Patents

Literature

66results about How to "Wide range of particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard compound reinforcing bridging agent

ActiveCN101671550AMake sure to enterStrong bridging supportFluid removalDrilling compositionFiberGeological exploration

The invention discloses a hard compound reinforcing bridging agent comprising the following materials in parts by weight: 30-40 parts of shell powder, 15-30 parts of calcium carbonate, 30-40 parts ofnatural hard rubber and 20-30 parts of natural hard fiber. A preparation method comprises the following step: uniformly mixing and stirring the materials in parts by weight at normal temperature and pressure. The hard compound reinforcing bridging agent is prepared by compounding elastic plugging materials with a certain rigidity according to a scientific mixing proportion, and rigid solid granules with different granule diameters enter leaking cracks, leaking pores and leaking passages in the plugging construction process and play bridging and supporting roles in the leaking cracks, the leaking pores and the leaking passages with different sizes. The invention has high supporting capability and plugging characteristic, wide using range, and the like and is widely applied to leakage prevention and plugging technologies of oil and geological exploration.

Owner:DONGYING TAIER GASOLINE TECH

Wide frequency high magnetic conductive ratio low loss manganese zincium soft magnetic ferrite material and preparation thereof

InactiveCN101419858ASmall particle sizeAvoid over-refinementInorganic material magnetismSoft magnetFerrite powder

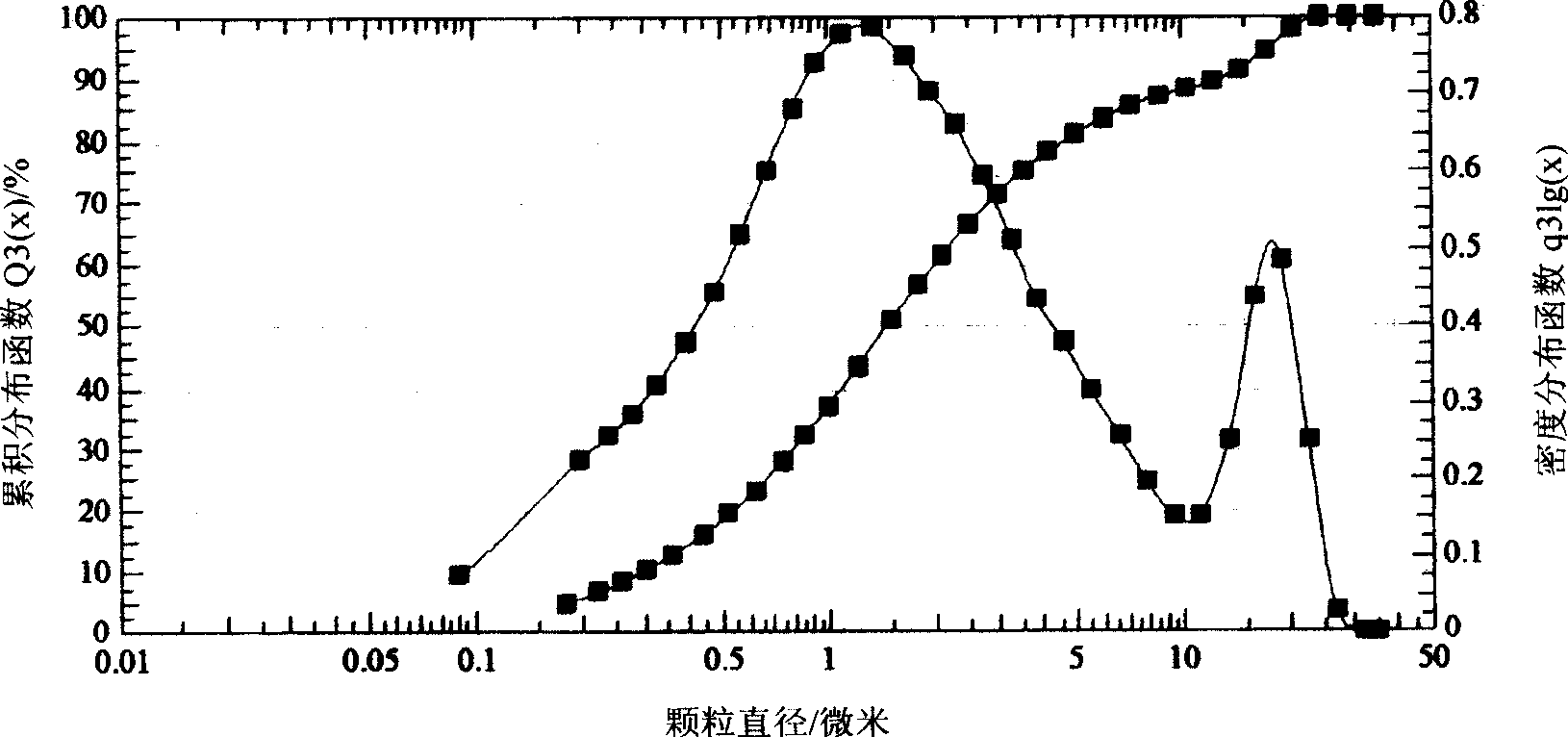

The invention relates to a soft magnet ferrite material, in particular to a broad-frequency high-magnet conductive rate low-wastage Mn-Zn soft magnet ferrite material as well as a preparation method for the material. The material consists of the main components of Mn-Zn series ferrite powder and the auxiliary components; the main components of the Mn-Zn series ferrite powder comprise Fe2O3, MnO and ZnO; wherein, Fe2O3 accounts for 68.8 to 70.2 percent of the total weight percentage, MnO accounts for 15 to 16.2 percent of the total weight percentage and ZnO accounts for 14.5 to 15.2 percent of the total weight percentage. The auxiliary components comprise Bi2O3, MoO, V2O5, CaCO3 and SnO2; the auxiliary components account for 0.8 to 1.8 percent of the total weight percentage. The preparation method of the material comprises the three steps of pre-processing, connecting multilevel sand milling in series and thermal processing, and can obtain the Mn-Zn soft magnet ferrite material which has the characteristics of broad frequency, high magnet conductive rate and low wastage.

Owner:JIANGSUSR MAGNETIC MATERIAL & DEVICE ENG TECH RES

Method for preparing smectite inorganic gel by mechanochemical modification

InactiveCN104760969AReduce the impact of suspension stabilityNo pollutionSilicon compoundsDispersityWater dispersible

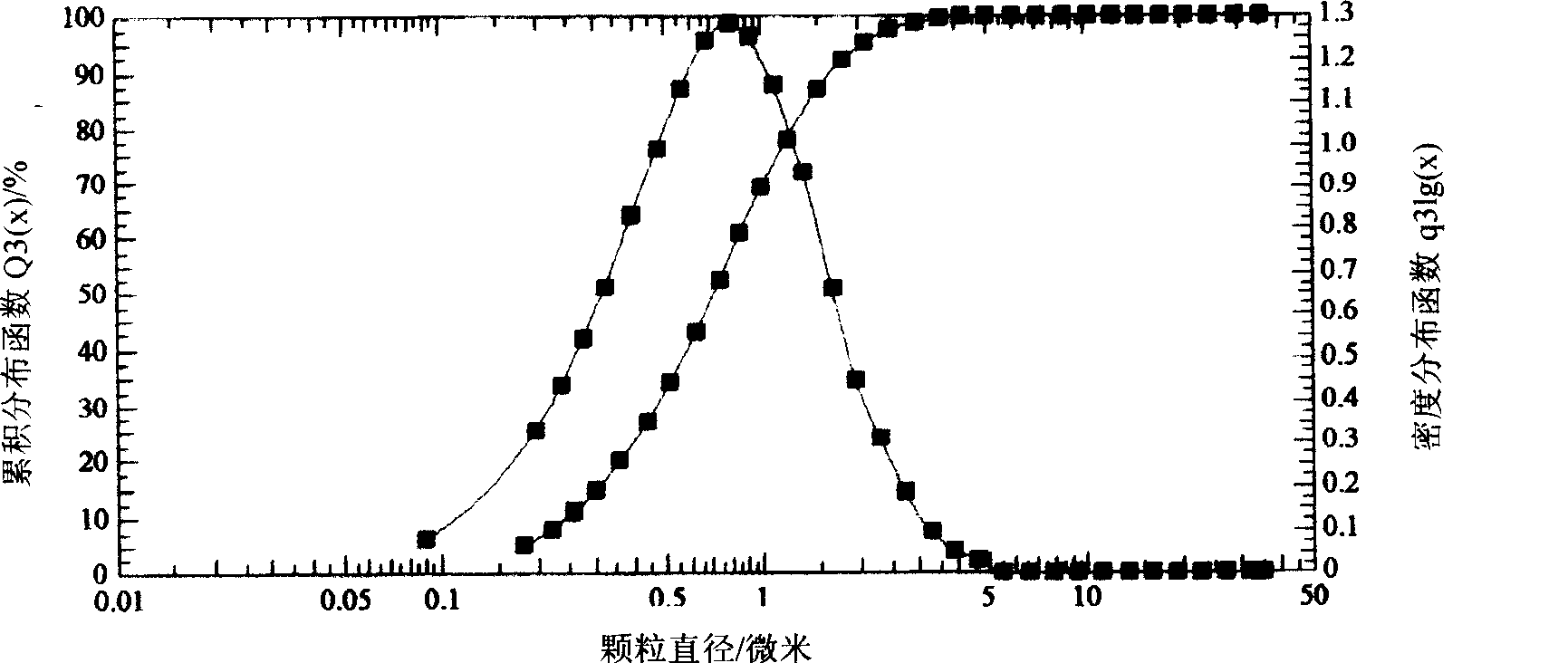

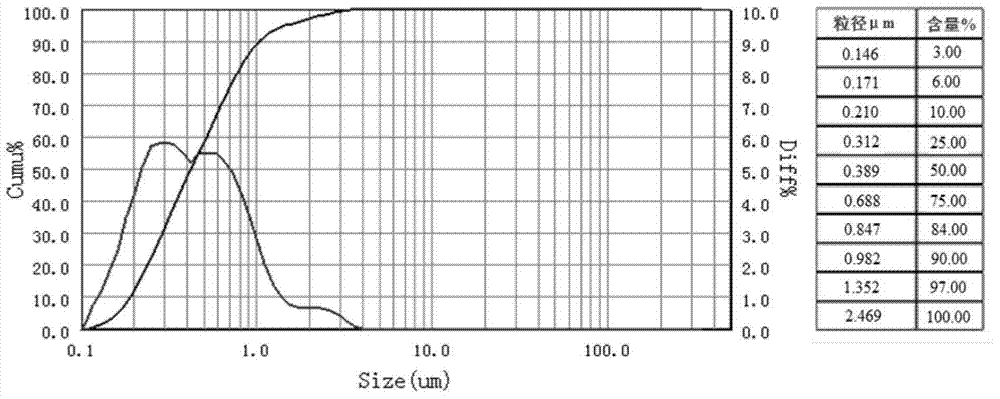

The invention discloses a method for preparing a smectite inorganic gel by mechanochemical modification, which comprises the following steps: adding water into the smectite raw material to prepare a slurry with the concentration of 5-20 wt%, stirring and dispersing uniformly, and pretreating with an ion exchange resin to obtain a pretreated smectite slurry; adding a modifier which is 0.6-1.2 times of smectite CEC, and stirring and dispersing uniformly; feeding the slurry into a wet-process superfine treatment device to perform superfine treatment, thereby obtaining the smectite slurry of which the particle size distribution is D50<=1.0 mu m and D90<=5.0 mu m; and adding an electrolyte which accounts for 0-5 wt% of the smectite into the superfine slurry, and stirring and dispersing uniformly to obtain the target product. The method obviously enhances the water dispersity, suspension stability and thickening property of the smectite, and especially has obvious improvement effects on high-level charged smectite.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

