Nano blocking agent as well as preparation method and application thereof

A nano plugging agent and nano calcium carbonate technology, applied in the field of oil drilling, can solve problems such as difficulty in achieving plugging effect, and achieve the effects of wide particle size distribution, good oil solubility and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides the preparation method of the above-mentioned nanometer plugging agent, comprising the following steps:

[0049] 1) adding a modifier in white oil, uniformly dispersing, then adding graphene therein, uniformly dispersing, to obtain a graphene mother liquor;

[0050] Using oxygen-containing functional groups such as hydroxyl and carboxyl groups in functionalized graphene nanosheets, and using n-dodecyltriethoxysilane with long-chain alkyl groups as modifiers, the functionalized graphene nanosheets can be chemically bonded In the form of grafting long-chain alkyl to change its suspension stability in white oil, the required graphene mother liquor was obtained through the previous steps;

[0051] 2) adding the stabilizer to the graphene mother liquor obtained in step 1), dispersing evenly, then adding nano-calcium carbonate and nano-silicon dioxide therein successively, using ultrasonic wave or microwave oscillation dispersion or ultra-h...

Embodiment 1

[0056] The present embodiment provides a method for preparing a nano-plugging agent for drilling fluid, which includes:

[0057] 1) Take 600g of light white oil W1-100, add 5g of n-dodecyltriethoxysilane modifier, use ultrasonic vibration dispersion (frequency 50KHz), add 5g graphene after vibration dispersion for 30 minutes, continue to shake Graphene mother liquor was obtained after 20 minutes;

[0058] 2) in the obtained graphene mother liquor, add 40g stabilizer, use ultrasonic vibration dispersion (frequency 50KHz), add 350g nano calcium carbonate, 50g nano silicon dioxide after vibration dispersion 30 minutes, continue to vibrate after 20 minutes to obtain The nano-blocking agent (1050g); the nano-blocking agent, in parts by weight, includes: white oil: 600 parts; graphene: 5 parts; modifier: 5 parts; nano-calcium carbonate: 350 parts; Nano silicon dioxide: 50 parts; stabilizer: 40 parts.

