: 88.9g, the source of raw materials is self-made.

[0042] (2) Stir the raw materials. Mix the 2-acrylamido-2-methylpropanesulfonic acid, acrylamide ...

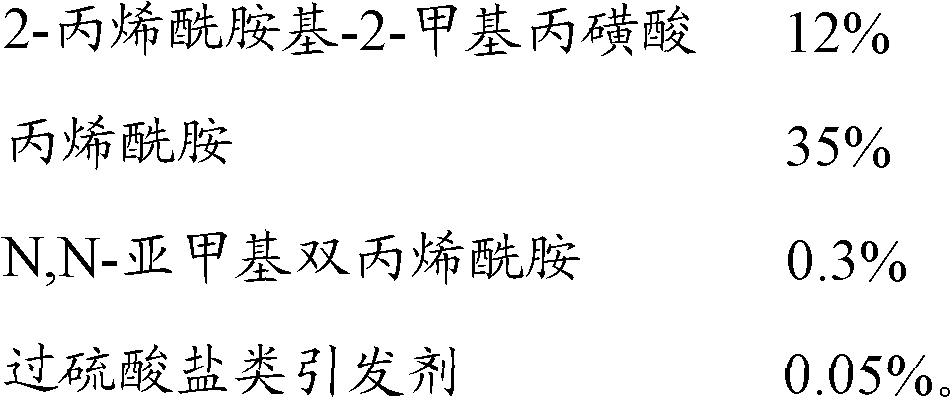

Embodiment 2-4

[0047] The preparation method of the water-absorbent resin for workover and plugging in Examples 2-4 of the present invention is the same as that of Example 1, and the contents of each component are shown in Table 2.

[0048] Table 2

[0049] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com