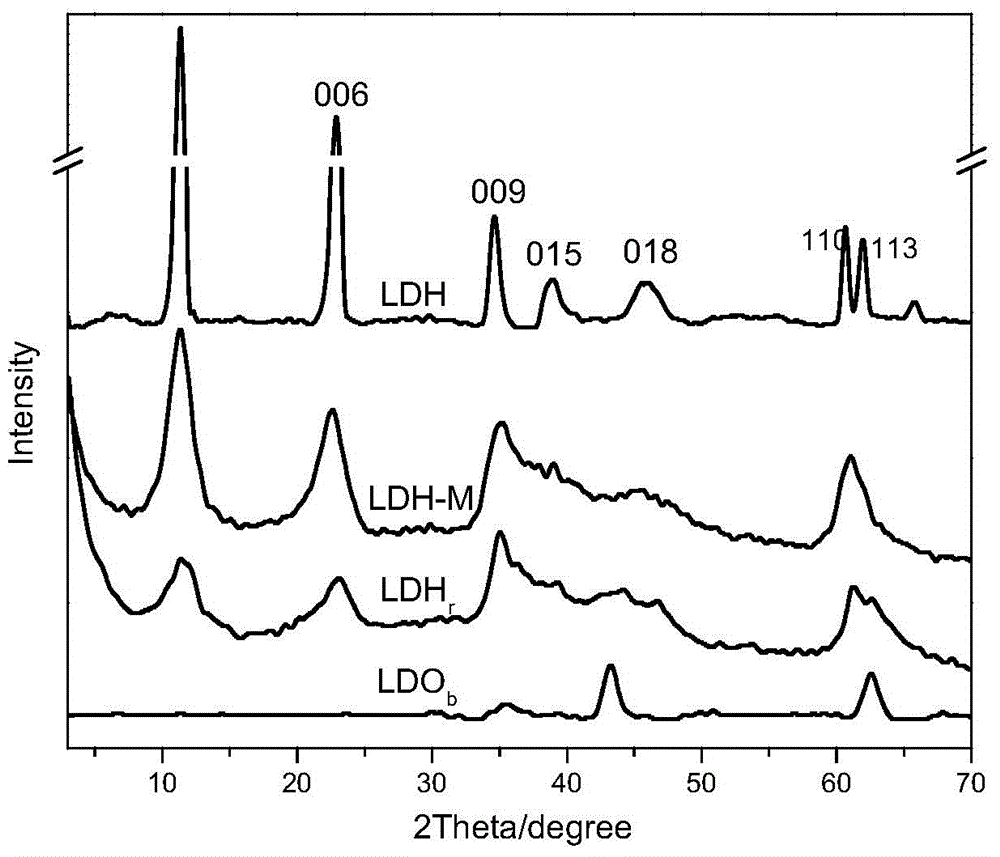

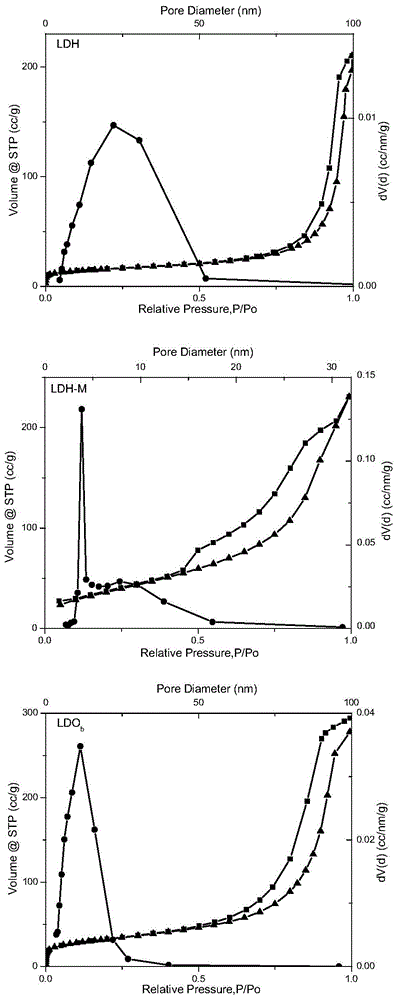

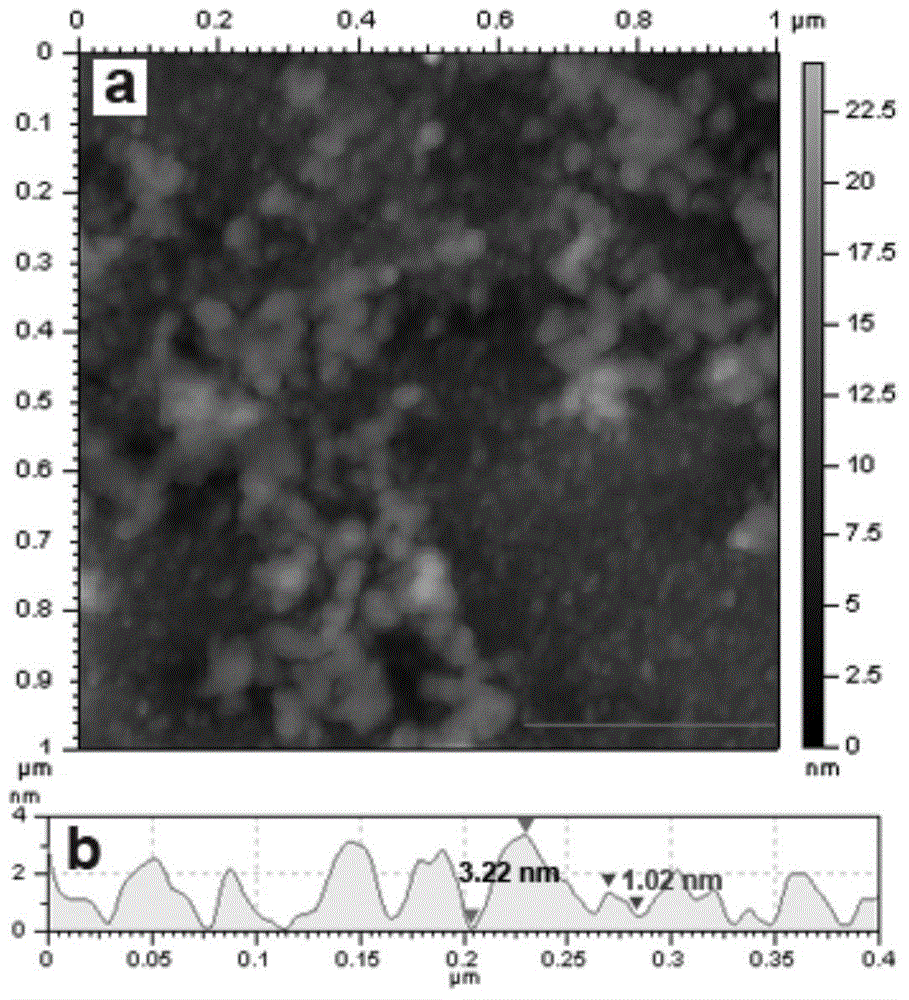

Preparation method of stratiform bimetallic oxide sorbent capable of effectively removing low-concentrated phosphate radical

ActiveCN105032342AImprove adsorption capacityResolve aggregationOther chemical processesWater/sewage treatment by sorptionPhosphateSorbent

The invention discloses a preparation method and application of a stratiform bimetallic oxide sorbent capable of effectively removing low-concentrated phosphate radical. According to the invention, a hydrophobic ionic liquid BmimPF6 is taken as oil phase, and N,N-dimethyl formamide (DMF) is taken as a cosolvent in a Bmim PF6 / DMF / H2O ionic liquid-in-water inverse surfactant-free microemulsion system, a small particle diameter ultrathin stratiform bimetallic hydroxide nanosheets precursor is prepared according to a double microemulsion coprecipitation method, calcination of the precursor is carried out at high temperature of 500 DEG C so as to prepare stratiform bimetallic oxides adsorbent. The obtained stratiform bimetallic oxides are 107.36-158.46 cm<2> / g in specific surface area, 8.56-11.17 nm in pore diameter, and 0.358-0.468 cm<3> / g in pore volume. The stratiform bimetallic oxides can restore and form stratiform bimetallic hydroxide nanosheets in an aqueous medium, wherein the particle diameter of nanosheets is 150-200 nm, the thickness is about 5 nm, and the distribution of particle diameters is uniform. The adsorption rate of the stratiform bimetallic oxides is far higher than that of large-grained hydrotalcite prepared from the precursor stratiform bimetallic oxides of the sorbent according to the traditional coprecipitation method.

Owner:肇庆市高要区永恒之辉金属制品有限公司

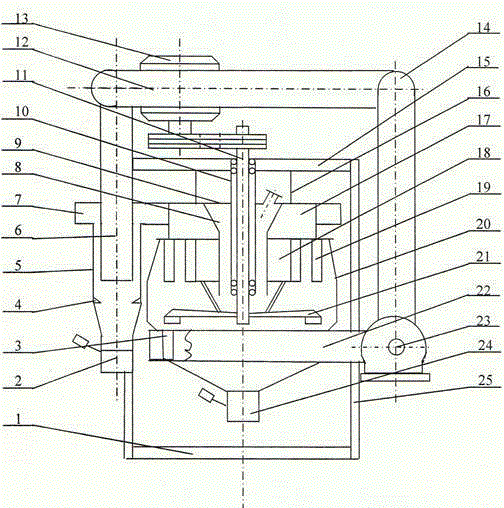

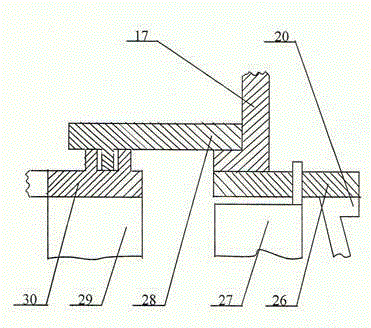

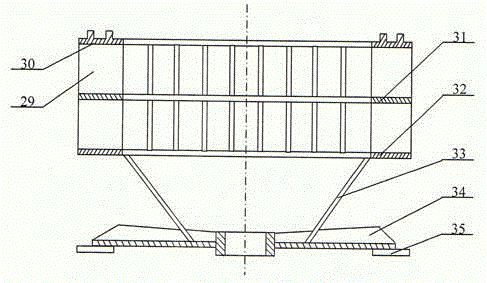

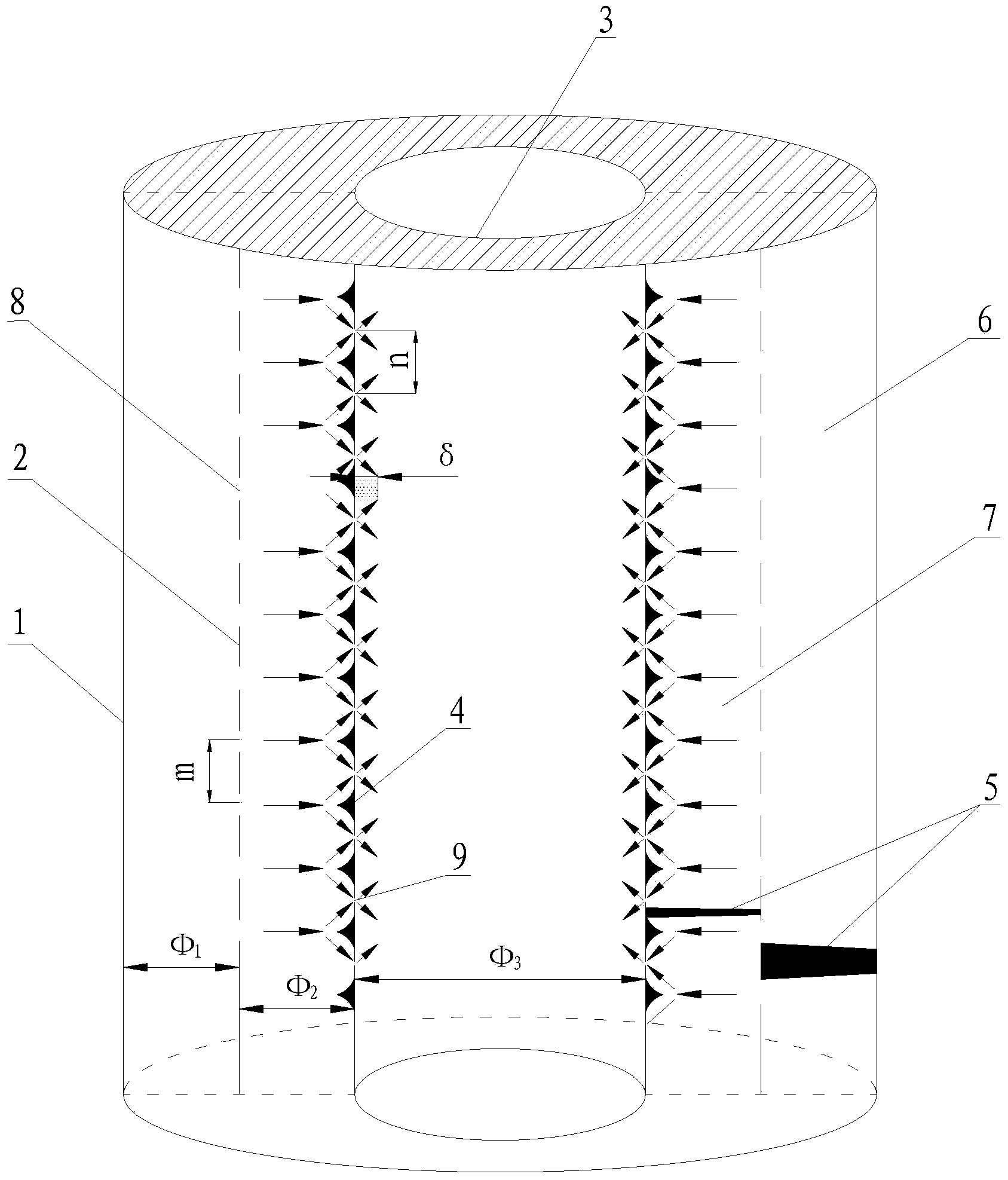

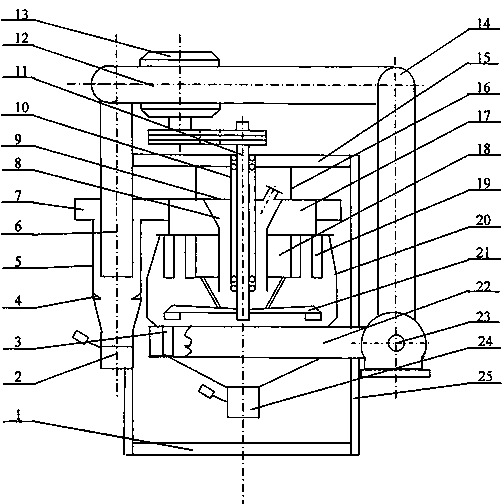

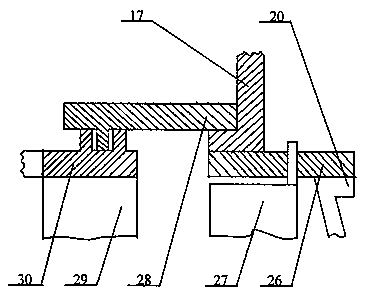

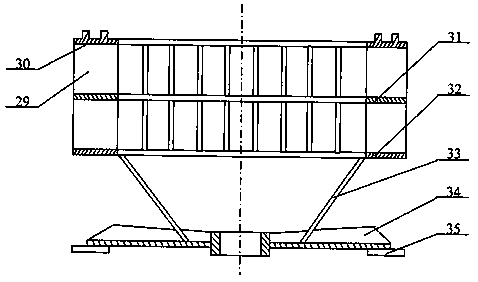

Cage type rotor eddy flow ultra-fine powder concentrator

ActiveCN106031901AEvenly dispersedAccurate dispersionReversed direction vortexGas current separationSlurryEngineering

The invention discloses a cage type rotor eddy flow ultra-fine powder concentrator, which comprises a host machine rack, a feeding device, a power transmission device, a host machine housing, a volute wind intake and return device, an ultra-fine sorting device, a cyclone gas-solid separation device, a control box and other operation function components, wherein the host machine rack is welded and fixed to form the rigid integrate having the frame structure form, the feeding cylinder, the power transmission device and the eddy flow powder collection chamber are directly installed on the horizontal reference connection plate of the host machine rack so as to provide the form and position reference and the position precision for the installation connection of the operation components, and the ultra-fine powder concentrator adopts a plurality of innovative technologies such as volute bottom lateral wind intake, double layer diversion blade directional wind inducing, cover plate type wind blocking sealing ring wind blocking leakage prevention, underlying slurry type powder throwing dish throwing dispersing lifting, cage type rotor duplex ultra-fine classification, cyclone gas-solid separation and the like, and has prominent characteristics of stable eddy flow wind force, uniform particle dispersion, accurate micro-powder grading, complete gas-solid separation, and the like.