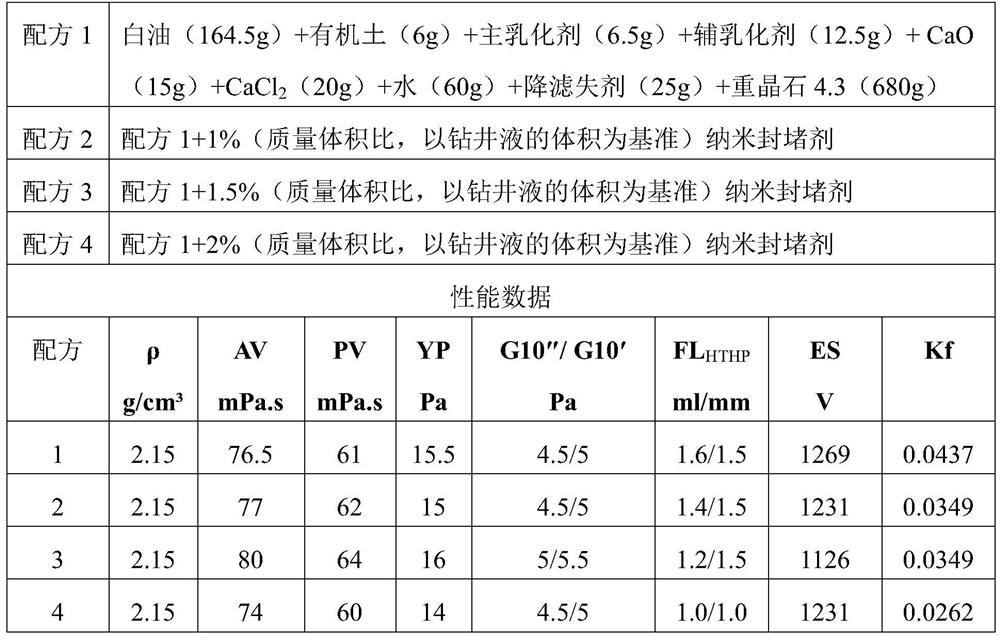

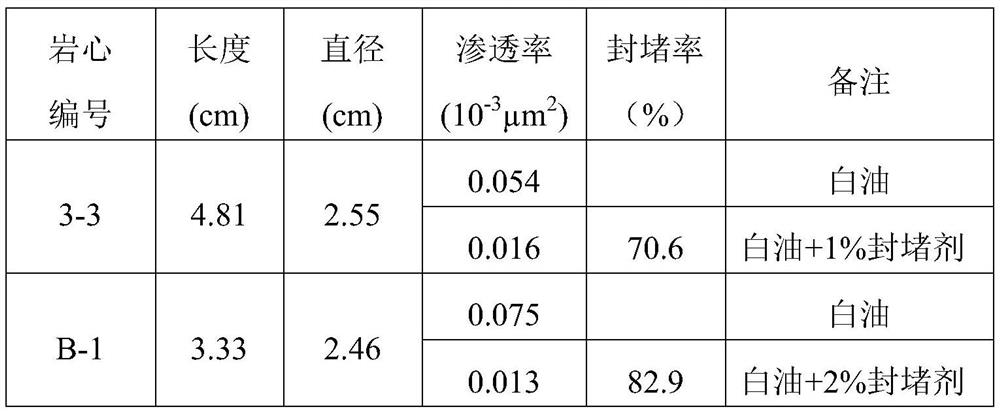

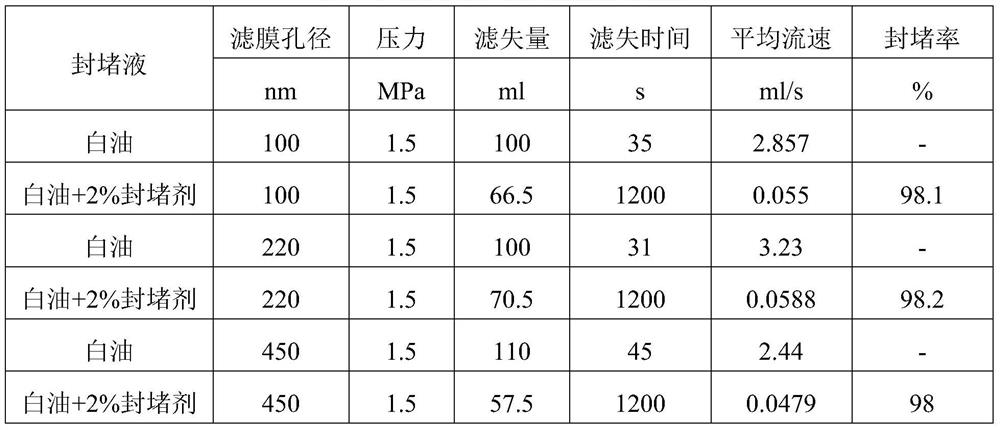

[0059] The drilling fluid nano-plugging agent prepared in Example 1 was subject...

Embodiment 2

[0088] The present embodiment provides a method for preparing a nano-plugging agent for drilling fluid, which includes:

[0089] 1) Take 500g of light white oil W1-90, add 5g of sodium oleate modifier, use ultrasonic vibration dispersion (frequency 50KHz), add 5g graphene after vibration dispersion for 30 minutes, and continue to vibrate for 20 minutes to obtain graphene mother liquor;

[0090] 2) in the obtained graphene mother liquor, add 20g stabilizer, use ultrasonic vibration dispersion (frequency 50KHz), add 300g nano calcium carbonate, 30g nano silicon dioxide after vibration dispersion 30 minutes, continue to vibrate after 20 minutes to obtain The nano-blocking agent (860g); the nano-blocking agent, in parts by weight, includes: white oil: 500 parts; graphene: 5 parts; modifier: 5 parts; nano-calcium carbonate: 300 parts ; Nano silica: 30 parts; Stabilizer: 20 parts.

[0091] The drilling fluid nano-plugging agent prepared in Example 2 is subjected to laser particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com