Owner:淮安市行健再生资源利用有限公司

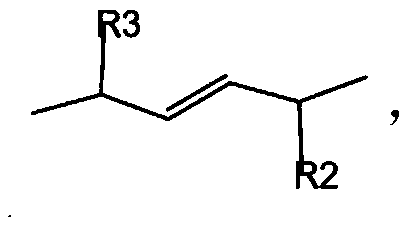

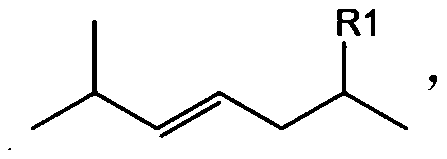

Preparation method and application of framework Co catalyst

ActiveCN106111160AWide range of particle size distributionReduce manufacturing costOrganic compound preparationAmino preparation by functional substitutionIsophoroneCycleanine dimethobromide

The invention discloses a preparation method and application of a framework Co catalyst. The method specially comprises the following steps of preparing Co-Al alloys through smelting, then crushing the Co-Al alloys into alloy powder, and then adding an organic binder, a lubricant, a high-temperature adhesive and a special adhesive; and performing shaping, performing drying, performing roasting, performing activation and performing post treatment, so as to obtain the catalyst. The catalyst is used for hydrogenation of 3-(aminomethyl)-3,5,5-trimethylcyclohexanamine (IPN) so as to prepare isophorone diamine(IPDA), wherein the conversion rate of IPN is as high as 100%, and the selectivity of the IPDA is as high as 98% or above.

Owner:WANHUA CHEM GRP

Water-based drilling fluid plugging material and preparation method thereof

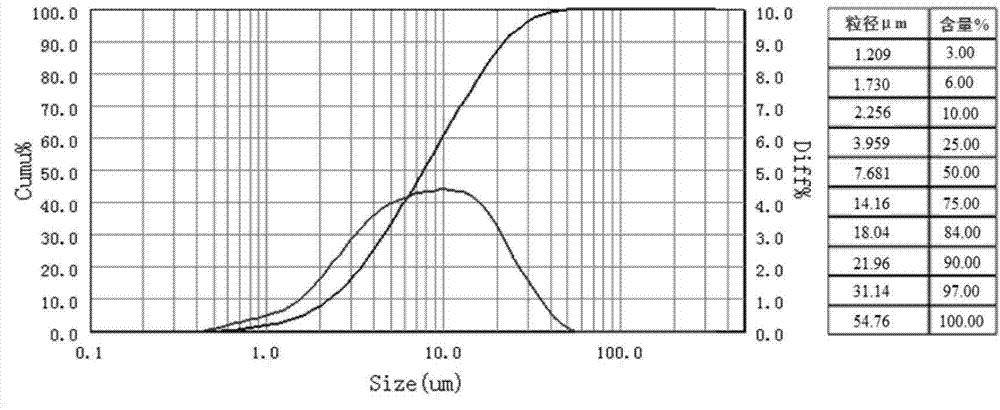

InactiveCN106609126AWide range of particle size distributionGood dispersionDrilling compositionFiberWater based

The invention discloses a water-based drilling fluid plugging material and a preparation method thereof, and relates to the technical field of water-based drilling fluid plugging materials. The water-based drilling fluid plugging material is characterized by comprising, by mass, 20-50% of water-soluble expansion materials, 5-15% of a cross-linking agent, 5-10% of a retarder, 10-25% of modified fibers and 10-30% of calcium carbonate. The water-based drilling fluid plugging material has the advantages of being large in plugging coverage, high in pressure bearing capacity, good in plugging effect, simple in site configuration process and the like, and can achieve the purposes of reducing the well leakage loss and reducing the composite cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Feed for promoting intestinal development of meat chickens in fattening period

InactiveCN106509471AImprove developmentPromote peristalsisFood processingAnimal feeding stuffBiotechnologyRapeseed

The present invention discloses a feed for promoting intestinal development of meat chickens in a fattening period. The feed comprises the following raw materials in parts by weight: 3-7 parts of microcrystalline cellulose, 3-5 parts of modified soybean proteins, 4-6 parts of salted duck egg yolk, 3-7 parts of puffed soybeans, 4-10 parts of soybean cake, 12-20 parts of rapeseed meal, 12-18 parts of rapeseed cake, 4-8 parts of lard, 25-55 parts of corn, 10-16 parts of wheat, 3-9 parts of malt powder, 4-12 parts of corn stalks, 1.5-2.5 parts of vital gluten, 1.5-2.5 parts of coix chinensis, 1.5-2.5 parts of haw powder, 0.5-1.5 parts of unprocessed rehmannia roots, 1.5-2.5 parts of grape leaves, 0.6-1 part of barley malt, 0.4-1 part of red date, 1.5-2.5 parts of honey, 1.5-3.5 parts of spirulina platensis powder, 1.5-2.5 parts of soybean lecithin, 1-3 parts of malt selenium, 0.2-0.8 part of red chili powder, 0.4-0.8 part of vitamin, 1.5-2.5 parts of calcium hydrogen phosphate and 2-4 parts of stone powder.

Owner:岳从军

Fire-flooding well self-degradable temporary plugging agent and preparation method and application thereof

ActiveCN109294541AEnhanced pumpabilityImprove temperature resistanceDrilling compositionReservoir typeCross-link

The invention provides a fire-flooding well self-degradable temporary plugging agent and a preparation method and an application thereof. By metering the total weight of the self-degradable temporaryplugging agent is 100%, the raw materials for preparing the self-degradable temporary plugging agent include: 0.3-0.8% of a main agent; 0.01-0.05% of a cross-linking agent; 0.5-2% of oil-solubility resin; 0.2-0.6% of fiber particles; 0.02-0.1% of a heat stabilizer; 0.1-0.5% of a fungicide; 0.2-0.6% of a cleanup additive; 1-3% of a fluid loss reducer; 0.001-0.004% of a slow release gel breaker, andthe balance of water. The fire-flooding well self-degradable temporary plugging agent has the characteristics of good pumping property, temperature resistance, simple preparation, and low cost, and the gel breaking time is adjustable, the sealing ability is strong, and the self-degradable temporary plugging agent is suitable for wide oil reservoir types, and is not easy to pollute the stratum andcan enter a deep part of the stratum, which can effectively solve the production problem of large gas production amount of the fire-flooding wells.

Owner:PETROCHINA CO LTD

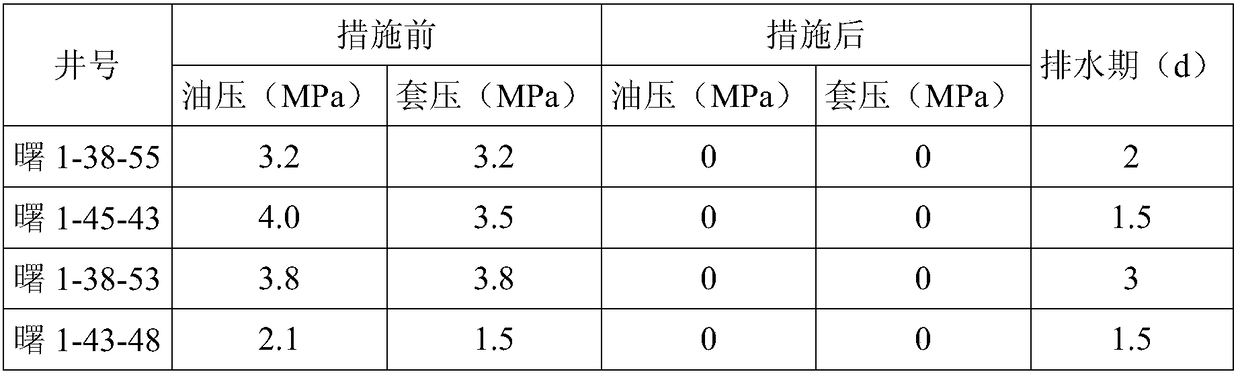

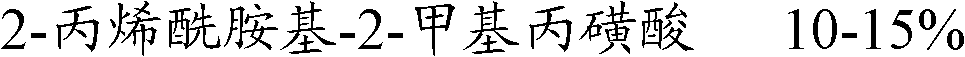

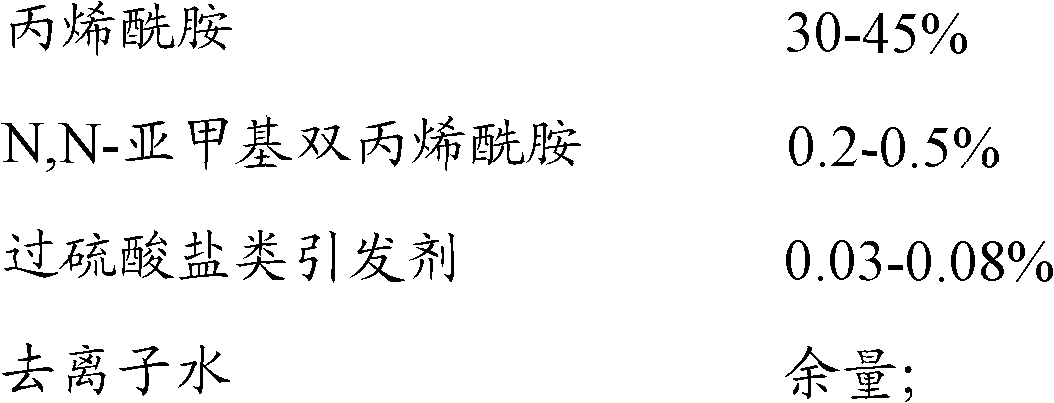

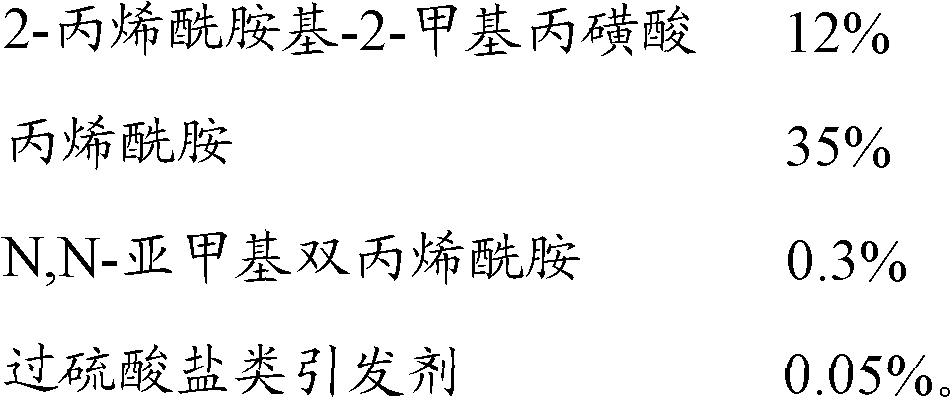

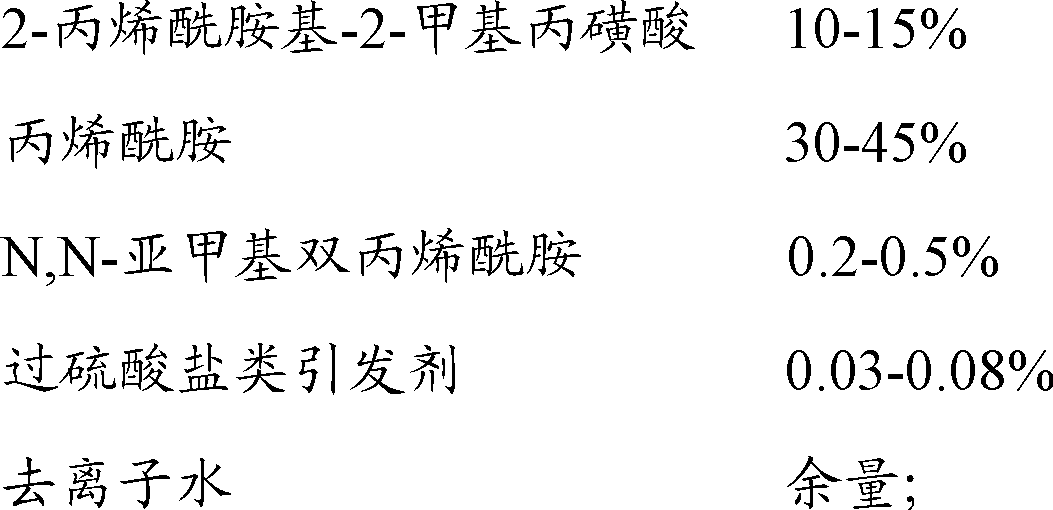

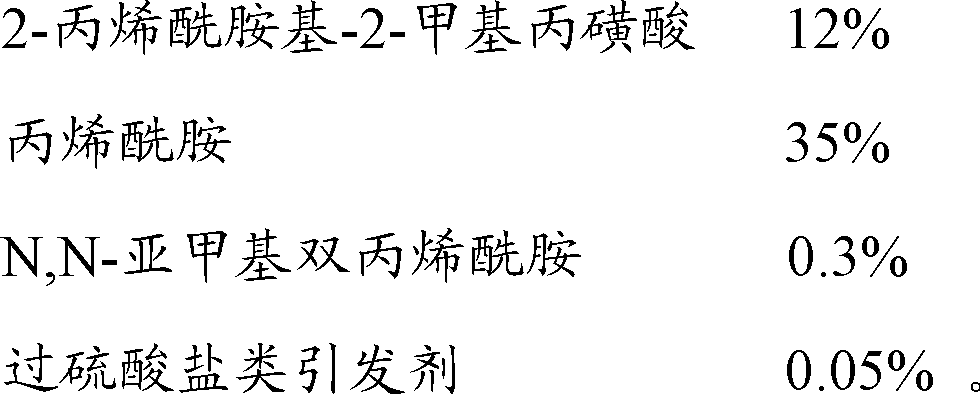

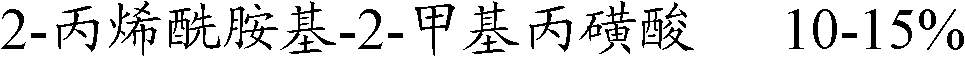

Water absorption resin for well repair and leaking stoppage and synthesis method thereof

ActiveCN102181008AGood effect in sealing formation seepageThe synthesis method is simpleDrilling compositionSynthesis methodsNitrogen

The invention relates to water absorption resin for well repair and leaking stoppage. The water absorption resin is prepared by the following synthesis steps of: a, mixing 10 to 15 percent of 2-acrylamide-2-methylpropanesulfonic acid, 30 to 45 percent of acrylamide, 0.2 to 0.5 percent of N,N-methylenebisacrylamide and deionized water in a weight ratio with stirring to form a mixture, wherein the stirring time is 5 to 10 minutes and the stirring temperature is 30 to 50 DEG C; b, putting the prepared mixture into a polymerization reaction kettle, stirring the mixture, introducing nitrogen for 30 minutes to displace air in the polymerization reaction kettle, simultaneously heating the polymerization reaction kettle to the temperature of between 40 and 50 DEG C, then adding 0.03 to 0.08 weight percent of persulfate initiator into the mixture, performing polymerization reaction on the mixture to generate the water absorption resin, and preserving heat for at least 6 hours after the polymerization reaction starts; and c, drying the prepared water absorption resin at the temperature of not more than 120 DEG C for 24 hours till complete drying, and crushing the dried water absorption resin into granules with a diameter of 0.5 to 40 millimeters to obtain the water absorption resin for well repair and leaking stoppage.

Owner:CHINA NAT OFFSHORE OIL CORP +1

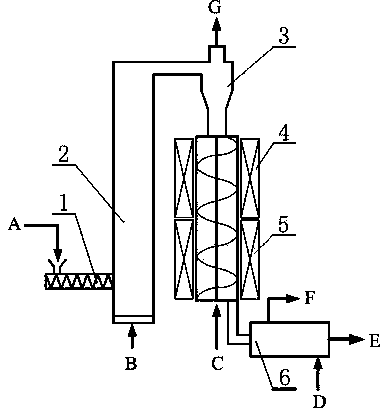

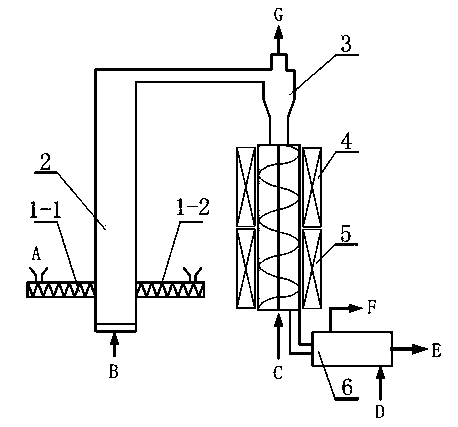

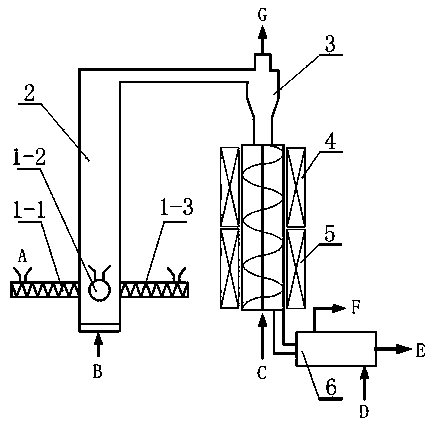

Device and process for manufacturing positive/negative electrode material of lithium battery

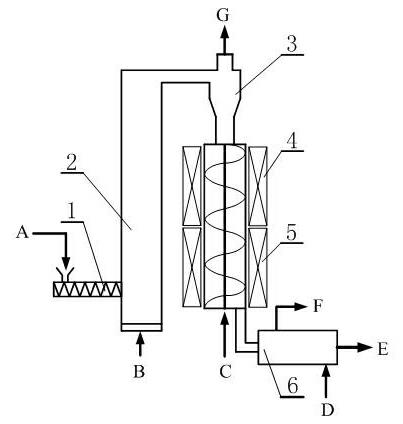

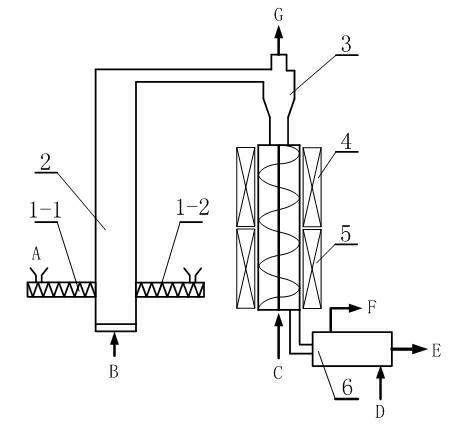

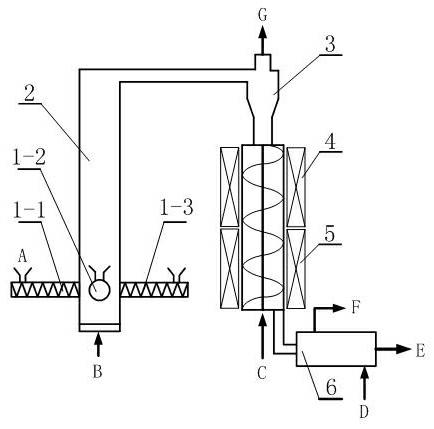

ActiveCN102427128AAddress the degree of automationSolve productivityCell electrodesFluidized bedEngineering

The invention relates to a device and process for manufacturing a positive / negative electrode material of a lithium battery. The device consists of a feeder, a fluidized bed mixer, a gas-solid separator, a spiral continuous feeding reaction device preheating section, a spiral continuous feeding reaction device reacting section, and a cooling device. The process for manufacturing the positive / negative electrode material of the lithium battery comprises the following steps of: firstly feeding raw materials for manufacturing the positive / negative electrode material of the lithium battery into the fluidized bed mixer through the feeder, fully mixing and then separating by the gas-solid separator, sequentially entering the spiral continuous feeding reaction device preheating section and the spiral continuous feeding reaction device reacting section, heating and reacting to generate the positive / negative electrode material of the lithium battery, and then entering the cooling device to be cooled, finally discharging the positive / negative electrode material of the lithium battery from a product outlet. The device and process provided by the invention can be used for continuously manufacturing the positive / negative electrode material of the lithium battery efficiently with low energy consumption.

Owner:济宁市无界科技有限公司

Dense-phase conveying pipeline for high-concentration powder

InactiveCN103818726AWide range of particle size distributionRich varietyBulk conveyorsHigh concentrationEngineering

The invention relates to a novel coaxial multi-passage powder conveying special-shaped pipeline which is composed of an outer pipe, a middle pipe, an inner pipe, an air baffling device with a baffling groove, and a wedge-shaped positioning block. High-concentration powder is pushed into the inner pipe through conveying carrying air, air film air enters a film-forming passage through the outer pipe and large holes, the direction of the air film air is corrected through the air baffling device, then the air film air enters the inner pipe through small holes and forms an air film with certain thickness near the wall of the inner pipe, and the conveying carrying air, the air film air and the high-concentration powder are converged in the inner pipe and are conveyed to a downstream work section in a slurry state under the stirring action of the air.

Owner:XIAN ORIGIN CHEM TECH

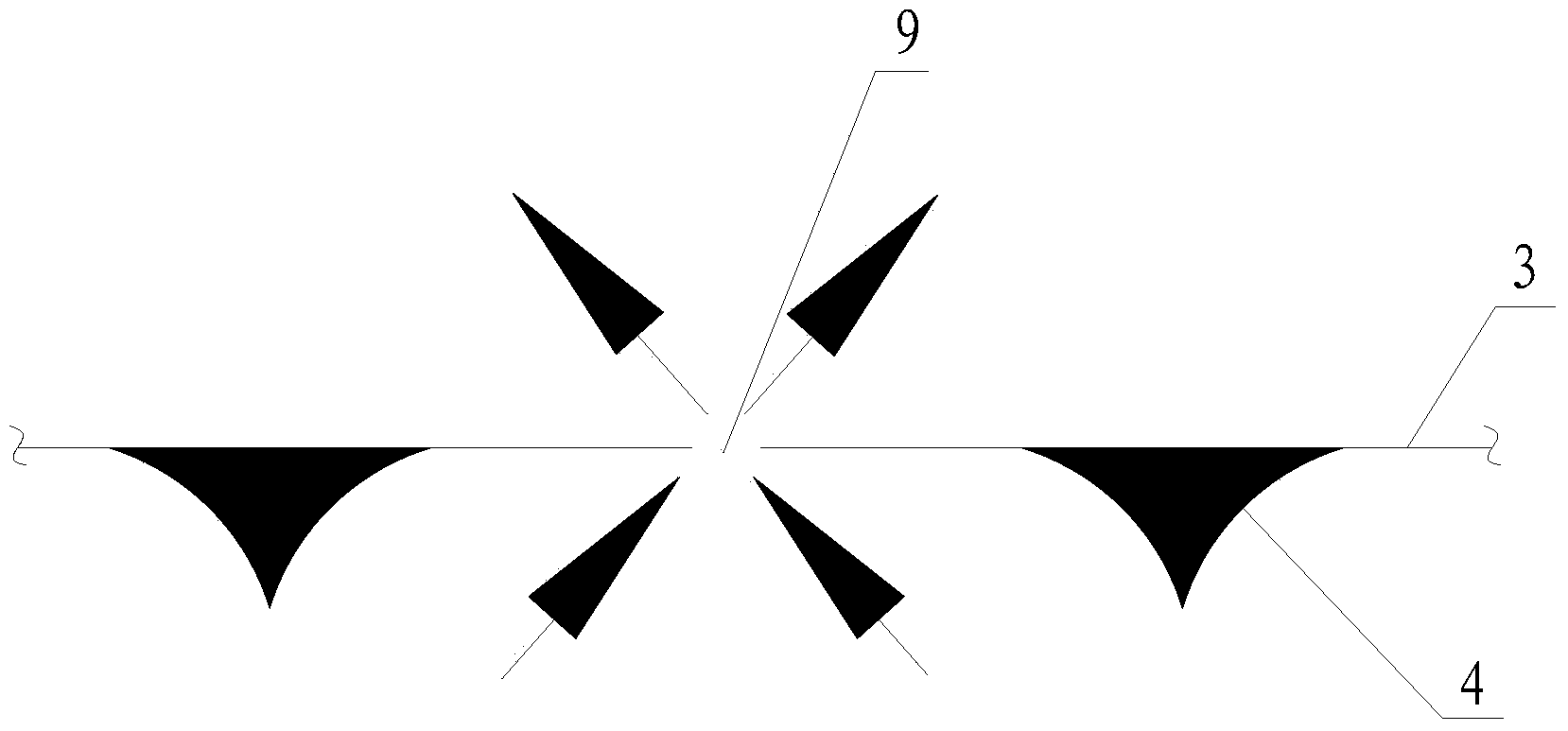

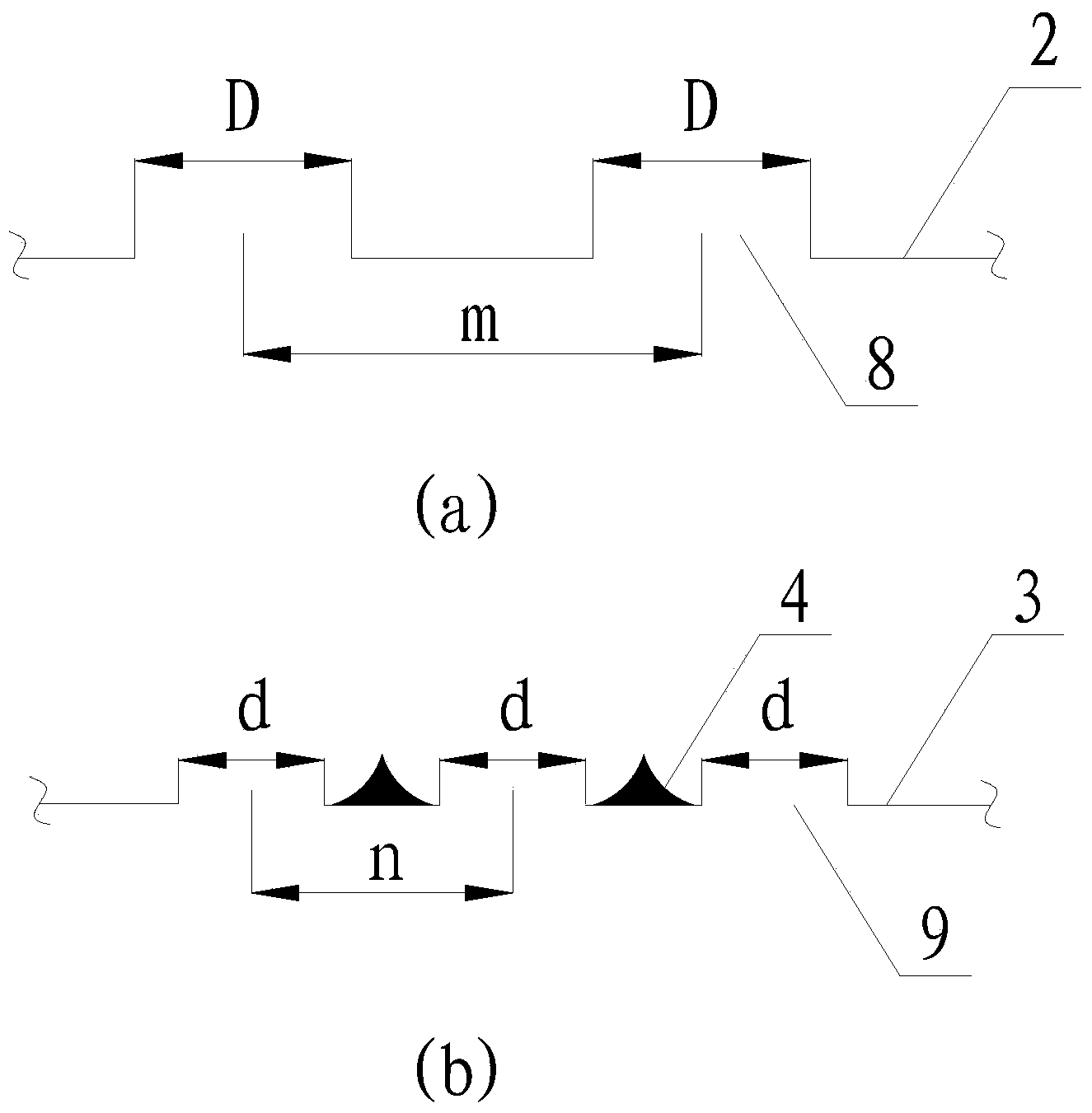

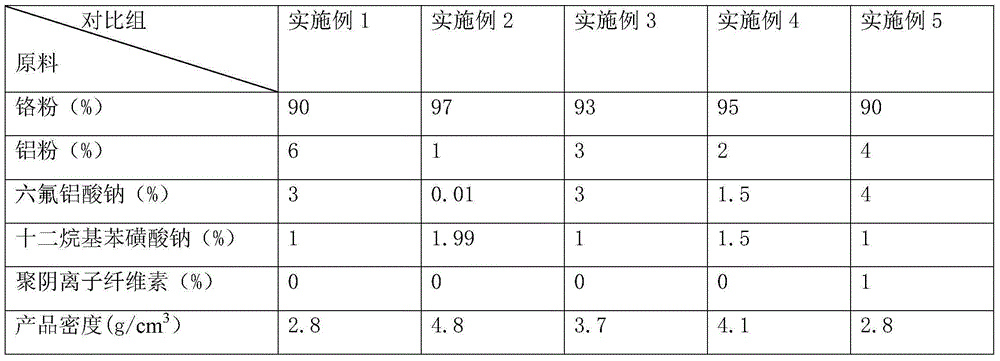

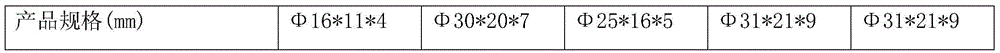

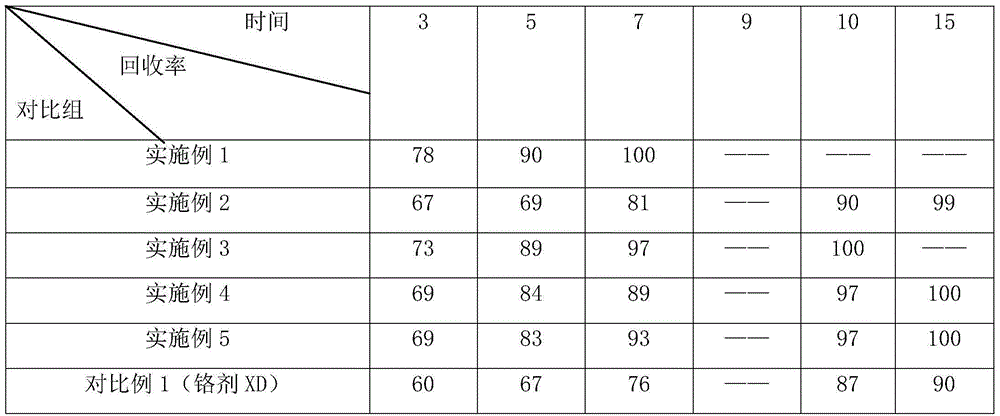

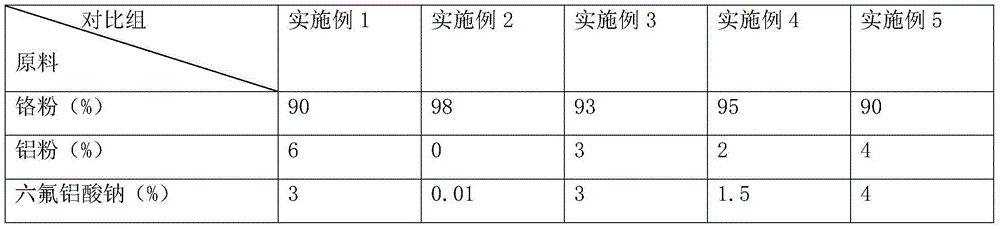

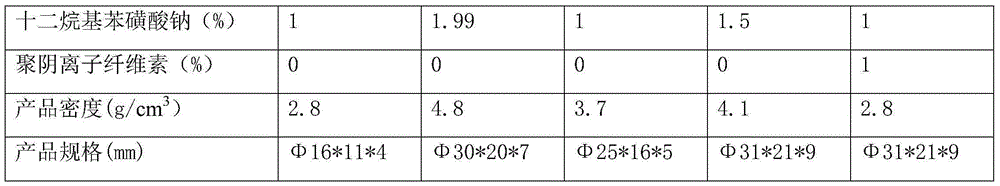

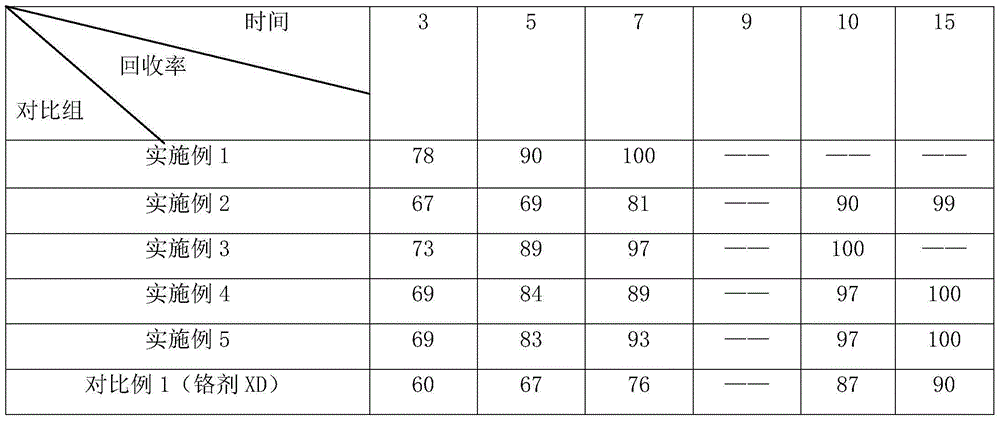

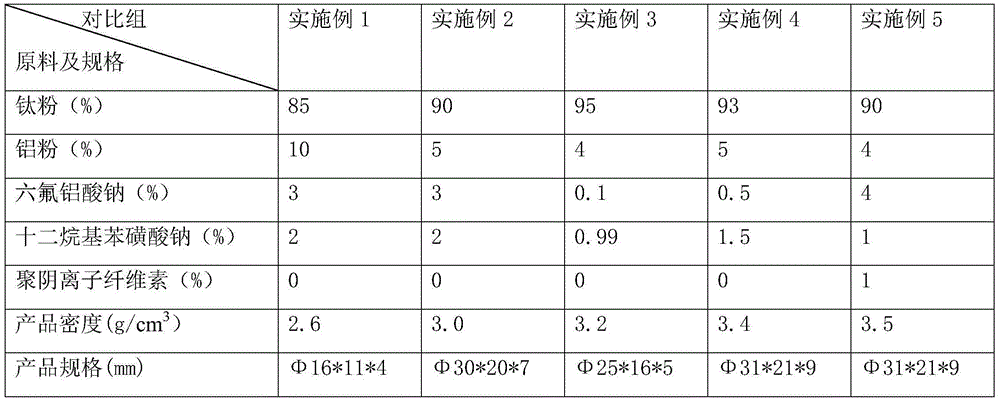

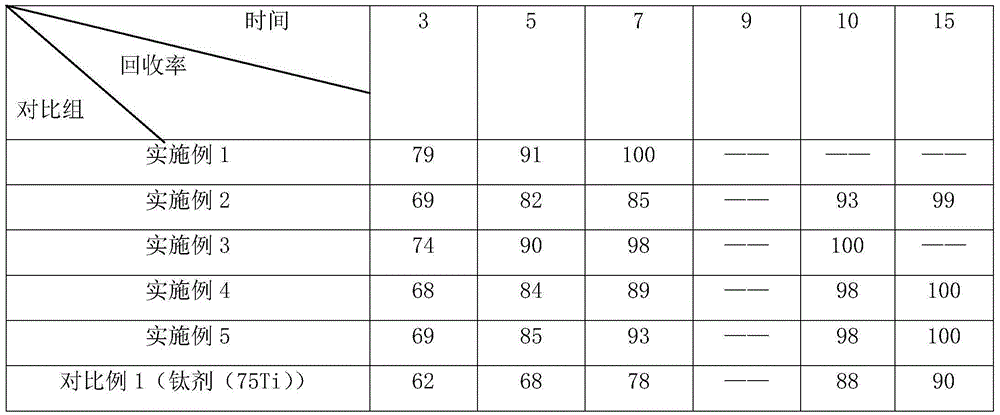

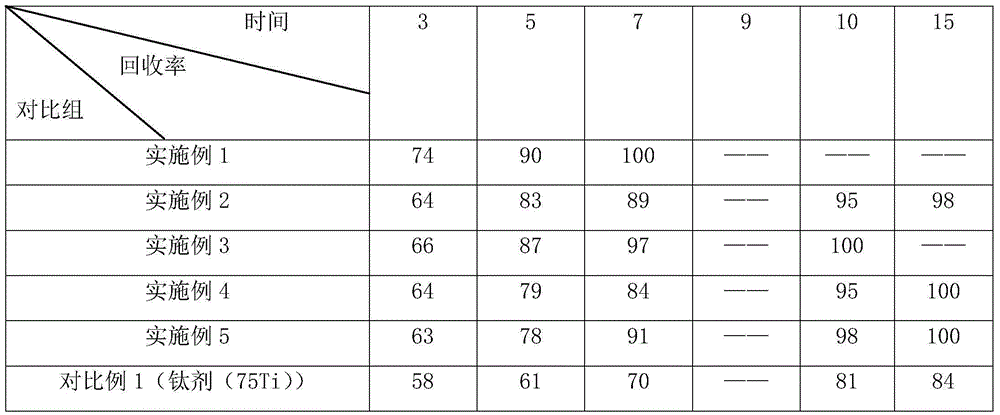

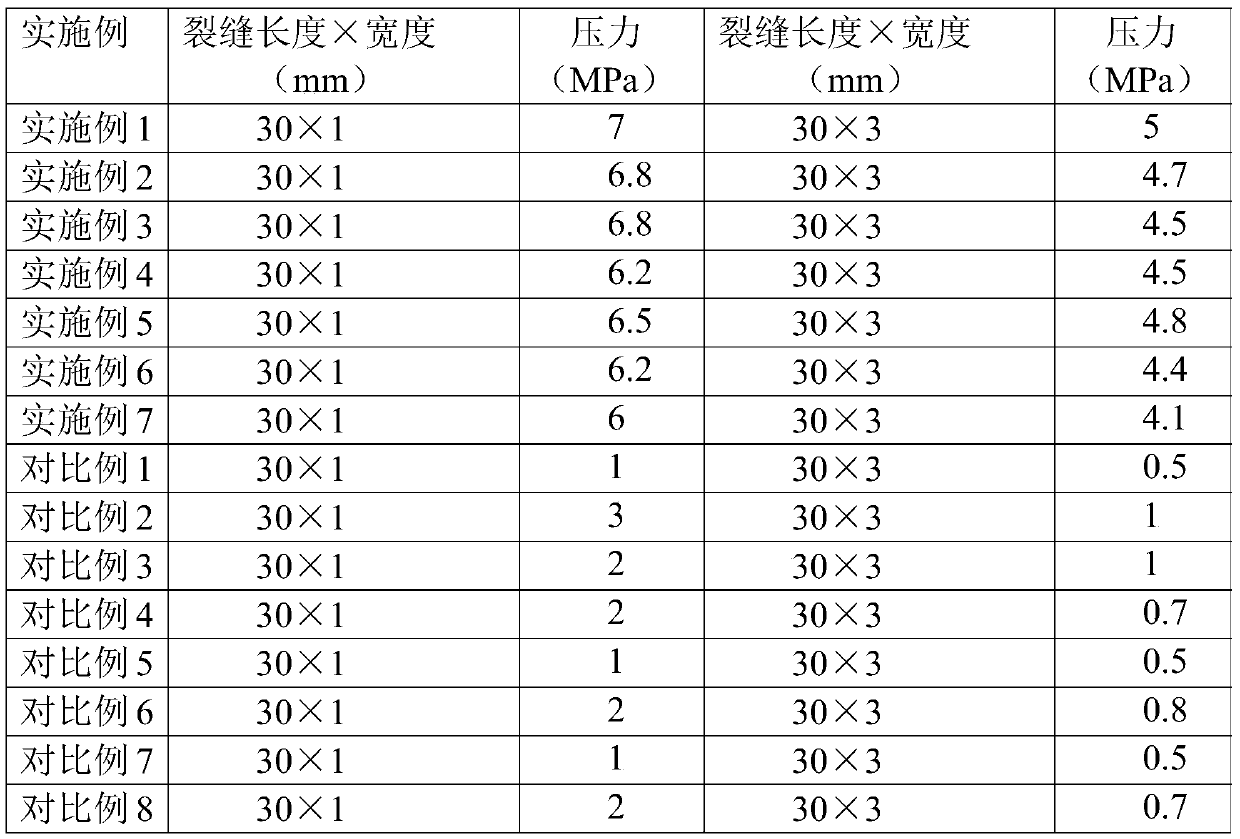

Fine powder chromium preparation for producing aluminium alloy and preparation method for fine powder chromium preparation

The invention belongs to the field of additives of aluminium alloy, and discloses a fine powder chromium preparation for producing aluminium alloy and a preparation method for the fine powder chromium preparation. The fine powder chromium preparation is a pie-shaped and rugby-shaped preparation formed by pressing chromium powder, aluminium powder and a fluxing agent, wherein the chromium powder and the aluminium powder are separately broken under the inert gas shield. The fine powder chromium preparation further comprises a surfactant. The fine powder chromium preparation comprises the following components in percentage by mass: 90%-97% of chromium powder, 0-9.39% of aluminium powder, 0.01%-5% of the fluxing agent and 0.5%-2% of the surfactant, wherein a, the range of particle size distribution of the chromium powder is 10-700 meshes; b, the range of particle size distribution of the aluminium powder and aluminium inorganic salt is 40-500 meshes. According to the chromium preparation disclosed by the invention, the content of chromium metallic element can reach up to 97%; the melting temperature is low by adopting the chromium additive disclosed by the invention; the additive can melt in an aluminium melt at a temperature as low as 670 DEG C; the melting time is short, and the additive can melt in 10-15 minutes; and the recovery rate of the chromium metallic element is as high as more than 95%.

Owner:CHONGQING RUNJI YUANDONG NEW MATERIAL TECH

Chromium additive for producing aluminum alloy and preparation method of chromium additive

The invention belongs to the field of additives for aluminum alloy and discloses a chromium additive for producing aluminum alloy and a preparation method of the chromium additive. The chromium additive for producing aluminum alloy is formed by mainly pressing chromium powder, aluminum powder and a fluxing agent and is in the shape of a cake or a football. The chromium powder and the aluminum powder are broken under the protection of inert gases. The chromium additive for producing aluminum alloy further comprises a surface active agent. Specifically, the chromium additive for producing aluminum alloy comprises, by mass, 90%-97% of the chromium powder, 2%-9.39% of the aluminum powder, 0.01%-5% of the fluxing agent and 0.5%-2% of the surface active agent. The density of the chromium agent formed by pressing all the components ranges from 2.8g / cm <3> to 5.0 g / cm <3>. The chromium content of the additive can be as high as 97%. According to the chromium agent, the melting temperature is low, an aluminum melt can melt at the temperature as low as 670 DEG C, the melting time is short, the aluminum melt can melt in ten to fifteen minutes, and the recovery rate of chromium metal can be as high as 95%.

Owner:CHONGQING RUNJI YUANDONG NEW MATERIAL TECH

Preparation method of water-based polyurethane, emulsion and product

InactiveCN105601881AWide range of particle size distributionImprove folding fastnessPolyurea/polyurethane coatingsWater basedPolyester

The invention provides a preparation method of a water-based polyurethane, an emulsion and a product. The method comprises the following steps: adding polyester polyol into a reaction kettle, starting a stirrer, carrying out vacuum dehydration at 110-130 DEG C for 1-3 hours, and cooling; when the temperature drops to 50-60 DEG C, adding isophorone diisocyanate into the reaction kettle, and controlling the reaction temperature at 85-95 DEG C for one hour; dropwisely adding an organic bismuth catalyst, continuing the reaction for one hour, cooling to 65-75 DEG C, adding dimethylolpropionic acid and dimethylformamide, controlling the reaction temperature at 80-90 DEG C for two hours, and detecting the NCO residue level; and when the NCO residue level reaches 3.5%, cooling to 45-55 DEG C, adding acetone and triethylamine, and stopping stirring after 10 minutes, thereby forming the prepolymer. The method solves the problem of imperfect effect of the water-based polyurethane product in the prior art.

Owner:FUJIAN DONGTAI HIGH POLYMER MATERIAL CO LTD

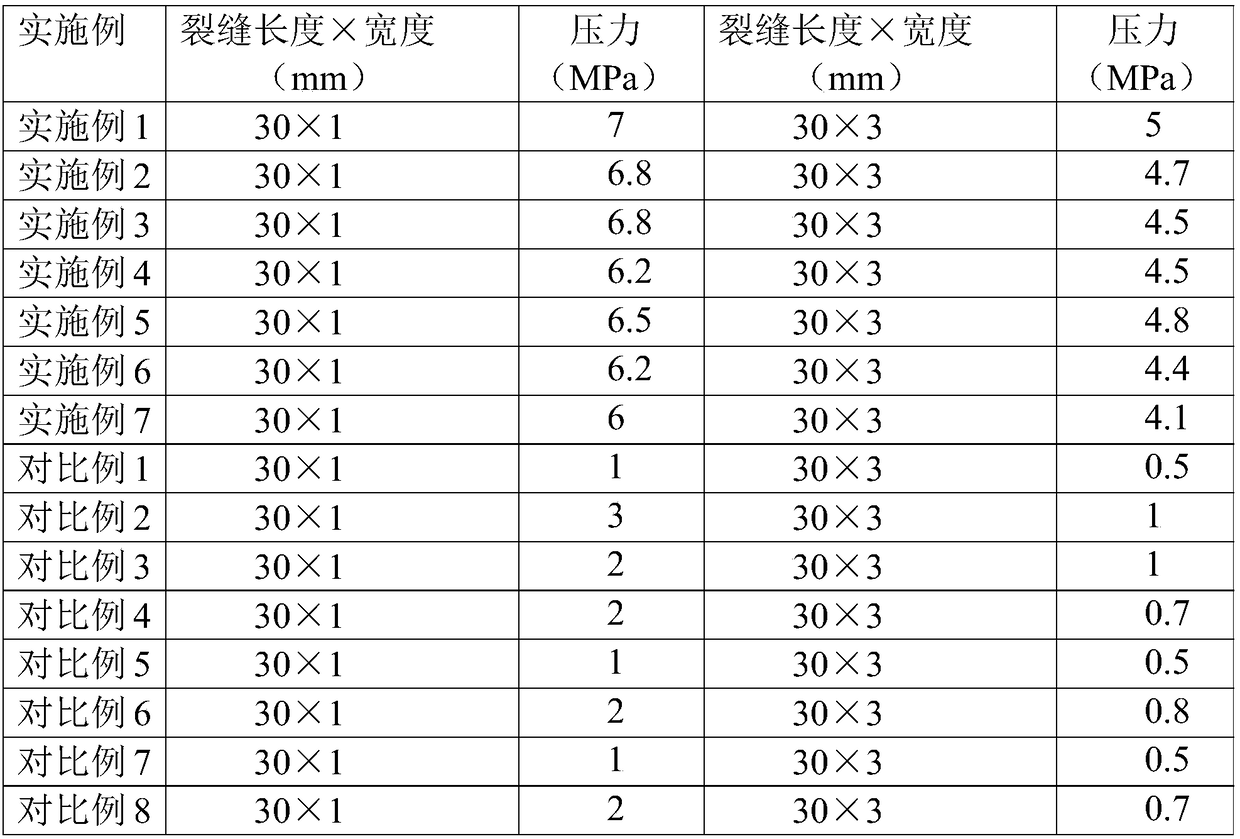

Efficient leak-stopping material for drilling, and preparation method thereof

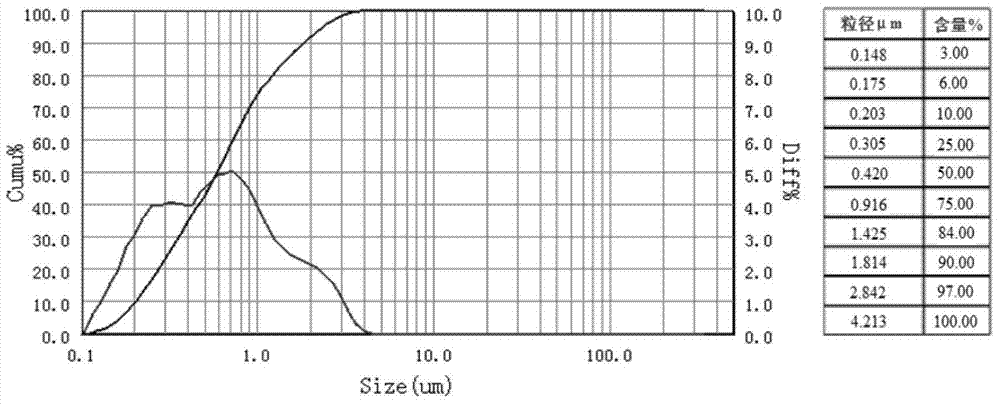

ActiveCN105482790AWide range of particle size distributionEasy to prepareDrilling compositionHigh pressureSawdust

The present invention discloses an efficient leak-stopping material for drilling, and a preparation method thereof, and relates to the technical field of oil and gas field drilling, wherein the efficient leak-stopping material is characterized by comprising by mass: 10-30% of sawdust, 30-50% of shell powder, 10-30% of elastic particles, and 10-20% of calcium carbonate, wherein the substances are mixed and uniformly stirred at a normal temperature under a normal pressure according to the ratio so as to obtain the efficient leak-stopping material for drilling. According to the present invention, the efficient leak-stopping material has characteristics of high pressure bearing capability, good blocking effect, simple on-site configuration process, safe and reliable construction, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fine powder titanium preparation for producing aluminium alloy and preparation method for fine powder titanium preparation

The invention belongs to the field of additives of aluminium alloy, and discloses a fine powder titanium preparation for producing aluminium alloy and a preparation method for the fine powder titanium preparation. The fine powder titanium preparation is a pie-shaped and rugby-shaped preparation formed by pressing titanium powder, aluminium powder and a fluxing agent, wherein the titanium powder and the aluminium powder are separately broken under the inert gas shield. The fine powder titanium preparation further comprises a surfactant. The fine powder titanium preparation comprises the following components in percentage by mass: 85%-95% of titanium powder, 4%-14.49% of aluminium powder, 0.01%-5% of the fluxing agent and 0.5%-2% of the surfactant, wherein a, the range of particle size distribution of the titanium powder is 10-700 meshes, and the average particle size is 100-400 meshes; b, the range of particle size distribution of the aluminium powder and the fluxing agent is 40-500 meshes, and the average particle size is 80-350 meshes. According to the additive disclosed by the invention, the content of titanium metallic element can reach up to 95%; the melting temperature is low by adopting the titanium additive disclosed by the invention; the titanium additive can melt in an aluminium melt at a temperature as low as 670 DEG C; the melting time is short, and the titanium additive can melt in 10-15 minutes; and the recovery rate of the chromium metallic element is as high as more than 98%.

Owner:CHONGQING RUNJI YUANDONG NEW MATERIAL TECH

Gel plugging slurry for drilling, preparation method of plugging slurry and slug plugging method

ActiveCN109054785BShort static waiting timeQuick resultsDrilling compositionSealing/packingBridge materialFilling materials

Disclosed are a gel plugging slurry for well drilling, a preparation method of the plugging slurry, and a slug plugging method. The gel plugging slurry comprises water, a specialty gel, a bridging material, a jointing material and a filling material, in amounts of 1-15 parts by weight of the specialty gel, 8-20 parts by weight of the bridging material, 20-40 parts by weight of the jointing material and 25-45 parts by weight of the filling material based on 100 parts by weight of water. The gel plugging slurry has a short wait-on-cement time at rest, exhibits a rapid effect, and can quickly form a structure at fractures in a leakage formation; and the bridging material, the jointing material and the filling material can effectively plug various fractures that vary widely in width. In the slug plugging method, a packer is lowered to pack a well bore, so as to ensure that the plugging slurry can accurately reach the leakage formation and to enhance plugging efficiency.

Owner:SOUTHWEST PETROLEUM UNIV

Gel leakage stoppage slurry for well drilling as well as preparation method of leakage stoppage slurry and plug leakage stoppage method

ActiveCN109054785AShort static waiting timeQuick resultsDrilling compositionSealing/packingBridge materialWell drilling

The invention relates to the field of well drilling leakage stoppage of petroleum industry, and discloses gel leakage stoppage slurry for well drilling as well as a preparation method of leakage stoppage slurry and a plug leakage stoppage method. The gel leakage stoppage slurry comprises water, special gel, a bridging material, a connecting material and a filling material; and by adopting 100 weight parts of water as a reference, the content of the special gel is 1 to 15 weight parts, the content of the bridging material is 8 to 20 weight parts, the content of the connecting material is 20 to40 weight parts, and the content of the filling material is 25 to 45 weight parts. The gel leakage stoppage slurry is short in time for waiting the solidification, fast in effectiveness, and capable of rapidly forming a structure at a crack of a leaking stratum; meanwhile, the bridging material, the connecting material and the filling material can effectively block various cracks of a great width;and in the gel plug leakage stoppage method for the well drilling, a packer is arranged to pack a shaft, so that the leakage stoppage slurry can be ensured to accurately reach the leaking stratum, and the plugging efficiency can be improved.

Owner:SOUTHWEST PETROLEUM UNIV

Cage Rotor Eddy Current Ultrafine Powder Concentrator

ActiveCN106031901BEvenly dispersedAccurate dispersionReversed direction vortexGas current separationUltra fineSlurry

The invention discloses a cage type rotor eddy flow ultra-fine powder concentrator, which comprises a host machine rack, a feeding device, a power transmission device, a host machine housing, a volute wind intake and return device, an ultra-fine sorting device, a cyclone gas-solid separation device, a control box and other operation function components, wherein the host machine rack is welded and fixed to form the rigid integrate having the frame structure form, the feeding cylinder, the power transmission device and the eddy flow powder collection chamber are directly installed on the horizontal reference connection plate of the host machine rack so as to provide the form and position reference and the position precision for the installation connection of the operation components, and the ultra-fine powder concentrator adopts a plurality of innovative technologies such as volute bottom lateral wind intake, double layer diversion blade directional wind inducing, cover plate type wind blocking sealing ring wind blocking leakage prevention, underlying slurry type powder throwing dish throwing dispersing lifting, cage type rotor duplex ultra-fine classification, cyclone gas-solid separation and the like, and has prominent characteristics of stable eddy flow wind force, uniform particle dispersion, accurate micro-powder grading, complete gas-solid separation, and the like.

Owner:淮安市行健再生资源利用有限公司

Hard compound reinforcing bridging agent

ActiveCN101671550BMake sure to enterStrong bridging supportFluid removalDrilling compositionFiberGeological exploration

Owner:DONGYING TAIER GASOLINE TECH

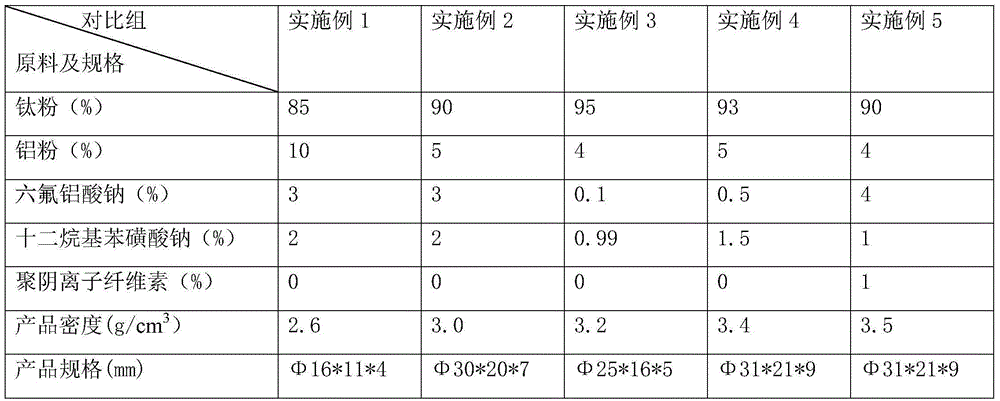

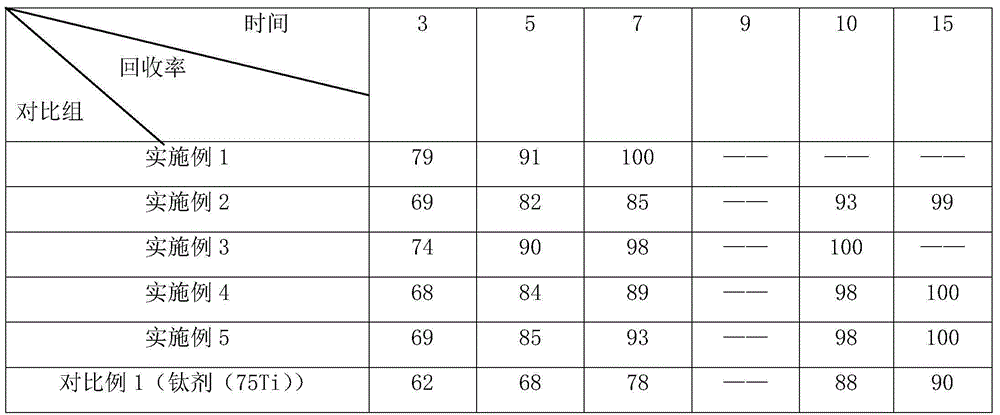

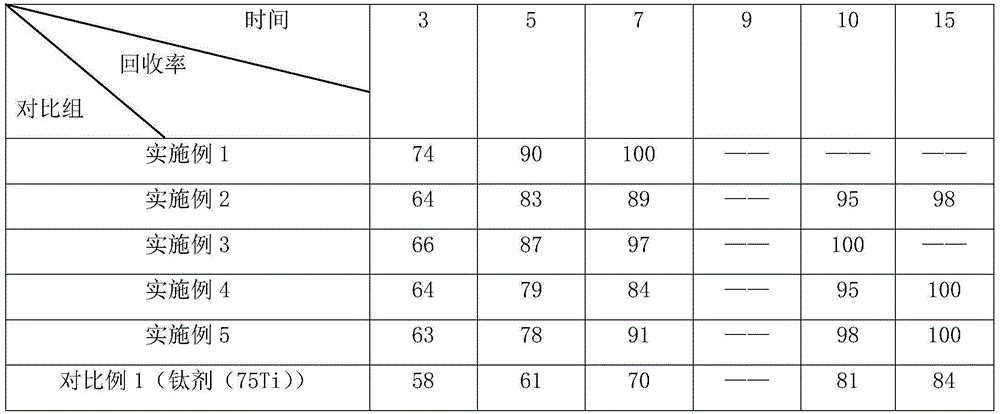

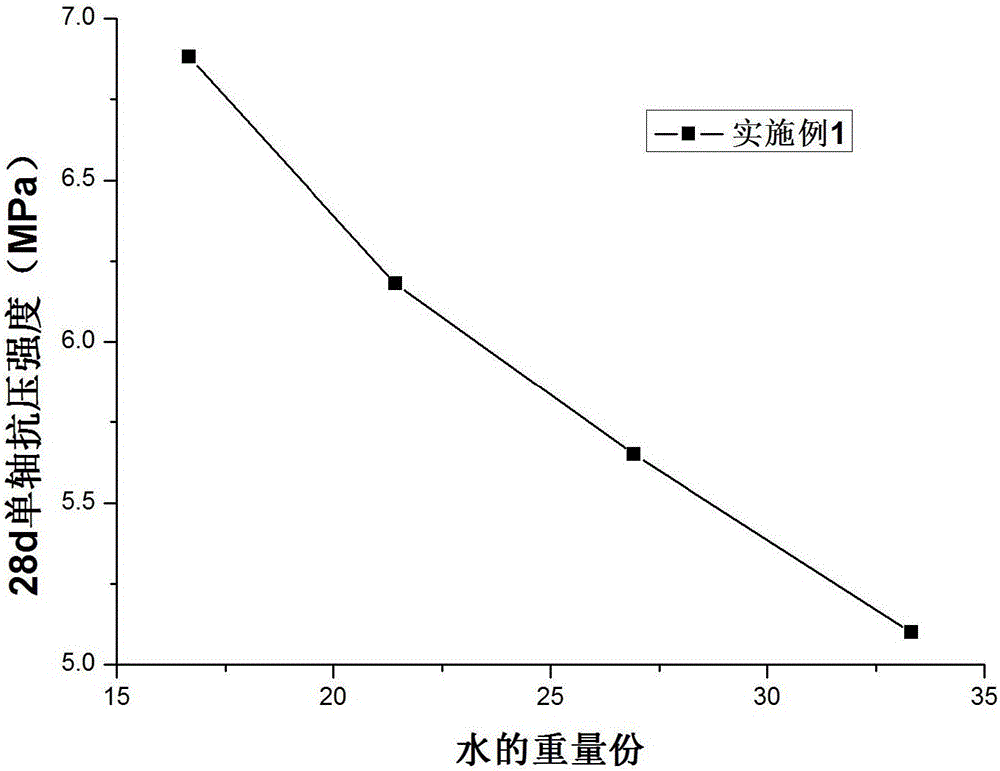

Titanium agent used for producing aluminum alloy and preparation method thereof

The invention belongs to the field of addition agents of aluminum alloy and discloses a titanium agent used for producing the aluminum alloy and a preparation method thereof. The titanium agent used for producing the aluminum alloy is mainly formed by pressing titanium powder, aluminum powder and fluxing agents to be in a cake shape or a rugby shape. The titanium powder and the aluminum powder are crushed under protection of insert gas. The titanium agent further comprises surface active agents. The titanium agent comprises, by mass, 85%-95% of the titanium powder, 4%-14.49% of the aluminum powder, 0.01%-5% of the fluxing agents and 0.5%-2% of the surface active agents; the density range is 2.6-3.5 g / cm<3> after the above elements are pressed and formed, wherein a: the granularity distribution range of the titanium powder is 10-700 meshes; b: the granularity distribution range of the aluminum powder is 60-300 meshes and the purity of the aluminum powder is greater than or equal to 98%; c: the granularity distribution range of the fluxing agents is 60-300 meshes. According to the titanium agent as the addition agent, the titanium metal element content can reach up to 95%; by the adoption of the titanium addition agent, the melting temperature is low, the titanium addition agent can melt in an aluminum melt as low as 670 DEG C, the melting time is short, the titanium addition agent can melt within 10-15 min, and the recovery rate of the titanium metal element is more than 98%.

Owner:CHONGQING RUNJI YUANDONG NEW MATERIAL TECH

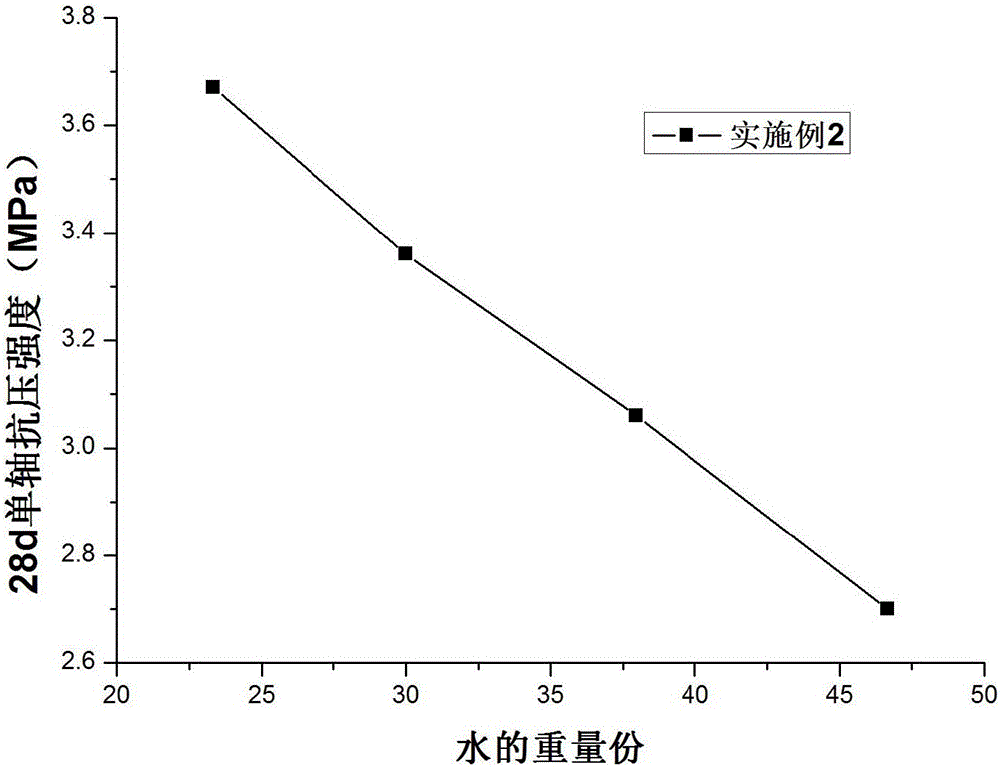

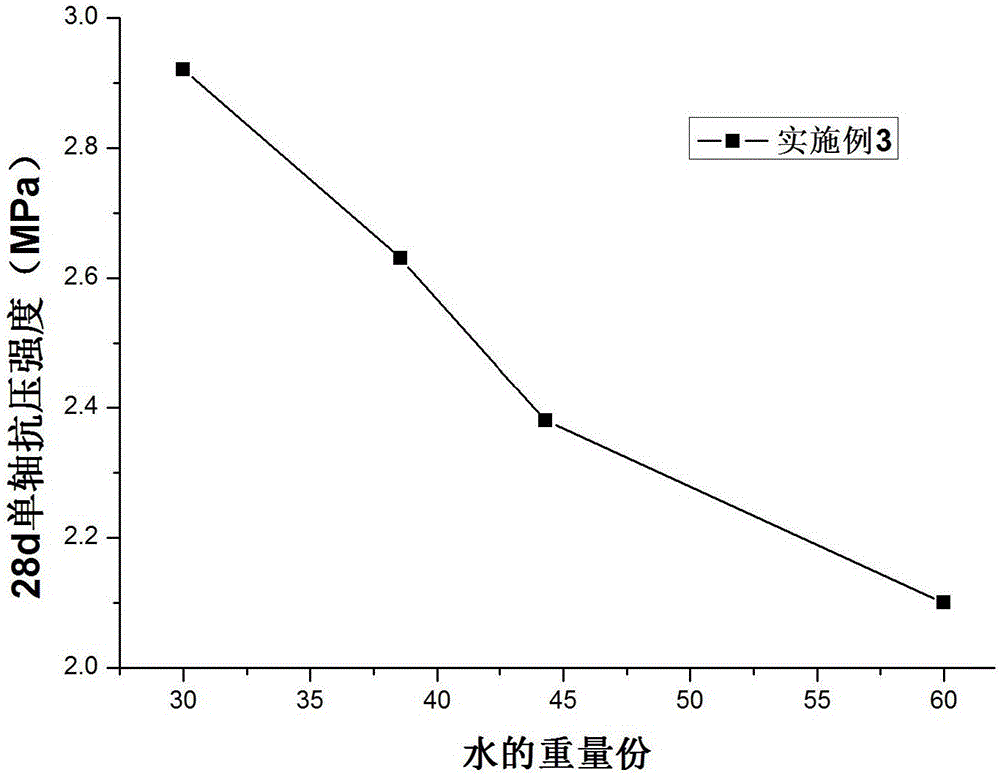

Cemented filling material for mine and preparation method thereof

The invention provides a cemented filling material for a mine and a preparation method thereof. The cemented filling material is prepared from the following raw materials in parts by weight: 40-100 parts of whole tailings, 10 parts of plastic bone powder, 16.67-73.33 parts of water and a flocculant, wherein, the addition amount of the flocculant is 10 g / t, and the concentration of a flocculant aqueous solution is 0.1%. The preparation method comprises the following steps: weighing the plastic bone powder, whole tailings and water according to the weight parts, weighing the flocculant according to a unit consumption account of 10 g / t, and preparing the flocculant aqueous solution with a mass concentration of 0.1%; fully mixing the weighted plastic bone powder and whole tailings in a stirrer, and then adding the weighted water while stirring so as to obtain a mixed material, wherein, stirring is primary stirring; and adding the prepared flocculant aqueous solution into the mixed material, performing uniform stirring, so that the flocculant is in full contact with the mixed material, after secondary stirring is completed, the filling material is prepared. The prepared cemented filling material by the invention is stable in performance, simple in preparation process, short in curing period, and suitable for mining with filling of the vast majority of mines.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

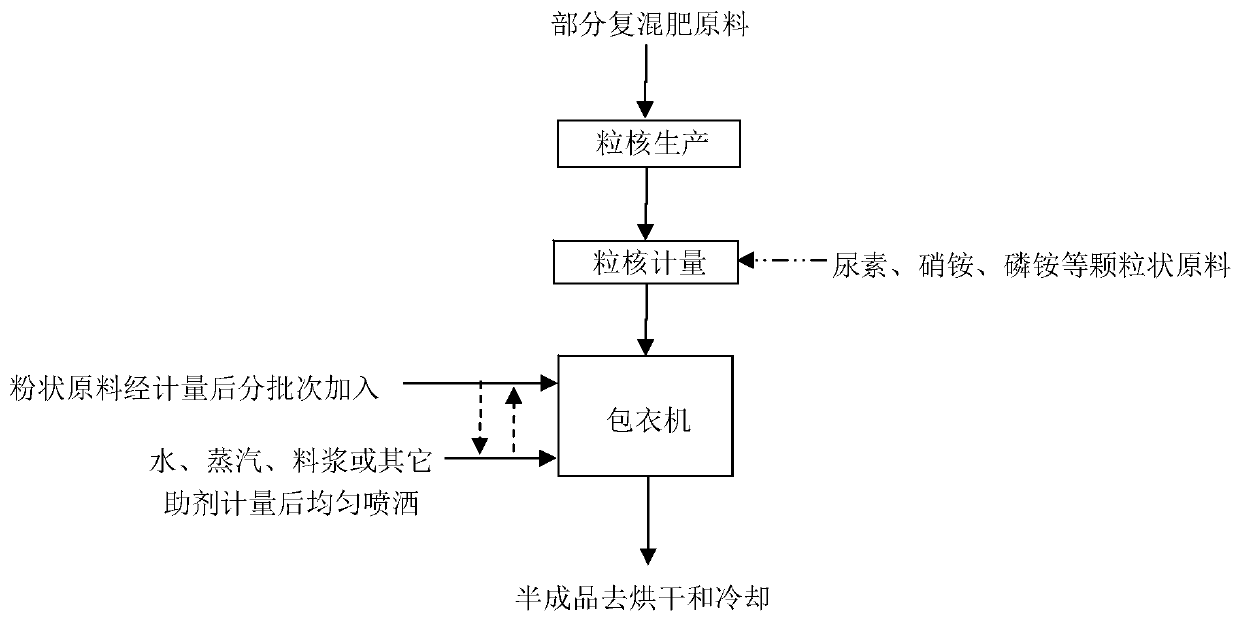

Method for producing granular compound fertilizer through coating and pelletizing

The invention relates to a method for producing a granular compound fertilizer through coating and pelletizing. The method comprises the following steps: producing granule cores from a part of a compound fertilizer raw material, or by taking a granule raw material of a compound fertilizer as granule cores, crushing the part of the compound fertilizer raw material to be less than 100 meshes, completely putting the granule cores into a coating machine in an amount of one-batch production, uniformly putting a powder raw material into the coating machine for multiple times, dispersing the powder raw material to the surfaces of the granule cores under the dispersion action of a rolling bed in the coating machine when the powder raw material is added each time, adding aids to enable the powder raw material to be solidly stuck to the surfaces of the granule cores, after one cycle, sequentially adding the powder raw material and the aids, and repeating the process to increase granules in a generally accordant granule increase tendency gradually; and after material addition is completed, continuously rolling for a while, discharging, and carrying out procedures such as drying and cooling ongranules of qualified particle sizes, thereby obtaining a finished product of the compound fertilizer. Pelletized materials are all granules of qualified particle sizes, and the produced granules areuniform in particle size and smooth in surface.

Owner:SHANGHAI RES INST OF CHEM IND

Self-expanding plugging agent

The invention discloses a self-expanding plugging agent which comprises the following components in parts by weight: 10-15 parts of self-expanding plugging polymer particles, 10-15 parts of sawdust, 5-10 parts of corn straw debris, 5-10 parts of asbestos fiber, 15-20 parts of calcium carbonate powder, 10-20 parts of coke particles and 5-10 parts of clam shell debris, wherein the self-expanding plugging polymer particles are a copolymer which is composed of a first monomer, a second monomer, a third monomer and a fourth monomer through copolymerization and has a number-average molecular weightof 8-14 million; the first monomer is acrylamide; the second monomer is at least one of methyl acrylate and butyl acrylate; the third monomer is at least one of potassium acrylate, sodium acrylate andacrylate; and the fourth monomer is a monomer containing double bonds. The self-expanding plugging agent is formed by multiple plugging support materials with different particle sizes and self-expanding polymer particles through mixing, meets filling of cracks and pores with different types of crack sizes of 1-5mm, and in addition, is simple in in-situ grouting, easy to operate and safe in construction.

Owner:CNPC BOHAI DRILLING ENG +1

Water absorption resin for well repair and leaking stoppage and synthesis method thereof

ActiveCN102181008BGood effect in sealing formation seepageThe synthesis method is simpleDrilling compositionSynthesis methodsNitrogen

The invention relates to water absorption resin for well repair and leaking stoppage. The water absorption resin is prepared by the following synthesis steps of: a, mixing 10 to 15 percent of 2-acrylamide-2-methylpropanesulfonic acid, 30 to 45 percent of acrylamide, 0.2 to 0.5 percent of N,N-methylenebisacrylamide and deionized water in a weight ratio with stirring to form a mixture, wherein the stirring time is 5 to 10 minutes and the stirring temperature is 30 to 50 DEG C; b, putting the prepared mixture into a polymerization reaction kettle, stirring the mixture, introducing nitrogen for 30 minutes to displace air in the polymerization reaction kettle, simultaneously heating the polymerization reaction kettle to the temperature of between 40 and 50 DEG C, then adding 0.03 to 0.08 weight percent of persulfate initiator into the mixture, performing polymerization reaction on the mixture to generate the water absorption resin, and preserving heat for at least 6 hours after the polymerization reaction starts; and c, drying the prepared water absorption resin at the temperature of not more than 120 DEG C for 24 hours till complete drying, and crushing the dried water absorption resin into granules with a diameter of 0.5 to 40 millimeters to obtain the water absorption resin for well repair and leaking stoppage.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Iron agent used for producing aluminum alloy and preparation method thereof

The invention belongs to the field of addition agents of aluminum alloy and discloses an iron agent used for producing the aluminum alloy and a preparation method thereof. The iron agent used for producing the aluminum alloy is mainly formed by pressing iron powder, aluminum powder and fluxing agents to be in a cake shape or a rugby shape. The iron powder and the aluminum powder are crushed under protection of insert gas. The iron agent further comprises surface active agents. The iron agent comprises, by mass, 90%-98% of the iron powder, 0%-9.48% of the aluminum powder, 0.01%-5% of the fluxing agents and 0.5%-2% of the surface active agents; the density range is 2.8-5.0 g / cm<3> after the above elements are pressed and formed. According to the iron agent as the addition agent, the iron metal element content can reach up to 98%; by the adoption of the iron addition agent, the melting temperature is low, the iron addition agent can melt in an aluminum melt as low as 670 DEG C, the melting time is short, the iron addition agent can melt within 10-15 min, and the recovery rate of the iron metal element is more than 98%.

Owner:CHONGQING RUNJI YUANDONG NEW MATERIAL TECH

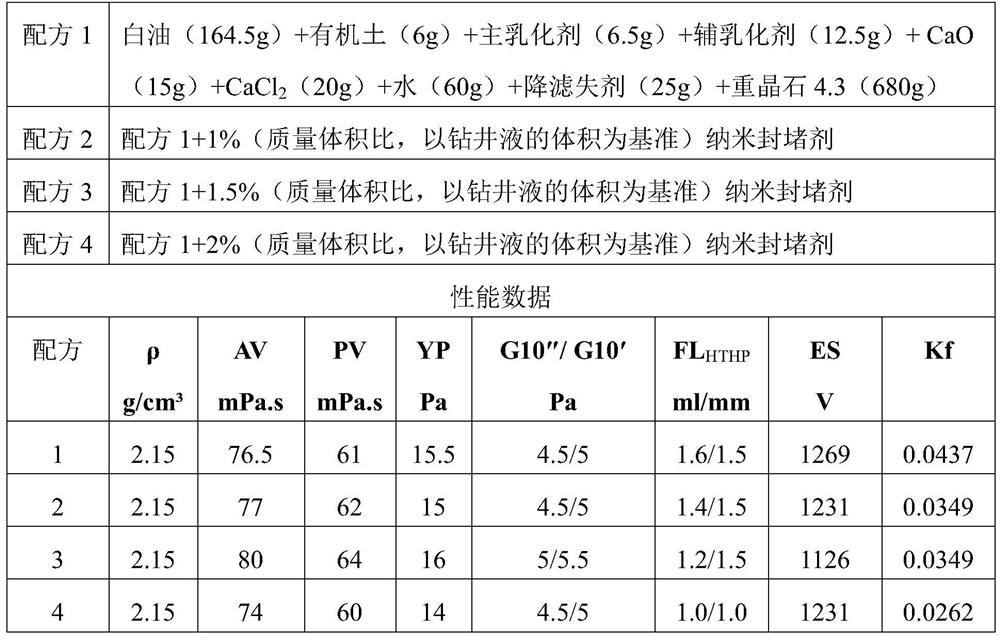

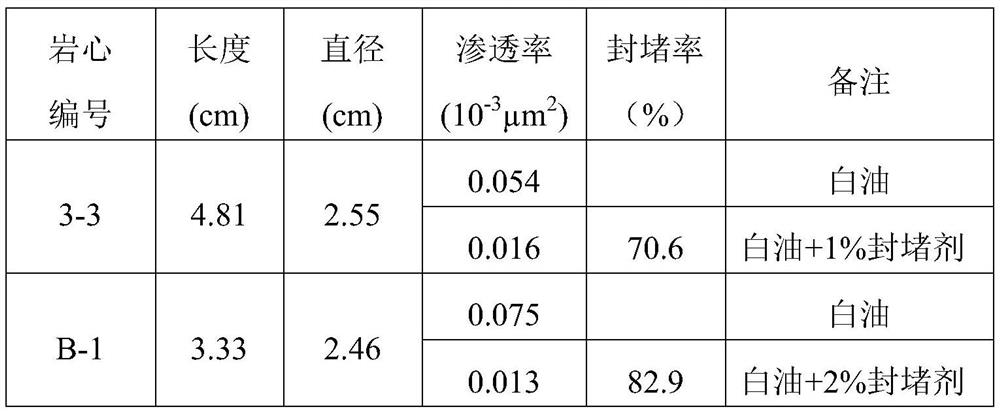

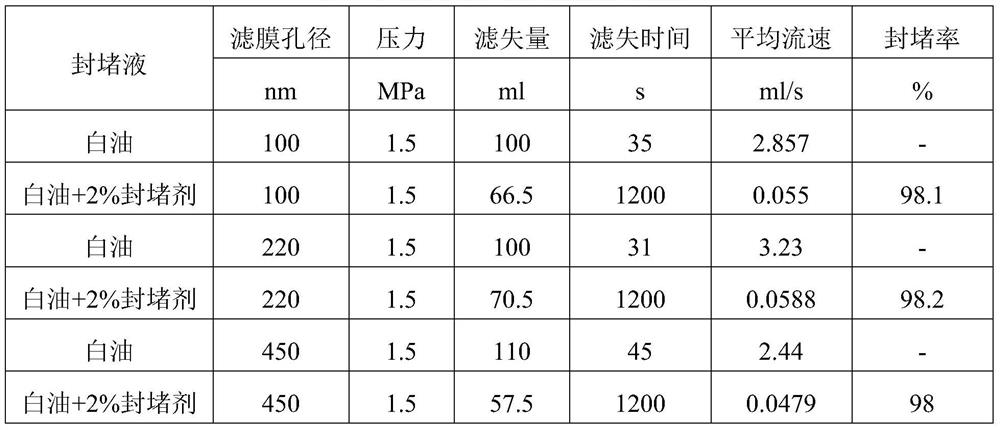

Nano blocking agent as well as preparation method and application thereof

InactiveCN112430455AWide range of particle size distributionMeet the blocking needsDrilling compositionSealing/packingWell drillingPhysical chemistry

The invention provides a nano blocking agent and a preparation method and an application thereof, and the nano blocking agent comprises the following components in parts by weight: 500-600 parts of white oil; 5 parts of graphene; 5 parts of a modifier; 300-350 parts of nano calcium carbonate; 30-50 parts of nano silicon dioxide; and 20-40 parts of a stabilizer. The nano blocking agent provided bythe invention is wide in particle size distribution range, and can meet the blocking requirements of nano hole seams of different shale formations in the drilling process.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Device and process for manufacturing positive/negative electrode material of lithium battery

The invention relates to a device and process for manufacturing a positive / negative electrode material of a lithium battery. The device consists of a feeder, a fluidized bed mixer, a gas-solid separator, a spiral continuous feeding reaction device preheating section, a spiral continuous feeding reaction device reacting section, and a cooling device. The process for manufacturing the positive / negative electrode material of the lithium battery comprises the following steps of: firstly feeding raw materials for manufacturing the positive / negative electrode material of the lithium battery into the fluidized bed mixer through the feeder, fully mixing and then separating by the gas-solid separator, sequentially entering the spiral continuous feeding reaction device preheating section and the spiral continuous feeding reaction device reacting section, heating and reacting to generate the positive / negative electrode material of the lithium battery, and then entering the cooling device to be cooled, finally discharging the positive / negative electrode material of the lithium battery from a product outlet. The device and process provided by the invention can be used for continuously manufacturing the positive / negative electrode material of the lithium battery efficiently with low energy consumption.

Owner:济宁市无界科技有限公司

Composite additive for reinforcing nickel laterite ore briquette and preparation method and application thereof

The invention provides a composite additive for reinforcing a nickel laterite ore briquette and a preparation method and application thereof. The composite additive comprises 5-10 wt% of water glass, 50-65 wt% of anthracite, 5-10 wt% of sodium humate and 10-30 wt% of limestone. The preparation method is to weigh and uniformly mix anthracite, sodium humate and limestone according to the mass ratios to obtain a mixture; and then, water glass is singly mixed. The composite additive can prominently improve the yield and the cold / hot-state strength of the nickel laterite ore briquette, and can be applied to the nickel laterite ore briquette.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com